Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

201 results about "Axis distance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

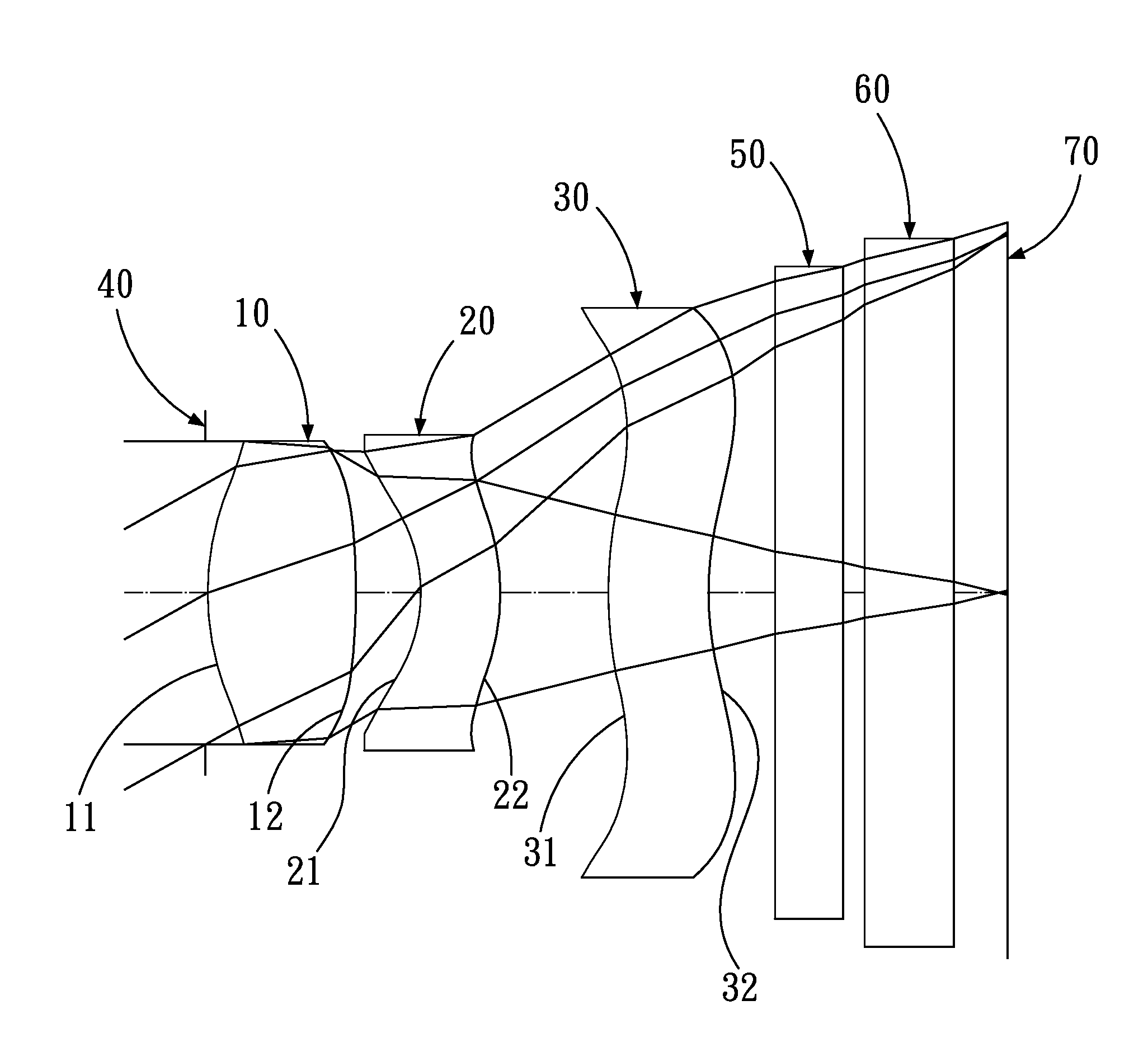

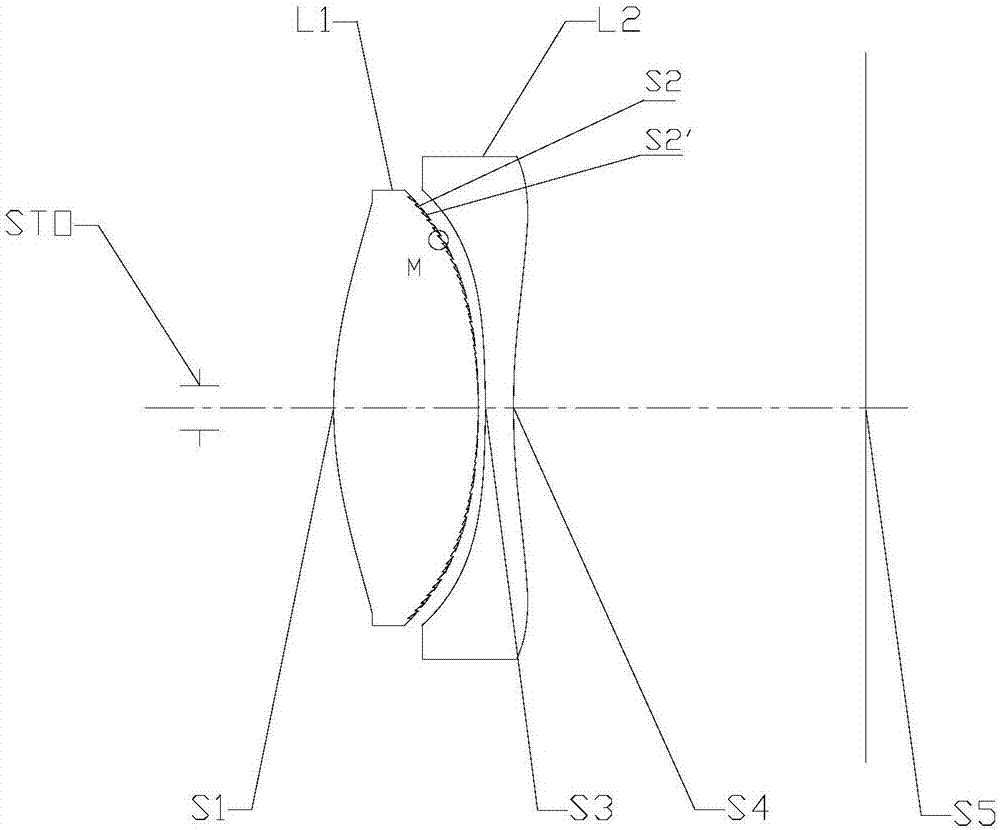

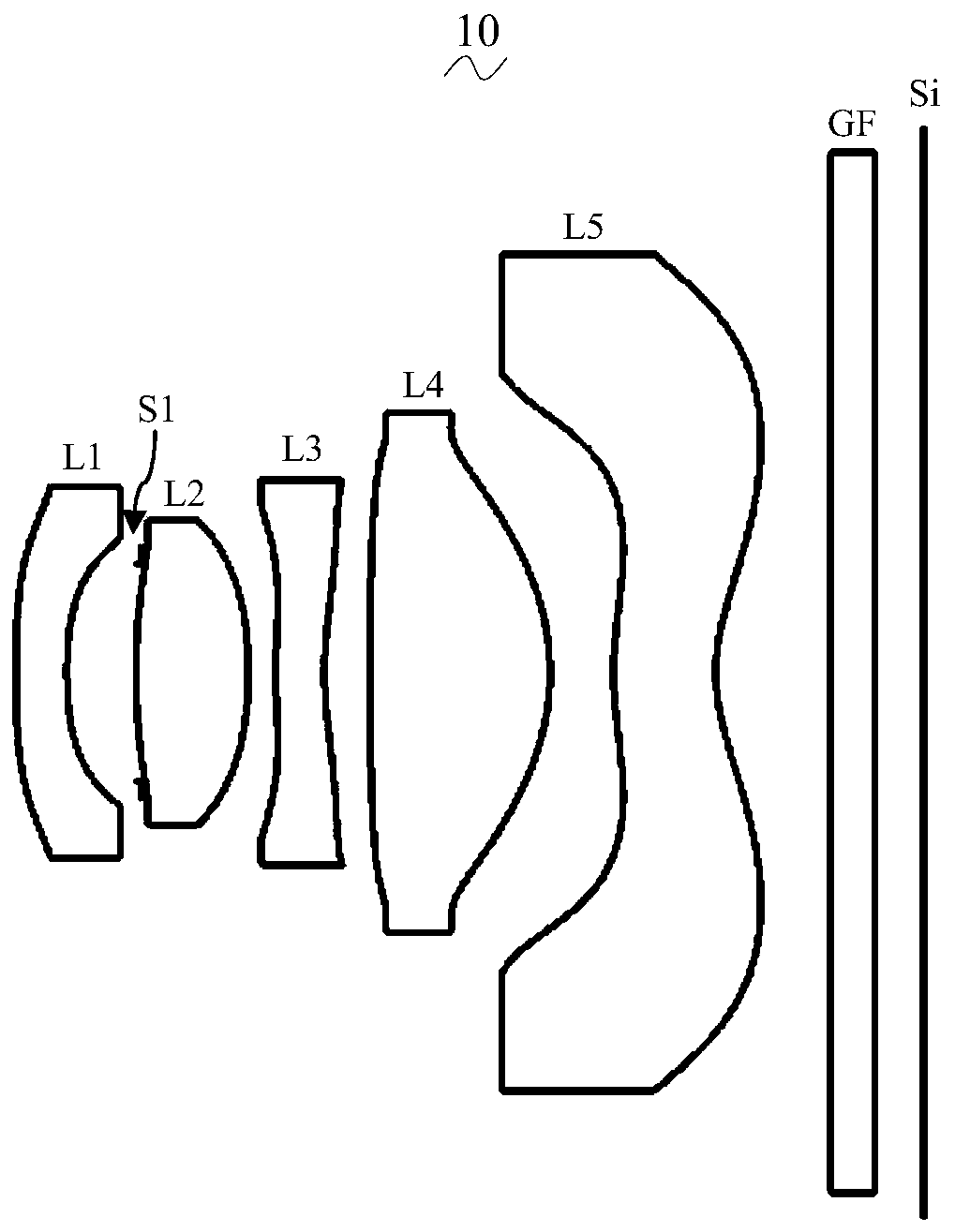

Optical lens system for taking image

An optical lens system for taking image has, in order from the object side to the image side: a positive first lens element with a convex object-side surface; a negative plastic second lens element with a concave object-side surface; a negative plastic third lens element with a concave object-side surface; a positive fourth lens element with a concave image-side surface; and an aperture stop located between an object to be photographed and the second lens element. The second lens element is provided with at least one aspheric surface, the third lens element is provided with at least one aspheric surface, and the fourth lens element is formed with inflection points. An on-axis distance between the first and second lens elements is T12, a focal length of the optical lens system for taking image is f, they satisfy the relation: (T12 / f)*100>0.7.

Owner:LARGAN PRECISION

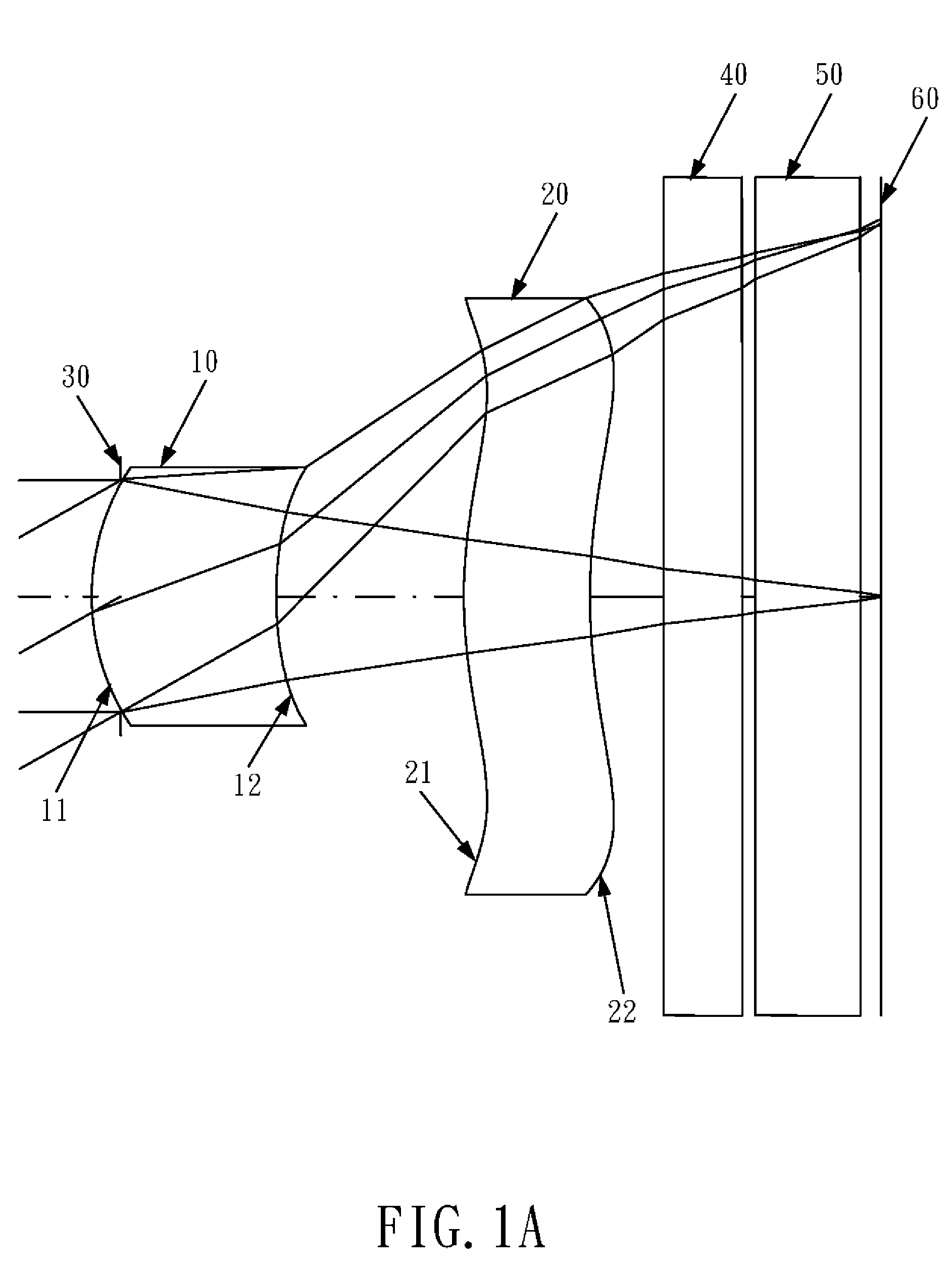

Optical lens system for taking image

An optical lens system for taking image comprises, in order from an object side to an image side: a first lens element with positive refractive power having an aspheric convex object-side surface and an aspheric concave image-side surface; a second lens element with positive refractive power having an aspheric convex object-side surface and an aspheric concave image-side surface. Radii of curvature of the object-side surface of the first lens element, the object-side and image-side surfaces of the second lens element are R1, R3 and R4 respectively, focal lengths of the optical lens system for taking image, the first and second lens elements are f, f1, f2 respectively, an on-axis distance between the first and second lens elements is T12, a center thickness of the second lens element is CT2, they satisfy the relations: 0.76 mm−1<1 / R1<2.0 mm−1; 0.4<R3 / R4<1.15; 0.35<(f / f1)−(f / f2)<0.72; T12 / CT2>1.0.

Owner:LARGAN PRECISION

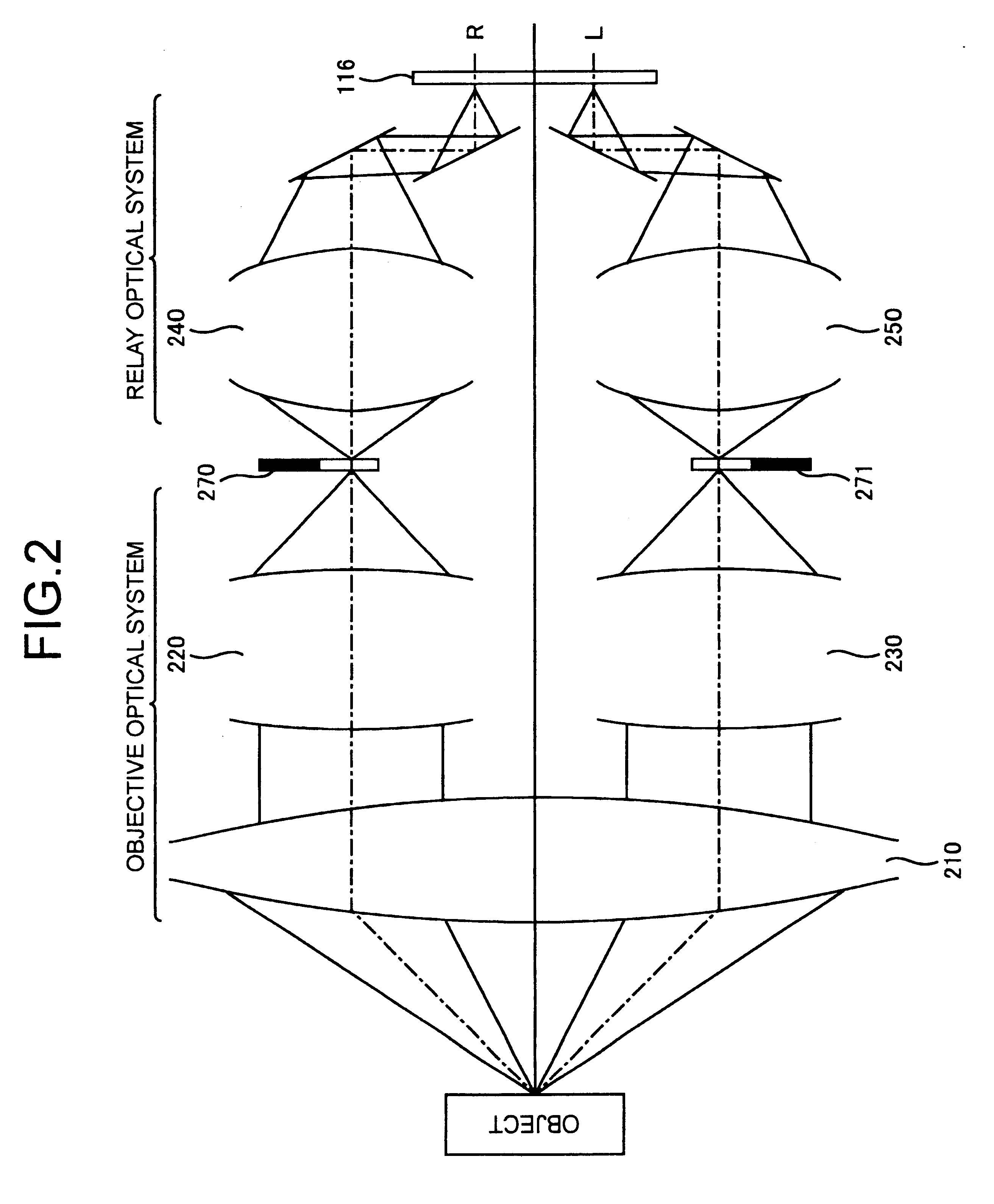

Stereoscopic microscope including zoom and relay optical systems

InactiveUS6396627B1Reduce distanceReduce spherical aberrationMicroscopesTelescopesParallaxSingle image

The stereoscopic microscope includes a common close-up optical system that faces an object, a pair of zoom optical systems that form a pair of primary image, a pair of field stops, a pair of relay optical systems that relay the primary images to form a pair of secondary images, an inter-axis distance reducing element, an image taking device and an illuminating optical system. The object light rays incident on the close-up optical system form the primary images having predetermined parallax at the field stops through the zoom optical systems. The inter-axis distance reducing element reduces the inter-axis distance of the right and left light rays. The primary images are re-imaged by the relay optical systems as the secondary images on the adjacent regions on the single image taking surface of the image taking device, respectively.

