Method for preparing vanadium pentoxide by treating vanadium-containing waste sulfuric acid catalyst through two-step method

A technology of vanadium pentoxide and waste catalyst, applied in the direction of improving process efficiency, etc., can solve the problems of difficult and impossible treatment of environmental protection, increase of hazardous waste generation, etc., and achieve high utilization rate of waste salt, low energy consumption, and environmentally friendly production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

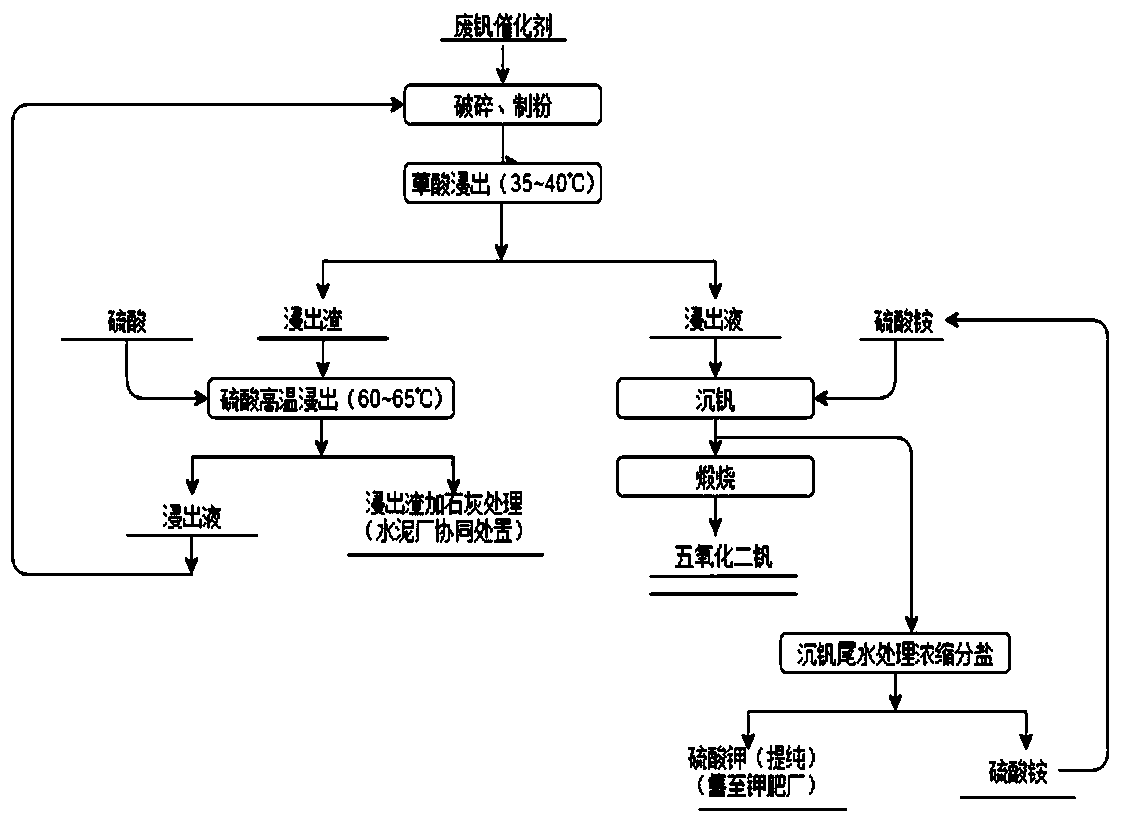

[0034] like image 3 Shown, a kind of two-step process process contains vanadium waste sulfuric acid catalyst and produces the method for vanadium pentoxide, comprises the following steps:

[0035] 1) First, the spent catalyst (dry basis) is pulverized, and 70-80% of the particle size is controlled at 200 mesh;

[0036] 2) The first leaching: add hot water to the container, then add spent catalyst, control the liquid-solid ratio between 3 and 4, then add oxalic acid to control the pH between 5.0 and 6.0, and stir for 4 Filtrate within 1 hour, collect the filter residue and use sulfuric acid for secondary leaching, collect the filtrate and let it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com