Combination electrode for all vanadium redox flow battery and preparation thereof

A technology for flow batteries and composite electrodes, applied in battery electrodes, circuits, electrical components, etc., can solve the problem of high volume resistivity, achieve high modulus, meet mechanical properties, and high conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0028] The following is a specific embodiment, and the preparation of the composite electrode includes the following steps:

[0029] 1. Thermoplastic polymer plasticization: Weigh the thermoplastic polymer at 150-200°C and plasticize it with a double-roll rubber mill for 5-10 minutes to make it into a uniform sheet.

[0030] 2. Composite conductive material: 5-10 parts of conductive graphite powder, 30-60 parts of conductive carbon black, and 20-40 parts of conductive carbon fiber are mixed evenly.

[0031] Conductive carbon fiber can be divided into: cellulose-based (rayon-based); polyacrylonitrile (PAN)-based; pitch-based, of which polyacrylonitrile-based carbon fiber is the fastest growing and most widely used.

[0032] The properties of several common conductive carbon fibers are shown in Table 1:

[0033] Table 1

[0034] Types of

product name

density

(g / cm 3 )

Tensile modulus

(GPa)

Tensile Strength

(MPa)

Resistiv...

Embodiment 1

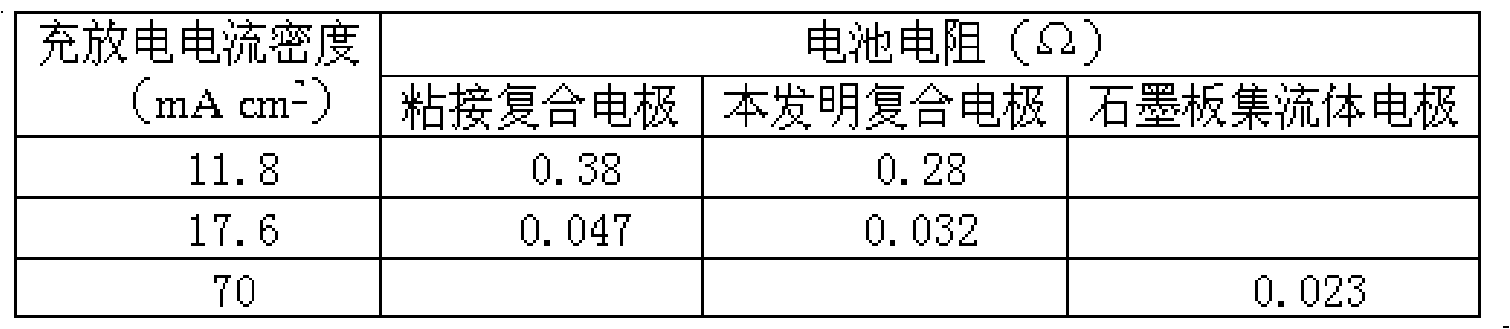

[0053] Embodiment 1: Screening of conductive filler

[0054] Weigh the thermoplastic elastomer polymer hydrogenated styrene-butadiene-styrene copolymer at 160°C for 5-10 minutes with a double-roll rubber mill to make it into a uniform sheet.

[0055] Weigh the conductive filler according to the ratio of the mass ratio of the thermoplastic elastomer polymer to 1:2.3; add it to the plasticized thermoplastic elastomer polymer and refine it with a double-roll rubber mill for 5 to 15 minutes, so that the conductive filler and thermoplastic The elastomer polymer is mixed evenly to obtain a sheet-like conductive material. Then put it into a metal mold frame, and use a flat vulcanizer to press this conductive material into a rectangular thermoplastic conductive plate at a temperature of 180°C.

[0056] Then place the graphite felt on the thermoplastic conductive plate, compress the graphite felt to 1 / 2 to 2 / 3 of the original thickness with a flat vulcanizer, and press at 180°C for 10...

Embodiment 2

[0068] Embodiment 2 is to the screening of base material thermoplastic polymer

[0069] The ratio of conductive materials in this embodiment is CB / C / CF=23 / 3 / 20.

[0070] Weigh the thermoplastic polymer mixture and plasticize it with a two-roll rubber mill at 160°C for 5-10 minutes, mix evenly, and make it into a uniform sheet.

[0071] Weigh the conductive material according to the ratio of thermoplastic polymer to conductive material mass ratio of 1:3; add it to the plasticized thermoplastic and refine it with a double-roller rubber mill for 5 to 15 minutes, so that the conductive filler is mixed with the thermoplastic Evenly, a sheet-like conductive material is obtained.

[0072] Then put the conductive material into a rectangular metal mold frame of a certain size, use a flat vulcanizer to press the conductive material into a rectangular conductive plate at a temperature of 180°C, then place graphite felt on the conductive plate, and use a flat vulcanizer to press the cond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| voltage efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com