Owner:ASAHI KOGAKU KOGYO KK

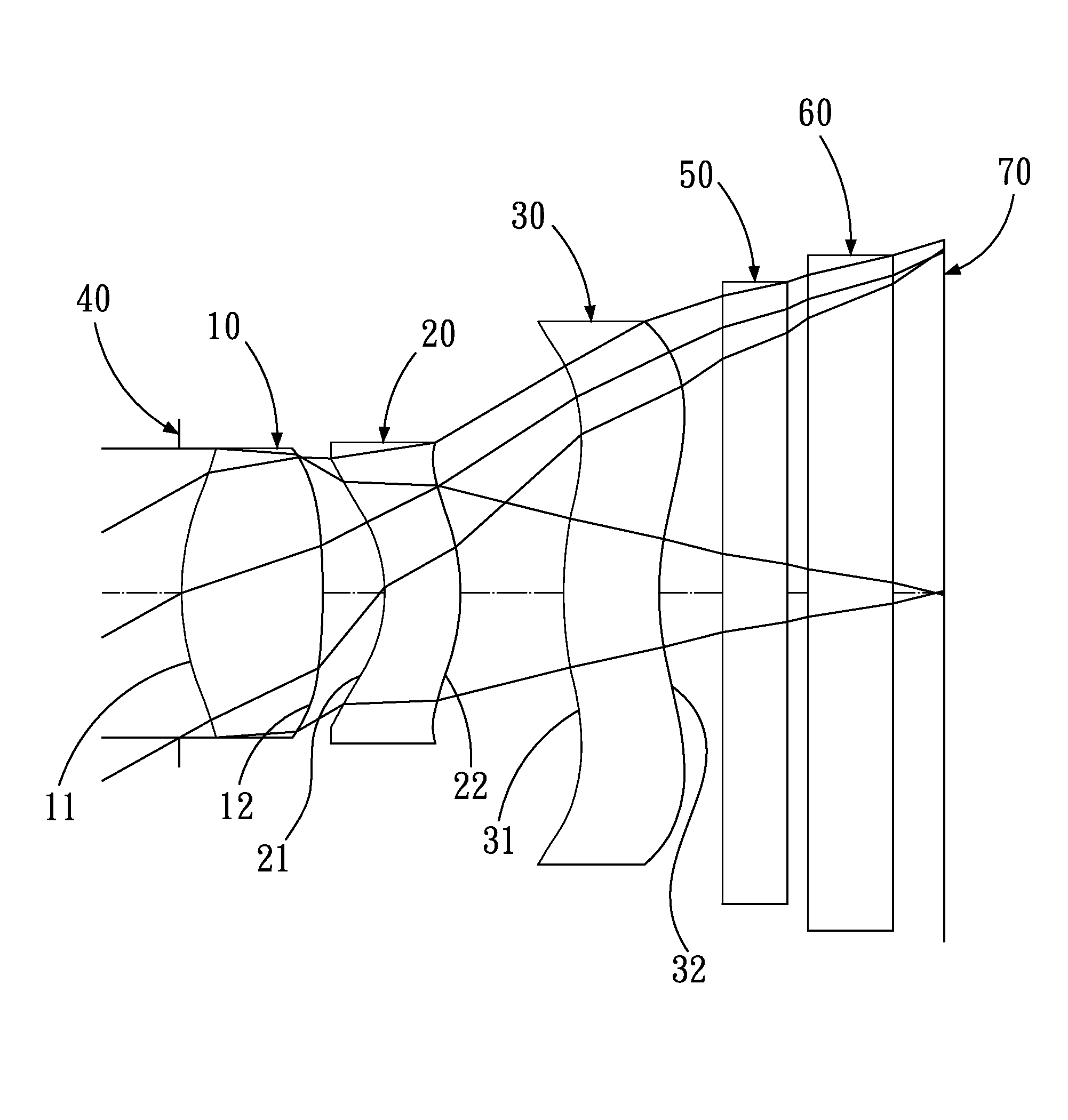

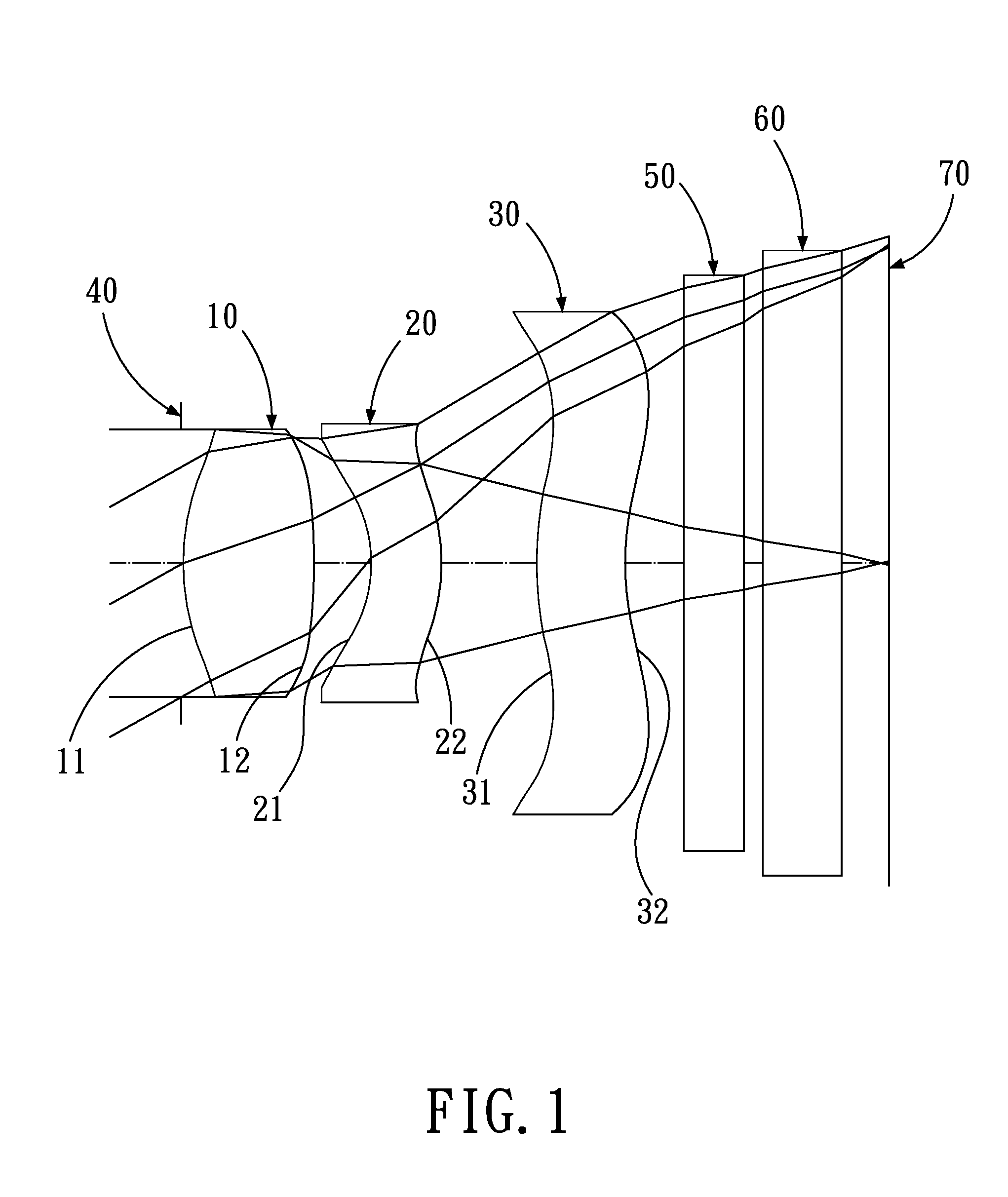

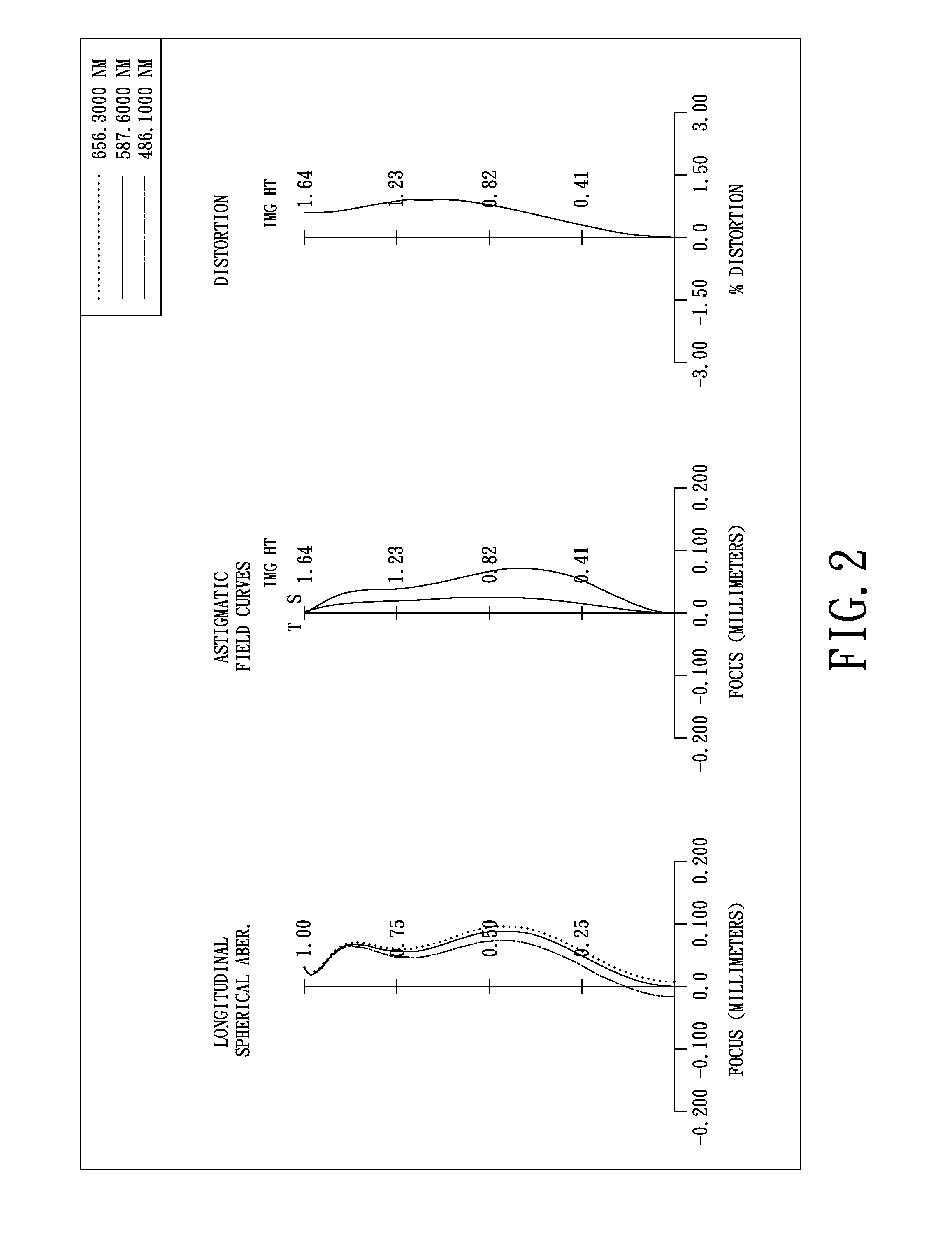

Optical lens system for taking image

An optical lens system for taking image comprises, in order from the object side to the image side: an aperture stop; a first lens element with positive refractive power having a convex object-side surface and a convex image-side surface; a plastic second lens element with negative refractive power having a concave object-side surface, a convex image-side surface and at least one aspheric surface; a plastic third lens element with negative refractive power having a convex object-side surface, a concave image-side surface and at least one aspheric surface. The number of the lens elements with refractive power being limited to three. Focal lengths of the optical lens system, the first lens element, the second lens element and the third lens element are f, f1, f2, f3 respectively; Abbe numbers of the first and second lens elements are V1, V2 respectively, an on-axis distance between second and third lens elements is T23, and they satisfy the relations: 0.8<f / f1<1.8; 0<|f / f2|<0.8; 0<|f / f3|<0.7; 20<V1−V2<38; 0.13<T23 / f<0.21.

Owner:LARGAN PRECISION

Apparatus and method for detecting multiple optical axis consistency of platform photoelectric instrument

ActiveCN103353285AEliminate systematic errorsImprove detection accuracyUsing optical meansOptical apparatus testingData controlTemplate matching

The invention provides an apparatus and method for detecting the multiple optical axis consistency of a platform photoelectric instrument. The detection method comprises a detection host, a support mechanism and a data control processing system. A catadioptric optical collimating system,a multiband target plate and a target light source are adopted for determining the axial direction of each optical system, a CCD aiming assembly is utilized for acquiring the image of the same fixed target in a distant scene, afterwards, an image processing module performs pretreatment, coupling and optical axis parallelism calculatingon the image by using a template coupling method so that the position deviations of the same fixed target in different images is obtained and a detection result of the light axis consistency among the multiple optical systems can be further obtained. The apparatus is free from the axis distance restrictions among optical sensors, no cooperation targets and no calibration adjustment are needed, the detection precision is high, the volume is small, the weight is light, the operation is convenient, and the automation degree is high, therefore, the apparatus and method well satisfy the on-line rapid detection needs for detecting the multiple optical axis consistency of the platform photoelectric instrument in a field environment.

Owner:ORDNANCE TECH RES INST OF THE GENERAL ARMAMENT DEPT PLA

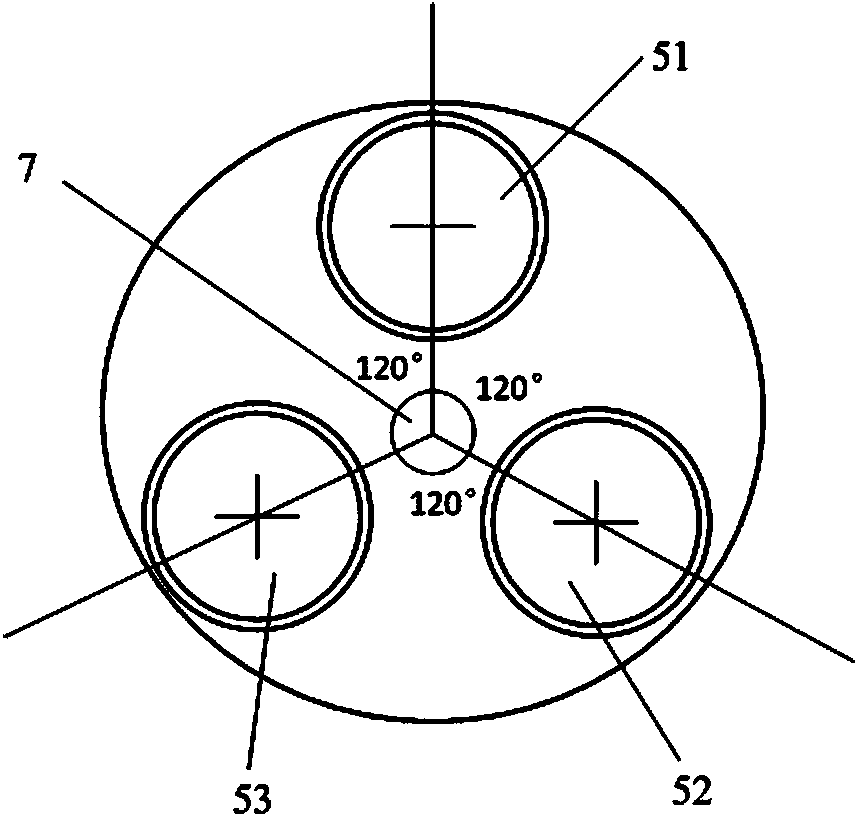

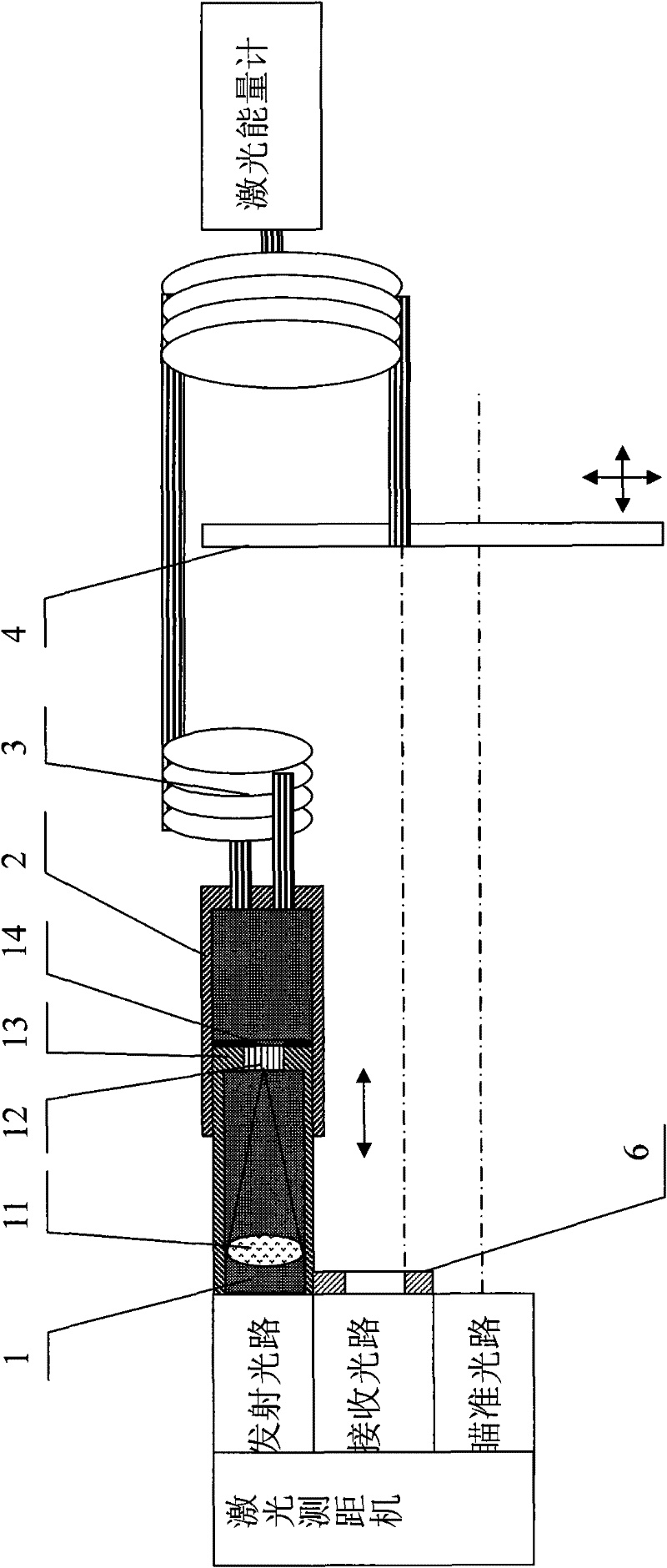

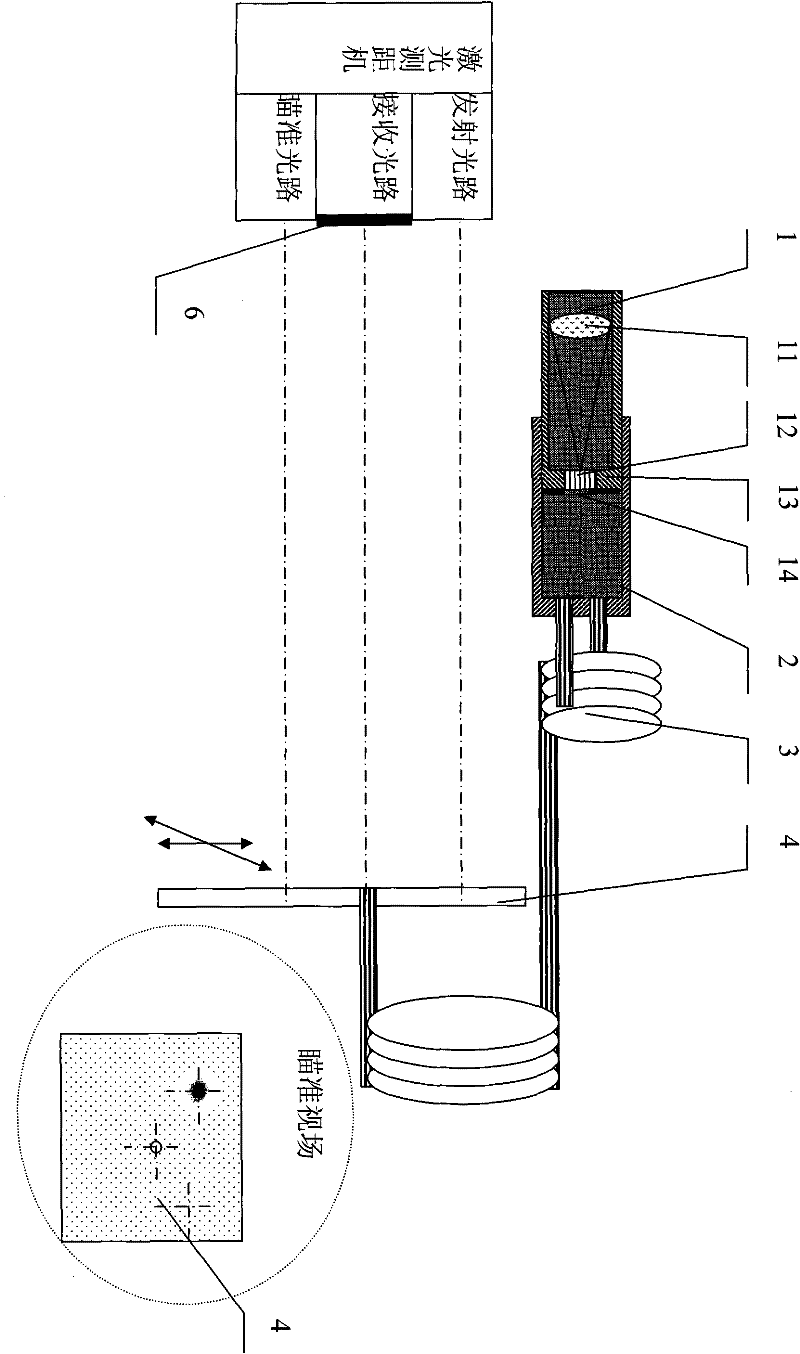

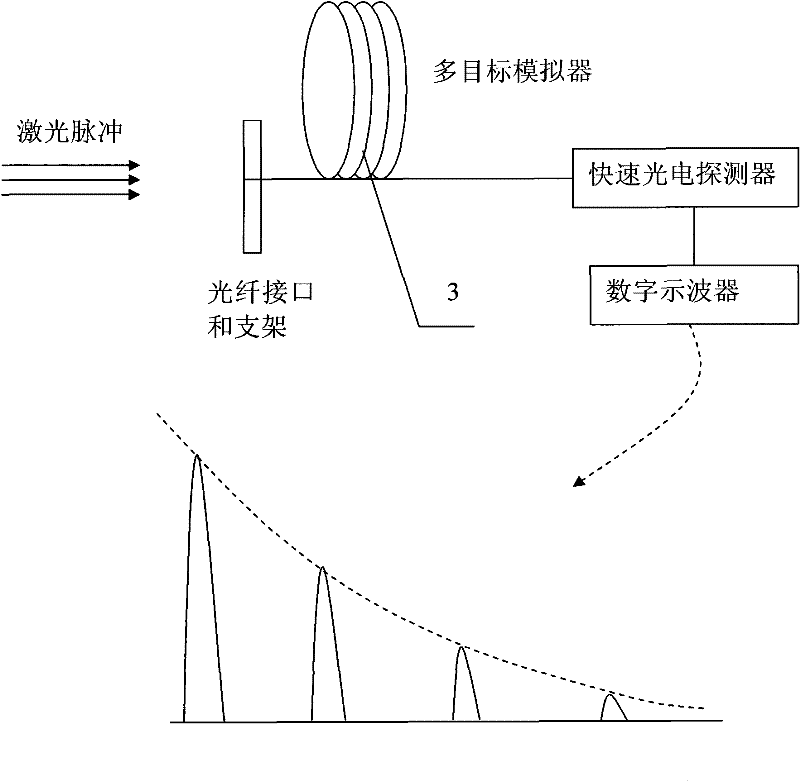

Detection device for laser rangefinder

InactiveCN102243301AShorten the lengthResolution timeWave based measurement systemsLaser rangingLaser target

The invention discloses a detection device for a laser rangefinder, composed of a sampler, an absorber, a multi-target simulator, a standard target and a variable diaphragm. The laser rangefinder emits a laser directed at the detection device; the sampler and the multi-target simulator simulate a laser target echo, and obtain an receiving optical axis and the minimum detectable power of the laser rangefinder via the maximum distance ranging result; a laser emitting optical axis and a collimation optical axis are corrected via a laser spot position and an axis distance; and the emission and the receiving of the laser rangefinder are quantitatively associated, in order to realize a ranging capacity evaluation of the laser rangefinder. The device disclosed by the invention has no need to be supplied with power, and is simple in operation and low in cost.

Owner:南瑶

Stereoscopic microscope

The stereoscopic microscope includes a common close-up optical system that faces an object, a pair of zoom optical systems that form a pair of primary image, a pair of field stops, a pair of relay optical systems that relay the primary images to form a pair of secondary images, an inter-axis distance reducing element, an image taking device and an illuminating optical system. The object light rays incident on the close-up optical system form the primary images having predetermined parallax at the field stops through the zoom optical systems. The inter-axis distance reducing element reduces the inter-axis distance of the right and left light rays. The primary images are re-imaged by the relay optical systems as the secondary images on the adjacent regions on the single image taking surface of the image taking device, respectively.

