Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "Evenly distributed around the circumference" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

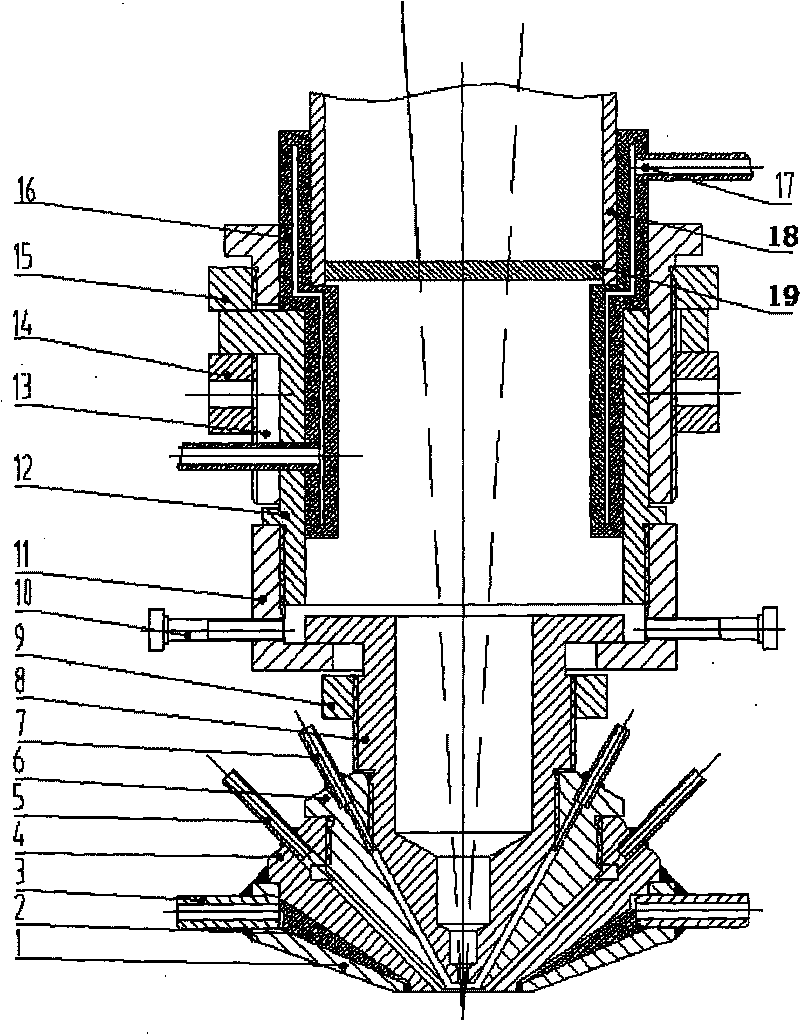

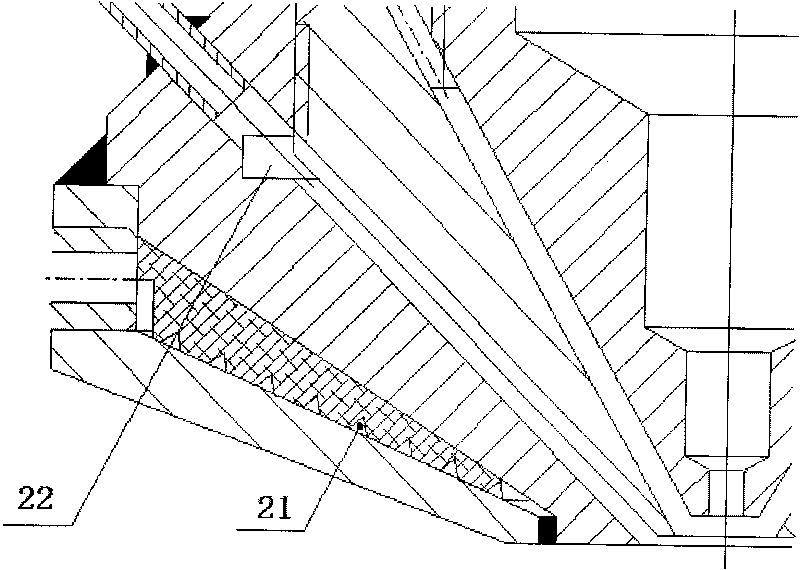

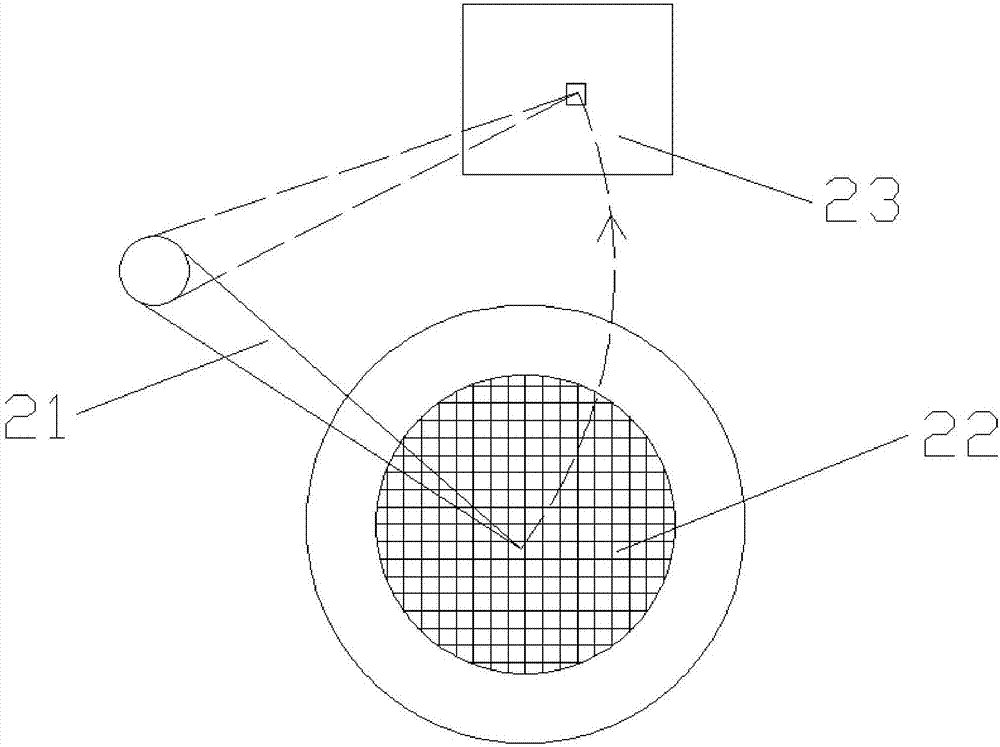

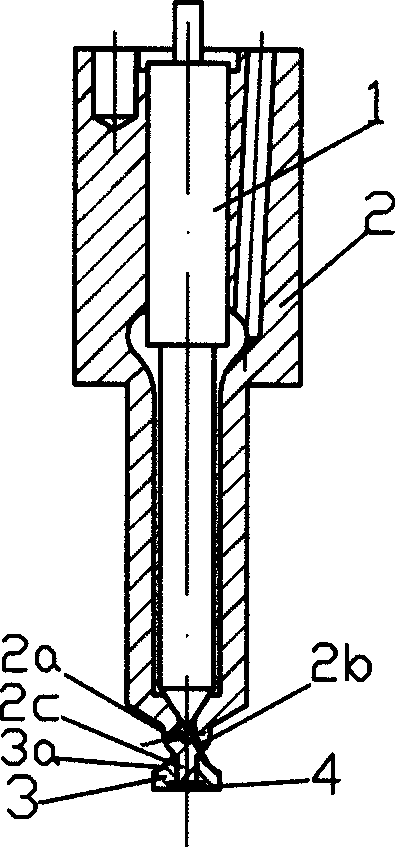

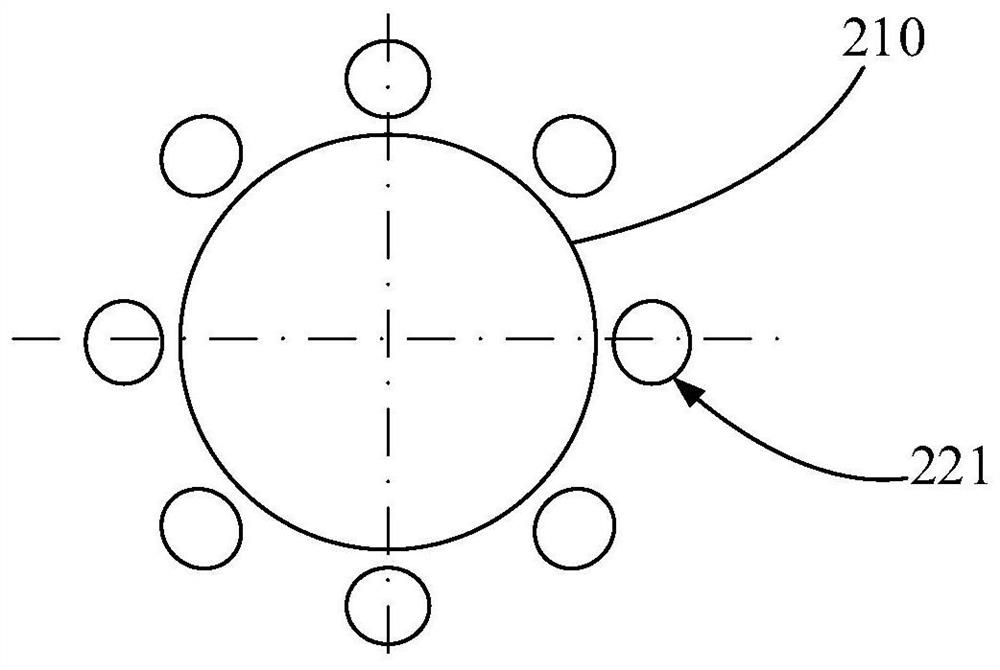

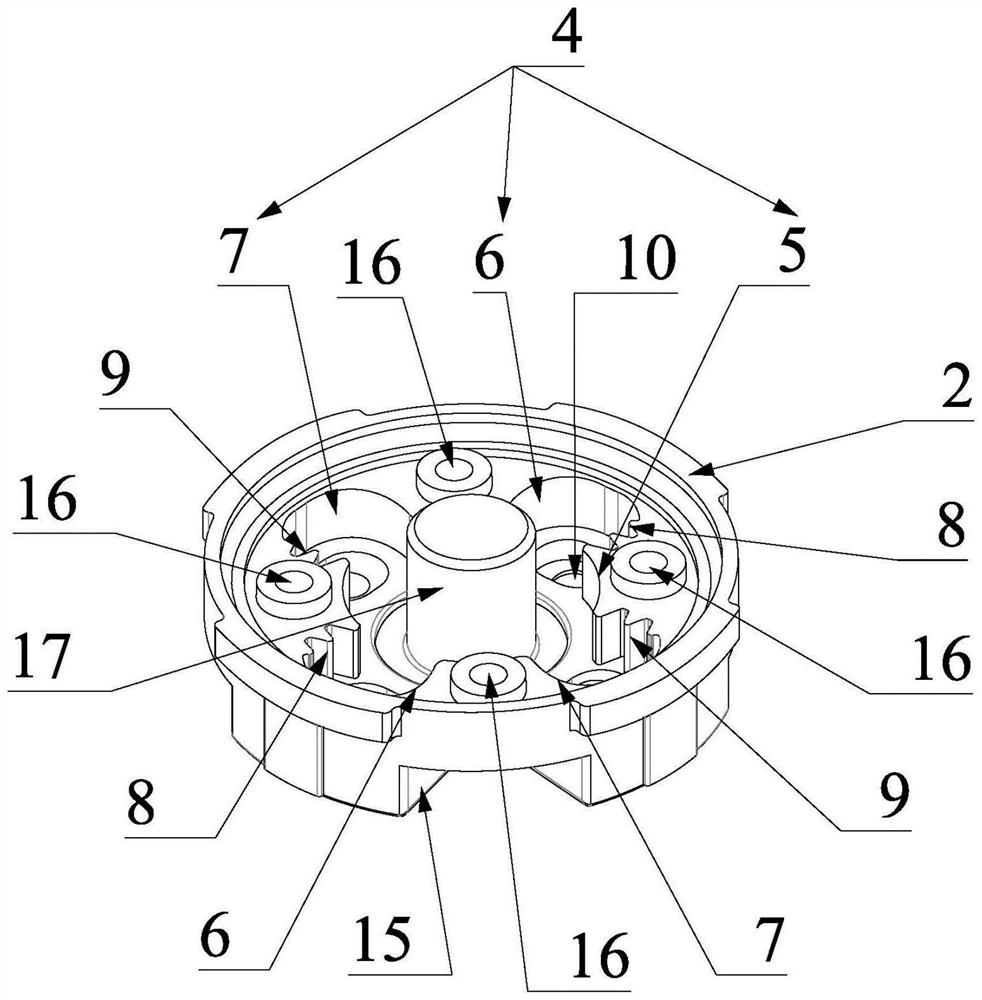

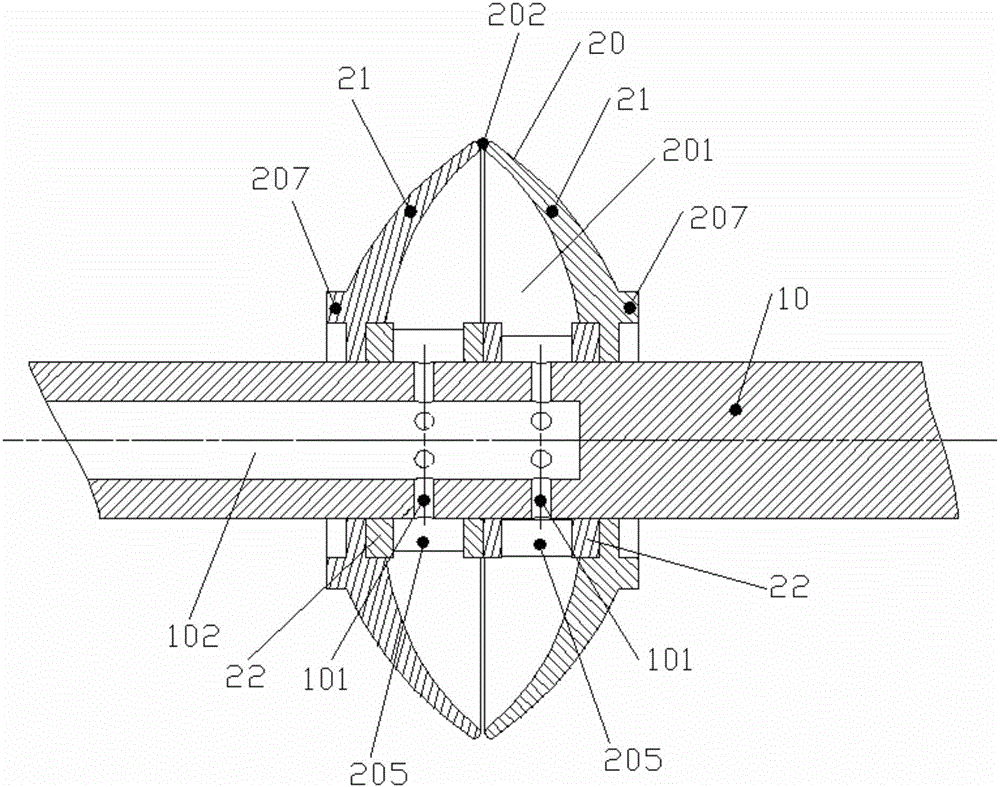

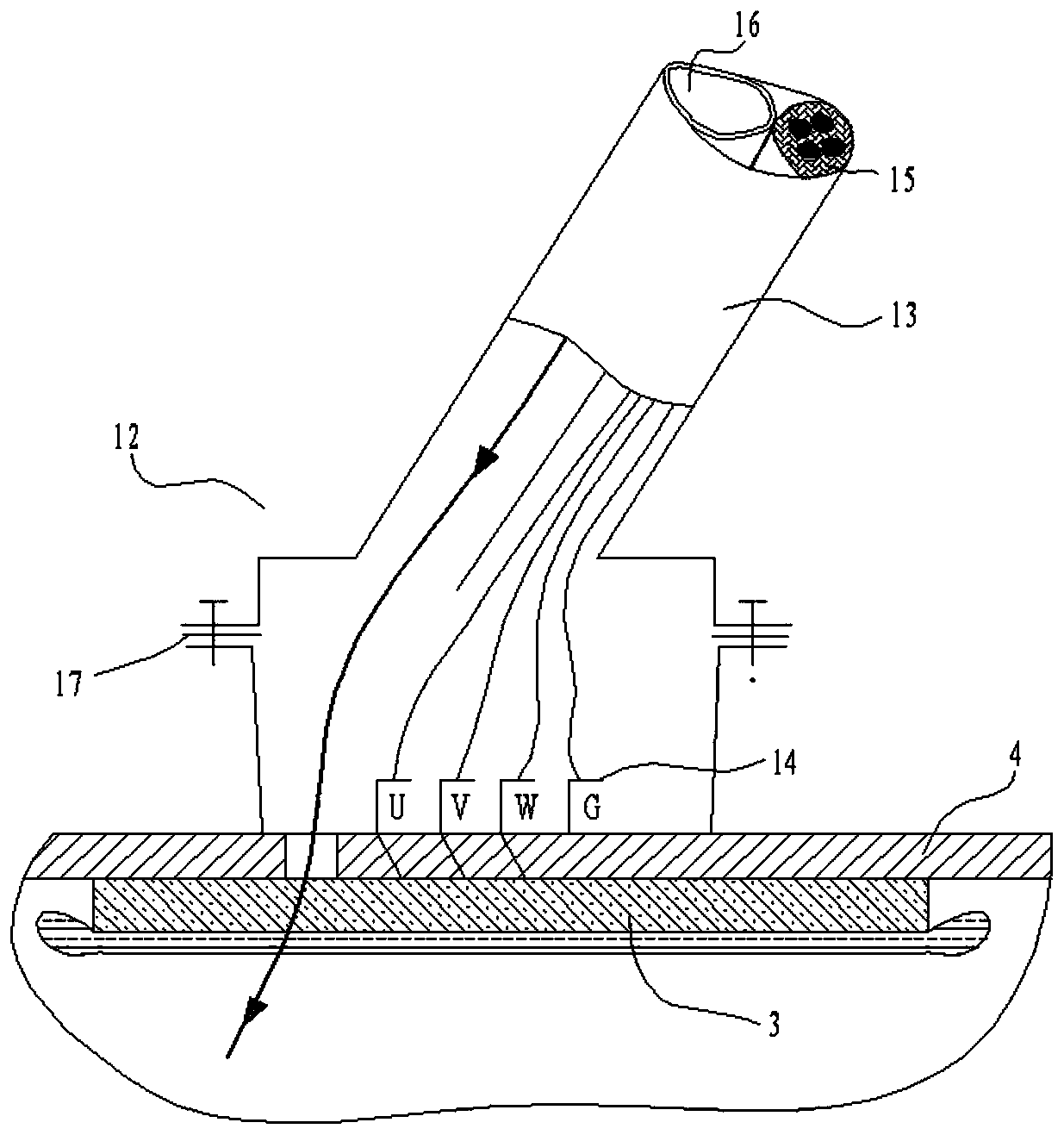

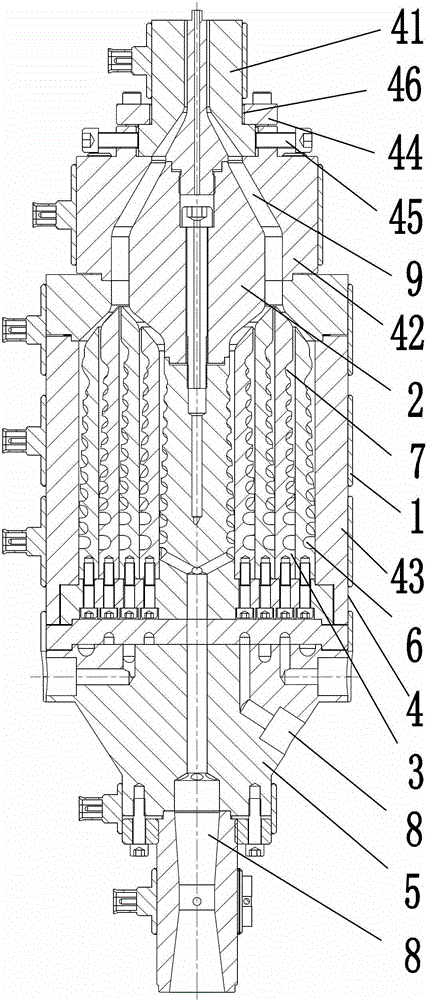

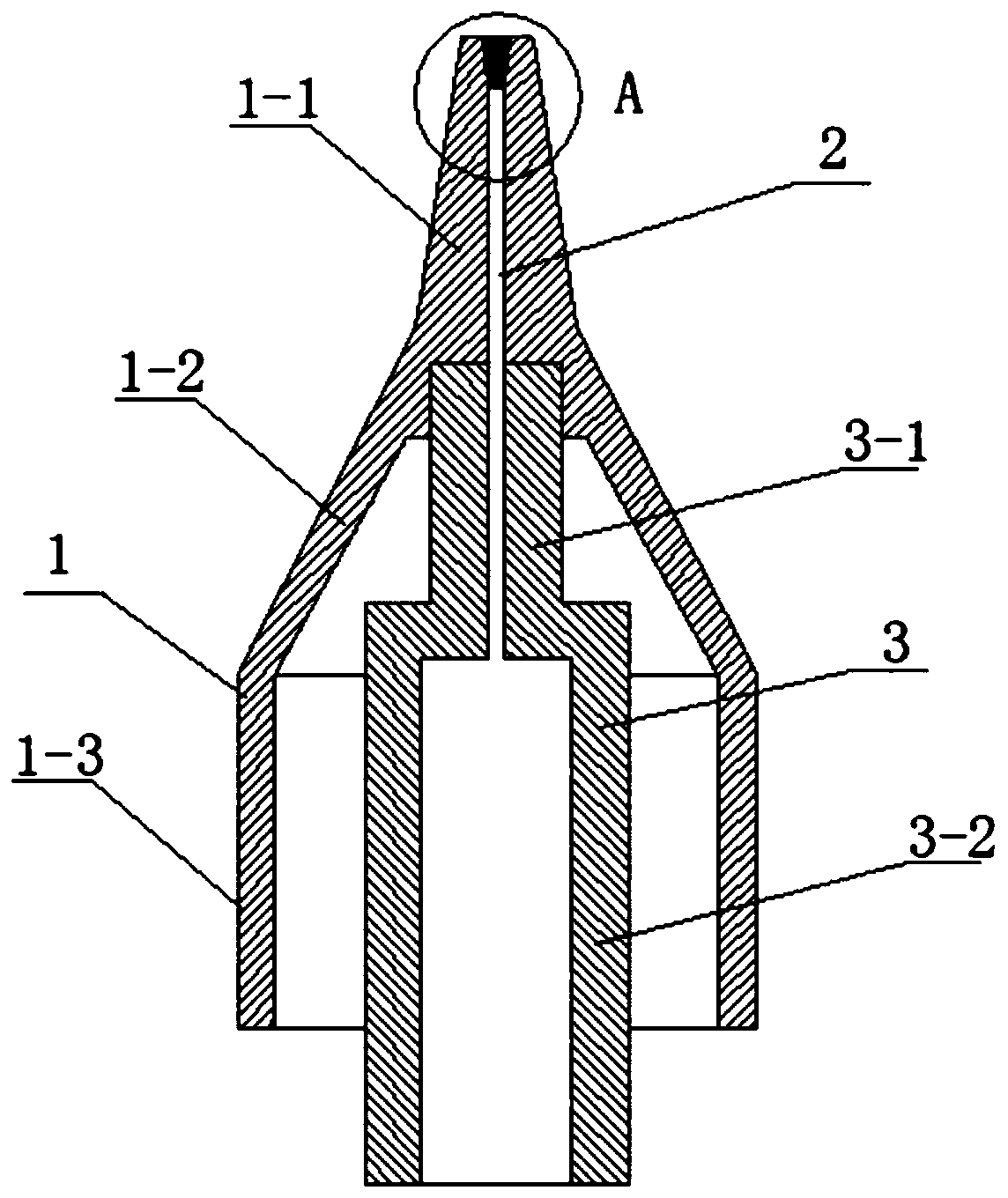

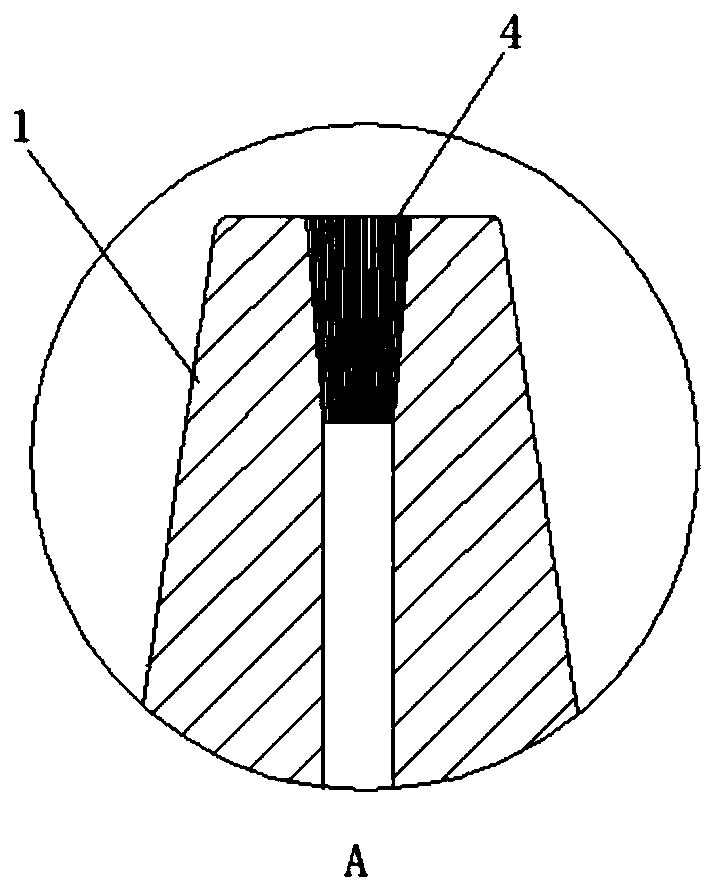

Adjustable laser coaxial powder feeding nozzle

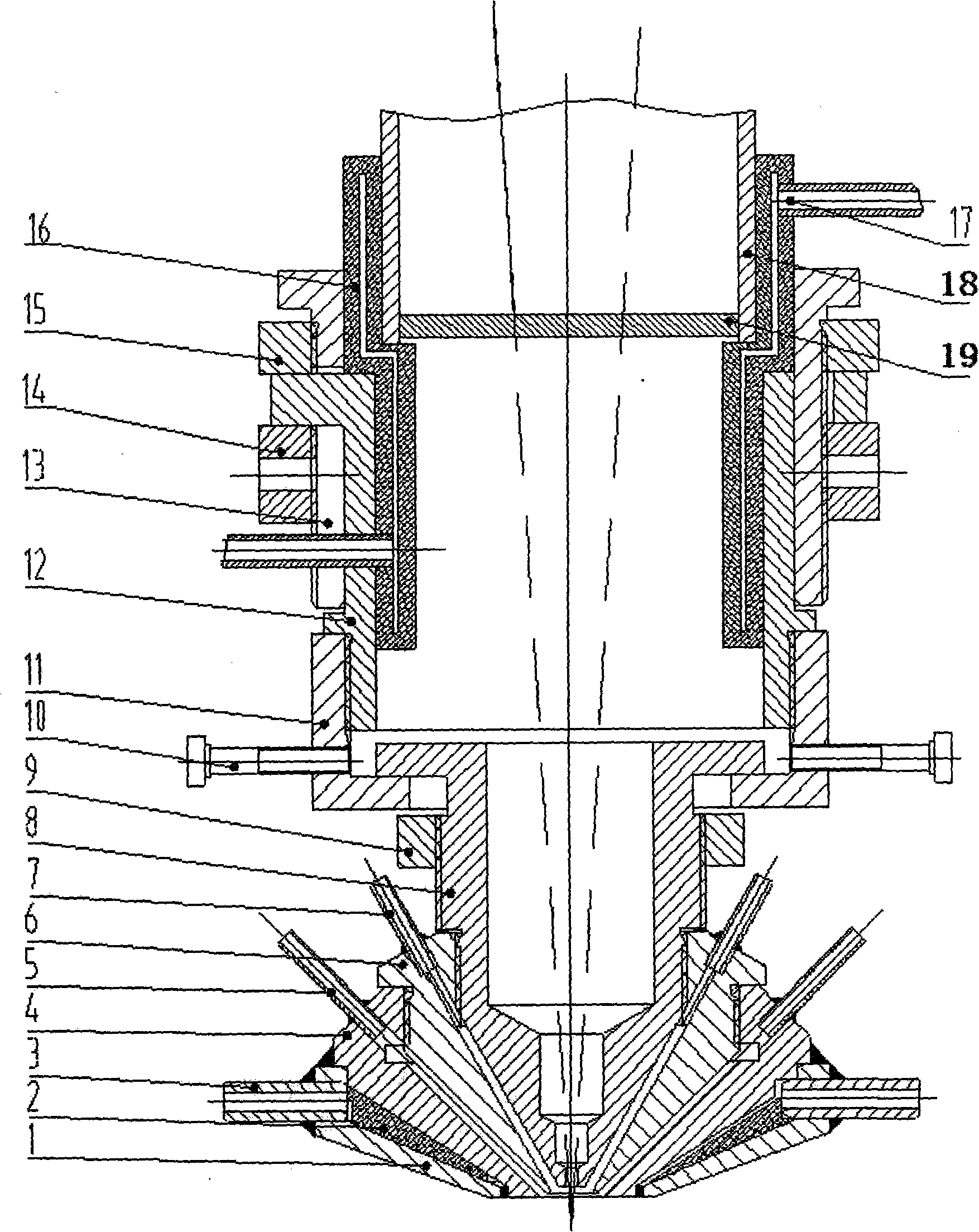

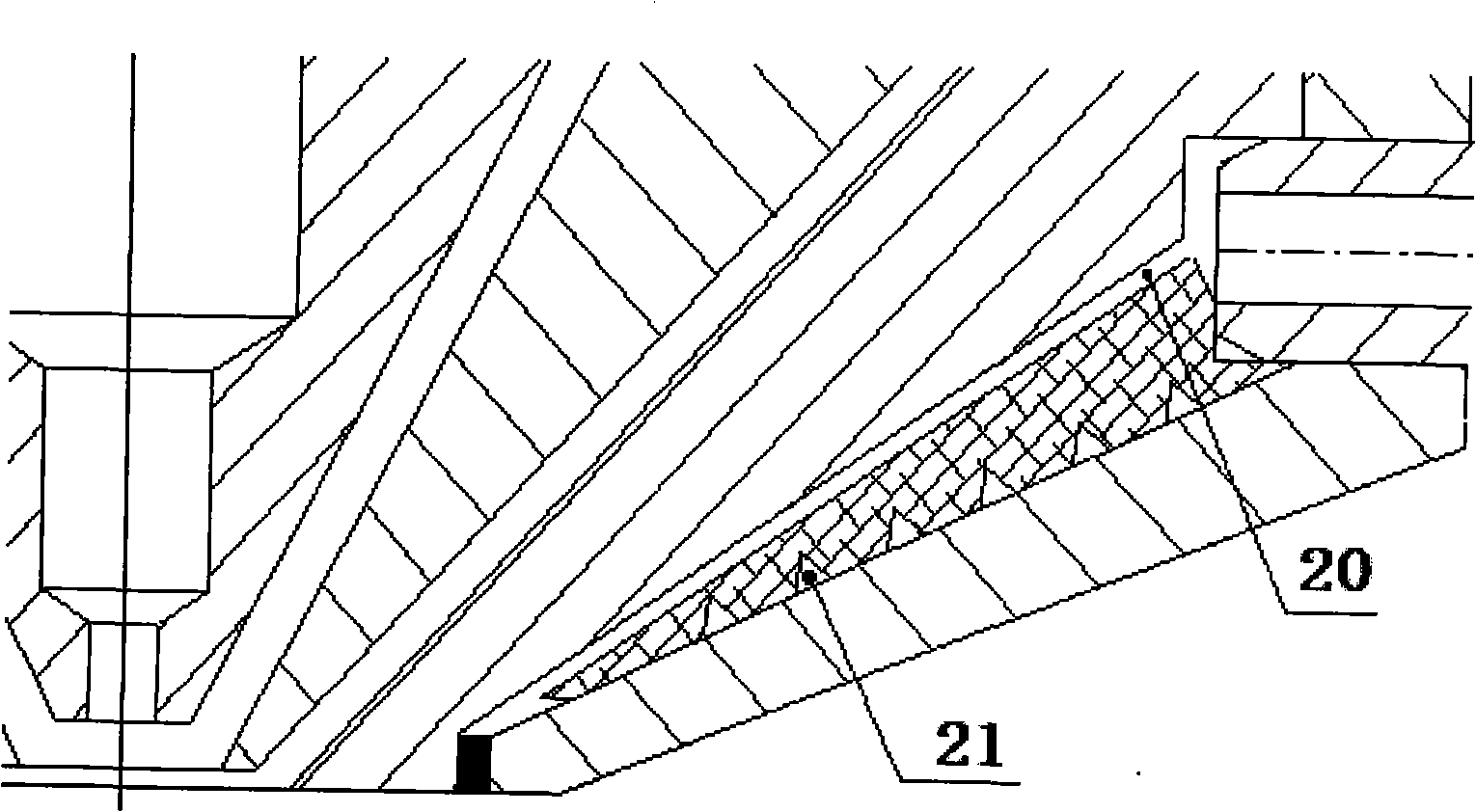

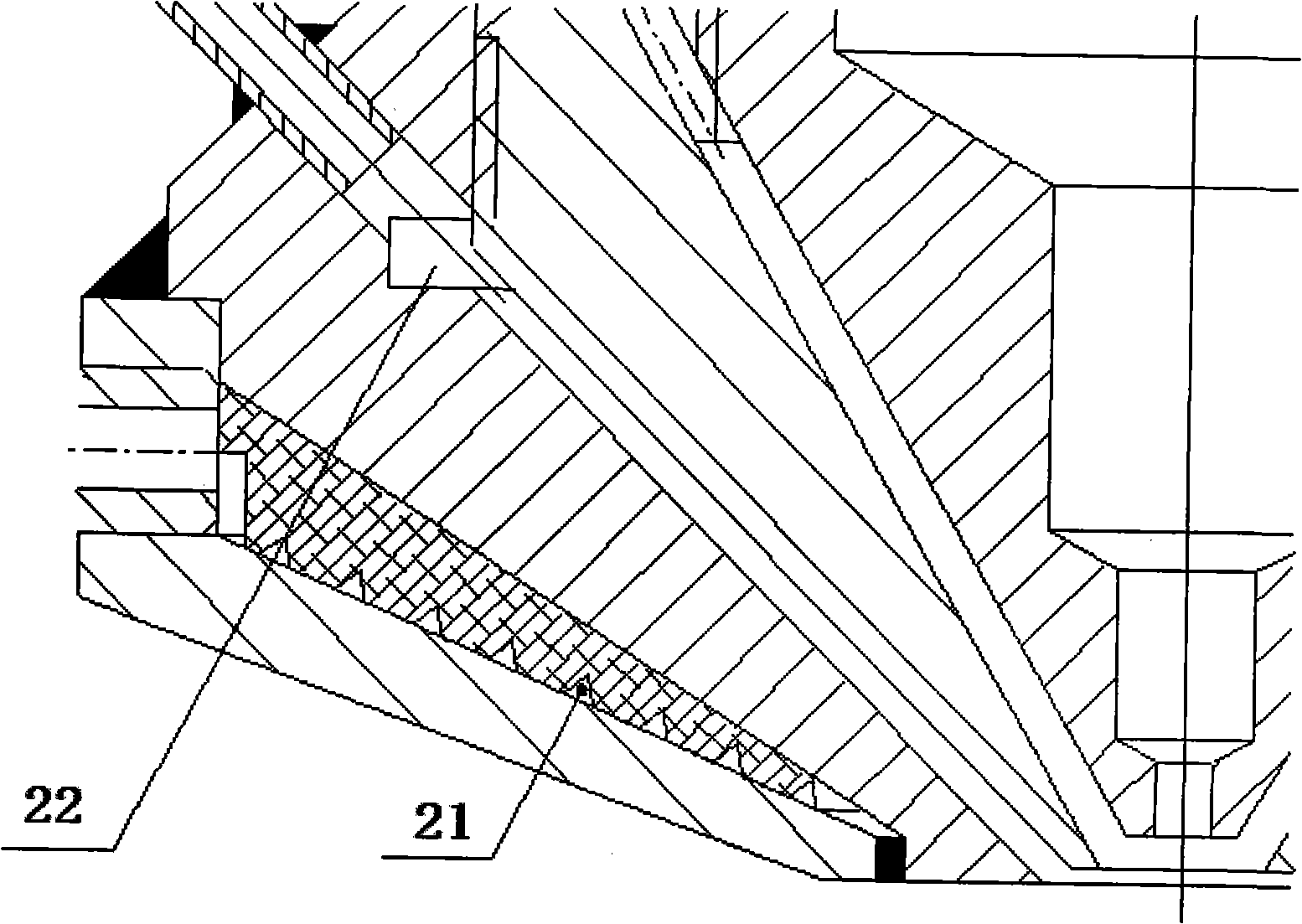

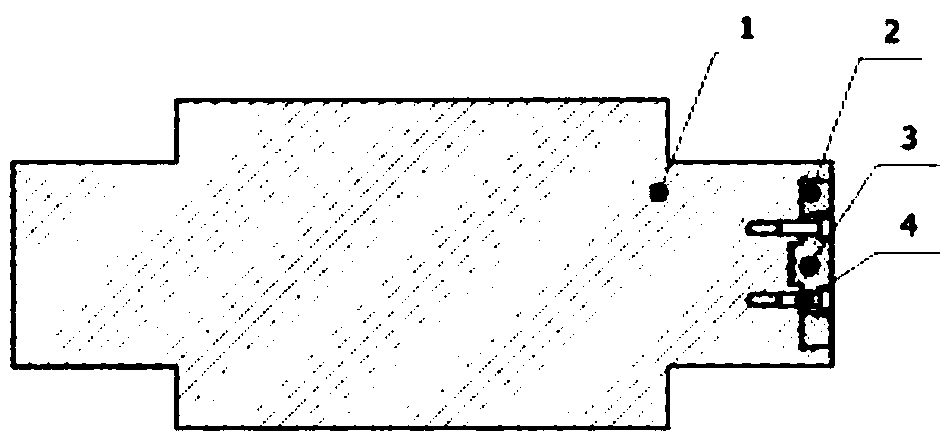

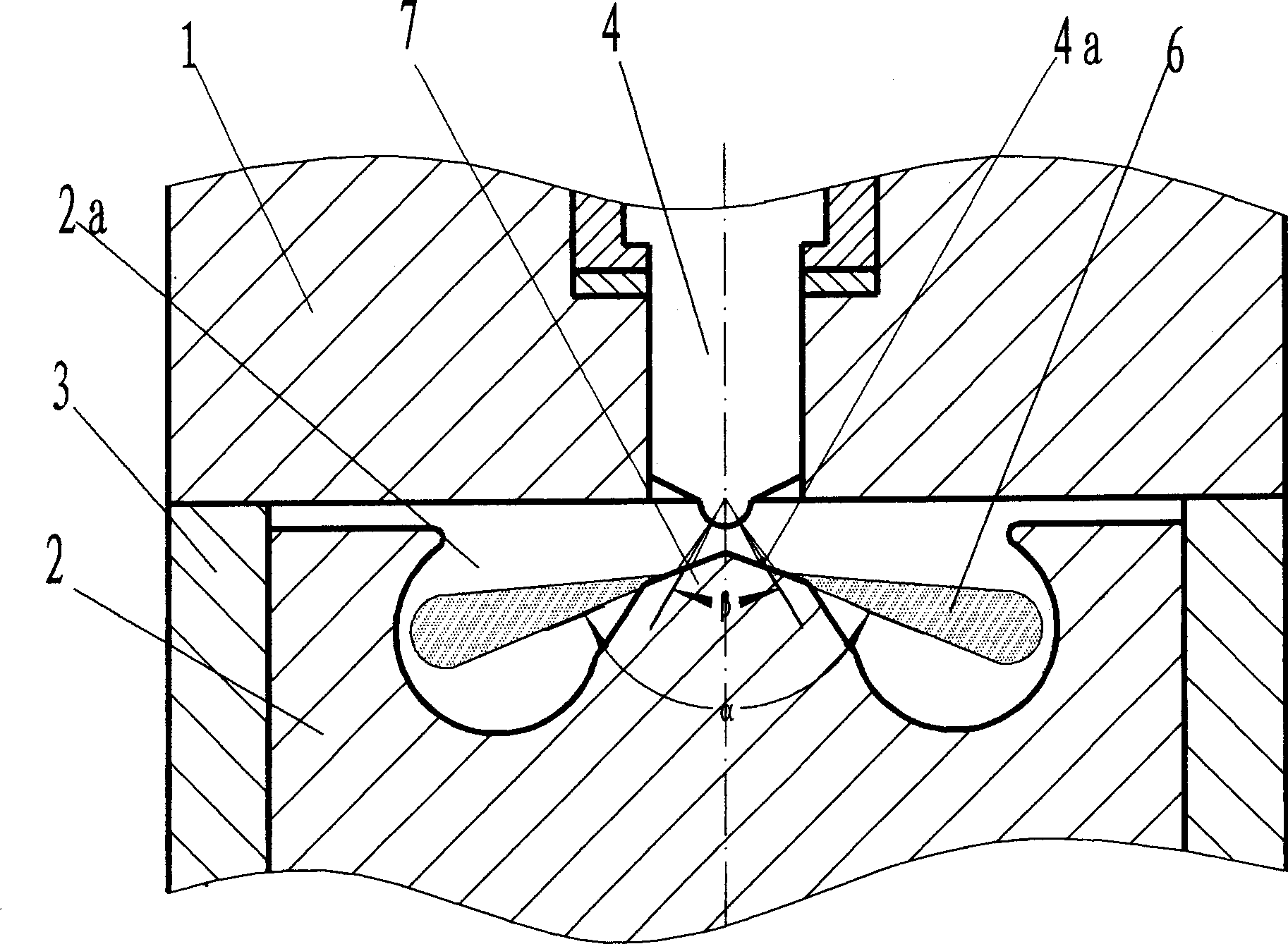

The invention discloses an adjustable coaxial laser nozzle for sending powder, comprising a laser head, a protection lens, a water-cooling sleeve for the protection lens and a column laser cavity arranged on the upper part, a coaxial conical laser cavity which is formed by the inner layer of a laser sleeve and arranged in the middle part, wherein a powder cavity, a secondary external protective cavity and an external water-cooling cavity are arranged on the lower part of the external part of the laser sleeve; the powder cavity is formed between the laser sleeve and a power cavity sleeve screwed together; the secondary external protective cavity is formed between the powder cavity and a protective air casing screwed together; the powder cavity and the protective sir casing are screwed together and adjustable between 1mm to 3mm; 4 to 6 power transmitting pipes and 4 to 6 air tubes are respectively positioned around the top parts of the cones of the powder cavity and the protective air cavity. The adjustable coaxial laser nozzle for sending