Normal-temperature regeneration method for waste rubber

A waste rubber, normal temperature technology, applied in the field of waste rubber regeneration at room temperature, can solve the problems of waste gas, secondary pollution of the environment, long process time, etc., and achieve the effect of reducing energy consumption and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

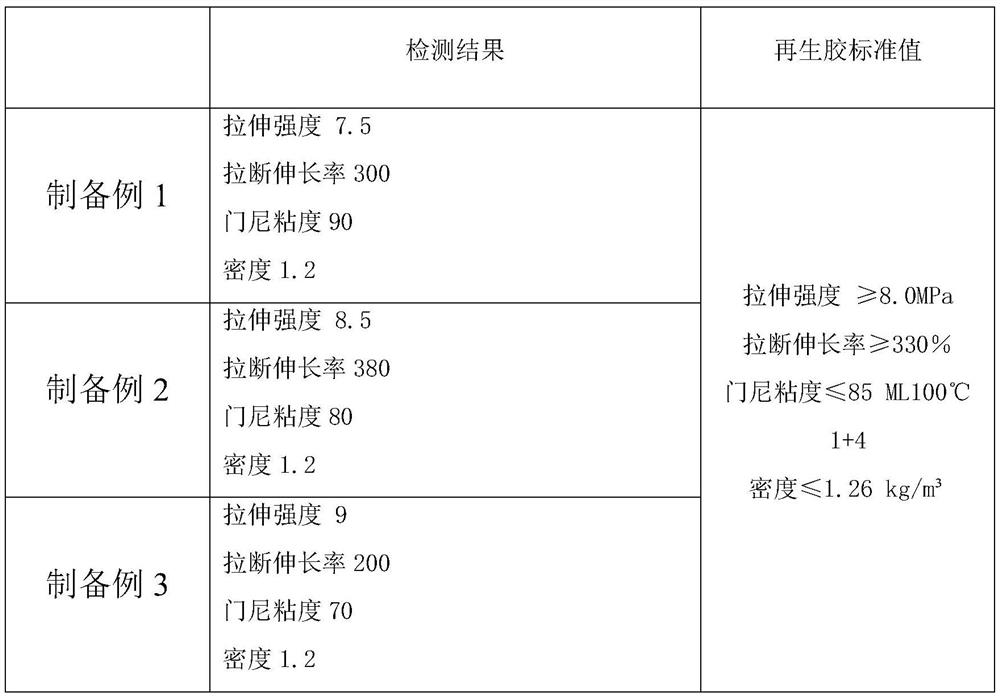

preparation example 1

[0105] In this preparation example, 20-mesh rubber powder is firstly obtained, and then the rubber powder is firstly refined by a refiner to form a mesh product A. Then, the product A is added to the agitator, and the reducing agent is put in at the same time, and the mixture is mixed at a speed of 500 revolutions per minute. Stirring for 4 minutes afforded Product B. Then, product B was refined 3 times by a refiner to obtain product C, and then product C was put into a kneader, and an initiator was added, kneaded for 8 minutes and discharged to obtain product D. Finally, the product D is refined 4 times through a refiner to obtain the finished reclaimed rubber.

[0106] Wherein, the components of the reducing agent in this preparation example consist of: sodium hydroxide: 1 part; iodine: 3 parts; ferrous chloride: 10 parts; carboxylic acid: 2 parts; zinc naphthenate: 2 parts; Oil: 10 parts; silane coupling agent: 1 part. The composition of the initiator is as follows: merca...

preparation example 2

[0109] In this preparation example, 26-mesh rubber powder is firstly obtained, and then the rubber powder is firstly refined by a refiner to form a mesh product A. Then, the product A is added to the mixer, and the reducing agent is put in at the same time, and the speed is 550 revolutions per minute. Stirring for 4 minutes afforded Product B. Then, product B was refined 3 times by a refiner to obtain product C, and then product C was put into a kneader, and an initiator was added, kneaded for 8 minutes and discharged to obtain product D. Finally, the product D is refined 4 times through a refiner to obtain the finished reclaimed rubber.

[0110] Wherein, the components of the reducing agent in this preparation example consist of: sodium hydroxide: 2 parts; iodine: 2 parts; ferrous chloride: 10 parts; carboxylic acid: 2 parts; zinc naphthenate: 2 parts; Oil: 5 parts. The composition of the initiator is: mercaptobenzothiazole: 1 part; stearic acid: 2 parts; disproportionated ...

preparation example 3

[0113] In this preparation example, 40-mesh rubber powder is firstly obtained, and then the rubber powder is firstly refined by a refiner to form a mesh product A. Then, the product A is added to the agitator, and the reducing agent is put in at the same time, and the mixture is mixed at a speed of 600 rpm. Stirring for 3 minutes gave Product B. Then, product B was refined 3 times by a refiner to obtain product C, and then product C was put into a kneader, and an initiator was added, kneaded for 5 minutes, and then discharged to obtain product D. Finally, the product D is refined three times through a refiner to obtain the finished reclaimed rubber.

[0114] Wherein, the components of the reducing agent in this preparation example consist of: sodium hydroxide: 2 parts; iodine: 1 part; ferrous chloride: 10 parts; carboxylic acid: 2 parts; zinc naphthenate: 2 parts; Oil: 5 parts. The composition of the initiator is as follows: thiol benzothiazole: 1 part; stearic acid: 1 part;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com