Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "Restore plasticity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

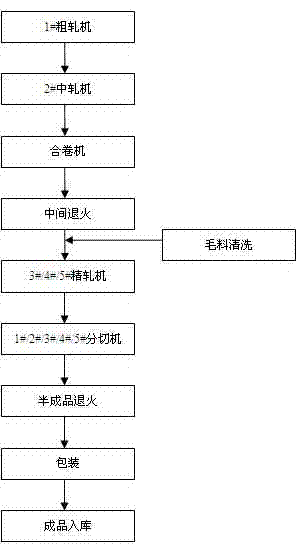

A production process for rolling double-zero aluminum foil

ActiveCN102284483AReduce the number of pinholesImprove mechanical propertiesMetal rolling arrangementsProfile control deviceSurface cleaningWork in process

The invention discloses a production process for rolling a light gauge aluminum foil, which comprises the following steps of: performing rough rolling, wherein the reduction per pass of the rough rolling is 0.3mm to 0.14mm to 0.07mm to 0.038mm; performing intermediate rolling, wherein the reduction per pass of the intermediate rolling is 0.038mm to 0.013mm; performing double rolling; performing intermediate annealing; cleaning a stock, namely performing surface cleaning on the aluminum foil stock by using rolling oil at a finish rolling inlet; performing finish rolling, wherein the reduction per pass of the finish rolling is 0.013mm to 0.005mm; slitting; annealing a semi-finished product; and packaging and warehousing. By adding the intermediate annealing and rolling oil cleaning processes for the aluminum foil, the mechanical property of the aluminum foil is improved while the thickness of the aluminum foil is reduced, and the breakage condition and a pinhole number in the rolling process are reduced.

Owner:JIANGSU ZHONGJI LAMINATION MATERIALS

Method for preparing seamless titanium alloy tube for aircraft engine

The invention discloses a method for preparing a seamless titanium alloy tube for an aircraft engine. The seamless titanium alloy tube for the aircraft engine which meets corresponding requirements is manufactured by improving the technological plasticity of the titanium alloy tube material. The method comprises the following steps of: firstly, smelting a spongy cast ingot to introduce interstitial elements as little as possible; secondly, cogging and forging heated cast ingot at large deformation and repeatedly upsetting and stretching the cast ingot to ensure that as-cast coarse grains are completely crushed and thinned, thermally processing formed tube billet under vacuum to eliminate residual stress produced during tube billet extrusion so as to improve the plasticity of the tube billet; thirdly, cogging and rolling the tube billet at large deformation and further thinning the grains; and finally, annealing at a low temperature after cold rolling of intermediate rolling and finished product rolling to effectively control the coarsening of the grains. Therefore, full recrystallization can be ensured by prolonging the heating time, and mechanical property and processing property required by material consumption of the aircraft engine can be met under the condition that the tube structure is fully recrystallized.

Owner:WESTERN TITANIUM TECH

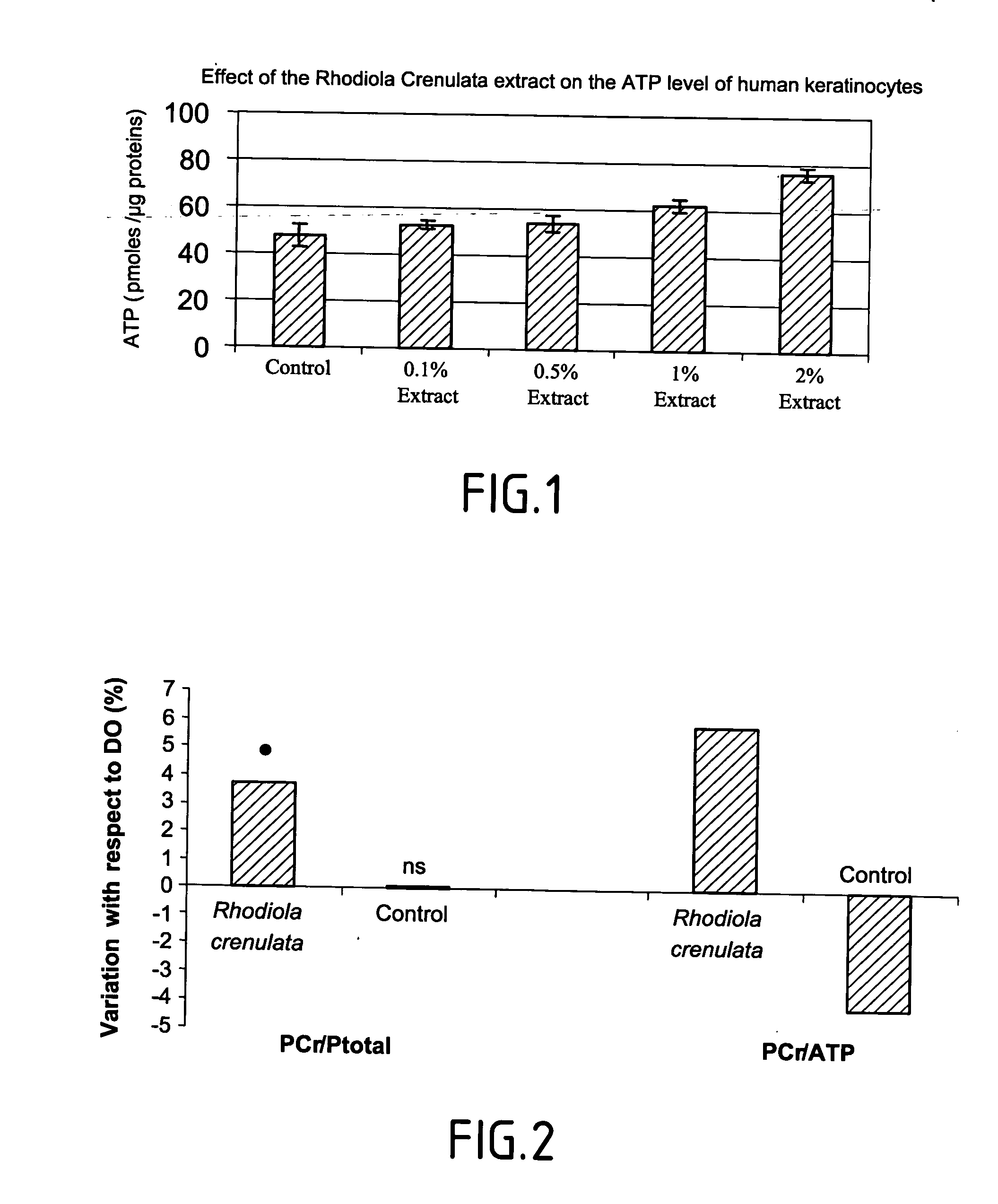

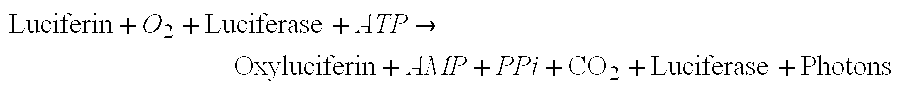

Use of Rhodiola crenulata extract via the topical route

InactiveUS20050048138A1Slow downImprove plasticityCosmetic preparationsBiocideActive agentDesquamation

The invention relates to the use of a Rhodiola crenulata extract, via the topical route, for increasing the energy metabolism of the cutaneous tissues of a subject. The invention relates notably to topical compositions which comprise an active agent for increasing the energy metabolism of the cutaneous tissues of a subject, said active agent being a Rhodiola crenulata extract. The present invention enables making a cosmetic care such as fighting against, or slowing down or preventing the loosening of the cutaneous tissue, increasing the plasticity of the cutaneous tissue, exerting an anti-wrinkle effect or slowing down or preventing the appearance of wrinkles, fighting against, slowing down or preventing the appearance of acne, exerting a depigmenting effect of the cutaneous tissue, in particular of the skin, and promoting desquamation of the cutaneous tissue (or “peeling”).

Owner:BASF BEAUTY CARE SOLUTIONS FRANCE SAS

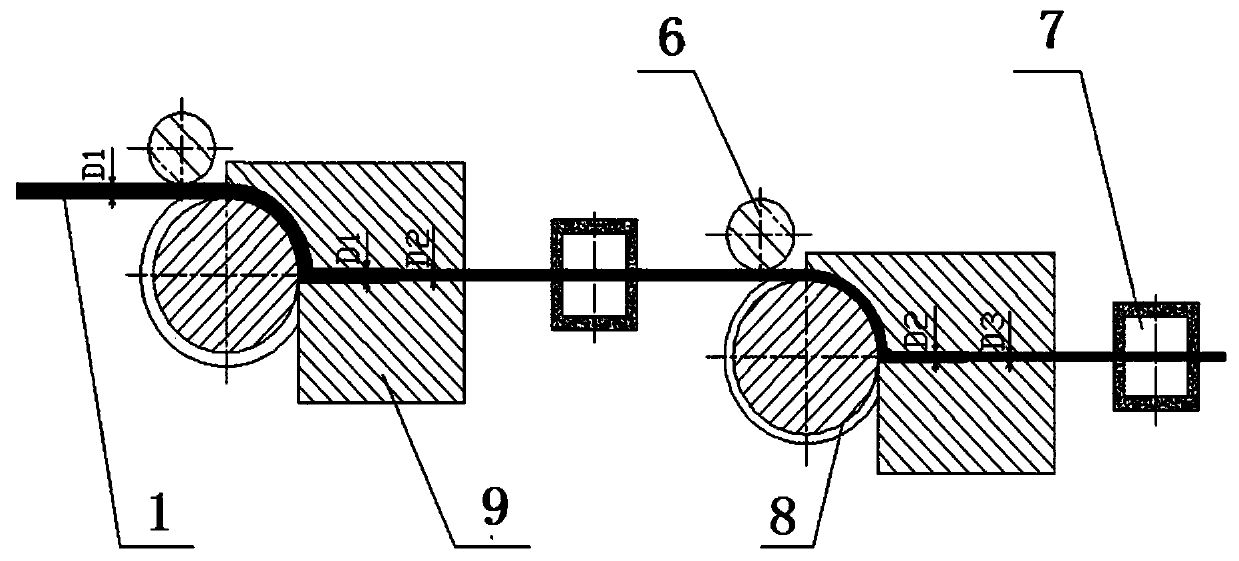

Al-Mg-Si alloy wire for added material manufacturing and preparation method thereof

The invention relates to the technical field of metal material preparation, and in particular, discloses an Al-Mg-Si alloy wire for added material manufacturing and a preparation method thereof. The acute plastic deformation is performed on Al-Ti-B intermediate alloys generated with TiB2 particles in situ to obtain Al-Ti-B intermediate alloys containing nanometer TiB2 particles; the Al-Ti-B intermediate alloys containing the nanometer TiB2 particles are used as basal body raw materials, and other metal or intermediate alloys are fed for smelting to obtain alloy melts; the alloy melts are manufactured as wire blanks; and the hot rolling, the drawing, the intermediate annealing and the surface treatment are performed on the wire blanks to obtain nanometer and submicron-scale TiB2 particle reinforced Al-Mg-Si alloy wires. After the Al-Mg-Si alloy wire prepared through the method is molten, the alloy structure can be prominently refined, the solidification hot crack sensitivity is reduced,and meanwhile, the alloy casting strength can be prominently improved; and the Al-Mg-Si alloy wire can be used for added material manufacturing and welding of high-strength alloy structural parts.

