Combined technology for treating copper sulfide ore

A combined process and technology of copper sulfide ore, applied in the field of metallurgy, can solve the problems of comprehensive recovery of difficult resources, environmental pollution, high metallurgical costs, etc., and achieve significant economic benefits, high comprehensive recovery rate, and reduce waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

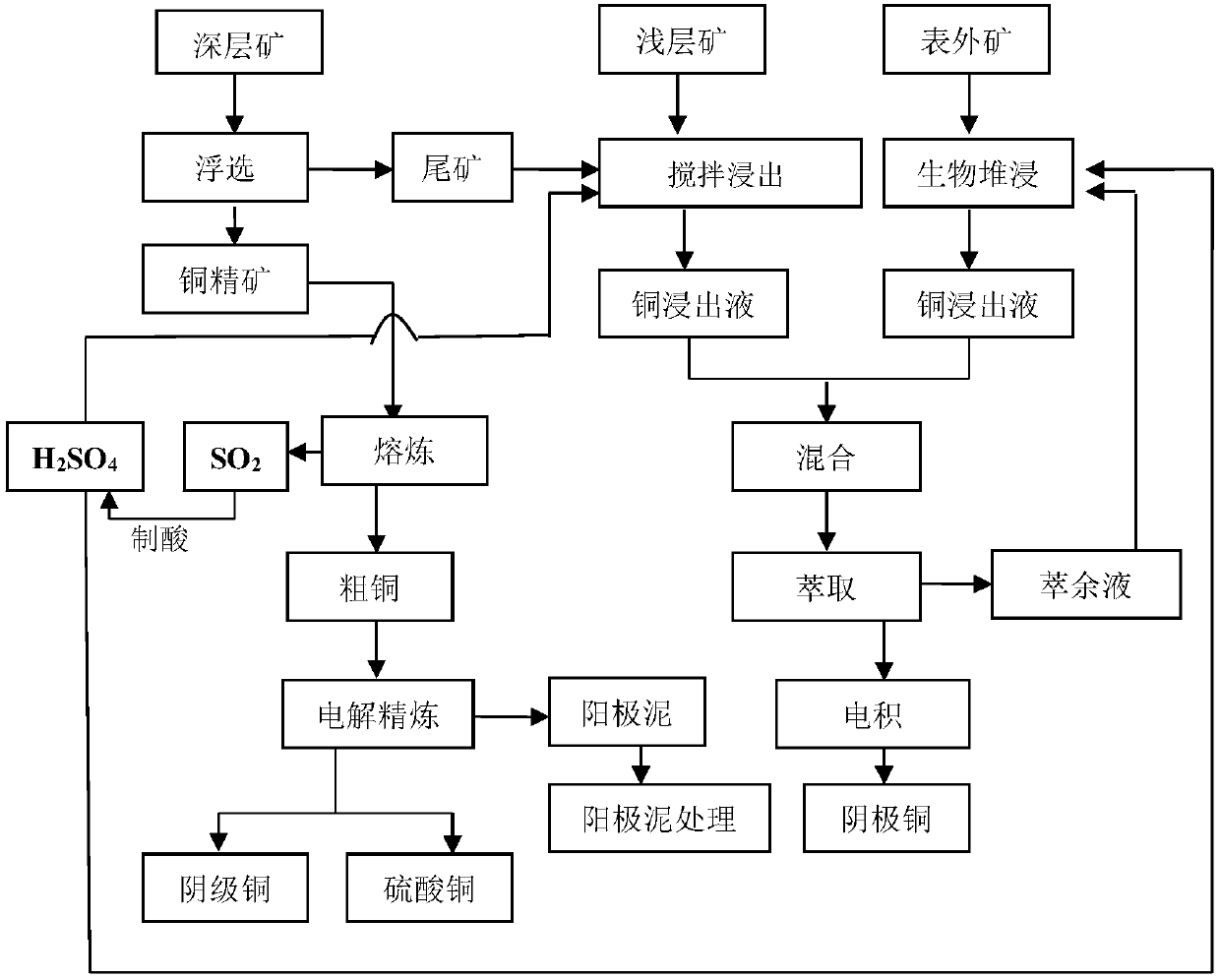

Method used

Image

Examples

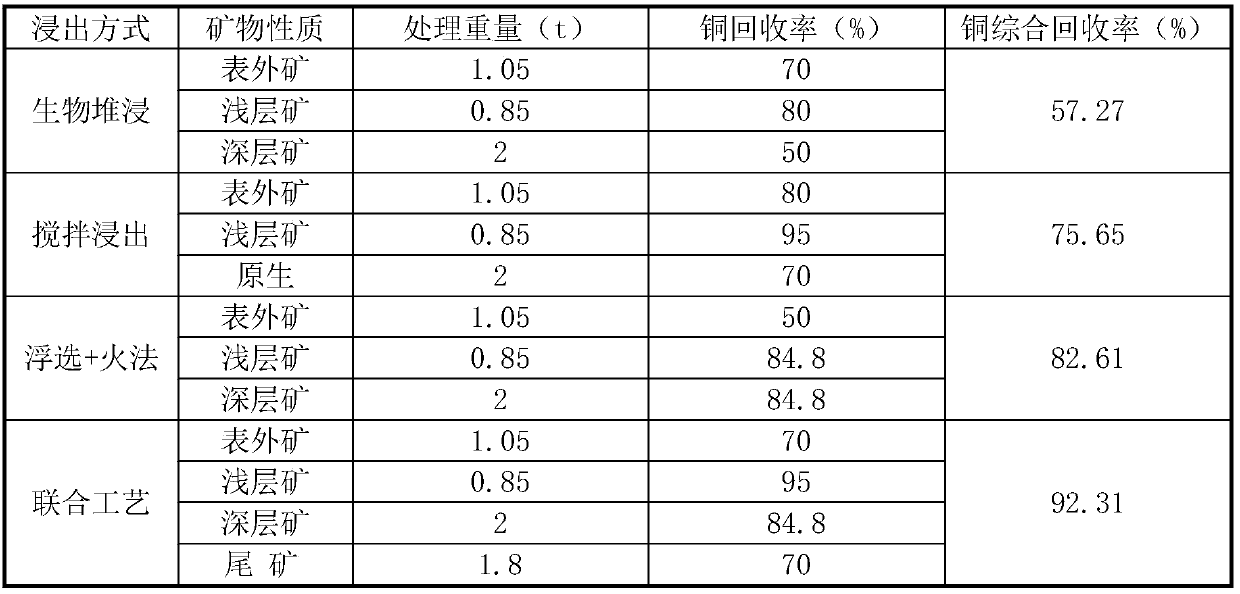

Embodiment 1

[0034] A copper mine in the Congo, the ore body from top to bottom are extrasurface ore (containing Cu 0.65%, S 1.05%, MgO4.71%, CaO 2.19%), secondary copper sulfide ore (containing Cu2.62%, S 2.13%, MgO 4.28%, CaO 2.53%), primary copper sulfide ore (containing Cu4.08%, S 2.51%).

[0035] (1) Theoretical calculation

[0036] by chemical reaction equation

[0037] MgO+H 2 SO 4 =MgSO 4 +H 2 o

[0038] CaO+H 2 SO 4 =CaSO 4 +H 2 o

[0039] 2S+3O 2 +2H 2 O=2H 2 SO 4

[0040] can be calculated

[0041] Theoretical acid consumption of off-surface ore per ton is 115.40+38.33=153.73kg, and acid production is 32.16kg;

[0042] The theoretical acid consumption per ton of secondary sulfide copper ore is 104.86+44.28=149.14kg, and the acid production is 65.23kg;

[0043] Based on the flotation sulfur recovery rate of 84.96%, the pyro-smelting desulfurization rate of copper concentrate is 99%, the conversion rate of sulfuric acid is 99%, the total utilization rate of sulfu...

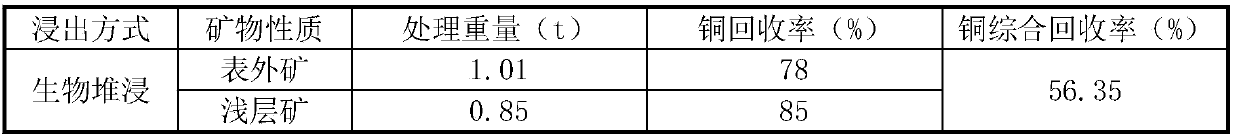

Embodiment 2

[0058] In a copper mine in Inner Mongolia, the ore bodies from top to bottom are extrasurface ore (containing Cu 0.31%, S 0.95%, MgO5.69%, CaO 1.87%), secondary copper sulfide ore (containing Cu1.59%, S 2.55%, MgO 4.66%, CaO 3.26%), primary copper sulfide ore (containing Cu3.58%, S 2.87%).

