Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

152results about How to "Realize environmentally friendly production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

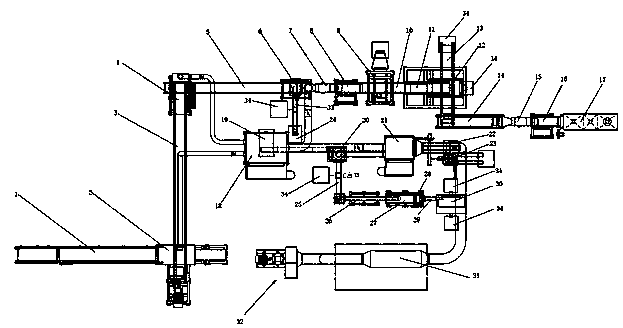

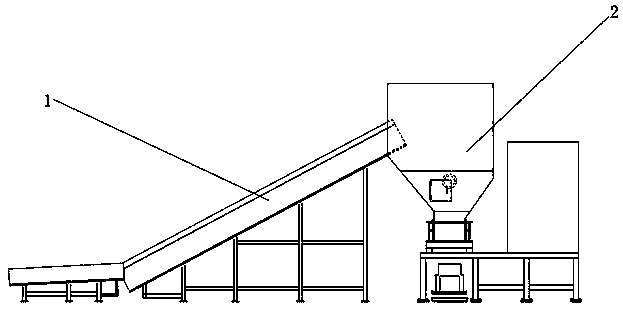

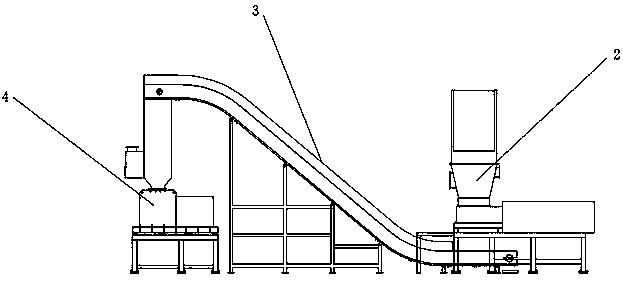

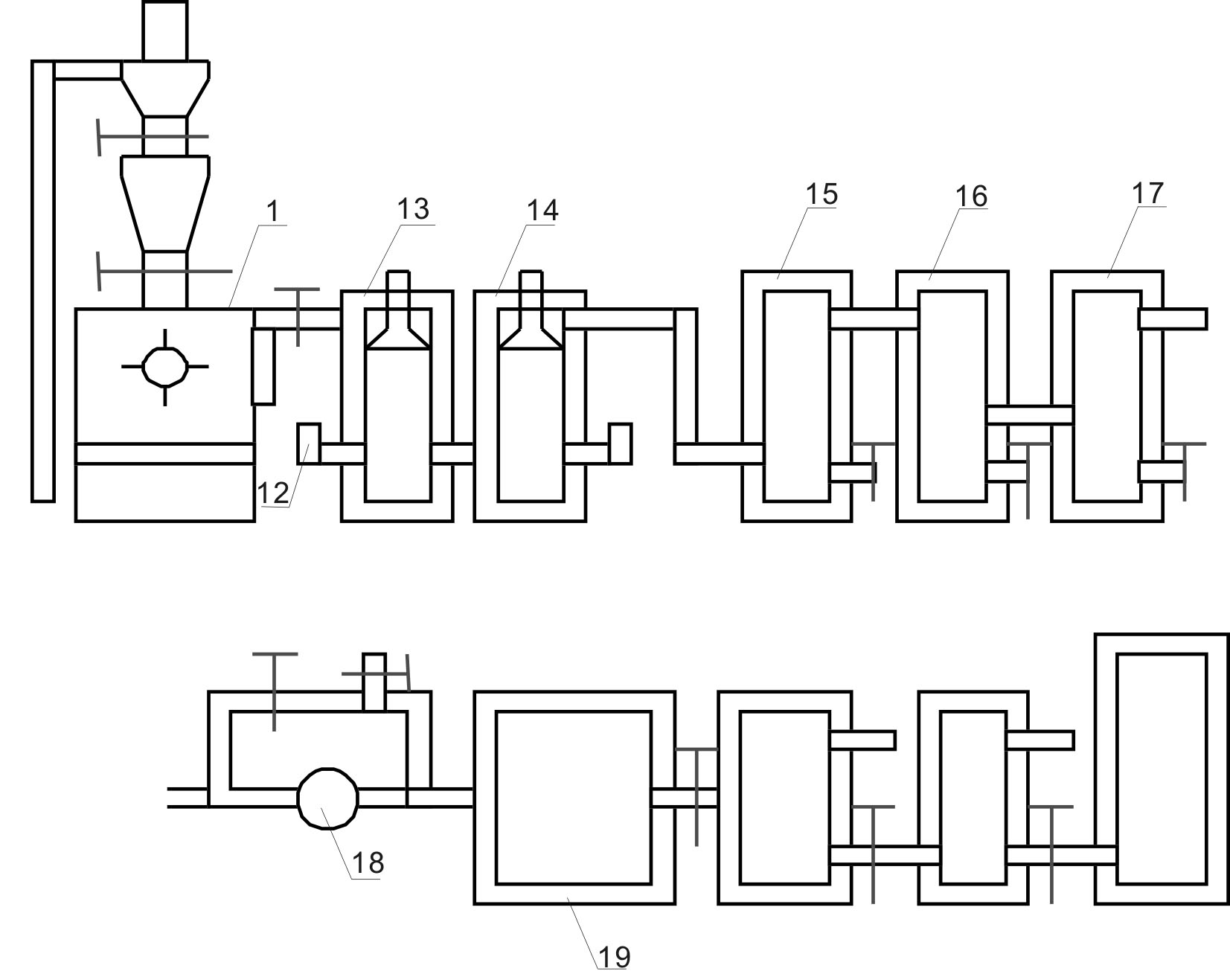

Recycling system for waste electrical and electronic products

InactiveCN103722003AReduce vacancy rateImprove efficiencySolid waste disposalGrain treatmentsProduction lineCollection system

The invention discloses a recycling system for waste electrical and electronic products. The recycling system is characterized by comprising a control system as well as a crushing system, a separation system, a dust collection system, a waste gas collection system and a draught fan which are controlled by the control system, wherein the crushing system comprises a knocking crusher, the separation system comprises a winnower and a plastic and metal separation device, and the knocking crusher, the winnower and the plastic and metal separation device are connected through conveyer devices sequentially to form a plastic and metal separation production line; the knocking crusher and an air outlet of the winnower are connected with the dust collection system respectively for collecting light materials and dust of the whole recycling system; an air outlet of the dust collecting system is connected with the waste gas collection system; and the draught fan is connected with the waste gas collection system, so that the knocking crusher, the winnower, the dust collection system and the waste gas collection system are in negative pressure states. The system can be applied to crushing and separation treatment of various waste electrical appliances such as a refrigerator, a circuit board and the like respectively.

Owner:CHINA NAT ELECTRIC APP RES INST +1

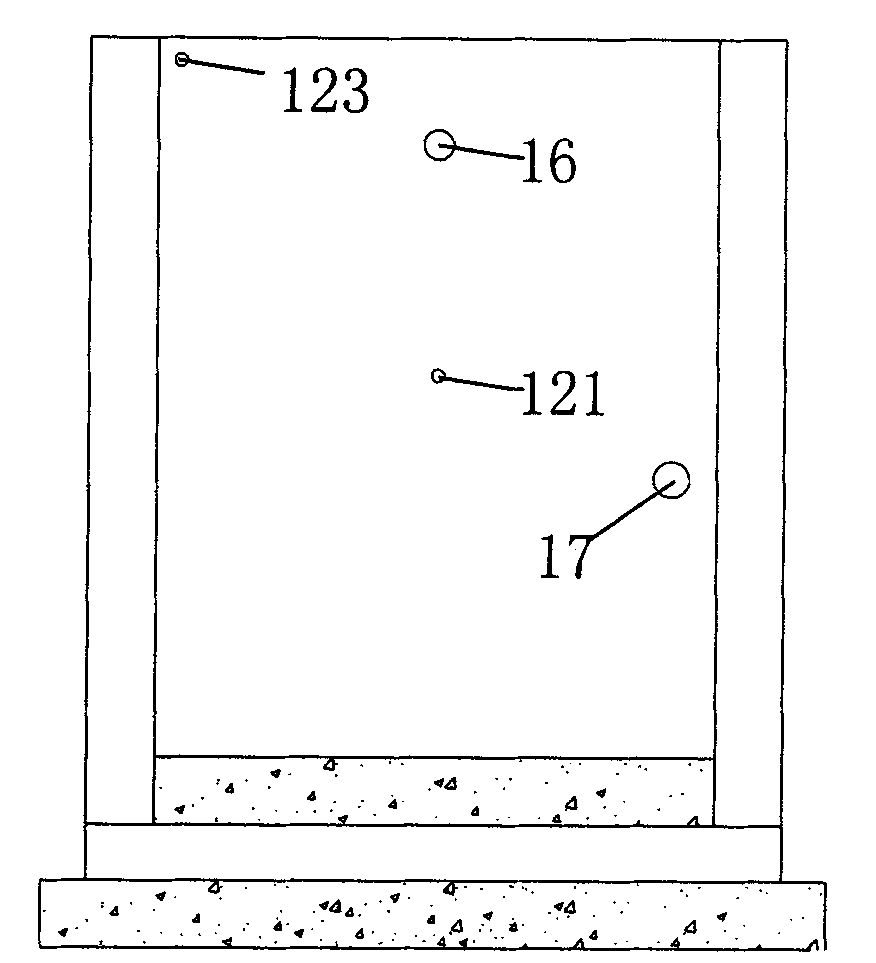

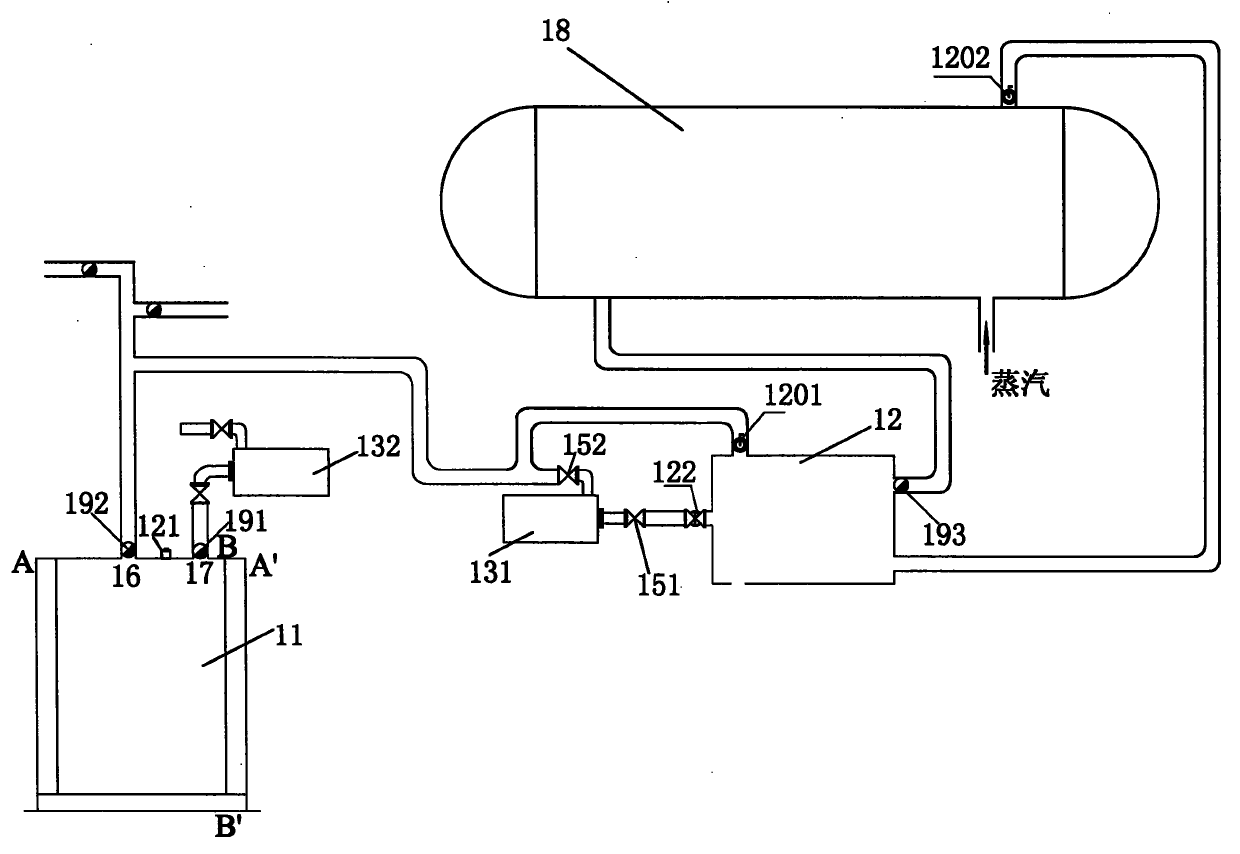

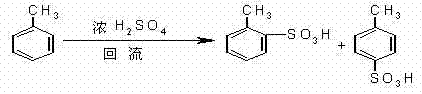

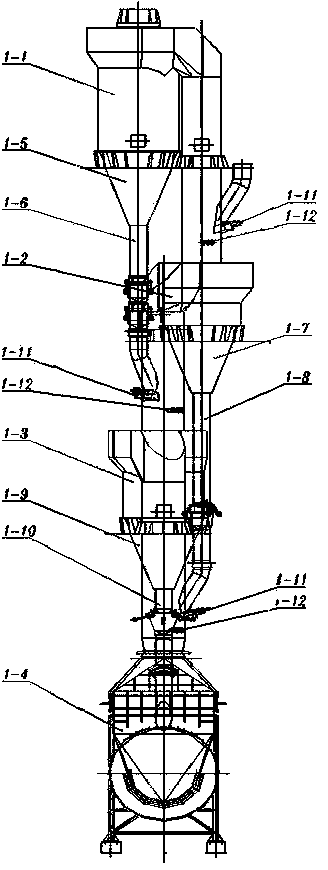

Water curing method and device for centrifuged pretensioned prestressed concrete pipe pile

ActiveCN101905486ATo overcome the lack of maintenance technologyRealize environmentally friendly productionCeramic shaping apparatusWater storage tankEngineering

The invention relates to a pipe pile water curing method. In the method, a water storage tank is arranged, and condensate water and residual steam in a still kettle are guided into the water storage tank; a pipe pile is placed in a steaming and curing pool, the condensate water in the water storage tank is guided into the steaming and curing pool, and the residual steam in water storage tank is guided into the steaming and curing pool; and steaming and curing the pipe pile in the steaming pool for 4-5 hours at 80-90 DEG C. The curing device comprises the steaming and curing pool, the water storage tank and the still kettle, wherein the steaming and curing pool is provided with a water-steam port; the water storage tank is provided with a residual steam outlet, a residual steam inlet, a condensate water outlet and a condensate water inlet; and the still kettle is provided with a steam inlet and a steam outlet. A condensate channel is arranged between the water-steam port of the steaming pool and the condensate water outlet of the water storage tank, and a steam channel is arranged between the water-steam port of the steaming pool and the residual steam outlet of the water storage tank. The condensate water inlet of the water storage tank is communicated with the condensate water outlet of the still kettle through a third electric control valve and a pipeline, and the steam inlet of the water storage tank is communicated with the steam outlet of the still kettle through a second steam valve and a pipeline.

Owner:JIANHUA CONSTR MATERIALS (JIANGSU) CO LTD

Method for extracting levodopa from cat beans

ActiveCN106631853AAvoid it happening againNo emissionsOrganic compound preparationAmino-carboxyl compound preparationAmmonium Hydrogen CarbonateImpurity

The invention provides a method for extracting levodopa from cat beans. The method comprises the following steps: flattening the cat beans and putting the cat beans into a reaction kettle with a water solution containing dissolved ammonium hydrogen carbonate, ammonium sulfate, tannic acid and sodium pyrosulfite; pressurizing with carbon dioxide; raising the temperature and extracting to obtain an extracting solution and cat bean dreg; precipitating the extracting solution by utilizing chitosan and filtering; after primarily separating impurities, decompressing and concentrating filtrate; separating out a crude product; eluting the crude product with an ethanol solution; recycling eluted ethanol and taking a filter cake; purifying the filter cake by adopting a traditional refining process; standing and separating out crystals; filtering to obtain the crystals; drying the crystals to obtain the levodopa with the content of no less than 99 percent and the yield of no less than 3 percent. Compared with a traditional acid water-resin process, a product of the extracting method provided by the invention is equivalent and the yield of the product can be improved to 3 percent from previous 2.5 percent; the emission amount of wastewater containing acid and alkali is reduced by 95 percent or more, and 60 percent of labor force can also be saved.

Owner:广西邦尔药业有限公司

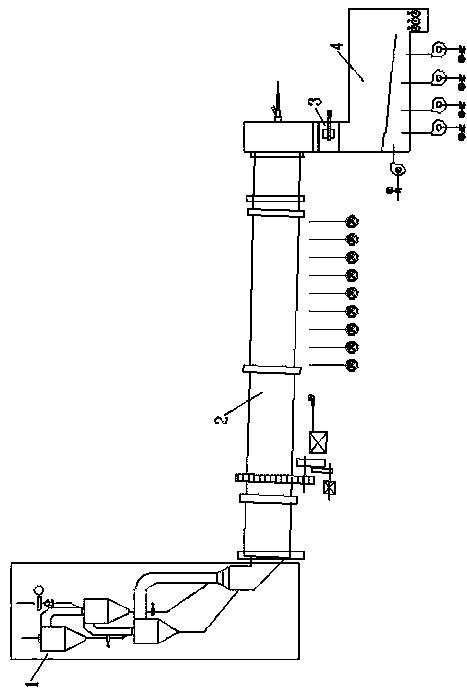

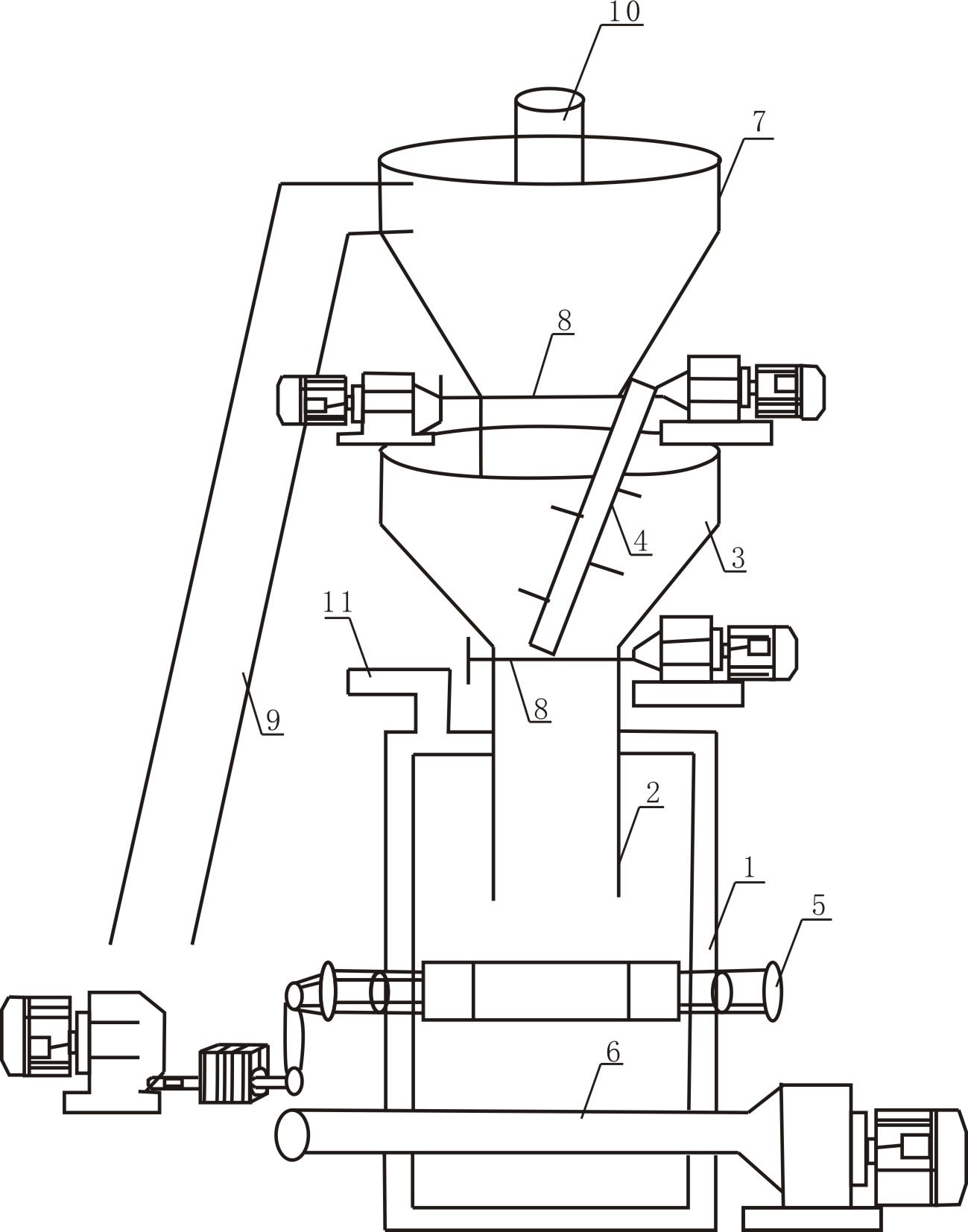

Continuous production device for calcining and whitening black talc and production process thereof

ActiveCN103803567AImprove insulation effectGood coolingAlkaline-earth metal silicatesEnergy inputBrickCooling effect

The invention discloses a continuous production device for calcining and whitening black talc and a production process thereof. The continuous production device comprises a coarse particle suspension preheater, a white talc rotary kiln and a grate type cooling machine with a heat preservation kettle, which are sequentially connected; the production process comprises the following steps: A. superfine-grinding black talc; B. preheating by a preheater at the kiln tail; C. calcining in the rotary kiln; and D. preserving heat by the heat preservation kettle and cooling. The design of the coarse particle suspension preheater is adopted and the tail gas waste heat of the white talc rotary kiln is fully utilized, so that the energy consumption is reduced; the calcining efficiency is improved due to a pickaxe-shaped spiral pushing device of the rotary kiln and spirally-arranged heat-resisting bricks with ribs, and the grate type cooling machine with the heat preservation kettle can achieve excellent heat-preservation and cooling effects; and the continuous production device can achieve large-scale continuously-mechanical production for calcining white talc and adopts center-control automatic operation, so as to greatly improve the labor productivity and achieve stable quality and environment-friendly production, thereby having good economic and environment-protection benefits.