powder has the advantages that the focus length of the focus lamp fit for the coaxial powder-sending nozzle is between 100mm to 300mm, which ensures convenient assembly and disassembly, even velocity, flexible adjustment of the powder converge diameter, convenient changeable lower coaxial conical parts (the powder cavity, the air casing and the water cavity).

Owner:XI AN JIAOTONG UNIV

Marble pillar cutter

InactiveCN104890126ACompact structureReasonable designWorking accessoriesGrinding machinesEngineeringMachine tool

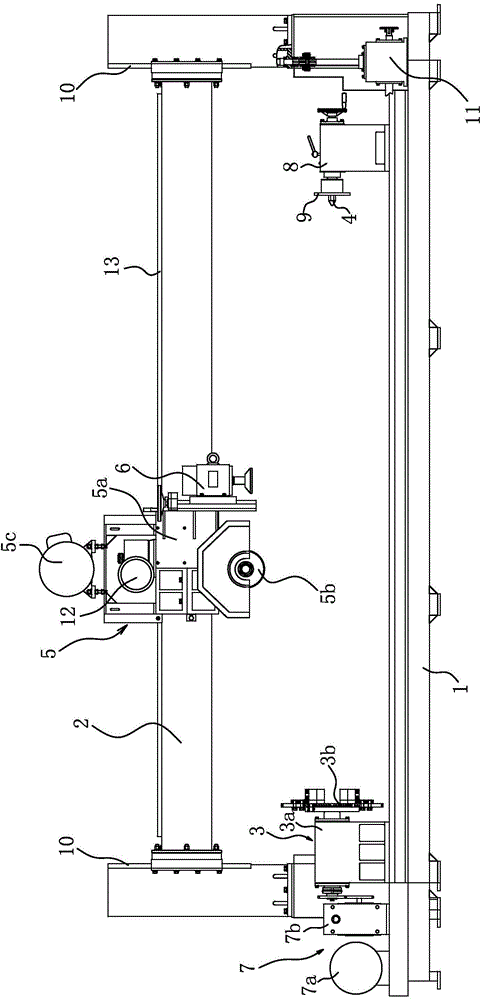

The invention provides a marble pillar cutter, belongs to the technical field of a machine tool, and solves the problems that an existing natural stone marble pillar can be manually processed. The marble pillar cutter comprises a frame and a cross beam, wherein the frame is fixed with a hand-piece component with a chuck and a first drive device capable of driving the chuck to rotate, and a central spindle of the chuck is horizontally arranged; the frame is provided with an ejector pin which is relative to the chuck, the cross beam is located above the hand-piece component, the two ends of the cross beam and the frame are connected with vertically arranged first guide rails and the frame is provided with a second driving device capable of driving the cross beam to do a lifting motion; the cross beam is provided with a cutting blade mounting disc and a power head device capable of moving horizontally along the cross beam. According to the marble pillar cutter provided by the invention, a channel of a glossy marble pillar can be automatically processed, and outer flanks can be polished; furthermore, by processing the marble pillar processed by the marble pillar cutter provided by the invention, the processing efficiency can be significantly improved, the skill requirements on workers can be reduced, and the production cost can be reduced.