Owner:ASAHI KOGAKU KOGYO KK

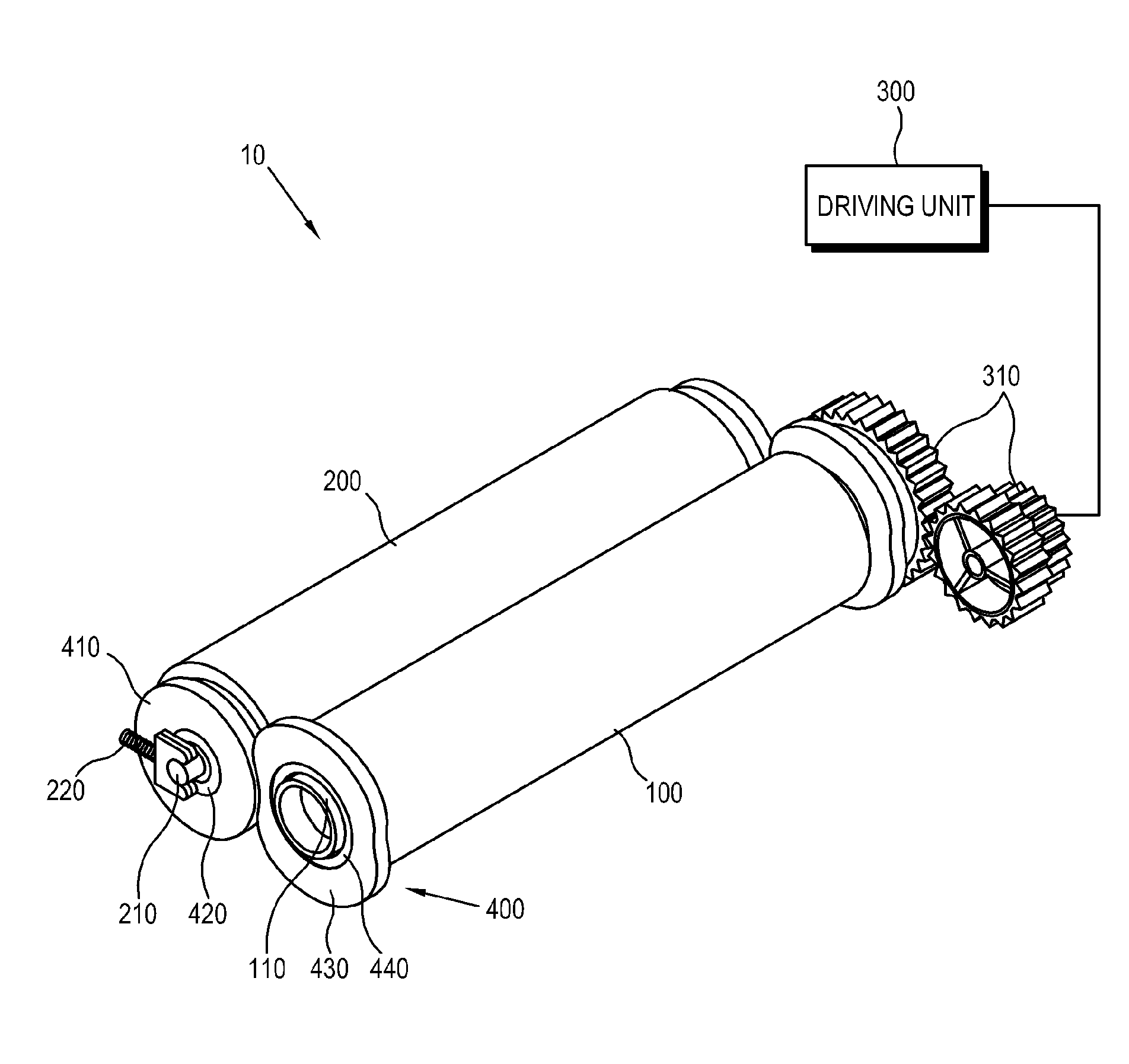

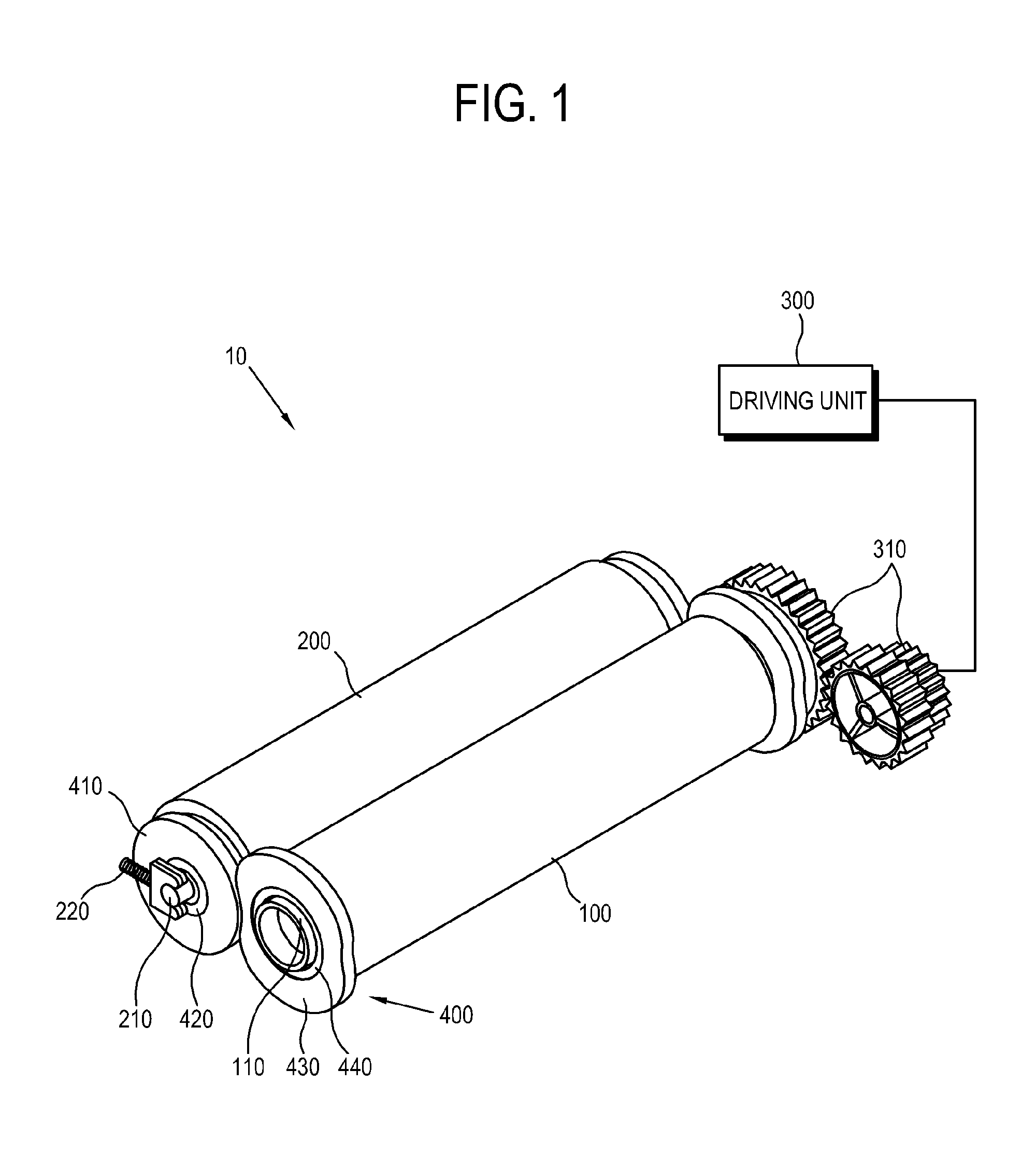

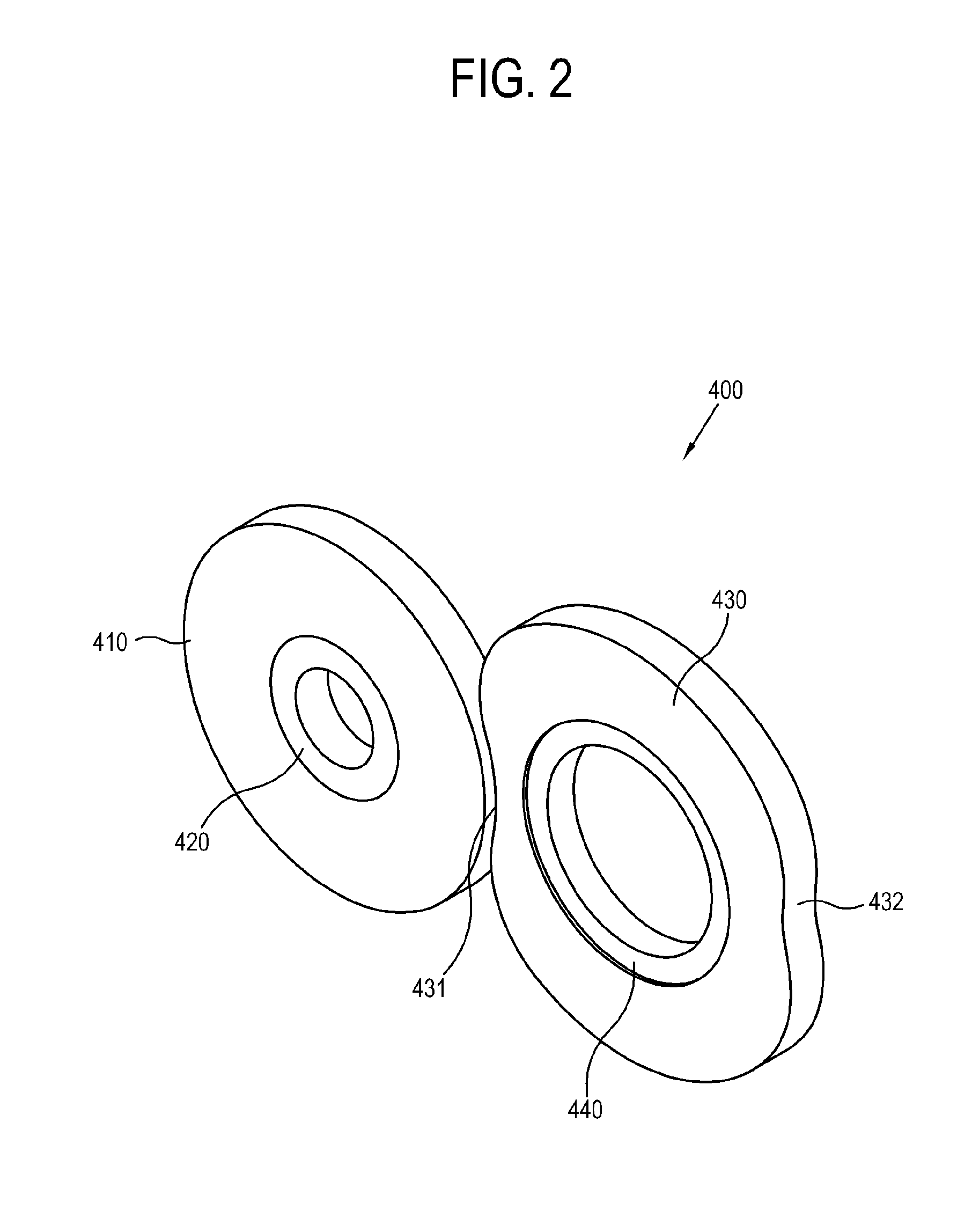

Electric power steering system

InactiveUS20130133974A1Accurately adjust backlashAvoid differencesRolling contact bearingsElectrical steeringElectric power steeringPerpendicular direction

There is provided an urging mechanism that elastically urges a second end portion of a worm shaft that is supported so as to be pivotable about a first end portion. The urging mechanism is configured to adjust a backlash between the worm shaft and a worm wheel by elastically urging the second end portion in a perpendicular direction that is perpendicular to a direction in which an inter-axis distance between the worm shaft and the worm wheel increases and decreases, in a state where increases and decreases in the inter-axis distance is prevented.

Owner:JTEKT CORP

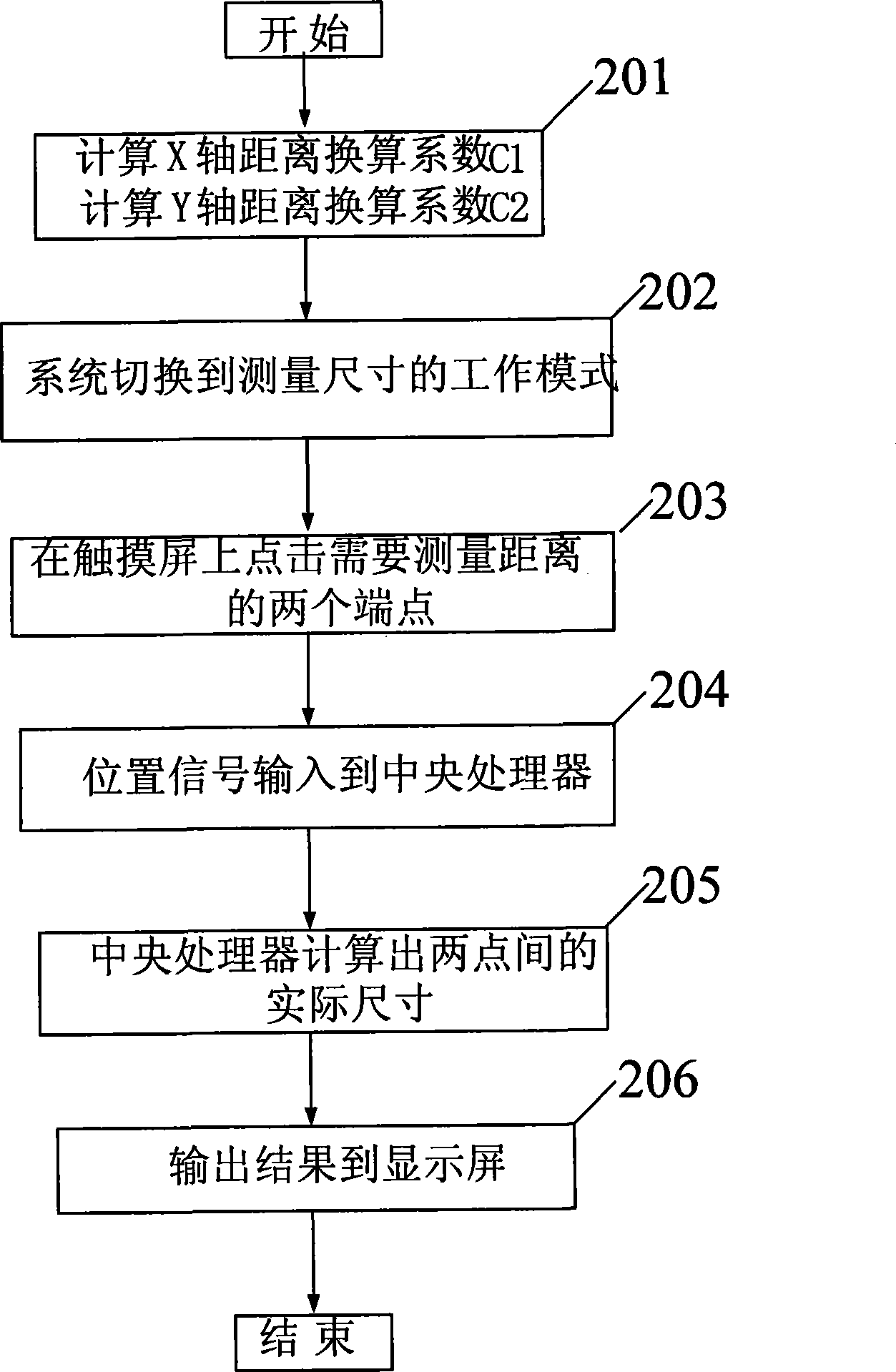

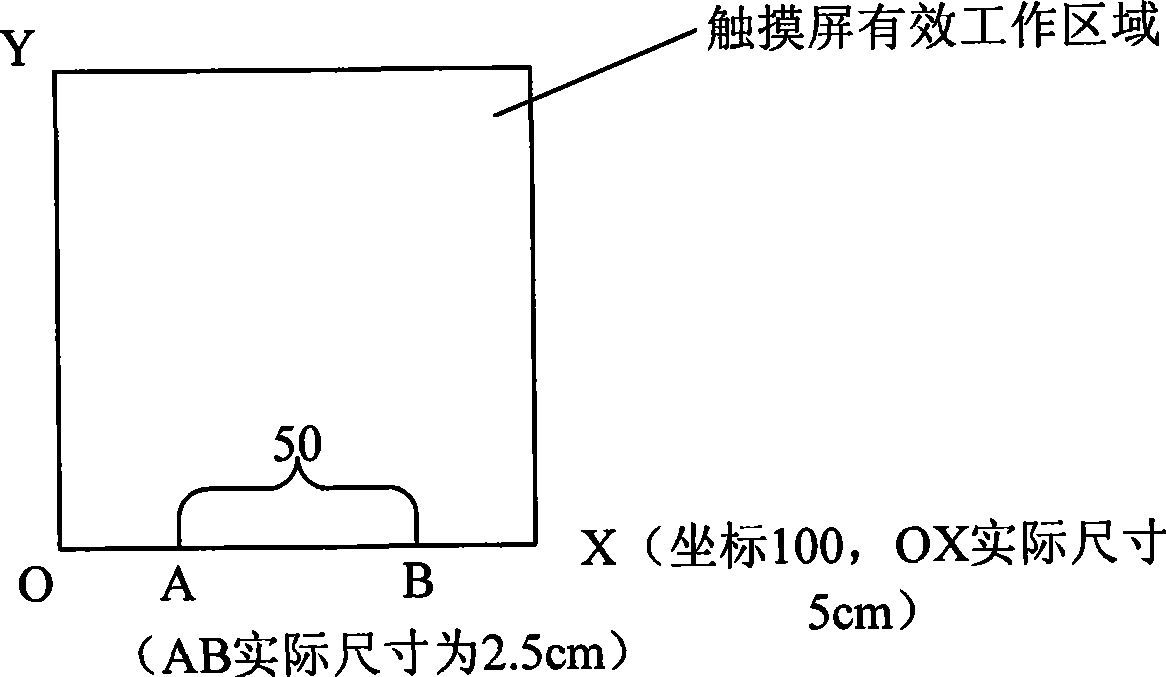

Method for measuring object dimension and angle through touch screen

InactiveCN101470548AEasy to useMeasurement devicesInput/output processes for data processingElectricityConversion coefficients

A method for measuring dimensions of objects by a touch screen includes steps of 1) calculating X-axis distance conversion coefficient C1 and Y-axis distance conversion coefficient C2, 2) using a touch pen to click two endpoints of a distance to be measured, 3) using the touch screen to transmit position coordinate signals (X1,Y1) and (X2,Y2) of the two endpoints to a central processing unit by electric conversion, 4) calculating actual physical dimensions D of the two endpoints by the central processing unit, and 5) outputting the actual physical dimensions D to an output device or a memory. Compared with the method for measuring dimensions of objects by the touch screen, a method for measuring angles of objects by the same includes using the touch pen to click three points of an angle to be measured according to the sequence of edge, angle and edge to calculate the included angle. The invention combines the digital processing technology and a digital display method, expands the application of the touch screen, and is convenient in use. Users can measure the dimensions and the angles of objects just by simple operations on the touch screen.