Owner:杭州坤利焊接材料有限公司

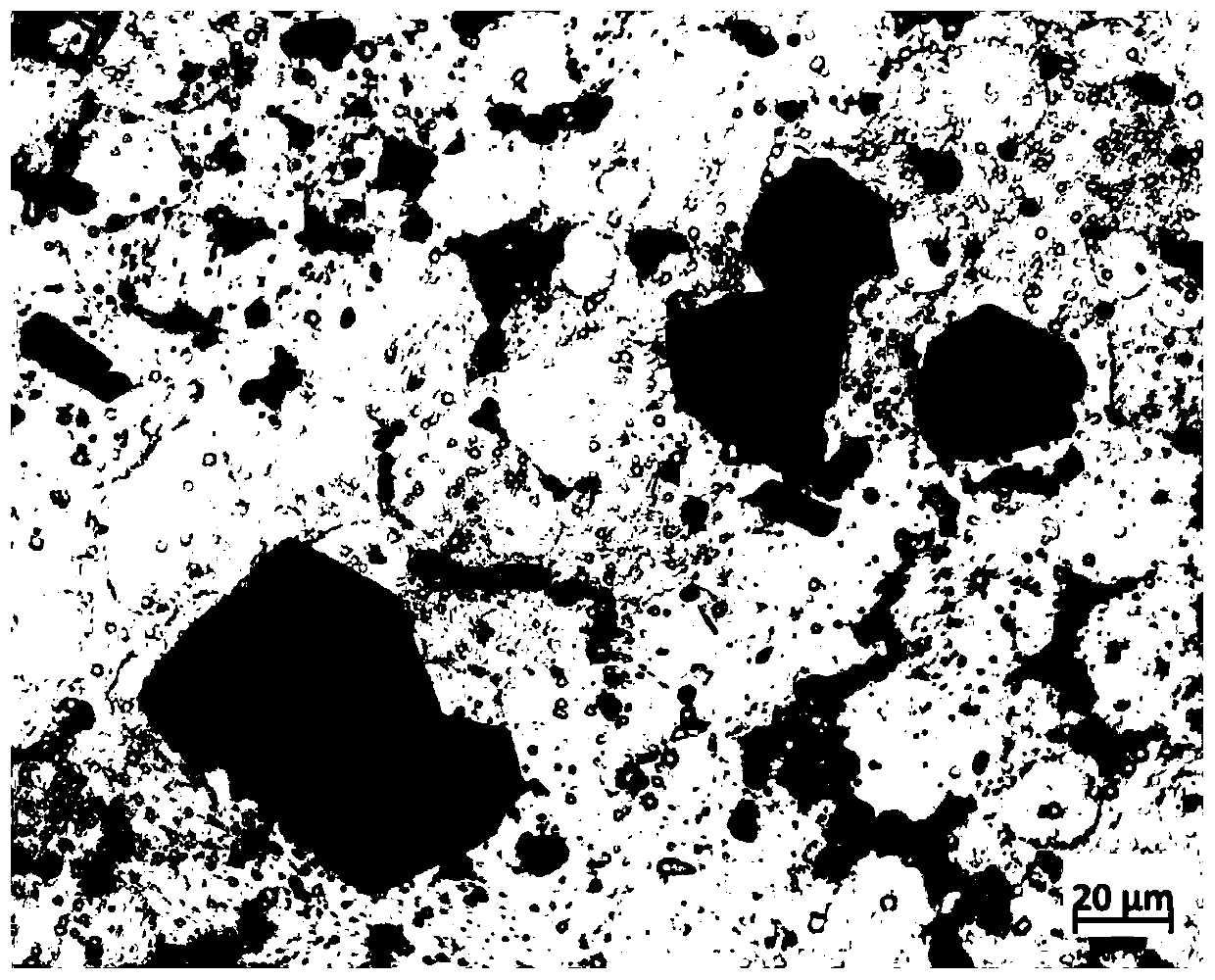

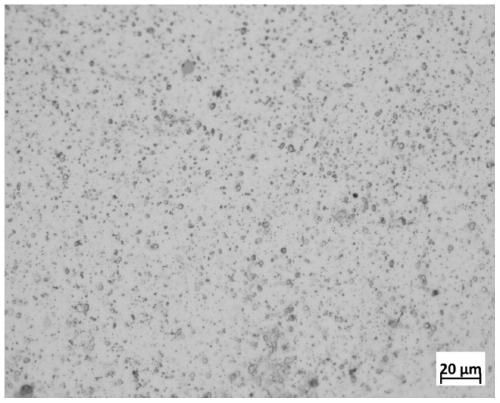

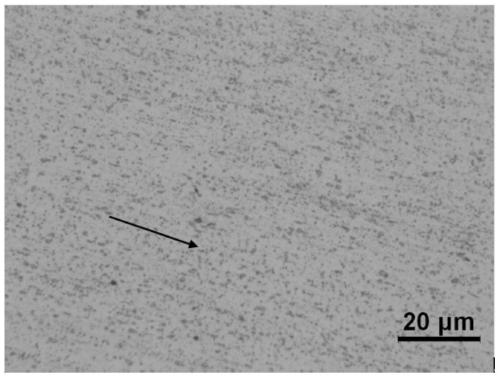

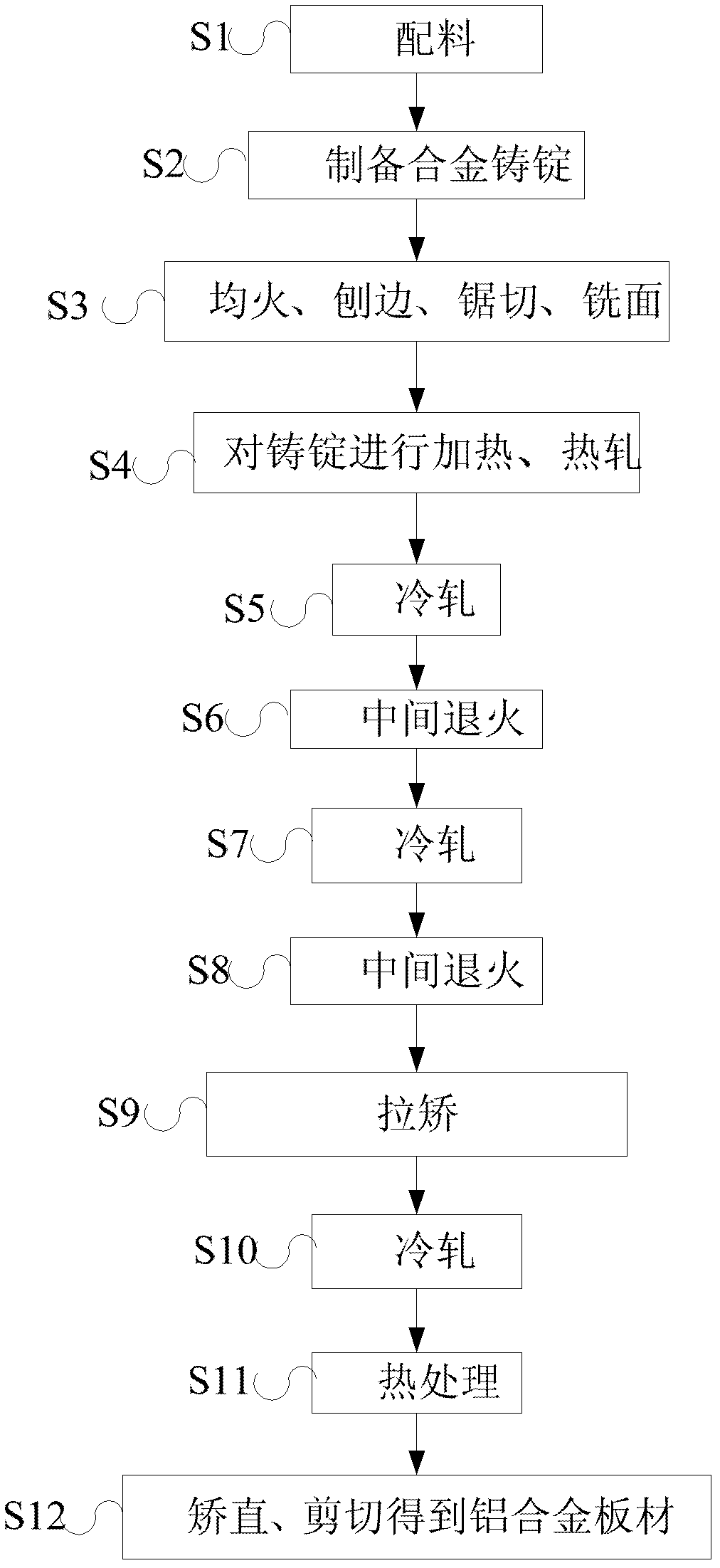

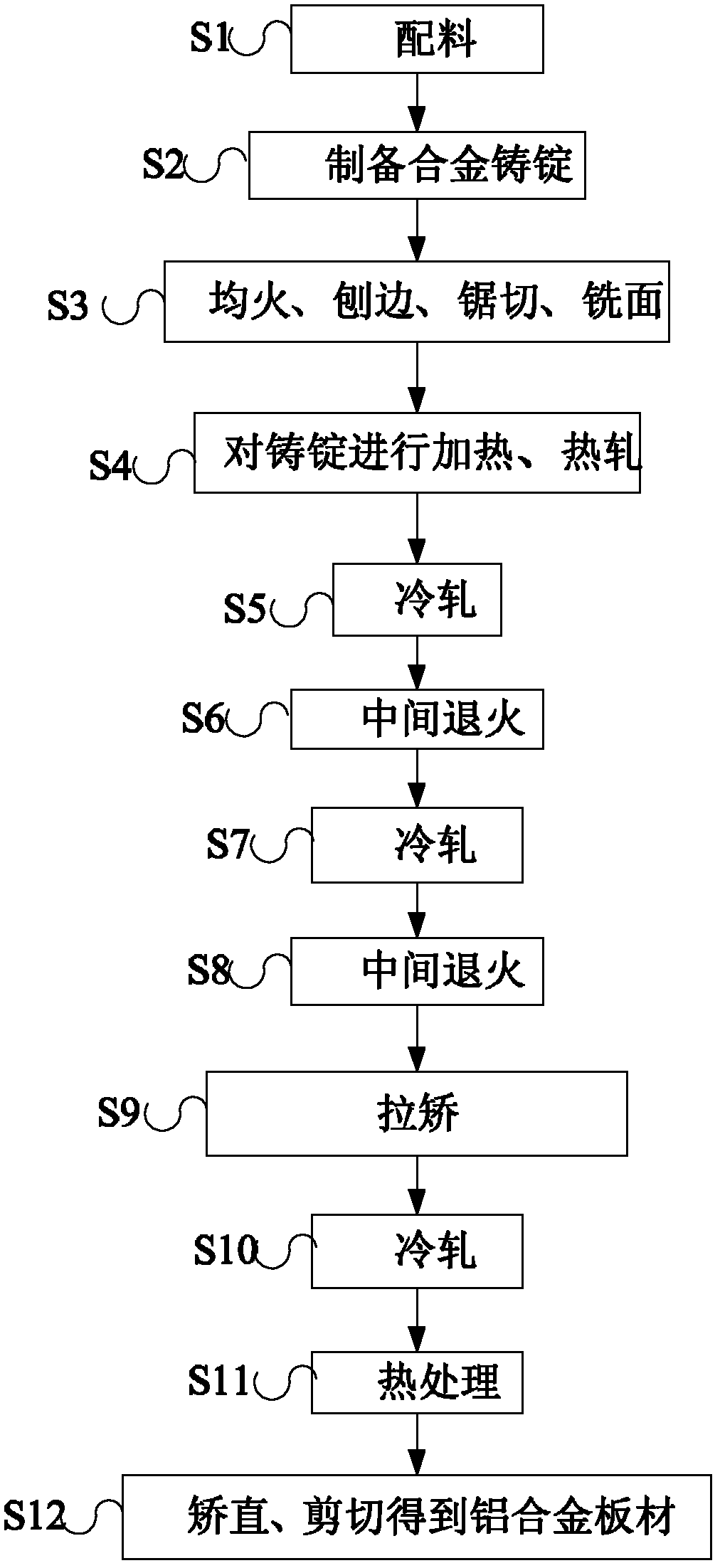

Method for producing aluminum alloy plate

The invention discloses a method for producing an aluminum alloy plate. The method comprises the following steps of: preparing materials: uniformly mixing 0.4% of Si, 0.6% of Fe, 4% of Cu, 0.1% of Mn, 0.22% of Cr, 0.06% of Ti, 2% of Mg, 0.2% of Zn and the balance of Al; processing the prepared materials into a cast alloy ingot; heating and hot-rolling the cast alloy ingot to obtain a blank; cold-rolling the blank; carrying out intermediate annealing; cold-rolling; carrying out intermediate annealing; drawing and straightening; cold-rolling; thermally treating; and straightening and sharing to obtain the aluminum alloy plate with the preset thickness. According to the invention, a cold-rolling process is carried out in two steps, the intermediate annealing is carried out after the cold-rolling so as to eliminate work hardening and recover metal plasticity, and finally, the thermal treatment is carried out to increase the performance of the aluminum alloy plate to meet a requirement so as to obtain the qualified aluminum alloy plate, so that the finished product rate of the aluminum alloy plate is increased.

Owner:SOUTHWEST ALUMINUM GRP

Production method of linearly cut molybdenum wire

InactiveCN106312456AHigh strengthImprove high temperature resistanceElectrical-based machining electrodesFiberRare earth

The invention provides a production method of a linearly cut molybdenum wire. Certain solid solution metal elements are added into molybdenum so as to realize a solid solution strengthening effect. The strength of the molybdenum wire can be properly improved, and the machining performance of the molybdenum wire can be improved. Certain rare earth oxides are added into the molybdenum so as to realize refined grain strengthening and dispersion strengthening effects, crystalline grains can be refined, fiber texture can be strengthened, and the strength, high temperature resistance and wear resistance of the molybdenum wire can be improved. By adopting an intermediate annealing technology, the plasticity can be restored, the internal stress is reduced, the machining difficulty is reduced, and the production and expansion of cracks are reduced or eliminated. By adopting a hot wire drawing machining technology, the plasticity of the material can be kept, and the hardening of the material during the machining of a semi-finished product is reduced. By adopting a finished product multi-mode cold wire drawing technology, work-hardening and strength enhancement effects can be realized. The tensile strength of the linearly cut molybdenum wire made by the production method generally can reach 1900-2300mpa and can meet the requirements of linear cutting users.

Owner:佛山朕华照明材料有限公司

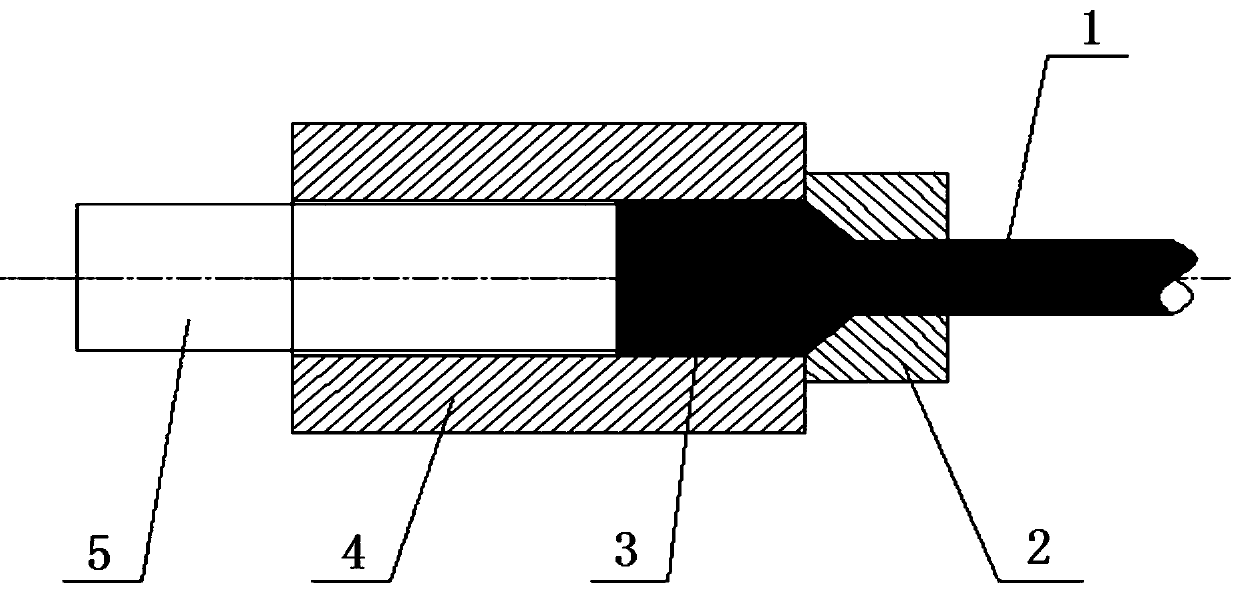

Spinning method of nickel base alloy bottom-carried cylindrical part

InactiveCN107309317AReduce consumptionReduce labor costsShaping toolsSocial benefitsEconomic benefits

The invention relates to a spinning method of a GH4169 nickel base alloy bottom-carried cylindrical part. The spinning method comprises the following steps: (1) a GH4169 nickel base alloy blank is prepared; (2) a core mold is preheated before spinning; (3) a nickel base alloy plate is heated in a heating furnace or directly heated on the core mold for spinning formation; and a lubricating agent is uniformly coated during spinning; (4) the spinning formation is performed on a spinning machine; (5) the spinning final formation is performed; after final formation, the annealing is performed in a vacuum furnace; and the furnace cooling or the air cooling is performed; and (6) a spun part is machined. The invention finds out a hot spinning process aiming at the GH4169 nickel base alloy bottom-carried cylindrical part; the material waste problem in the production process of the nickel base alloy bottom-carried cylindrical part can be reduced; and huge economic benefit and social benefit are achieved.

Owner:CHANGCHUN UNIV OF SCI & TECH

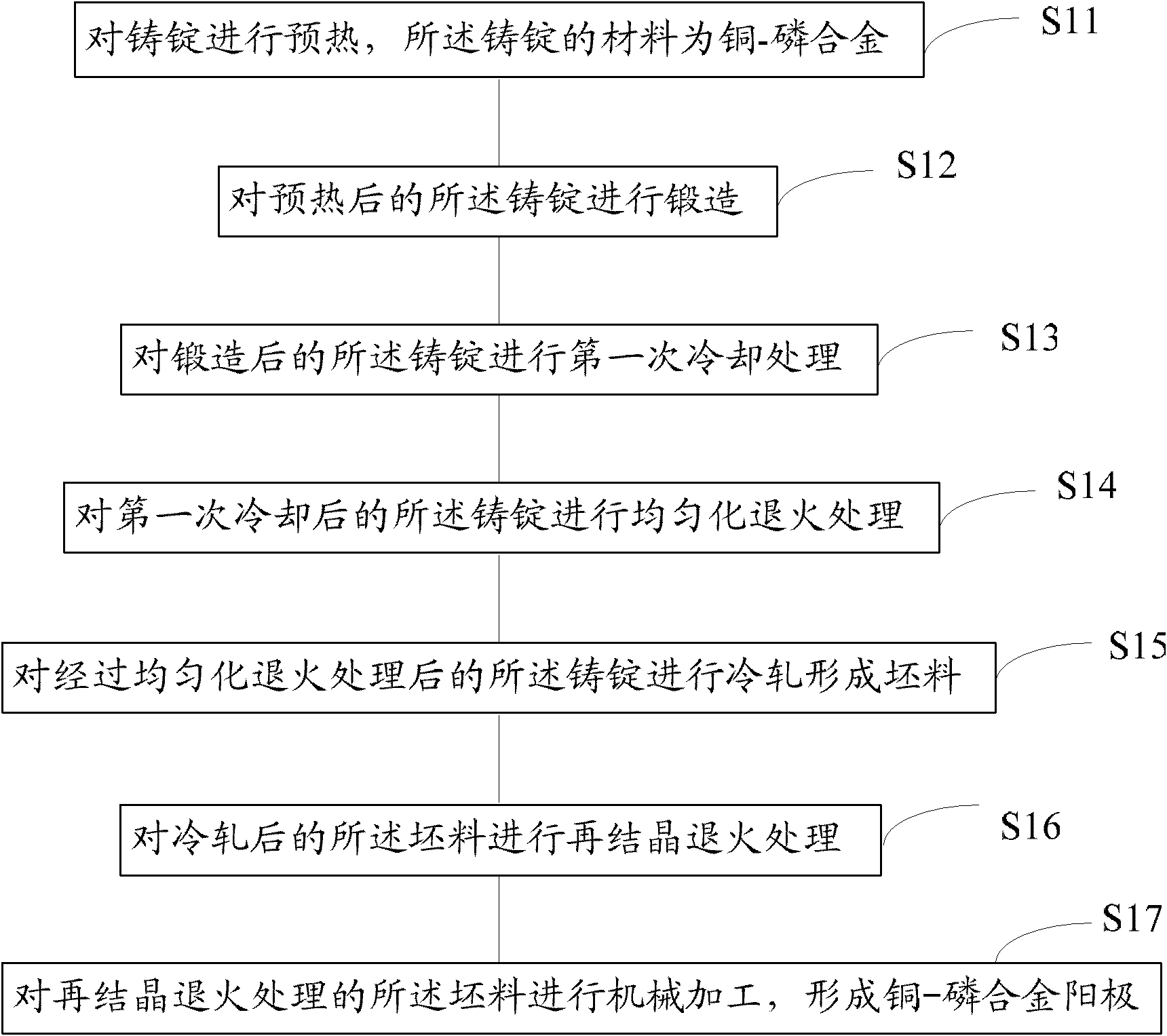

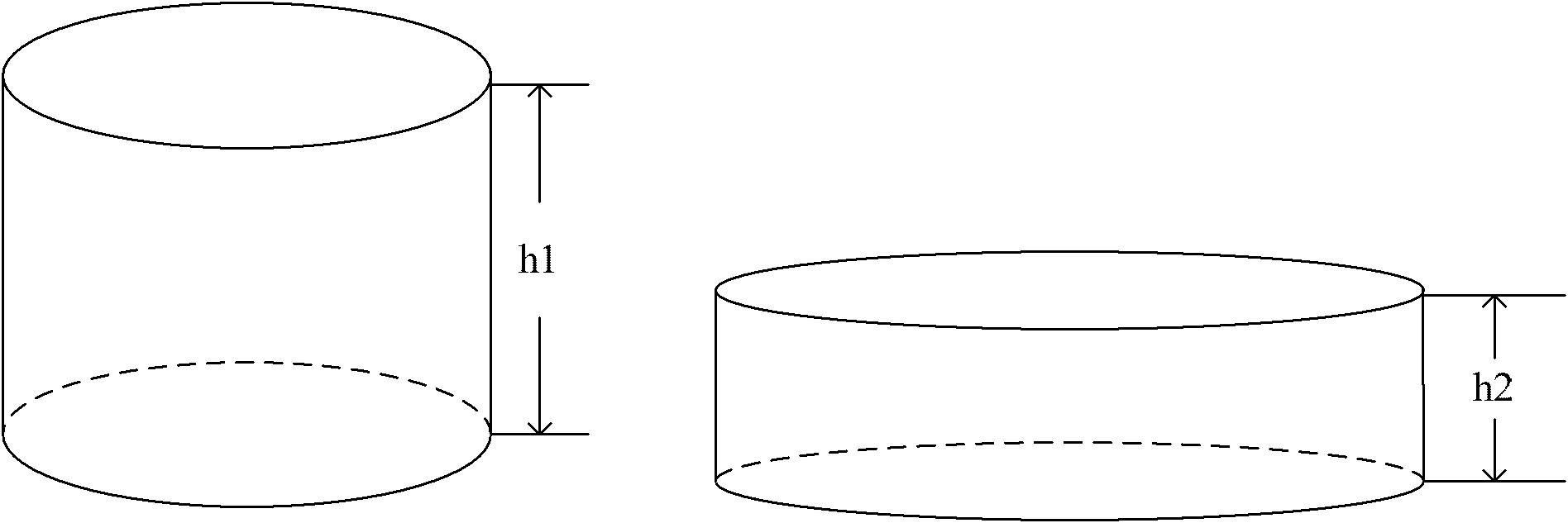

Method for preparing anode made of copper-phosphorus alloy

A method for preparing an anode made of a copper-phosphorus alloy comprises the following steps in sequence: preheating an ingot made of the copper-phosphorus alloy; forging the ingot; conducting homogenized annealing treatment on the ingot; conducting cold rolling on the ingot to form a blank; conducting recrystallization annealing treatment on the blank; and machining the blank, so as to form the anode made of the copper-phosphorus alloy. According to the method, the combination of repeated plastic deformation with a specific deformation rate and annealing treatment under specific temperature is mainly adopted, and the deformation rate of the plastic deformation, the temperature during the annealing treatment, and the time of the annealing treatment are controlled, so as to produce the anode meeting the requirements on compact and uniform internal structure and no lamination for electroplating.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