Owner:ZHEJIANG CHANGZHI MACHINERY

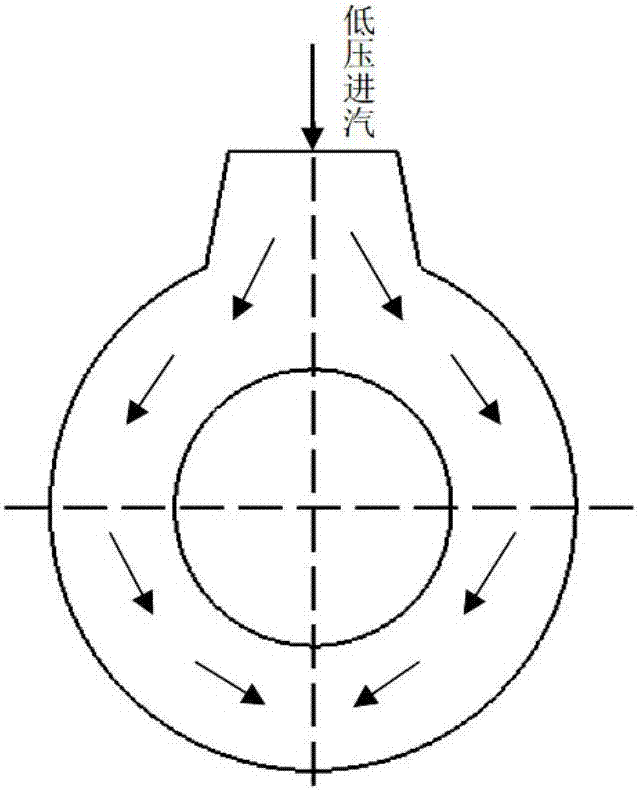

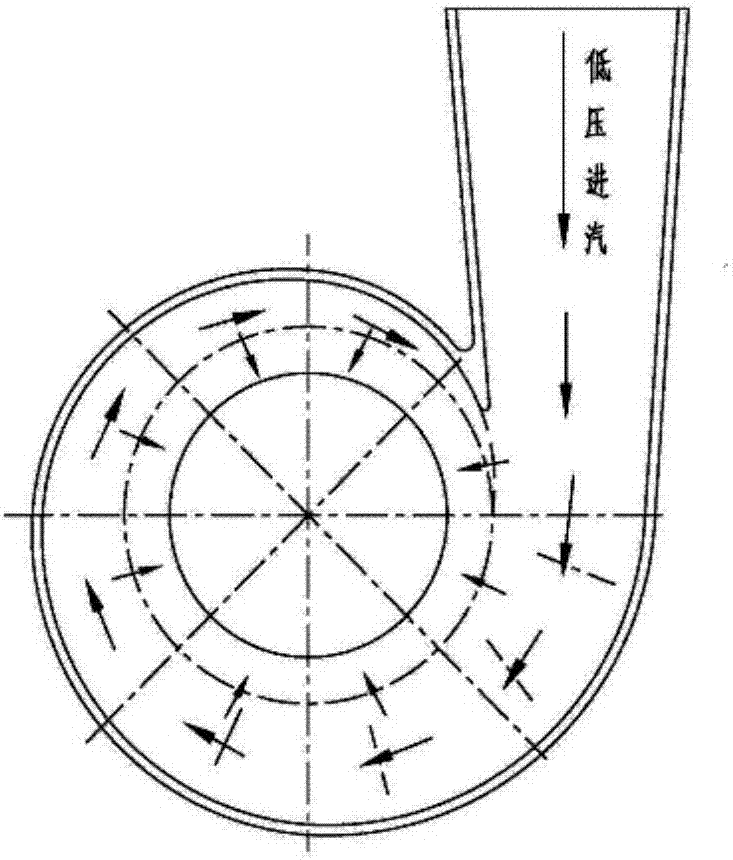

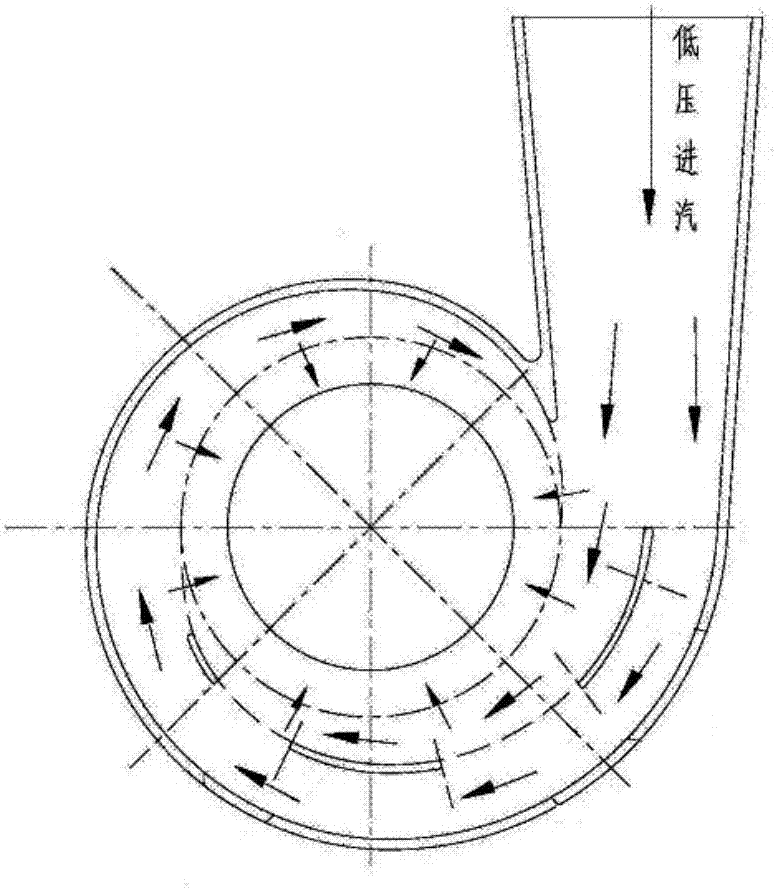

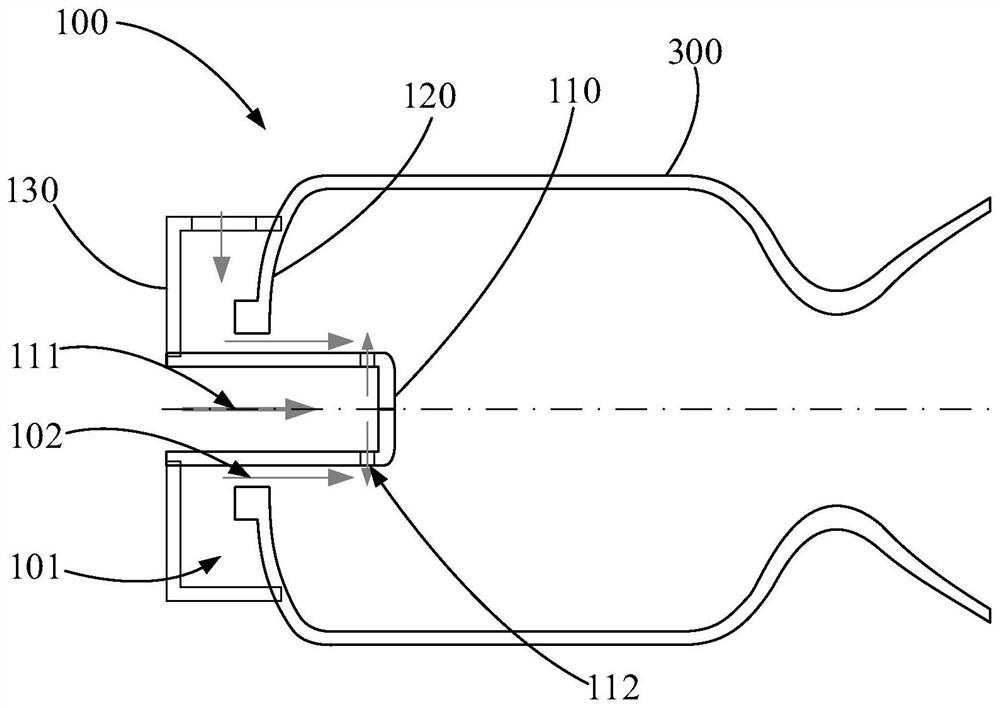

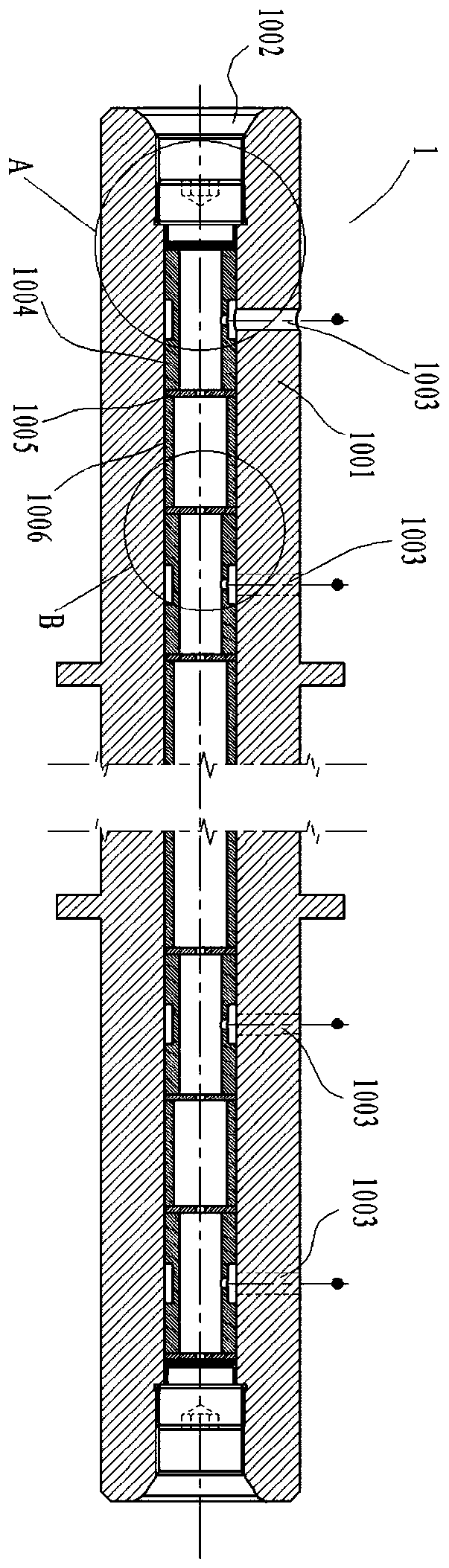

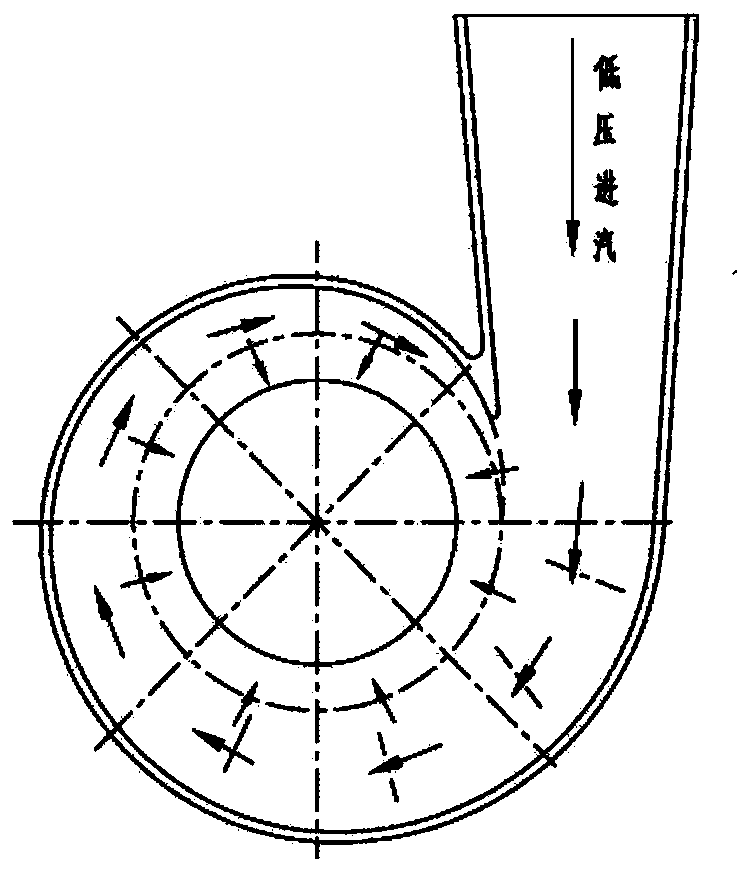

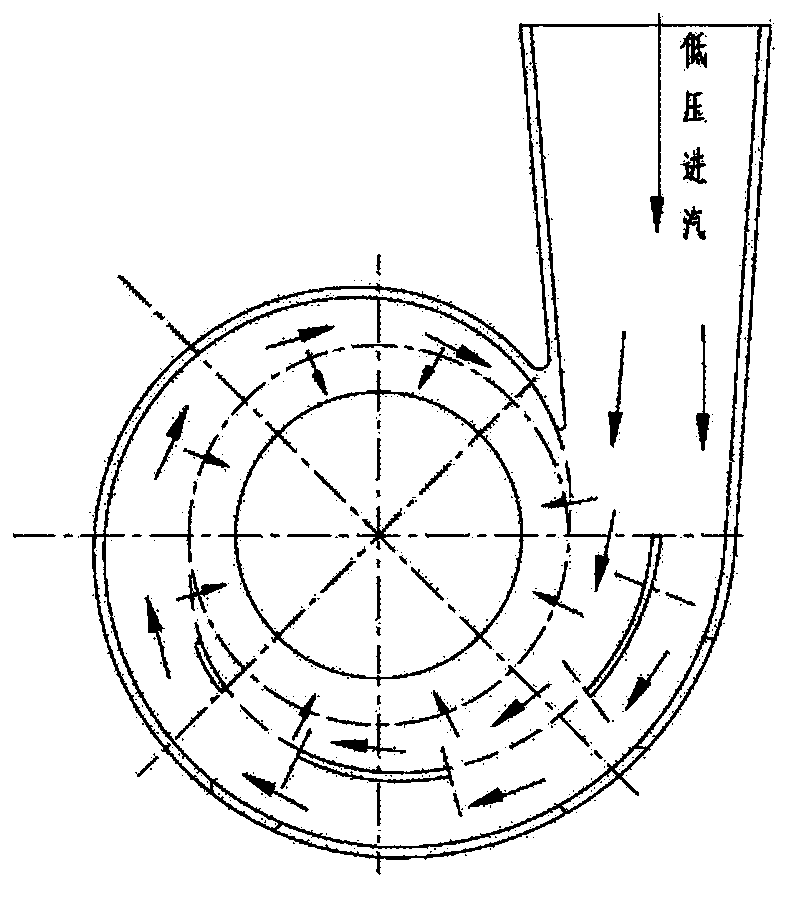

Uniform steam admission/supplement device for steam turbine

ActiveCN107965354AImprove efficiencyRealize a reasonable distributionStatorsMachines/enginesUnit operationEngineering

The invention discloses a uniform steam admission / supplement device for a steam turbine. The uniform steam admission / supplement device comprises an annular steam admission flow passage housing and ansteam admission pipeline housing communicating with the steam admission flow passage housing; a steam admission flow passage of a steam flow passage housing is arranged in an axially symmetrical mode,and a cross-sectional area of the steam admission flow passage decreases monotonously in the flow direction of steam admission; the steam admission flow passage housing communicates with the largestcross-sectional area of the steam admission flow passage, and a plurality of steam flow guide vanes are axially and symmetrically arranged on the inner wall of the steam admission flow passage of thesteam flow passage housing. From the point of view of reducing the steam loss and reducing the impact of a steam flow on a rotor, the uniform steam admission / supplement device for the steam turbine adopts a variable cross-section cavity design to adapt to the flow variation of steam during the flowing process, the flow velocity distribution of the steam in each section of the steam admission flowpassage tends to be uniform, the steam admission pressure and temperature loss are reduced, and the efficiency of the steam turbine is improved; the steam admission volume tends to be evenly distributed in the circumferential direction by rationally arranging the steam flow guide vanes, the steam flow force generated by the steam admission to the rotor is reduced, and the safety and stability of the unit operation are improved.

Owner:XI AN JIAOTONG UNIV

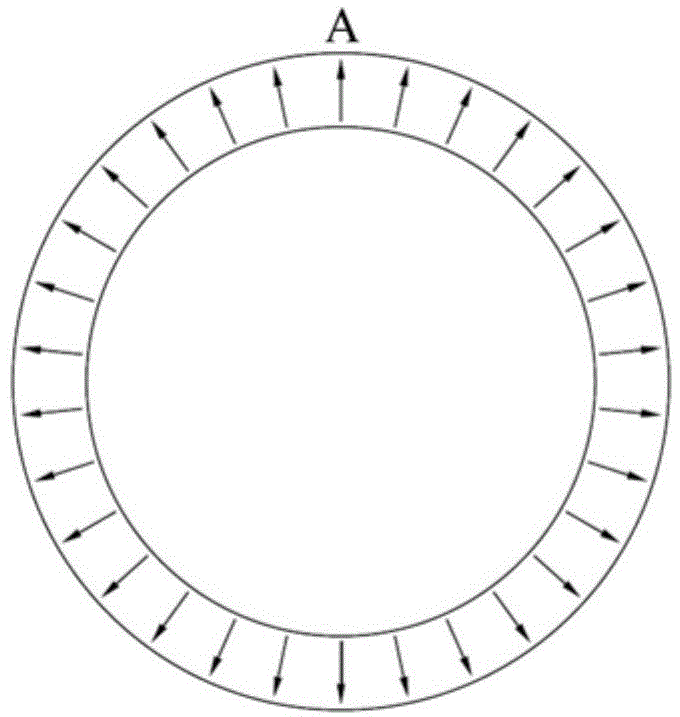

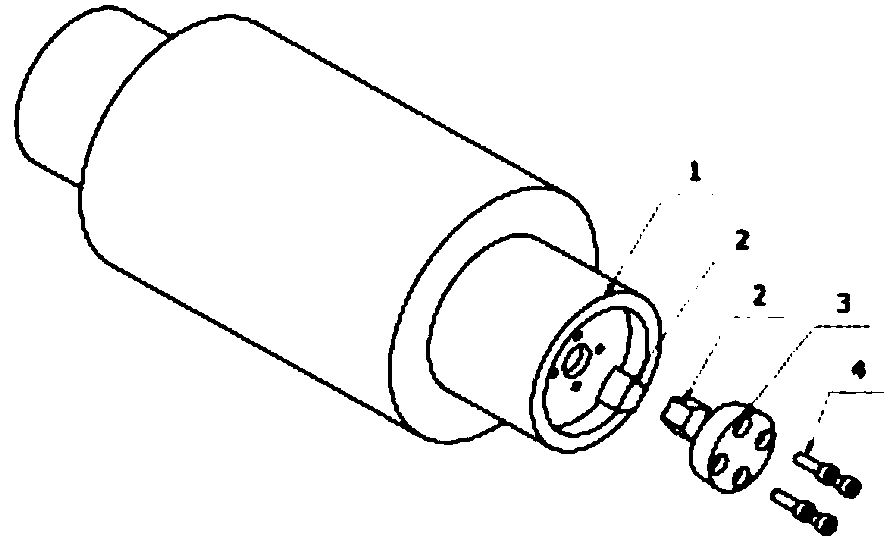

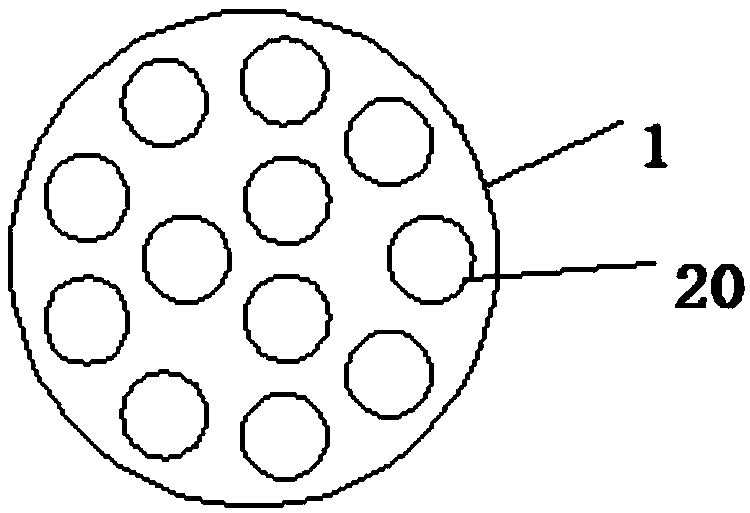

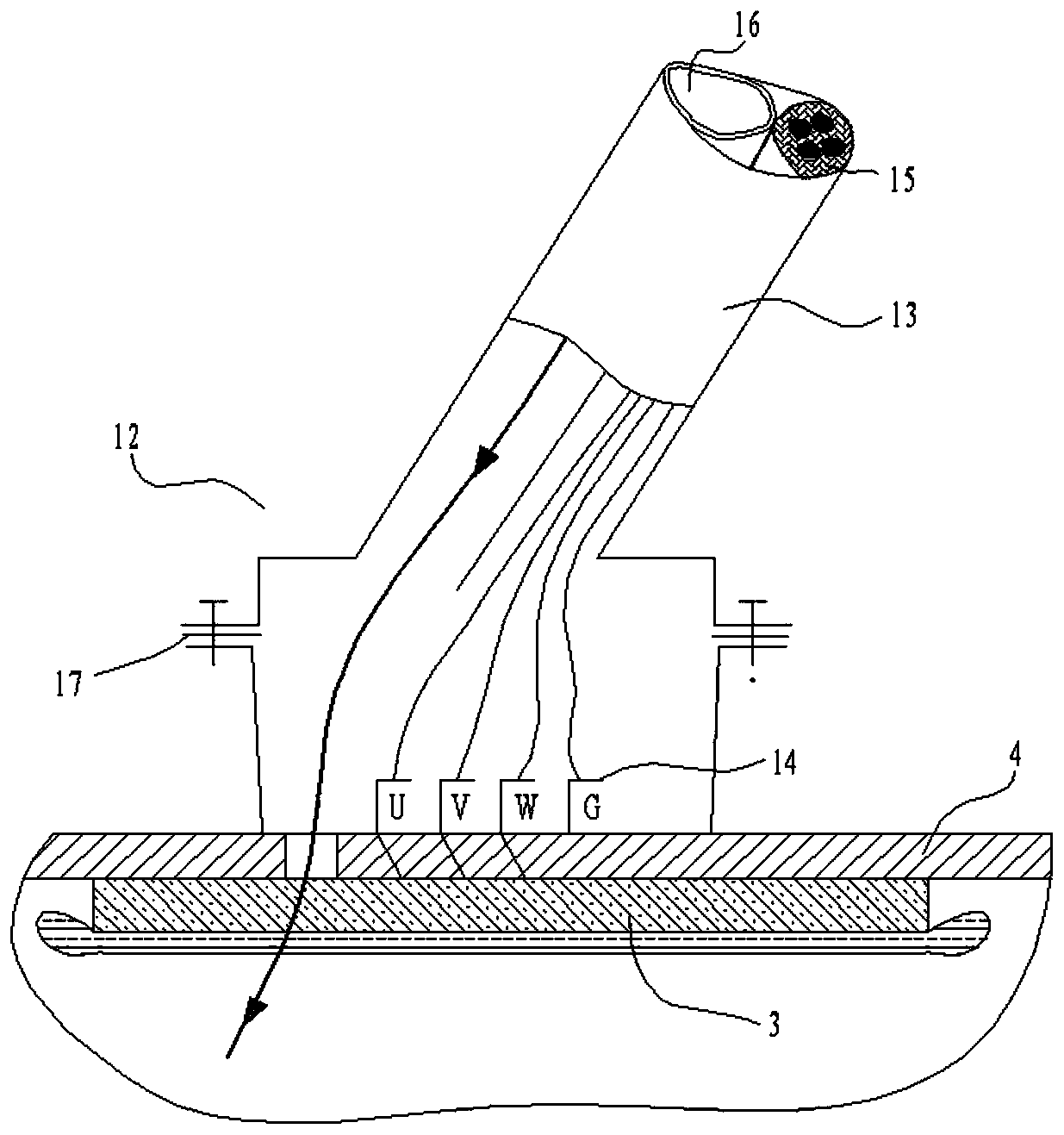

Permanent magnetic ring component and manufacturing method thereof

ActiveCN104157387AManufacturing and processing precision is easy to controlEasy to processInductances/transformers/magnets manufactureMagnetic materialsManufacturing technologyMagnetic poles

The invention belongs to the technical field of instruments and meters, and relates to the manufacturing technology of a permanent magnetic torquer component for an inertia type instrument, in particular to a rare earth-cobalt-based radial permanent magnetic ring component and a manufacturing method thereof. The permanent magnetic ring component is made of rare earth- cobalt-based permanent magnetic alloy materials. Multiple radial magnetic pole blocks (1) are prepared through a powder metallurgy method, each radial magnetic pole block (1) has a single magnetic pole direction A, and the multiple radial magnetic pole blocks (1) are bonded and fixed to form the cylindrical permanent magnetic ring component. The permanent magnetic ring component is reliable in mechanical strength, magnetic elements can be precisely manufactured under a neutral state, the radial magnetic field of the surface of a magnetic pole after the permanent magnetic ring component is magnetized is high in strength and good in uniformity, and the problems that a radial permanent magnetic ring is low in surface magnetic performance, poor in uniformity and stability, and not high in assembling precision are solved.