Owner:SHANGHAI CHENXING ELECTRONICS SCI & TECH CO LTD

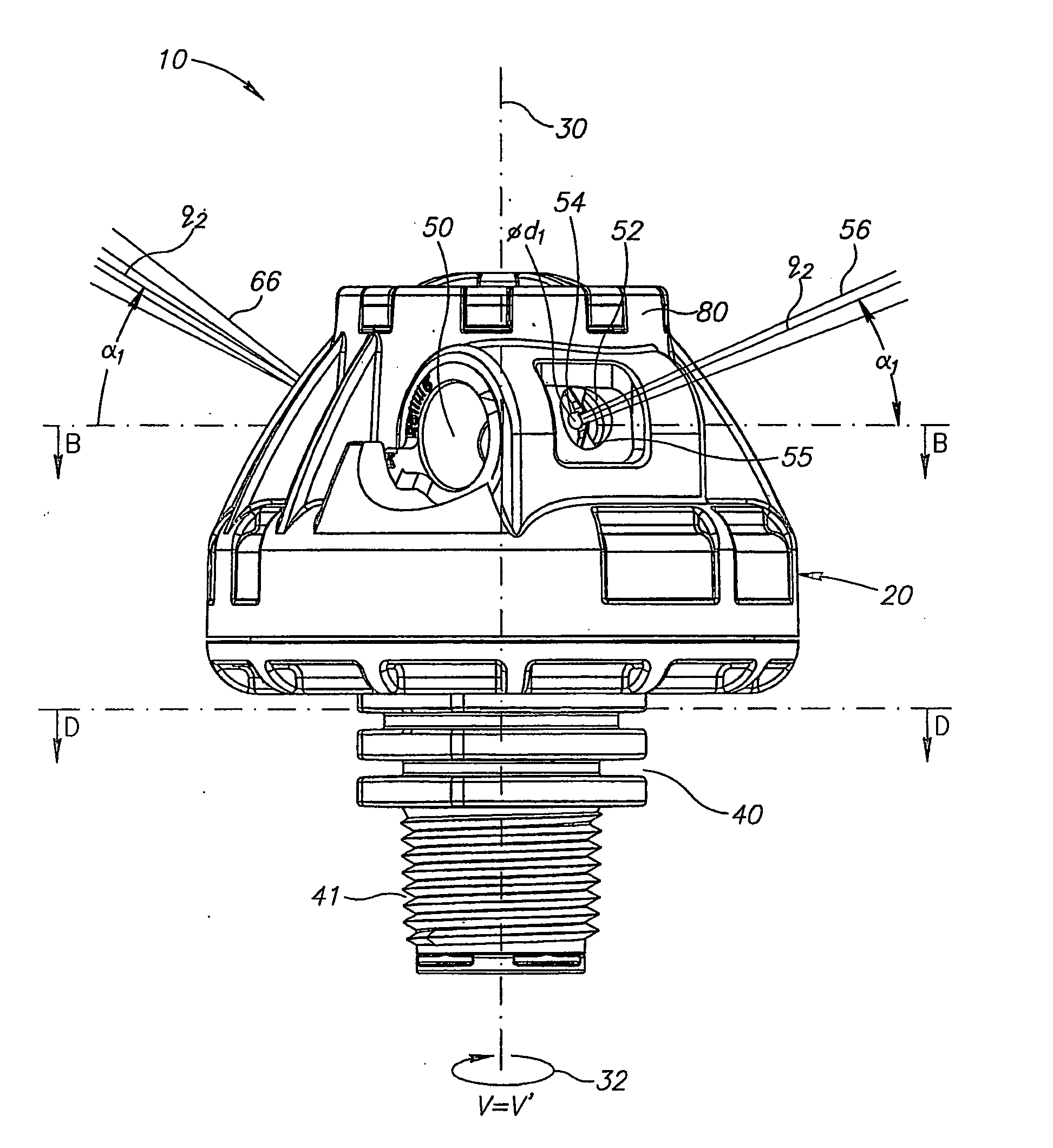

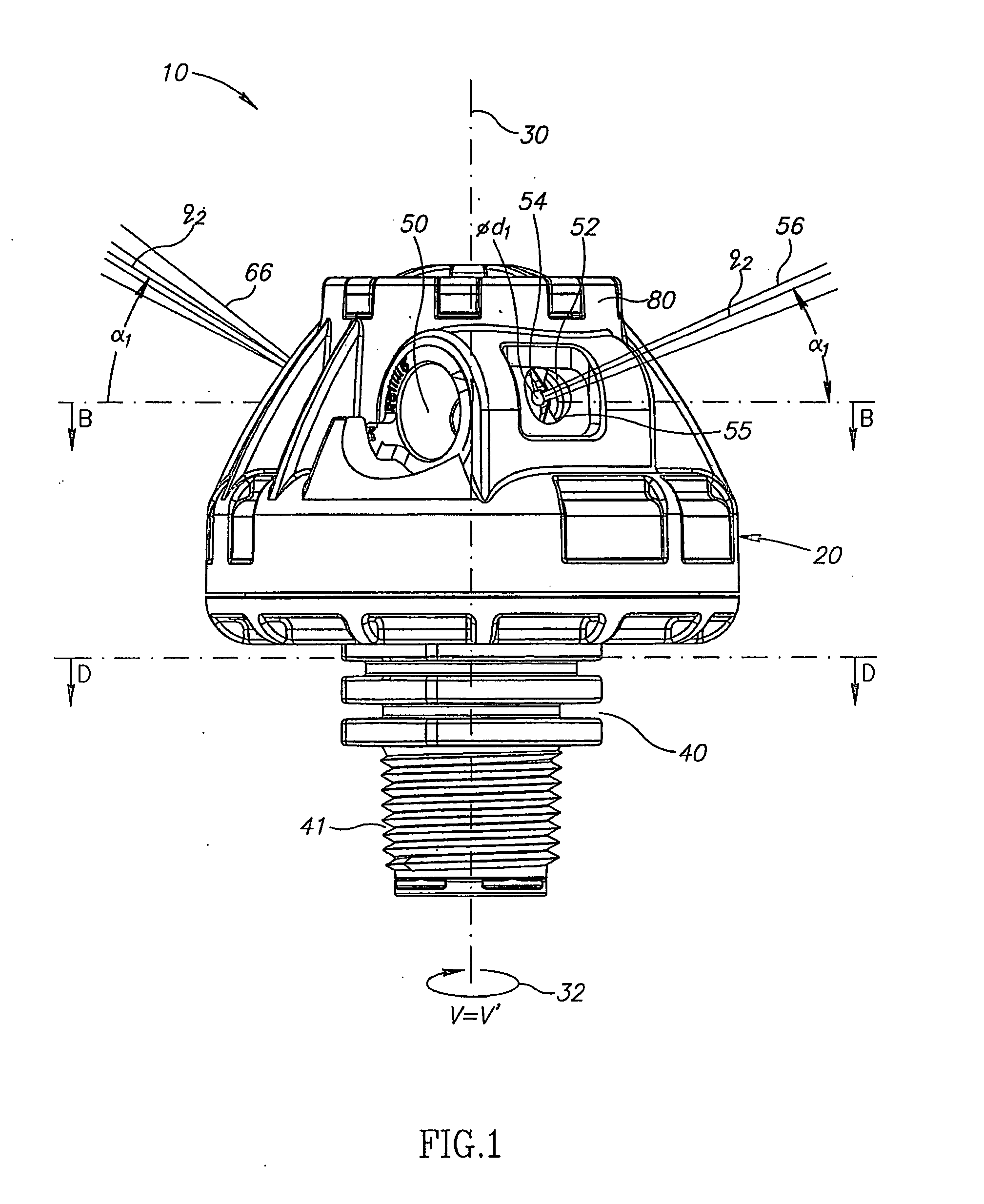

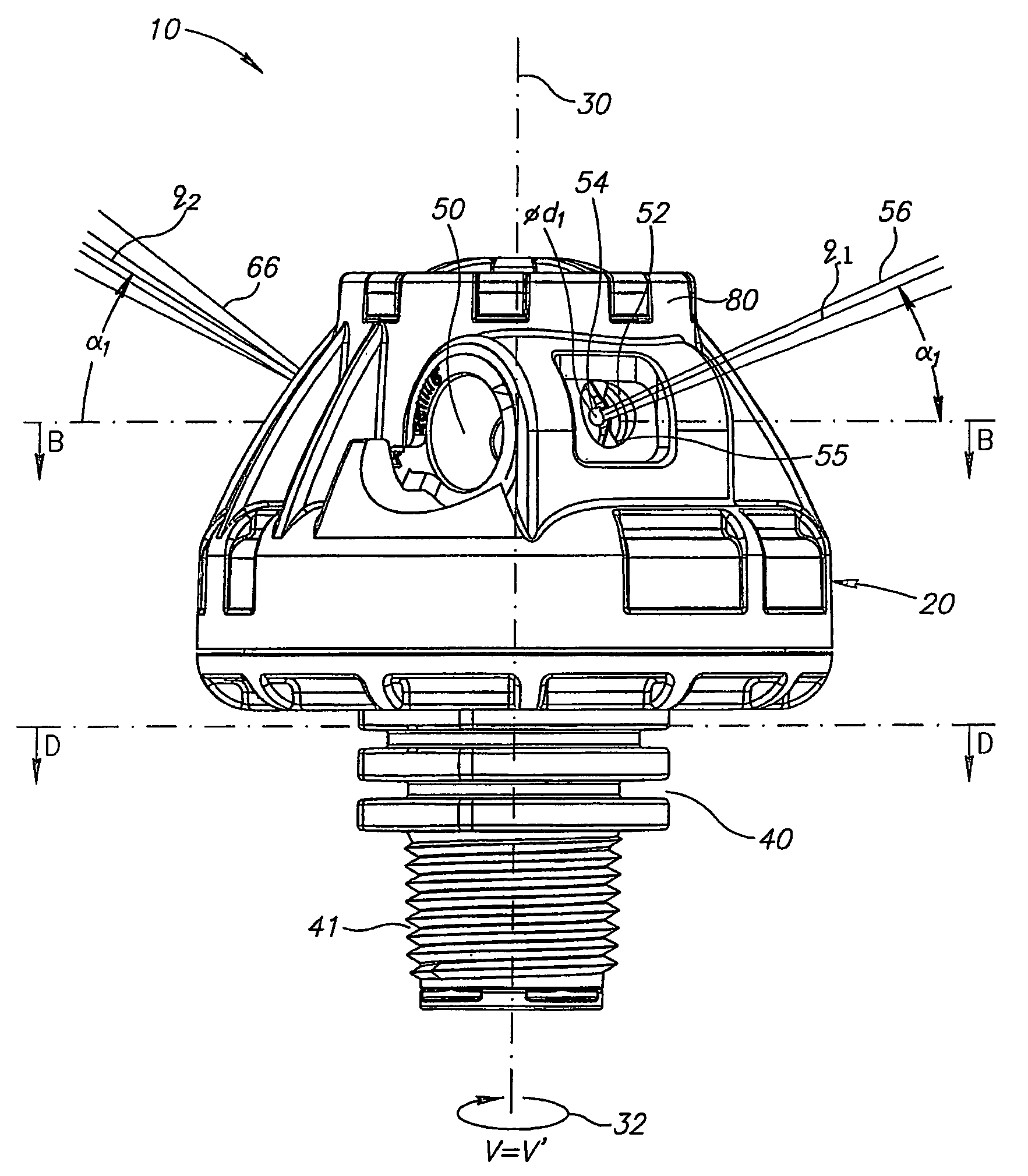

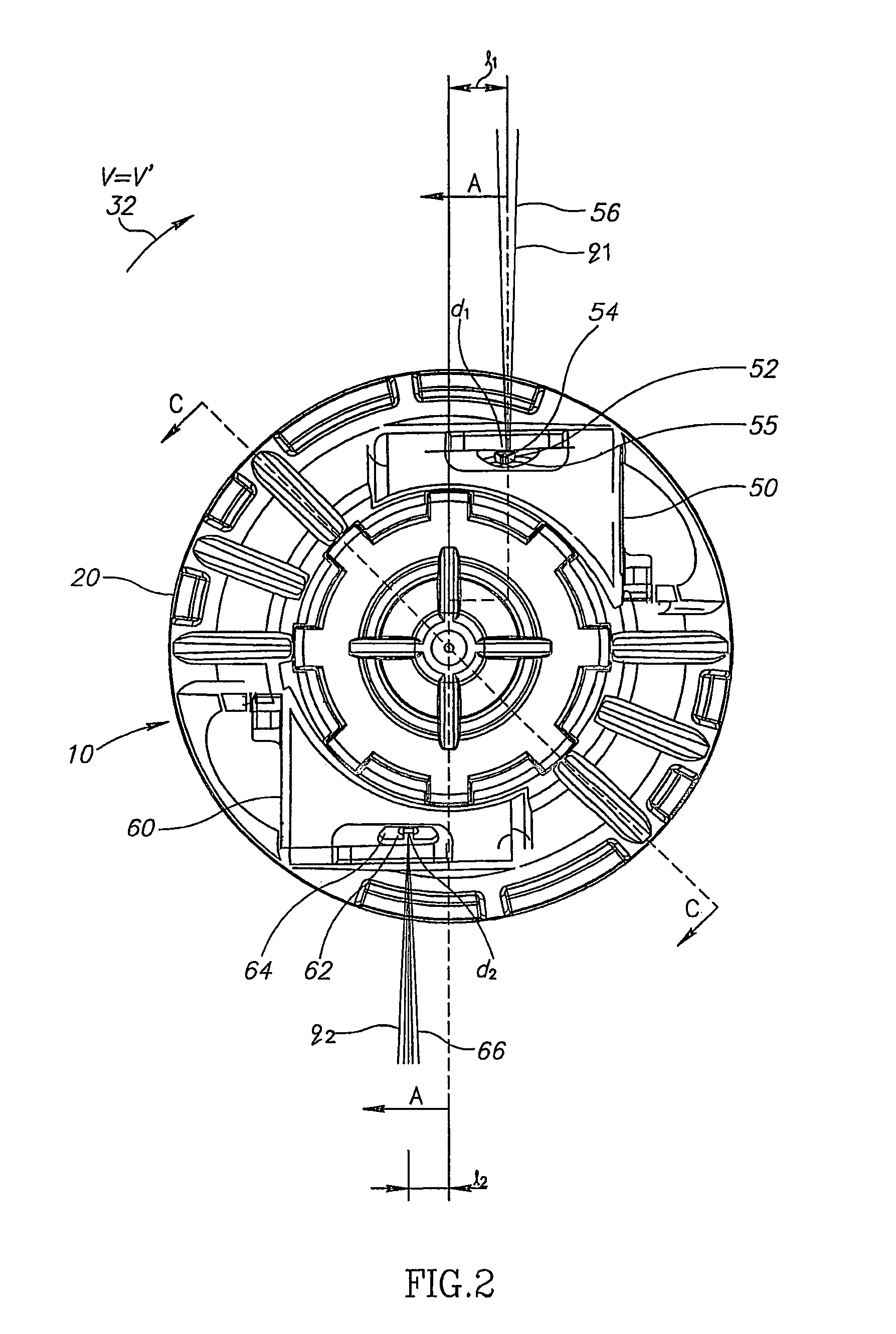

Revolving sprinkler

InactiveUS20060054716A1None of solutions is adequateMovable spraying apparatusFire rescueRotational axisRotation velocity

A revolving sprinkler comprises a rotatable turret assembly revolving around a rotation axis and formed with mouthpiece(s) suited to sprinkle liquid under pressure. The revolving sprinkler accommodates exchangeable mouthpieces with different throughputs—nozzle to rotation axis distance relationships, without changing a rotation velocity of the turret assembly.

Owner:RIVULIS PLASTRO LTD

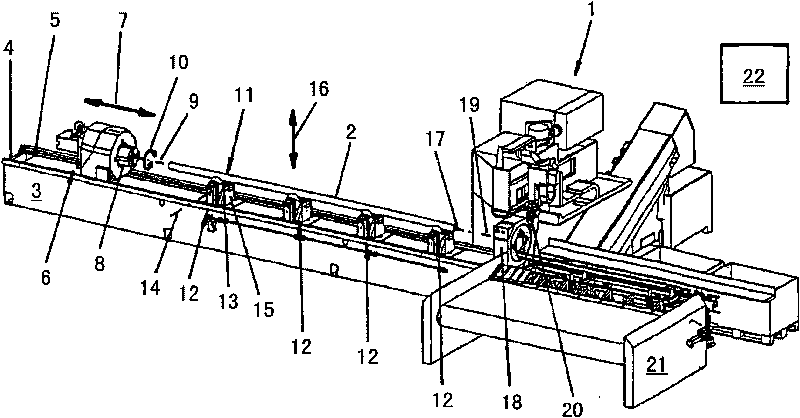

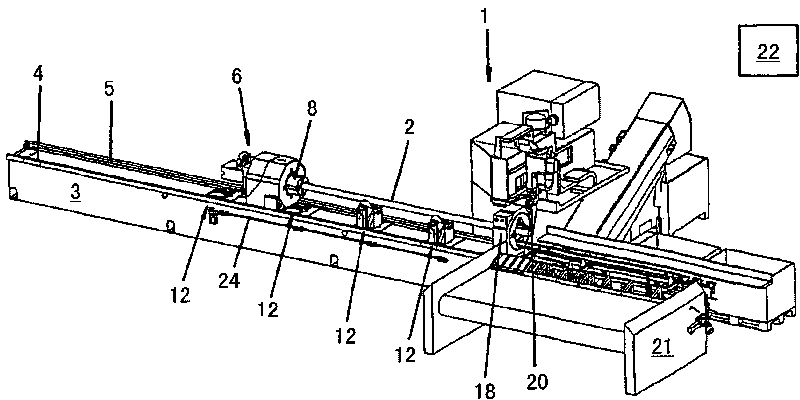

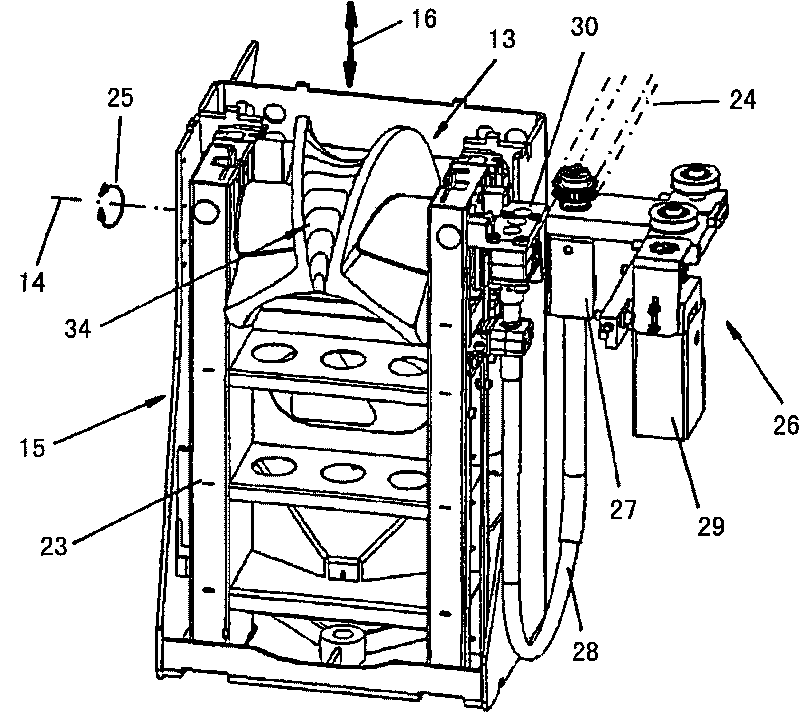

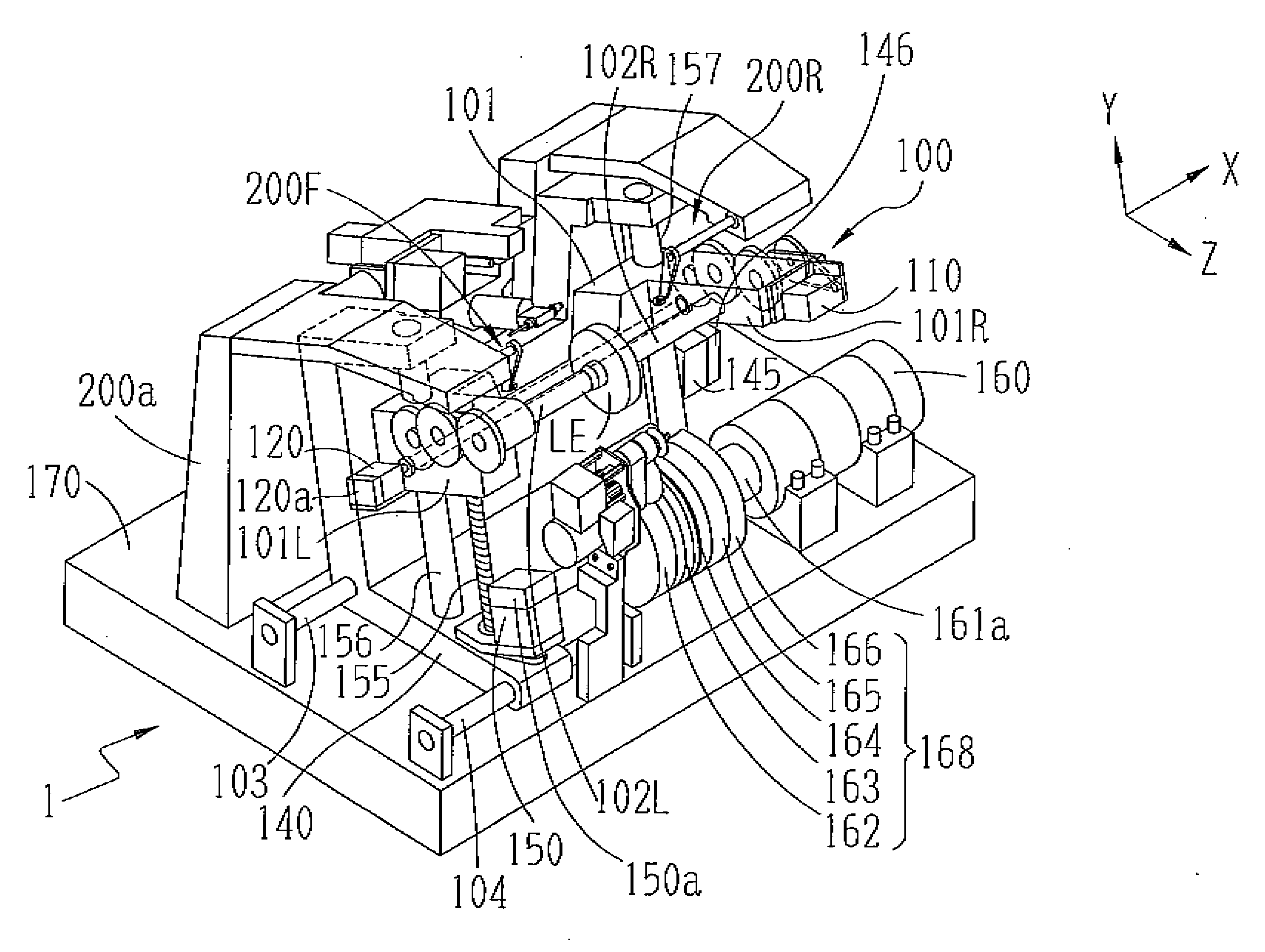

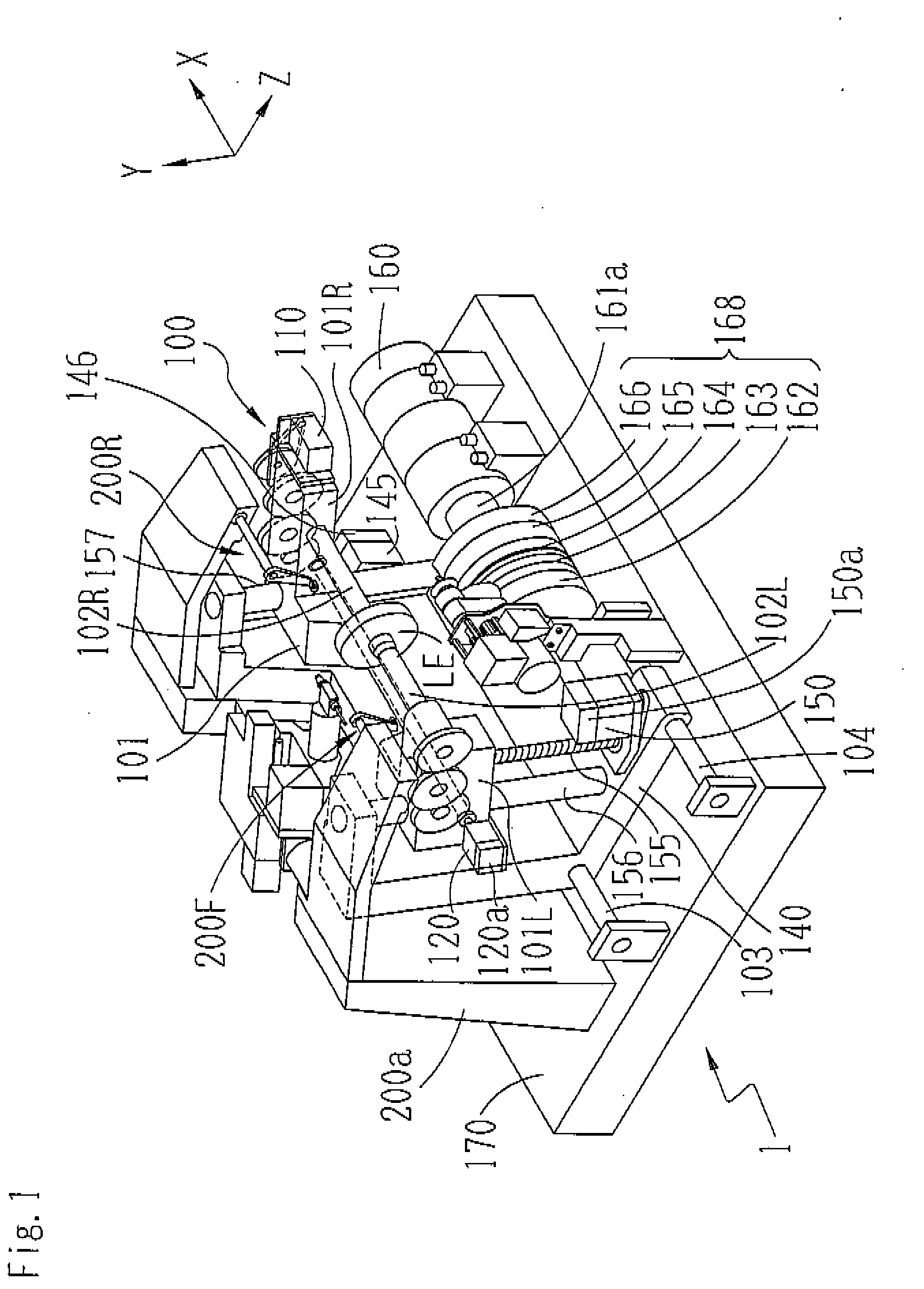

Machine arrangement for machining bar-like workpieces having a device for workpiece support

ActiveCN101754827AEasy to adjustReliable functional supportAutomatic conveying/guiding stockMachine tool componentsEngineeringMachining

The invention relates to a machine arrangement (1) for machining bar-like workpieces, particularly pipes, comprising a machining device (20) for workpiece machining, a workpiece moving device (6) for moving workpieces (2) relative to the machining device (20), and a device (11) for workpiece support in the direction of gravity. The device (11) for workpiece support comprises at least one supporting roller (13) forming a workpiece contact surface on the outer circumference thereof. The workpiece contact surface on the outer circumference of the supporting roller (13) runs about a roller rotary axis (14) of the supporting roller (13) at a varying axis distance. The supporting roller (13) is controllably rotatably about the roller rotary axis (14) and thus is adjustable to various rotary settings.