[0059] (1) Theoretical calculation is the same as that of Example 1, and can be calculated

[0060] The theoretical acid consumption per ton of waste ore is 138.37+32.73=171.10kg, and the acid production is 29.09kg;

[0061] The theoretical acid consumption per ton of secondary sulfide copper ore is 113.32+57.05=170.37kg, and the acid production is 78.09kg;

[0062] Based on the flotation sulfur recovery rate of 82.31%, the copper concentrate pyromelting desulfurization rate of 99%, and the sulfuric acid conversion rate of 99%, the total utilization rate of sulfur in the primary ore is 80.67%, and the theoretical acid production per ton of raw ore copper sulfide ore is 70.90kg;

[0063] ...

Embodiment 3

[0077] In a copper mine in Heilongjiang, the orebodies from top to bottom are extrasurface ore (containing Cu0.42%, S 2.56%, MgO4.66%, CaO 1.86%), secondary copper sulfide ore (containing Cu1.63%, S 2.55%, MgO3.56%, CaO 3.42%), primary copper sulfide ore (containing Cu2.46%, S 3.55%).

[0078] (1) Theoretical calculation is the same as that of Example 1, and can be calculated

[0079] The theoretical acid consumption of ton of off-surface ore is 113.33+32.55=145.85kg, and the acid production is 78.4kg;

[0080] The theoretical acid consumption per ton of secondary sulfide copper ore is 86.57+59.85=146.42kg, and the acid production is 78.09kg;

[0081] Based on the flotation sulfur recovery rate of 89.56%, the copper concentrate pyromelting desulfurization rate of 99%, and the sulfuric acid conversion rate of 99%, the total utilization rate of sulfur in the primary ore is 87.78%, and the theoretical acid production per ton of raw ore copper sulfide ore is 95.43kg;

[0082] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com