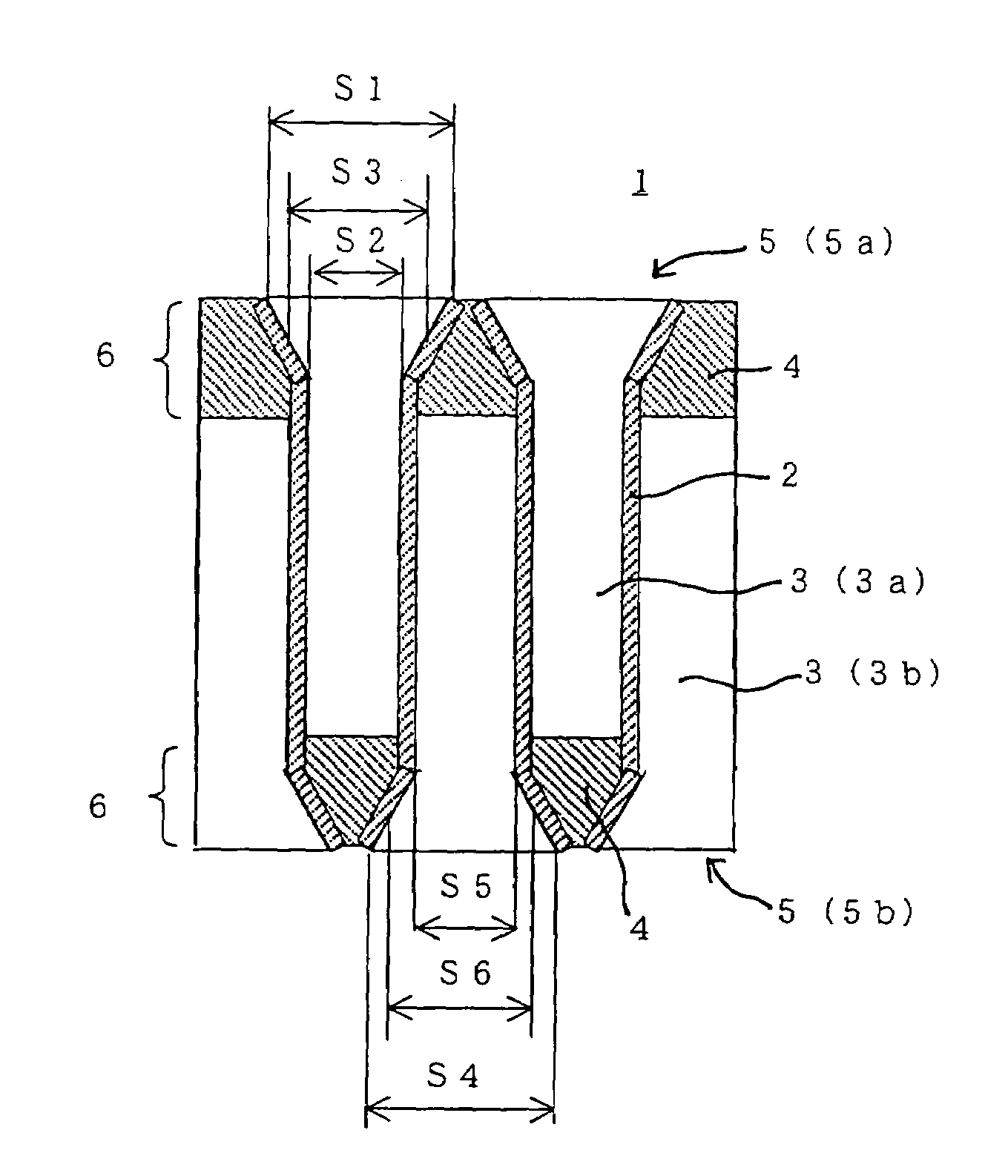

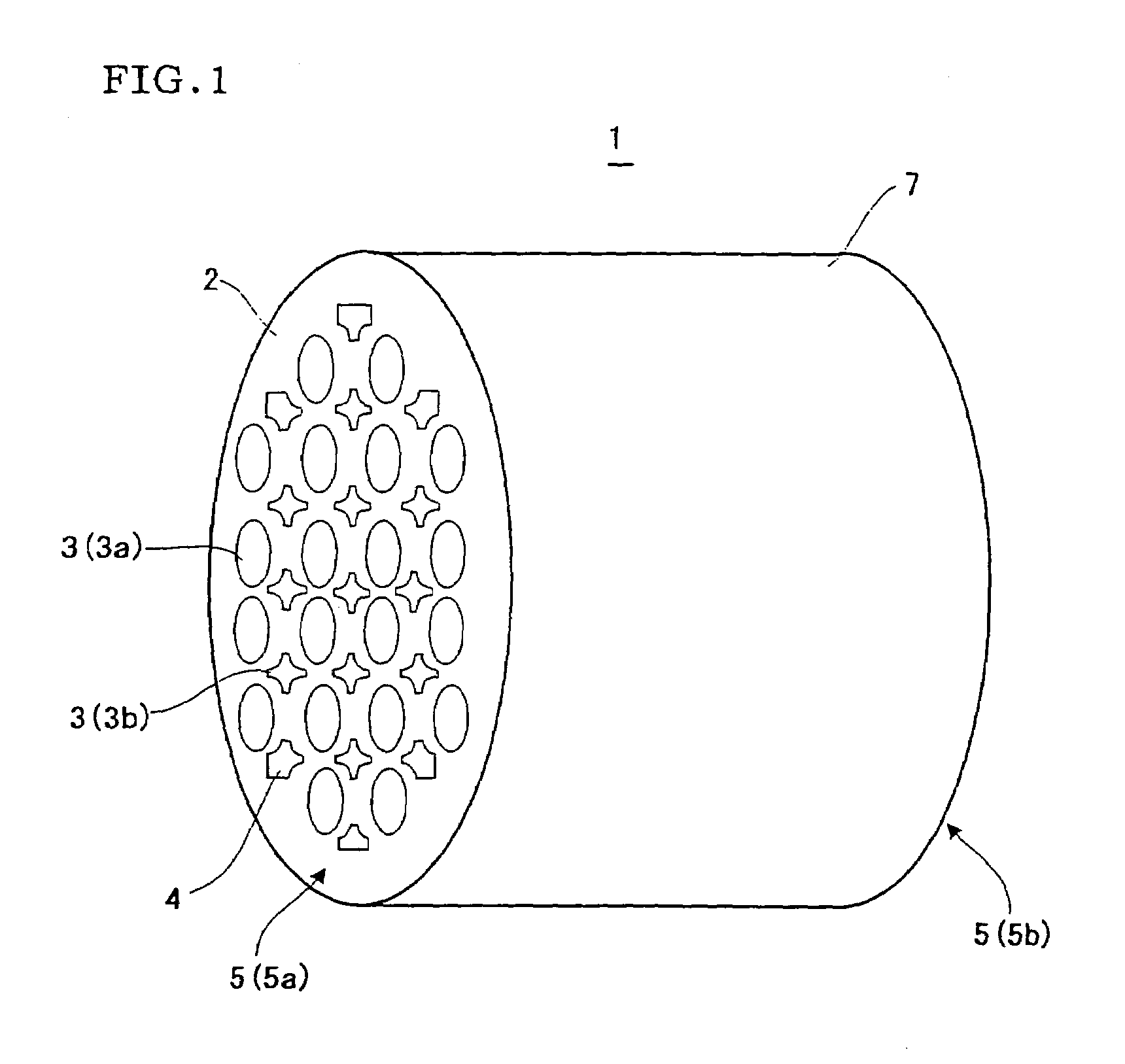

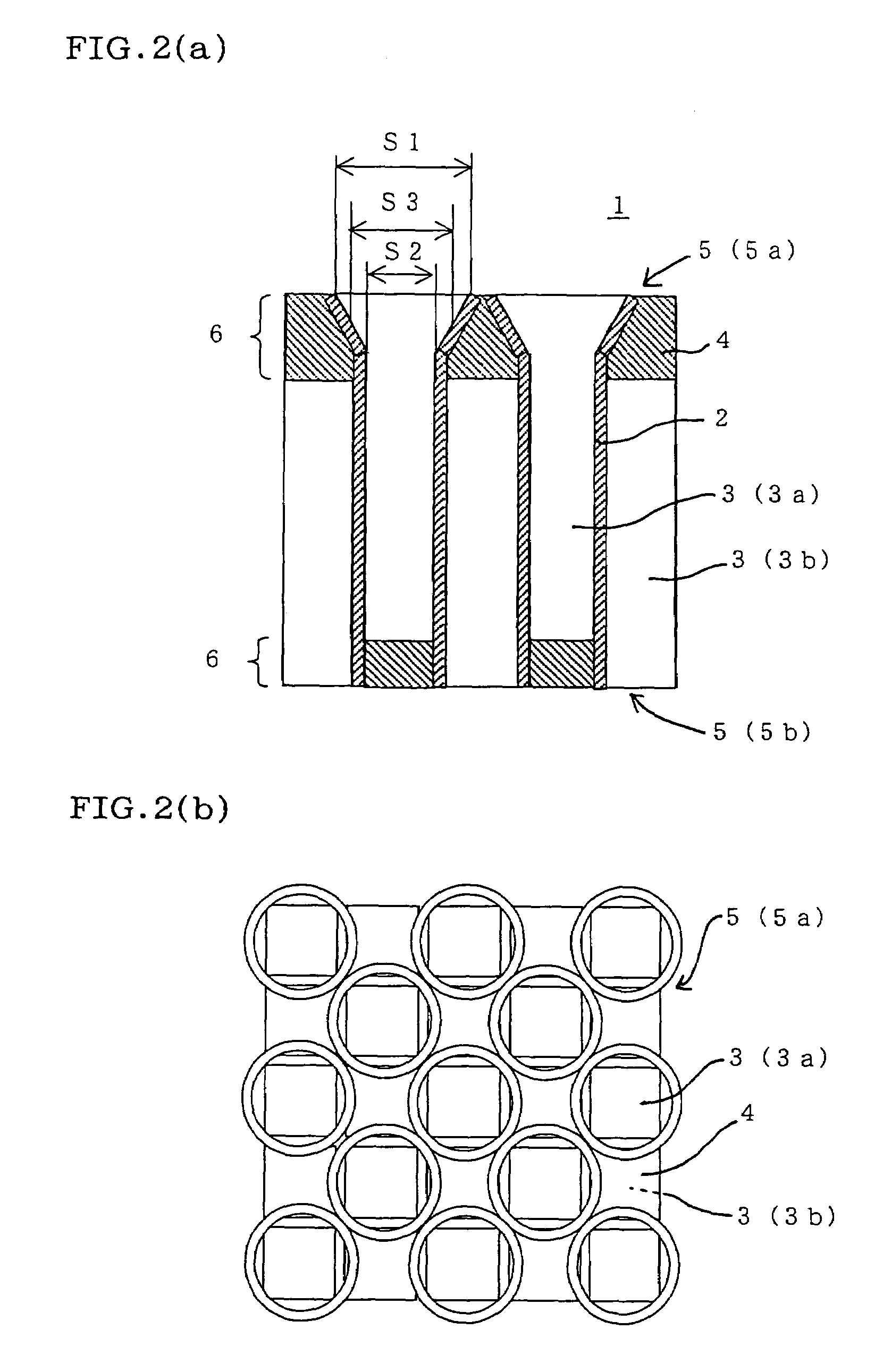

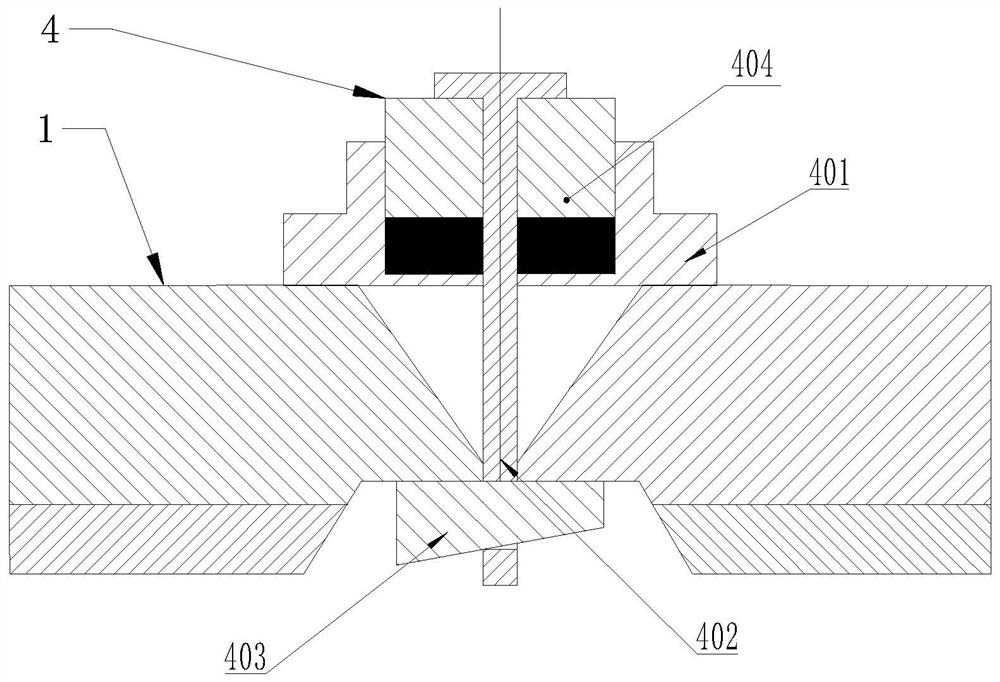

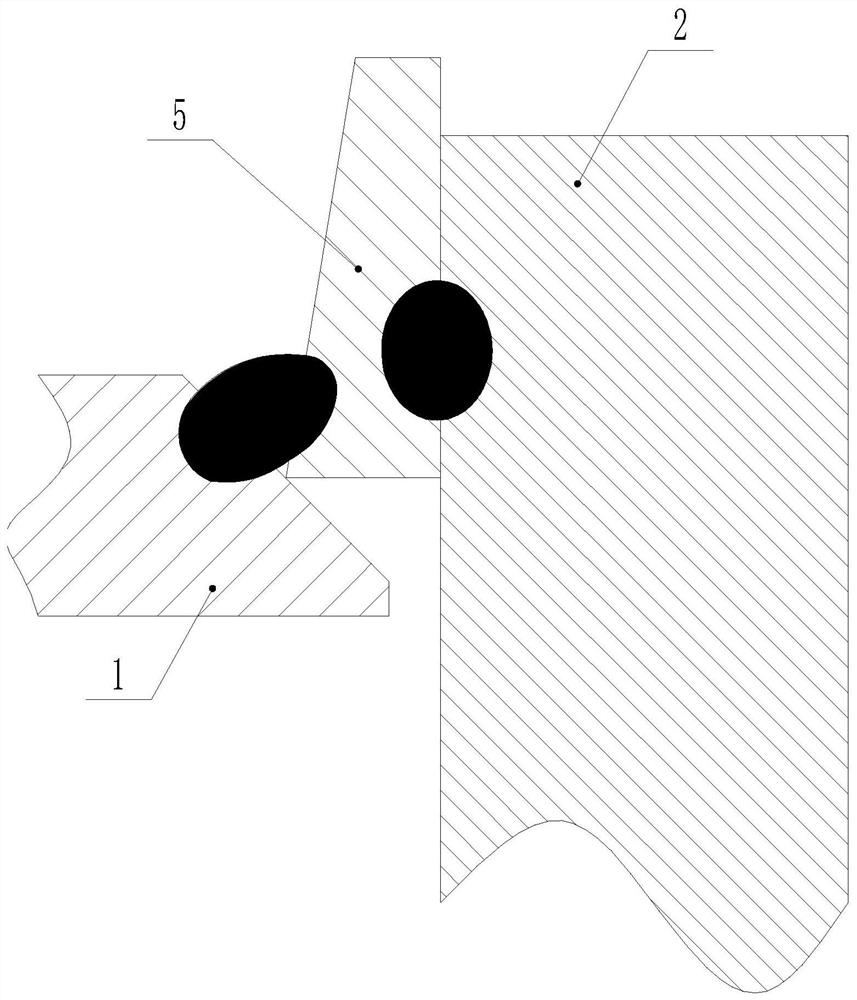

Honeycomb structure and method of manufacturing the same

InactiveUS7285214B2Restore plasticityInternal combustion piston enginesExhaust apparatusParticulatesSewage

There are disclosed a honeycomb structure which is preferably usable as a filter, for example, for trapping particulates in an exhaust gas of an internal combustion engine, boiler or the like or for filtering liquids such as city water and sewage and in which an increase of a pressure loss at a use time is inhibited. A honeycomb structure 1 comprises: two end surfaces 5 consisting of first and second end surfaces; a porous body 2 in which a plurality of fluid channels 3 extending to a second end surface 5b from a first end surface 5a are formed; and plugging members 4 for plugging end portions 6 on end surfaces 5 side of the fluid channels 3. One or more of first fluid channels 3a are formed in a shape in which an opening area (area (S1)) in the first end surface 5a is larger than a sectional area (area (S2)) vertical to a central axis in a position in a predetermined depth from the first end surface 5a and in which a sectional area (area (S3)) vertical to the central axis in a middle between the first end surface 5a and the position in the predetermined depth gradually decreases to the area (S2) from the area (S1).