Owner:TRUMPF WERKZEUGMASCHINEN GMBH & CO KG

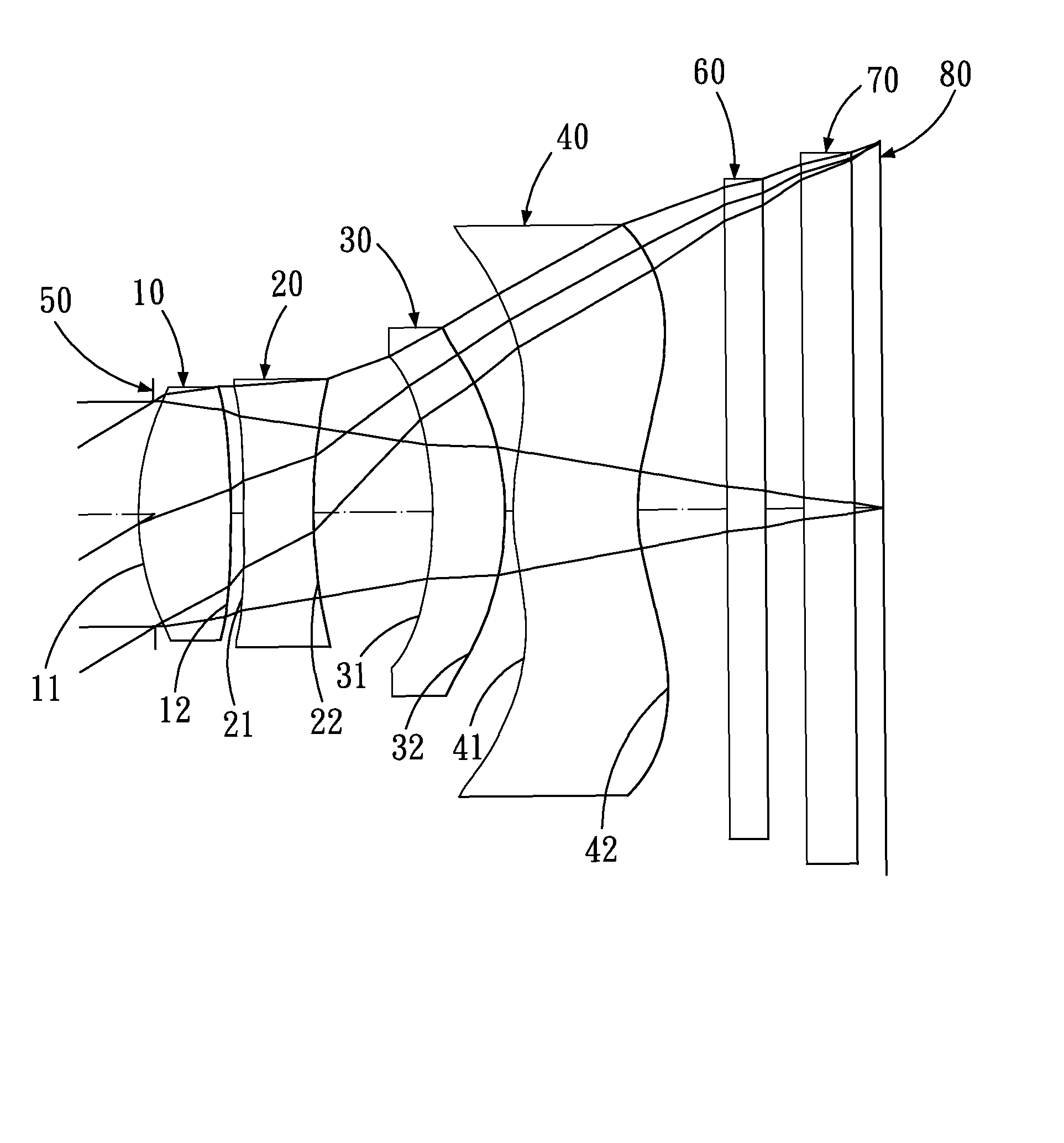

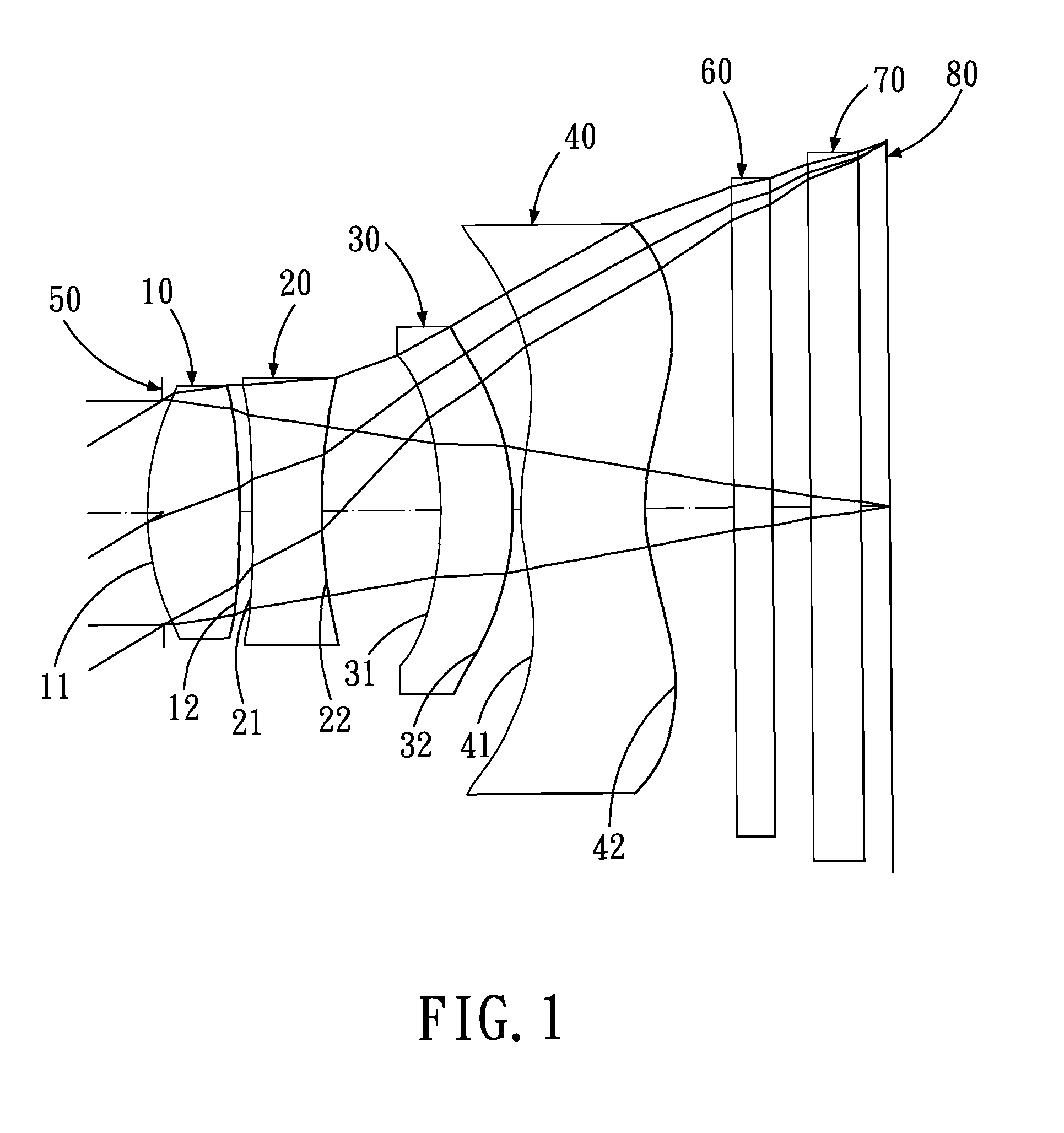

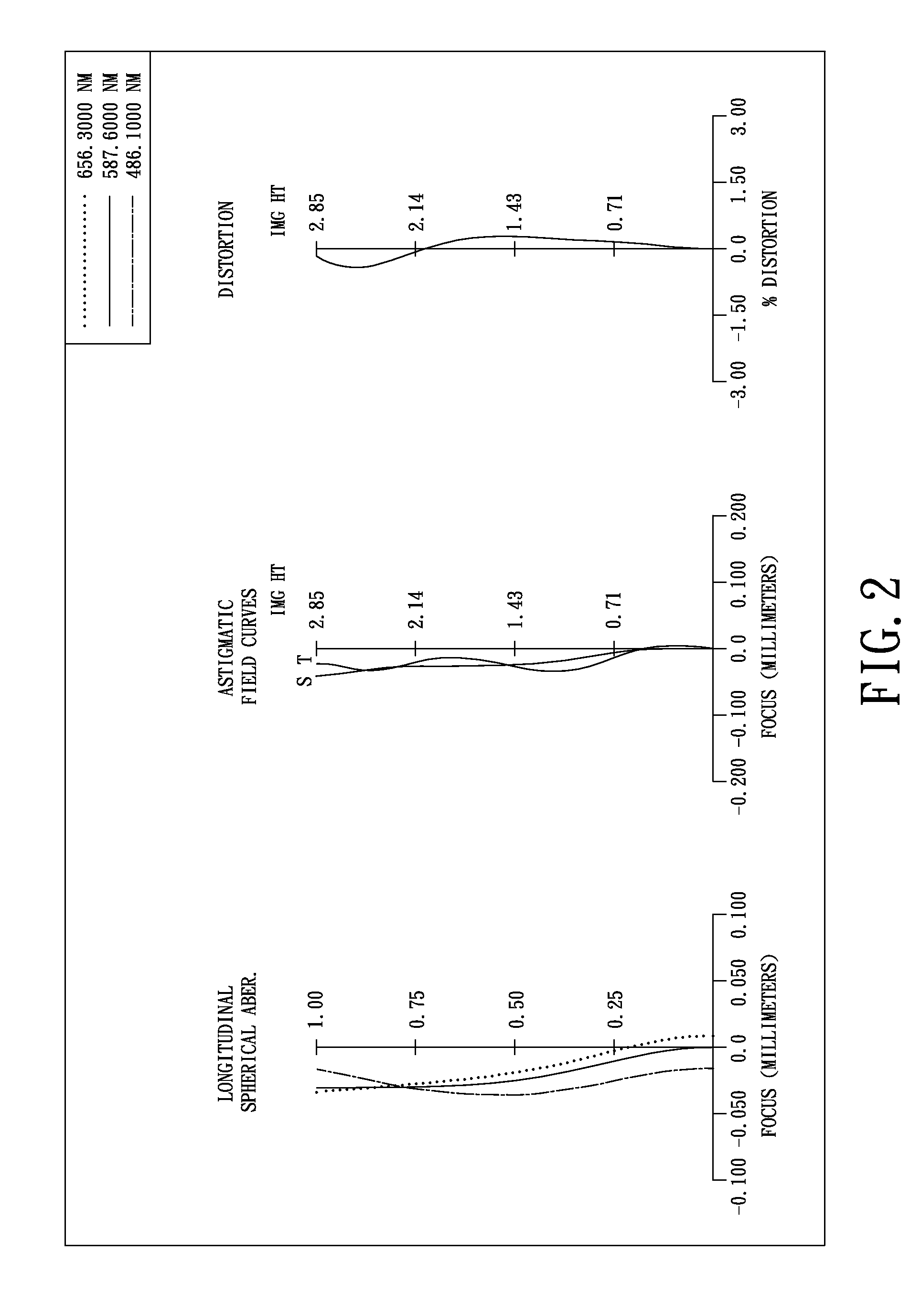

Optical Lens System for Taking Image

An optical lens system for taking image comprises, in order from the object side to the image side: an aperture stop; a first lens element with positive refractive power having a convex object-side surface and a convex image-side surface; a plastic second lens element with negative refractive power having a concave object-side surface, a convex image-side surface and at least one aspheric surface; a plastic third lens element with negative refractive power having a convex object-side surface, a concave image-side surface and at least one aspheric surface. The number of the lens elements with refractive power being limited to three. Focal lengths of the optical lens system, the first lens element, the second lens element and the third lens element are f, f1, f2, f3 respectively; Abbe numbers of the first and second lens elements are V1, V2 respectively, an on-axis distance between second and third lens elements is T23, and they satisfy the relations: 0.8<f / f1<1.8; 0<|f / f2|<0.8; 0<|f / f3|<0.7; 20<V1−V2<38; 0.13<T23 / f<0.21.

Owner:LARGAN PRECISION

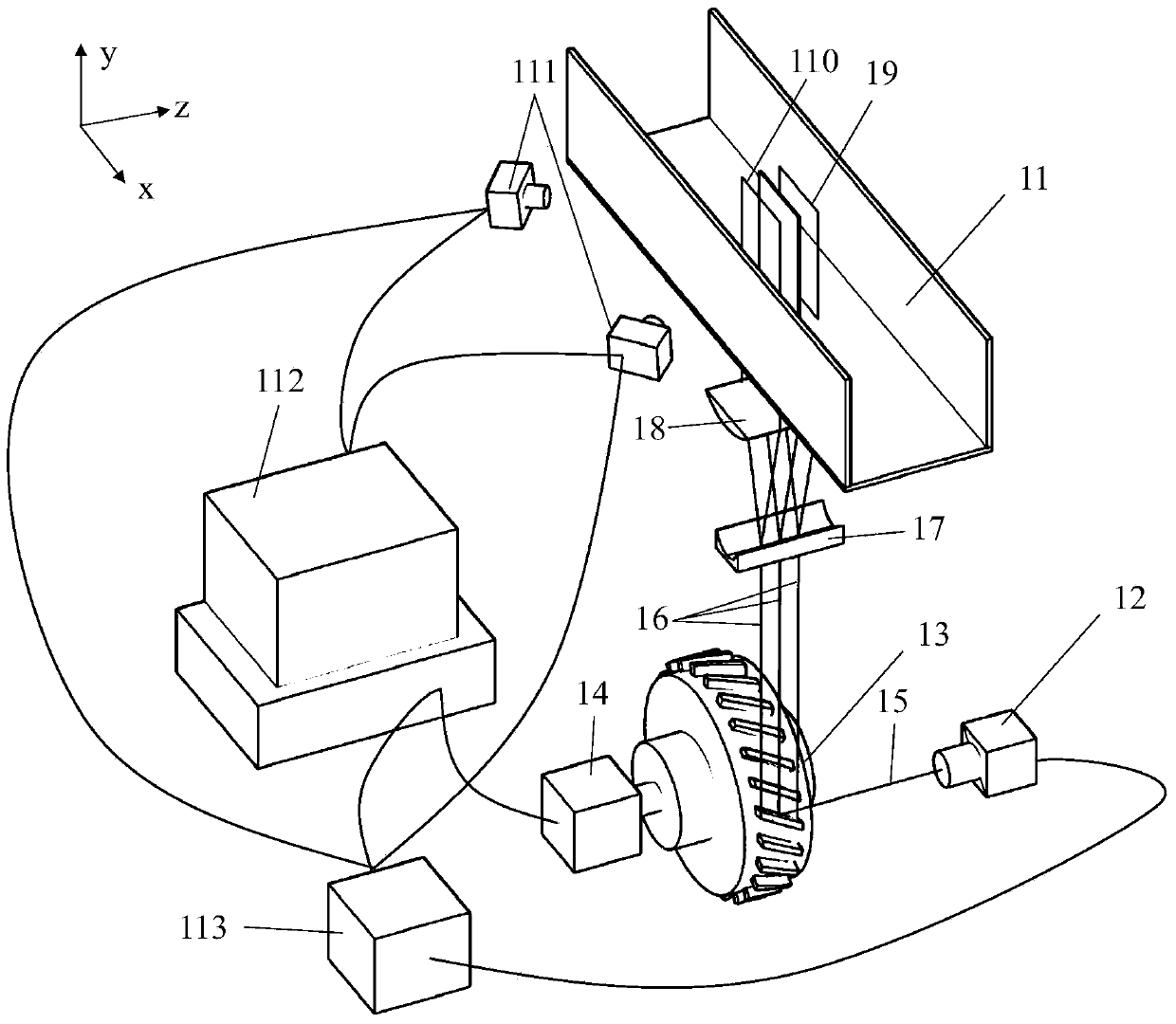

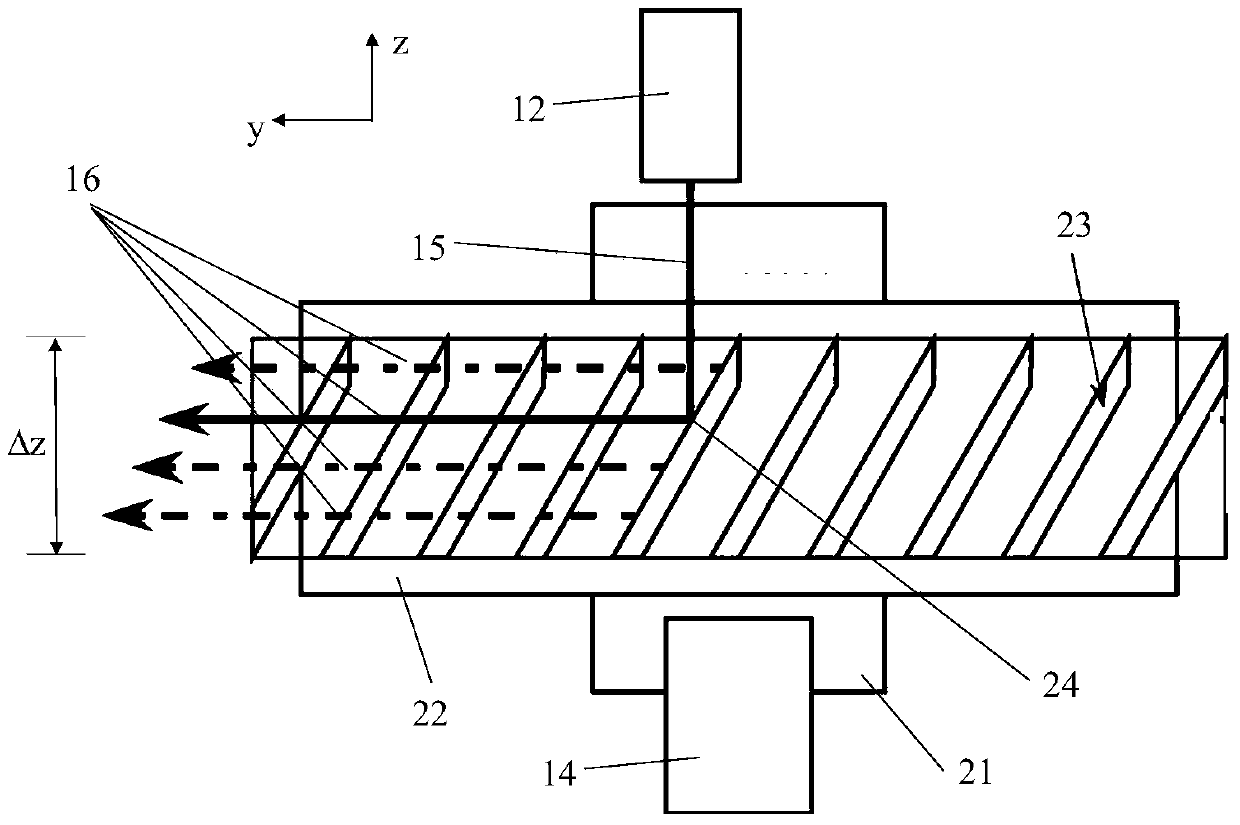

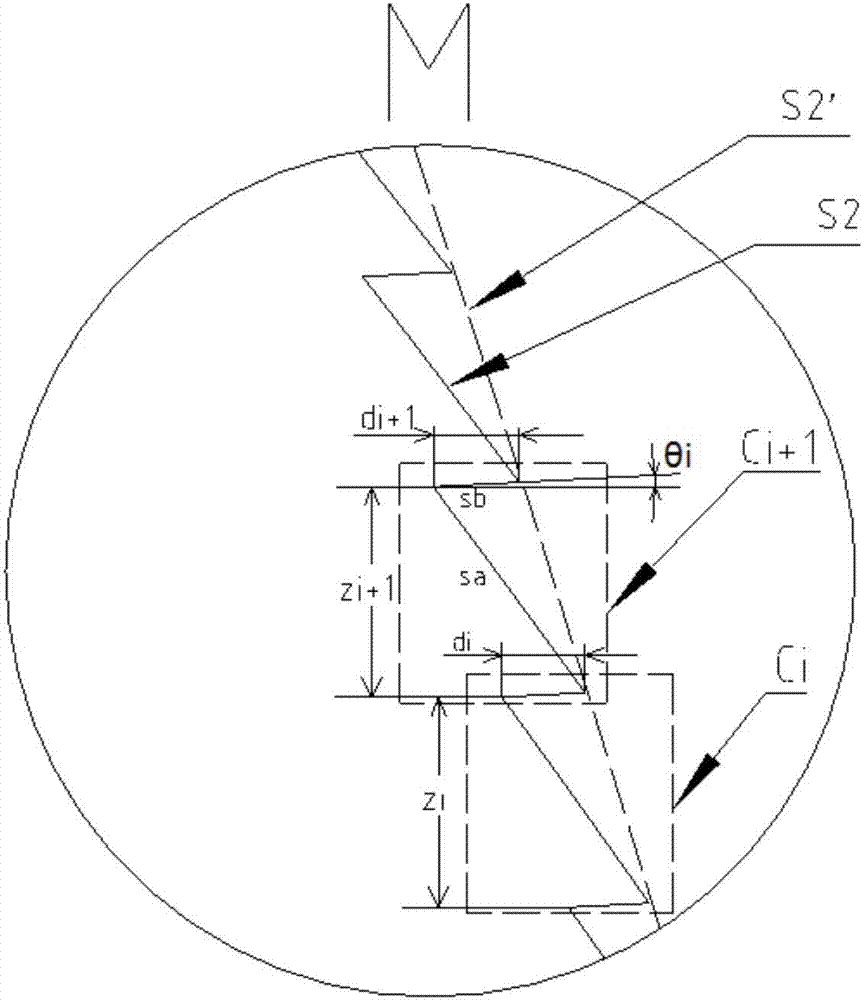

Three-dimensional flow field high-frequency measurement device based on light sheet scanning of particle pictures and method of three-dimensional flow field high-frequency measurement device

InactiveCN104133078ARealize measurementEnables high frequency measurementsHydrodynamic testingFluid speed measurementExperimental researchMeasurement device

The invention relates to a three-dimensional flow field high-frequency measurement device based on light sheet scanning of particle pictures and a method of the three-dimensional flow field high-frequency measurement device, and belongs to the research field of experimental fluid mechanics. The device comprises a laser, a rotating gear, a stepping motor, a cylindrical concave lens, a cylindrical convex lens, two high-speed cameras, a synchronizer and a computer, wherein the rotating gear is provided with N light reflecting teeth. The N thread-shaped light reflecting teeth are arranged on the cylindrical surface of the rotating gear at equal intervals and are in lap joint end to end, and in the rotating process, the rotating gear reflects an incoming laser beam with an invariable axis distance with the rotating gear into a reflected laser beam used for conducting unidirectional sequential scanning in a fixed plane, and the reflected laser beam is converted into a rectangular scanning light sheet after passing through the cylindrical concave lens and the cylindrical convex lens. Due to the fact that one-time scanning is achieved through each light reflecting tooth, the actual three-dimensional scanning speed of the device can be N times of the rotating speed of the stepping motor, high-frequency measurement of a three-dimensional flow field can be achieved actually, a spatial-temporal evolution process of the three-dimensional flow field is obtained, and significant application value is achieved for experimental research of the fluid mechanics.