Owner:SICHUAN CALCINER TECH

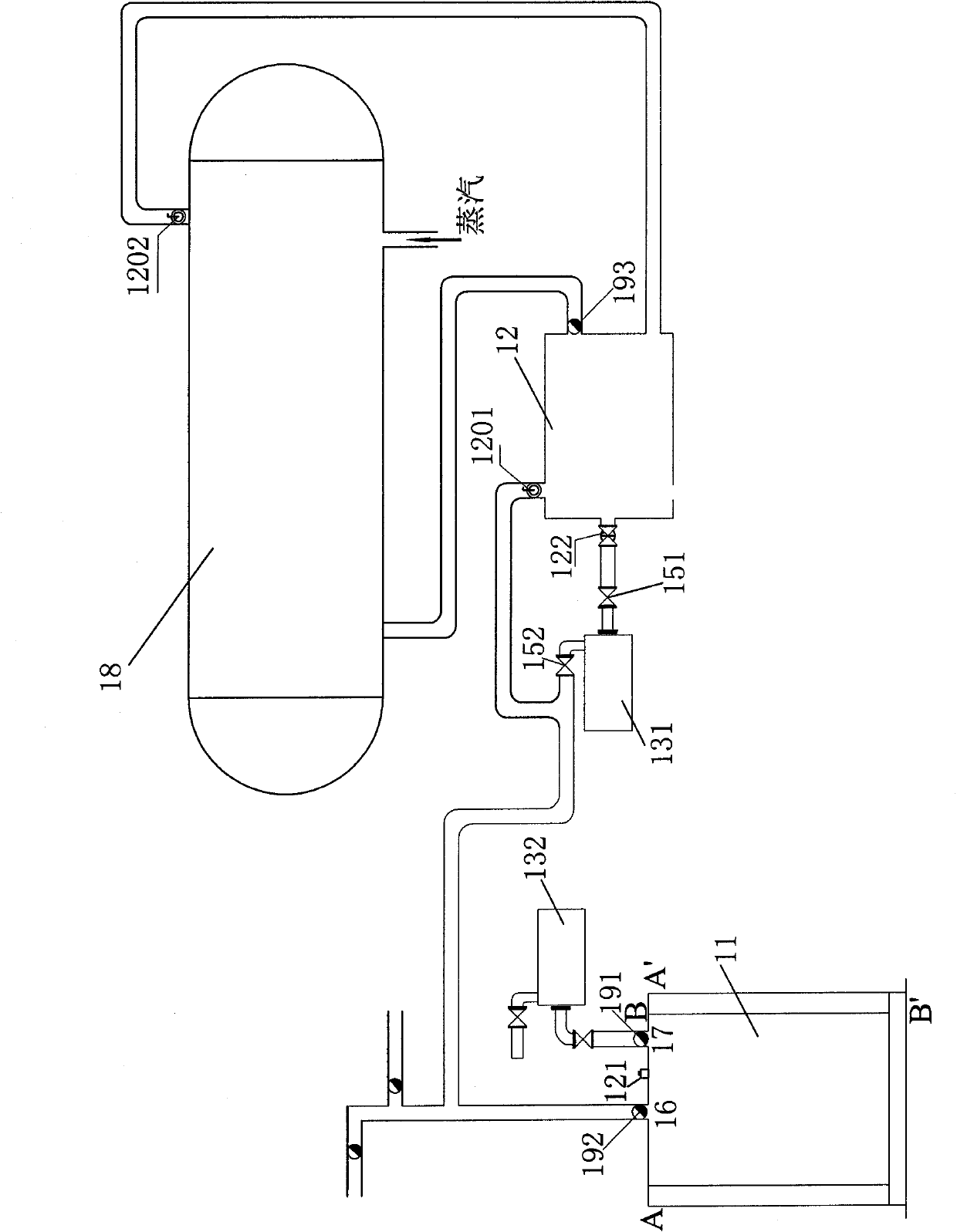

Production method for sulfonic acid curing agent used for casting

InactiveCN102516132AUnique process methodRealize environmentally friendly productionFoundry mouldsFoundry coresAlcoholSteam pressure

The invention relates to a production method for sulfonic acid curing agent and especially to a production method for sulfonic acid curing agent used for casting without generation of three wastes (waste gas, waste water and industrial residue). The method is characterized by comprising the following steps: a, closing a kettle bottom valve, opening a vacuum pump and taking in toluene with a desired weight; b, closing a vacuum valve, opening an air release valve and a sulfuric acid feeding valve, starting a mixer and adding concentrated sulfuric acid with a desired weight; c, opening a steam valve, maintaining steam pressure to be 0.2 to 0.3 MPa, allowing temperature to rise to 100 to 118 DEG C within 40 to 50 min and carrying out insulation for 90 min; d, opening a cooling water valve, allowing temperature to drop to 60 DEG C and slowly adding organic alcohol with a desired weight through an elevated tank; e, slowly adding water with a desired weight through the elevated tank after addition of organic alcohol is finished; and f, after addition of water is finished, allowing temperature to drop to 45 DEG C, adding an aqueous hydrogen peroxide solution with a desired weight, carrying out stirring for 20 min and carrying out inspection by sampling. According to the invention, control of total acidity of the curing agent and free acid is realized, production efficiency is effectively improved, and no discharge of industrial three wastes is realized.

Owner:NINGXIA KOCEL GRP CO LTD +1

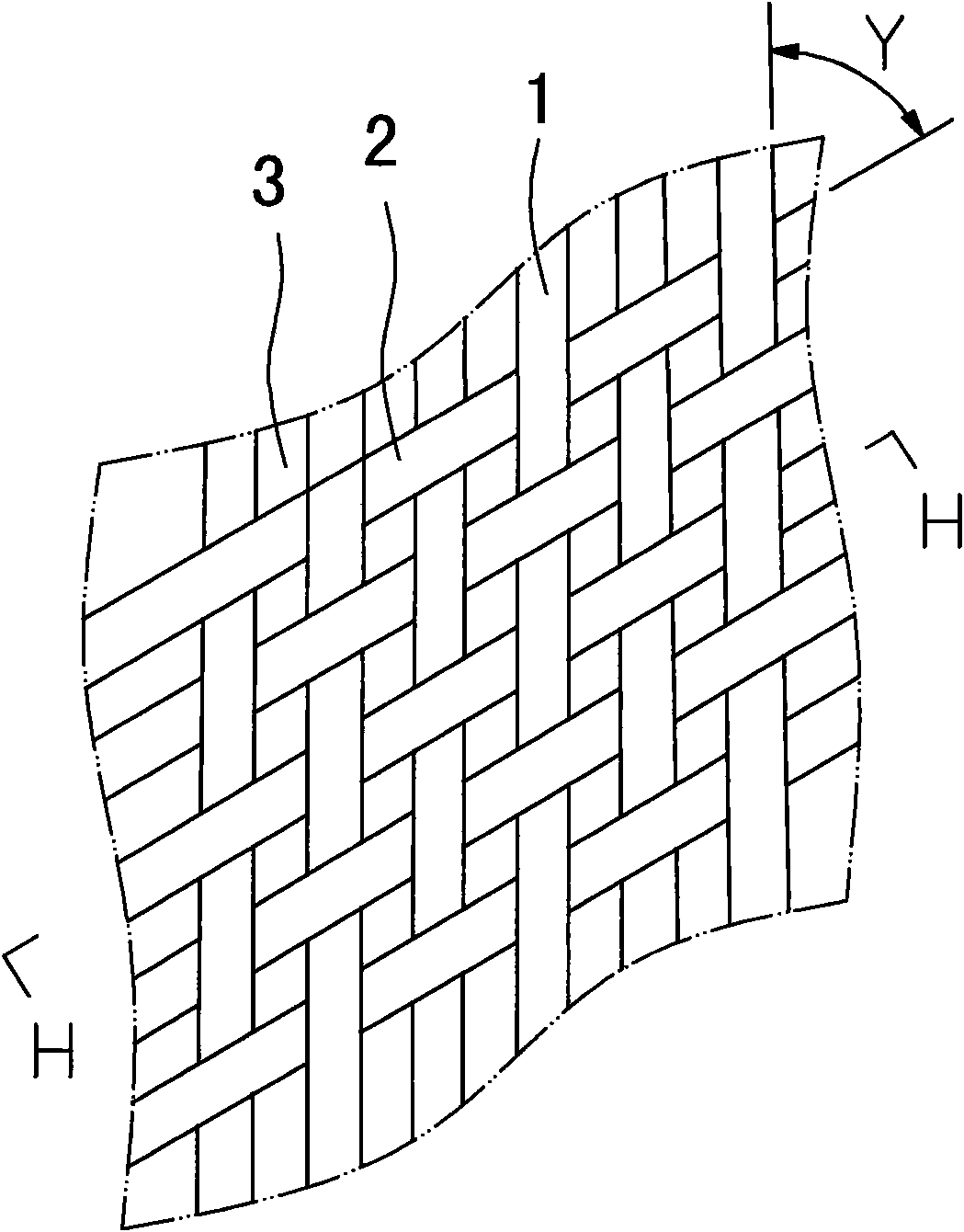

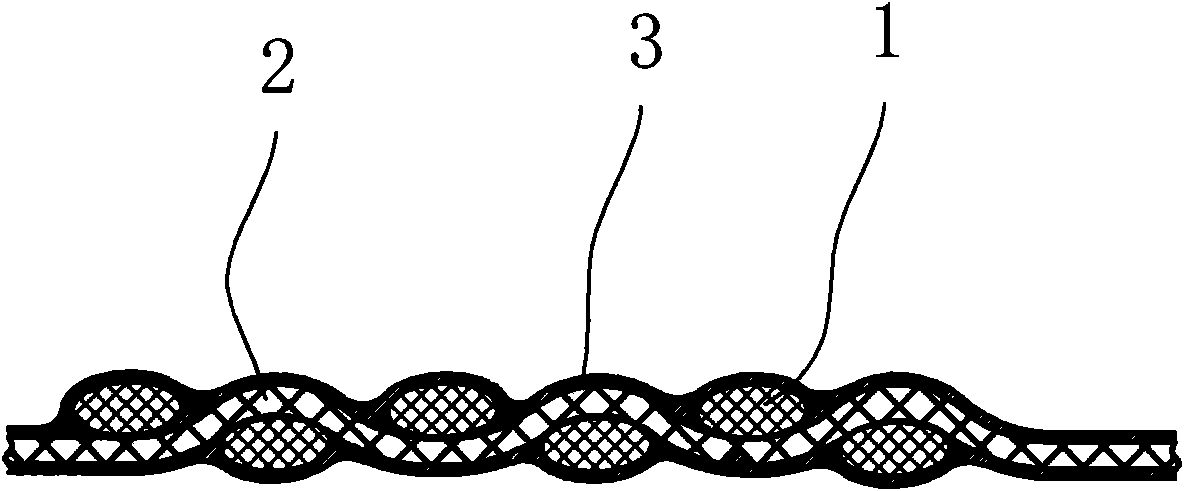

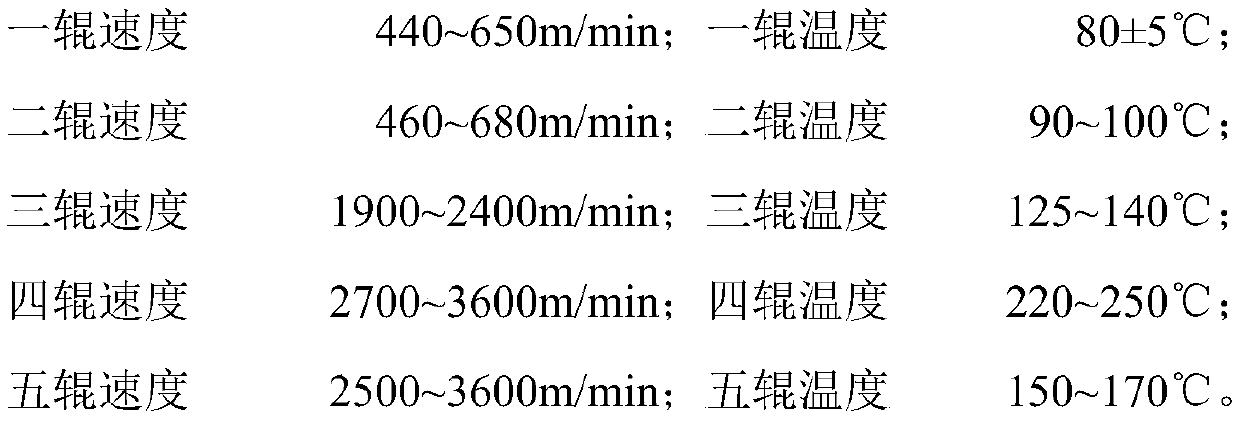

Wide-angle latex-dipped canvas and production process thereof

The invention relates to a wide-angle latex-dipped canvas and a production process thereof, belonging to the technical field of textile. The production process comprises the steps of angle adjustment, weaving, latex dipping, drying, shaping and packaging. The weaving included angle between the warp thread and the fill thread of cloth weaved by the process is 1-179 degrees, and the outer surface of weaved wide-angle canvas is soaked with a layer of latex. The invention has the advantages that a warp and fill thread has high angle stability, and the product has strong adhesivity; when in use, the product can be processed by mechanical latex spreading, latex pasting, dipping and latex scraping, and the angles of the warp and fill threads of canvas are not changed. With high finished productrate, simple production process and low cost, the wide-angle latex-dipped canvas can be used as the framework of rubber, plastic and such products or used as wrapping material.

Owner:ZHEJIANG GUOLI TEXTILE

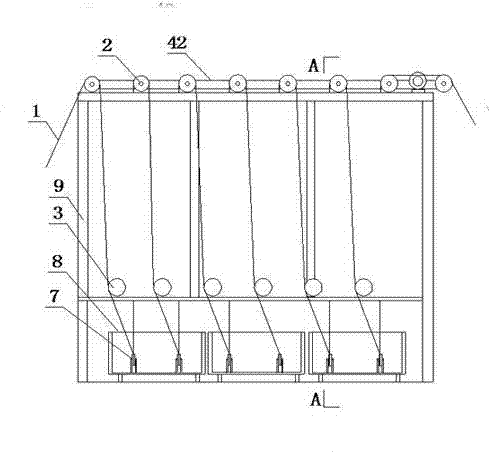

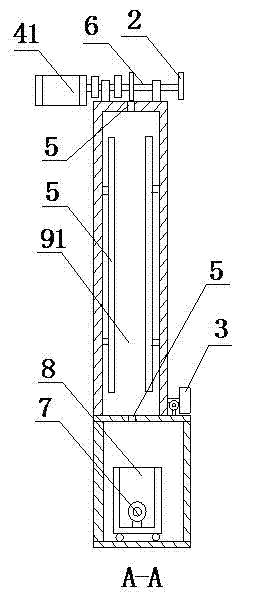

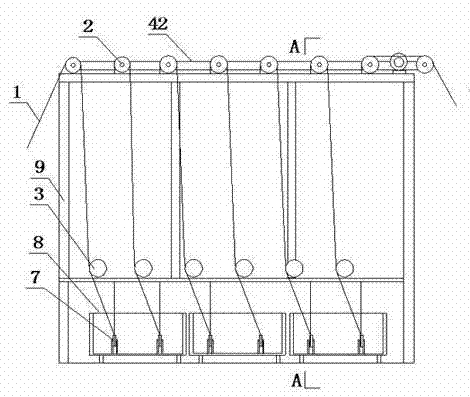

Automatic impregnation machine for latex tube

InactiveCN102247942AQuality improvementFlat surfacePretreated surfacesCoatingsEnvironmental resistanceWastewater

The invention discloses an automatic impregnation machine for a latex tube. The machine comprises a shell, a traction mechanism and a plurality of upper pulleys, middle pulleys and lower pulleys. The equipment has a simple and practical structure and a high automatic degree, does not need a large quantity of manpower and material resources or steam, cannot generate waste smoke or wastewater, adopts an electric heating mode, greatly improves the production condition, and realizes environment-friendly production; and impregnation and drying are repeated for multiple times in the process of producing the latex tube until the requirement of a processing technology is met. The original outdated workshop production mode is changed, and automatic mechanical production is adopted, so that the production speed of the latex tube can reach 10 to 15 meters / min, production efficiency is dozens of times the original production efficiency, large-scale production can be realized, and high practical value is achieved.