Owner:NGK INSULATORS LTD

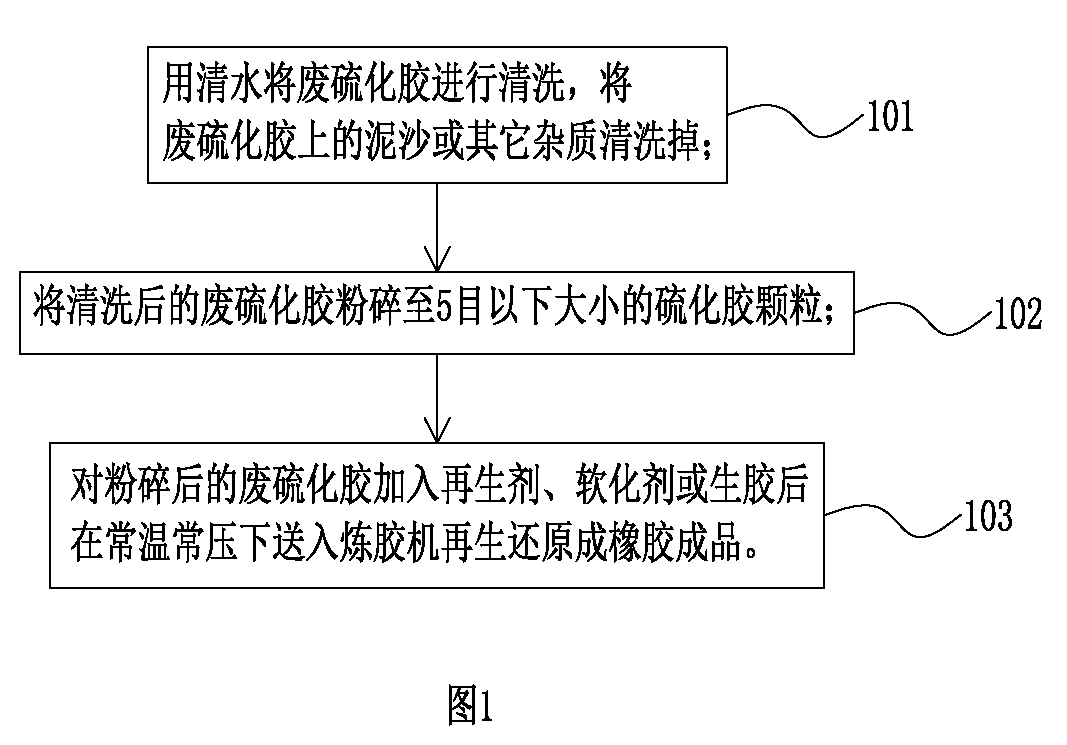

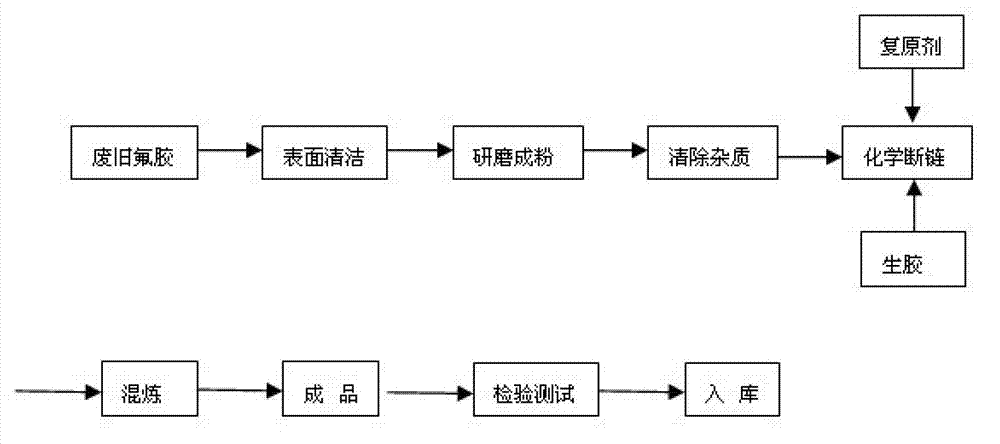

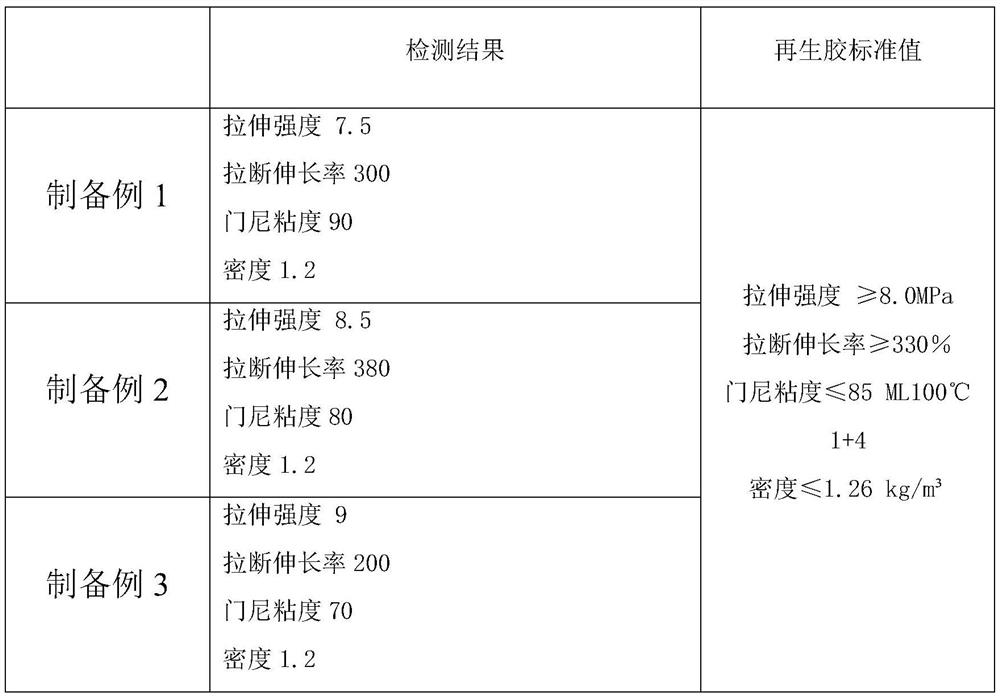

Regenerated rubber production method

The invention provides a regenerated rubber production method. The method mainly comprises the following steps of: washing and removing impurities from waste vulcanized rubber; grinding the washed waste vulcanized rubber; and adding a regenerating agent, a softening agent or raw rubber to the ground waste vulcanized rubber, and then regenerating the mixture to obtain the finished product of the rubber. The method has the beneficial effects that the crosslink bonds among rubber molecules are broken without damaging rubber macromolecules by utilizing the substitution reaction of chemical substances; due to production at normal temperature, the destructive effects of oxygen on the rubber are greatly reduced; the plasticity of the rubber is restored by adopting the method of breaking the crosslink bonds; meanwhile, the compatibility of the rubber with the raw rubber is enhanced so that the rubber becomes a rubber compound; and the production method truly achieves wastewater-free, waste gas-free and pollution-free environment-friendly production, thus truly achieving rubber recycling.

Owner:陈漫远

High-strength Al-Si alloy welding wire and preparation method thereof

InactiveCN110205511AImprove mechanical propertiesExcellent welding fluidityWelding/cutting media/materialsSoldering mediaMaterials preparationSilicon alloy

The invention relates to the technical field of metal material preparation, and particularly discloses a high-strength Al-Si alloy welding wire and a preparation method thereof. The method comprises the following steps that an Al-Ti-B intermediate alloy with TiB2 particles in-situ generated is subjected to violent plastic deformation to obtain the Al-Ti-B intermediate alloy containing the nano TiB2 particles, wherein the size of the nano TiB2 particles ranges from 50 nm to 1000 nm; the Al-Ti-B intermediate alloy containing the nano TiB2 particles is used as a matrix raw material, and an Al-Scintermediate alloy and an Al-Si intermediate alloy are added for smelting treatment to obtain an alloy melt; the alloy melt is prepared into a wire blank with the diameter of 8-10 mm; and hot rolling,cold drawing, intermediate annealing and surface treatment processes are carried out on the wire blank to obtain the aluminum-silicon alloy welding wire with the nano-scale TiB2 particles. Accordingto the aluminum-silicon alloy welding wire prepared through the method, the mechanical property of a welding seam is remarkably improved while the original excellent welding mobility and the low welding crack sensitivity are inherited, the aluminum-silicon alloy welding wire can be used for welding high-strength and ultrahigh-strength aluminum alloys, is especially suitable for alloys which are high in welding crack sensitivity (such as a 7000 series aluminum alloy) and the field which has high requirements on the welding strength, and has high industrial application value.

Owner:JIANGXI UNIV OF SCI & TECH

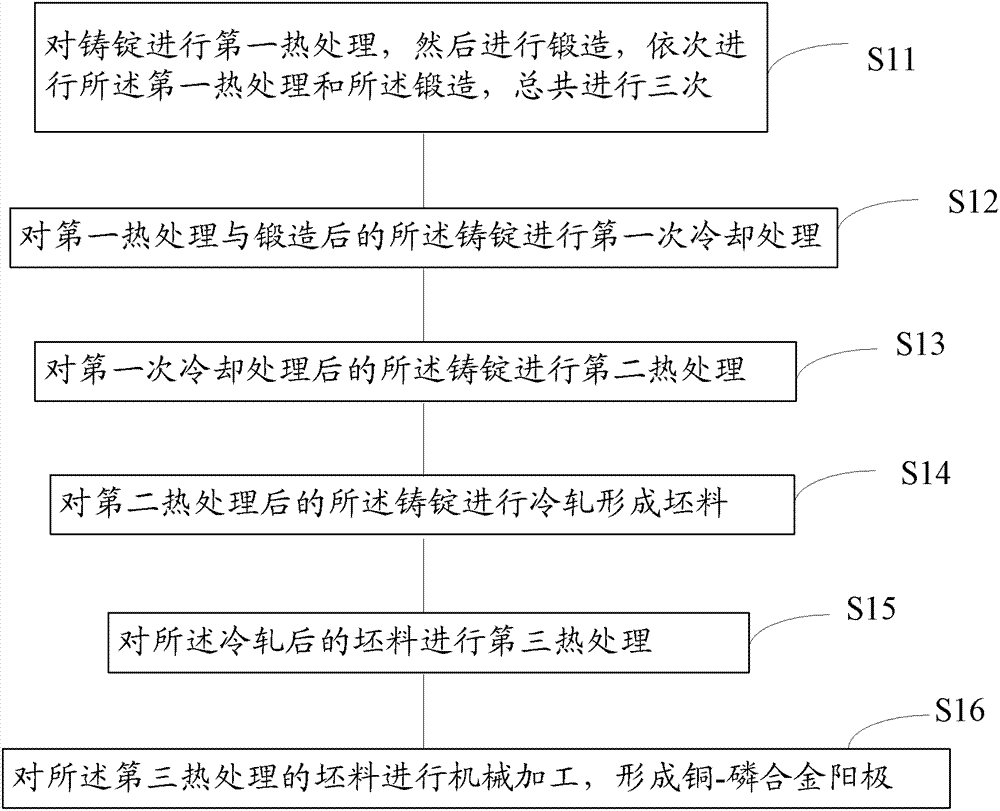

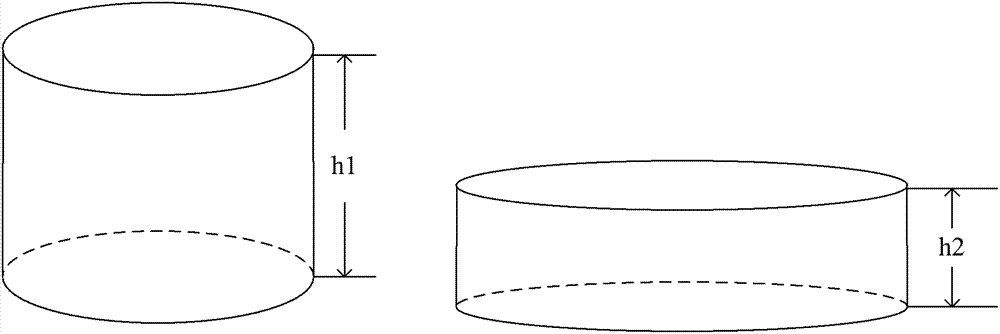

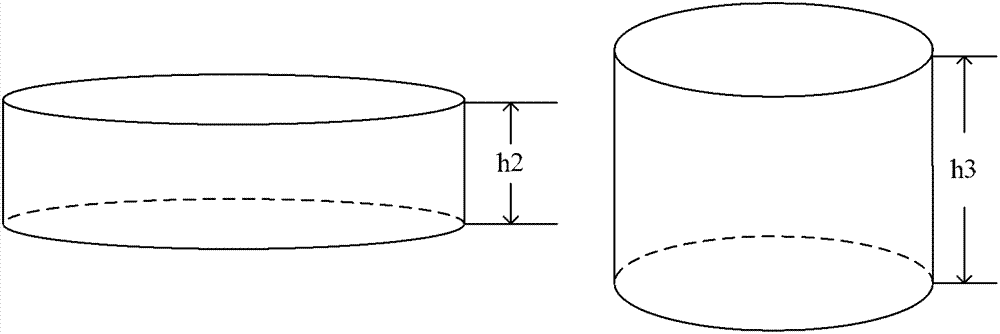

Method for preparing anode made of copper-phosphorus alloy

ActiveCN102517621AMeet electroplating requirementsImprove organizational structureElectrodesIngotCopper

A method for preparing an anode made of a copper-phosphorus alloy comprises the following steps in sequence: conducting first heat treatment on an ingot and forging in sequence for three times; conducting second heat treatment on the ingot after the last time of forging; conducting cold rolling on the ingot to form a blank; conducting third heat treatment on the blank; and machining the blank after the third heat treatment, so as to form the anode made of the copper-phosphorus alloy. According to the method, the combination of repeated plastic deformation with a specific deformation rate and annealing treatment under specific temperature is mainly adopted, and the deformation rate of the plastic deformation, the temperature during the annealing treatment, and the time of the annealing treatment are controlled strictly, so that the anode meeting the requirements on internal grain size and grain orientation for electroplating can be produced.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Methods of assessing wolframin protein activity

InactiveUS7037695B2Increasing Wolframin protein activityReduced activityCompound screeningApoptosis detectionWolframin proteinMolecular biology

The present invention relates to a method of assaying modulators of the interaction between Wolframin protein and its identified cellular binding partner.