Owner:TSINGHUA UNIV

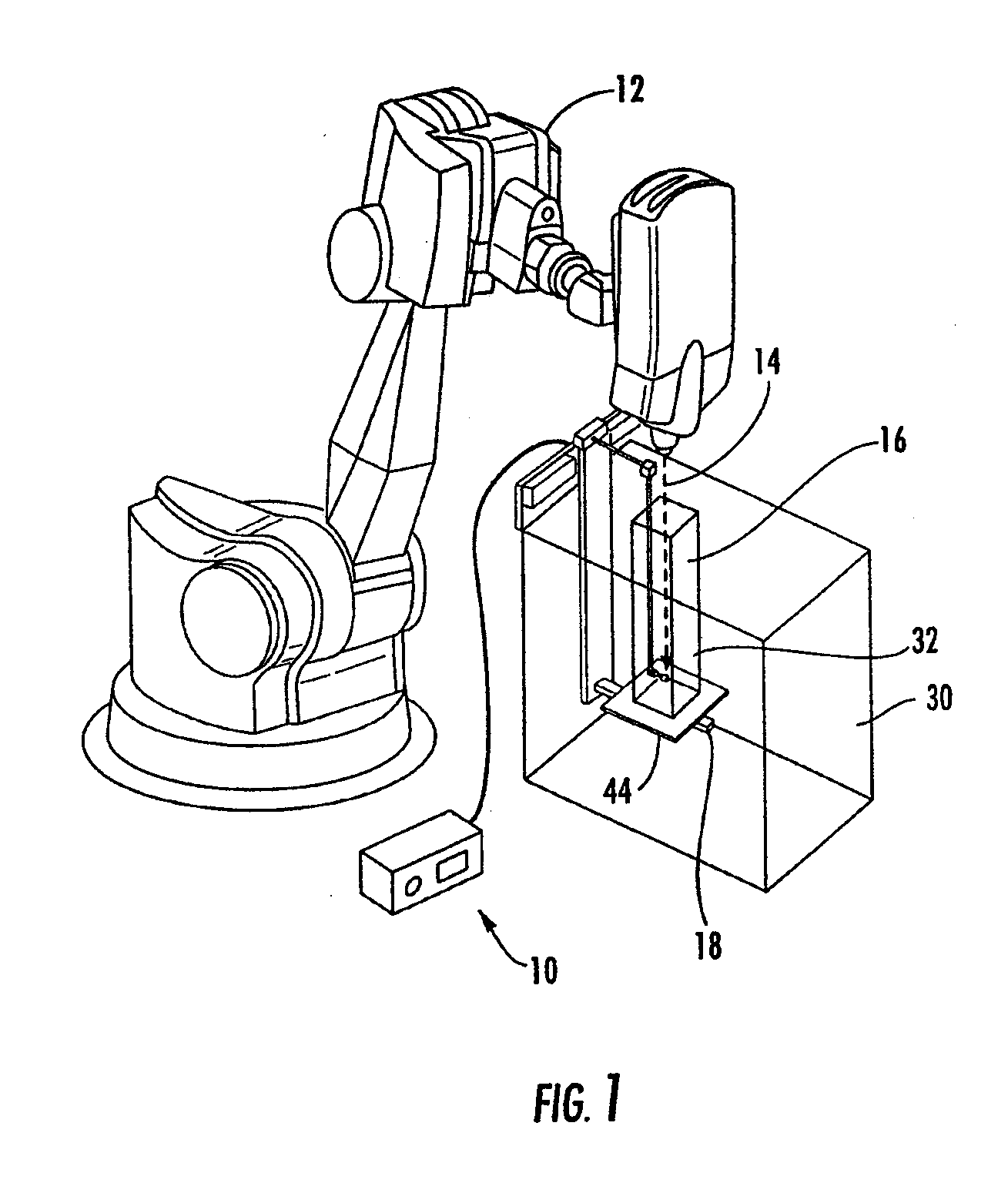

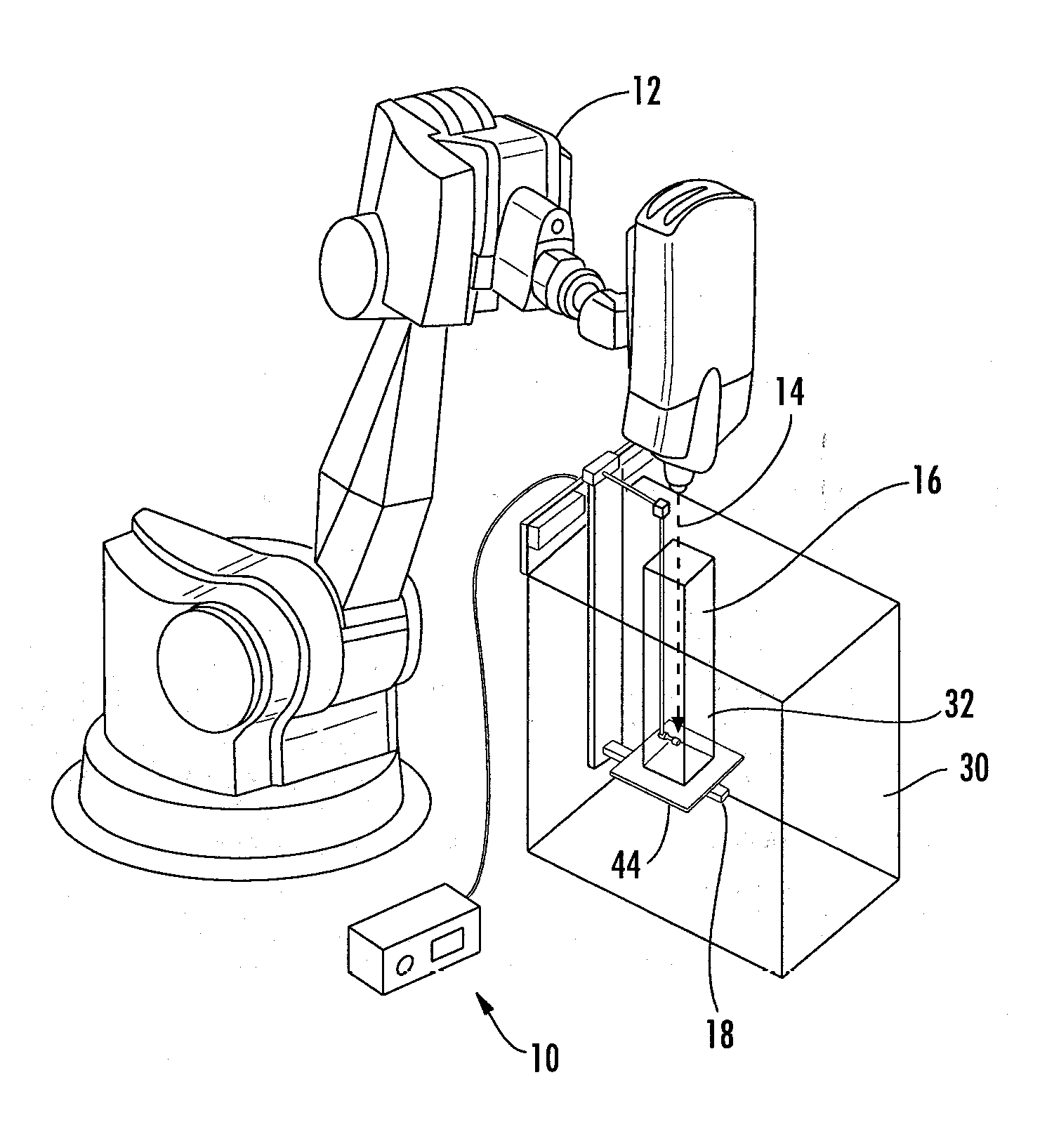

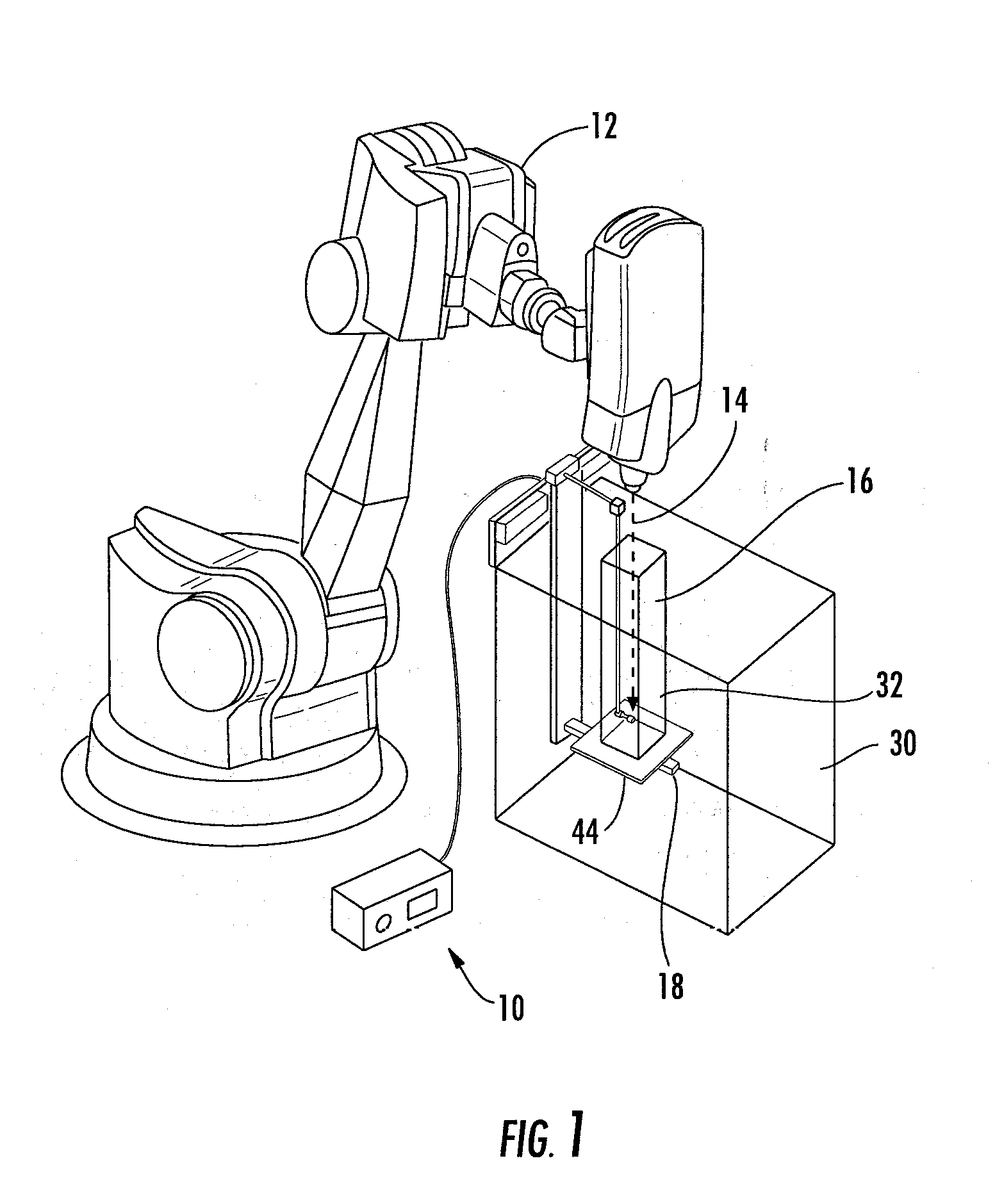

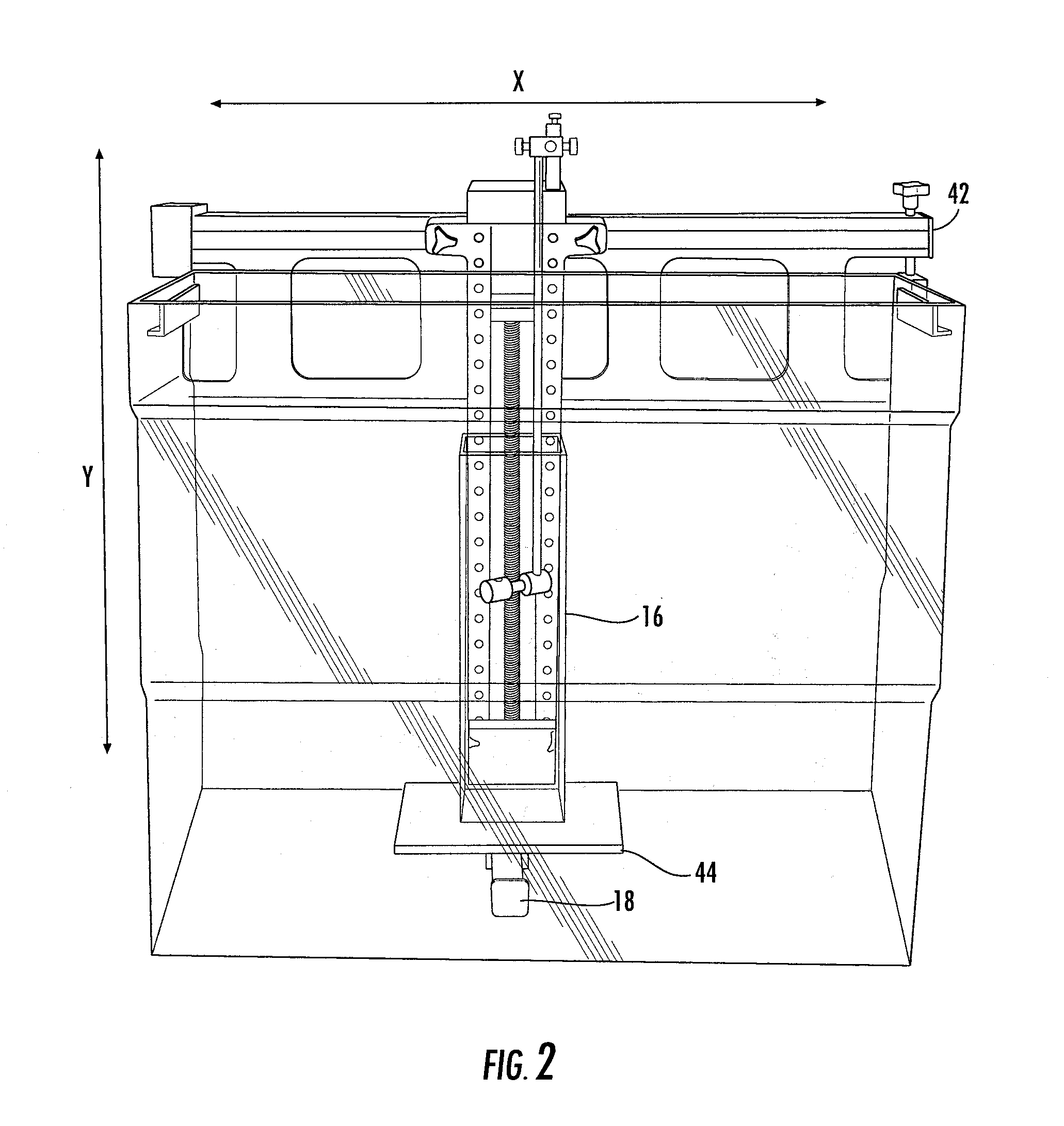

Radiation Beam Analyzer And Method

ActiveUS20110278444A1Precise positioningGood repeatabilityMaterial analysis using wave/particle radiationRadiation/particle handlingFixed positionCyberknife

A radiation beam analyzer for measuring the distribution and intensity of radiation produced by a Cyberknife®. The analyzer employs a relative small tank of water into which a sensor is placed to maintain a constant SAD (source to axis distance). A first method maintains a fixed position of detector, and raises or lowers the small tank of water. A second method moves the detector up, down or rotationally synchronously in opposite directions with respect to the small tank of water to keep the SAD constant. These methods position the detector relative to the radiation source to simulate the location of a malady within a patient's body. An embodiment of the present invention enables measurements of substantially larger fields. This is accomplished by rotating a tank of water 90 degrees from a first position to a second position

Owner:NAVARRO DANIEL

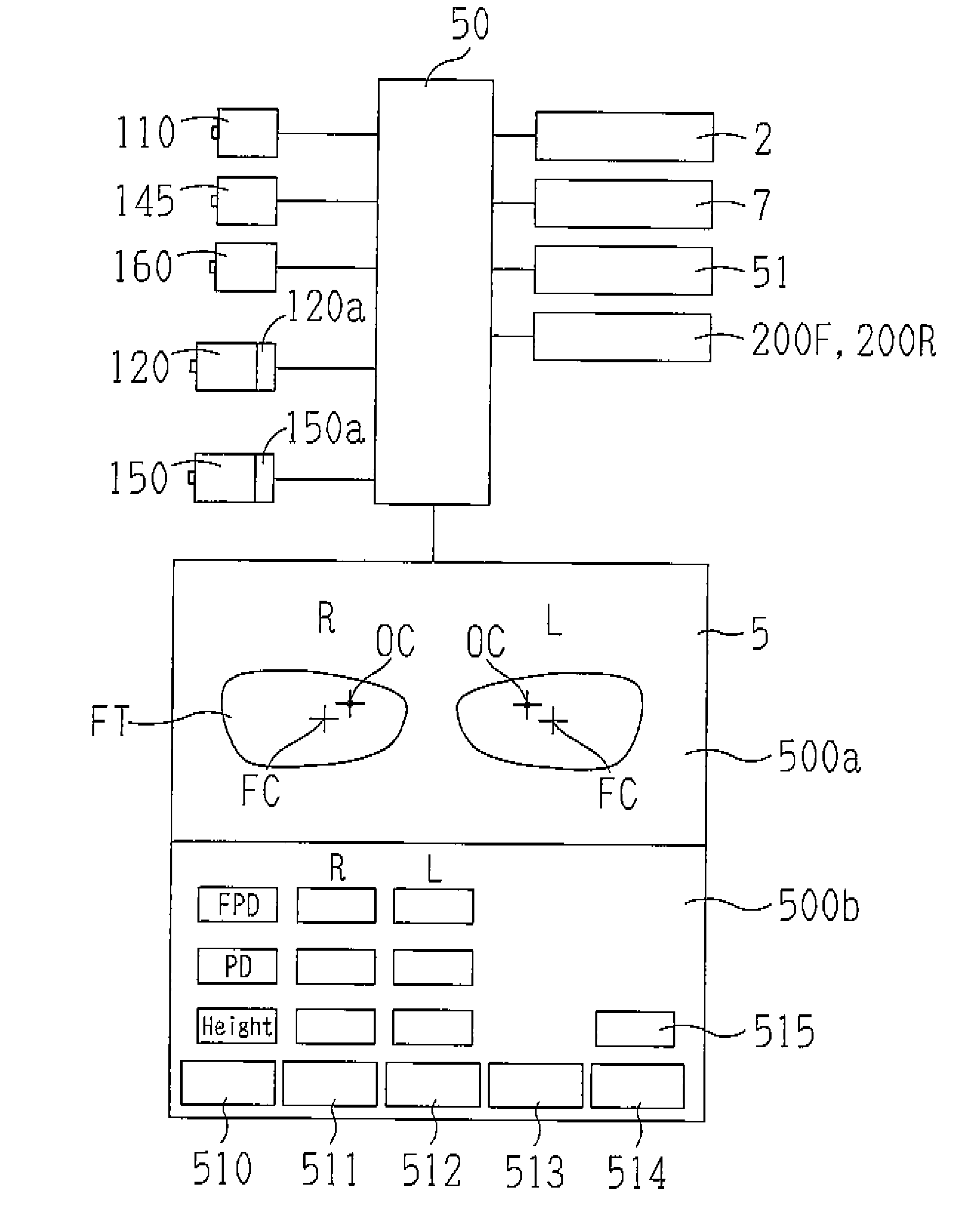

Eyeglass lens processing apparatus

ActiveUS20100197198A1Effective preventionExtended processing timeEdge grinding machinesPolishing machinesCamera lensEyewear

An eyeglass lens processing apparatus includes: a lens rotation unit rotating a lens; a processing tool rotation unit processing the lens; an axis-to-axis distance changing unit for changing an axis-to-axis distance between the chuck shaft and the processing tool rotation shaft; a lens surface configuration acquiring unit which acquires a front surface curve configuration and a rear surface curve configuration of the lens; a lens outer diameter acquiring unit which acquires an outer diameter of a lens; a calculation unit which calculates a thickness of the lens and calculates a cutting depth of the lens, so that torque applied onto the chuck shaft in rough processing becomes substantially constant, based on the calculated lens thickness and a processing distance from the rotation center of the lens; and a control unit which controls the axis-to-axis distance changing unit in accordance with the calculated cutting depth and for rough processing the lens.

Owner:NIDEK CO LTD

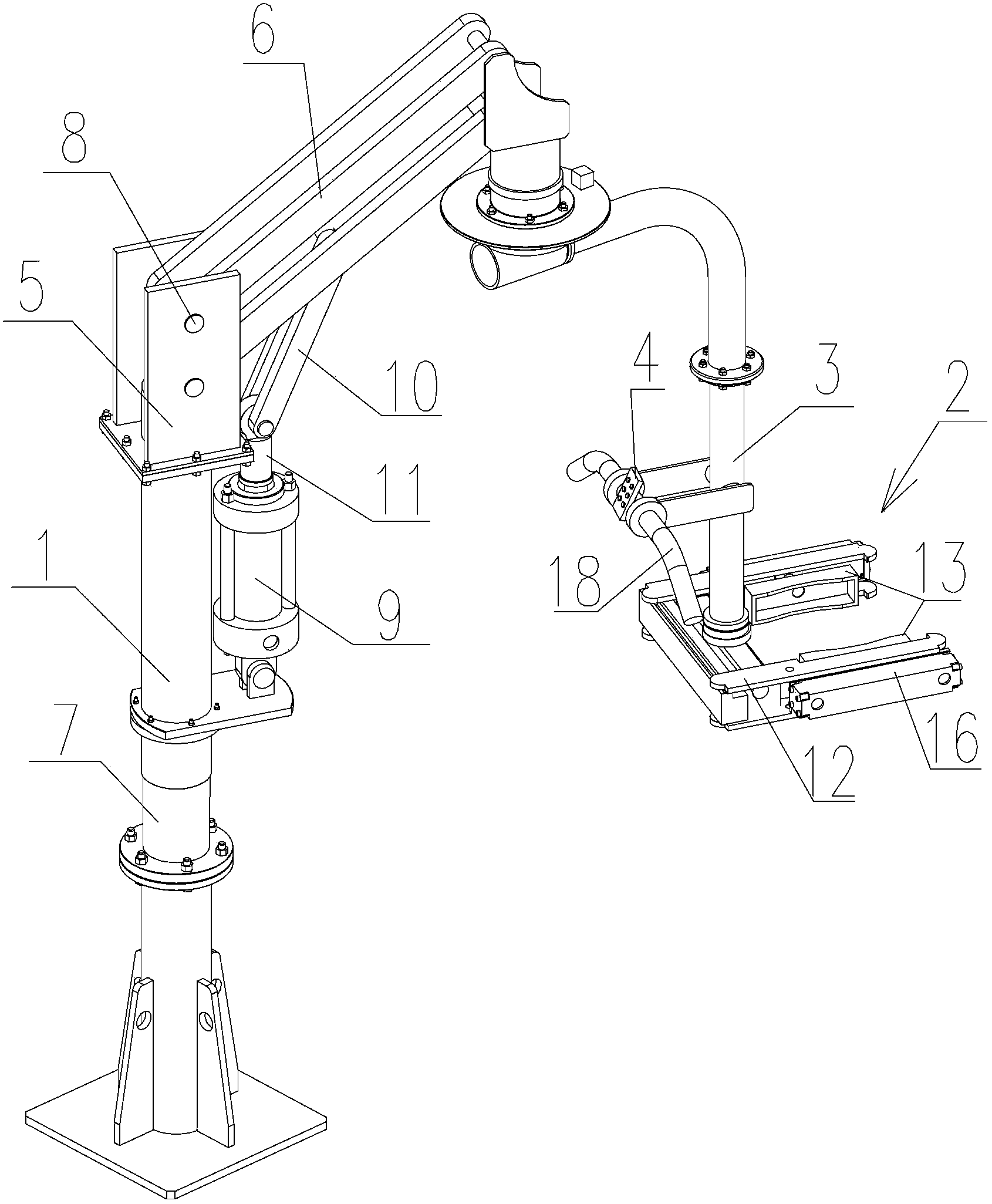

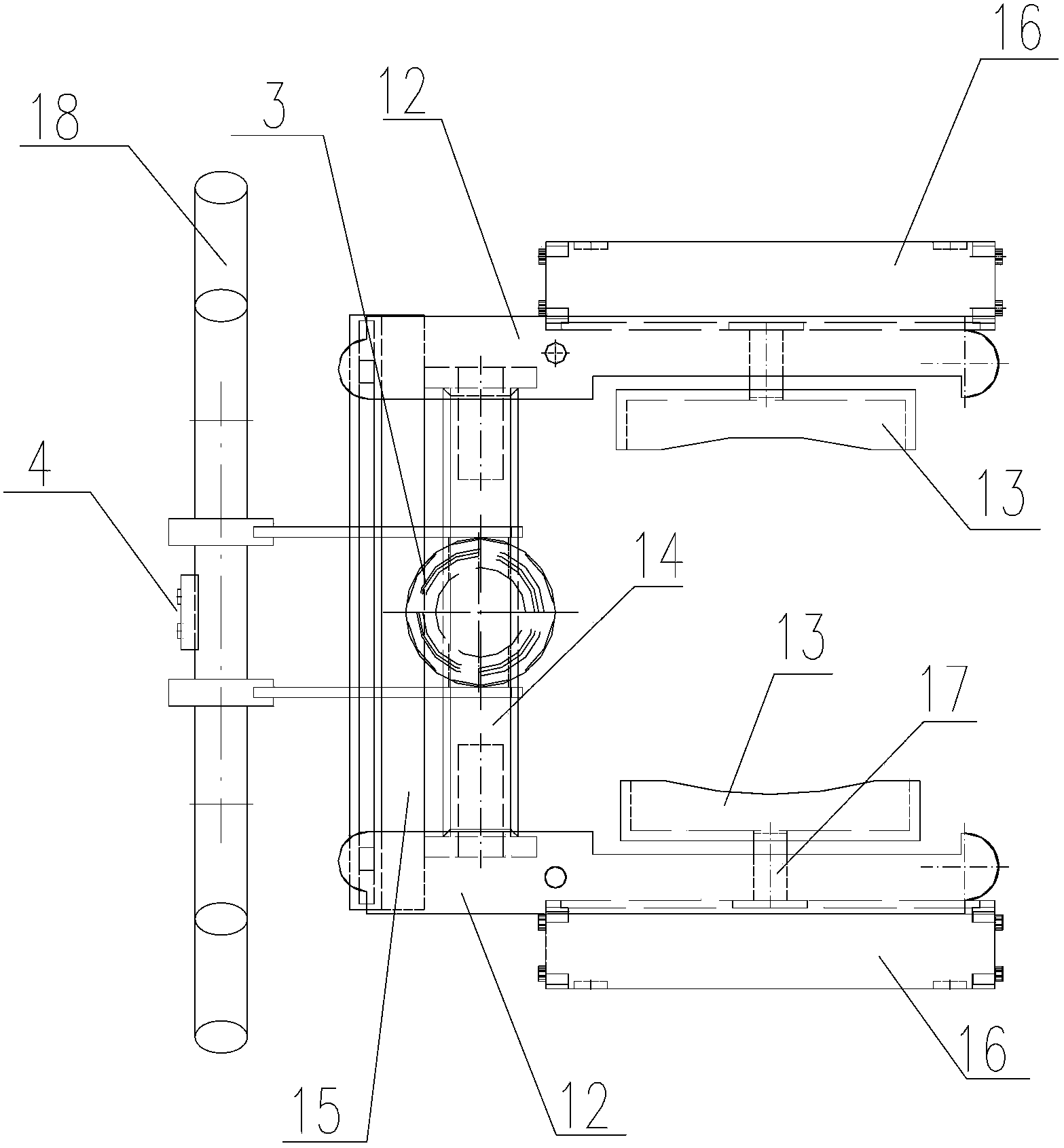

Multi-freedom-degree manipulator fixture

ActiveCN103481279ASimple structureSatisfy fine-tuning requirementsProgramme-controlled manipulatorGripping headsMulti degree of freedomEngineering

The invention relates to a multi-freedom-degree manipulator fixture, which comprises a manipulator main machine, a clamping mechanism, a connecting arm which is used for connecting the manipulator main machine and the clamping mechanism, and a controller. The clamping mechanism comprises a pair of rotatable grips which is used for clamping a workpiece, a clamping device which is used for adjusting X-axis distance between the two grips, and a moving device which is used for driving the grips to move along a Y-axis, wherein the clamping device and the moving device are electrically connected with the controller. The multi-freedom-degree manipulator fixture has the advantages that the structure is simple, the multi-freedom-degree clamping of workpieces with different sizes and shapes can be realized, the operation is safe and convenient to perform, the universality is high, the grips can move linearly along the Y-axis, the requirement on the fine adjustment of the workpieces during clamping and placing, the 180-degree turnover of the workpieces can be realized, the clamping force of the grips can also be adjusted and the requirement on different clamping force for clamping different workpieces is met.

Owner:CRRC QINGDAO SIFANG CO LTD

Revolving sprinkler

InactiveUS7458527B2None of solutions is adequateMovable spraying apparatusFire rescueRotational axisSpray nozzle

A revolving sprinkler comprises a rotatable turret assembly revolving around a rotation axis and formed with mouthpiece(s) suited to sprinkle liquid under pressure. The revolving sprinkler accommodates exchangeable mouthpieces with different throughputs-nozzle to rotation axis distance relationships, without changing a rotation velocity of the turret assembly.

