A method of processing embrittled high-chromium ferritic stainless steel plate

A high-chromium ferrite and stainless steel plate technology, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problem of high-chromium ferritic stainless steel plate plastic toughness not up to standard, and achieve the effect of restoring plastic toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

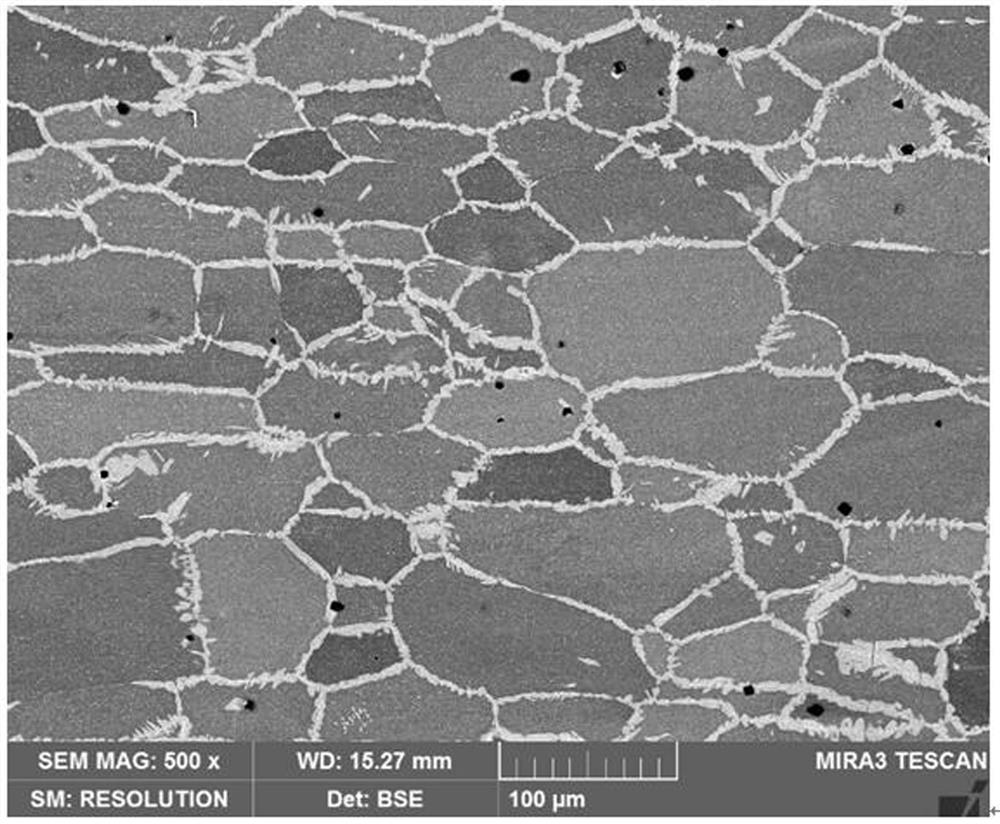

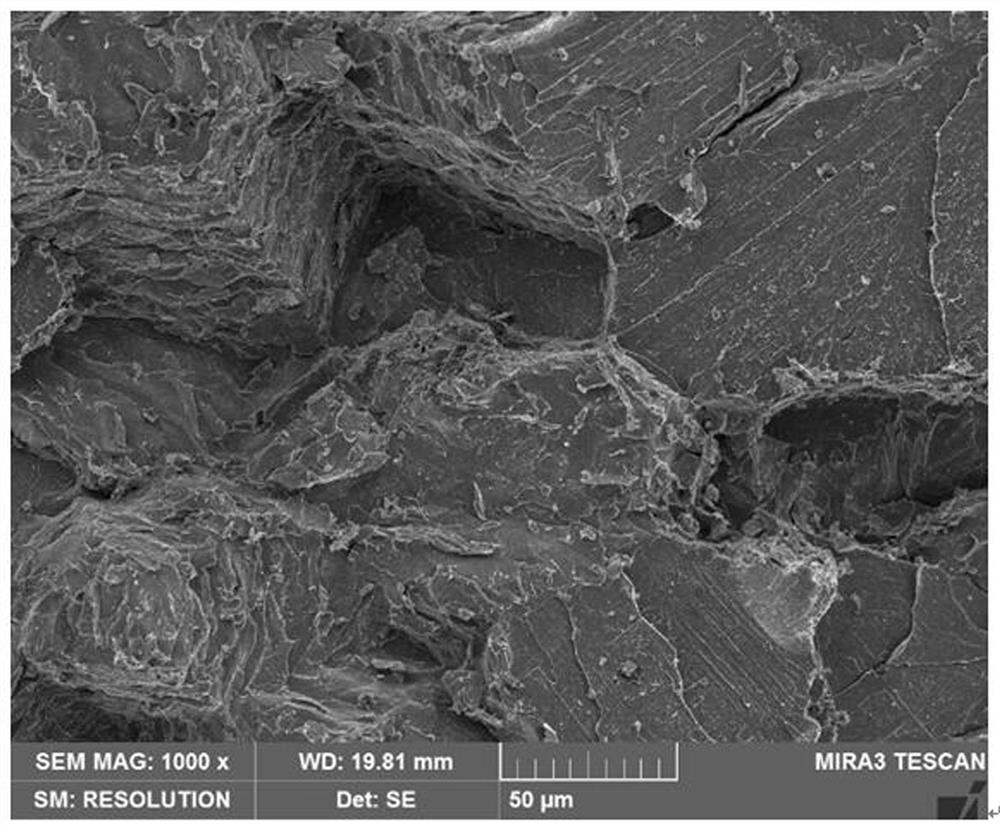

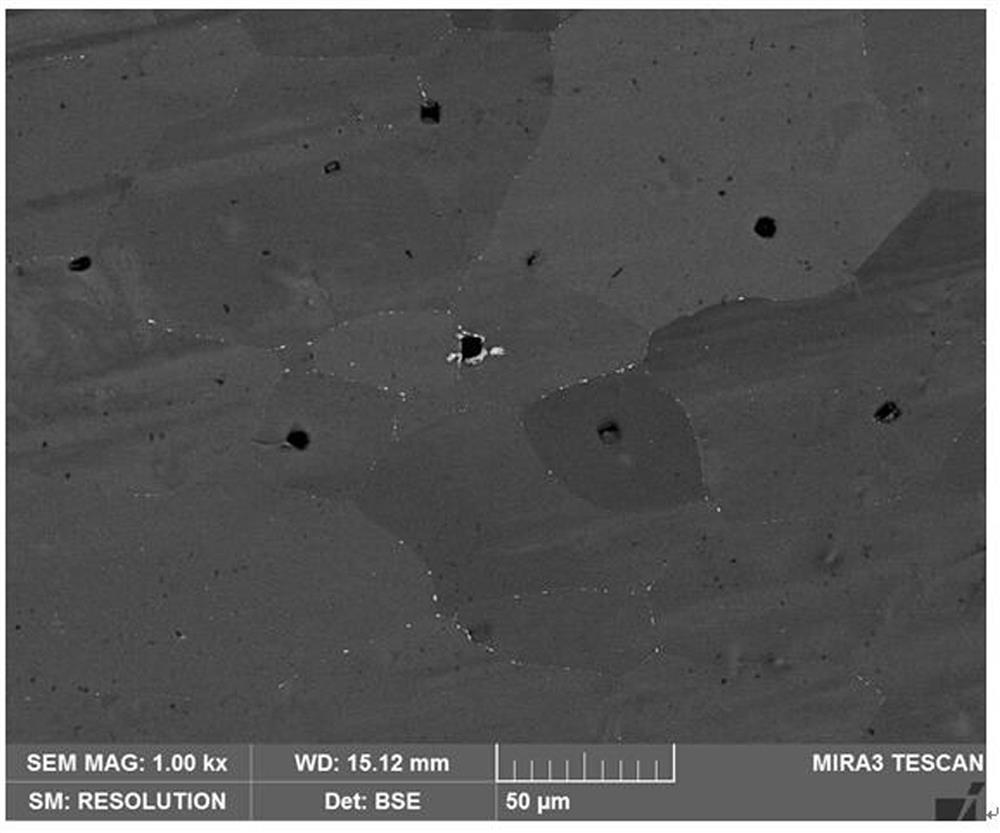

Image

Examples

Embodiment 1

[0017] Embodiment 1: a method for processing embrittled high-chromium ferritic stainless steel plate, wherein, when preparing high-chromium ferritic stainless steel plate, the weight percentage of each element of the smelting raw material is: 24.5% Cr, 4.5% Cr Mo, 3.8% Ni, 0.02% C, 0.005% N, 0.40% Nb, 0.02% Ti, 0.01% Al, 0.002% O, the rest are Fe and inevitable impurities, after embrittlement The thickness of the high-chromium ferritic stainless steel plate is 4.5mm. The embrittled high-chromium ferritic stainless steel plate is treated by heat treatment. The heat treatment steps are as follows:

[0018] 1) Heating of high chromium ferritic stainless steel plate

[0019] The embrittled high-chromium ferritic stainless steel plate is placed in a heating furnace and heated to 1050°C, and the heating rate is 40°C / min;

[0020] 2) Keep warm after heating

[0021] The holding time is 15min;

[0022] 3) Cool down after insulation

[0023] After the embrittlement of the high-chro...

Embodiment 2

