Energy-saving environment-friendly low-pressure die-casting machine heat-preserving furnace

A low-pressure casting machine, energy-saving and environment-friendly technology, which is applied in the field of energy-saving and environment-friendly low-pressure casting machine holding furnaces, can solve the problems of poor working environment for workers, energy loss, and shortened service life of surrounding cables and supporting facilities, and achieve high equipment utilization and strong Heat storage, compact structure and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

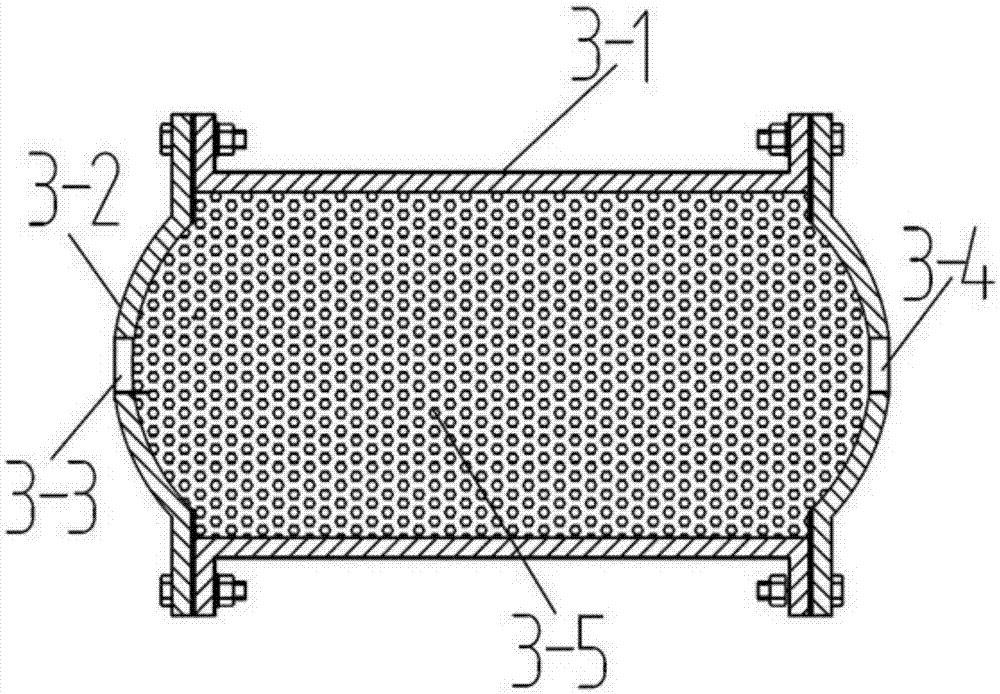

[0017] Depend on Figure 1-2 It can be seen from the shown embodiment that this embodiment includes a die-casting machine holding furnace 1, which is provided with a furnace body inlet and outlet holes, and the furnace body inlet and outlet holes are connected to the heat storage chamber 3 and the compressed air switch in turn through the pipeline 2 The valve 4 is connected with the compressed air source, and the inlet and outlet holes of the furnace body are also communicated with the regenerator 3, the exhaust valve 5 and the atmosphere through the pipeline 2 in turn; the regenerator 3 includes a closed shell, and there is a The heat accumulator 3-5, the closed shell is provided with the hot end connection hole that communicates with the inlet and outlet holes of the furnace body, and the hole that communicates with the compressed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com