Owner:CENT IRON & STEEL RES INST

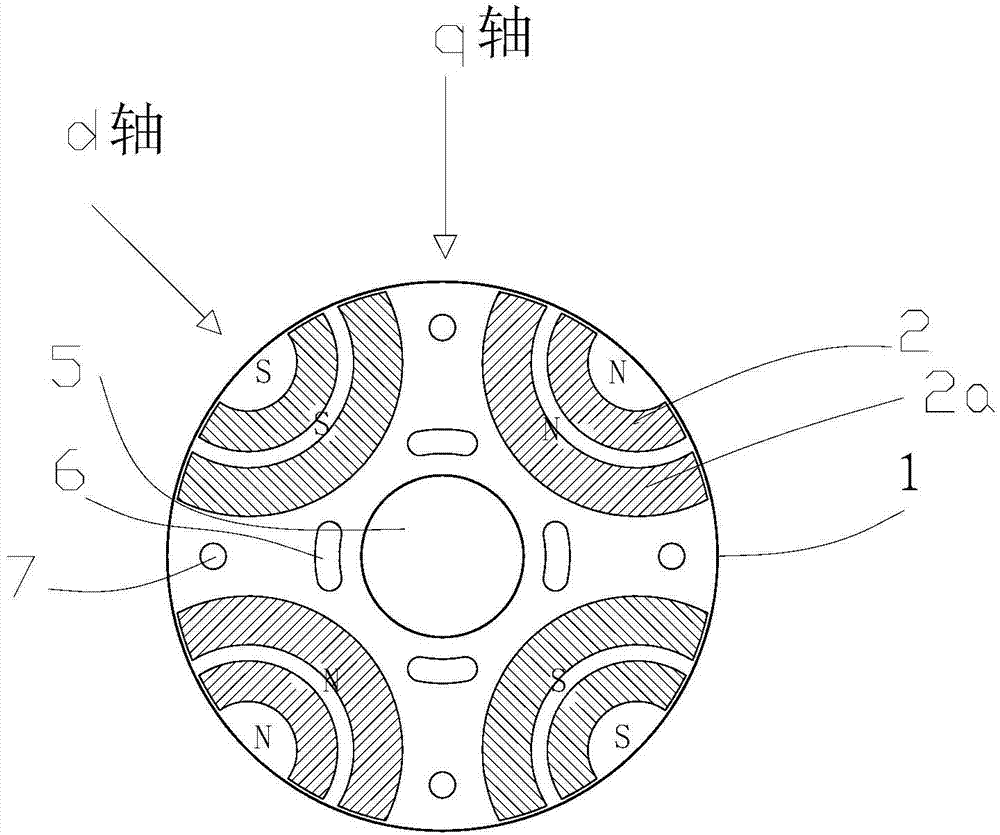

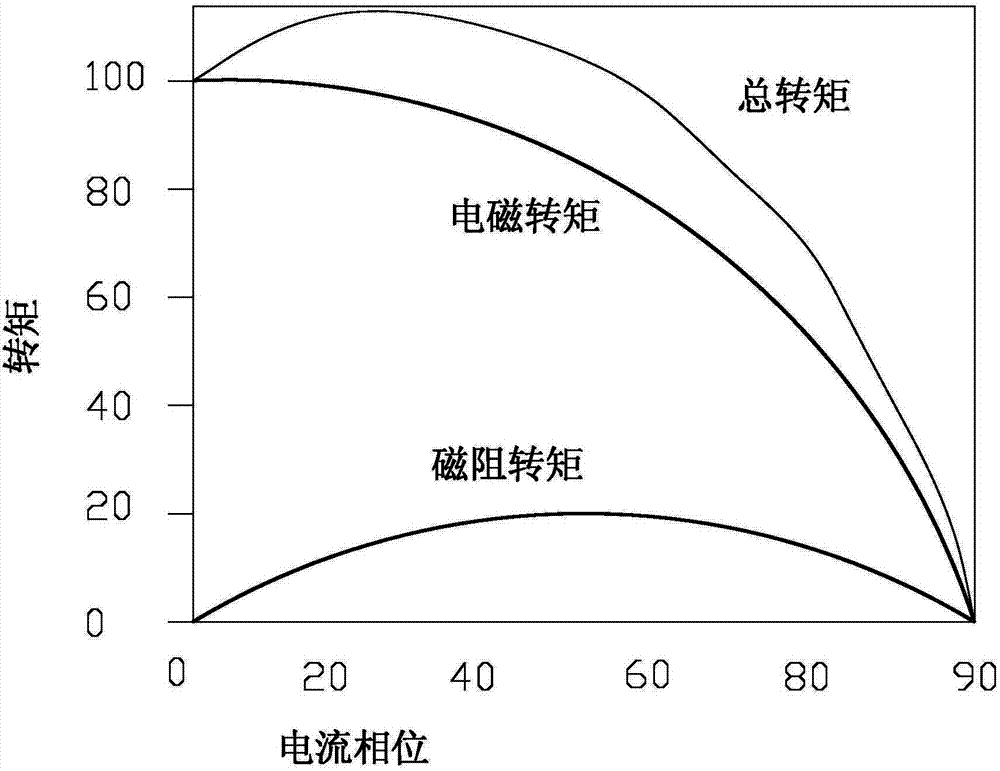

Rotor of electromotor

ActiveCN103501067AIncrease electromagnetic torqueImprove efficiencyMagnetic circuit rotating partsPhysicsElectromagnetic torque

The invention discloses a rotor of an electromotor. The rotor of the electromotor comprises a rotor core and multiple sets of permanent magnets, wherein the multiple sets of permanent magnets are buried in the rotor core. Each set of permanent magnets comprise multiple permanent magnet layers which are mutually arranged in the radial direction of the rotor core at intervals. The permanent magnet layer, closest to the surface of the outer circumference of the rotor core, of the multiple permanent magnet layers is a ferrite permanent magnet layer. The other permanent magnet layers of the multiple permanent magnet layers are rare earth neodymium ferrum boron permanent magnet layers. By the adoption of the rotor of the electromotor, the reluctance torque and the electromagnetic torque of the electromotor can be increased, efficiency of the electromotor is increased without increasing cost of the electromotor, and the problems of noise and vibration deterioration of the electromotor can not be caused. Besides, operating reliability of the electromotor can also be guaranteed, and the electromotor can also be stably operated under high frequency.

Owner:GUANGDONG MEIZHI COMPRESSOR

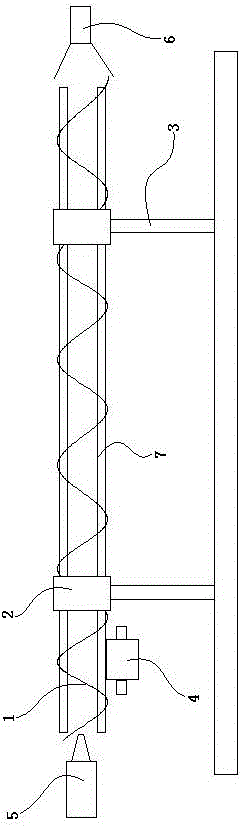

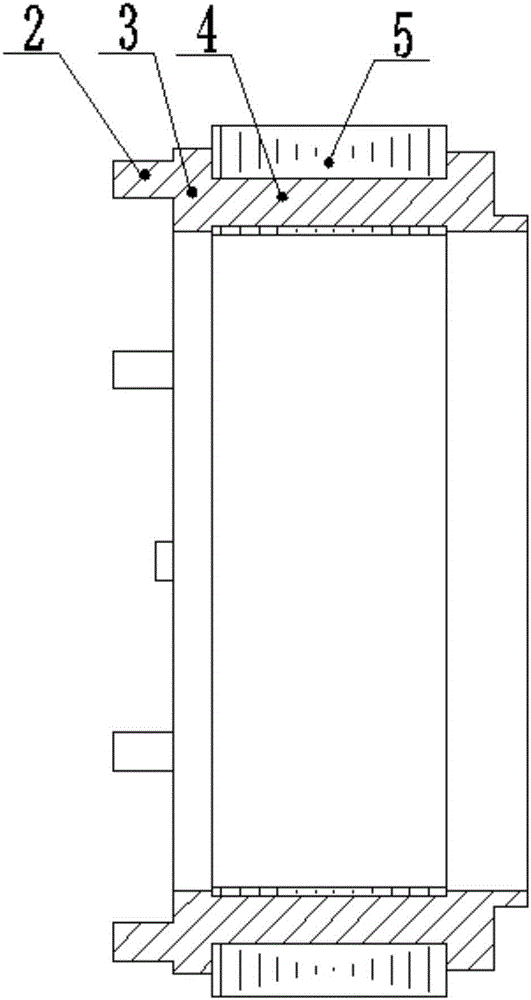

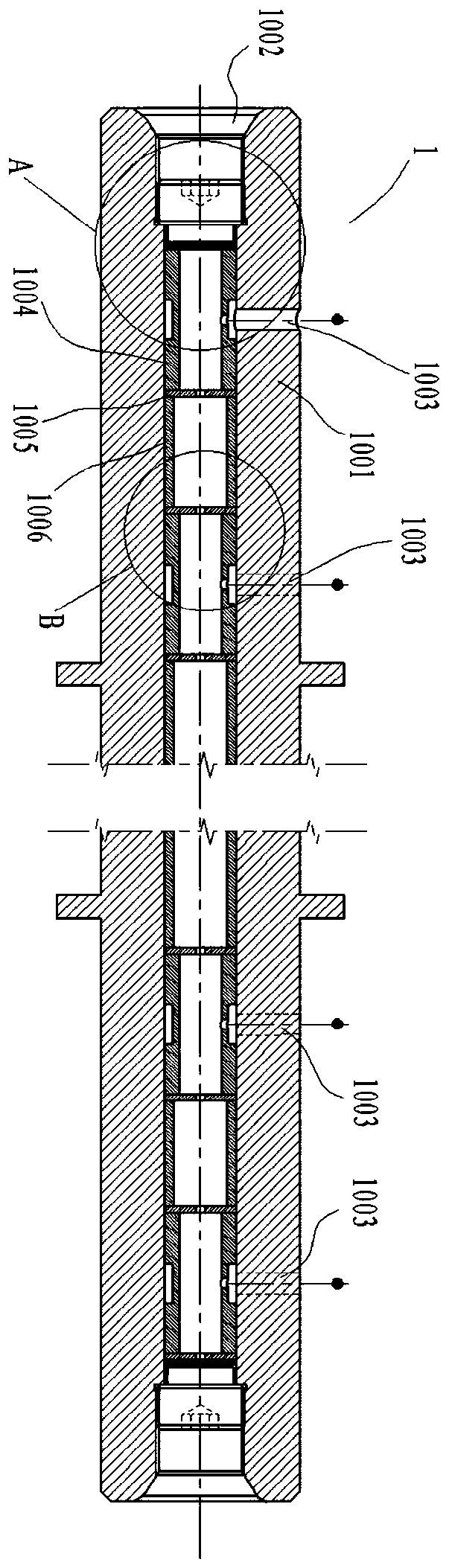

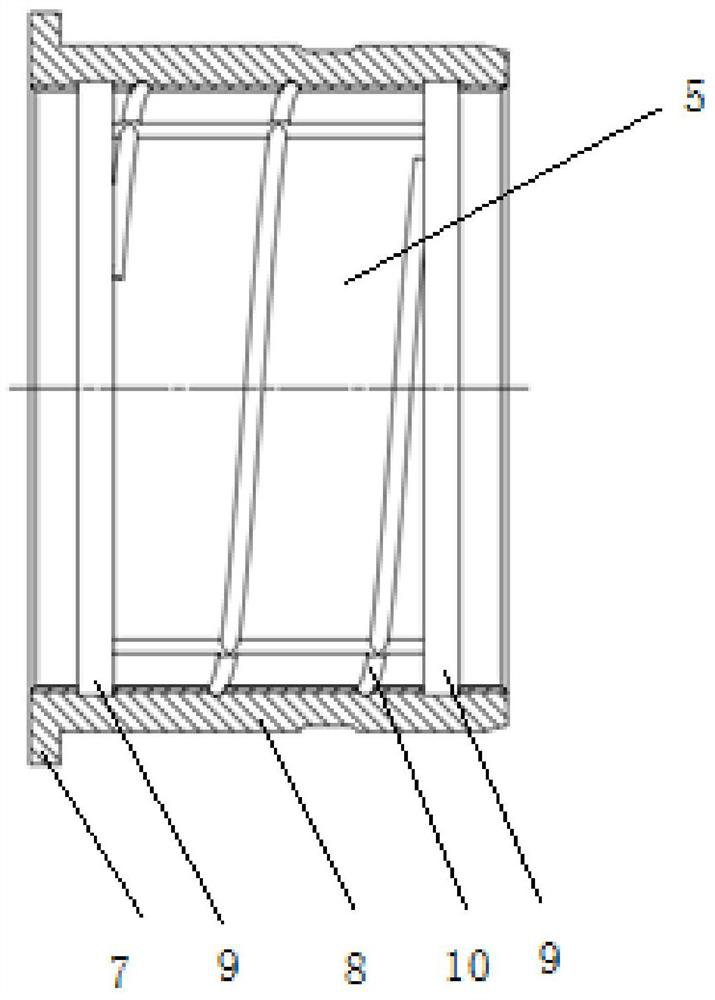

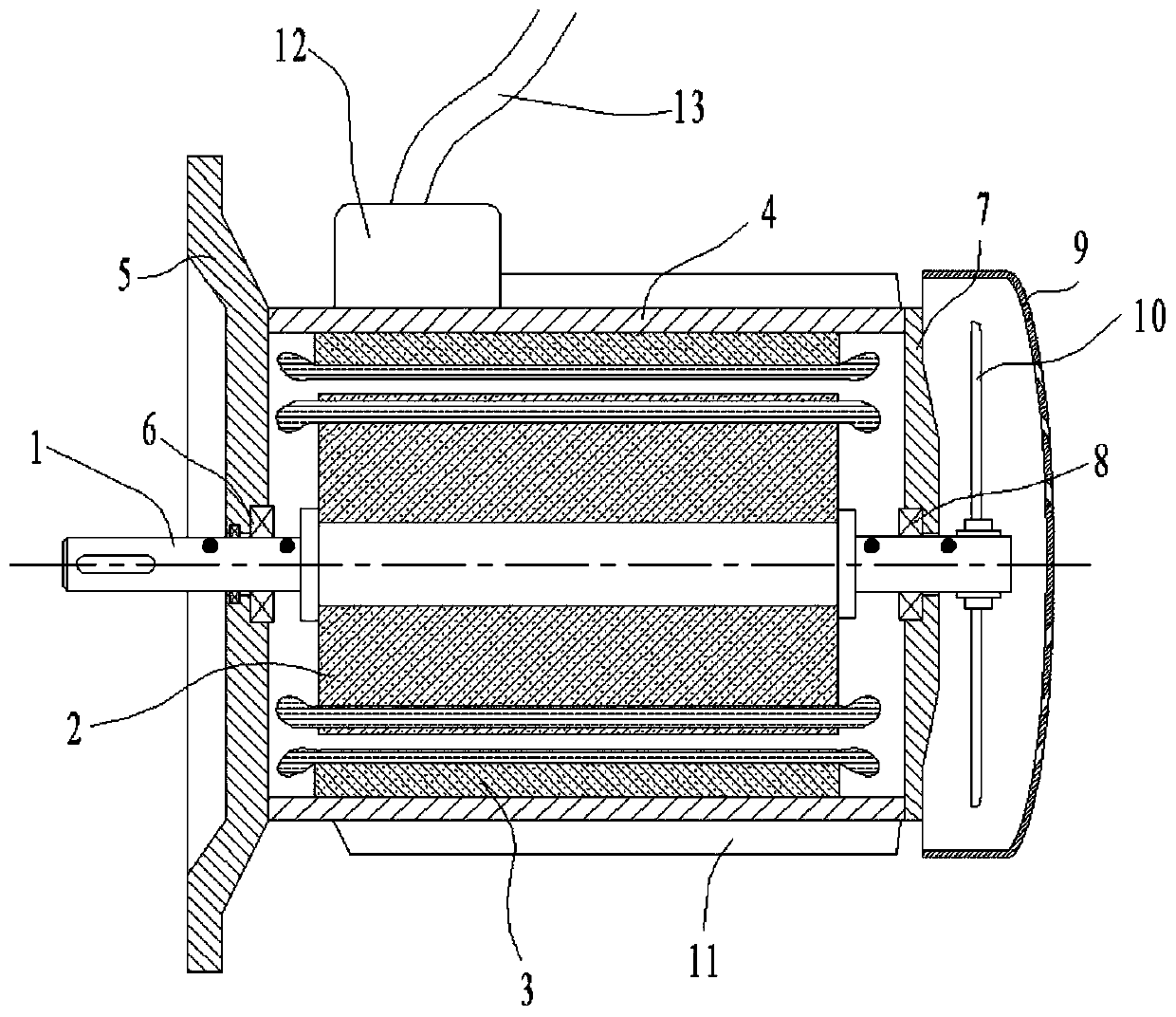

Film-coating device for inner wall of steel pipe

InactiveCN105935649AEvenly distributed around the circumferencePretreated surfacesCoatingsEngineeringPowder Spray

The invention relates to a film-coating device for an inner wall of a steel pipe. The film-coating device comprises a horizontally-arranged high-frequency heating coil barrel body, wherein two bearings arranged along the axial direction of the high-frequency heating coil barrel body are arranged in the high-frequency heating coil barrel body; a powder spraying device is arranged at one end of the high-frequency heating coil barrel body; and a nozzle of the powder spraying device faces the inner cavity of the high-frequency heating coil barrel body. A steel pipe arranged in the inner cavity of the high-frequency heating coil barrel body is heated through the high-frequency heating coil barrel body, then a powder is sprayed towards the inner cavity of the steel pipe through the powder spraying device, the powder is polymer powder particles and can be adhered to the high-temperature inner wall of the steel pipe, and a layer of polymer film is formed on the inner wall of the steel pipe through continuous heating and powder spraying. A drive roll wheel is driven through a motor, then is pressed onto an outer wall of the steel pipe, and then drives the steel pipe to rotate, thus uniform peripheral distribution of the powder on the inner wall of the steel pipe is ensured. A dust absorption device can absorb redundant powder to facilitate recycling.