Owner:牟建锋

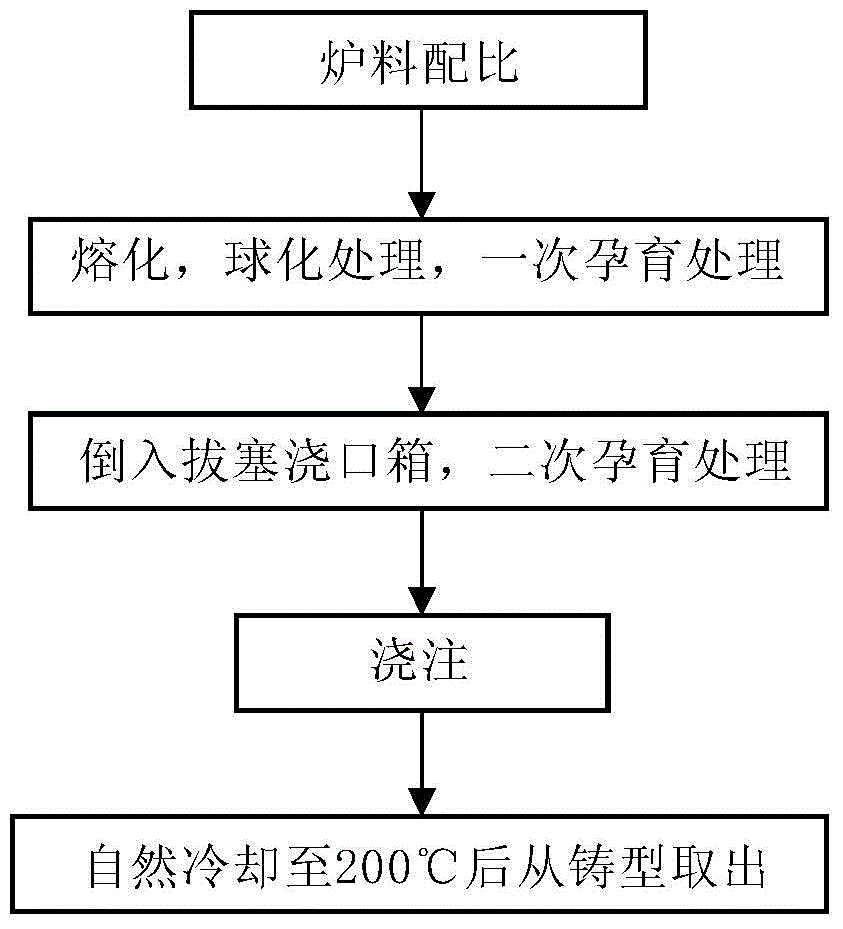

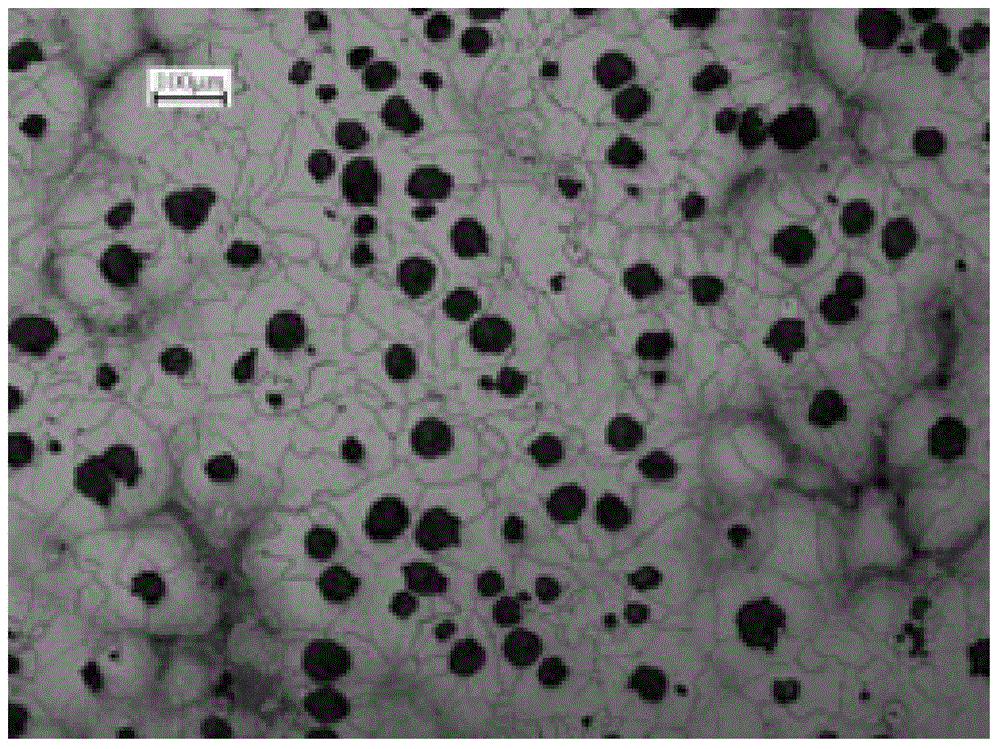

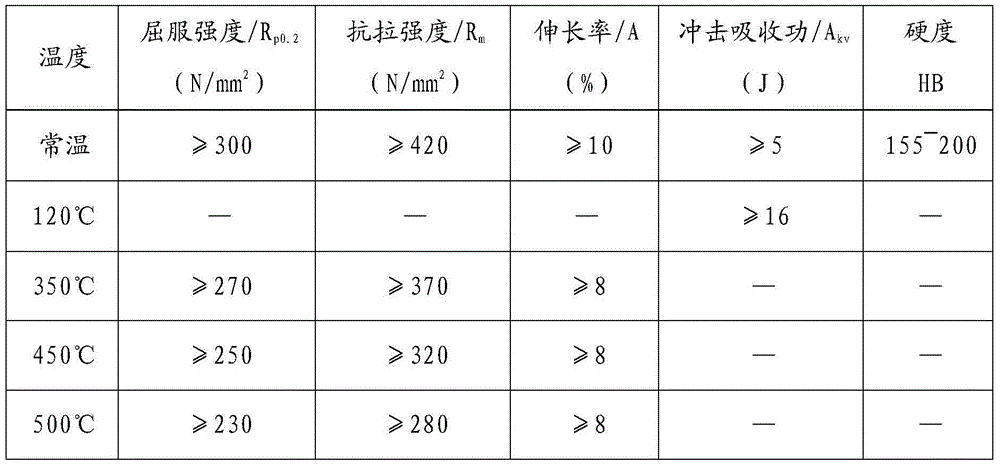

High-temperature-resistant silicon molybdenum ferrite nodular cast iron for steam turbine and preparation technology therefor

InactiveCN104911461AIncrease the brittle-ductile transition temperatureIncrease the number ofIntermediate frequencyFerrosilicon

The invention discloses high-temperature-resistant silicon molybdenum ferrite nodular cast iron for a steam turbine and a preparation technology therefor. The nodular cast iron comprises components: 3.0-3.5% of C, 2.8-3.2% of Si, less than 0.2% of Mn, less than 0.040% of P, less than 0.015% of S, 0.5-0.8% of Mo, less than 0.010% of Re, 0.040-0.055% of Mg, and 0.004-0.007% of Sb, the balance being iron and residual elements. The preparation technology comprises furnace charge matching; intermediate frequency induction furnace fusing; spheroidizing and addition of first inoculation ferrosilicon; control of contents of elements; pouring into a pulling runner box for secondary inoculation; casting moulding. The obtained nodular cast iron has good combination properties and a low cost, the nodularity reaches more than 80% of the nodularity prescribed by GB / T9441-2009 nodular cast iron metallographic examination, the ferrite amount is more than 90%, and normal temperature and high temperature mechanical properties meet production requirements.

Owner:上海宏钢电站设备铸锻有限公司

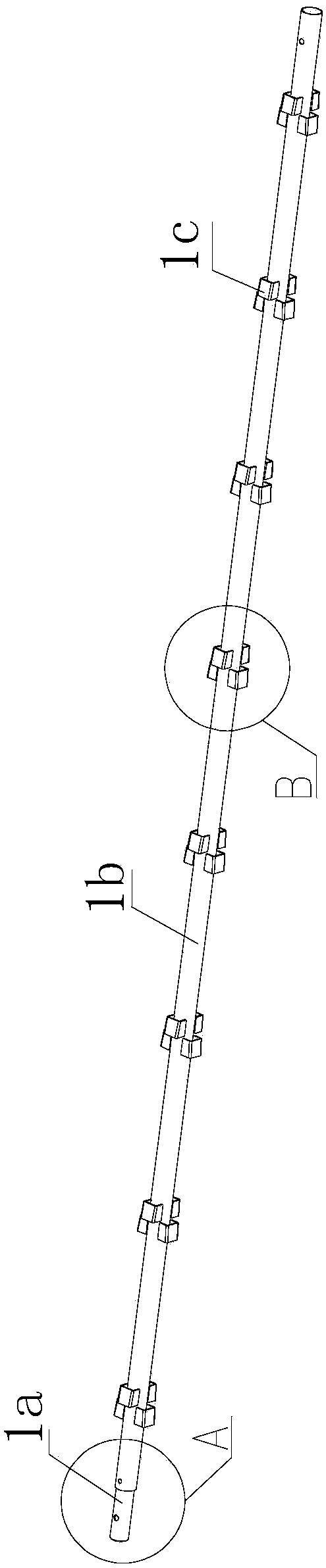

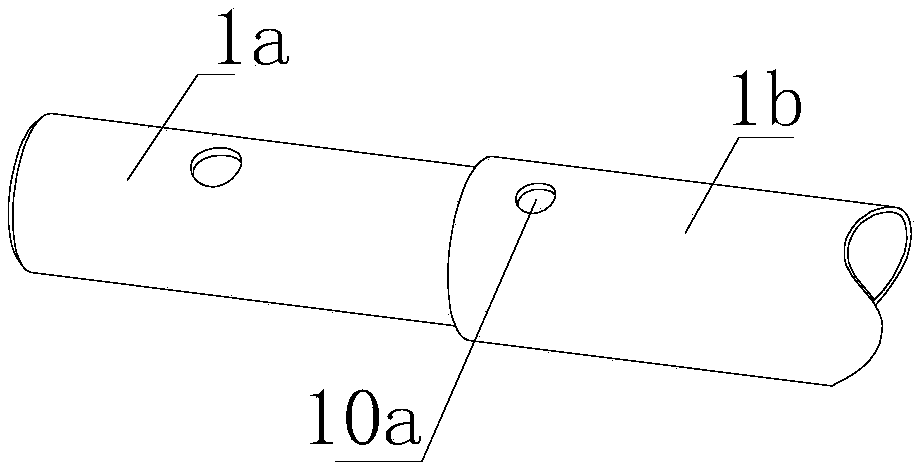

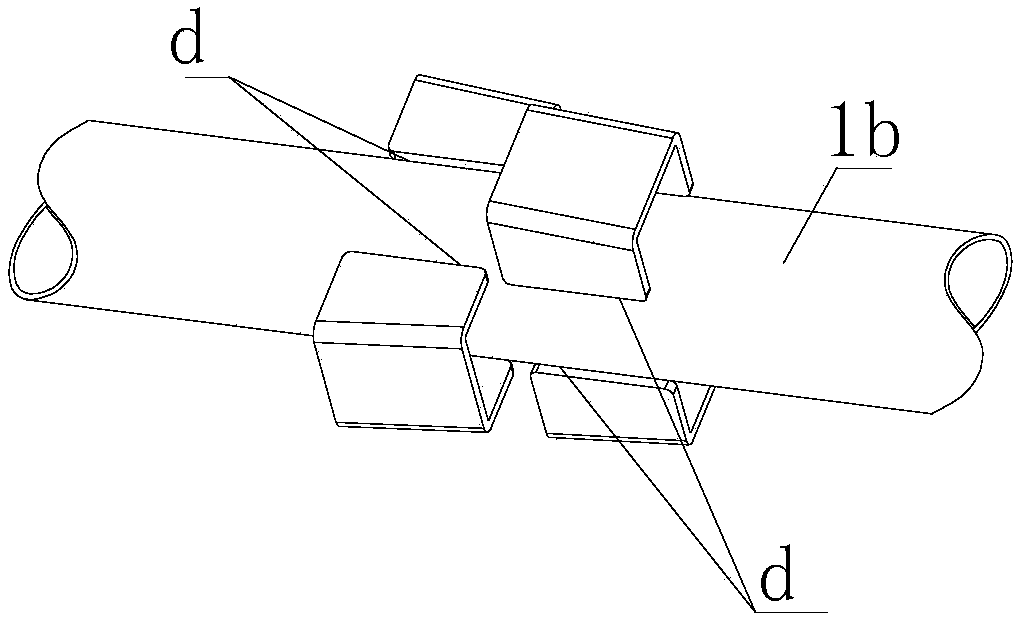

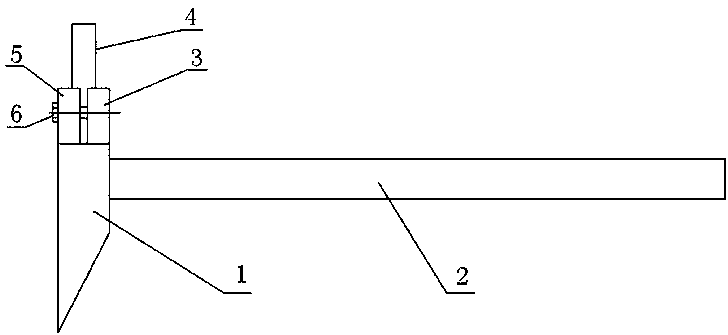

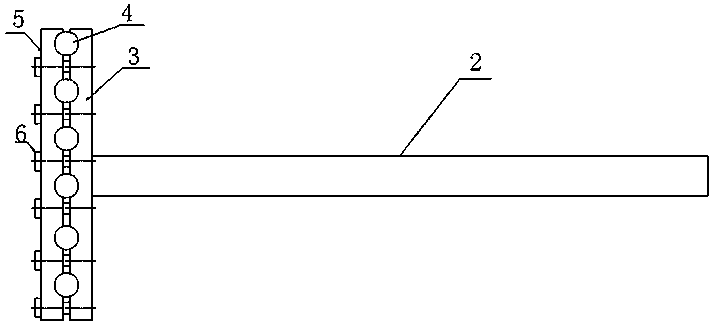

Automatic scaffold welding machine and welding method thereof

ActiveCN108098126AFast solderingEasy to replaceResistance electrode holdersWelding/soldering/cutting articlesEngineeringSpot welding

The invention provides an automatic scaffold welding machine. The welding machine is used for automatic welding of a main steel pipe serving as a vertical rod in a steel pipe scaffold with socket andspigot joints and a socket pipe and an U-shaped socket part. The welding machine comprises a base, the front side of the base is provided with a three-shaft position-changing device for switching a feeding station with a workpiece to be welded and a welding station and realizing rapid welding of the two surfaces of the workpiece to be welded through 180-degree-rotation of the welding station; twogantry type welding gun supports which are vertically arranged are installed on the two sides of the rear side of the base, a cross frame beam is arranged between the two welding gun supports, and thecross frame beam is provided with a spot welding mechanism which is used for carrying out spot welding on the socket pipe which is at the welding station of the three-shaft position-changing device and fixed on the main steel pipe and a multiple sets of double-gun welding mechanisms which are used for simultaneously welding weld joints of all U-shaped socket parts; and one end of the cross framebeam is provided with a welding gun walking mechanism which is used for pulling the multiple sets of double-gun welding mechanisms to move at the same time to carry out welding on the welding joints of all the U-shaped socket parts correspondingly. The invention further provides a welding method of the automatic scaffold welding machine.

Owner:ZHUHAI RUILING WELDING AUTOMATION CO LTD

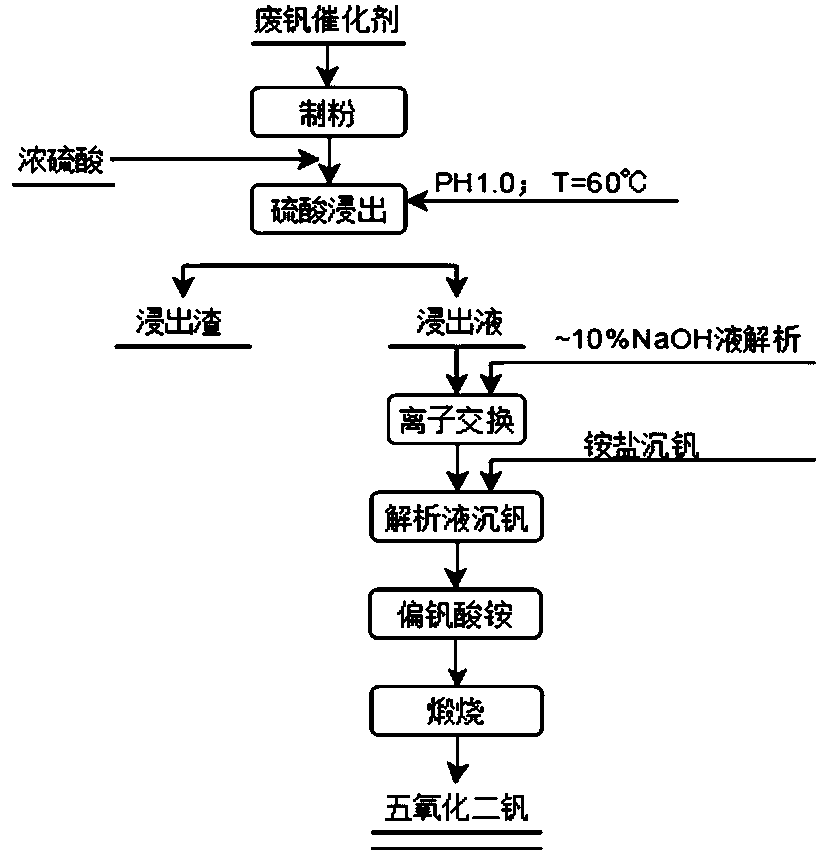

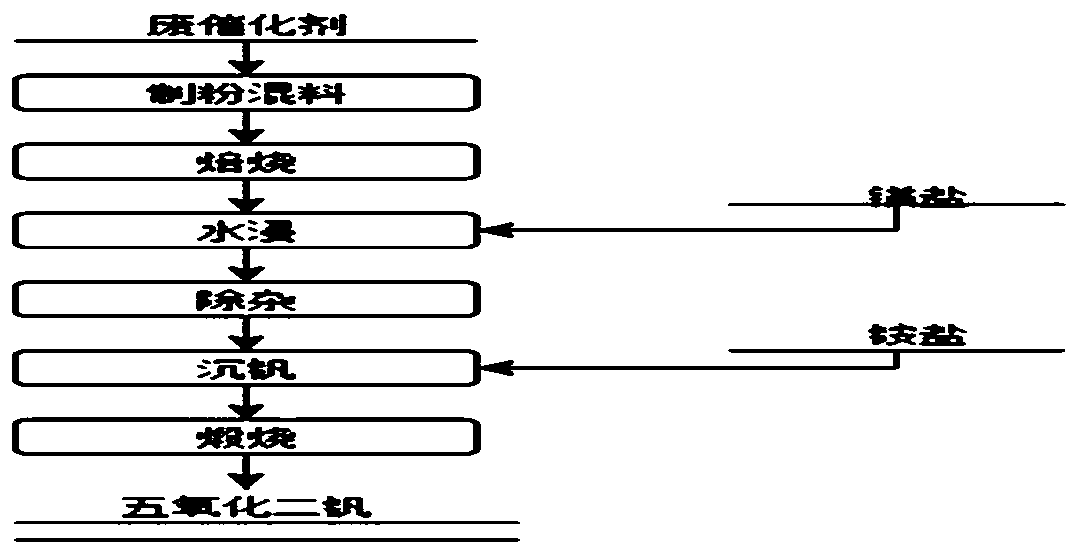

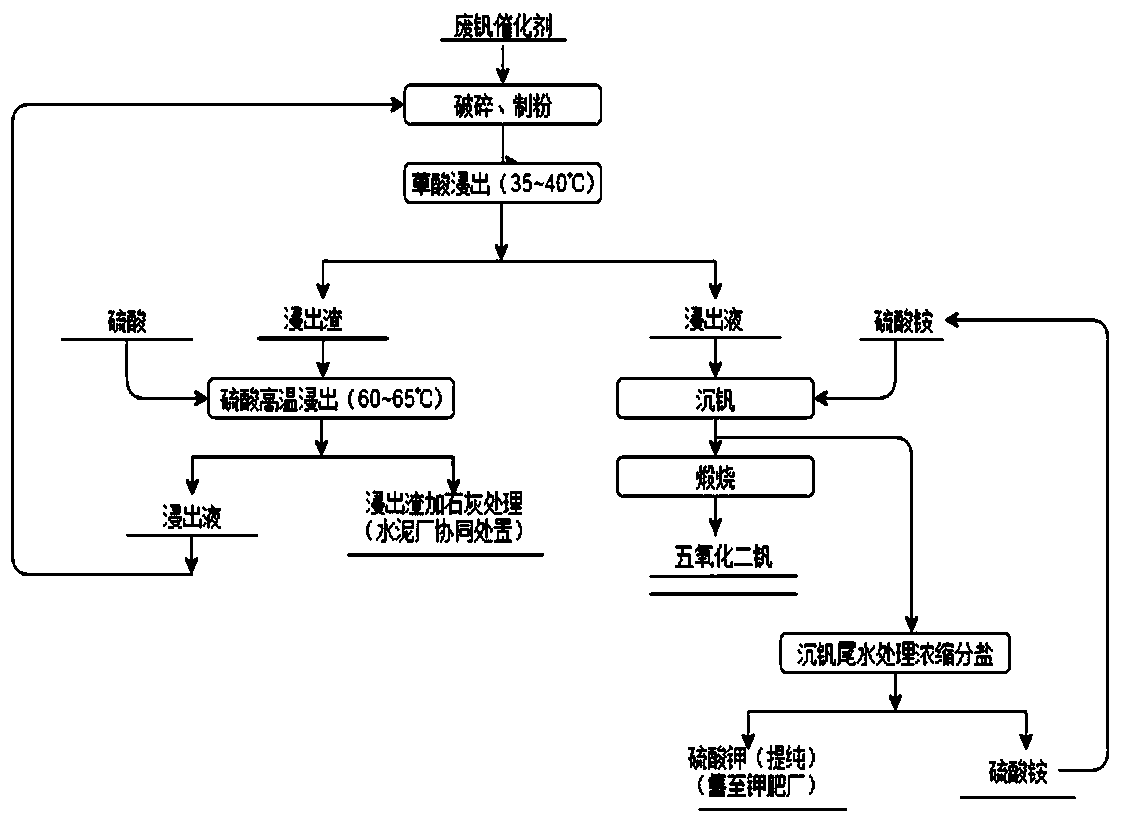

Method for preparing vanadium pentoxide by treating vanadium-containing waste sulfuric acid catalyst through two-step method

ActiveCN111455186AControl leaching rateReduce processing difficultyProcess efficiency improvementOXALIC ACID DIHYDRATEPtru catalyst

The invention discloses a method for preparing vanadium pentoxide by treating a vanadium-containing waste sulfuric acid catalyst through a two-step method. The pH value is controlled to be 5-6 throughoxalic acid leaching in a first step, namely the leaching rate of vanadium is controlled to be between 65% and 75%, and simultaneously a large amount of impurities (Al, Ni, Cu and the like) are inhibited from being separated out; the PH is controlled to be 1.5-2.0 through sulfuric acid leaching in a second step, the leaching accumulation of vanadium is controlled to be larger than or equal to 90%, meanwhile, a small amount of impurities such as Al are leached, leaching liquid returns to the first step of oxalic acid leaching (when the small amount of impurities leached in the second step return to the first step of leaching, precipitates are generated again and enter slag), and meanwhile, the first-step leaching is completed by utilizing the temperature of the leaching liquid, so that thecost is reduced; leaching residues are washed in the second step, the leaching residues are centrally collected, lime is added to be mixed, and the mixture is sold to a cement plant to serve as clinker of the cement plant; the leaching liquid is prepared after the first step of oxalic acid leaching, vanadium precipitation of ammonium sulfate is directly adopted to prepare an ammonium polyvanadateintermediate product, concentrated sulfuric acid needs to be added in the production process, residual oxalic acid in the leaching liquid completely reacts with the concentrated sulfuric acid to eliminate obstacles for subsequent water treatment, and solid ammonium sulfate prepared after water treatment returns to a production system, and potassium sulfate is purified and sold to potash fertilizer production enterprises to be used as a raw material.