Owner:PHARMACIA & UPJOHN CO

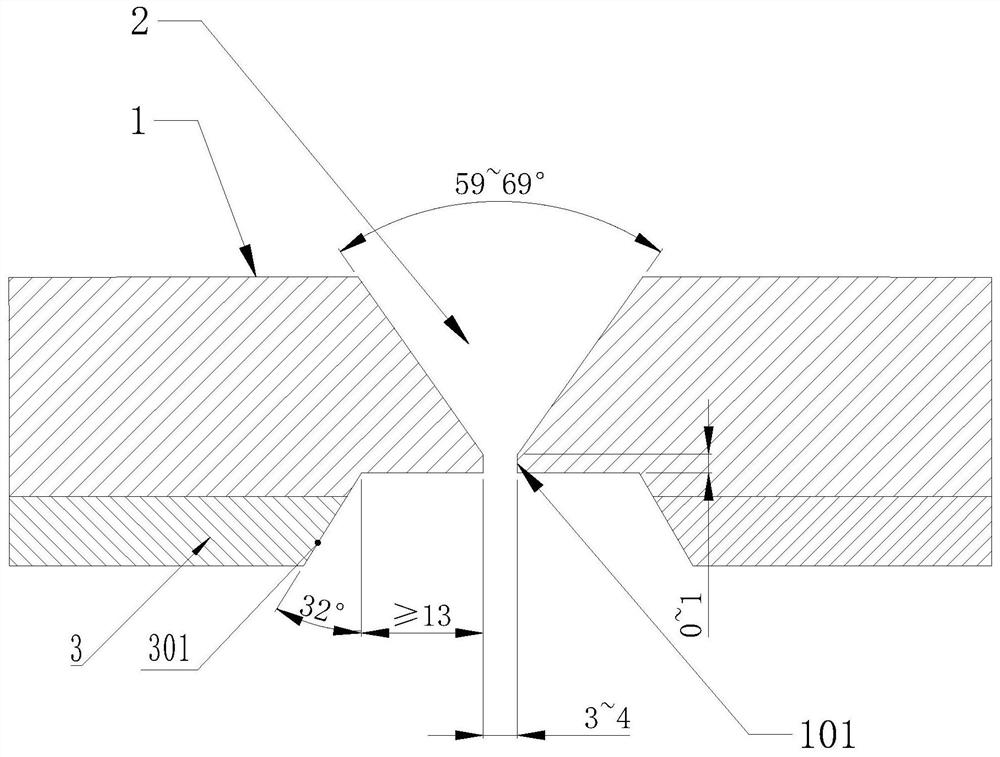

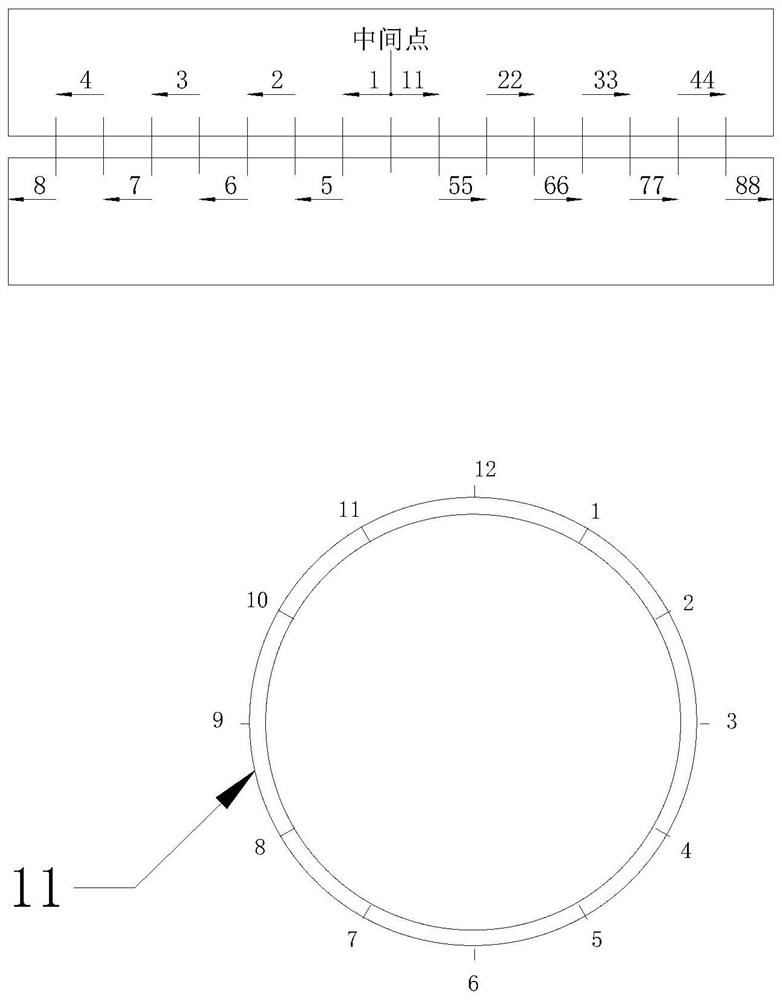

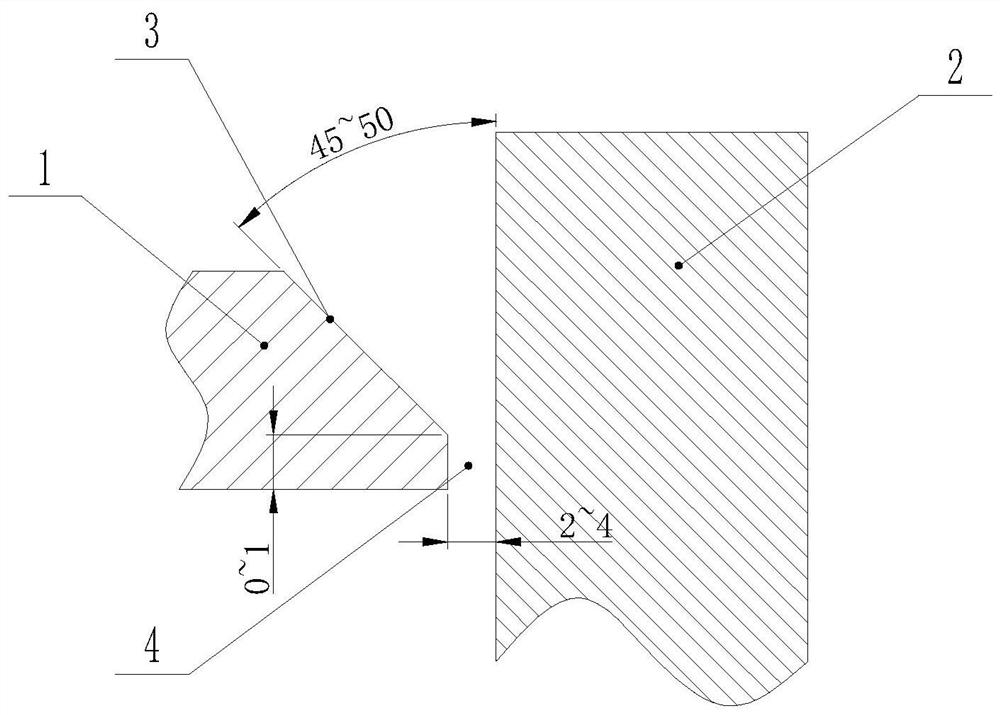

Hastelloy alloy composite material welding and heat treatment process method in modular production

ActiveCN114247965AGuarantee welding qualityUniform thicknessWelding accessoriesStress relievingAlloy composite

The invention discloses a Hastelloy alloy composite material welding and heat treatment process method in modular production, which is used for welding Hastelloy alloy composite materials in modular production, and can be suitable for welding annular welding seams and longitudinal welding seams. The method comprises the following steps: firstly, welding a groove of a base layer base metal to form a base layer welding seam, then, back chipping and polishing, then, carrying out back cover welding, welding two transition layers, and carrying out stress relief heat treatment, so that the welding stress during welding of a hastelloy covering layer base metal can be reduced, and finally, welding a groove of the covering layer base metal to form a covering layer welding seam. According to the welding and heat treatment process, the strength and toughness of the base layer material are met, the strong internal stress generated by hastelloy deposited metal of the coating base material on the base layer base material, especially the bonding surface base material, is eliminated, and the product welding seam quality is stable and reliable.

Owner:江苏利柏特股份有限公司

Production process of galvanized wire

InactiveCN109440039AEliminate hydrogen embrittlementRestore plasticityHot-dipping/immersion processesZincMaterials science

The invention provides a production process of galvanized wire. The production process of the galvanized wire comprises the following steps that S1, raw materials are selected, and a production mode is determined; S2, pretreatment before drawing is carried out; S3, drawing and forming are carried out; S4, hot galvanizing treatment is carried out; and S5; whether a finished product is qualified ornot is checked. According to the production process of the galvanized wire, a zinc coating has good quality and little pollution.

Owner:天津五星金属制品有限公司

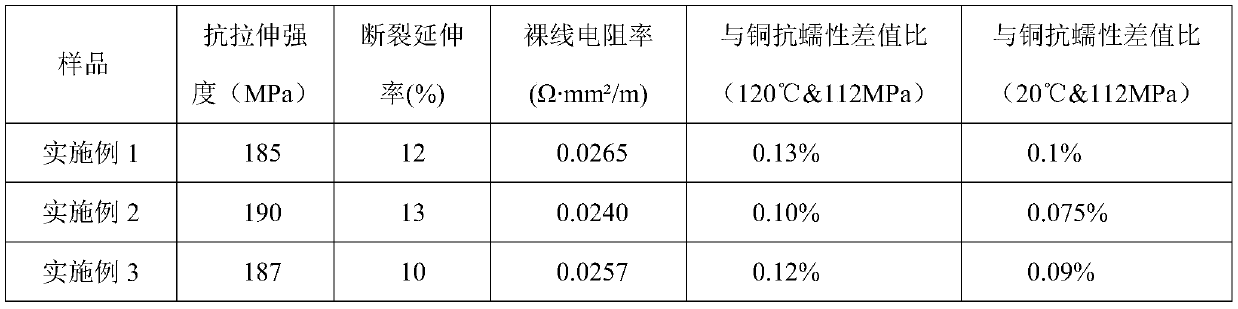

Creep-resistant high-conductive copper-clad aluminum alloy conductor and preparation method thereof

InactiveCN109903889AImproved compressive creep performanceImprove conductivitySingle bars/rods/wires/strips conductorsInsulated cablesElectrical conductorCerium

The invention relates to the technical field of electric wires, and in particular relates to a creep-resistant high-conductive copper-clad aluminum alloy conductor and preparation method thereof. Thecreep-resistant high-conductive copper-clad aluminum alloy conductor comprises an aluminum alloy rod and a copper layer; the copper layer uniformly and centrically coats the surface of the aluminum alloy rod; the aluminum alloy rod comprises the following materials in percentage by weight: 0.05-3.00% of iron, 0.005-0.60% of copper, 0.005-0.50% of magnesium, 0.005-0.50% of cerium, 0.005-0.05% of boron and the balance of aluminum and inevitable impurities. The preparation method of the creep-resistant high-conductive copper-clad aluminum alloy conductor comprises the following steps of smelting,continuous casting and rolling, coating and welding, annealing and wiredrawing. The creep-resistant high-conductive copper-clad aluminum alloy conductor provided by the invention is high in electricconductivity and good in mechanical strength, has the extension strength capable of being up to 185MPa, and can be applied to electric wire conductors.

Owner:SHENZHEN SHENZHOU CABLE

Technique for recovering hydrogenated nitrile-butadiene rubber

The invention discloses a technique for recovering hydrogenated nitrile-butadiene rubber, relating to a processing technique for recovering and regenerating waste and old hydrogenated nitrile-butadiene rubber materials. The invention can promote the rupture of the carbon-sulfur bond in an atmospheric pressure and temperature environment so as to restore the linear structure of the rubber. The technique uses waste and old hydrogenated nitrile-butadiene rubber as the raw material, and sequentially comprises the steps of cleaning, grinding, impurity removal, recovery reaction and mixing, wherein the recovery reaction is implemented by adding 1.5-2.5 wt% of recovering agent into the raw material; the recovering agent is composed of zinc diethyl dithiocarbamate, mercaptobenzothiazole and zinc oxide; and the mixing step is implemented at 18-30 DEG C for 28-48 minutes with a mixer. The technique is implemented in a way that: the recovering agent is added into waste and old hydrogenated nitrile-butadiene rubber particles, evenly stirred, and repeatedly rolled under atmospheric pressure and temperature to initiate replacement reaction by using the shearing force and temperature generated by the shearing friction force, so that the carbon-sulfur bond is ruptured, sulfur is ionized, and the molecular reticular structure in the waste rubber is restored into the linear structure in the rubber mixing process, thereby restoring the plasticity of the rubber.

Owner:JIANGSU GREENSTAR ECO RUBBER TECH CO LTD

Copper strip production process

The invention discloses a copper strip production process. The copper strip production process specifically comprises the following steps of (1) smelting and continuous casting; (2) surface milling; (3) hot rolling; (4) annealing; (5) acid pickling and cleaning; (6) fine rolling; and (7) shearing, packaging and warehousing. The copper strip production process has the beneficial conditions that after a raw material smelting alloy material is added, the weight of the raw material is controlled and the heating temperature and the heating environment are controlled during hot rolling, the oxidation burning loss of a copper material in a heating furnace can be reduced to a large extent, the yield of a finished product is controlled, a series of quality problems caused by heating oxidation of the copper material are reduced, annealing parameters are controlled, deformation resistance is lowered, the plasticity is restored, and the quality performance of the finished copper strip product produced by a method is good.

Owner:温州铜丰铜业有限公司

Normal-temperature regeneration method for waste rubber

InactiveCN111925558ARealization of normal temperature regenerationReduce energy consumptionPlastic recyclingWaste rubberExhaust fumes

The invention provides a normal-temperature regeneration method for waste rubber. The method comprises the following steps: crushing waste tires into rubber powder, refining the rubber powder to forma netty product A, adding a reducing agent into the product A, carrying out stirring to form a product B, refining the product B to form a product C, adding an initiator into the product C, carrying out kneading to form a product D, and refining the product D to obtain a reclaimed rubber finished product. According to the normal-temperature regeneration method for waste rubber, the waste rubber can be regenerated at normal temperature, no waste water or waste gas is generated, production efficiency is high, energy is saved, and the environment is protected.

Owner:SANHE GREAT WALL RUBBER

Preparation method of copper-phosphorus alloy anode

ActiveCN102517621BMeet electroplating requirementsImprove organizational structureElectrodesIngotCopper

A method for preparing an anode made of a copper-phosphorus alloy comprises the following steps in sequence: conducting first heat treatment on an ingot and forging in sequence for three times; conducting second heat treatment on the ingot after the last time of forging; conducting cold rolling on the ingot to form a blank; conducting third heat treatment on the blank; and machining the blank after the third heat treatment, so as to form the anode made of the copper-phosphorus alloy. According to the method, the combination of repeated plastic deformation with a specific deformation rate and annealing treatment under specific temperature is mainly adopted, and the deformation rate of the plastic deformation, the temperature during the annealing treatment, and the time of the annealing treatment are controlled strictly, so that the anode meeting the requirements on internal grain size and grain orientation for electroplating can be produced.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