Owner:SUZHOU YONGTONG STAINLESS STEEL CO LTD

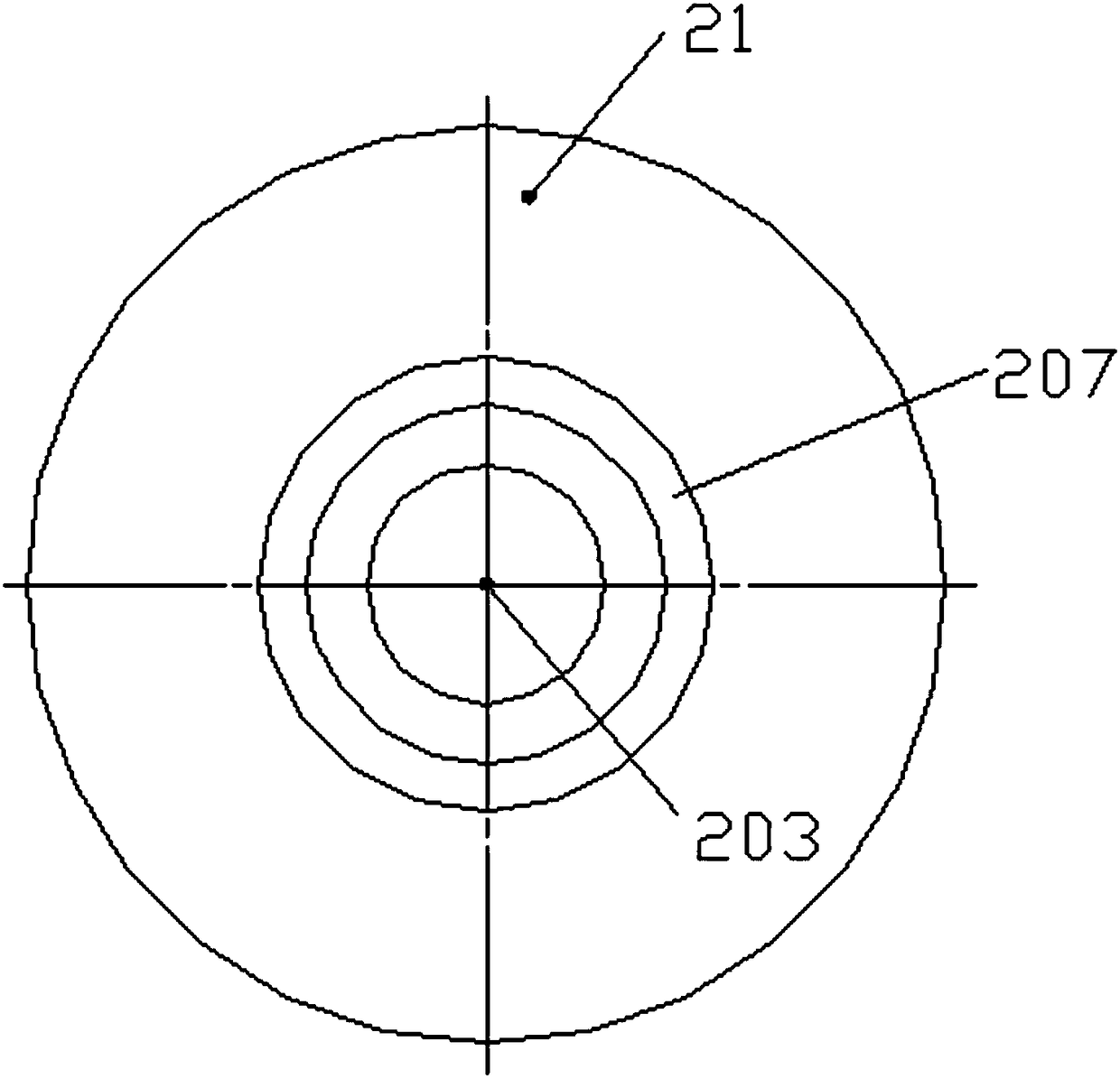

Adjustable laser coaxial powder feeding nozzle

The invention discloses an adjustable coaxial laser nozzle for feeding powder, comprising a laser head, a protection lens, a water-cooling sleeve for the protection lens and a column laser cavity arranged at the upper part, a coaxial conical laser cavity which is formed by the inner layer of a laser sleeve in the middle part; wherein, a powder cavity, a secondary external protective cavity and anexternal water-cooling cavity are arranged on the lower part of the external part of the laser sleeve; the powder cavity is formed between the laser sleeve and a power cavity sleeve screwed together;the secondary external protective cavity is formed between the powder cavity and a protective air casing screwed together; the powder cavity and the protective air casing are screwed together and adjustable between 1mm to 3mm; 4 to 6 power transmitting pipes and 4 to 6 air tubes are respectively positioned around the top parts of the cones of the powder cavity and the protective air cavity. The adjustable coaxial laser nozzle for feeding powder has the advantages that the focus length of the focus lamp fit for the coaxial powder-feeding nozzle is between 100mm to 300mm, which ensures convenient assembly and disassembly, even velocity, flexible adjustment of the powder converge diameter, and convenient changeable lower coaxial conical parts (the powder cavity, the air casing and the water cavity).

Owner:XI AN JIAOTONG UNIV

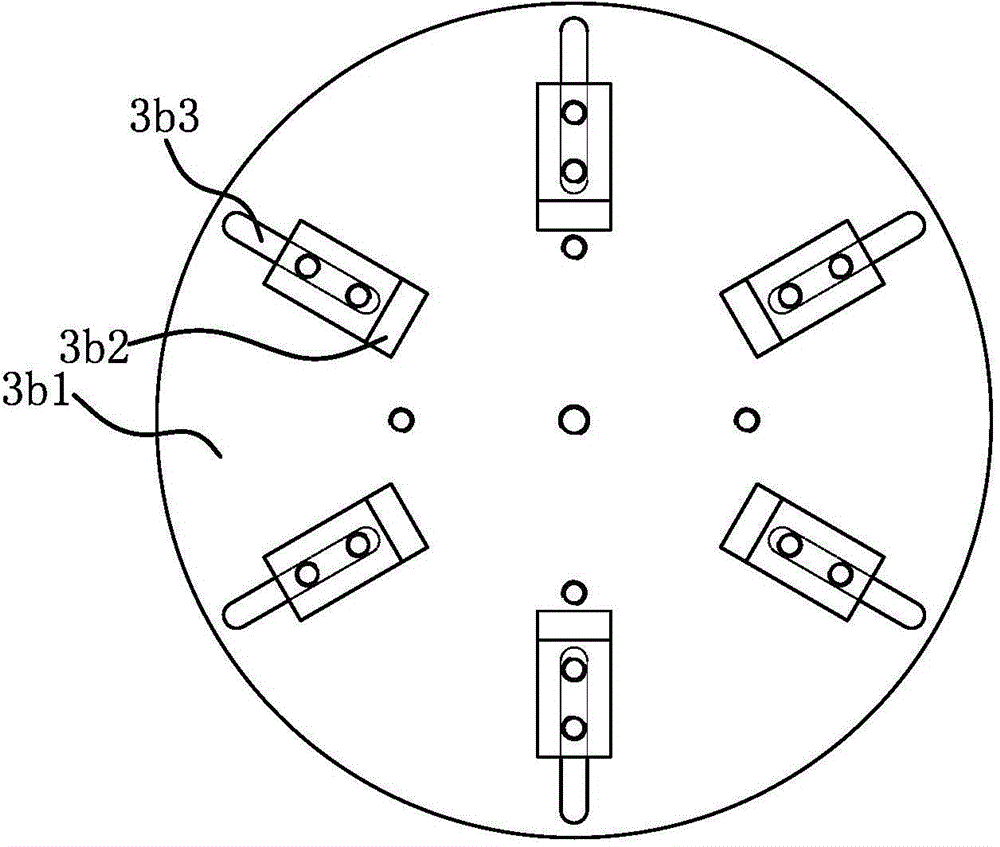

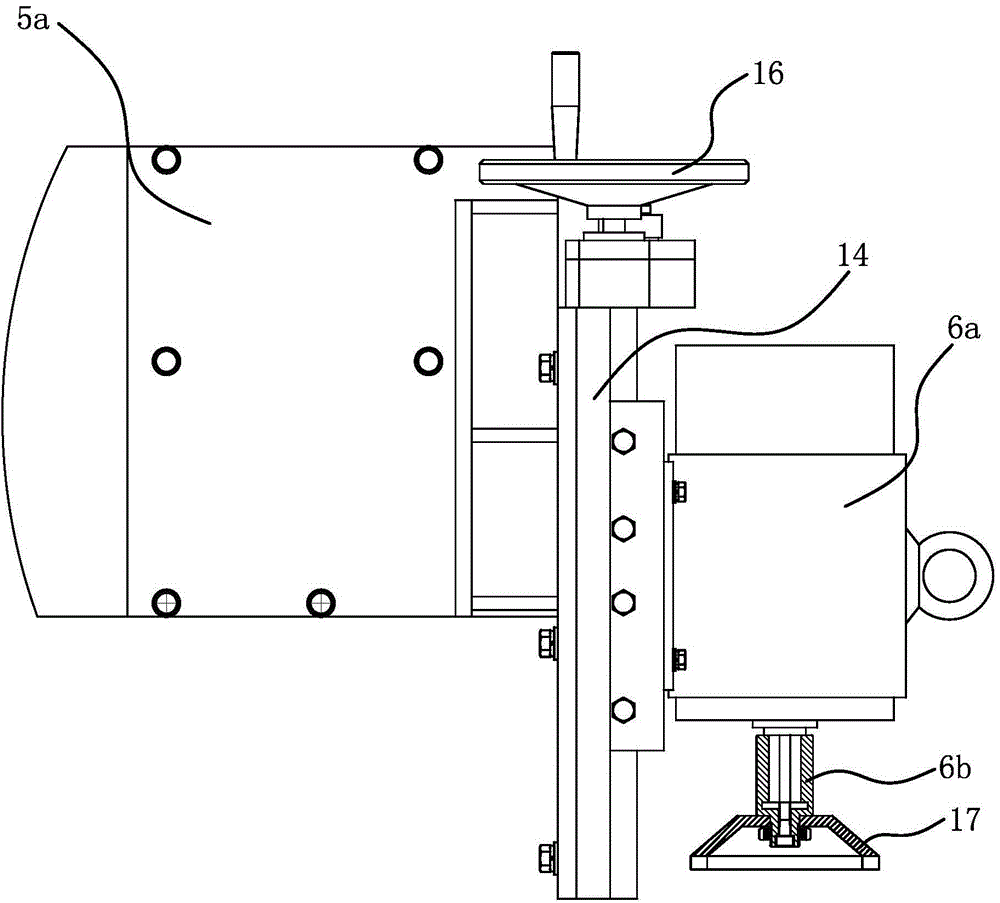

Vertical grain taking and die bonding mechanism and vertical die bonding machine using the same

PendingCN106876307AShort vertical movementShorten the vertical distanceSemiconductor/solid-state device manufacturingRotational axisEngineering

The invention discloses a vertical grain taking and die bonding mechanism comprising a wafer table, a first drive unit, and a welding head assembly. The first drive unit is used for driving the welding head assembly to make vertical circumferential rotation relative to the wafer table. The welding head assembly includes at least one welding head for carrying out grain taking and die bonding; and the rotation axis of the welding head assembly is parallel to the wafer table. The mechanism has the following beneficial effects: the welding head makes a vertical circumferential motion along the wafer table above or below the wafer table; when grain taking and die bonding are carried out, the motion track of the welding head relative to the wafer table is an arc one; on the basis of the vertical circumferential rotation of the welding head, the horizontal motion distance of the welding head can be reduced; adaptability to substrates with different dimensions is high; the horizontal motion time is short during the grain taking and die bonding processes; the production efficiency can be improved substantially; and the production cost can be lowered.

Owner:SUZHOU ACCURACY ASSEMBLY AUTOMATION CO LTD

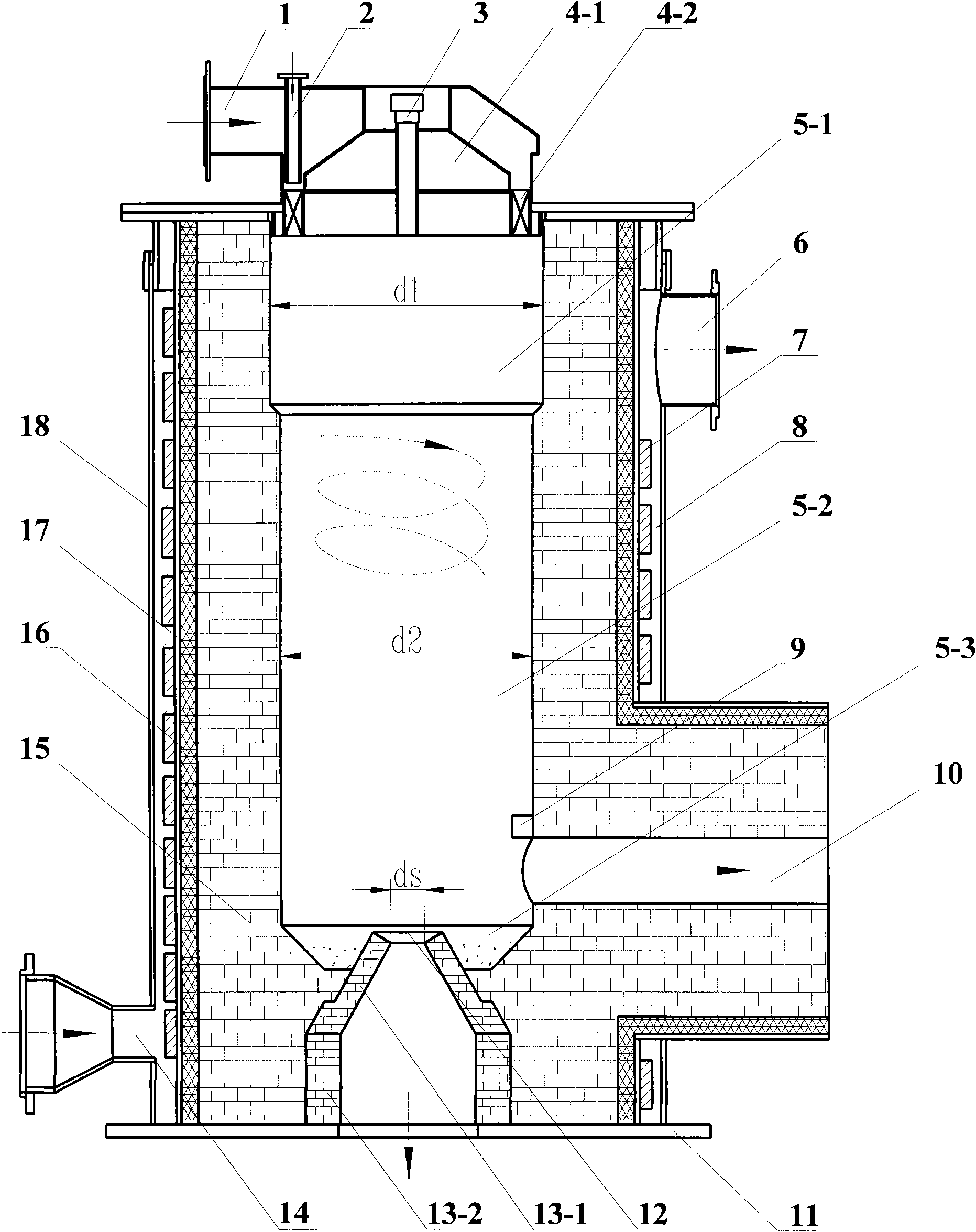

Vertical air-cooled pulverized coal burner capable of realizing continuous slag tapping

ActiveCN101806453ASafe and stable operationReduce heat dissipationPulverulent fuel combustion burnersCombustion chamberCombustor

The invention discloses a vertical air-cooled pulverized coal burner capable of realizing continuous slag tapping, comprising a secondary air pre-swirl chamber, an approximately cylinder-shaped burning chamber and a slag tapping chamber which are vertically communicated with each other in sequence, and a cooling air chamber. The invention is characterized in that the burner comprises an inlet end face arranged at the top end of the burning chamber and an outlet end face arranged on the side wall at the lower end of the burning chamber; fireproof thermal insulating layers are laid on the outer surfaces of the burning chamber and the slag tapping chamber and in the burner; thermal barriers are laid outside the fireproof thermal insulating layers; the internal cylinder wall and the outer cylinder wall of the burner are arranged outside the thermal barriers; a gap and the cooling air chamber are arranged between the internal cylinder wall and the outer cylinder wall; a certain number of heat-exchange fins are arranged in the cooling air chamber and on the surface of the internal cylinder wall; the burning chamber is divided into an upper cavity, a lower cavity and a molten slag confluence chamber from top to bottom in sequence; a secondary air inlet, a pulverized coal inlet and an ignition hole are all arranged on the inlet end face; a horizontal axial fire outlet communicated with the lower cavity is arranged on the outlet end face; the slag tapping chamber is vertically arranged at the bottom of the burner and comprises diffusion tubes and straight cylinder type tubes which are connected with each other; and a slag hole communicated with the molten slag confluence chamber is arranged at the upper ends of the diffusion tubes.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

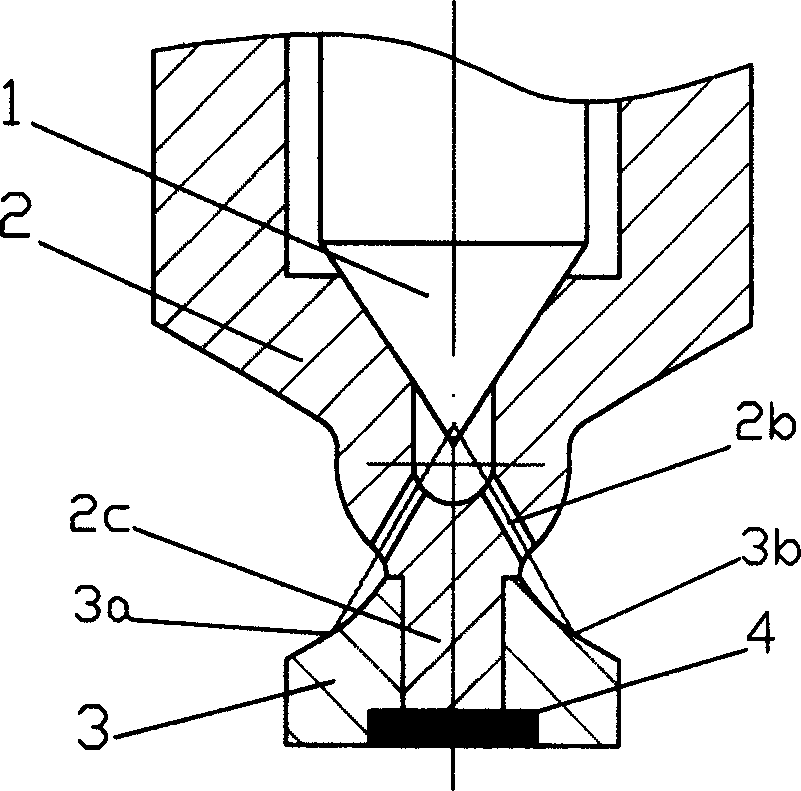

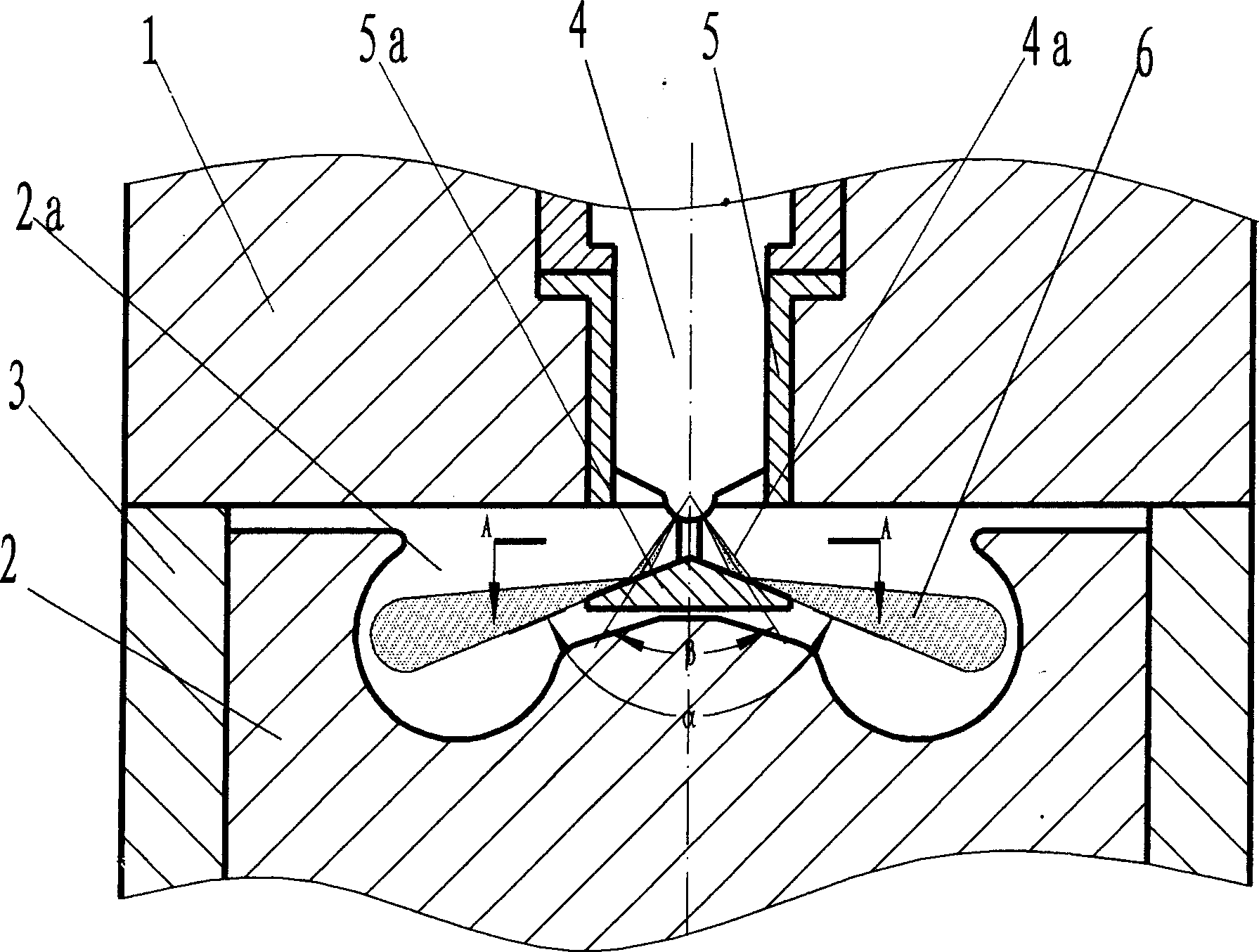

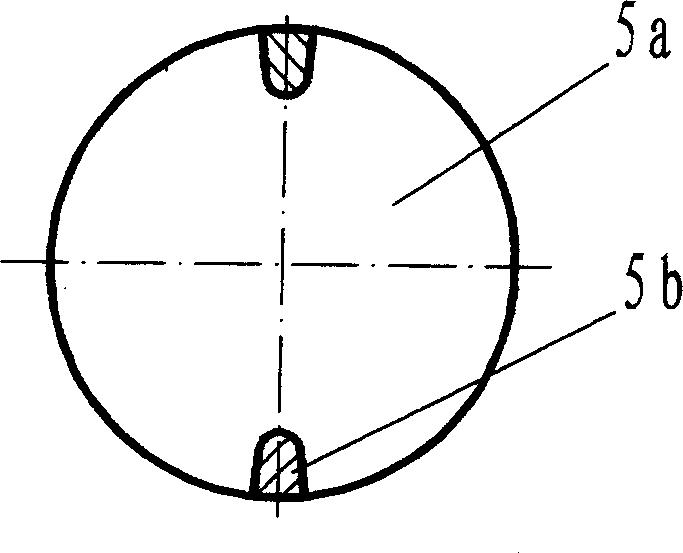

Guide table type oil jet nozzle

InactiveCN1616814AGood atomization performanceEvenly distributed around the circumferenceFuel injection apparatusMachines/enginesMixed fuelNeedle valve

The present invention relates to formation and combustion of mixed gas in engine. The guide table type oil jetting nozzle has one guide table and oil jetting holes in the nose of its needle valve body. When there is one row of oil jetting holes, the whole or partial oil beam of the oil jetting holes is jetted to the conic cambered surface on the guide table; and when there are two rows of oil jetting holes, the whole or partial oil beam of the oil jetting holes in the lower row is jetted to the conic cambered surface on the guide table and the two rows of oil jetting holes are crossed and homogeneously circumferential distributed. By means of the guiding of the conic cambered surface, the secondary oil beam has homogeneous spatial distribution, high atomizing effect and controllable penetrating distance, and this improves the formation of mixed fuel gas, speeds the combustion and improves the performance of the engine.