Owner:江苏美东环境科技有限公司

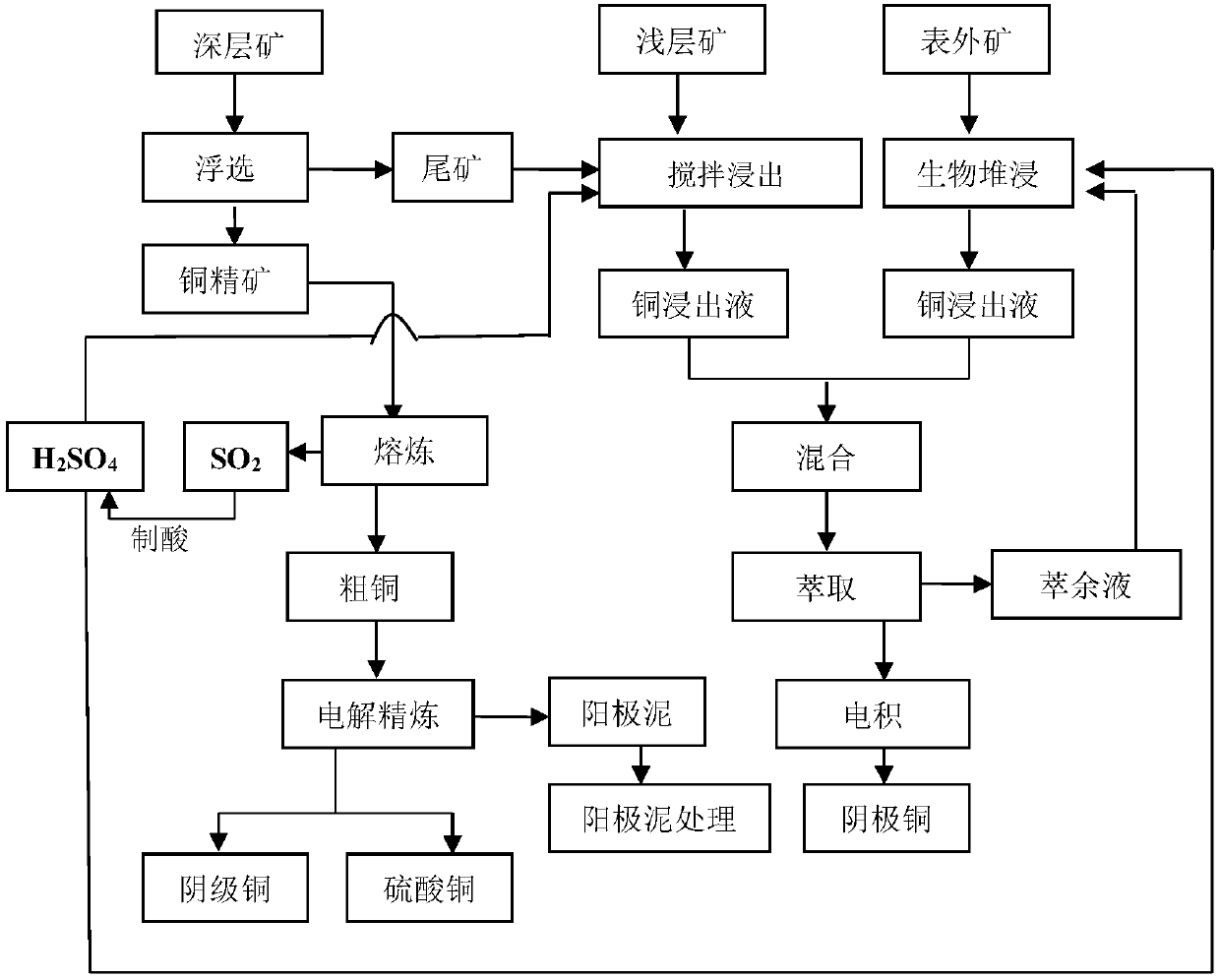

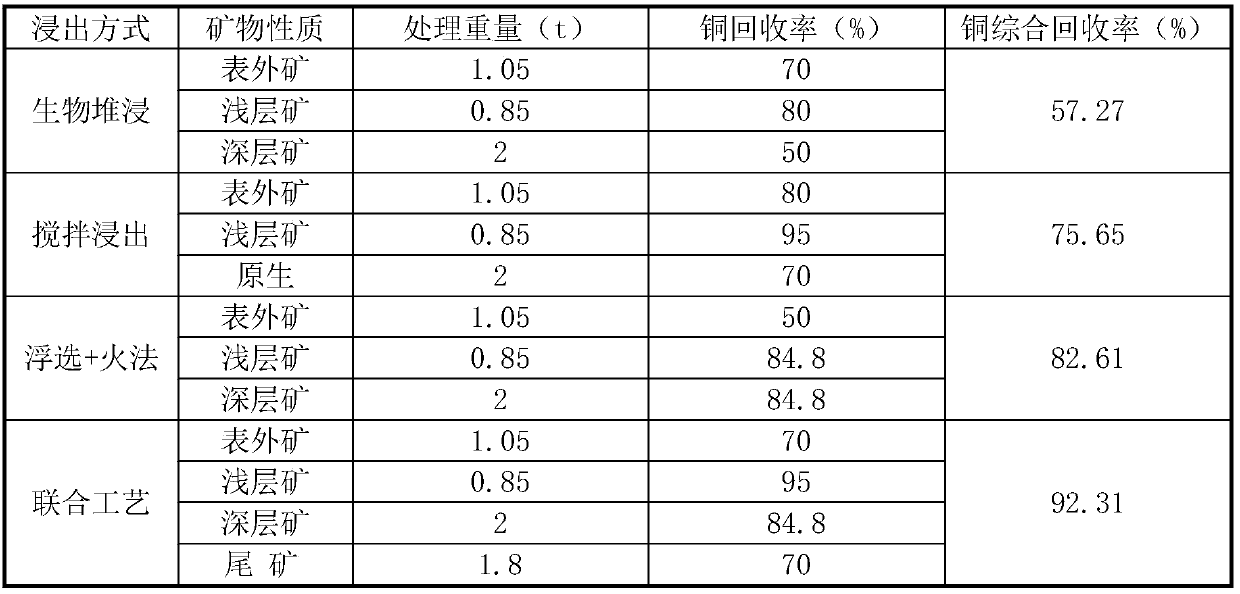

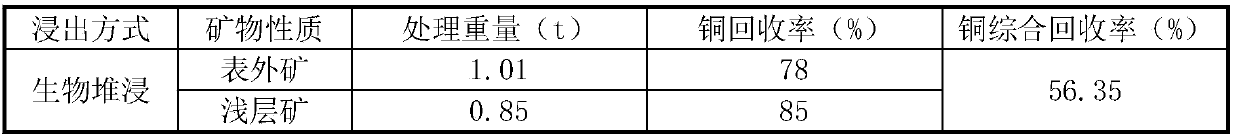

Combined technology for treating copper sulfide ore

ActiveCN107779596AComprehensive recovery rate is highGood economic benefitsPhotography auxillary processesProcess efficiency improvementCopper leachingHeap leaching

The invention relates to a combined technology for treating copper sulfide ore. The combined technology comprises a biological heap leaching technology, a stirring and leaching technology, and a flotation and fire-process technology; an ore body is divided into three types according to the following technology: firstly, carrying out crushing, ore grinding and flotation on deep-layer ore to obtaincopper concentrate and floated tailings; carrying out fire-process smelting on the copper concentrate to obtain crude copper and sulfuric acid; carrying out electrolytic refining on the crude copper to obtain cathode copper, copper sulfate and anode mud; recycling rare bulk noble metal from the anode mud; then stirring and leaching by utilizing sulfuric acid generated by a fire process, and carrying out crushing, ore grinding, acid leaching, biological stirring and leaching, extraction and electrodeposition on shallow-layer ore to obtain the cathode copper; carrying out the biological stirringand leaching to obtain a copper leaching solution and carrying out biological heap leaching; carrying out crushing, acid leaching, biological heap leaching, extraction and electrodeposition on surface ore to obtain the cathode copper; carrying out biological heap leaching to obtain a copper leaching solution; then commonly extracting the copper leaching solution of the two steps to obtain an electric pregnant solution and raffinate; and carrying out electrodeposition on the pregnant solution to obtain the cathode copper. The combined technology provided by the invention has the advantages ofcomplementary technology advantages, acid balance in a production process, environment friendliness, high comprehensive recycling rate, remarkable economic benefits, no resource waste and the like andis suitable for application of extracting the copper from various copper sulfide ores.

Owner:ZIJIN MINING GROUP +1

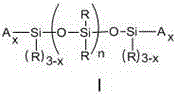

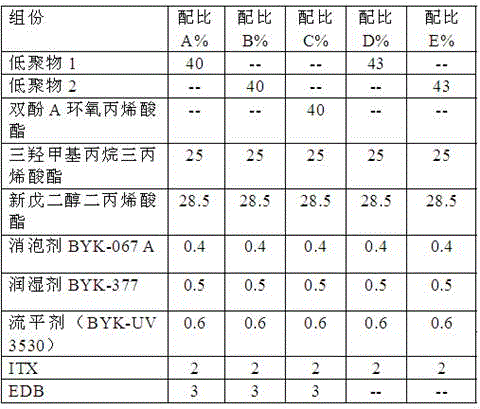

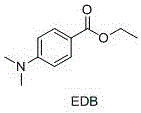

Amino-containing polysiloxane-acrylic ester and preparation method and application thereof

The invention provides a novel weather-resistant amino-containing polysiloxane-acrylic ester oligomer for photocuring of LED (light emitting diodes). The polysiloxane-acrylic ester oligomer is prepared by the following steps of using amino-terminated polysiloxane in formula I as raw material, reacting with one or two types of single-function group acrylic ester or methacrylate, and then reacting with one or two types of double-function group acrylic ester or methacrylate, so as to obtain the oligomer shown in the attached figure. The polysiloxane-acrylic ester oligomer has the advantages that a large amount of tertiary amine structures and siloxane structures is contained, the anti-oxidizing and polymerization inhibition effects of a photocuring formula under an LED light source are greatly improved, and the surface dryness function of a coating is promoted; the compatibility is good, the preparation is easy, the cost is low, and the storage is easy.

Owner:TIANJIN JIURI NEW MATERIALS CO LTD

Device for producing spodumene and preparation process

ActiveCN103922355AMeet heat transfer needsReduce energy consumptionAluminium silicatesCooling effectProcess engineering

The invention discloses a device for producing spodumene and a preparation process. The device comprises a coarse particle suspension preheater, a rotary kiln, a separating valve and a leakage-free grate type cooling machine which are sequentially connected. The preparation process comprises the steps of preheating by adopting the coarse particle suspension preheater, roasting and transforming by adopting the rotary kin, separating by adopting the separating valve, and cooling by adopting the leakage-free grate type cooling machine. According to the device, by designing the coarse particle suspension preheater, tail gas of the rotary kiln is fully utilized for preheating, thus the energy consumption is reduced; by adopting the separating valve, the spodumene discharged out from the kiln can be effectively separated, and the safe and smooth operation of the whole system is ensured; by adopting the leakage-free grate type cooling machine, an optimal cooling effect can be achieved, and heat carried away by the spodumene discharged out from the kiln is fully utilized, thus the energy consumption of the system is reduced. The device realizes large-scale production and central automatic operation control of the spodumene, thereby greatly increasing the labor productivity and being better in economic benefit and environment protection benefit.

Owner:SICHUAN CALCINER TECH

Feces clearing tool used for sow production bed

The invention provides a fences clearing tool used for a sow production bed. The fences clearing tool comprises a flat scraping plate, a handle, a fixing plate, a pressing plate and column-shaped brushing bristles composed of steel wires. The handle is fixedly connected to the flat scraping plate, multiple circular-arc grooves for containing the column-shaped brushing bristles are correspondingly formed at certain intervals in the fixing plate and the pressing plate, the fixing plate is fixedly welded to the back face of the scraping plate, and the column-shaped brushing bristles are fixed at intervals through screws, the pressing plate and the fixing plate and form a steel wire brush. The flat scraping plate can be adopted for effectively clearing away dry fences accumulated on a cracked floorboard of the sow production bed in time, the dry fences remaining in cracks of the cracked floorboard can be directly cleared away through the steel wire brush, then in cooperation with water flushing, thorough clearing is performed, and therefore the fences clearing tool achieves clean, efficient and environmentally friendly production.

Owner:竹溪县塔二湾种猪扩繁场(普通合伙)

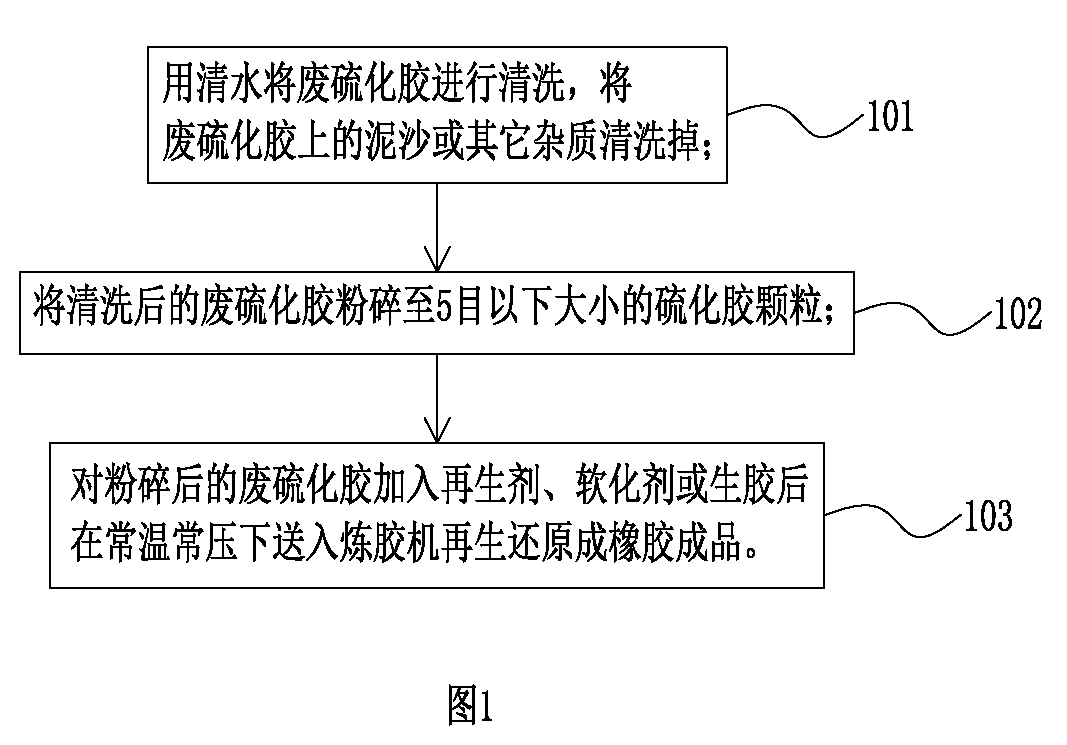

Regenerated rubber production method

The invention provides a regenerated rubber production method. The method mainly comprises the following steps of: washing and removing impurities from waste vulcanized rubber; grinding the washed waste vulcanized rubber; and adding a regenerating agent, a softening agent or raw rubber to the ground waste vulcanized rubber, and then regenerating the mixture to obtain the finished product of the rubber. The method has the beneficial effects that the crosslink bonds among rubber molecules are broken without damaging rubber macromolecules by utilizing the substitution reaction of chemical substances; due to production at normal temperature, the destructive effects of oxygen on the rubber are greatly reduced; the plasticity of the rubber is restored by adopting the method of breaking the crosslink bonds; meanwhile, the compatibility of the rubber with the raw rubber is enhanced so that the rubber becomes a rubber compound; and the production method truly achieves wastewater-free, waste gas-free and pollution-free environment-friendly production, thus truly achieving rubber recycling.

Owner:陈漫远

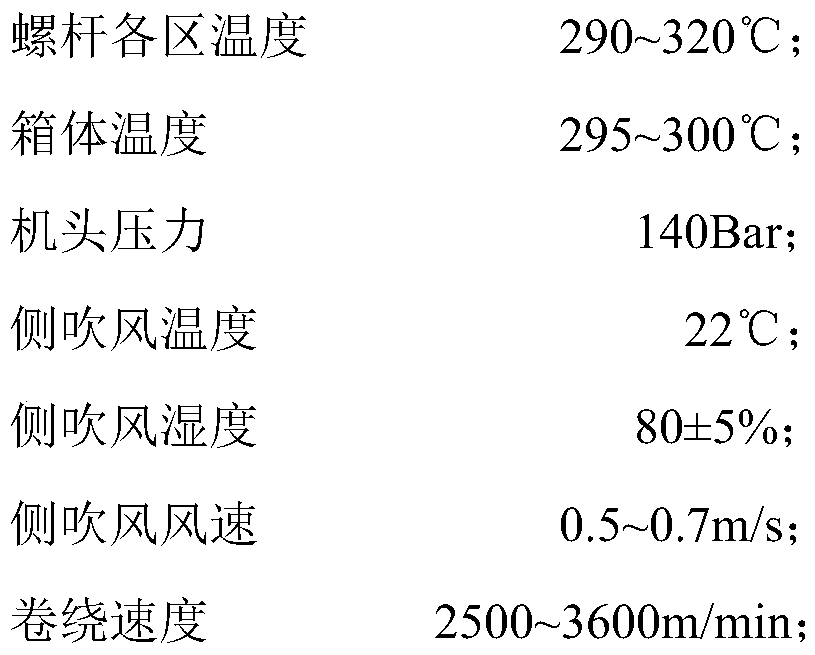

Method for preparing marine polyester cable

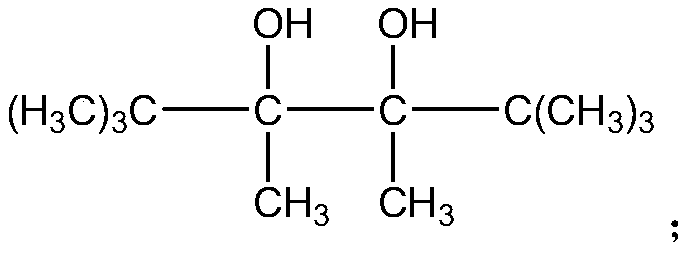

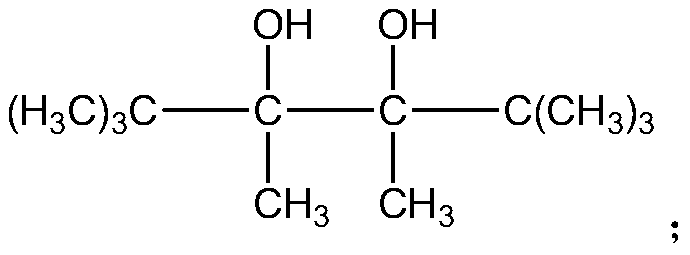

ActiveCN109735935AImprove dipping effectHigh breaking strengthArtificial filament heat treatmentMelt spinning methodsSolid phasesDisiloxane

The invention relates to a marine polyester cable and a preparation method thereof. The marine polyester cable is prepared by the following steps: twisting modified polyester industrial yarns, and performing impregnation treatment on the woven rope, thereby obtaining the marine polyester cable. The modified polyester industrial yarns are prepared by performing solid phase polycondensation tackifying on modified polyester melt and performing spinning; the preparation method of the modified polyester before solid phase polycondensation tackifying comprises the following steps: uniformly mixing terephthalic acid, ethylene glycol, dihydric alcohol containing silicon on the main chain, 2,5,6,6-tetramethyl-2,5-heptandiol and metal oxide doped modified Sb2O3 powder, and sequentially carrying outan esterification reaction and a polycondensation reaction; the dihydric alcohol containing silicon on the main chain comprises dimethyl silicone diol, dimethyl diphenyl disiloxane diol or tetramethyldisiloxane diol; and the prepared marine polyester cable has the linear density of 1200+ / -3ktex and the breaking strength of more than or equal to 480kN. The method disclosed by the invention is simple in process, and the prepared marine polyester cable is high in breaking strength and high in quality.

