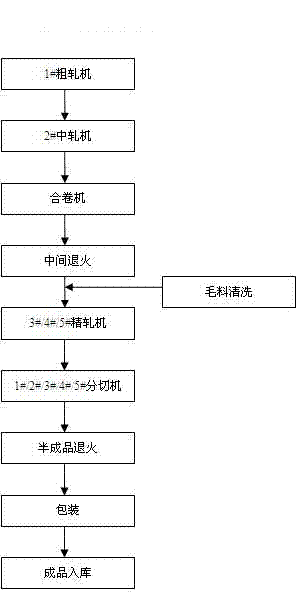

Production process for rolling light gauge aluminum foil

A kind of double zero aluminum foil, production process technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0009] The first step is rough rolling. The aluminum billet coil is put into the rough rolling mill and lubricated with rolling oil. The rough rolling pass is 0.3mm→0.14mm→0.07mm→0.038mm m, and the pass reduction rate is in order 53%, 51%, 55.8%, control parameters: first pass, 800-1000m / min, rolling pressure 1100-1500kN, pre-tension stress 30N / mm 2 , the post-tension stress is 25-45N / mm 2 , the oil temperature is 30-40°C, the oil pressure is 5.5-6.0Pa; the second pass, 1100-1200m / min, the rolling pressure is 1300-1700kN, and the pre-tension stress is 30N / mm 2 , the post-tension stress is 25-45 / mm 2 , the oil temperature and oil pressure remain unchanged, the third pass, the rolling speed is 1300-1400m / min, the rolling pressure is 1300-1700kN, and the pre-tension stress is 35N / mm 2 , the post-tension stress is 40-50N / mm 2 , the oil temperature and oil pressure remain unchanged.

[0010] The second step is intermediate rolling. The aluminum foil wool after rough rolling is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com