Owner:DALIAN UNIV OF TECH

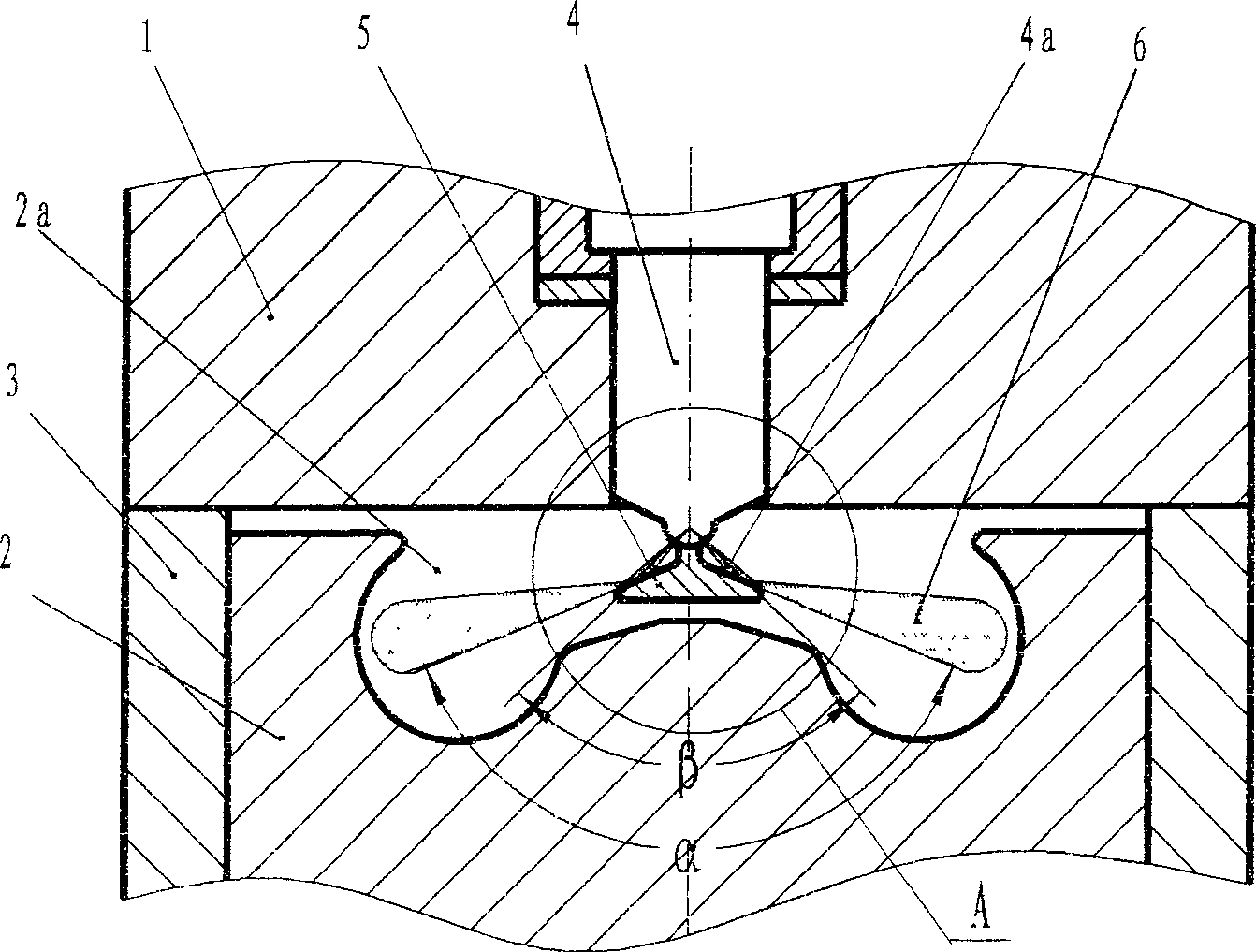

Injection system for internal combustion engine

InactiveCN1529049AQuality improvementImprovements in emission indicatorsFuel injection apparatusMachines/enginesCombustionExternal combustion engine

The invention is a kind of combustion spraying system, which belongs to engine mixed gas forming and combustion field. It sets a guiding cone under the oil sprayer, the guiding cone and the oil sprayer is connected together, forms a integral body. When the oil ejected from the multi-hole oil sprayer reaches the cone, under the guiding of cone surface, by using the secondary oil beam, forms pulverization with even distribution, good pulverization, controllable penetration distance, it speeds up the combustion of gas, thus the power, and economic performance and discharging index of engine are improved prominently.

Owner:DALIAN UNIV OF TECH

High-speed motor dynamic balance self-adjusting device

InactiveCN109428453AEvenly distributed around the circumferenceCentering/balancing rotorsDynamic balanceEngineering

The invention belongs to the technical field of motor dynamic balance, and particularly relates to a high-speed motor dynamic balance self-adjusting device. The device comprises a rotating shaft, weight balancing blocks, a fixed plate and a locking piece, wherein the rotating shaft is connected with a self-contained rotating shaft of the motor; the weight balancing blocks are connected with the fixed plate and are locked to the rotating shaft through the locking piece, and the weight balancing blocks are evenly distributed around the rotating shaft in the circumferential direction. The whole weight balancing device is externally arranged outside the motor, so that the dynamic balance of the whole motor can be adjusted anytime and anywhere. The weight required to be balanced is calculated only in the process of running and correcting, and then the weight balancing and locking are carried out on the fixed plate, so that the weight balancing can be rapidly completed. According to the structure, the whole motor is not required to be detached, and a dynamic balance test is carried out independently. Meanwhile, the dynamic balance of the motor during operation is ensured. The weight balancing blocks are convenient to machine and easy to realize standardization. The structure is wide in application range, and can be popularized to other rotary equipment to be used for correcting dynamic balance.

Owner:张峰

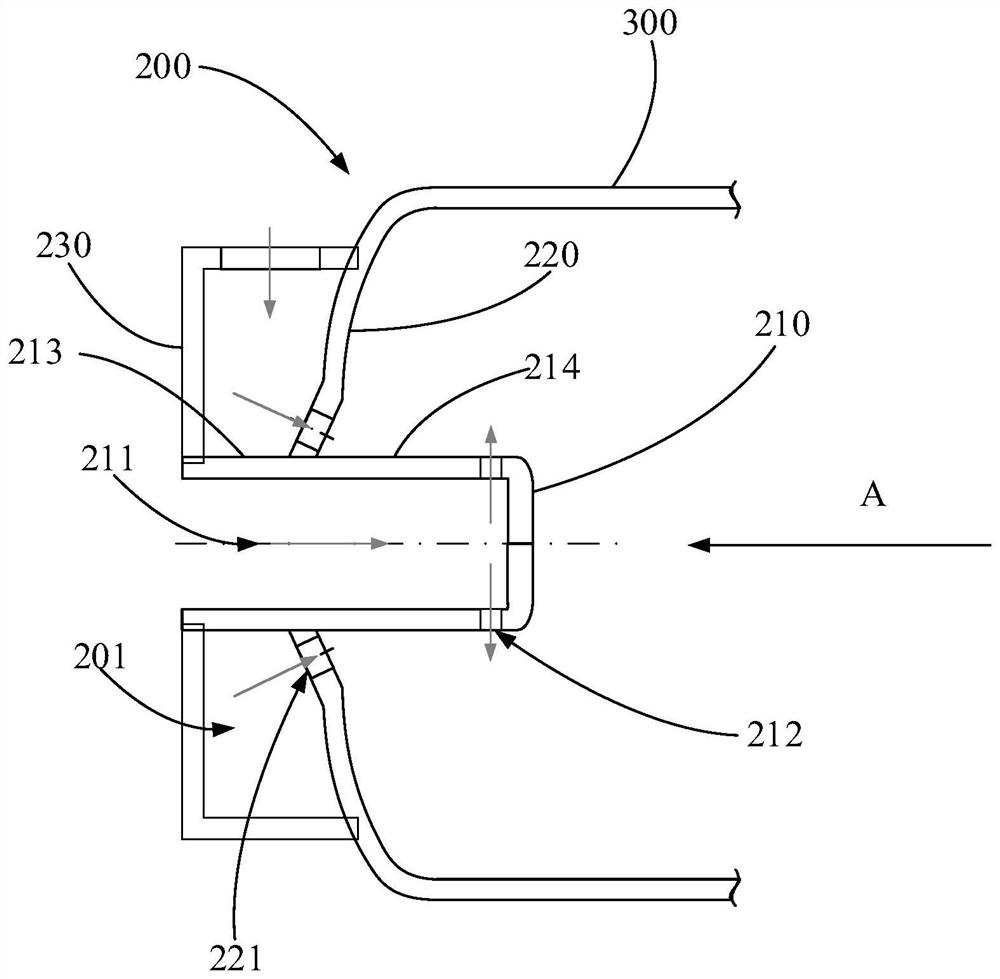

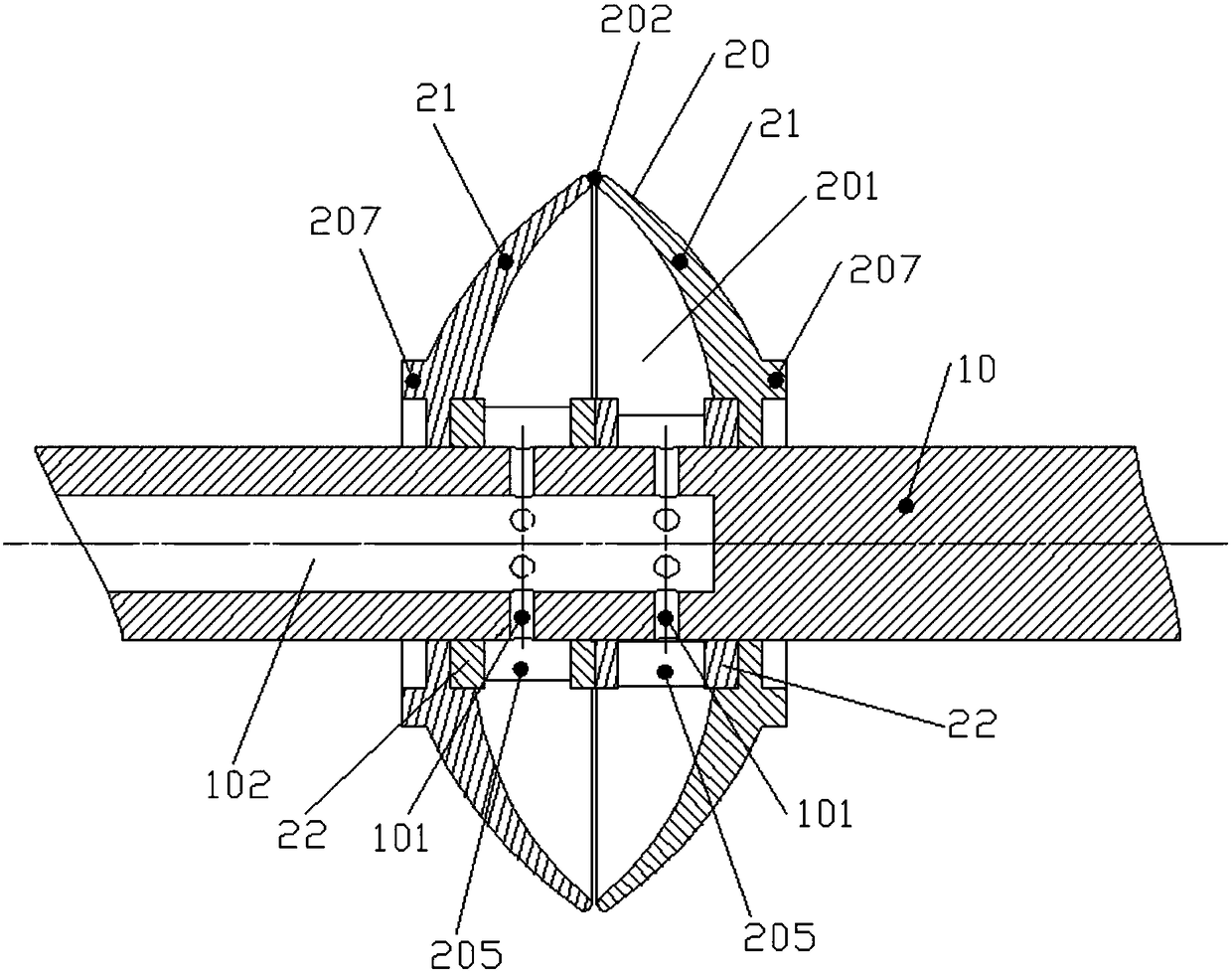

Pintle injector and liquid rocket engine

ActiveCN112502857AEvenly distributed around the circumferenceImprove combustion efficiencyRocket engine plantsEngineeringPhysics

The invention relates to a pintle injector and a liquid rocket engine. The pintle injector comprises a panel, a cover body and a pintle. The panel is provided with a first inner hole. The cover body is connected with the panel, and a second inner hole opposite to the first inner hole in a spaced manner is formed in the cover body. The pintle is arranged in the first inner hole and the second innerhole in a penetrating manner, the pintle is in sealing fit with the hole wall of the first inner hole and the hole wall of the second inner hole, and the pintle, the cover body and the panel are in cooperation to form a collection cavity. The pintle is provided with an inner flowing channel, the circumferential side of the pintle is provided with an injection part communicating with the inner flowing channel, the injection part is located outside the collection cavity, multiple first injection holes are formed in the side wall, close to the injection part, of the collection cavity, and the first injection holes are evenly formed around the axis of the pintle at intervals. The pintle comprises a first section and a second section connected with the first section, the first section cooperates with the panel and the cover body to form the collection cavity, the injection part is arranged on the circumferential side of the second section, and the first injection holes are opposite to theouter side wall of the second section.

Owner:NAT UNIV OF DEFENSE TECH

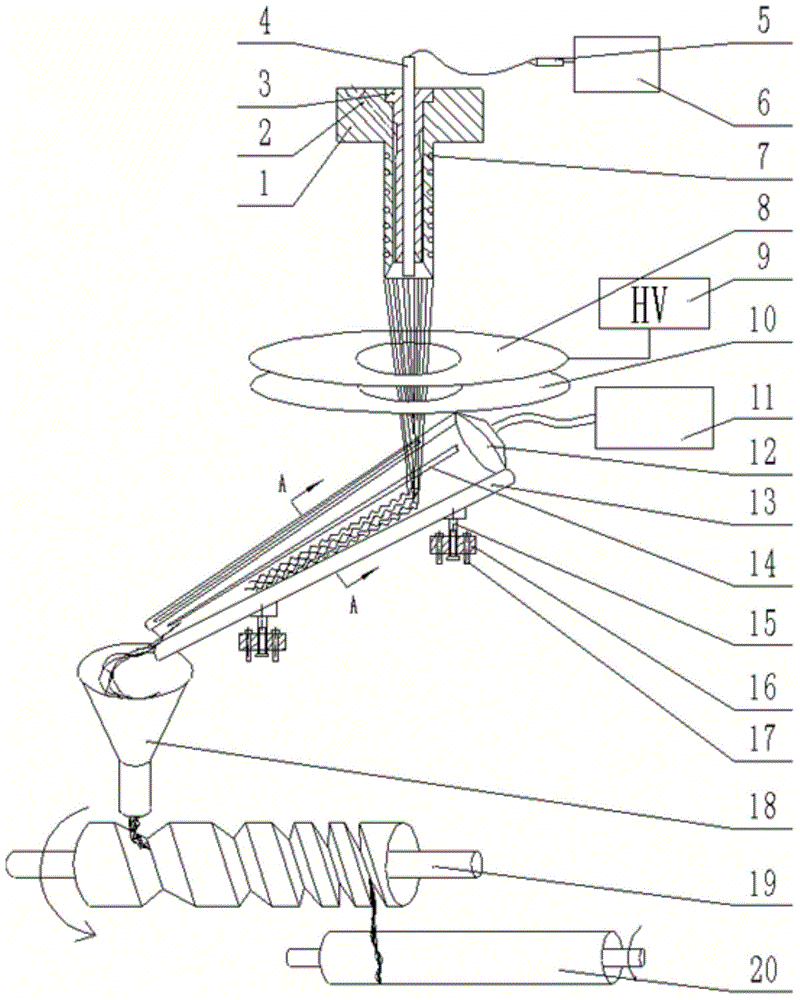

Differential melt electro-spinning device adopting high-velocity water flow assisted twisting

ActiveCN104963008AGuaranteed validityEvenly distributed around the circumferenceFilament/thread formingAir compressorWater channel

The invention relates to a differential melt electro-spinning device adopting high-velocity water flow assisted twisting and belongs to the field of electrostatic spinning. The differential melt electro-spinning device mainly comprises a spray head outer cylinder, a material flow pass, a spray head core rod, an air flow guide tube, a hot air gun, an air compressor, a heating coil, a perforated electrode plate, an electrostatic generator, a perforated insulation plate, a water pump, a water flow inlet channel, an annular water channel, an annular water flow channel, adjusting screws, adjusting-fixing plates, fixing screws, a twisting funnel, a grooved roller and a collection roller. The differential melt electro-spinning device utilizes high-velocity water flow to orderly arrange and deliver multiple fibers in the water channel, the fibers are fed into the twisting funnel along with the water flow to be rotatably twisted, the twisting degree can be adjusted by controlling an inclination angle of the water channel, twisted fibers fall into the grooved roller to be drawn close through compaction, and finally compact twisted single-fiber bundles are collected through the collection roller. The differential melt electro-spinning device can efficiently card fibers on the premise that normal spinning of an original spinning device is not influenced, and polymer melts can be made into twisted threads through electrostatic spinning in a one-time forming mode.

Owner:BEIJING UNIV OF CHEM TECH

Concentric double-layer ring supergravity rotating bed

InactiveCN112934126AIncreased turbulenceEvenly distributed around the circumferenceLiquid-gas reaction of thin-film typeChemical/physical/physico-chemical stationary reactorsPhysicsConcentric ring

The invention discloses a concentric double-layer ring supergravity rotating bed which comprises a cavity, wherein a rotor is arranged in the cavity; the rotor consists of an upper disc and a lower disc, a group of concentric double-layer concentric rings with uniformly increased diameters are fixed between the upper disc and the lower disc, each double-layer concentric ring consists of a sieve hole ring and a bulged hole ring, the sieve hole ring is positioned in the bulged hole ring, the diameter of the sieve hole ring is smaller than that of the bulged hole ring, the bulged hole ring is provided with protruding bulged holes, the sieve hole ring is provided with sieve holes and a non-perforated area, the sieve holes in the sieve hole ring and the bulged holes in the bulged hole ring are staggered in position, and the non-perforated area of the sieve hole ring right faces the bulged holes of the bulged hole ring. The positions of the sieve holes and the bulged holes in the rotor are staggered, so that linear flow of gas is avoided, the gas passes through the sieve holes in the two sides of the non-perforated area in an S-shaped zigzag flow manner, the turbulence degree of the gas is increased, the gas-phase mass transfer coefficient of the rotating bed is increased, and the gas-liquid mass transfer efficiency of the rotating bed is improved.

Owner:ZHEJIANG UNIV OF TECH

Diesel oil engine secondary atomization combustion system

InactiveCN1479008AQuality improvementImprovements in emission indicatorsFuel re-atomisation/homogenisationMachines/enginesCombustion systemCombustion

A secondary-atomizing conbustino system for diesel engine features that a guiding conic body is arranged under the oil nozzle, and when the oil sprayed by multi-hole nozzle is in touch with said conic body, it is further atomized and uniformly distributed to form a combustible mixed gas. Its advantage is high combustion speed.

Owner:DALIAN UNIV OF TECH

Baffle plate reinforced fluidized bed external catalyst cooler

PendingCN109282679AConducive to stable long-term operationIncrease local solid holdupCatalytic crackingChemical/physical/physico-chemical processesVertical tubeFluidized bed

The invention discloses a baffle plate reinforced fluidized bed external catalyst cooler. The baffle plate reinforced fluidized bed external catalyst cooler comprises a shell, a vertical tube bundle,baffle plates, and a gas distributor; a catalyst inlet is formed in the upper portion of the shell, a catalyst outlet is formed in the bottom of the shell, the vertical tube bundle comprises multipleheat exchange pipes vertically distributed in the shell, each heat exchange pipe comprises a water pipe and a steam pipe arranged outside the water pie in a sealed sleeving manner, the top end of eachheat exchange pipe extends out of the outer portion of the shell, the top of each water pipe is provided with a water inlet, steam outlets are formed in the tops of the steam pipes, the baffle platesare spirally arranged or symmetrically arranged in a staggered manner in the shell in the length direction of the vertical tube bundle, the heat exchange pipes penetrate through the baffle plates andare in fastened connection with the baffle plates, the baffle plates and the vertical tube bundle are connected into a whole, the gas distributor is arranged at the position, below the vertical tubebundle, in the shell, and a fluidizing air inlet communicating with the gas distributor is formed in the shell.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

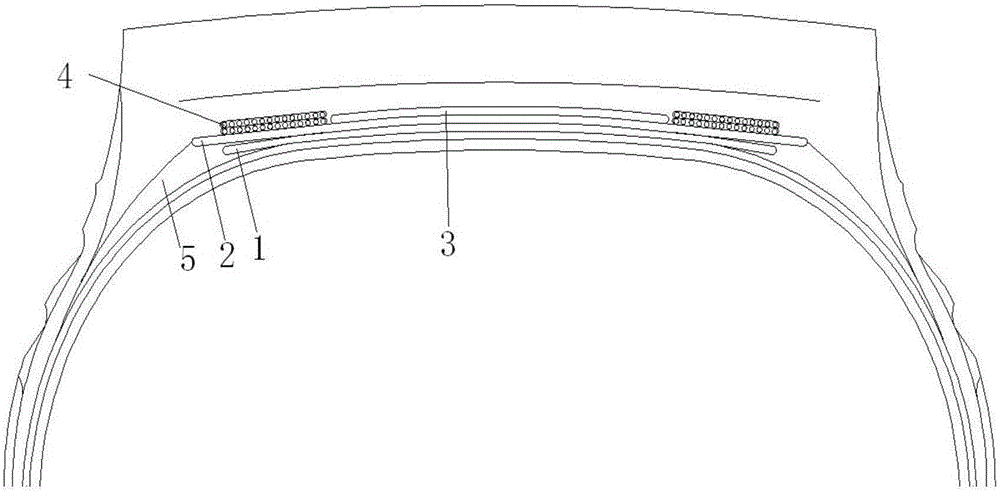

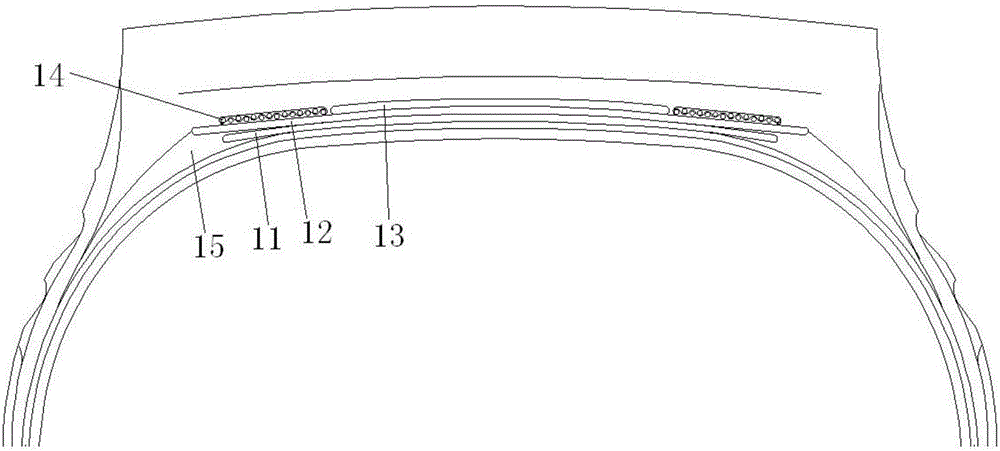

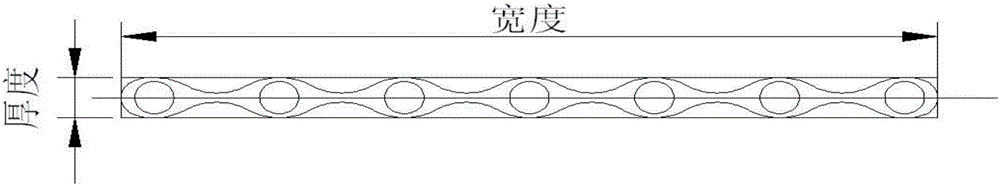

Method for preparing tire through wavy zero belt

InactiveCN106827969AReduce weightImprove high-speed performanceTyresPneumatic tyre reinforcementsVolumetric Mass DensityEngineering