Owner:JIANGSU HENGLI CHEM FIBER

Method for preparing p-phenylenediamine

InactiveCN109651158AReduce manufacturing costControl conversion rateOrganic compound preparationAmino compound preparationHydrogenP-Nitroaniline

The invention discloses a method for preparing p-phenylenediamine. A reduction reaction is carried out on paranitroaniline with hydrogen in the presence of a catalyst. According to the preparation method, the temperature, pressure and reaction time in the reduction reaction are controlled, and the conversion rate of p-phenylenediamine is controlled. According to the method, a hydrogenation reduction production mode is adopted, environment-friendly production is achieved, pollution is low, the conversion rate of paranitroaniline is increased, and high-purity p-phenylenediamine is obtained.

Owner:安徽高盛化工股份有限公司

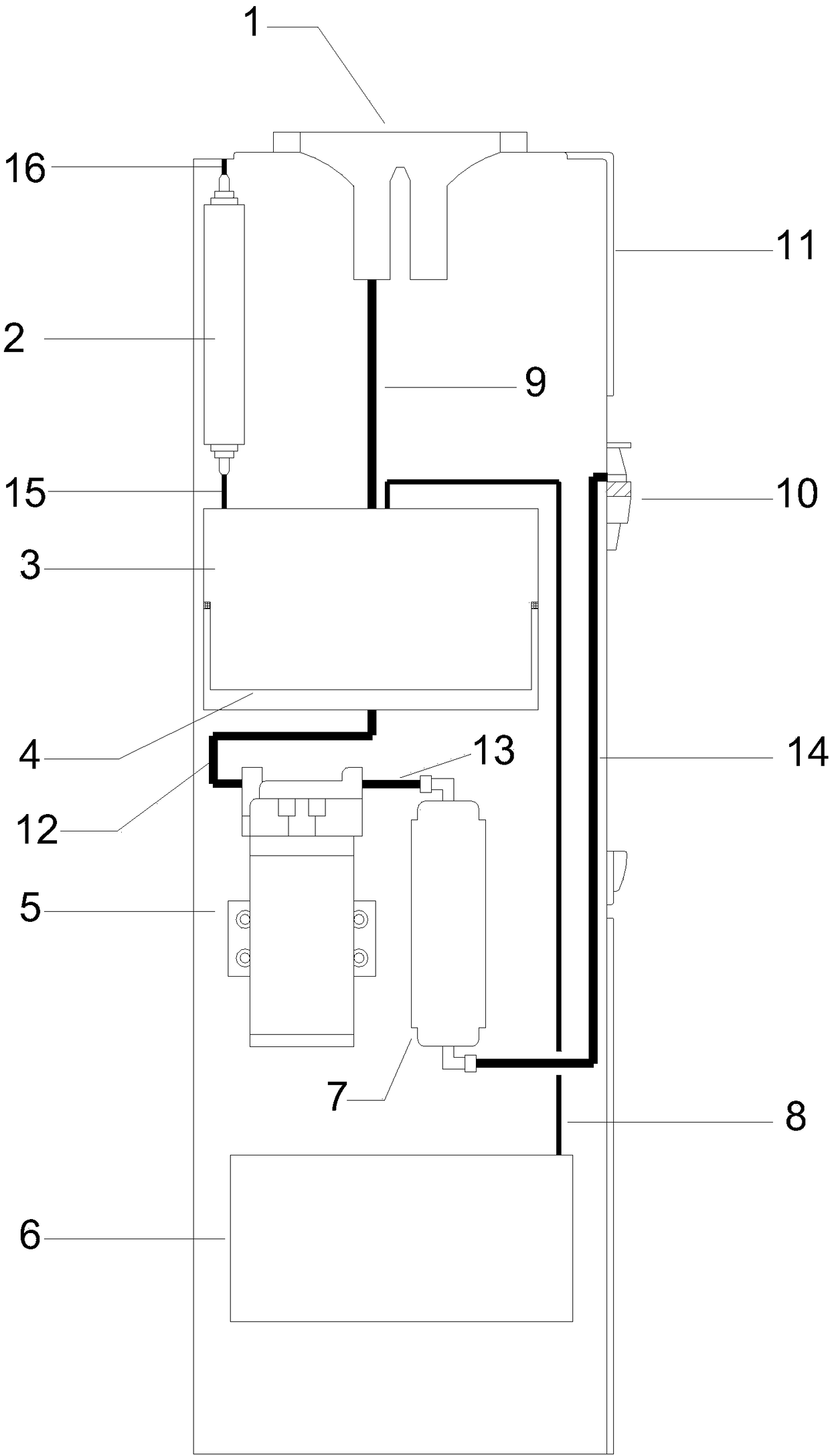

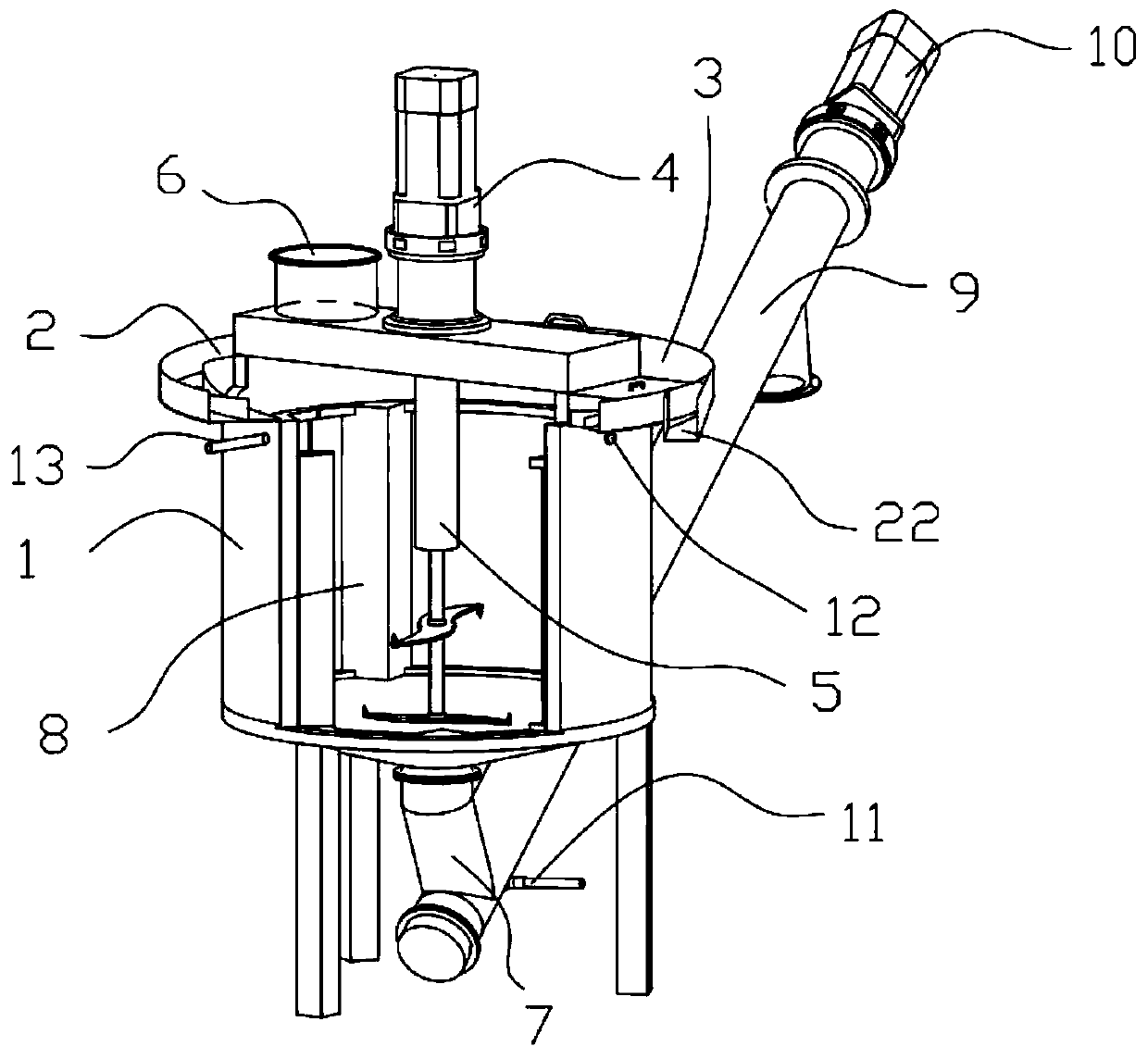

Preparation device for pearl essence selenium-enriched nutrient solution

PendingCN108585291AEasy to introduceAvoid introducingWater treatment compoundsTreatment involving filtrationParticulatesDecomposition

The invention relates to a preparation device for a pearl essence selenium-enriched nutrient solution. The preparation device comprises a housing, wherein the housing is internally provided with a smart seat, a reactive oxygen molecule destruction device, a reaction tank, a stainless steel screen mesh, a booster pump, a reactive oxygen molecule generating device, a PP cotton filtering core, connecting pipelines, connecting water pipes and a faucet. Pure water enters the reaction tank through the smart seat. In the reaction tank, through a super-high oxidative decomposition effect of active oxygen molecules, beneficial substances of pearl powder and black jade are effectively promoted to be released in water to obtain suspension rich in various trace elements such as amino acids, polypeptides, selenium and the like. The suspension is filtered through the stainless steel screen mesh to remove large particulate matter and then filtered through the PP cotton filtering core to obtain the pearl essence selenium-enriched nutrient solution. According to the device, introduction of harmful additives is avoided, the risk of a preparation process is reduced, process flows are simplified, lessland is occupied, energy consumption is low, environmentally friendly production of the pearl nutrient solution is achieved, preparation of the pearl nutrient solution is introduced to daily life, and the device has a great popularization prospect and a high application value.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

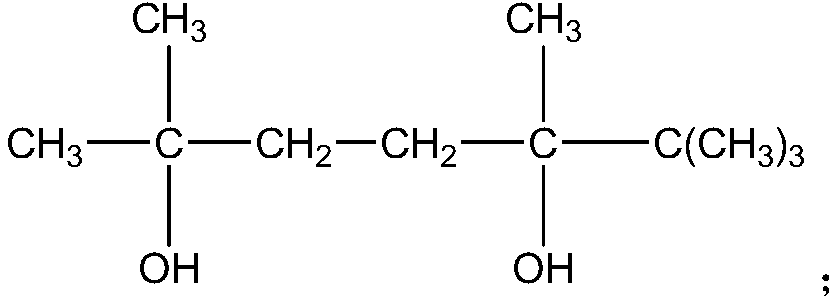

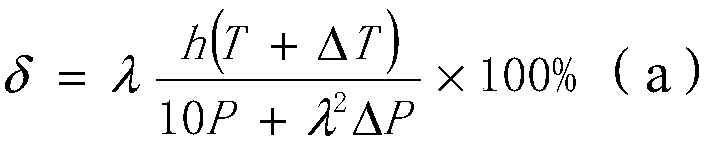

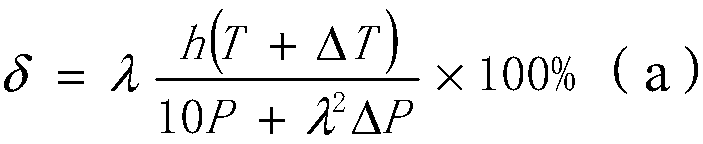

Easily-dyed porous modified polyester fiber and preparation method thereof

ActiveCN109735926AIncrease the void free volumeImprove permeabilityAntimony oxides/hydroxides/oxyacidsMonocomponent polyesters artificial filamentFiberDisiloxane

The invention relates to an easily-dyed porous modified polyester fiber and a preparation method thereof. The easily-dyed porous modified polyester fiber is prepared by a porous spinneret plate through an FDY process. The preparation method of modified polyester comprises the following steps: uniformly mixing terephthalic acid, glycol, dihydric alcohol with a silicon-containing main chain, 2,2,3,4,5,5-hexamethyl-3,4-hexanediol and a metal oxide doped and modified Sb2O3 powder, and sequentially carrying out esterification reaction and condensation polymerization reaction, wherein dihydric alcohol with the silicon-containing main chain is dimethylsilyl diol, dimethyl diphenyl disiloxane diol or tetramethyldisiloxane diol, and the structural formula of 2,2,3,4,5,5-hexamethyl-3,4-hexanediol isas follows: formula (shown in the description). The dyeing rate and K / S value of the prepared easily-dyed porous modified polyester fiber are high. The method is simple in process, and the finally prepared modified polyester fiber is good in dyeing performance and good in quality.

Owner:JIANGSU HENGLI CHEM FIBER

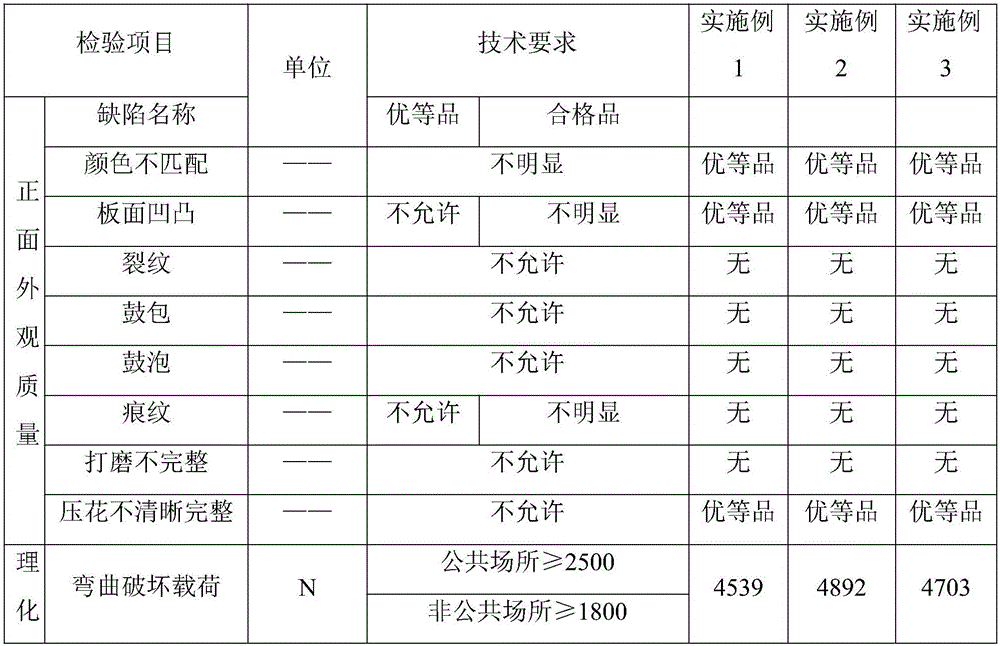

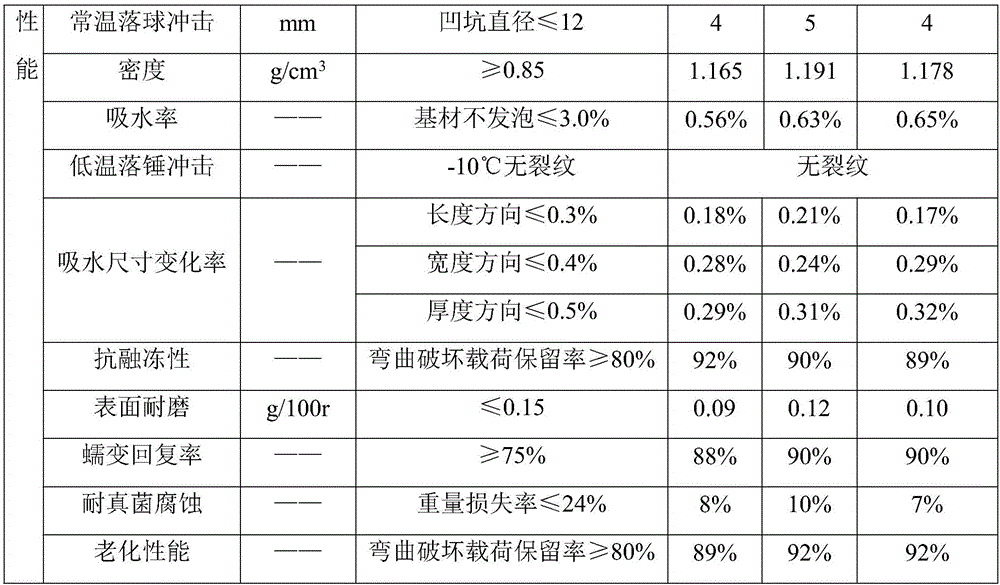

Enteromorpha wood and plastic floor and preparation method thereof

The invention relates to an enteromorpha wood and plastic floor and a preparation method thereof. The enteromorpha wood and plastic floor is prepared from the following components in parts by weight: 30 to 50 parts of enteromorpha dry powder, 10 to 20 parts of tea meal, 10 to 20 parts of straw powder, 10 to 20 parts of shell powder, 30 to 50 parts of recycled plastic, 10 to 20 parts of polyvinyl chloride, 0.5 to 1.5 parts of titanate coupling agent, 0.3 to 0.5 part of silane coupling agent, 5 to 15 parts of medical stone, 0.4 to 0.8 part of AC foaming agent, 0.3 to 0.5 part of toughening agent, 0.3 to 0.5 part of stabilizer, 1 to 2 parts of calcium propionate, and 1 to 3 parts of zinc stearate. The product provided by the invention has the advantages of environmental protection, wide raw material source, reasonable use of resources, low cost, good quality, low shrinkage rate and expansion rate, low density, light weight, and convenience in transport and installation.