[0027] Embodiment 2: a method for treating embrittled high-chromium ferritic stainless steel plate, wherein, when preparing high-chromium ferritic stainless steel plate, the weight percentage of each element in the smelting raw material is: 27.5% Cr, 3.5% Cr Mo, 3.1% Ni, 0.01% C, 0.008% N, 0.35% Nb, 0.017% Ti, 3.0% Al, 0.001% O, the rest are Fe and inevitable impurities, after embrittlement The thickness of the high-chromium ferritic stainless steel plate is 6.5mm. The embrittled high-chromium ferritic stainless steel plate is treated by heat treatment. The heat treatment steps are as follows:

[0028] 1) Heating of high chromium ferritic stainless steel plate

[0029] The embrittled high-chromium ferritic stainless steel plate is placed in a heating furnace and heated to 1100°C, and the heating rate is 90°C / min;

[0030] 2) Keep warm after heating

[0031] The holding time is 100min;

[0032] 3) Cool down after insulation

[0033] After the embrittlement of the high-chrom...

Embodiment 3

[0037] Embodiment 3: a method for processing embrittled high-chromium ferritic stainless steel plate, wherein, when preparing high-chromium ferritic stainless steel plate, the weight percentage of each element in the smelting raw material is: 29.7% Cr, 3.0% Cr Mo, 2.1% Ni, 0.01% C, 0.003% N, 0.53% Nb, 0.02% Ti, 0.1% Al, 0.003% O, the rest are Fe and inevitable impurities, after embrittlement The thickness of the high-chromium ferritic stainless steel plate is 0.5mm. The embrittled high-chromium ferritic stainless steel plate is treated by heat treatment. The heat treatment steps are as follows:

[0038] 1) High chromium ferritic stainless steel plate heating

[0039] The embrittled high-chromium ferritic stainless steel plate is placed in a heating furnace and heated to 1150°C, and the heating rate is 100°C / min;

[0040] 2) Keep warm after heating

[0041] The holding time is 5min;

[0042] 3) Cool down after insulation

[0043] After the embrittlement of the high-chromium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com