Owner:SHANDONG LINGLONG TIRE

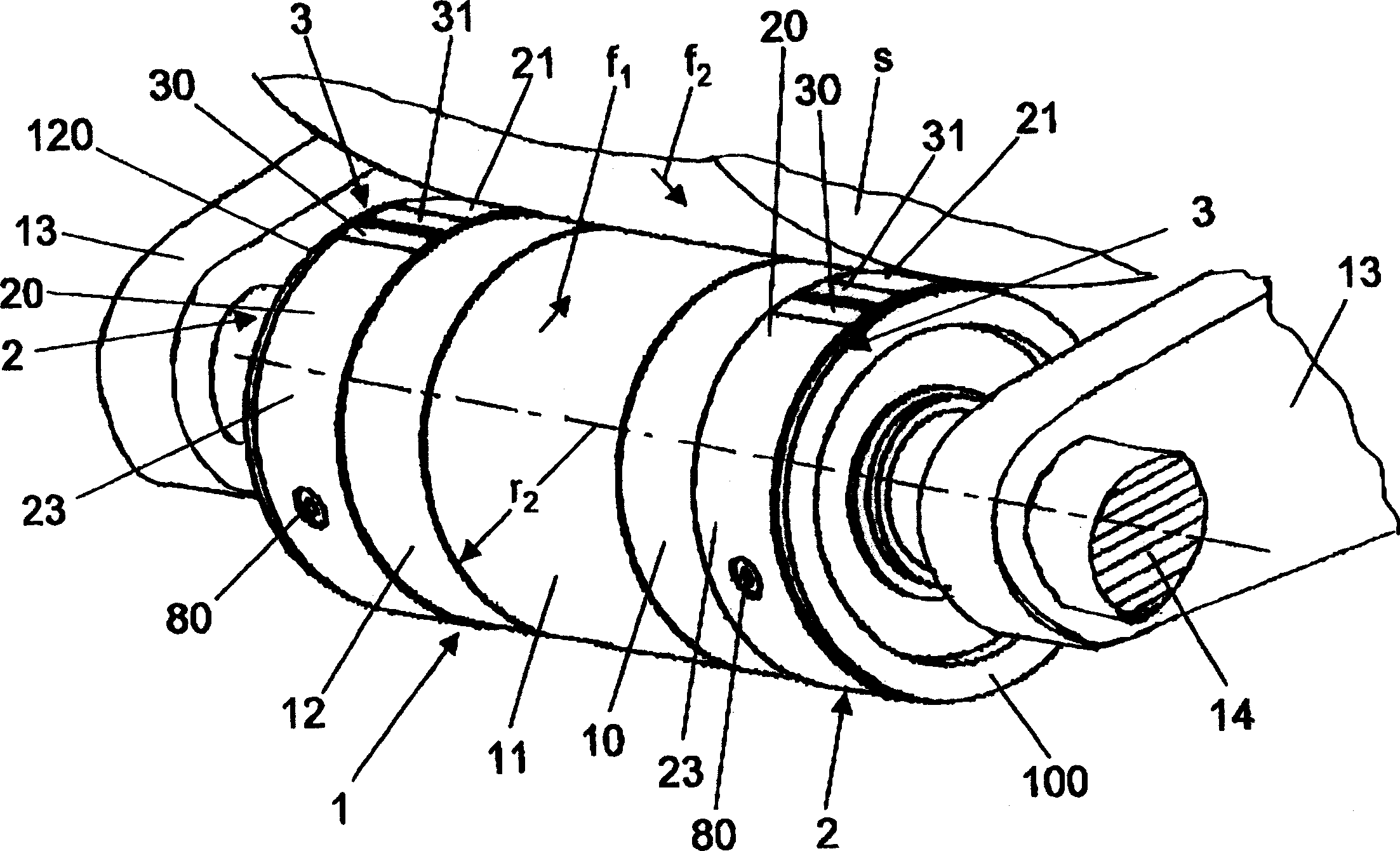

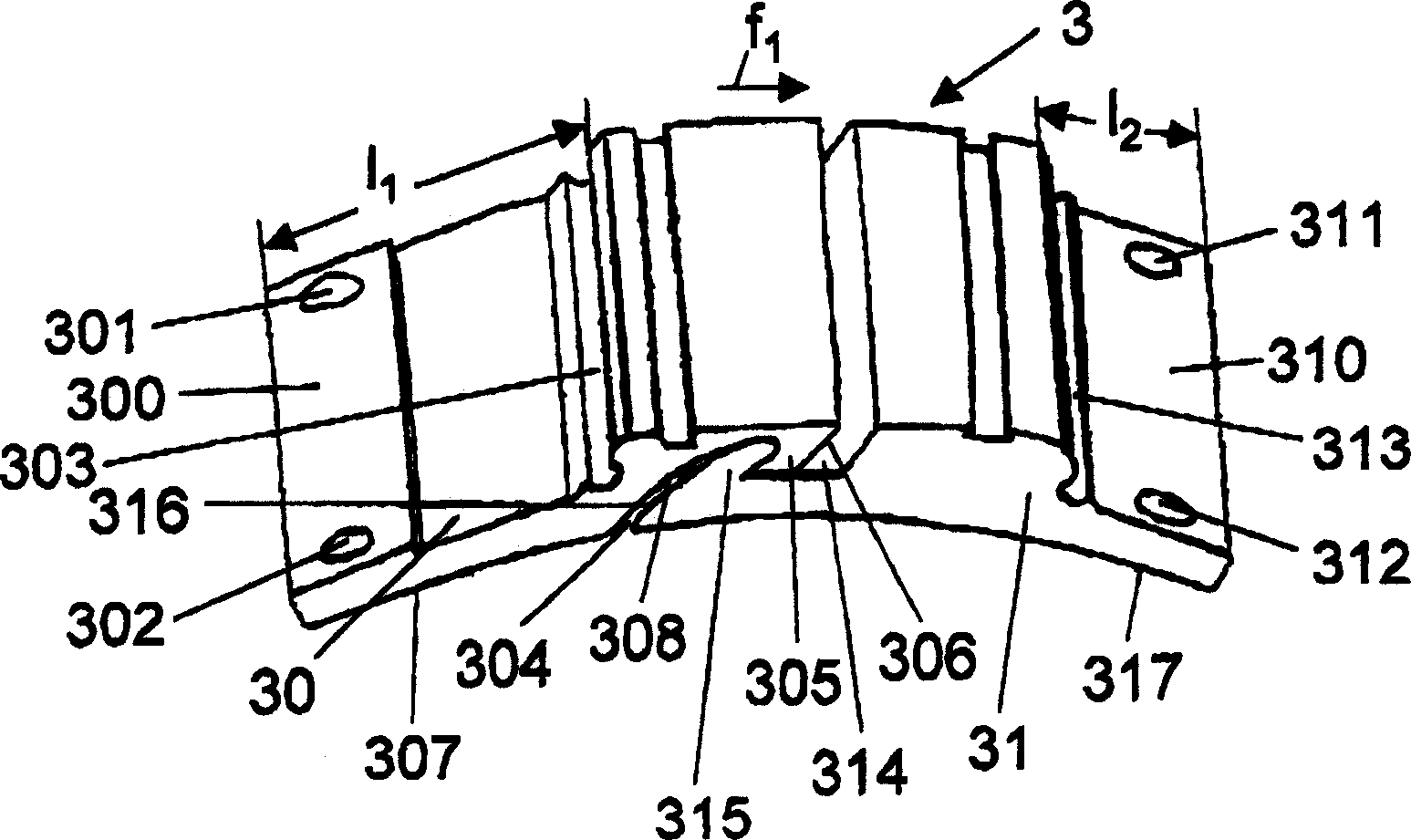

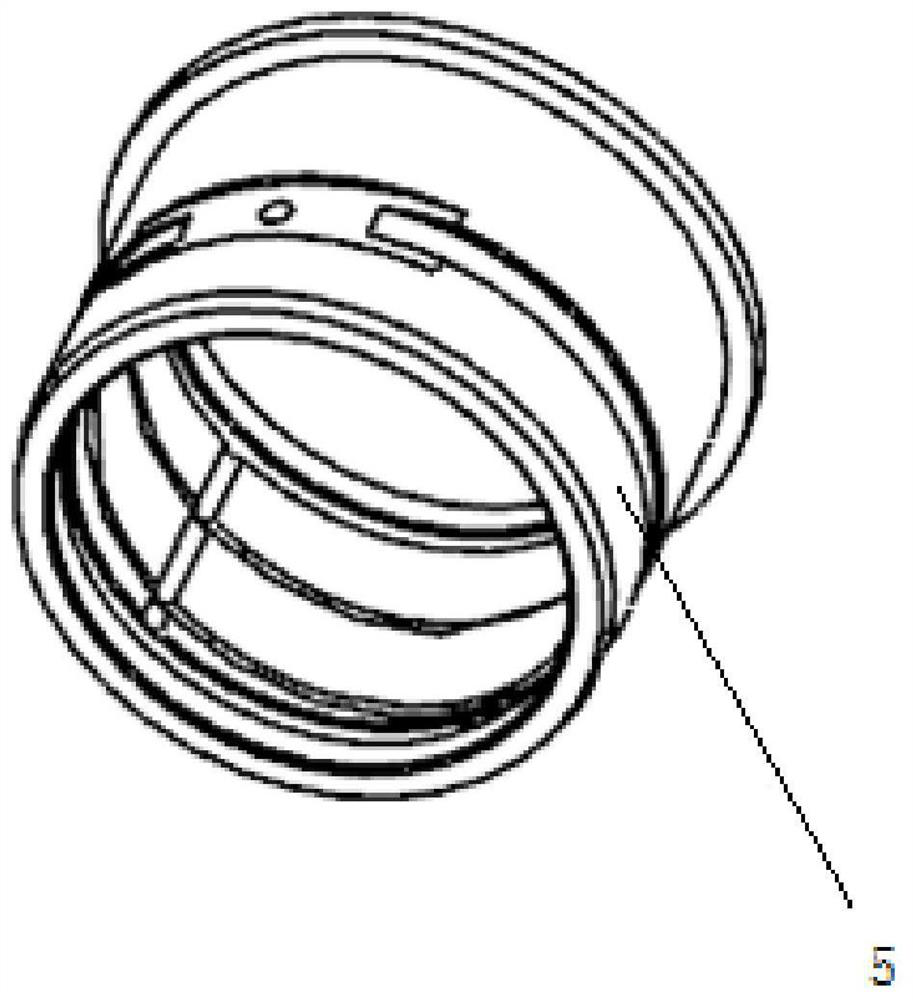

Friction pad of friction roller for driving bobbin on spinning and weaving machine

ActiveCN1513747AFeatures a fixtureEvenly distributed around the circumferenceFilament handlingBobbinFastener

In order to drive a spool on a textile machine, a friction roll is provided, having a rotating body, carrying at least one friction ring. This friction ring is designed in the manner of a belt with two, open ends that are clasped together by two connectors. The two connectors, when linked together, form a releasable end fastening apparatus. The two connectors exhibit in this linkage, interlinking hooks. The fastening apparatus for the friction ring ends can serve simultaneously as a ring fastener to the friction roll. Further, the friction ring can be affixed, at a distance away from the two open ends, onto the friction roll with additional fasteners, which are uniformly distributed around the circumference of the friction roll. The two connectors and / or the friction ring exhibit a preselected radius of curvature which adapts to the radius of curvature of the outer circumference of the friction roll.

Owner:RIETER INGOLSTADT SPINNEREIMASCHENBAU AG

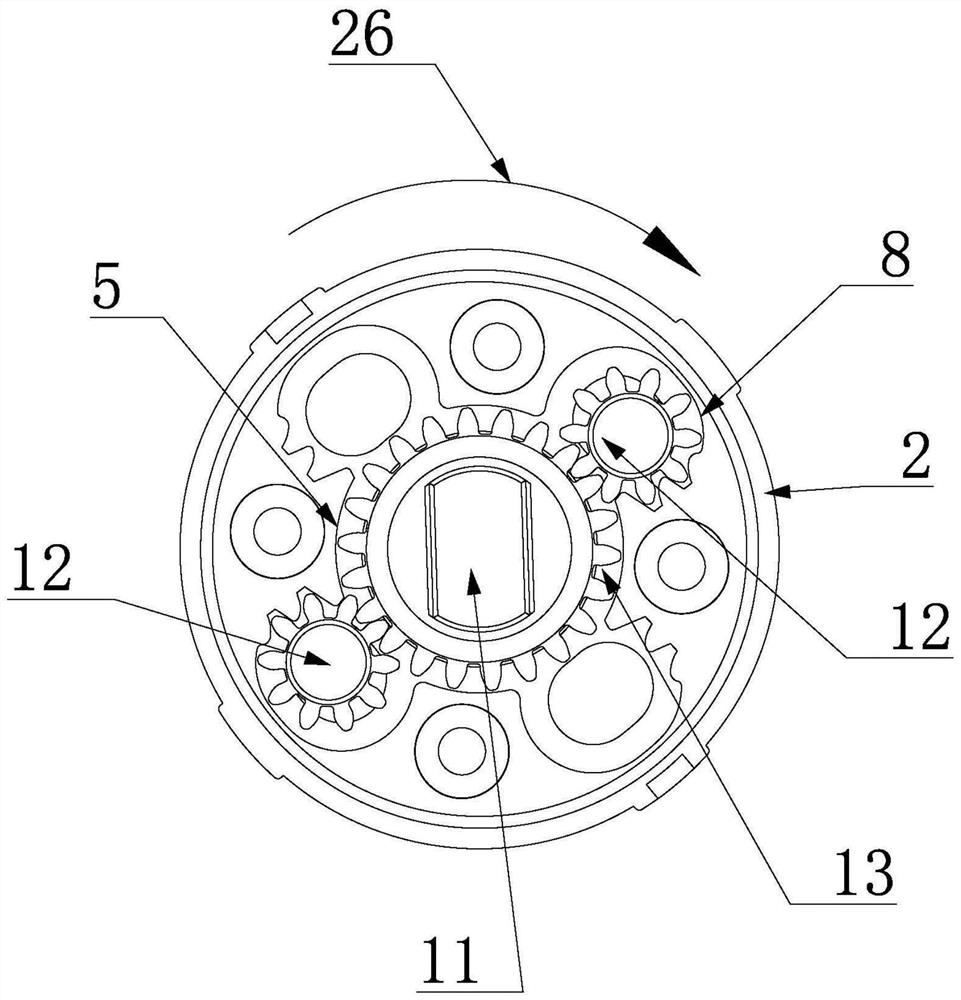

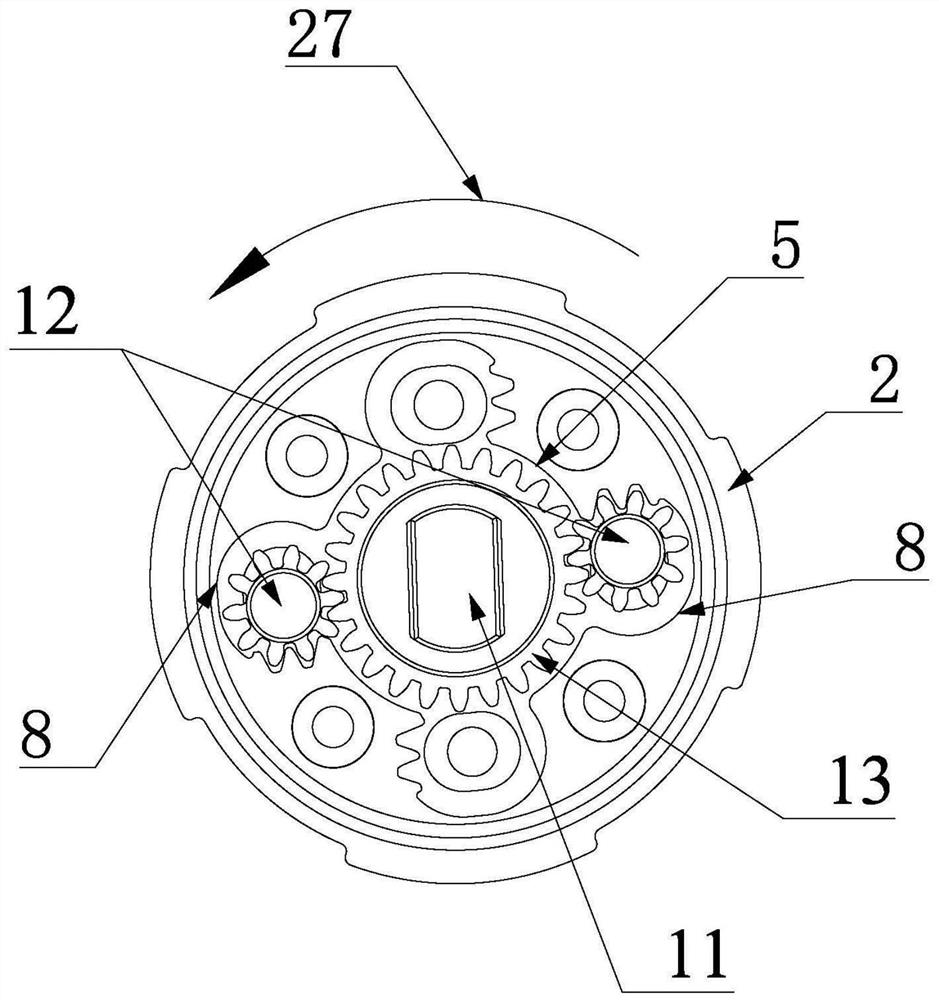

Damping rotating body and damper

The invention discloses a damping rotating body, and relates to the technical field of dampers. The damping rotating body comprises a rotating main body and a groove cover, and first gear grooves capable of being engaged with clamping gears are formed in the side wall faces, opposite to the clockwise direction around the axis of a positioning circular groove, of all clockwise arc-shaped grooves; second gear grooves capable of being engaged with the clamping gears are formed in the side wall surface, opposite to the anticlockwise direction around the axis of the positioning circular groove, of all anticlockwise arc-shaped grooves; first oil passing holes communicating gear containing grooves with the interior of a damper shell are formed in the rotating main body; and second oil passing holes communicating the gear containing grooves with the interior of the damper shell are formed in the groove cover. The invention further discloses a damper. The damper comprises a damper shell, a shell cover and the damping rotating body; the shell cover seals the damper shell; the shell cover and the damper shell form a containing cavity; the damping rotating body is arranged in the containing cavity; and the production cost can be reduced, and the damping performance of the damper is improved.

Owner:GANZHOU HEYING AUTO PARTS

Centrifugal throwing oil atomization structure

ActiveCN106196170AEvenly distributed around the circumferenceGood fuel atomizationContinuous combustion chamberCentrifugationFuel distribution

The invention discloses a centrifugal throwing oil atomization structure. The centrifugal throwing oil atomization structure comprises a rotating main shaft communicated with an oil tank of an engine; and the rotating main shaft is provided with a throwing oil atomizer for outwards throwing introduced fuel in an oil film state under the effect of centrifugal force to atomize the fuel. A throwing oil cavity is formed in the throwing oil atomizer; and the rotating main shaft is provided with multiple oil outlet holes for introducing the fuel in the throwing oil cavity. An annular oil outlet gap is formed in the throwing oil atomizer, and is communicated with the throwing oil cavity; and when the throwing oil atomizer rotates along with the rotating main shaft, the fuel fed in the throwing oil cavity from the oil outlet holes is outwards thrown in the oil film state from the oil outlet gap under the effect of centrifugal force after forming an oil film on the inner wall of the throwing oil cavity. The centrifugal throwing oil atomization structure is more uniform in peripheral fuel distribution, and is better in fuel atomization effect and dispersed distribution; and when the rotating speed of the main shaft is lower, the fuel atomization effect is excellent, the ignition is easy, and the combustion efficiency is high.

Owner:CHINA AVIATION POWER MACHINE INST

Novel rotor

InactiveCN107181335AHigh strengthHard materialMagnetic circuit rotating partsEngineeringMechanical engineering

The invention relates to the field of motor, and discloses a novel rotor which includes an end cover (1), an end ring (3), a conducting bar (4) and a rotor iron core (5). The rotor iron core (5) is provided with the end ring (3) and the conducting bar (4) thereon. The end ring (3) and the conducting bar (4) are formed integrally. The end cover (1) is connected with the end ring (3). The end cover (1) is a steel end cover (1) or a silicon-aluminum end cover (1). The end ring (3) is a pure aluminum end ring (3). The conducting bar (4) is a pure aluminum conducting bar (4). The end cover (1) is provided with a shaft sleeve (6) thereon. The rotor of the invention has the advantages of being capable of stably maintaining the rotation of the rotor, improving the motor efficiency and avoiding the deformation of the rotor.