Owner:RIVULIS PLASTRO LTD

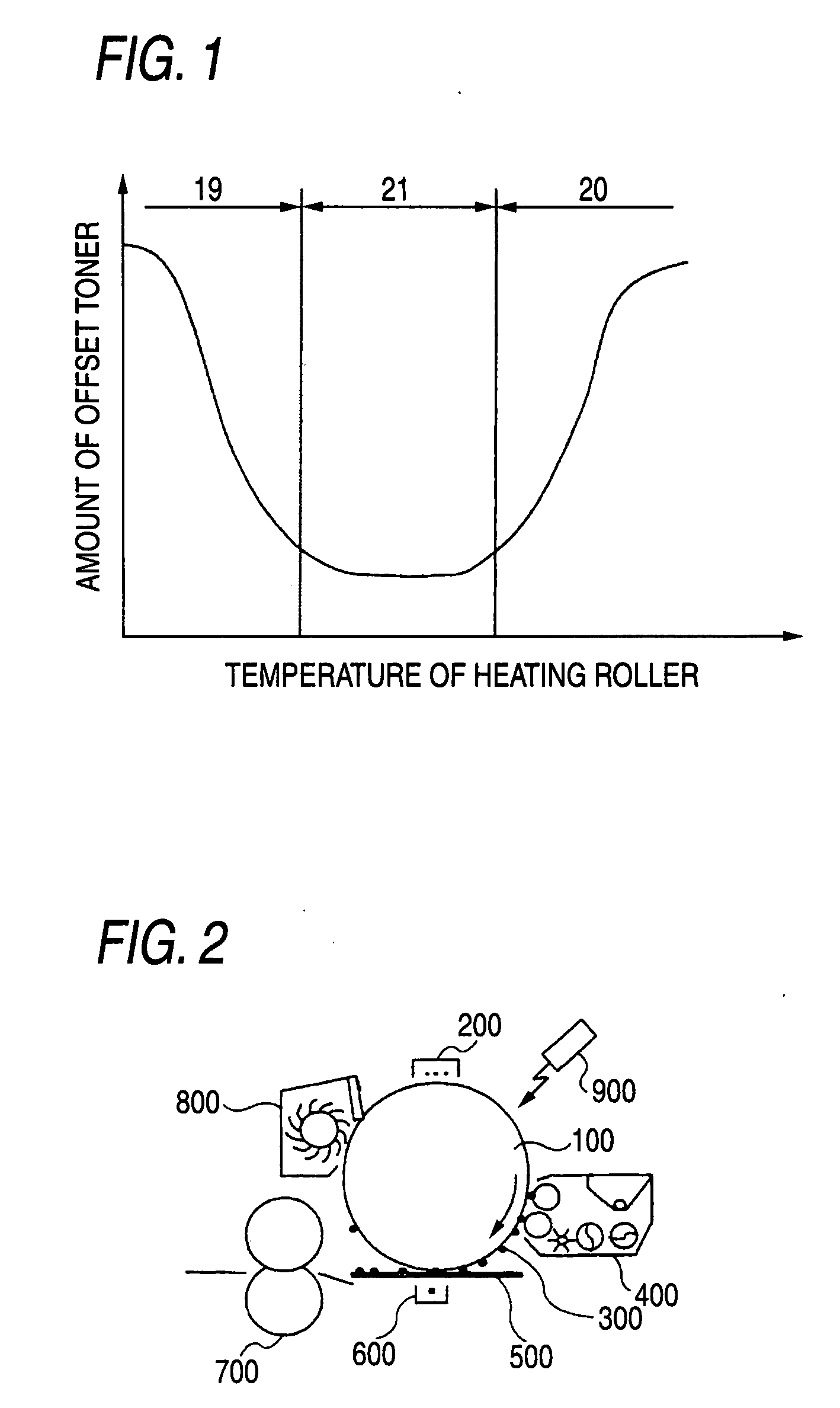

Fixing device and electro-photographic recording apparatus using the same

InactiveUS20070212085A1Decreasing degree of freedomIncrease in sizeElectrographic process apparatusPulp and paper industryAxis distance

An axis-to-axis distance between a heating roller and a back-up roller is expanded beforehand in inserting a thick paper to prevent a rush / exhaust impact when fixing the thick paper without changing a condition of pressing mechanism.

Owner:RICOH KK

Eyepiece and display device with same

The invention provides an eyepiece. The eyepiece is successively provided with a first lens with positive focal power and a convex object side and a second lens along the optical axis from the object side to the image side. The second lens has a concave image side. At least one of the object side of the first lens, the image side of the first lens, the object side of the second lens and the image side of the second lens is a Fresnel structure plane. The maximum half field angle HFOV of the eyepiece is greater than 40 degrees. According to the on-axis distance TTL from the object side of the first lens to an imaging face and the total effective focal length f of the eyepiece, 1<TTL / f<1.5. According to the total effective focal length f of the eyepiece and the on-axis distance TD from the object side of the first lens to the image side of the second lens, 2<f / TD<5. According to the effective radius DT11 of the object side of the first lens and the effective radius DT21 of the object side of the second lens, 2.7<DT11 / DT21<1.

Owner:ZHEJIANG SUNNY OPTICAL CO LTD

Fixing unit and image forming apparatus having the same

InactiveUS20100086333A1Simple processSimple structureElectrographic process apparatusImage formationEngineering

Disclosed is a fixing unit of an image forming apparatus, the fixing unit including a first roller; a second roller which forms a nip together with the first roller; and a nip adjuster which is provided in at least one end part of the first roller and includes a restrictive ring formed with a plurality of cam profiles for regulating an axis distance between the first roller and the second roller to be varied to adjust a width of the nip.

Owner:HEWLETT PACKARD DEV CO LP

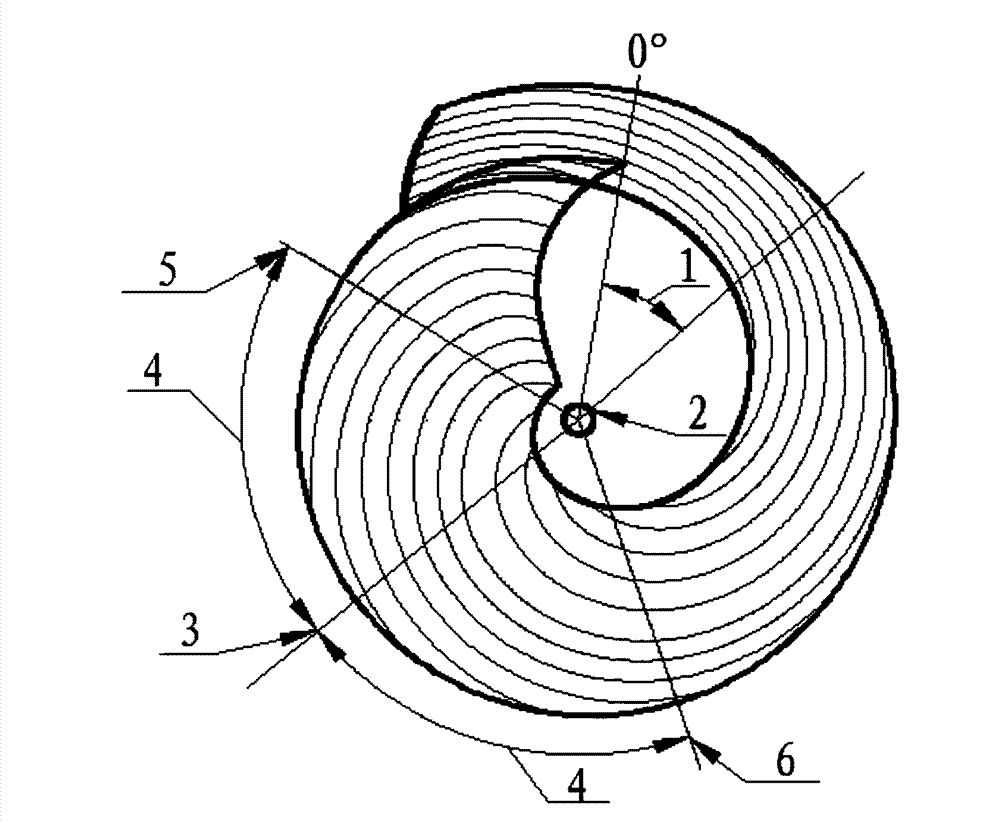

Method for eliminating unbalanced force of single-blade pump impeller

ActiveCN102734232AEliminate unbalanced forcesImprove performancePump componentsPumpsImpellerGravity center

The invention relates to a method for eliminating unbalanced force of a single-blade pump impeller. The method is characterized by comprising a step of determining a blade gravity shifting angle (1), non-thickening gravity position (2), a thickening central line (3), a single side thickening range (4), a thickening starting line (5), a thickening ending line (6), a thickening radius starting point derivation axes distance (7), a hub thickening radius (8) and a hub thickening thickness (9). Based on a key point, when the blade is designed, unbalance of the single-blade pump impeller is considered; solid modeling is performed to the blade by a three-dimensional modeling software PROE; a gravity position is found in the software so as to count a derivation angle; the hub is thickened or the blade is thickened on a position opposite to the gravity position; by dint of a pre-accentuation method, weighted quality can be estimated; data is fed back to an impeller mould; therefore, the impeller achieves quality balance initially.

Owner:JIANGSU GUOQUAN PUMP MFG CO LTD

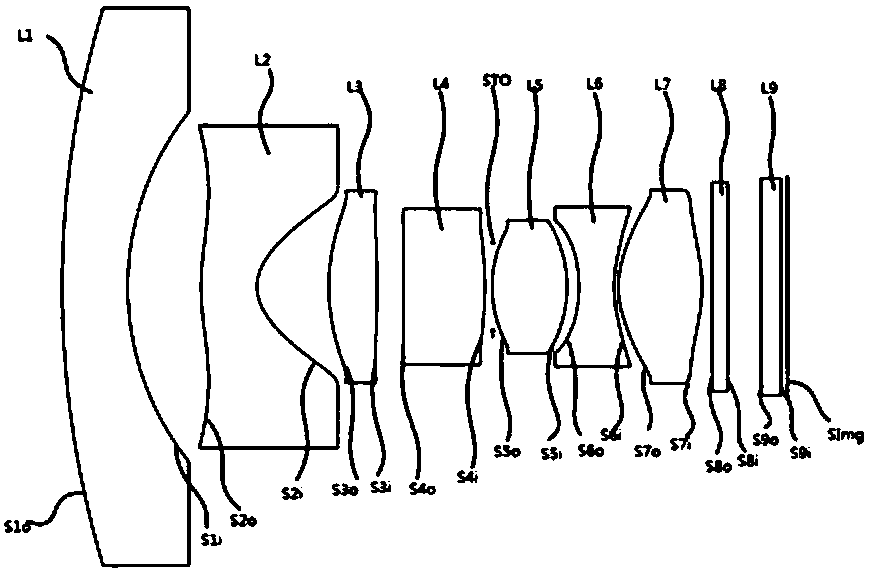

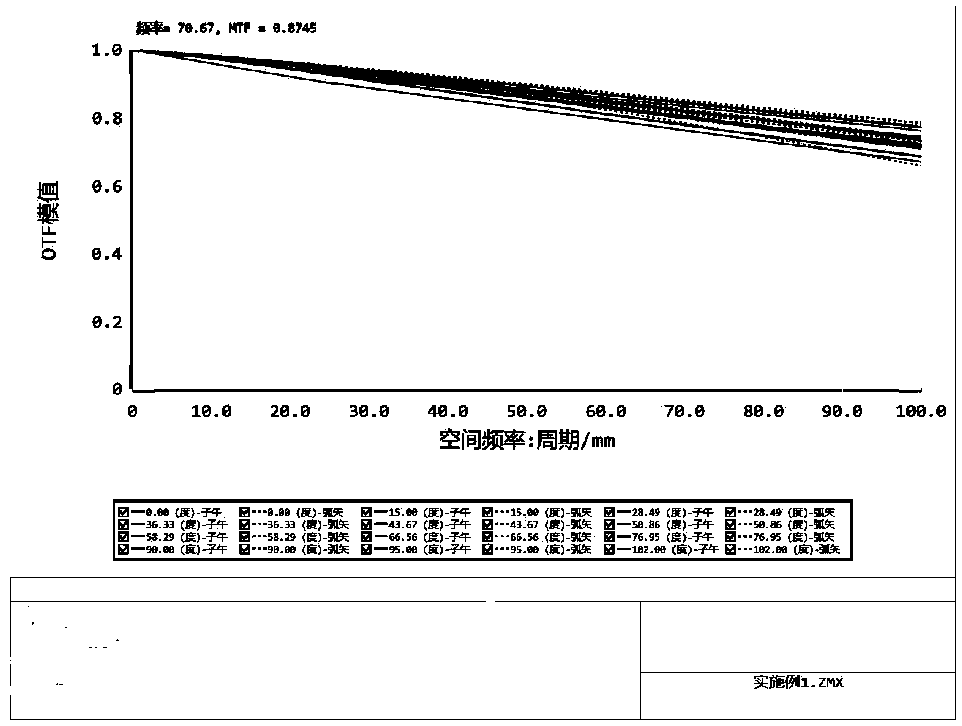

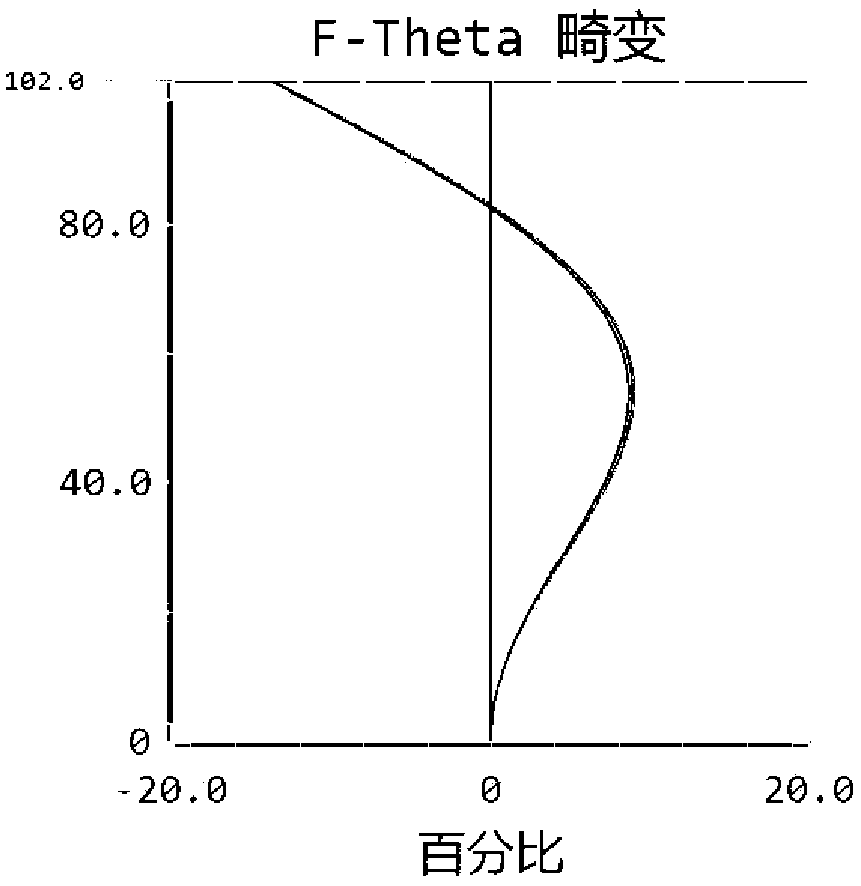

Fixed-focus optical system

PendingCN108490589ARealize large-scale monitoringRealize the effect of low temperature driftOptical elementsSystems designImaging quality

The invention discloses a fixed-focus optical system which successively comprises seven lenses from the object side to the image side, wherein the first lens is provided with negative power, a objectside convex surface and an image side convex surface; the second lens is provided with negative power, a object side convex surface and an image side convex surface; the third lens is provided with positive power and double convex surfaces; the image side surface of the fourth lens is a convex surface, when the focal power is positive, C4o is greater than or equal to 0, and the C4o is the curvature of the object side face of the fourth lens; when the focal power is negative, the object side face of the fourth lens is a concave surface; the fifth lens is provided with positive power and doubleconvex surfaces; the sixth lens is provided with negative powder and two concave surfaces; the seventh lens is provided with positive power and double convex surfaces; and the relationship is met: Imeg / f is greater than 1.28 but less than 2.22, and Imeg / TTL is greater than 0.105 but less than 0.167, wherein Imeg is the highest half image height, TTL is the axis distance from the object side face of the first lens to the image side face, and f is system focal distance. The system has the advantages that the power is reasonably matched; by means of reasonable parameter matching, a miniature optical system design which is high in resolution, good in image quality and low in cost is achieved.

Owner:NINGBO YONGXIN OPTICS

Double-eccentric bushing regulating device for rotation balance of high-rotating-speed polishing head

ActiveCN103009246AChange axis distanceIncrease rotation speedGrinding/polishing safety devicesRotation velocityGravity center

The invention discloses a double-eccentric bushing regulating device for the rotation balance of a high-rotating-speed polishing head. The double-eccentric bushing regulating device is applied to the driving and high-speed polishing processing of optical elements with medium and large calibers, a small eccentric bushing, a large eccentric bushing and a cylinder body form a double-eccentric bushing structure for regulating the eccentricity, and an eccentric hole per se (a matched and connected position of the small eccentric bushing and the cylinder body) is driven to do revolution movement around an axial line of a main shaft in the rotating process of the small eccentric bushing; through the relative rotation, the relative circumference position of the small eccentric bushing and the large eccentric bushing is regulated, the axis distance between the small eccentric bushing and the large eccentric bushing is changed, the polishing distance is regulated, and a polishing disc can obtain different revolution radii for adapting to the polishing requirements of different workpieces; and in the eccentric distance regulating process, the whole mass gravity center is always on the rotating center of the main shaft. When the structure is adopted, greater centrifugal force cannot be generated in the polishing rotation process, the rotary movement stability is ensured, and the rotating speed of the rotary polishing head can be improved, so the polishing efficiency of a polishing machine is improved.

Owner:CHANGCHUN EQUIP TECH RES INST

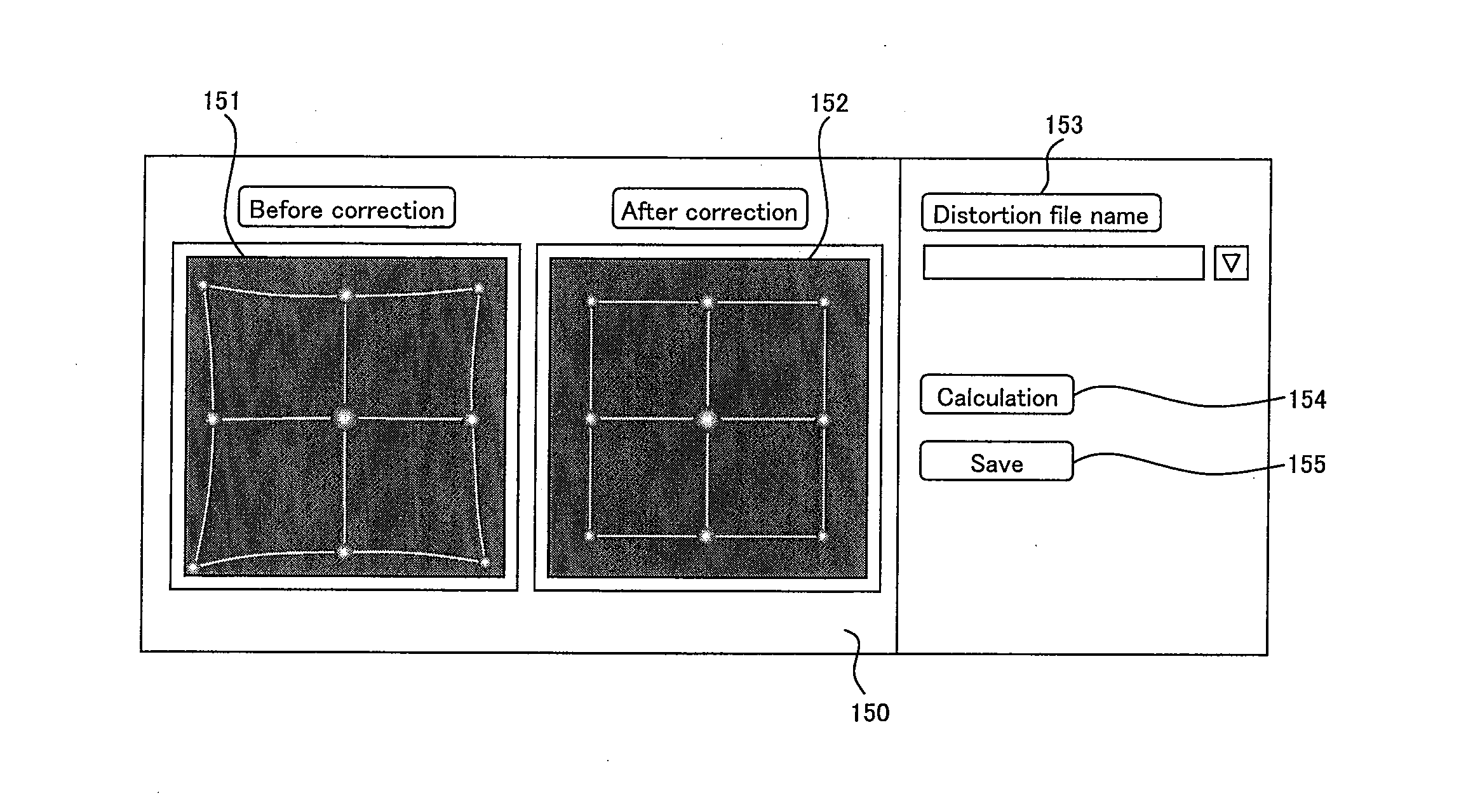

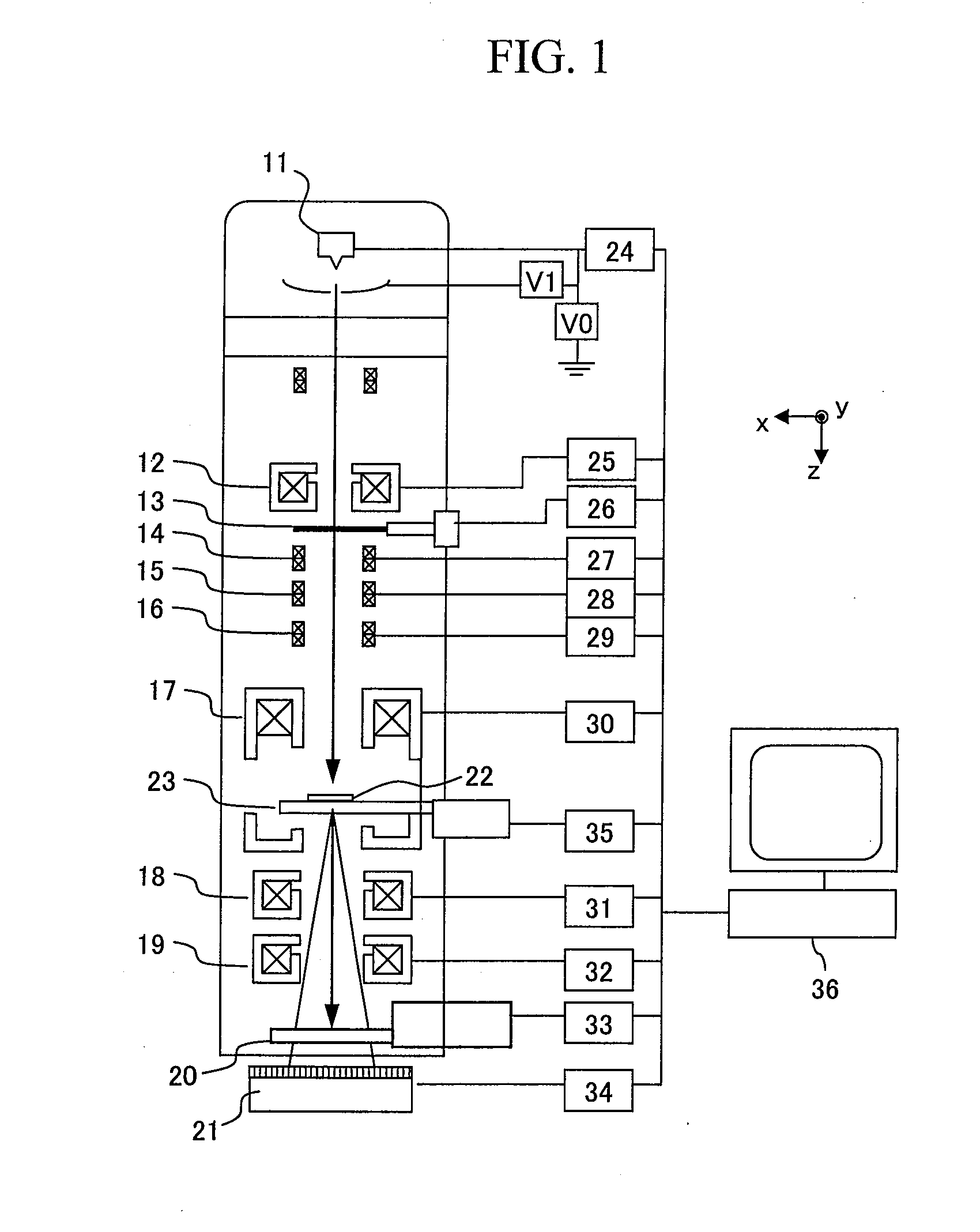

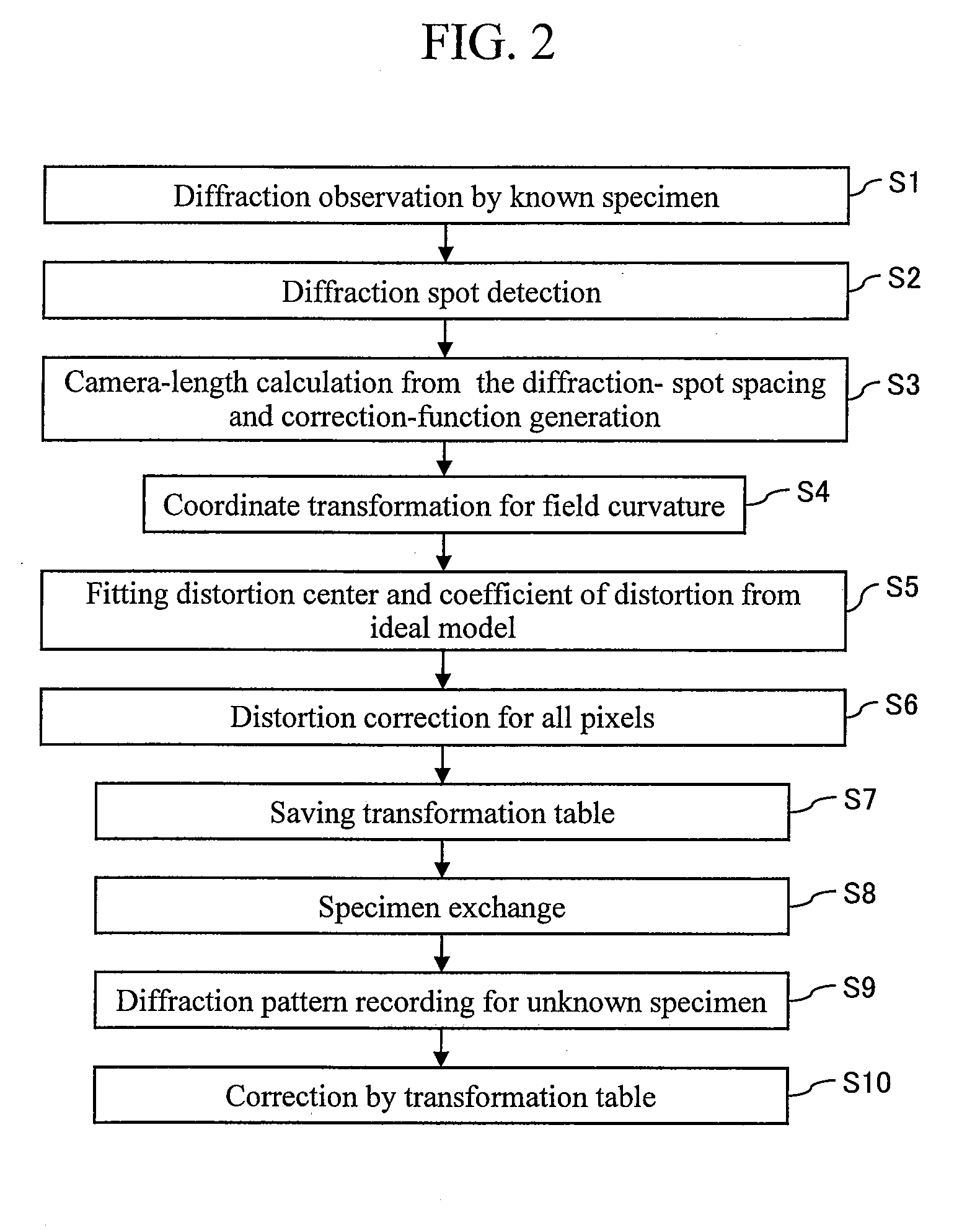

Diffraction pattern capturing method and charged particle beam device

InactiveUS20110049344A1Accurate analysis of structureCorrect distortionMaterial analysis using wave/particle radiationElectric discharge tubesOptical axisStructural analysis

A charged particle beam microscope device of the present invention is configured such that in a diffraction pattern obtained by radiating a parallel charged particle beam onto a sample (22) having a known structure, a distance (r) between spots of a diffraction pattern, which reflects the structure of the sample, is measured, and the variation of a distance (L) between the sample and a detector, which depends on a diffraction angle (θ), is corrected. This enables the correction of distortion that varies with an off-axis distance from the optical axis in a diffraction pattern, and a high precision structural analysis by performing accurately analyzing the spot positions of the diffraction pattern.