Owner:QINGDAO HAIZHIXING BIOLOGICAL SCI & TECH

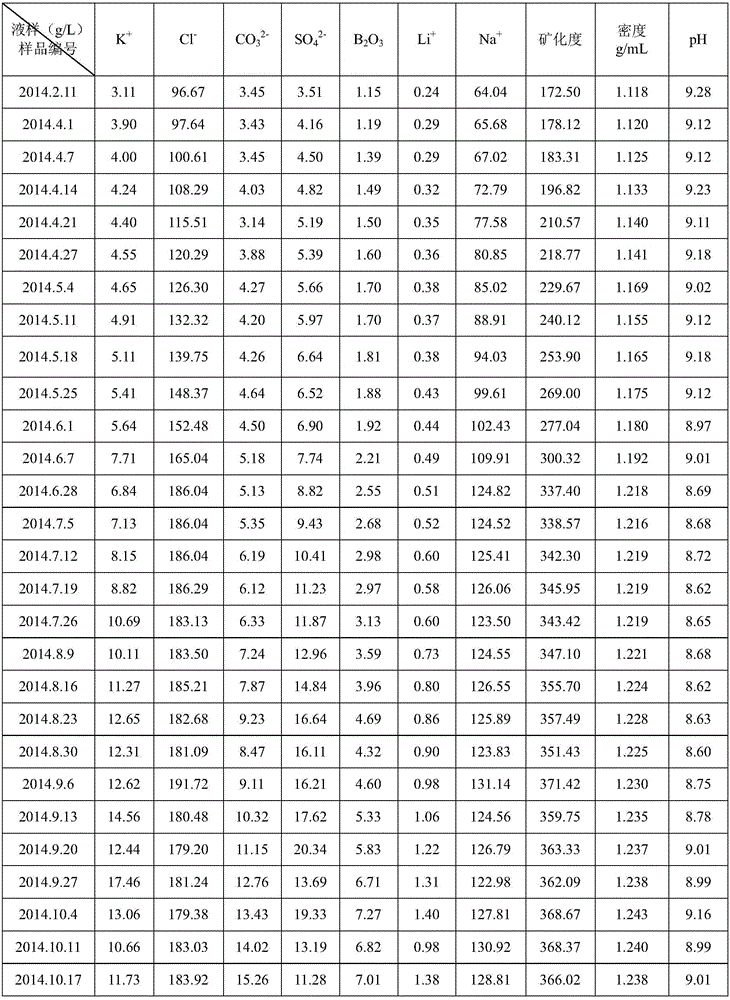

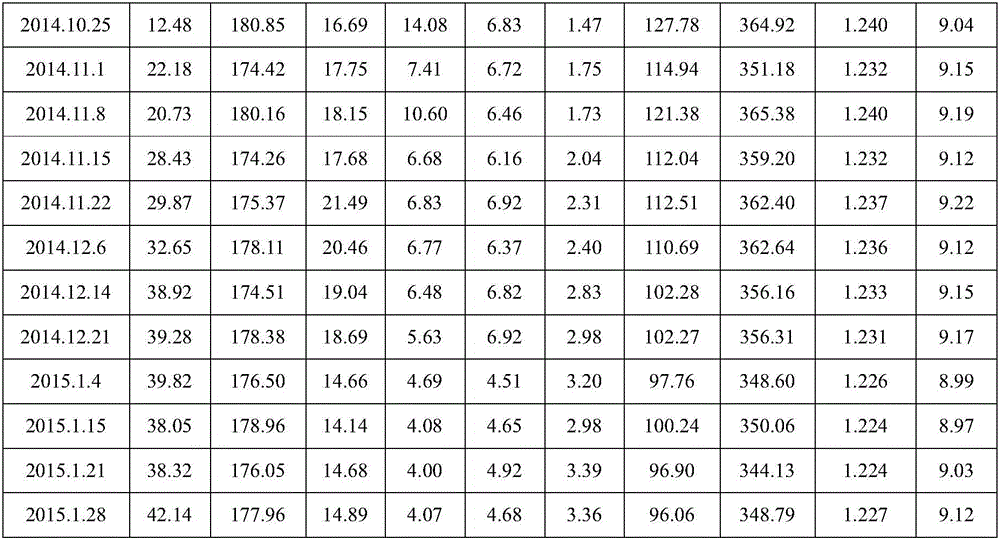

Method for preparing lithium carbonate from plateau carbonate bittern

ActiveCN105905929ARapid enrichmentGet rid of dependenceGeneral water supply conservationMultistage water/sewage treatmentLithium carbonateEvaporation

The invention provides a method for preparing lithium carbonate from plateau carbonate bittern. The method comprises the following steps: subjecting original carbonate bittern A to evaporation before autumn and winter, adjusting the concentration of lithium ions so as to allow the lithium ions not to be precipitated in the form of minerals and introducing the carbonate bittern A to a deep-pool salt field for evaporation when the concentration of lithium ions reaches 1.2 to 1.8 g / L; as considerable mirabilite decahydrate is precipitated at first when temperature is -15 to -5 DEG C and the concentration of lithium ions rapidly increases, carrying out solid-liquid separation so as to obtain bittern B when the concentration of sulfate ions decreases to 4 to 7 g / L and the concentration of lithium ions increases to 2.6 to 3.5 g / L; introducing the bittern B into a heating system for heating to 20 to 60 DEG C, allowing a first batch of lithium carbonate concentrate and bittern C to be precipitated; subjecting the bittern C to refrigeration at a temperature of -20 DEG C or below so as to realize precipitation of mixed salt I and carrying out solid-liquid separation when the concentration of sulfate ions decreases to 15 g / L or below and the concentration of lithium ions increases to 2 g / L or above so as to obtain bittern D; and continuing evaporating the bittern D, adding bittern with a carbonate ion concentration of 60 g / L or above when the concentration of lithium ions reaches 2.6 to 3.5 g / L again and carrying out heating to 20 to 60 DEG C so as to allow a second batch of lithium carbonate concentrate to be precipitated.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +1

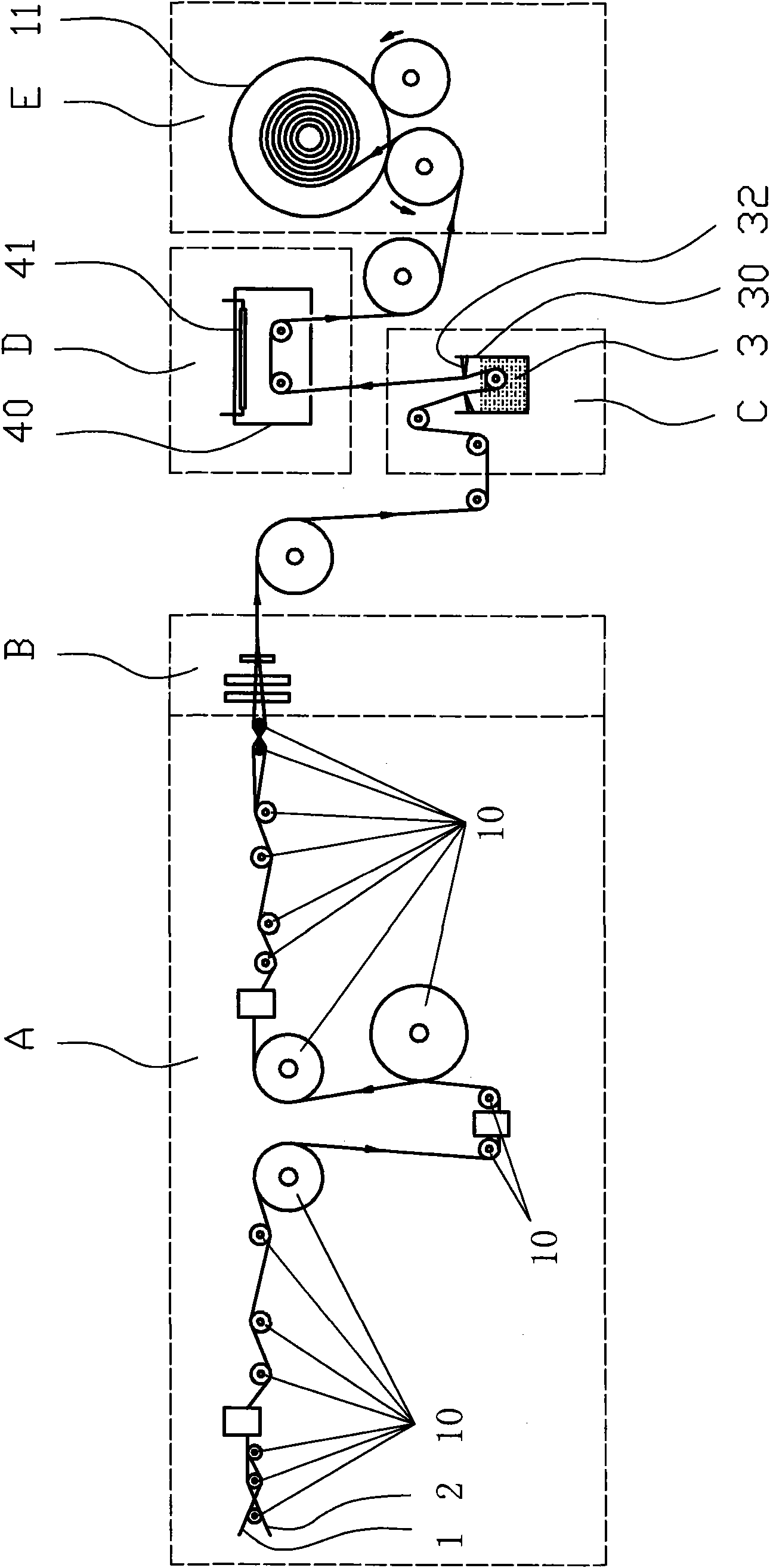

Eggshell membrane separation device, method and production line

The invention discloses an eggshell membrane separation device, method and production line. The eggshell membrane separation device includes a shell, a drainage plate, an upper cover plate and a mixing motor. The drainage plate is provided with a diversion groove and a collecting groove, the diversion groove communicates with the collecting groove, the output end of the mixing motor is connected with a mixing paddle, and the mixing paddle is provided with a first large blade and a second small blade; and the shell is further internally provided with a plurality of arc baffles, the baffles aremovably attached to the inner wall of the shell, and each baffle is provided with one or more bulges. Under the combined action of mechanical agitation, shear breaking and physical water separation ofthe device, the cleaning of eggshell membranes and the high-efficiency continuous automatic separation discharging are realized simultaneously. By using the separation method, device and production line, the purity of the eggshell membranes obtained by separation can reach up to 97% or more, and moreover, by additionally arranging a recovery and purification water pool behind an egg membrane collection device, production water can be recycled. The separation method has the significant advantages of convenient operation, high separation efficiency, high purity of the separated egg membranes, continuous and automatic operation and cost saving.

