Radiation cooling film and preparation method and application thereof

A technology of thin films and ceramic particles, applied in the direction of coatings, etc., can solve the problems of complex preparation requirements, and achieve the effects of strong universality, improved reflectivity, and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Stir and mix 200g of spherical alumina powder particles with a particle size (average particle size, the same below) of 2 microns and 220g of PDMS solution evenly, add 22g of tetraethyl orthosilicate curing agent to the above-mentioned curing precursor solution, and fully stir to mix Uniform; put the mixed solution into a vacuum drying oven to evacuate for 30 minutes, then slowly ventilate into the atmosphere until the air pressure is equal to the external pressure, and take out the mixed solution.

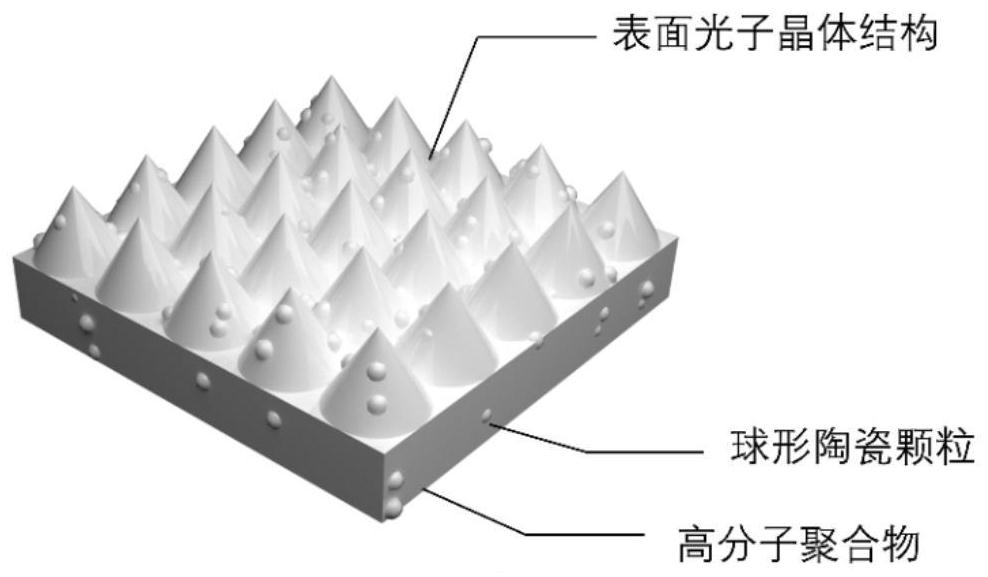

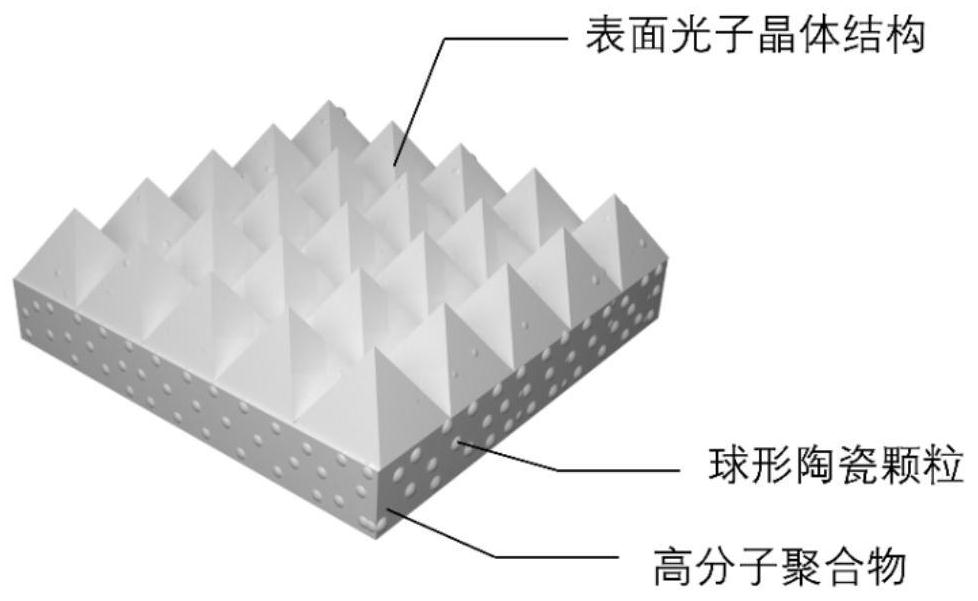

[0060] Put the multi-etched silicon wafer template for photolithography, dry etching, and wet etching on the glue homogenizer. The surface morphology of the template is composed of an array of pyramidal grooves with a width of 8 microns and a depth of 6 microns with an interval of 2 microns. The array of pyramidal grooves can be as figure 1 As shown; the mixed solution is slowly poured onto the template and left to stand for 20 minutes, then adjust the speed of the homogen...

Embodiment 2

[0064] Stir and mix 30g of zinc oxide powder particles with a particle size of 5 microns and 30g of PTFE solution evenly, add 3g of dicumyl peroxide curing agent to the above-mentioned curing precursor solution, stir fully to make it evenly mixed; put the mixed solution into Vacuum in a vacuum drying oven for 30 minutes, then slowly ventilate into the atmosphere until the air pressure is equal to that of the outside world, and take out the mixed solution.

[0065] Put the nickel-plated stainless steel template after ultra-precision processing on the glue homogenizer. The surface of the template is composed of a pyramid groove array with a width of 2 microns, a depth of 6 microns, and an interval of 3 microns; the mixed solution is slowly poured onto the template, and static Leave it for 5 minutes, then adjust the speed of the homogenizer from 0 to 500RPM for 10s, keep the speed of 500RPM for 30s, and then stop.

[0066] The template was removed and placed on a hot plate. The t...

Embodiment 3

[0068] Add 8g of spherical magnesia particles with a particle size of 0.5 microns and 16g of angular zirconia powder particles with a particle size of 2 microns to 30g of PDMS solution and stir to mix evenly; add 2g of dicumyl peroxide curing agent and continue stirring; mix the mixture Put it into a vacuum drying oven to evacuate and keep it for 60 minutes, then slowly ventilate into the atmosphere until the air pressure is equal to that of the outside world, and take out the mixed solution.

[0069] The IPS template after nanoimprinting was placed on a homogenizer. The surface morphology of the template was composed of an array of elliptical cylindrical grooves with a width of 15 microns, a depth of 10 microns, and an interval of 5 microns; the mixed solution was slowly poured onto the template and left to stand. Leave it for 5 minutes, then adjust the speed of the homogenizer from 0 to 750RPM for 10s, keep the speed of 750RPM for 15s, and then stop.

[0070]Remove the templ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com