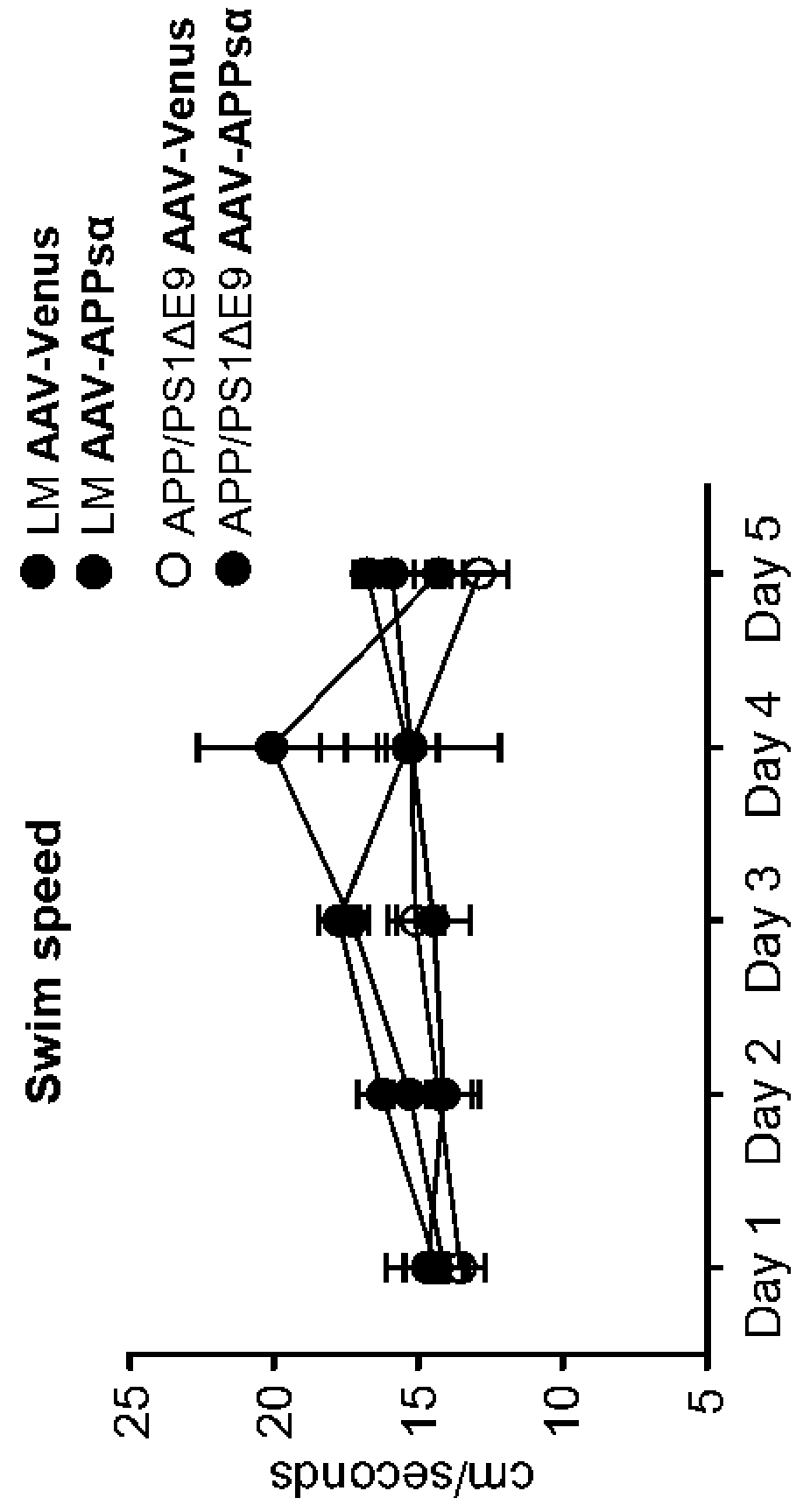

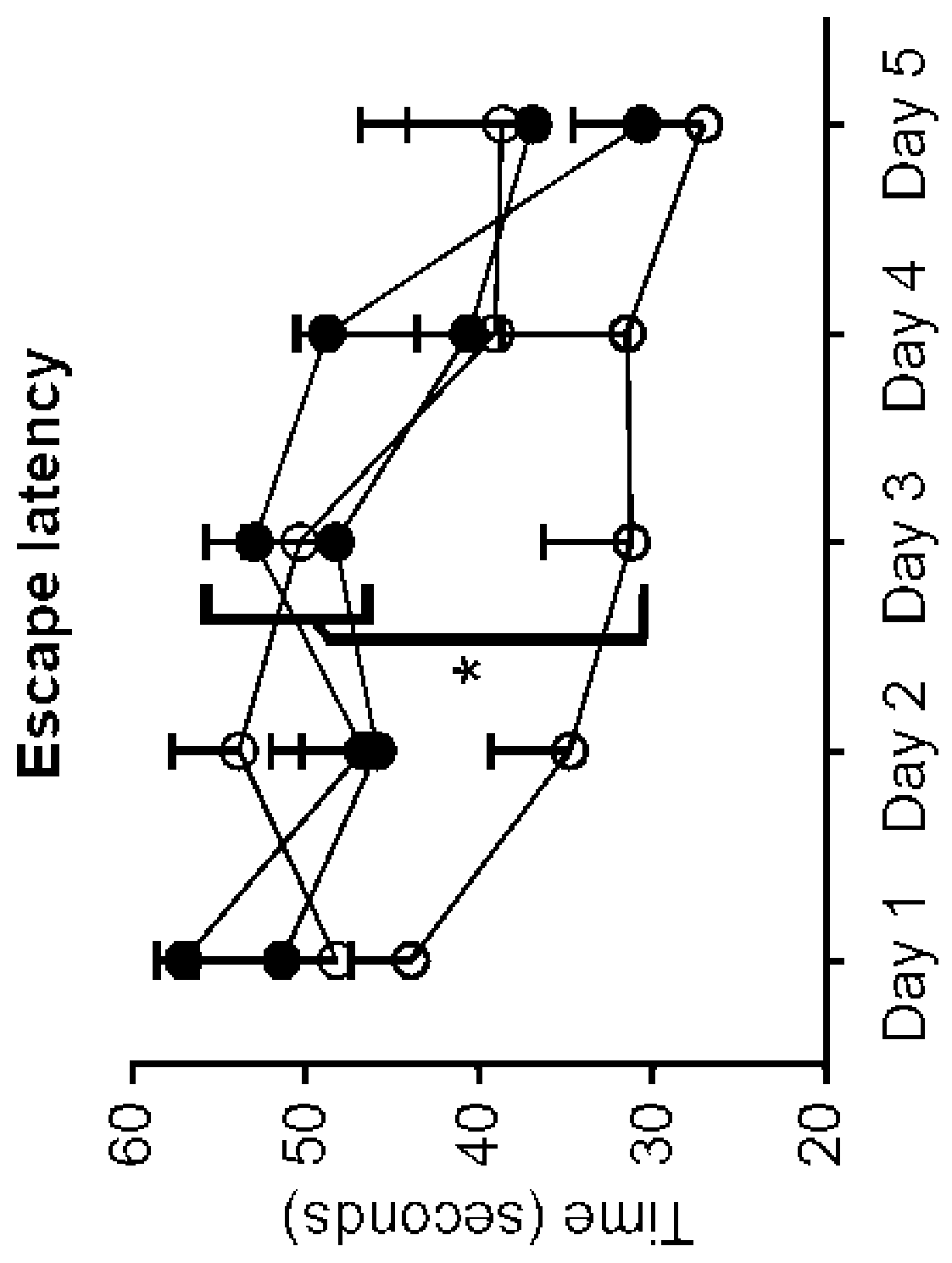

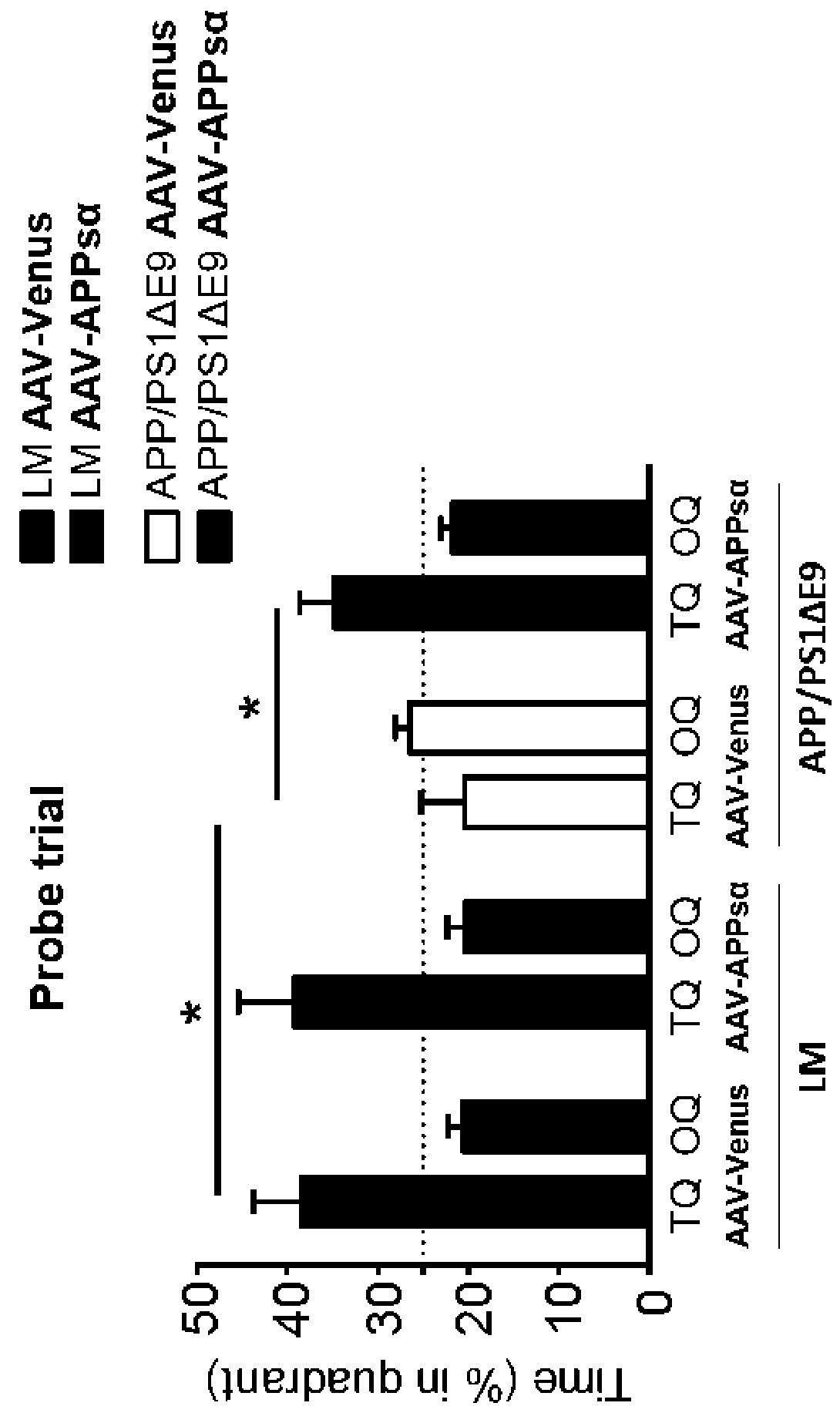

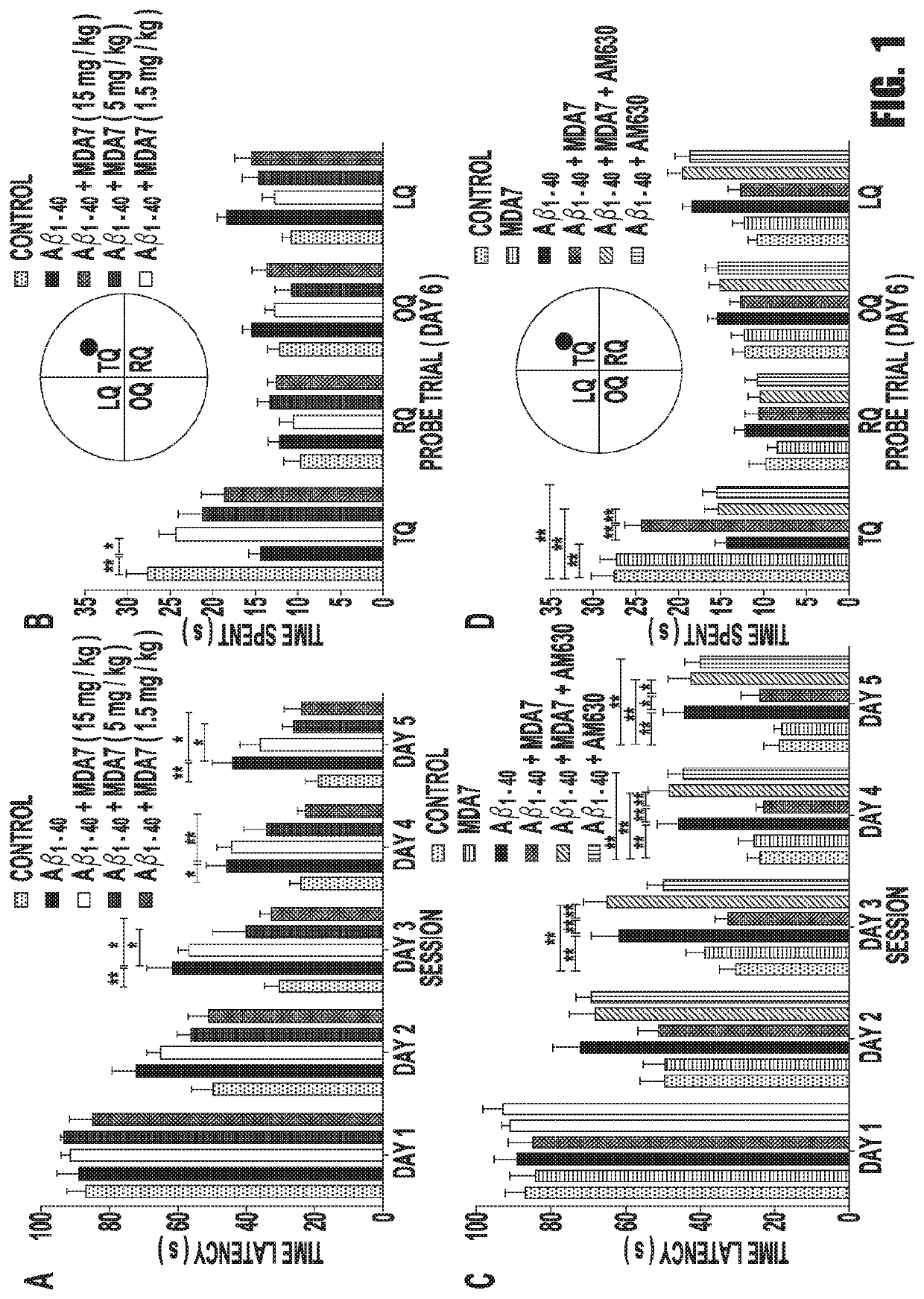

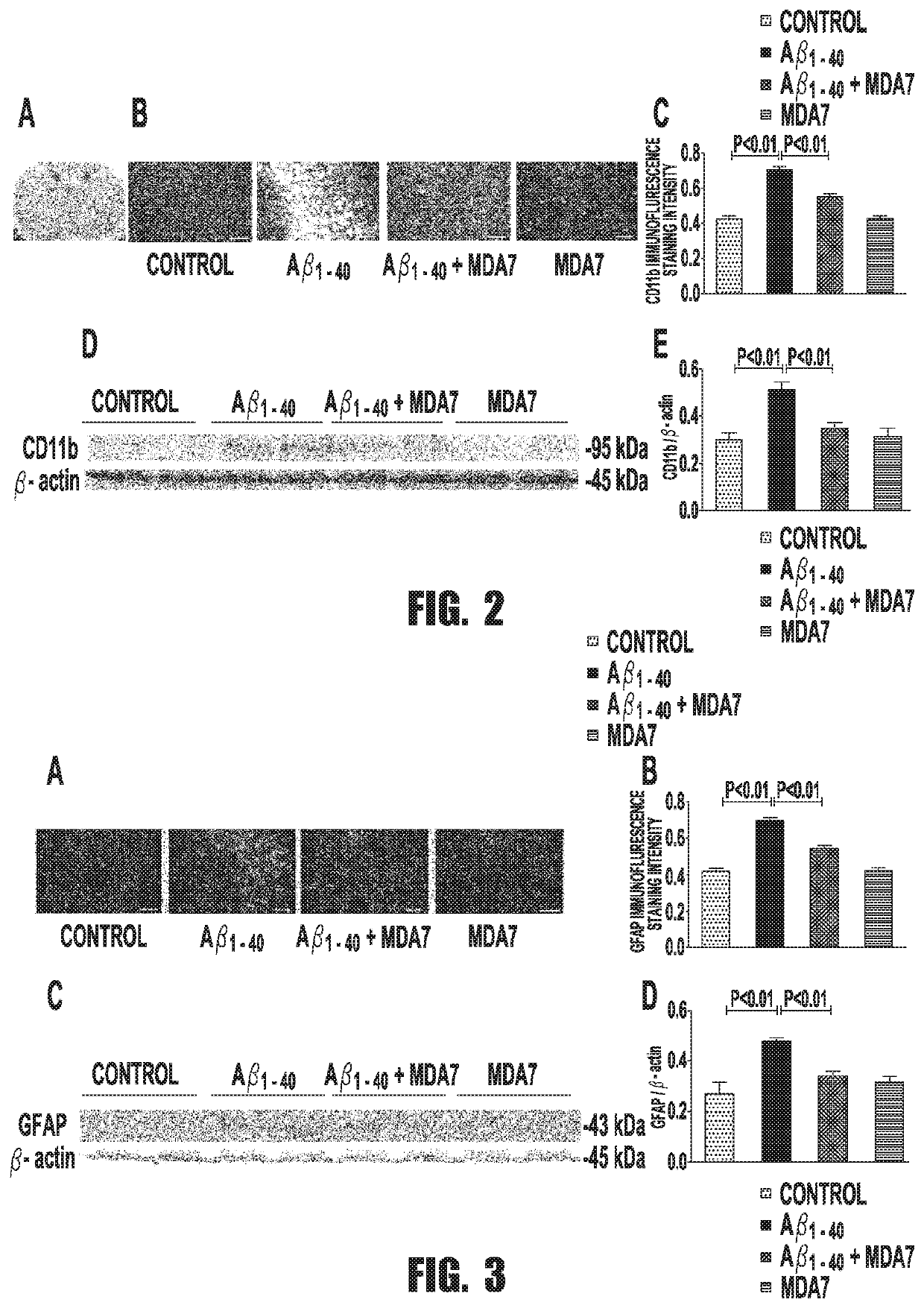

Methods and pharmaceutical composition for the treatment of alzheimer's disease

InactiveUS20180161395A1Ameliorate and rescue structural and electrophysiological and behavioral deficitImprove plasticityNervous disorderVectorsCancer researchAmyloid Protein Precursor

The present invention relates to methods and pharmaceutical compositions for the treatment of Alzheimer's disease. In particular the present invention relates to a method of treating Alzheimer's disease in a subject in need thereof comprising administering to the subject a therapeutically effective amount of a vector which comprises a nucleic acid molecule encoding for a polypeptide which is a soluble member of the APP (amyloid precursor protein) family.