Owner:湖北神地农业科贸有限公司 +2

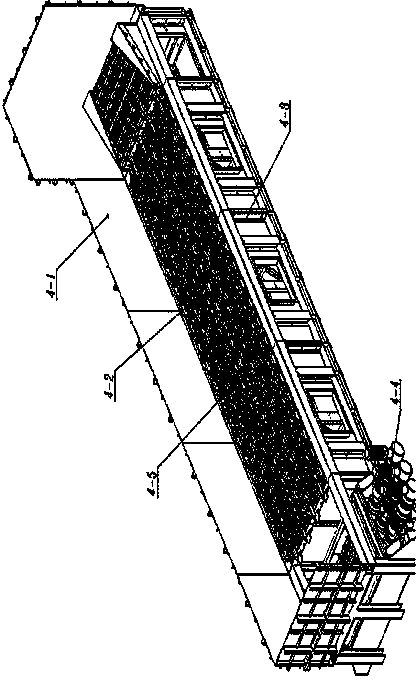

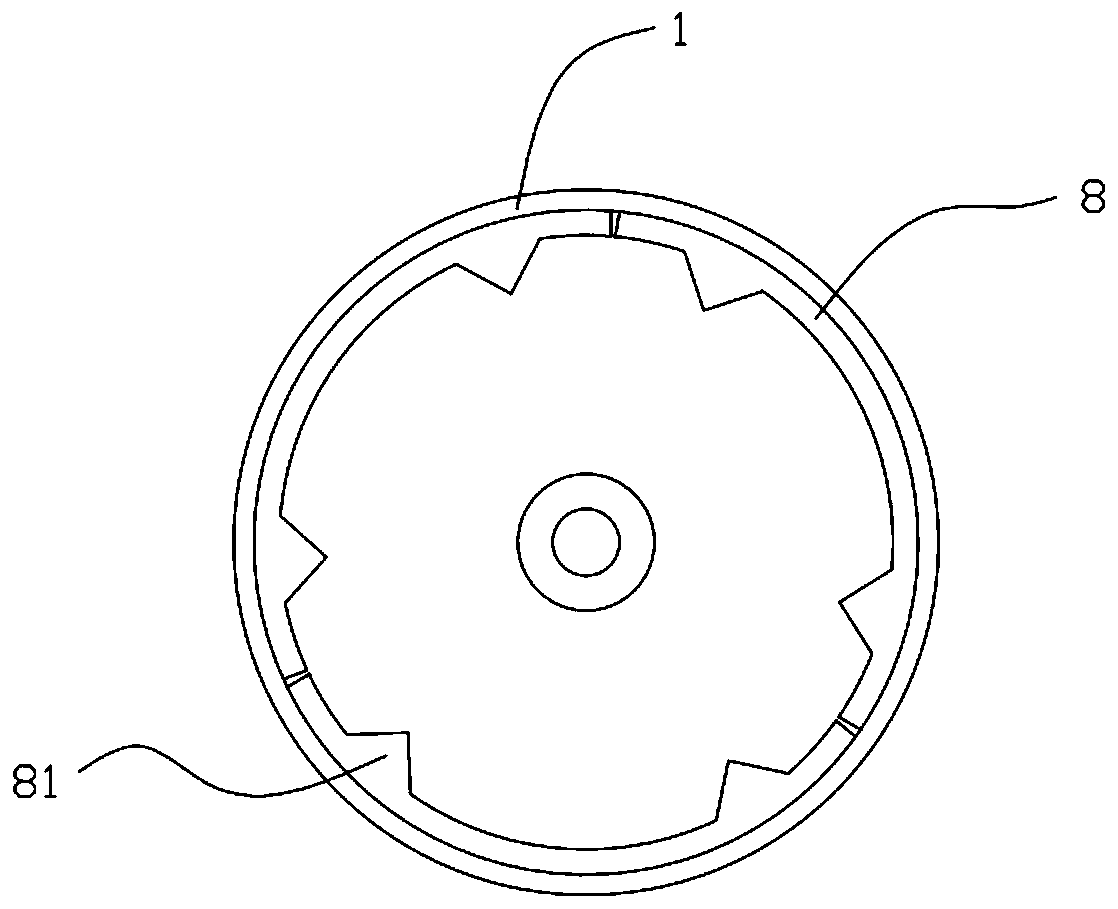

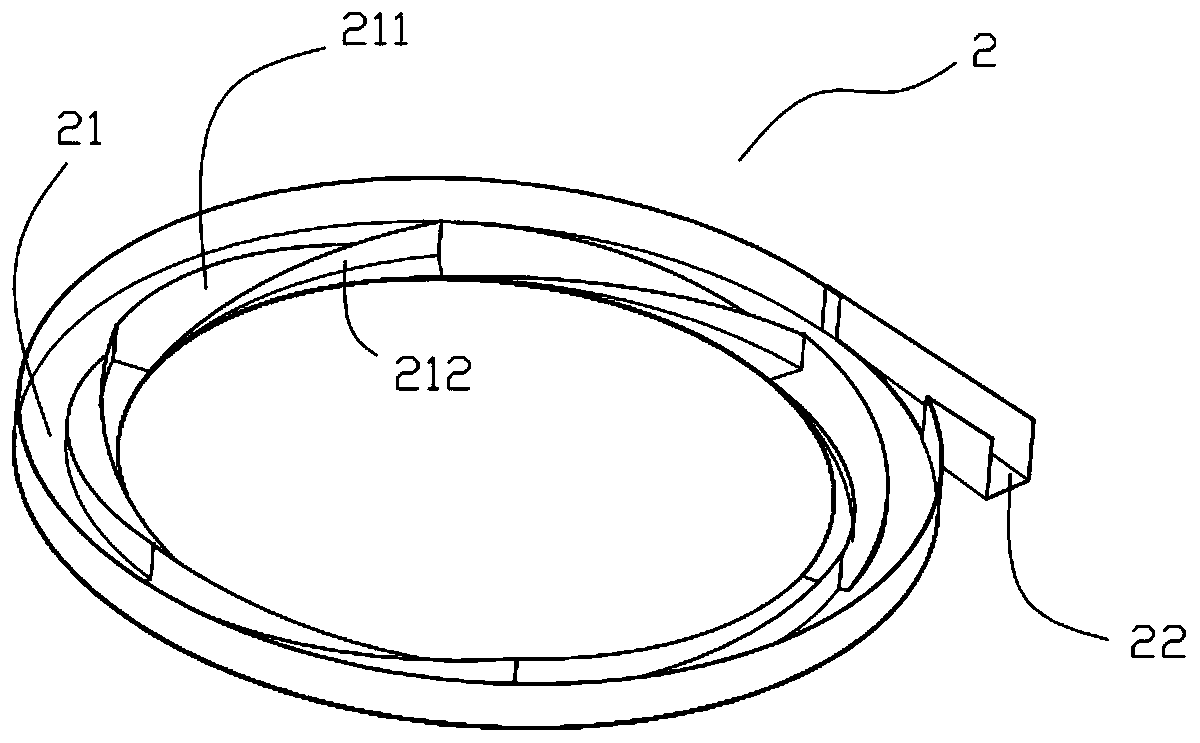

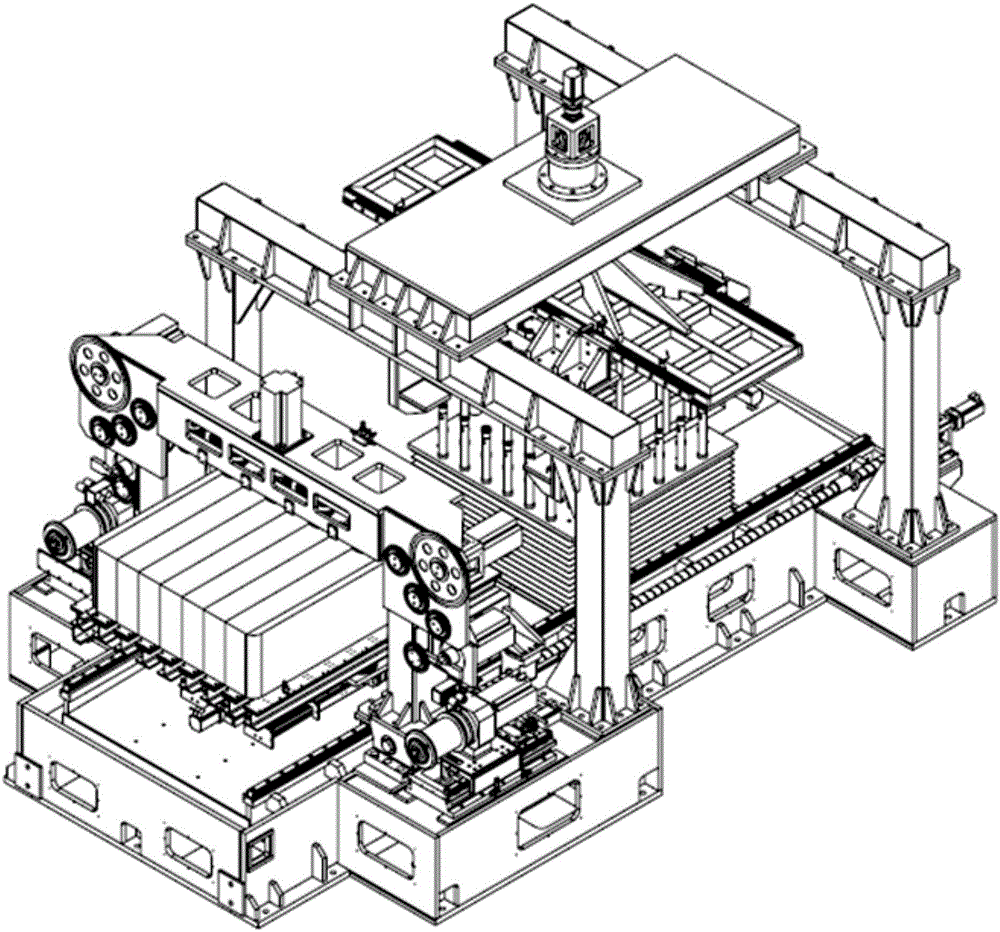

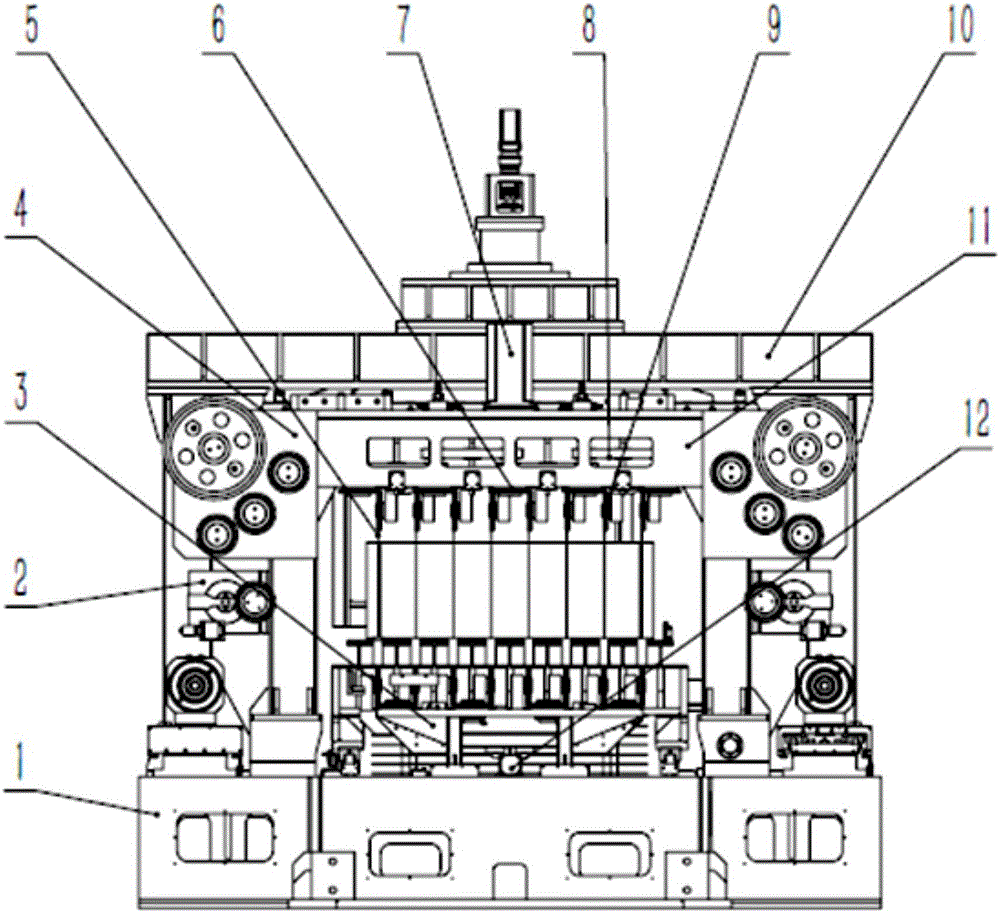

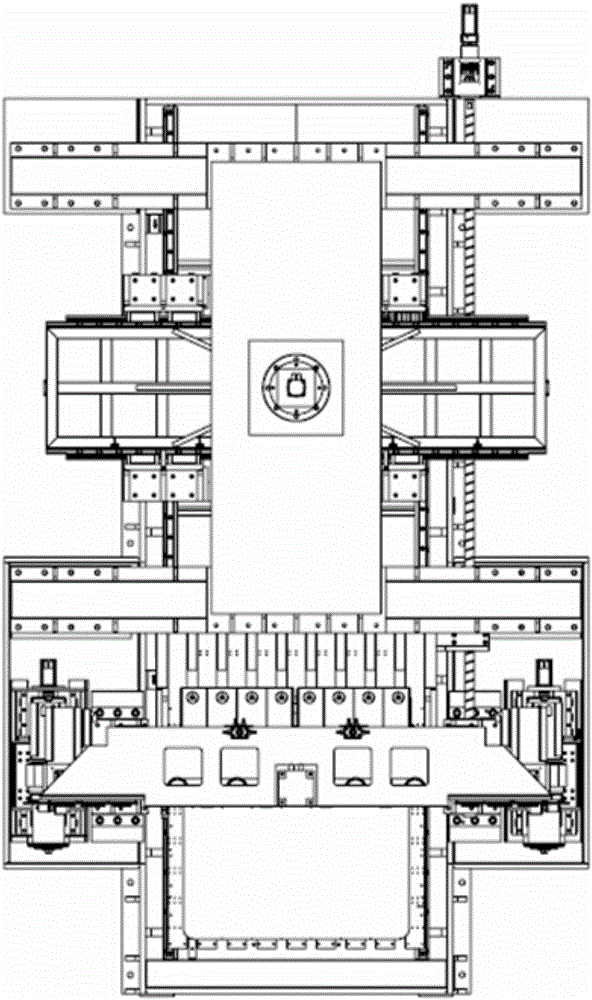

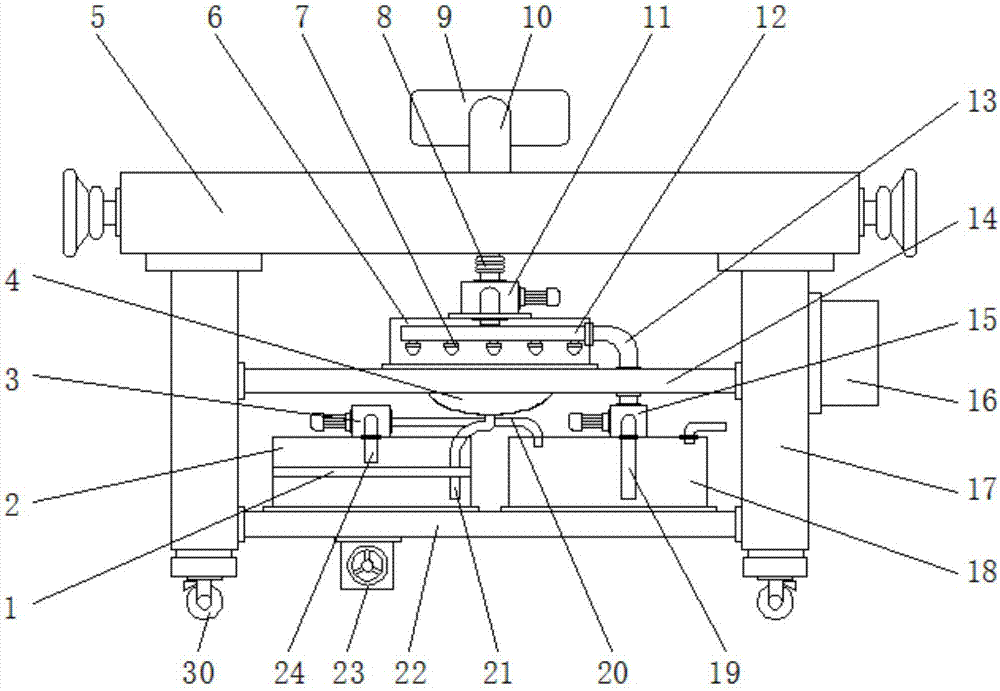

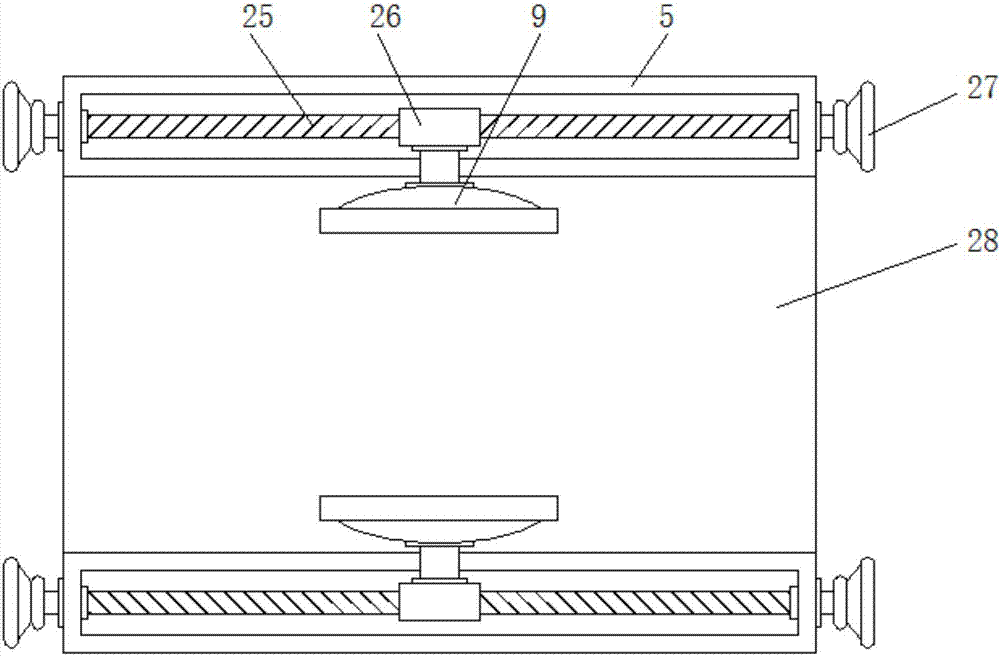

Diamond wire crystal ingot squarer

ActiveCN106182480AReduce lossSmall cutting marksFine working devicesDiamond wire sawWorking environment

The invention relates to cutting equipment special for polycrystalline silicon processing and aims to provide a diamond wire crystal ingot squarer. The diamond wire crystal ingot squarer comprises a large bottom frame, a workbench, a workbench horizontal moving motor, a speed reducer, a main screw, a manipulator part, a cutting chamber part, a lifting mechanism, a take-up and payoff part, a tension part and a bottom guide wheel part. According to the diamond wire crystal ingot squarer, a diamond wire saw is adopted for cutting, a cutting mark is small, a cutting face is high in quality, material loss is reduced greatly, and the work environment is improved. According to the diamond wire crystal ingot squarer, a novel rotary mechanism is adopted for decreasing the height of the workbench, and thus the axis distance of a cutting guide wheel is reduced. The wire arch is small, cutter feeding is fast, the cutting efficiency is high, and the cutting dimensional deviation caused by a hard point is avoided. According to the diamond wire crystal ingot squarer, a horizontal moving function is added to a bottom guide wheel, a cutting line is changed into an oblique line from a vertical line during second time of cutter feeding, only a cutting-in opening is cut in the upper portion of a crystal ingot, and thus the uncontrollable size and edge breakage are avoided.

Owner:ZHEJIANG JINGSHENG MECHANICAL & ELECTRICAL

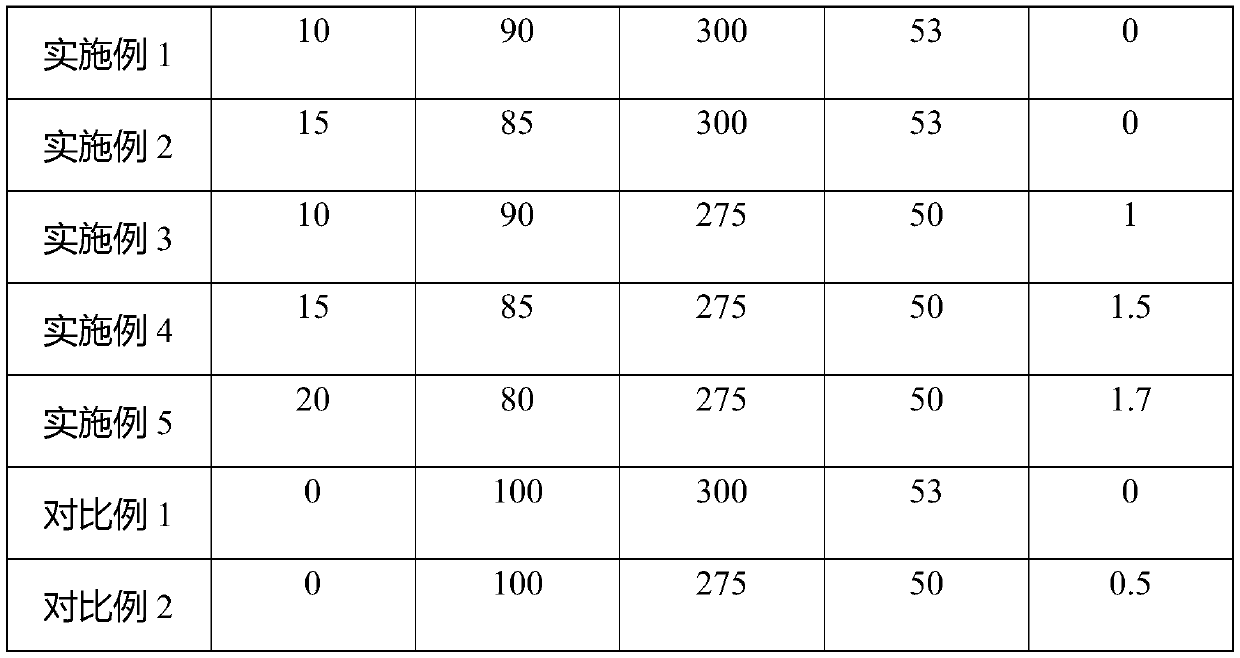

Method for manufacturing mold core of inorganic binder sand cold core box for casting

InactiveCN110711846AReduce the amount addedRealize environmentally friendly productionFoundry mouldsFoundry coresCastingCeramic materials

The invention discloses a method for manufacturing a mold core of an inorganic binder sand cold core box for casting. The method comprises the following steps of: filling a mixture of an inorganic binder for casting, an optional additive and crude sand into a mold, and hardening the mold core by blowing, wherein the blowing process is a mode I or a mode II, the mode I is a mode of blowing CO2 gasand compressed gas in sequence, and the mode II is a mode of blowing the compressed gas, the CO2 gas and the compressed gas in sequence, and the CO2 gas and the compressed gas have pressure. The method can solve the problems of easy over-blowing, high binder adding amount, low sand mold strength and the like in the process of hardening the mold core by blowing CO2 through water glass sand for casting in the prior art. Compared with the common CO2 blowing method, the method has the advantages that the strength of the manufactured mold core can be obviously improved, and the used sand can be regenerated and recycled.

Owner:CHINA FIRST AUTOMOBILE +1

Dust treatment device used in stone material processing

ActiveCN107497211AEfficient removalReduce pollutionGas treatmentUsing liquid separation agentWater resourcesEngineering

The invention discloses a dust treatment device used in stone material processing, which includes a workbench, two auxiliary fixing boards, and two dust collecting covers. The auxiliary fixing boards are fixed to both sides of the workbench. A screw rod is movably installed in the inner side of each auxiliary fixing board through a bearing. Two ends of each screw rod respectively penetrate through the two ends of each auxiliary fixing board and are respectively connected to adjustment knobs. A moving block is movably installed on each screw rod. Each dust collecting cover is respectively fixed on one side, which is closed to the workbench, of each moving block. Four supporting legs are installed on the four corners of the bottom of the workbench through bolts. A first mounting plate is fixedly connected between the four supporting legs. A second mounting plate is arranged above the first mounting plate and is fixedly connected between the four supporting legs. A water tank and a settlement tank are arranged parallelly on the first mounting plate. A sprinkling box is installed on the second mounting plate. A water solution in the settlement tank can be recycled, so that the dust treatment device not only effectively removes dust but also is reduced in production cost and saves water resource.

Owner:贵州天韵石尚有限公司

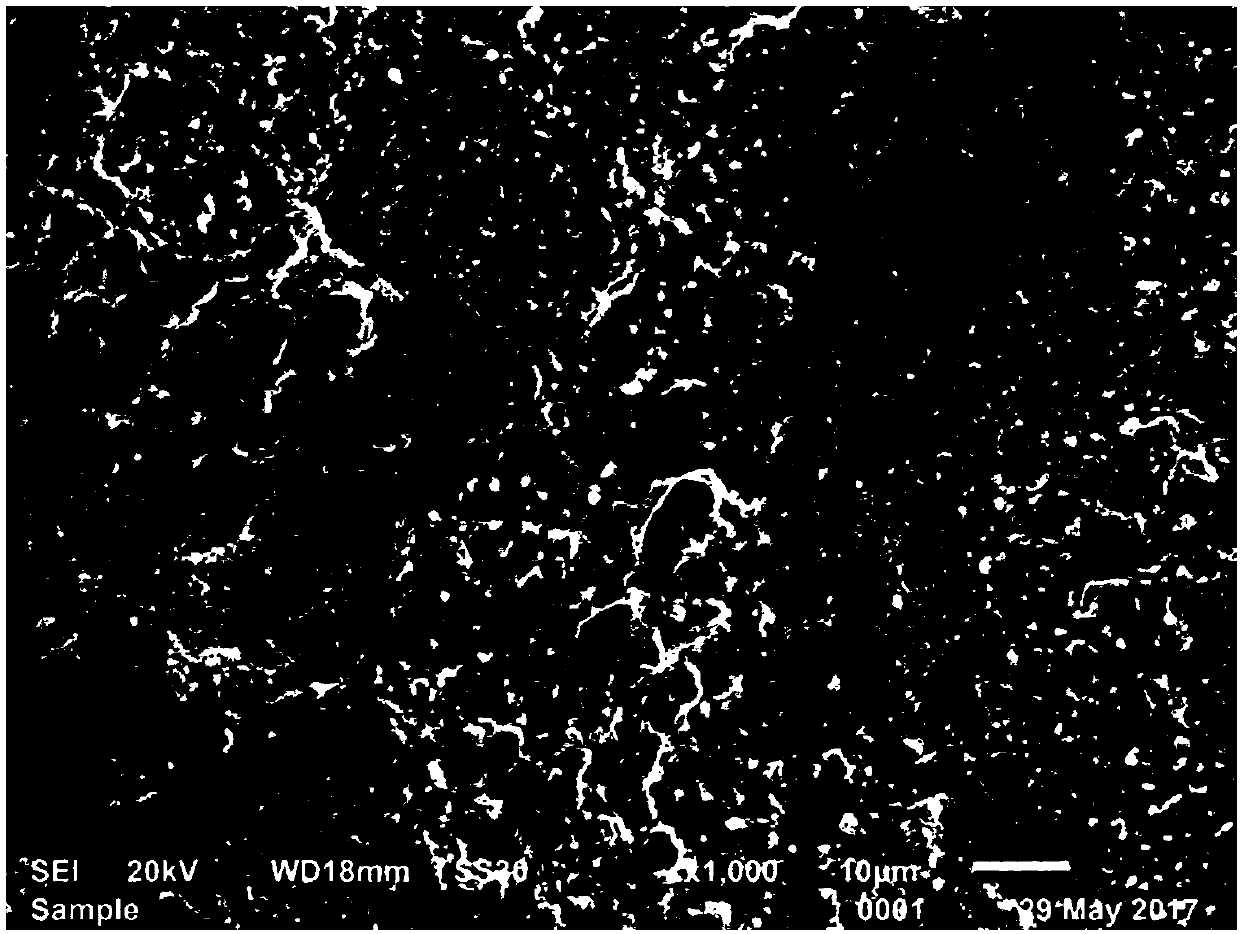

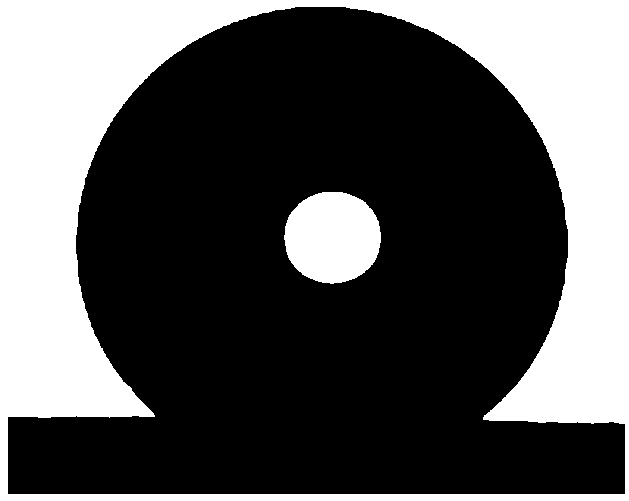

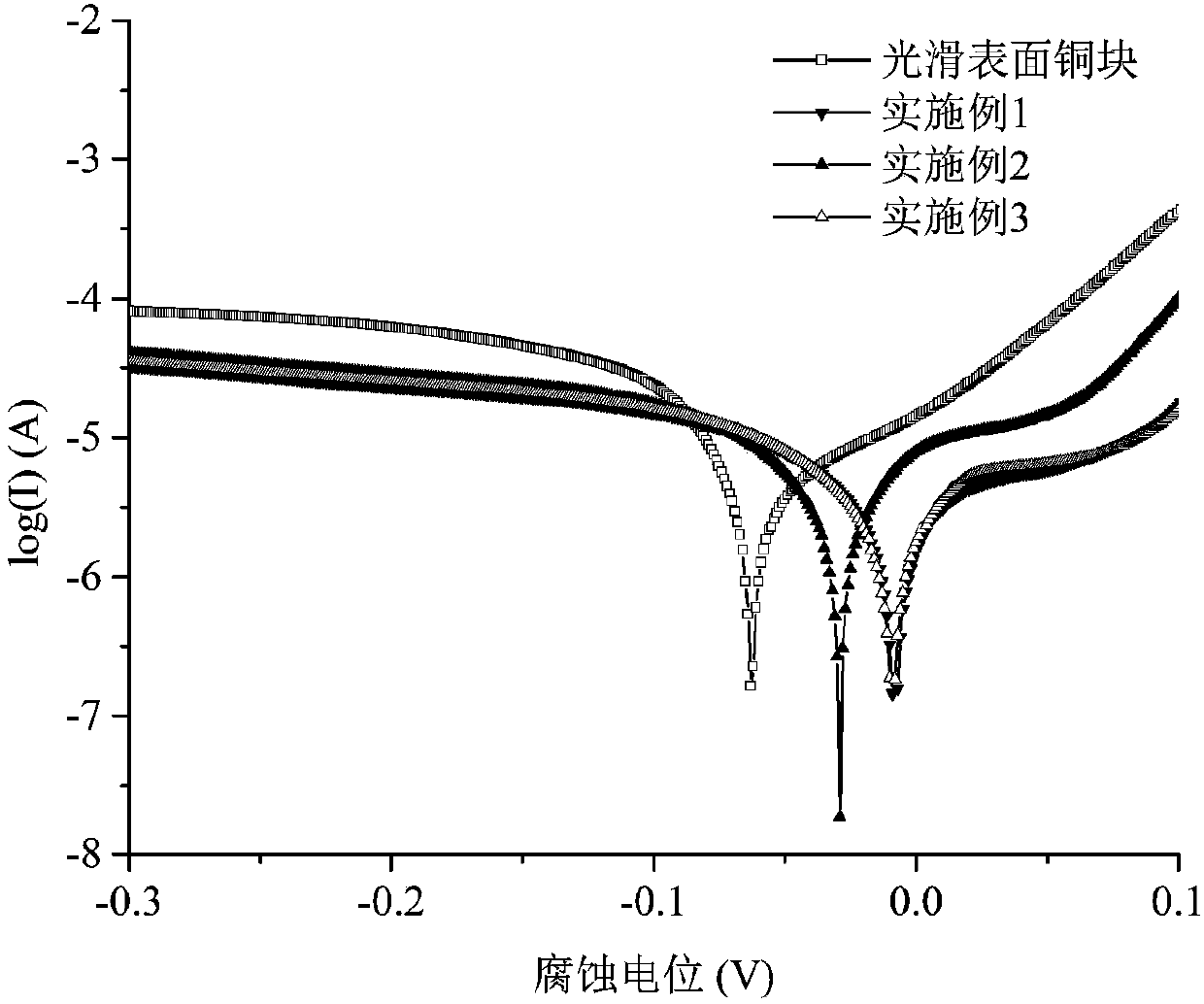

Method for machining and preparing copper anti-scale micro-nano composite structure layer by electric spark

