Temperature gradient energy storage heat exchanger

A temperature gradient and heat exchanger technology, applied in heat exchanger types, indirect heat exchangers, heat storage equipment, etc., can solve the problem of not considering the volume change of phase change materials, low heat transfer efficiency of smooth metal plates, and production safety Hidden dangers and other problems, to achieve the effect of solving the uneven energy distribution time and space, improving energy recovery and utilization rate, and occupying a small area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

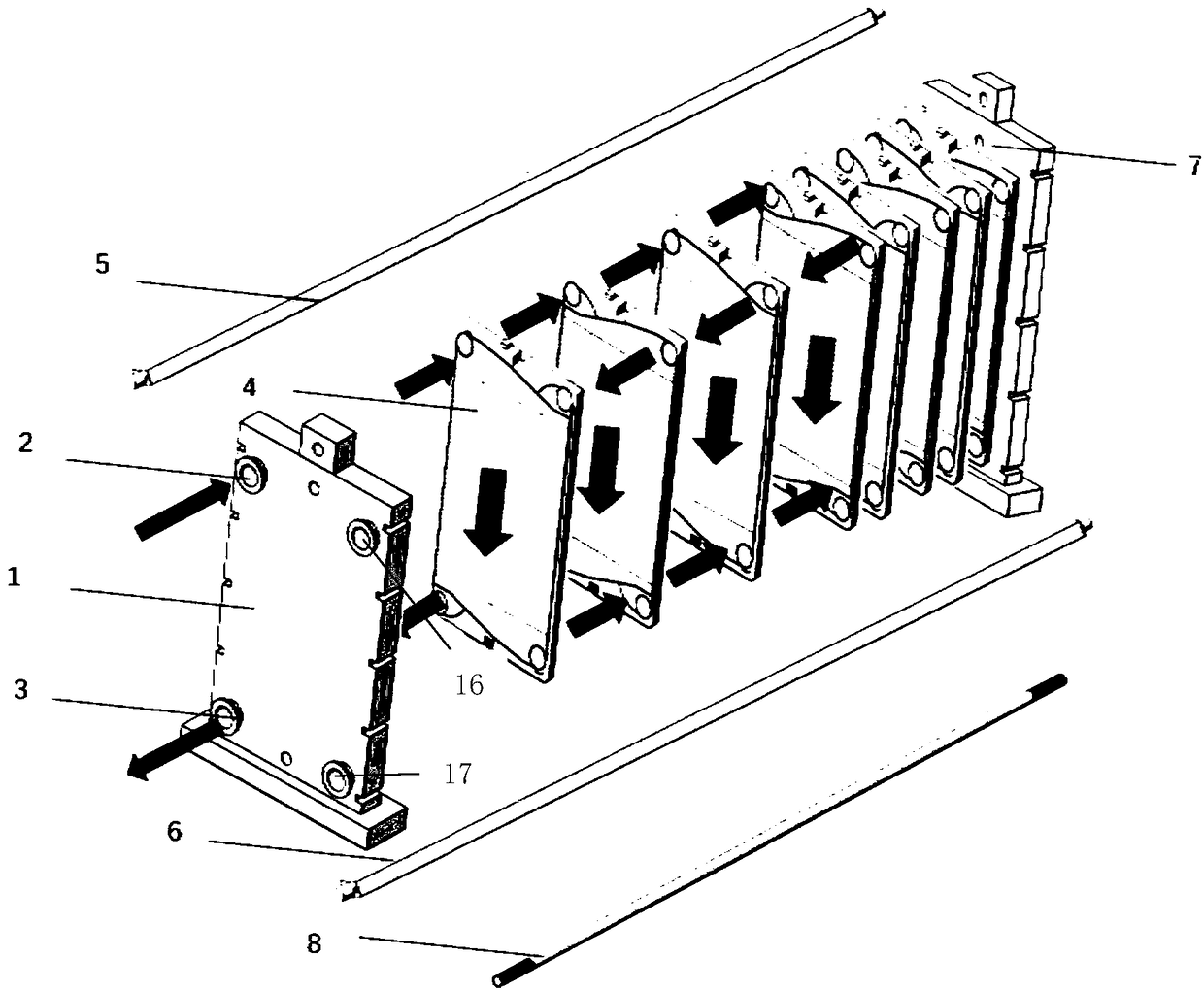

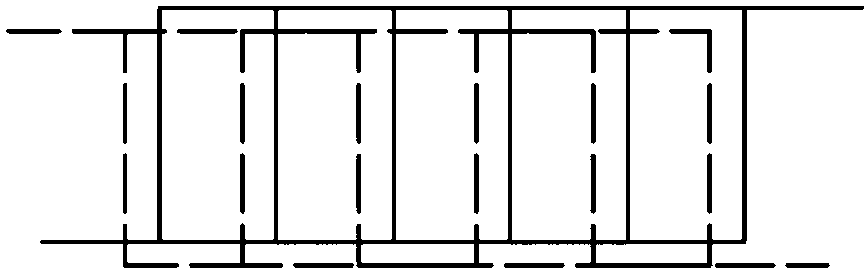

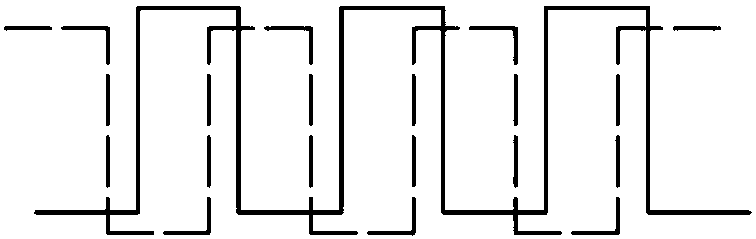

[0036] Such as figure 1 with Image 6 As shown, a temperature gradient energy storage heat exchanger includes a front splint 1, a rear splint 7, and at least two groups of plates 4 that are sequentially sealed and stacked between the front splint 1 and the rear splint 7 to form a fluid channel. An upper guide rod 5 and a lower guide rod 6 are respectively fixed between the upper and lower ends of the front splint 1 and the rear splint 7 , and the front splint 1 , the rear splint 7 and the plate 4 are clamped and connected by a plurality of fastening bolts 8 . The four corners of the front splint 1 are provided with a circular hot fluid inlet 2, a cold fluid outlet 3, a first exhaust hole 16, and a first sewage outlet 17, and the four corners of the rear splint 7 are provided with a circular cold fluid inlet 9, The hot fluid outlet 10, the second exhaust hole 18, the first sewage outlet 19, the four corners of the plate 4 are correspondingly provided with a circular fluid flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com