Owner:INST NAT DE LA SANTE & DE LA RECHERCHE MEDICALE (INSERM) +4

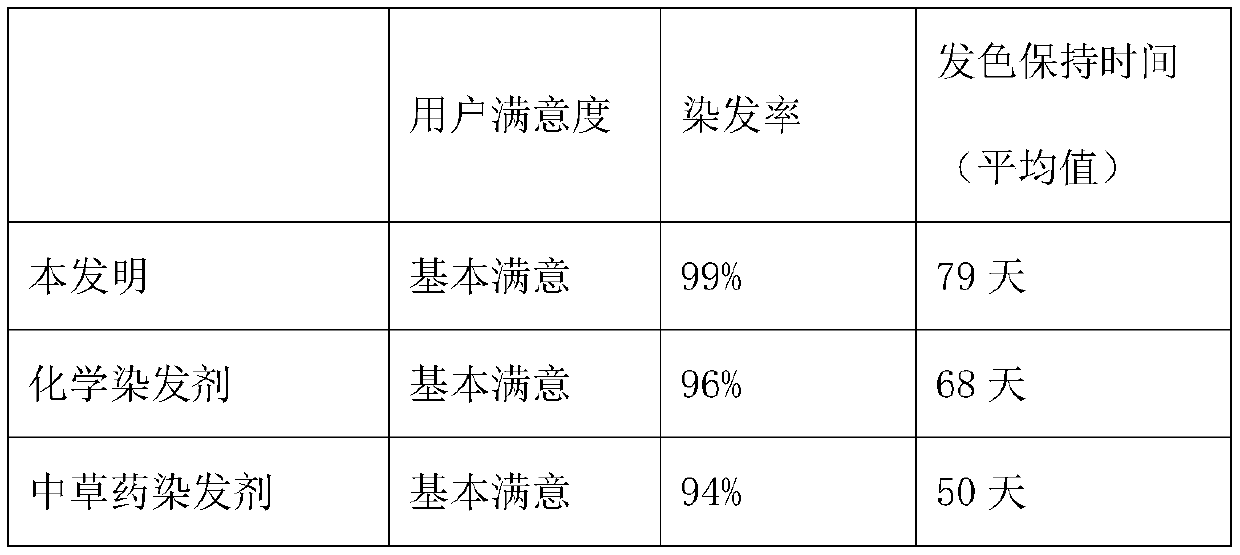

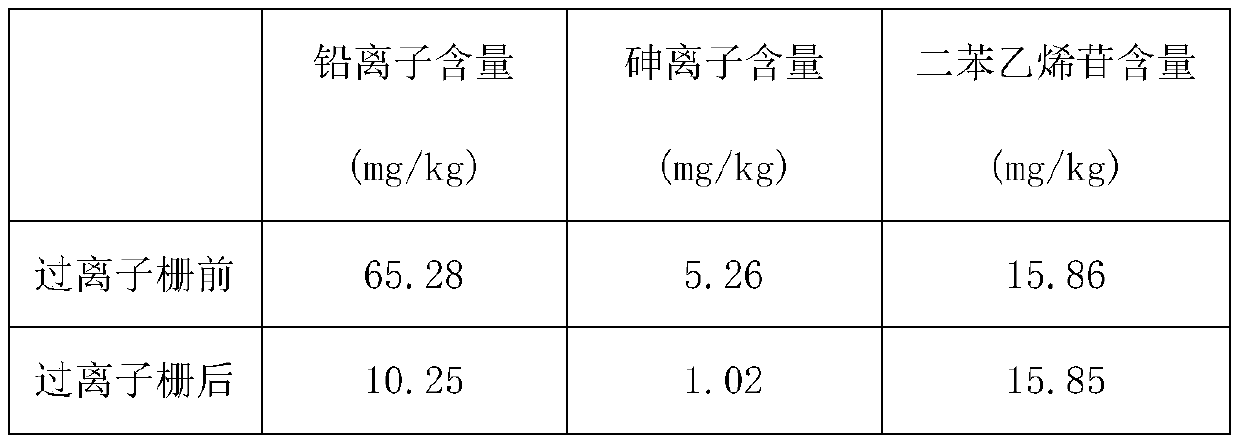

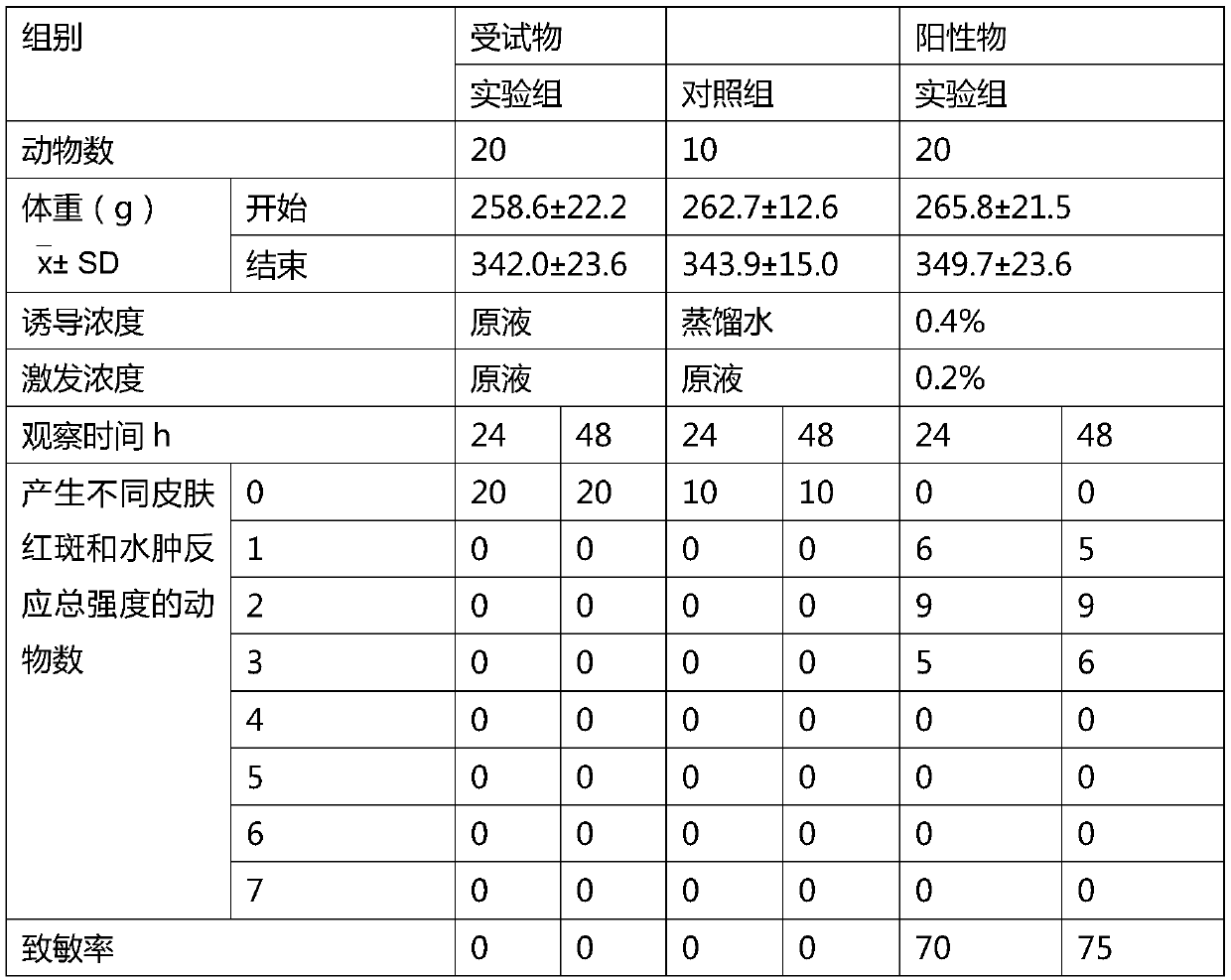

Anti-allergy hair dye containing plant extracts and preparation method thereof

InactiveCN110974753ASecondary damageGuaranteed hair coloring effectCosmetic preparationsHair cosmeticsBiotechnologyGrape seed

The invention discloses an anti-allergy hair dye containing plant extracts and a preparation method of the anti-allergy hair dye. The anti-allergy hair dye comprises the following components in partsby weight: 10-20 parts of cetostearyl alcohol, 10-20 parts of cetostearyl alcohol polyether 20, 5-8 parts of ammonia, 5-8 parts of mercaptoacetic acid, 5-8 parts of water, 120-140 parts of water, 80-100 parts of chitosan, 10-13 parts of ferrous sulfate, 2-4 parts of maltodextrin, 5-15 parts of a polygonum multiflorum extract, 10-20 parts of a black mulberry fruit extract, 20-40 parts of a grape seed extract, 2-5 parts of methylparaben, 2-5 parts of propyl hydroxybenzoate, 2-4 parts of zinc oxide, 3-8 parts of beta-sitosterol, 15-20 parts of a modified coloring agent and 30-40 parts of glycerinum. The anti-allergy hair dye overcomes the problems that hair quality damage is caused by chemical hair dyeing, durability of plant hair dyeing components is poor, perming forming is difficult afterhair dyeing, anaphylactic reaction is likely to happen to a human body, and plant extraction effectiveness is low in existing hair dyes.

Owner:北京九州益华化妆品有限公司

GH4169 alloy welding stick short process preparing method

ActiveCN108672980AExcellent high temperature strengthStrong corrosion resistanceWelding/cutting media/materialsSoldering mediaCorrosionChemical composition

The invention relates to a GH4169 alloy welding stick short process preparing method. Chemical compositions in the method comprise, by weight, 50.0%-55.0% of Ni, 17.0-21.0% of Cr, 5.00%-5.50% of Nb, 2.80%-3.30% of Mo, 0.75%-1.15% of Ti, 0.30%-0.70% of Al, 0.02%-0.06% of C and the balance Fe. Welding stick preparing technological processes mainly include the steps of matching, smelting, ingot casting, homogenizing annealing, bar extrusion, continuous annealing, multi-pass continuous extrusion and the other processes. A prepared alloy welding stick has the excellent high-temperature strength, oxidation resistance, creep resistance and resistance to corrosion and has the good fatigue property and weldability. In particular at the high temperature being 650 DEG C, the mechanical property of the alloy welding stick has the good stability, certain working pressure can be borne under 600 DEG C-1200 DEG C, and the alloy welding stick can be widely applied to welding pieces for blades, turbinediscs, turbine discs and long-service life aerospace engines.

Owner:LANZHOU WEITE WELDING MATERIAL FURANCE BURDEN

Aluminum air conditioner foil with breathability and preparation method thereof

ActiveCN105459499ANot easy to crackHigh flanging heightLaminationLamination apparatusDuctility6061 aluminium alloy

The invention discloses an aluminum air conditioner foil with breathability and a preparation method thereof, the aluminum foil is made from lithium titanate crystal whiskers and 6061 aluminium alloy, two sides of the aluminum foil with breathability are respectively compounded with a hydrophilic film and a hydrophobic film, an air conditioner foil product obtained through the material and the method has tensile strength being up to 160 to 180Mpa, and ductility being greater than 18 percent. Meanwhile, the air conditioner foil product has good hydrophilicity and hydrophobicity, can greatly improve heat exchange efficiency of an air conditioner, and prevent the air conditioner from frosting.

Owner:苏州福羊自控科技有限公司

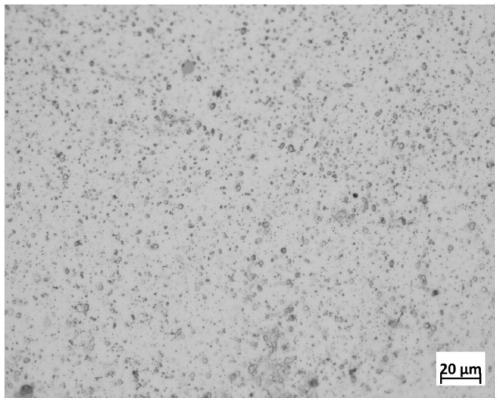

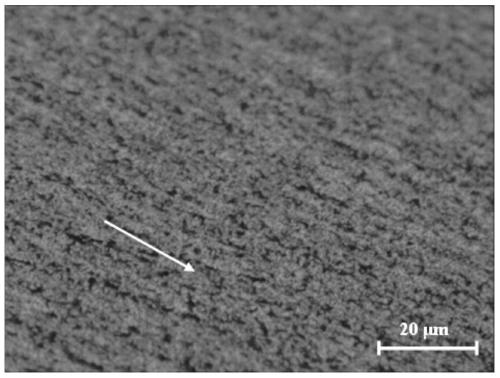

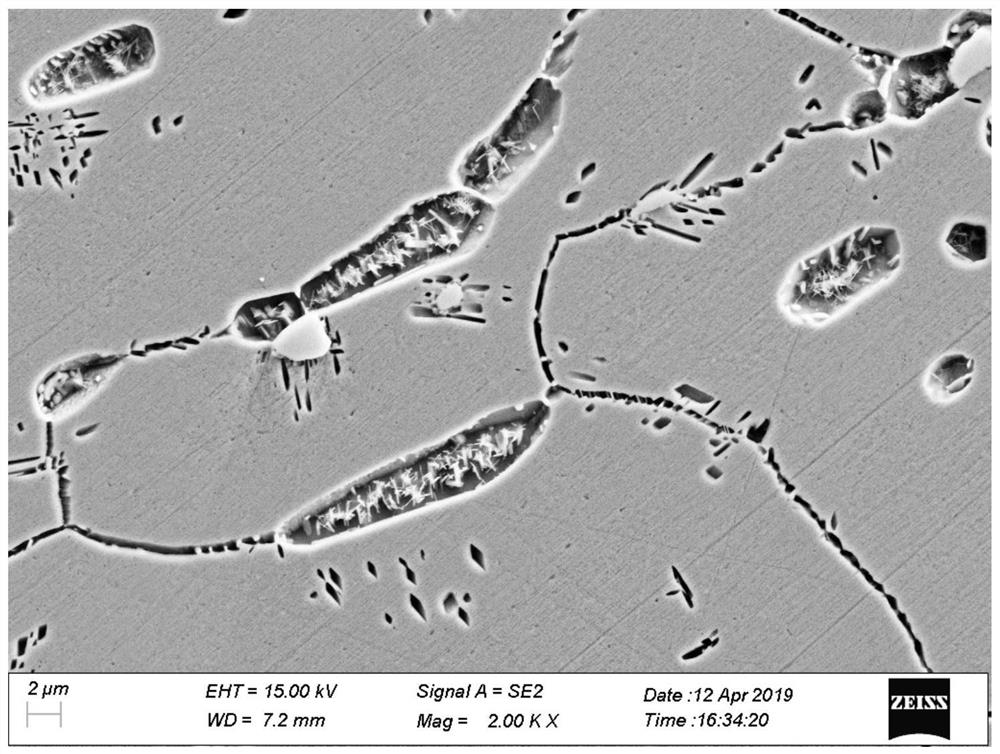

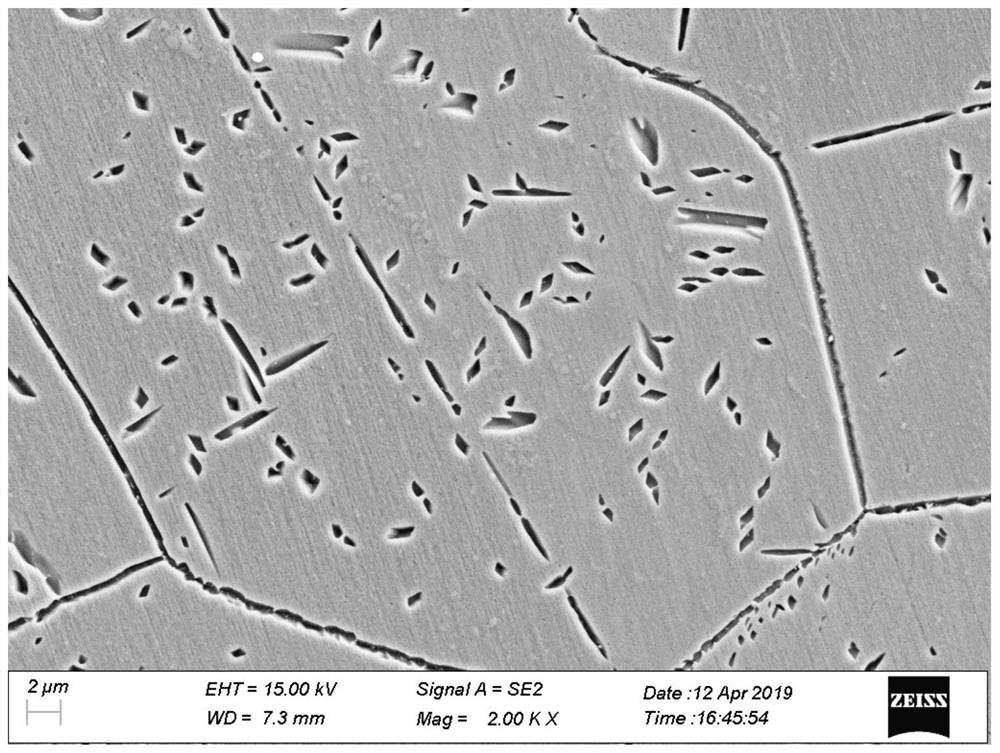

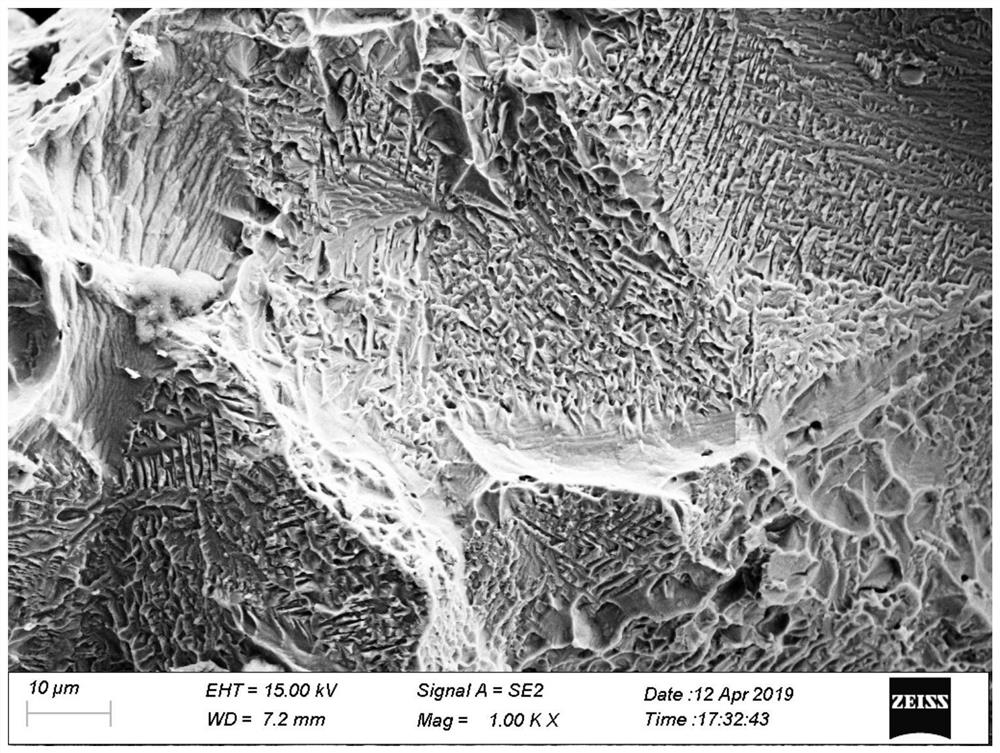

Heat treatment method for eliminating laves phases in beta phases in high temperature alloy incone1783 bolt

The invention discloses a heat treatment method for eliminating laves phases in beta phases in a high temperature alloy incone1783 bolt. An incone1783 bolt sample of the laves phases in the beta phases is subjected to solution treatment, beta aging treatment and gamma' aging treatment in sequence. Through the heat treatment method disclosed by the invention, Nb solid solutions in the laves phasesenter an austenitic matrix, and the Laves phases in the beta phases are refined, so that lots of needle-like Laves phases are converted into fine rod-like Laves phases, or even the Laves phases are completely eliminated; thus, the plasticity and toughness of materials are restored; and through the heat treatment method disclosed by the invention, the size of the beta phase can be refined, and theplasticity and toughness of the materials are restored.

Owner:HEFEI UNIV OF TECH

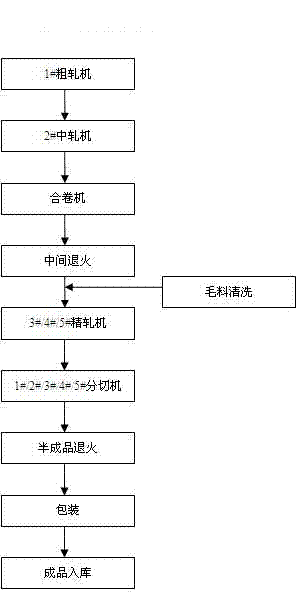

Production process for rolling light gauge aluminum foil

ActiveCN102284483BReduce the number of pinholesImprove mechanical propertiesProfile control deviceMetal rolling arrangementsSurface cleaningWork in process

The invention discloses a production process for rolling a light gauge aluminum foil, which comprises the following steps of: performing rough rolling, wherein the reduction per pass of the rough rolling is 0.3mm to 0.14mm to 0.07mm to 0.038mm; performing intermediate rolling, wherein the reduction per pass of the intermediate rolling is 0.038mm to 0.013mm; performing double rolling; performing intermediate annealing; cleaning a stock, namely performing surface cleaning on the aluminum foil stock by using rolling oil at a finish rolling inlet; performing finish rolling, wherein the reduction per pass of the finish rolling is 0.013mm to 0.005mm; slitting; annealing a semi-finished product; and packaging and warehousing. By adding the intermediate annealing and rolling oil cleaning processes for the aluminum foil, the mechanical property of the aluminum foil is improved while the thickness of the aluminum foil is reduced, and the breakage condition and a pinhole number in the rolling process are reduced.

Owner:JIANGSU ZHONGJI LAMINATION MATERIALS

Stellite alloy welding and heat treatment process for modular production

The invention discloses a Stellite alloy welding and heat treatment process method for modular production, comprising the following steps: A, preparation before welding; B, pairing preparation; C, groove pairing and spot welding; D, welding Seam welding, including the following sub-steps: d1) Surface quality inspection: d2) Preheating and welding process, including the following sub-steps: d21) Preheating the welding part; d22) The welding process is GTAW, linear bead, pressure pass welding , the joints are staggered; d3) according to the type of weld, select the corresponding welding method for welding; d4) root welding; d5) manual argon tungsten arc welding to fill the cover; E, post-heat treatment and disinfection of the weld Stress heat treatment; F) weld VT inspection; G) weld PT inspection; H) weld RT inspection. The welding and heat treatment process adopts post-heating and stress-relief heat treatment steps to eliminate hydrogen gas inside the deposited metal, eliminate residual stress in the weld seam and heat-affected zone, reduce welding deformation, and make the metal structure of the weld seam dense.