InactiveCN107931762AThe processing method is simple and convenientReduce pollutionMicro nanoMolding machine

The invention discloses a method for machining and preparing a copper anti-scale micro-nano composite structure layer by electric spark. The method comprises the steps that a copper block is installedon an electric spark molding machine fixture, and the sufficient contact of the copper block and the fixture is guaranteed; the spraying direction of an electric spark machining liquid spraying mouthis adjusted to point to the surface of the copper block and form an angle range of 2-15 degrees with the surface of the copper block, and electric spark machining parameters are set; and an electricspark molding machine is started to machine the surface of the copper block, the machining depth is 1-2 mm, macroscopic electrical erosion characteristic structures are evenly distributed on the surface of the copper block, and the copper anti-scale micro-nano composite structure layer is obtained. The method for machining and preparing the copper anti-scale micro-nano composite structure layer bythe electric spark is simple and efficient, the copper anti-scale micro-nano composite structure layer can be prepared by only one machining procedure, an electric spark machining liquid can be recycled, the pollution of machining waste liquids to the environment is reduced, and the additional cost caused by treatment of the waste liquids is lowered.

Owner:GUANGDONG UNIV OF TECH

Pure water-base cold spray lacquer as well as preparation method and application thereof

InactiveCN106833202AImprove surface propertiesIncrease brightnessSlide fastenersClothes buttonsBenzeneWater based

The invention relates to a pure water-base cold spray lacquer as well as a preparation method and an application thereof. The pure water-base cold spray lacquer comprises the following components in parts by weight: 45-60 parts of modified pure water-base polyhydric alcohol resin, 2-4 parts of diethanol amine, 12-25 parts of water-base amino resin and 15-26 parts of water. The preparation method comprises the following steps: adding diethanol amine into the modified pure water-base polyhydric alcohol resin; uniformly mixing and then adding water; uniformly mixing again, and then adding the water-base amino resin; uniformly dispersing and then de-foaming and filtering; and collecting filtrate, thereby acquiring the pure water-base cold spray lacquer. In the pure water-base cold spray lacquer provided by the invention, water is adopted for replacing a thinning agent in oil paint; after the completing of the paint spraying, water is used for washing, so that the effect of cold paint spraying surface is promoted; the use method is simplified; the production cost is lowered; the harmful matters, such as, benzene, added into the oil paint can be prevented; the pure water-base cold spray lacquer is environment-friendly and nontoxic; the prepared pure water-base cold spray lacquer has the qualified flexibility, adhesive force, salt mist resistance and water washing resistance.

Owner:珠海富邦新材料科技有限公司

Method for preparing combustible gas from municipal domestic waste and plant waste

InactiveCN102146295ASave energyAchieve scaleClimate change adaptationBioloigcal waste fertilisersWater filterEnergy source

The invention relates to a method for preparing combustible gas from municipal domestic waste and plant waste, which comprises steps as follows: after mixing and pulverizing selected municipal domestic waste and plant waste, the mixture is sent into a synthesizing tower to be subjected to pyrolysis, and generated gas is filtered by a water filter tank, a CO2 filter, a sponge filter tank, a palm leaf filter tank and an active carbon filter tank, and sucked into a gas storage tank to be stored. The invention also provides a synthesizing tower for preparing combustible gas. A jacket above a high-temperature rotating heating unit penetrates through the upper wall of the synthesizing tower body and is communicated with a second material warehouse, a mixer is arranged in the second material warehouse, and a deslagging port on the bottom of the synthesizing tower body is provided with a deslagging propeller. The method for preparing combustible gas from municipal domestic waste and plant waste and the synthesizing tower provided by the invention can be used for preparing combustible gas by treating municipal domestic waste and plant waste, and synthesizing methanol by directly utilizing or utilizing the existing equipment and technique, thereby saving the energy sources and protecting the environment.

Owner:何文华

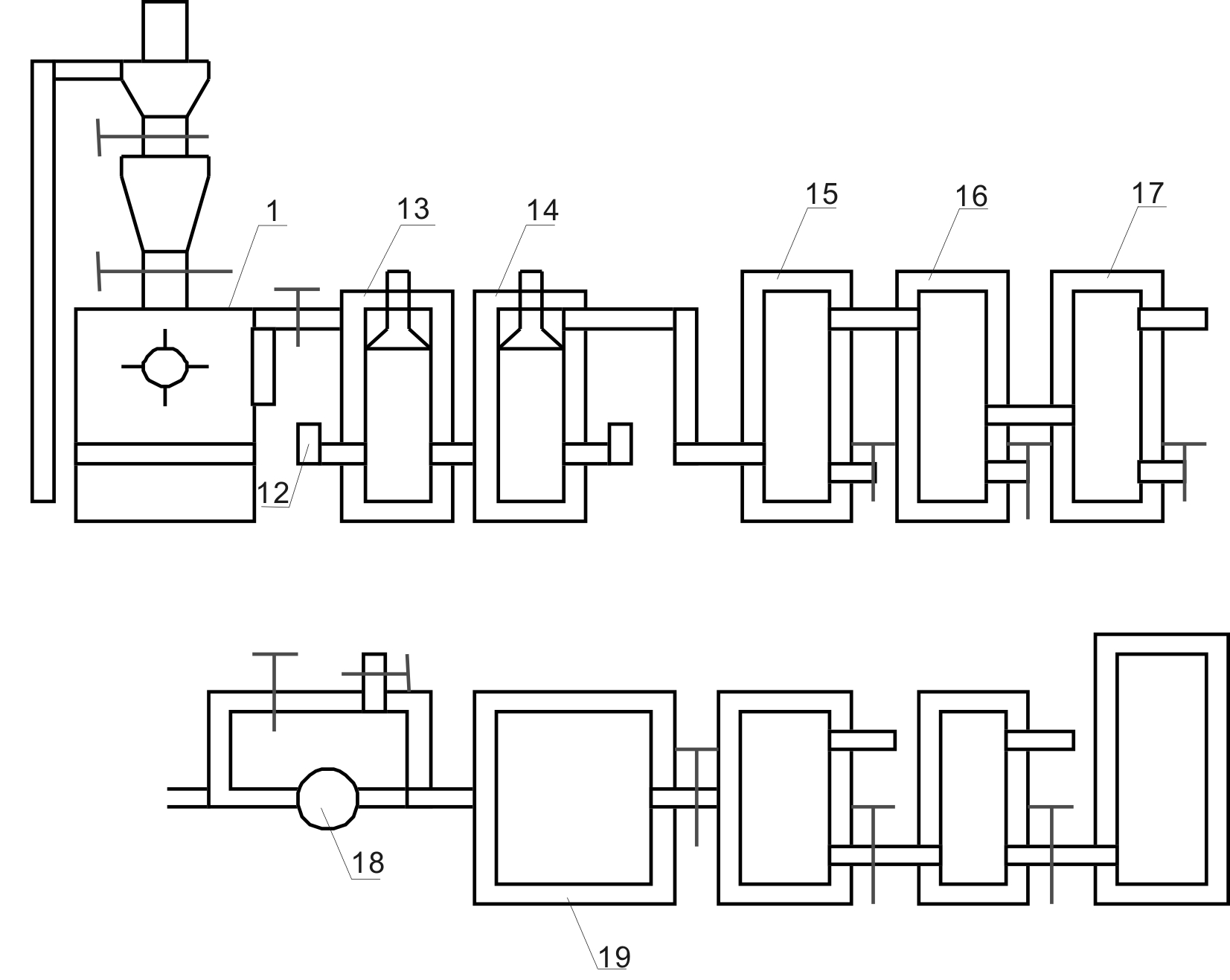

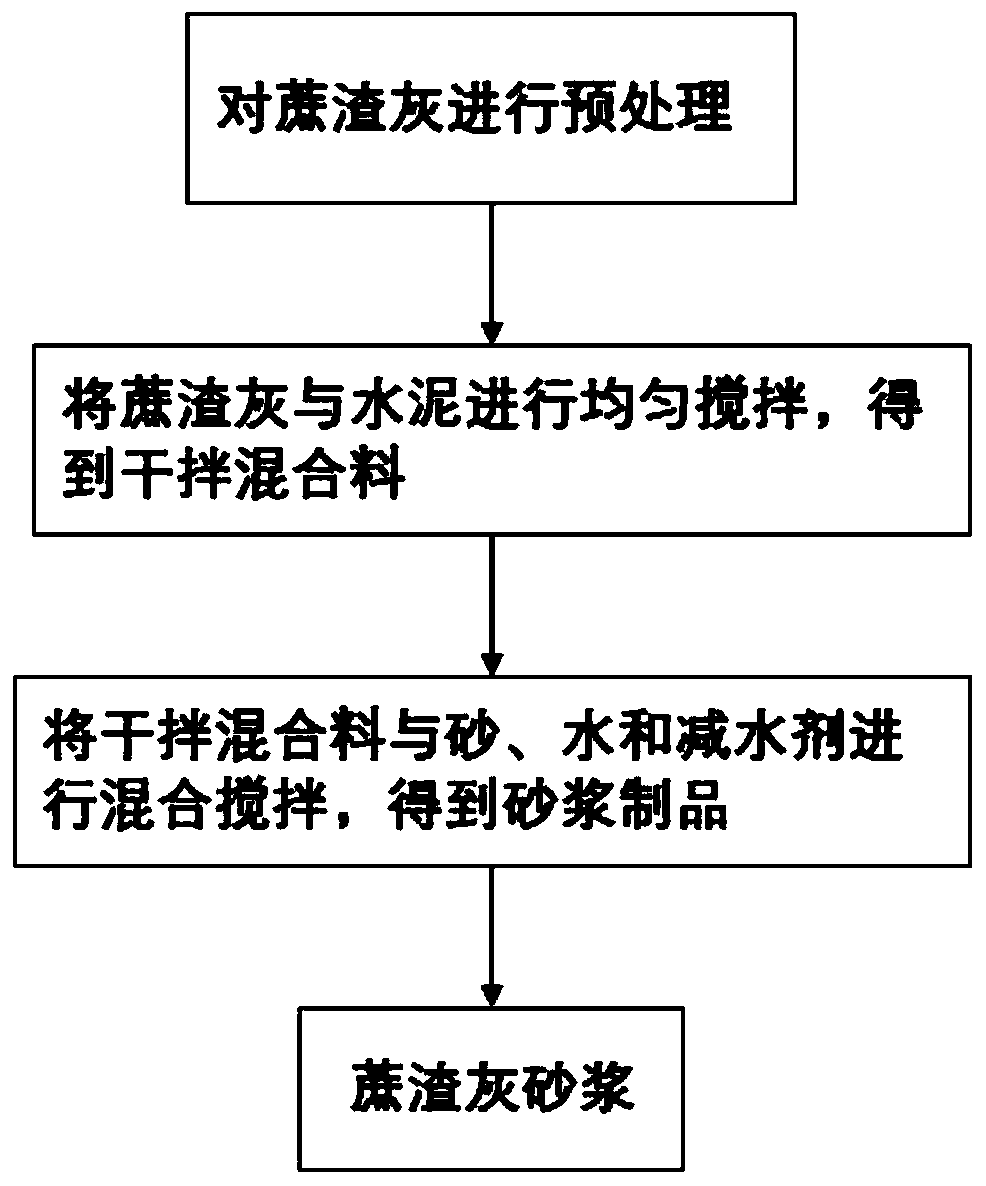

Preparation method for bagasse ash mortar

InactiveCN110282917AIncreased pozzolanic activityImprove compactnessSolid waste managementResource consumptionUltimate tensile strength

The invention discloses a preparation method for bagasse ash mortar. The preparation method comprises the following steps that bagasse ash discharged from a burning furnace of a sugar refinery is pretreated, so that the activity of the bagasse ash is improved; and the pretreated bagasse ash serves as a raw material for preparing the mortar, the pretreated bagasse ash, sand, water, cement and a water reducer are mixed, stirred, poured and vibrated so as to prepare a bagasse ash mortar product, and standard curing is further adopted. The bagasse ash mortar prepared through the preparation method has higher structural strength and durability. Compared with traditional mortar, the bagasse ash mortar prepared through the preparation method has the advantages that on the premise that the performance is improved, the bagasse ash can be fully reused, the resource consumption is reduced, and economical and environmentally-friendly production is facilitated.

Owner:GUANGXI UNIV +1

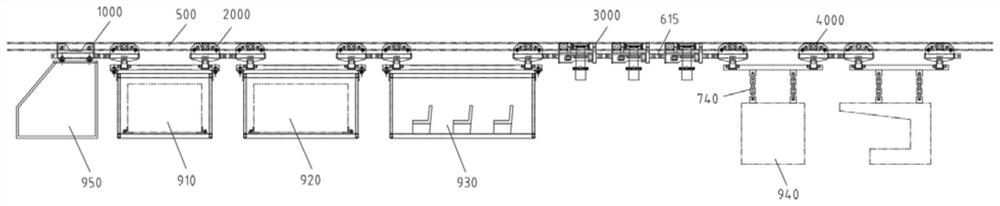

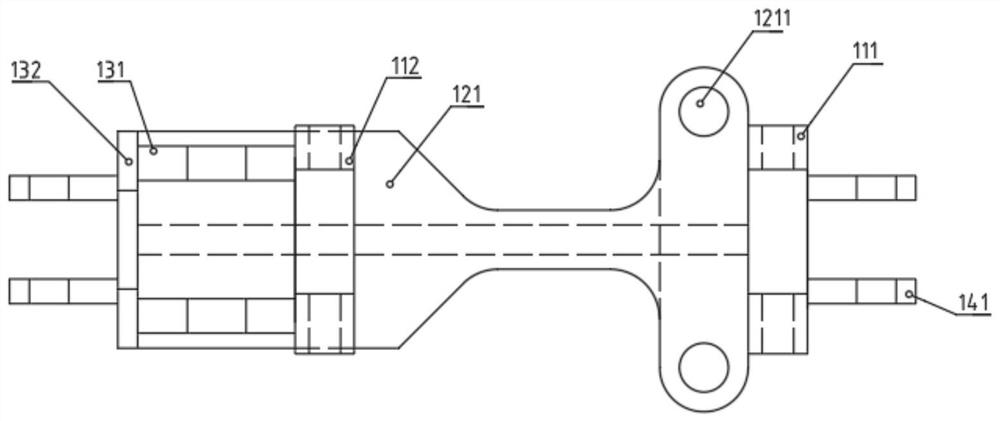

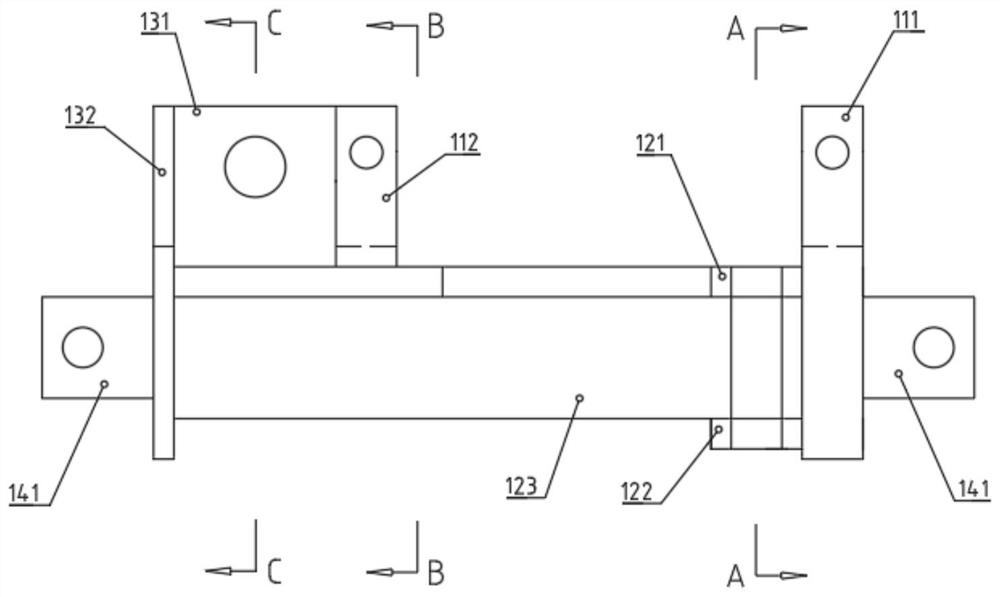

Electric monorail crane locomotive

PendingCN112208555ANo pollution in the processNo noiseRope railwaysTrack-braking member co-operationLow noiseElectrical battery

The invention discloses an electric monorail crane locomotive which comprises a battery cabinet used for installing a storage battery pack, a frequency conversion cabinet used for installing a motor frequency conversion control device, two cabinet body hanging devices hinged to each other and a plurality of driving devices hinged in sequence. Each cabinet body hanging device comprises a cabinet body hanging support used for hanging a cabinet body and a plurality of hanging mechanisms which are hung on an I-shaped rail of the monorail crane and can walk on the I-shaped rail, and the hanging mechanisms are connected to the cabinet body hanging support in a horizontal rotating mode. The battery cabinet and the frequency conversion cabinet are detachably hung on cabinet body hanging supports of the two cabinet body hanging devices respectively, the driving device is driven by a motor, and one hanging mechanism is hinged to the driving device adjacent to the hanging mechanism. The electricmonorail crane locomotive provided by the invention is powered by the storage battery to realize electric driving, the green operation of zero emission, no pollution, low noise and the like of the monorail crane locomotive are realized, and the underground working environment of a coal mine is improved.

Owner:SHANDONG ENERGY HEAVY EQUIP MFG GRP TAIZHUANG ENG EQUIP MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com