Method for preparing lithium carbonate from plateau carbonate bittern

A carbonate type, lithium carbonate technology, applied in lithium carbonate;/acid carbonate, chemical instruments and methods, water/sewage treatment, etc., can solve the impact of large carbonate consumption and stable production of salt lake resources , long production cycle and other issues, to achieve the effect of increasing the precipitation rate, rapidly enriching lithium ions, and environmentally friendly production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

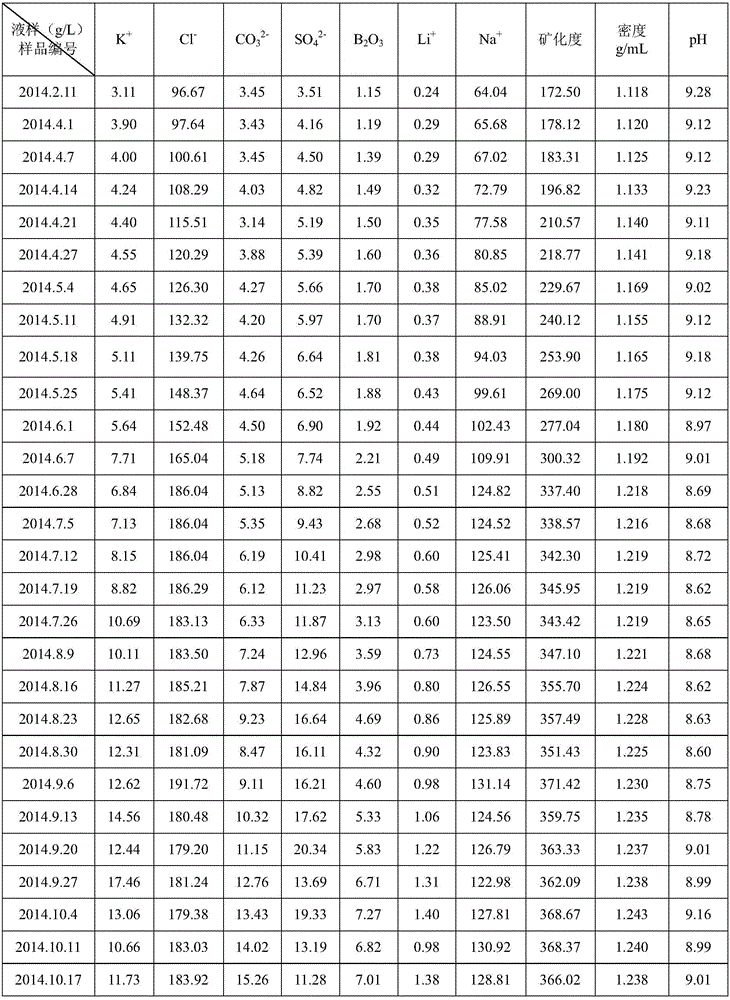

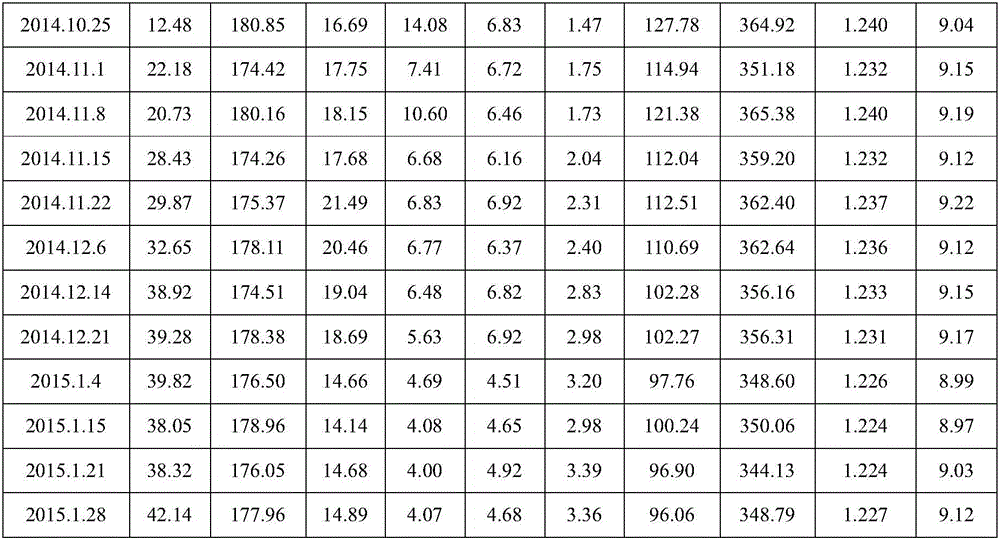

[0029] The present invention aims at the social economy and natural state characteristics of the Qinghai-Tibet Plateau, and proposes a method of utilizing natural energy and brine composition to realize the production of various minerals in carbonate-type salt lakes. To illustrate the feasibility of this method, the utilization of Jieze Chaka is taken as an example. It can be understood that this invention is not only applicable to the development of Jiezechaka, but also applicable to the development of salt lake resources under similar environmental conditions.

[0030] The method for preparing lithium carbonate from plateau ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com