Owner:江苏利柏特股份有限公司

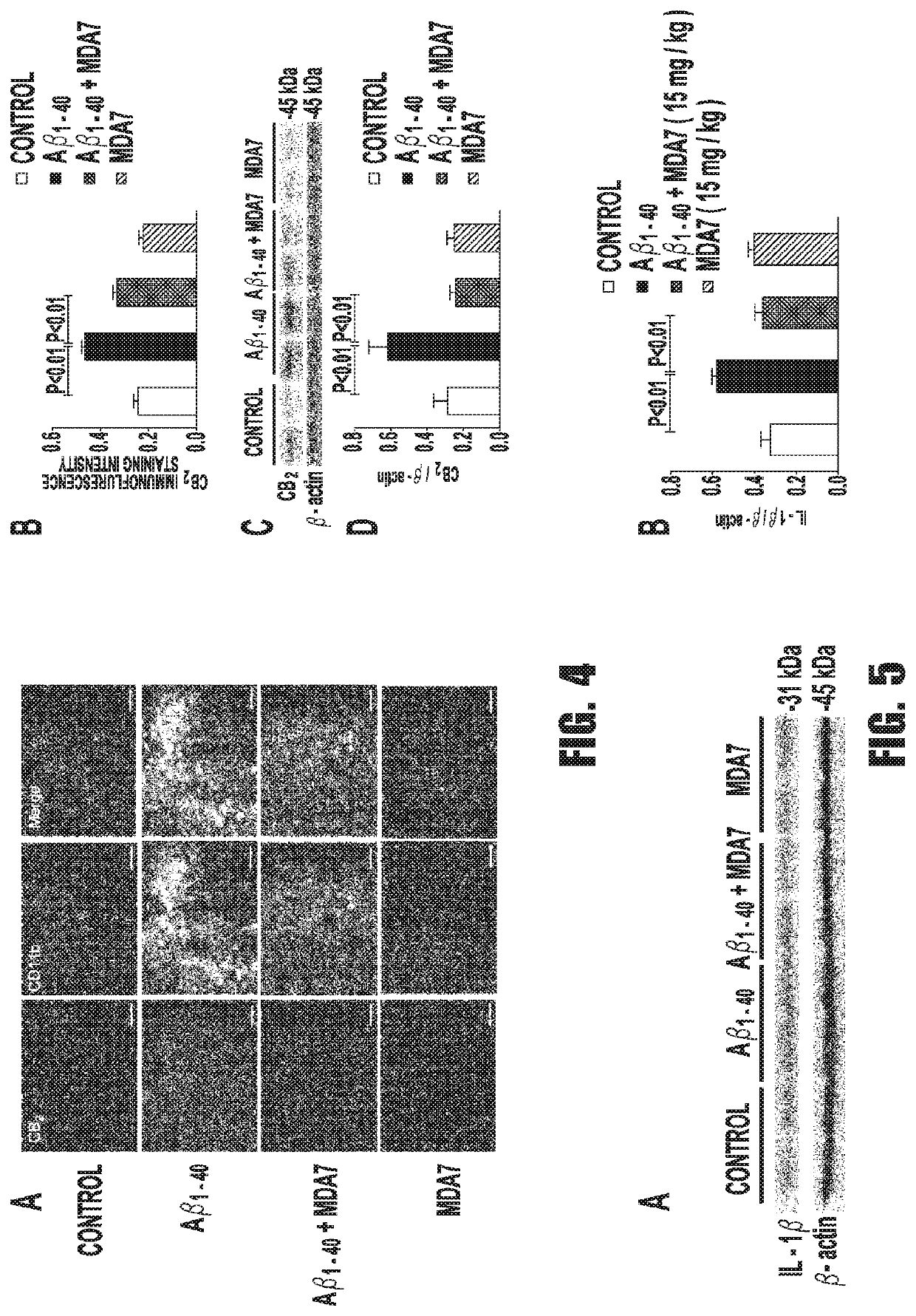

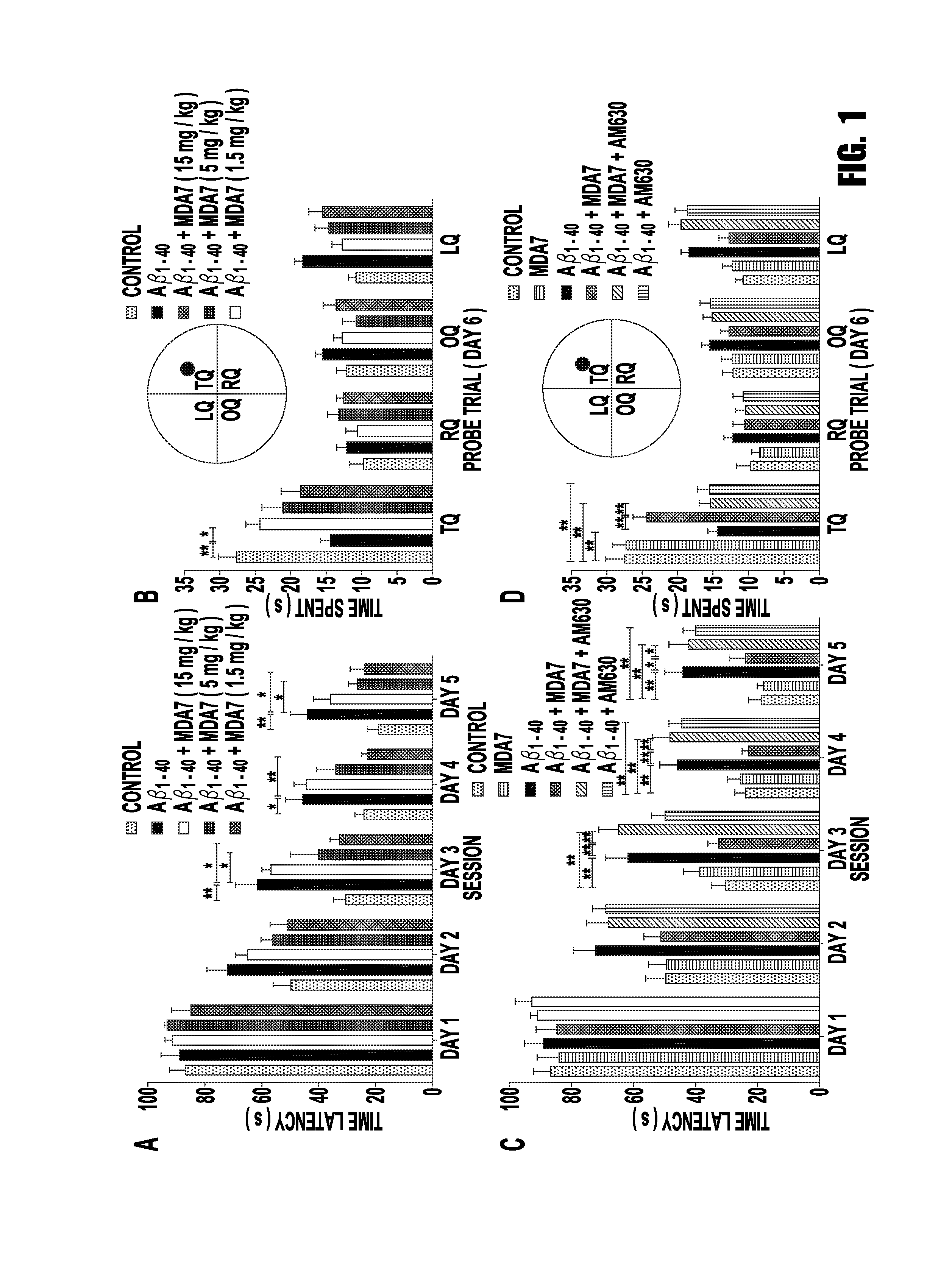

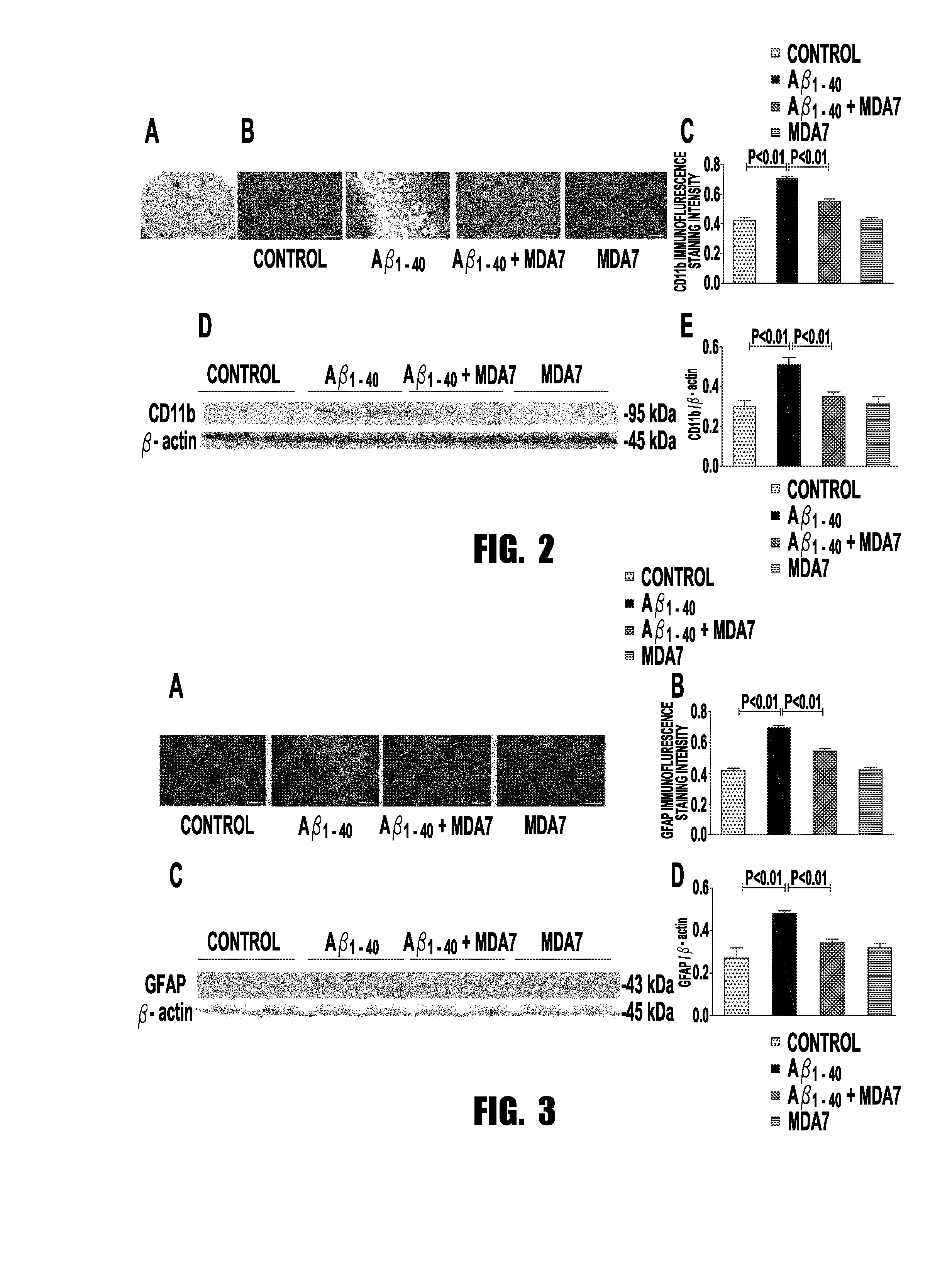

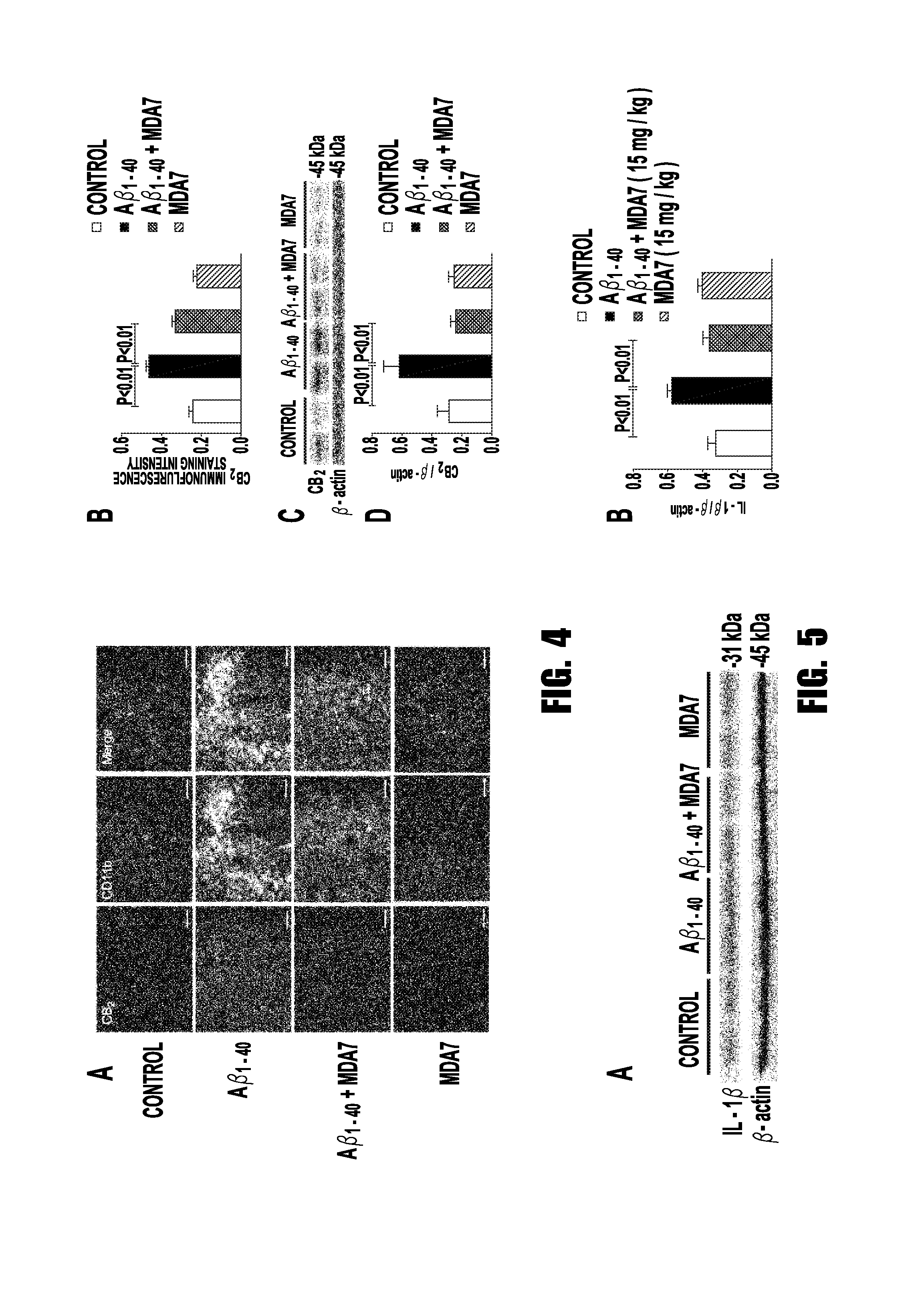

Neuroprotective cb2 receptor agonists

ActiveUS20200085811A1Lacks impairmentHigh expressionOrganic active ingredientsNervous disorderNeuro-degenerative diseasePharmaceutical medicine

A method of treating or preventing a neuroinflammatory and / or neurodegenerative disease in a subject by administering a pharmaceutically effective amount of a CB2 receptor agonist is described. The CB2 receptor agonist can be a compound according to formula I or a pharmaceutically acceptable salt thereof, with R1 and R2 as defined herein. Administration of the CB2 receptor agonist activates CB2 receptors in the microglia, can restore syntaptic plasticity, cognition, and memory in subjects having elevated levels of amyloid-βpeptide in the brain.

Owner:THE CLEVELAND CLINIC FOUND

Neuroprotective cb2 receptor agonists

A method of treating or preventing a neuroinflammatory and / or neurodegenerative disease in a subject by administering a pharmaceutically effective amount of a CB2 receptor agonist is described. The CB2 receptor agonist can be a compound according to formula I (structurally represented) or a pharmaceutically acceptable salt thereof, with R1 and R2 functional groups as defined herein. Administration of the CB2 receptor agonist activates CB2 receptors in the microglia, and can restore synaptic plasticity, cognition, and memory in subjects having elevated levels of amyloid-13 peptide in the brain.

Owner:THE CLEVELAND CLINIC FOUND

A method of processing embrittled high-chromium ferritic stainless steel plate

ActiveCN114086087BGuaranteed plasticityRestore plasticityFurnace typesHeat treatment furnacesHeat treatingEmbrittlement

The invention relates to a high-chromium ferritic stainless steel plate, in particular to an embrittled high-chromium ferritic stainless steel plate, and in particular to a method for processing the embrittled high-chromium ferritic stainless steel plate. In order to solve the problem that the plastic toughness of the high-chromium ferritic stainless steel plate is not up to standard caused by the precipitation of the brittle phase in an efficient and economical way, the present invention provides a method for treating the embrittled high-chromium ferritic stainless steel plate . The present invention obtains a high-chromium ferritic stainless steel plate with no brittle phase precipitation and no obvious coarsening of crystal grains by applying the heat treatment of rapid heating, short-term heat preservation and high-speed cooling to the embrittled high-chromium ferritic stainless steel plate , and then restore the plastic toughness of the ferritic stainless steel sheet after precipitation and embrittlement.

Owner:ZHONGBEI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com