Production method for sulfonic acid curing agent used for casting

A production method and curing agent technology, applied in sulfonic acid preparation, casting molding equipment, casting molds, etc., can solve the problems of unsatisfactory production efficiency and environmental protection requirements, long dehydration time, etc., achieve broad market application prospects and improve production efficiency , The effect of shortening the production man-hour

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

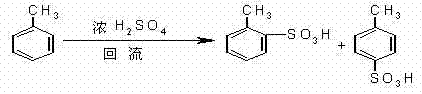

Method used

Image

Examples

Embodiment 1

[0020] Embodiment one: a kind of production method of casting sulfonic acid curing agent is characterized in that: it comprises the following steps

[0021] a. Close the bottom valve of the kettle, turn on the vacuum pump, and inhale 5% to 8% of toluene;

[0022] b. Close the vacuum valve, open the vent valve, open the sulfuric acid feeding valve, start the mixer, and add 30% to 35% of concentrated sulfuric acid;

[0023] c. Open the steam valve, maintain the steam pressure at 0.2-0.3MPa, raise the temperature to 100-118°C within 40-50 minutes, and keep the temperature for 90 minutes;

[0024] d. Open the cooling water valve, lower the temperature to 60°C, and slowly add 20% to 30% of organic alcohol through the high-level tank;

[0025] e. After adding the organic alcohol, slowly add 30% to 40% of water through the high tank;

[0026] f. After adding water, cool down to 45°C, add 1% hydrogen peroxide aqueous solution, stir for 20 minutes and take samples for inspection.

...

Embodiment 2

[0028] Embodiment two: a kind of production method of sulfonic acid solidifying agent for foundry, it comprises the following steps: a. close the bottom valve of the tank, open the vacuum pump, inhale 5%~8% of toluene;

[0029] b. Close the vacuum valve, open the vent valve, open the sulfuric acid feeding valve, start the mixer, and add 35% to 40% of concentrated sulfuric acid;

[0030] c. Open the steam valve, maintain the steam pressure at 0.2-0.3MPa, and raise the temperature to 100°C-118°C within 40-50 minutes; keep warm for 90 minutes;

[0031] d. Open the cooling water valve, lower the temperature to 60°C, and slowly add 20% to 30% of organic alcohol through the high-level tank;

[0032] e. After adding the organic alcohol, slowly add 25% to 35% of water through the high tank;

[0033] f. After adding water, cool down to 45°C, add 1% hydrogen peroxide aqueous solution, stir for 20 minutes and take samples for inspection.

[0034] The sulfonic acid curing agent is suita...

Embodiment 3

[0035] Embodiment three: a kind of production method of casting sulfonic acid curing agent, it comprises the following steps: a. close the bottom valve of the tank, open the vacuum pump, inhale 5%~8% of toluene;

[0036] b. Close the vacuum valve, open the vent valve, open the sulfuric acid feeding valve, start the mixer, and add 40% to 50% of concentrated sulfuric acid;

[0037] c. Open the steam valve, maintain the steam pressure at 0.2-0.3MPa, raise the temperature to 100-118°C within 40-50 minutes, and keep the temperature for 90 minutes;

[0038] d. Open the cooling water valve, lower the temperature to 60°C, and slowly add 20% to 30% of organic alcohol through the high-level tank;

[0039] e. After adding the organic alcohol, slowly add 15% to 25% of water through the high tank;

[0040] f. After adding water, cool down to 45°C, add 1% hydrogen peroxide aqueous solution, stir for 20 minutes and take samples for inspection.

[0041] The sulfonic acid curing agent is su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com