Owner:HITACHI LTD +1

Chain link assembly, chain and film stretching device capable of reducing longitudinal shrinkage ratio

The invention discloses a chain link assembly, a chain and a film stretching device. Transition chain links are arranged in the chain link assembly, conventional chain links can be folded in the radial direction, the axis distance between the adjacent transition chain links is changed while folding is carried out, the chain link assembly is arranged in the chain, clamps for clamping a film are arranged, the length of the chain of the film stretching device is changed wholly along with bending deformation of the chain link assembly, and accordingly the distance between the adjacent clamps is reduced; when transverse stretching is carried out, the clamping gap between the clamps shrinks, and the aim of longitudinal retraction is achieved while the transverse pulling process is carried out; and when the film stretching device caries out film transverse stretching work, longitudinal tensile force of the film is reduced under the high-temperature state, the film can be sufficiently and longitudinally pre-retracted, and the problem that the longitudinal shrinkage ratio is too large is solved in advance.

Owner:北京华腾佳和科技有限公司

Eyeglass lens processing apparatus

ActiveUS8241091B2Effectively preventExtended processing timeEdge grinding machinesPolishing machinesCamera lensEyewear

An eyeglass lens processing apparatus includes: a lens rotation unit rotating a lens; a processing tool rotation unit processing the lens; an axis-to-axis distance changing unit for changing an axis-to-axis distance between the chuck shaft and the processing tool rotation shaft; a lens surface configuration acquiring unit which acquires a front surface curve configuration and a rear surface curve configuration of the lens; a lens outer diameter acquiring unit which acquires an outer diameter of a lens; a calculation unit which calculates a thickness of the lens and calculates a cutting depth of the lens, so that torque applied onto the chuck shaft in rough processing becomes substantially constant, based on the calculated lens thickness and a processing distance from the rotation center of the lens; and a control unit which controls the axis-to-axis distance changing unit in accordance with the calculated cutting depth and for rough processing the lens.

Owner:NIDEK CO LTD

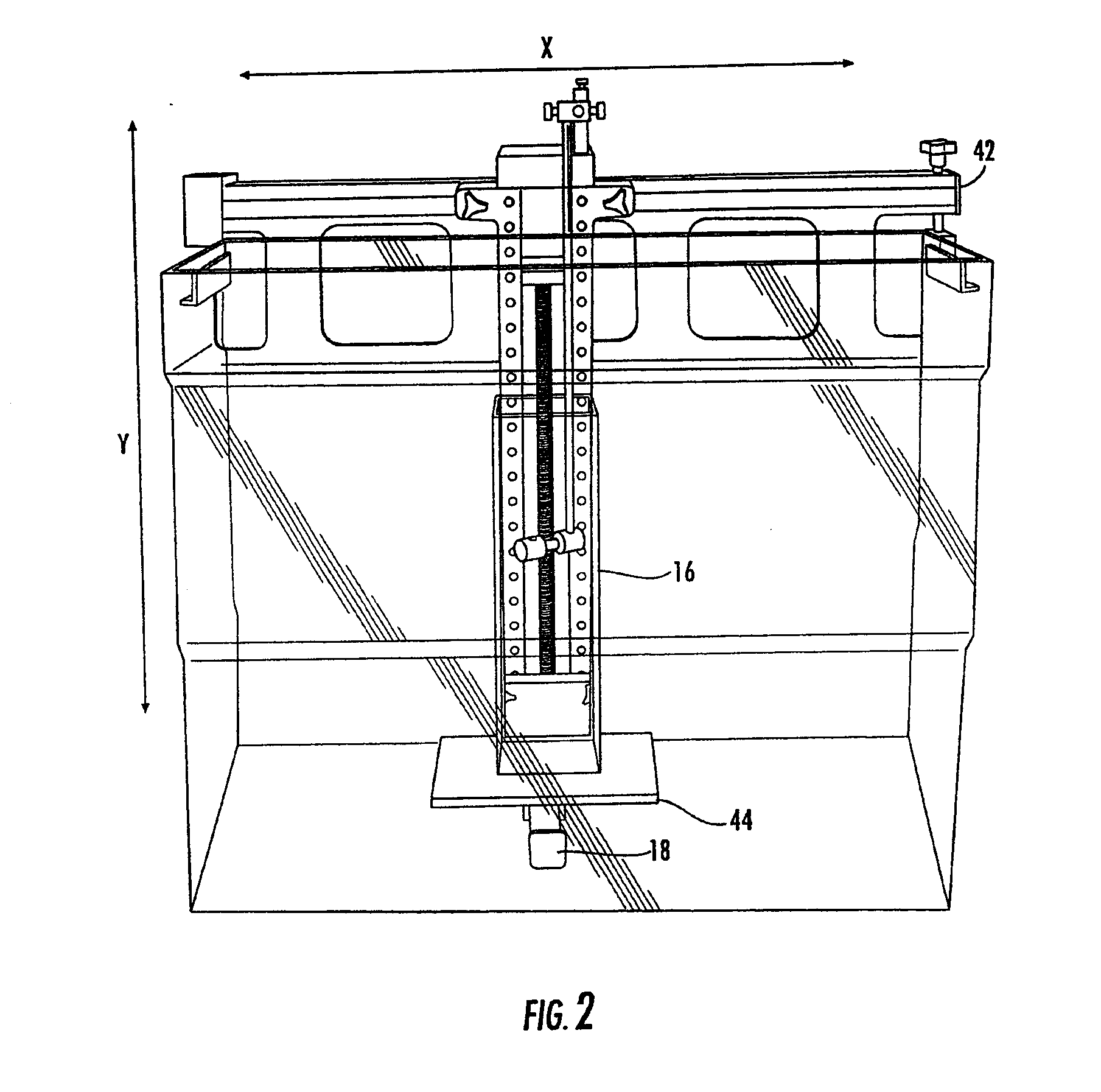

Radiation Beam Analyzer And Method

ActiveUS20100176284A1Precise positioningGood repeatabilityElectric discharge tubesDosimetersProper treatmentDistance sensors

A radiation beam analyzer for measuring the distribution and intensity of radiation produced by a CyberKnife®. The analyzer employs a relative small tank of water into which a sensor is placed. The distance between the sensor and the radiation source is not varied. The tank of water is raised and lowered relative to the sensor to simulate the location of a malady within a patient's body. This movement of the tank permits the radiation from the CyberKnife® to be properly calibrated and adjusted for a proper treatment of a malady in a patient. In a second embodiment a radiation beam analyzer measures the distribution and intensity of radiation produced by a radiation source. The analyzer employs a relative small tank of water into which a sensor or detector is placed. The distance between the sensor and the radiation source is not varied. There are two methods to maintain the SAD (source to axis distance) constant. A first method maintains the position of detector fixed, utilizing a holder designed to retain the detector, and raises or lowers the small tank of water. A second method moves the detector up or down with a raising and lower mechanism in one direction and synchronically moves the small tank of water in the opposite direction with another raising and lowering mechanism. The second method also keeps the SAD constant. These methods position the detector relative to the radiation source to simulate the location of a malady within a patient's body. This movement of the tank permits the radiation from the radiation beam source to be properly isocentrically measured.

Owner:NAVARRO DANIEL

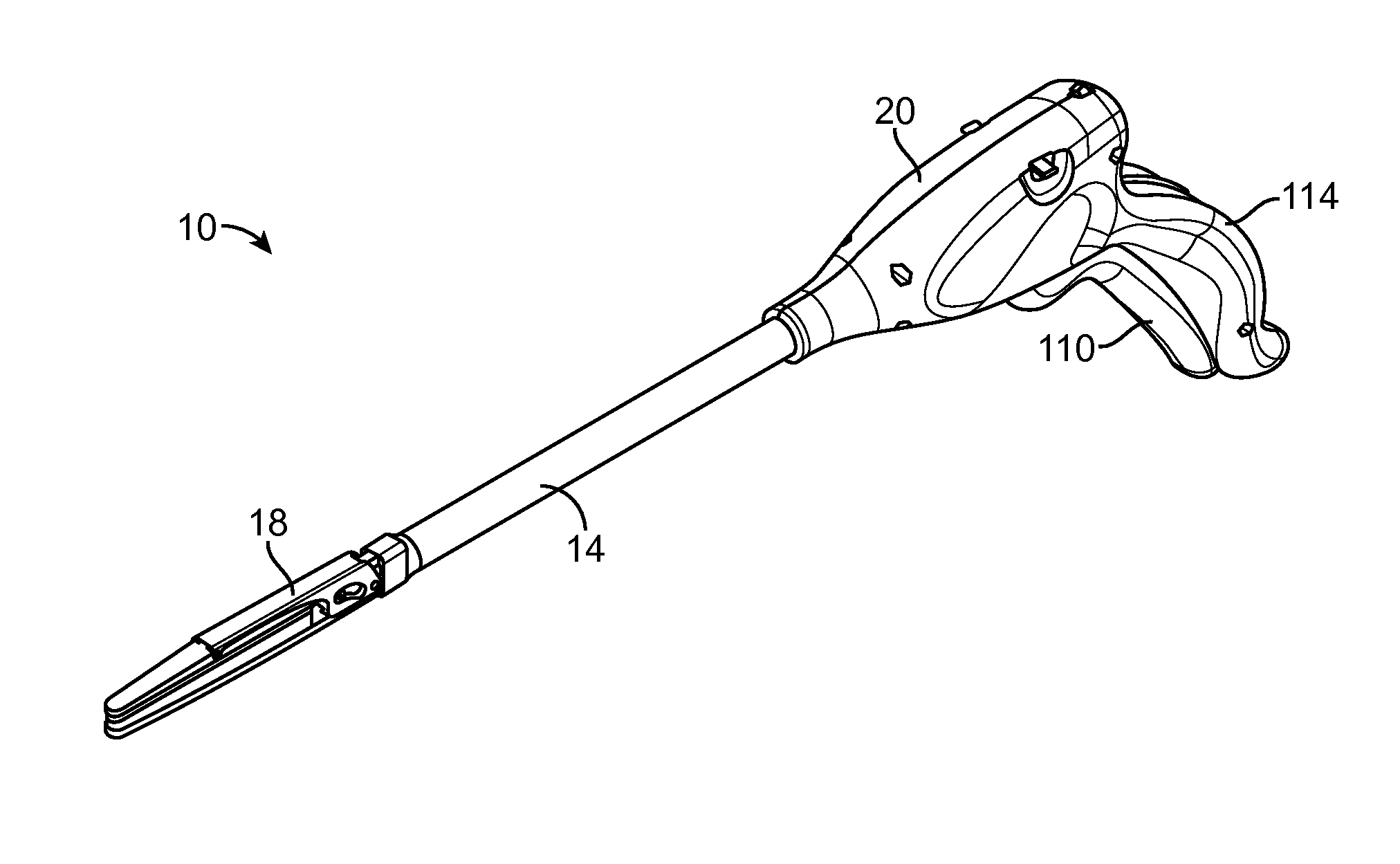

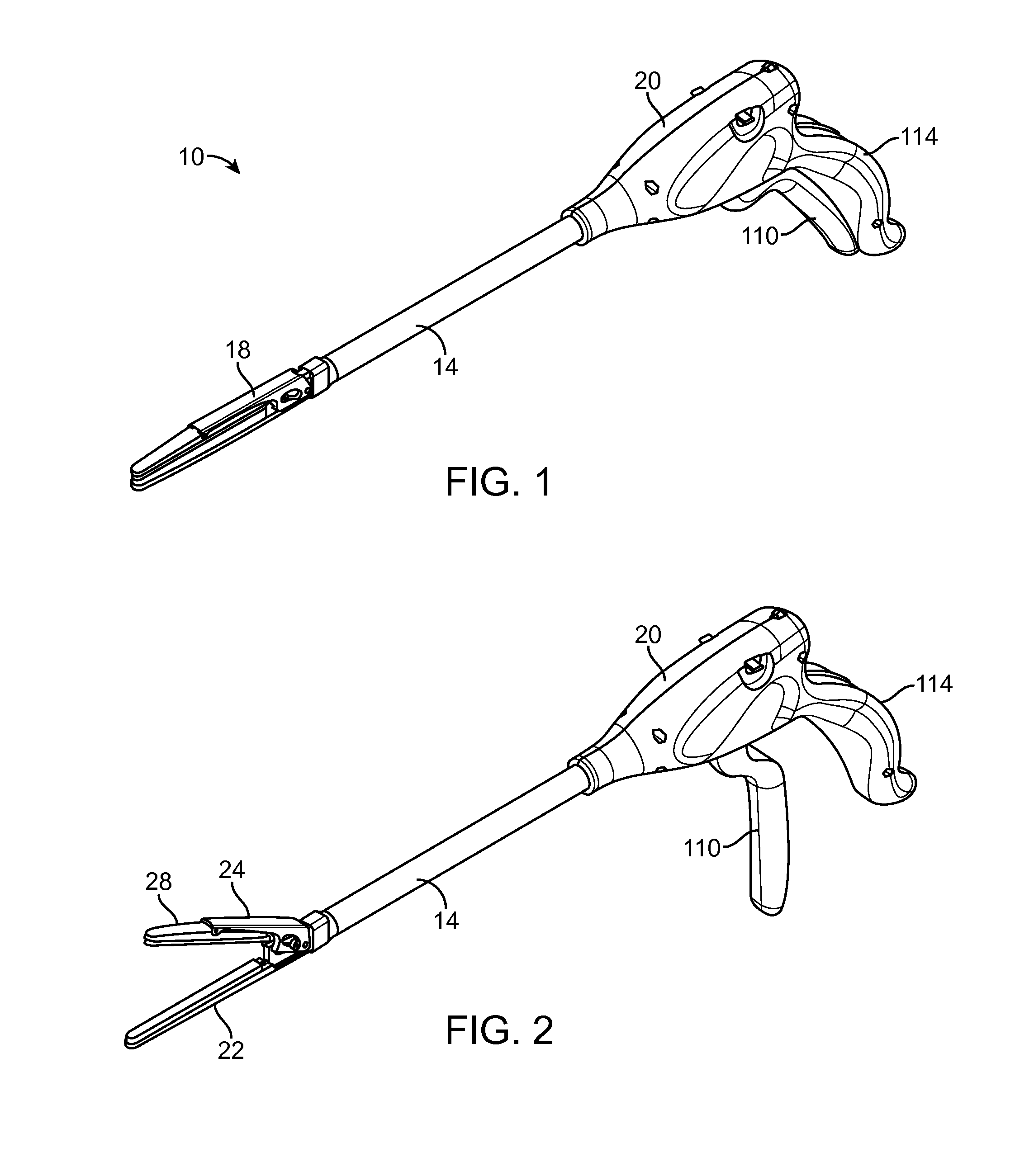

Aortic cross clamp

An aortic cross clamp includes an elongated handle and a clamp head. The clamp head has opposing jaws having open and closed positions. At least one of the jaws is pivotally mounted to a jaw actuator so as to be pivotal relative to the opposing jaw and about an axis distanced from the opposing jaw. A locking mechanism is provided for locking the jaws in the closed position. A jaw drive mechanism is operable through the elongated handle for moving the jaws between the open and closed positions. A method of clamping the aorta is also disclosed.

Owner:CORCYM SRL

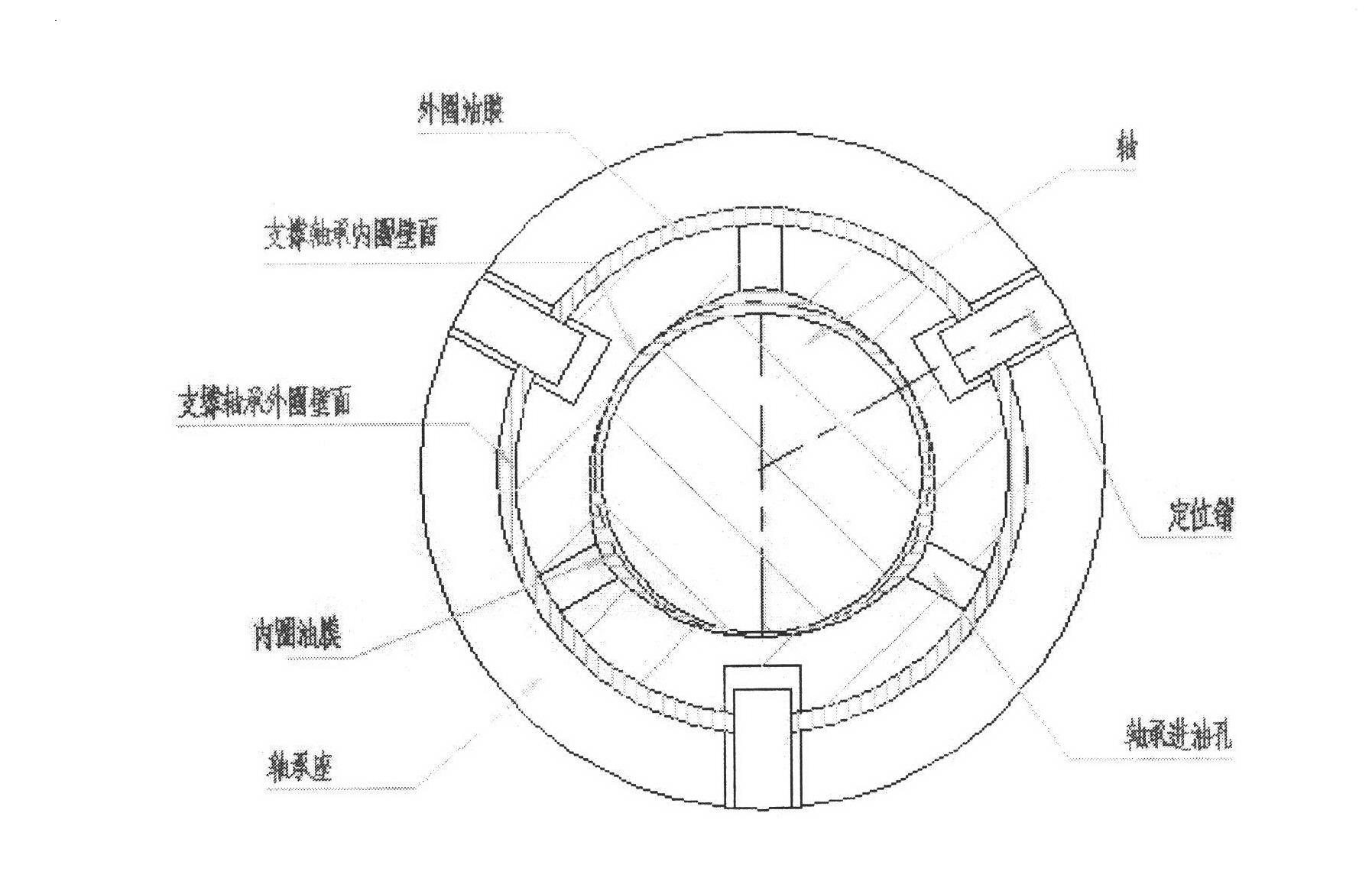

Method for determining shape of semi-floating supporting bearing inner bore oil wedge of supercharger

ActiveCN102192238ANo problem of inconsistent appearance qualityReduce processing requirementsShaftsBearing componentsEngineeringBearing design

The invention discloses a method for determining the shape of a semi-floating supporting bearing inner bore oil wedge of a supercharger. The method is characterized by comprising the following steps: drawing two concentric circles which are concentric with an axle with the radius of Rb and R2 according to the limited conditions of the value of a1 and b, and axle radius Rs, the base radius of the bearing inner bore (Rb=Rs+b), and the axis distance (R2=Rs+a1) of the deepest point distance axle manufactured on the inner wall of the supporting bearing; dividing the two concentric circles into n equal parts according to the number n of oil wedges; and connecting 2n along ents sequentially by virtue of a curve, wherein the polar equation of the curve is rho=Rm+e*sin(n*t) or rho=Rm+e*cos(n*t), and the curve is in the shape of the supporting bearing inner bore oil wedges. According to the invention, a more simple method is used for designing and describing the oil wedges of the bearing inner wall, not only can the limiting requirement of the bearing design be satisfied, but also the design and drawing difficulty is reduced, the drawing label is simplified, the manufacturing difficulty is reduced, and the consistency of the appearance of the product is ensured.

Owner:CHONGQING TURBO FLOW MACHINERY MFG

Camera optical lens

The invention discloses a camera optical lens. The camera optical lens comprises a first lens, a second lens, a third lens, a fourth lens and a fifth lens from the object side to the image side. The focal length of the camera optical lens is f. The focal length of the first lens is f1. The focal length of the third lens is f3. The focal length of the fourth lens is f4. The focal length of the fifth lens is f5. The radius of curvature of the object side of the fourth lens is R7. The radius of curvature of the image side of the fourth lens is R8. The on-axis thickness of the first lens is d1. The on-axis distance from the image side of the first lens to the object side of the second lens is d2. The on-axis thickness of the second lens is d3. The on-axis distance from the image side of the third lens to the object side of the fourth lens is d4. According to the camera optical lens, (f1+f3+f5) / f is between 8.50 and -6.50; (R7+R8) / (R7-R8) is between 0.00 and 1.00; d2 / d1 is between 1.20 and2.00; f4 / f is between 0.80 and 1.50; and d3 / d4 is between 3.20 and 5.00. The camera optical lens provided by the invention has good optical performances, and can meet the design requirements of largeaperture, wide angle and being ultra-thin.

Owner:AAC OPTICS SOLUTIONS PTE LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com