Owner:HANGZHOU DUNLI ELECTRIC APPLIANCES

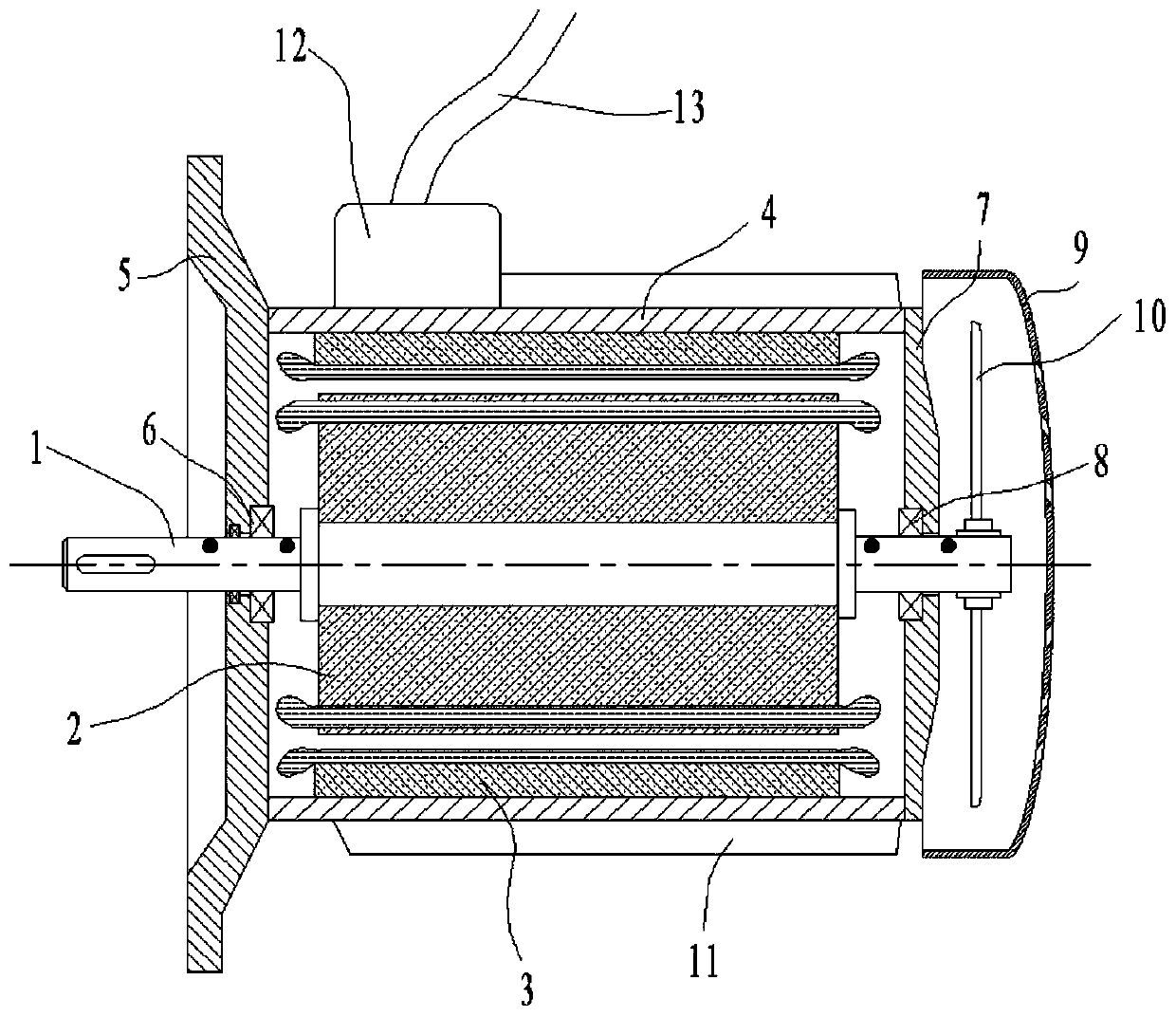

Explosion-proof three-phase asynchronous motor suitable for mine working conditions

ActiveCN110620485AEvenly distributed around the circumferencePrevent leakageShaftsAsynchronous induction motorsPositive pressureThree phase asynchronous motor

The invention discloses an explosion-proof three-phase asynchronous motor suitable for mine working conditions. The motor comprises a main shaft assembly, a rotor, a stator, a shell, a front end coverand a tail end cover, wherein a front cover bearing is arranged at the position where the main shaft assembly penetrates through the front end cover, a junction box is arranged on an outer surface ofthe shell, an external power supply is connected into a motor through a power line, a sealing gasket is arranged on a contact surface of the front end cover and the shell, a rotating shaft seal is arranged in the center of the front end cover and on one side, facing the outside, of the front cover bearing, positive-pressure safety gas is introduced into the shell, a through hole is formed on thewall shell of the machine shell, the through hole is connected with the interior of the machine shell and the space in the junction box, and the positive pressure safety gas introduced into the machine shell is introduced through a power line. The power line comprises a cable and an air pipe, a binding post is arranged in the junction box and connected with the stator, the cable is connected withthe binding post, the air pipe extends into the junction box, and one end, away from the junction box, of the air pipe blows the air on the ground surface through an external draught fan.

Owner:ZHONGQUAN PUMP IND GROUP ZHEJIANG

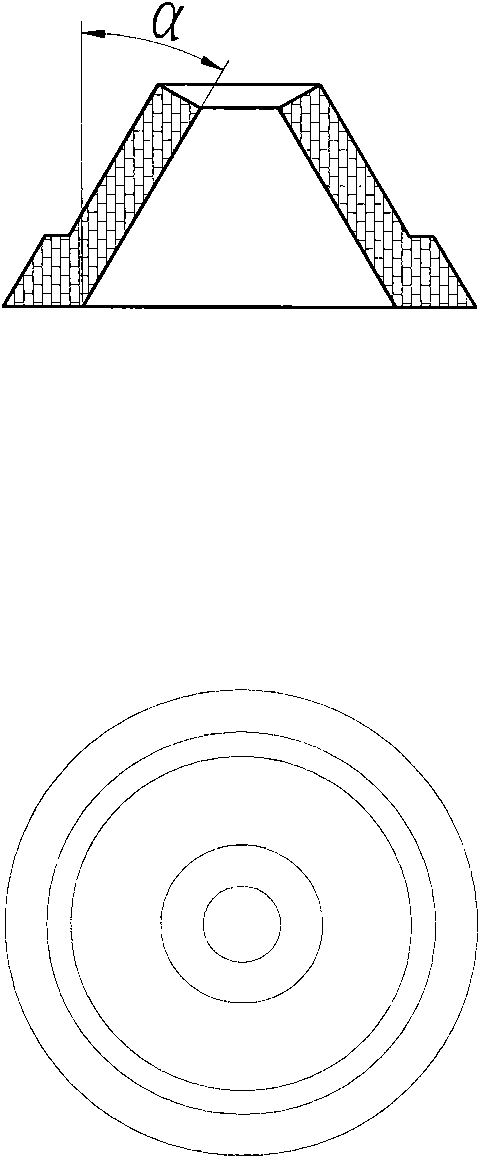

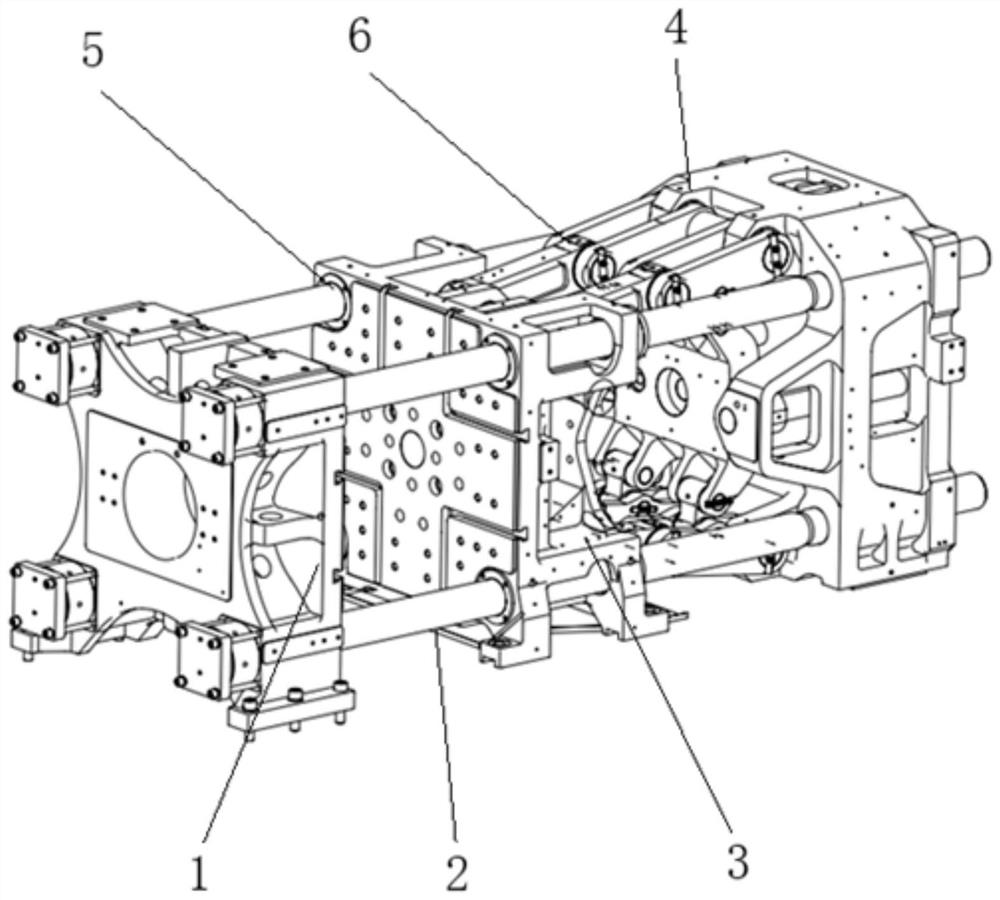

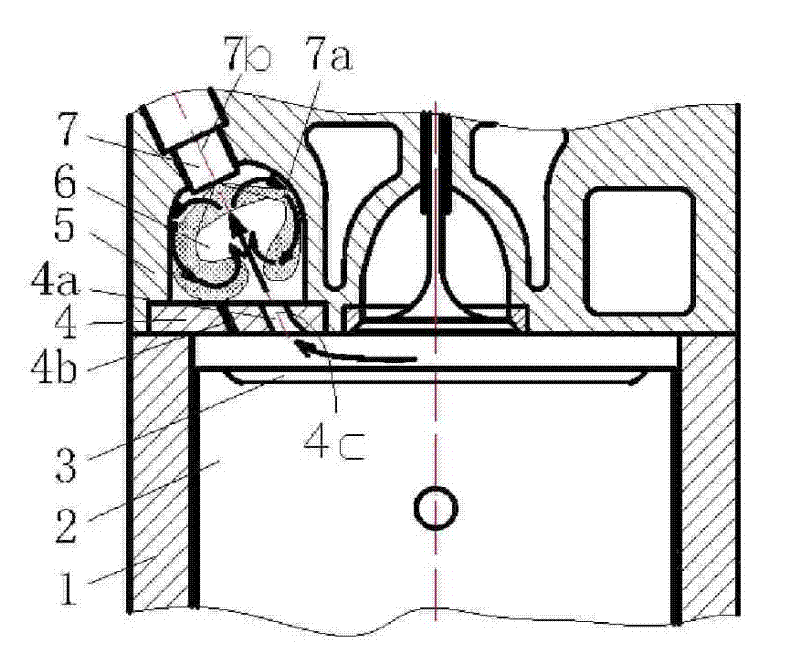

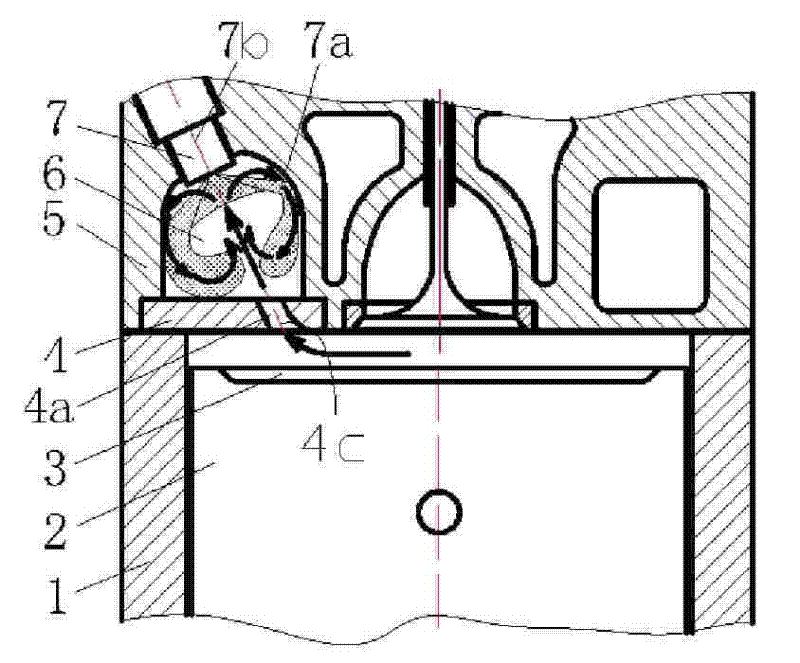

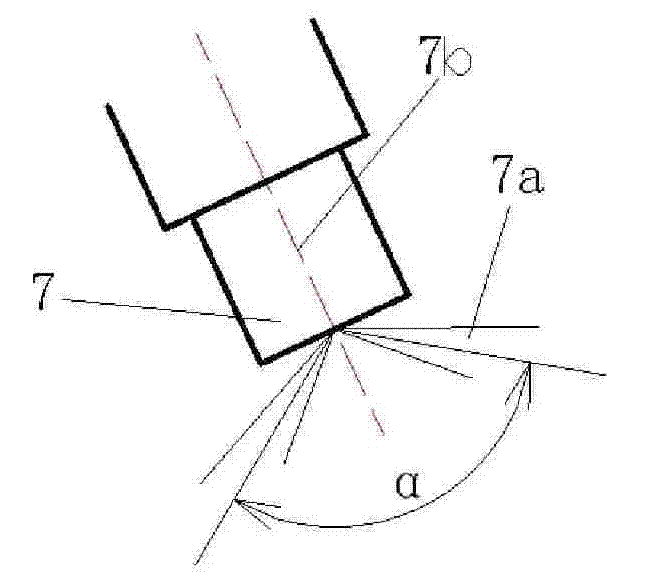

Toggle rod type injection molding machine mold closing mechanism

The invention discloses a toggle rod type injection molding machine mold closing mechanism which comprises a mold moving guide sleeve on the basis of an existing toggle rod type injection molding machine mold closing mechanism. The mold moving guide sleeve comprises a guide sleeve body and a flange, the mold moving guide sleeve is made of a steel-clad copper material, and the inner surface of the guide sleeve adopts a structural form of concentric grooves and spiral grooves. The mold moving guide sleeve body is of a cylindrical structure, the flange is arranged on the outer side of one end of the guide sleeve body, and when the guide sleeve body is matched with a movable mold plate, the flange is 3-4 mm higher than an outer hole of the guide sleeve body in the radial direction, consumables are reduced, cost is reduced, and meanwhile waste in the machining process is avoided. The outer layer of the mold moving guide sleeve is made of a steel-clad copper material made of tin bronze on the inner wall of 20# carbon structural steel, and the wear resistance is improved due to the steel-clad copper structure. Compared with an existing mold moving guide sleeve of a single concentric groove structure, the concentric groove and spiral groove structure can improve the guide effect on lubricating oil, the lubricating oil is more evenly distributed in the circumferential direction of a pull rod, lubrication is more sufficient, the abrasion resistance of moving parts is improved, abrasion is reduced, and the maintenance cost is reduced.

Owner:TEDERIC MACHINERY

Five-layer coextrusion plastic pipe forming die

ActiveCN102765179BIncrease flow rateEvenly distributed around the circumferenceInlet channelEngineering

The present invention relates to the field of plastic forming, and aims to provide a five-layer coextrusion pipe plastic pipe forming die with uniform wall thickness of billet and without generating a confluent line, wherein incompletely plasticized plastic is easy to be plasticized continuously in the die. The five-layer coextrusion plastic pipe forming die comprises a die core, four cover dies coaxially sleeved outside an lower part of the die core, an outer die sleeved outside the die core and the cover die, a shunt and a heating device. The lower part of the die core and the outer body side of the cover die are equipped with one-head or multi-head spiral grooves and flow choking rings; the lower end of the die core, the lower end of the die cover and the lower end of the outer die are respectively fixedly connected with the shunt; the shunt is provided with a plurality of inlet channels communicating with the spiral grooves; and the upper part of the outer body side of the die core and the upper part of the inner body side of the outer die form an outlet passage, and the lower part of the outlet passage communicates with flow choking rings. The five-layer coextrusion plastic pipe forming die can enable incompletely plasticized plastic to be easily and continuously plasticized in the die, has uniform wall thickness of billet, and does not generate the confluent line.

Owner:ZHEJIANG SHUANGLIN PLASTIC MACHINERY

Centrifugal oil throwing atomization structure

ActiveCN106196170BEvenly distributed around the circumferenceGood fuel atomizationContinuous combustion chamberFuel distributionCentrifugation

Owner:CHINA AVIATION POWER MACHINE INST

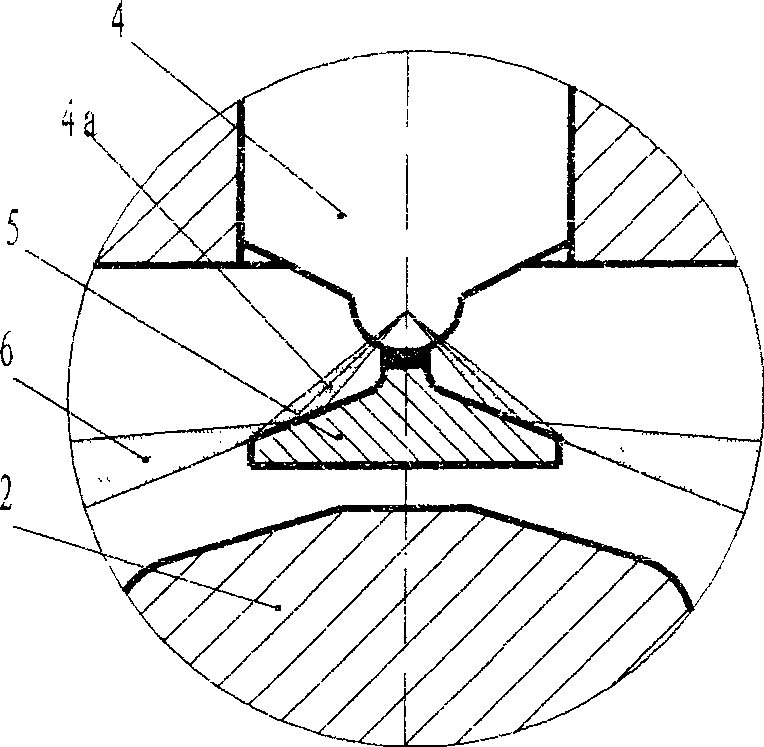

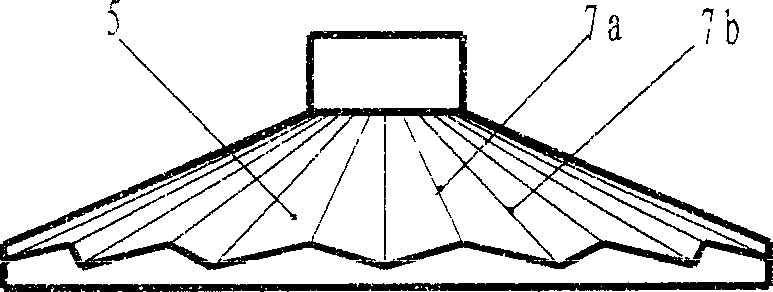

Vortex chamber combustion system utilizing umbrella-shaped spray

InactiveCN101655029BWell mixedEfficient mixingInternal combustion piston enginesCombustion systemEngineering

The invention relates to a vortex chamber combustion system utilizing umbrella-shaped spraying, which belongs to the fields of formation and combustion of engine mixing gases. The vortex chamber combustion system utilizing an oil nozzle with an umbrella-shaped spraying has the structural characteristics that the center line of the oil nozzle with an umbrella-shaped spraying way is superposed withthe center line of a main passage so that the air which flows into a vortex chamber from a compression stroke via the main passage turns back along the wall surface of the vortex chamber to form vortex after reaching the vicinity of the head part of the oil nozzle; the direction of the vortex is just along the diffused direction of the umbrella-shaped spraying so as to accelerate oil and gas mixture and improve the combustion. Because the characteristics of short penetrating distance, even circumferential distribution and high granulation of the umbrella-shaped spraying are reasonably utilized, the favorable mixture and combustion can be obtained at lower vortex strength, thereby reducing heat dissipation loss and throttling loss and further improving the heat efficiency of an engine. Experiments on a single-cylinder 195 diesel engine indicate that the power is improved by 10 percent, the oil consumption is reduced by 8 percent, the discharge of NOx is reduced by 10 percent and the discharge of soot is reduced by 20 percent after the vortex chamber combustion system utilizing the oil nozzle with a umbrella-shaped spraying way is adopted.

Owner:DALIAN UNIV OF TECH

Hollow ingot for spinning of vortex spinning equipment

PendingCN111394838AImprove the wrapping effectQuality improvementContinuous wound-up machinesOpen-end spinning machinesYarnTextile technology

The invention relates to a hollow ingot for spinning of vortex spinning equipment, and belongs to the technical field of vortex spinning. The hollow ingot comprises a hollow ingot body, a yarn guide hole, a doffing tube and a yarn inlet hole. The hollow ingot body is hollowed inside and is further provided with the yarn guide hole in the axial direction, and the yarn guide hole penetrates throughthe hollow ingot body. The yarn inlet hole is formed in the front end of the yarn guide hole. The rear end of the hollow ingot body is further connected with the doffing tube. The hollow ingot for spinning of the vortex spinning equipment is simple and reasonable in structure, the yarn forming effect is good, the winding effect of formed yarns is good, the core yarn exposure phenomenon is avoided,yarn levelness is achieved and quality is good.

Owner:JIANGNAN UNIV

Explosion-proof three-phase asynchronous motor suitable for mine working conditions

ActiveCN110620485BEvenly distributed around the circumferencePrevent leakageShaftsAsynchronous induction motorsRotational axisElectric machine

The invention discloses an explosion-proof three-phase asynchronous motor suitable for mine working conditions, which includes a main shaft assembly, a rotor, a stator, a casing, a front end cover and a rear end cover, and a front cover bearing is arranged where the main shaft assembly passes through the front end cover. A junction box is set on the outside of the shell, the external power is connected to the motor through the power cord, a gasket is provided on the contact surface between the front end cover and the casing, a gasket is provided on the contact surface between the rear end cover and the casing, the center of the front cover, the front cover bearing The side facing the outside is provided with a rotary shaft seal, and positive pressure safety gas is introduced into the casing. A through hole is provided on the shell of the casing, and the through hole connects the interior of the casing with the space in the junction box, and the positive pressure safety gas introduced into the casing is introduced through the power cord. The power line includes cables and air pipes. Terminals are installed in the junction box. The terminal is connected to the stator. The cable is connected to the terminal. The air pipe extends into the junction box. The end of the air pipe away from the junction box is blown into the ground through an external fan. on the air.

Owner:ZHONGQUAN PUMP IND GROUP ZHEJIANG

A uniform steam inlet/admission device for a steam turbine

ActiveCN107965354BImprove efficiencyRealize a reasonable distributionStatorsMachines/enginesUnit operationEngineering

The invention discloses a uniform steam inlet / admission device for a steam turbine, which comprises an annular steam inlet flow path casing and a steam inlet pipe casing connected with the steam inlet flow path casing; wherein, the steam flow The steam inlet channel of the channel shell is arranged axially symmetrically, and the cross-sectional area of the steam inlet channel decreases monotonously along the direction of the steam inlet flow. A plurality of steam flow guide vanes are arranged axially symmetrically on the inner wall of the steam inlet channel of the channel housing. The present invention proceeds from the two angles of reducing the loss of the inlet steam and the impact of the steam flow on the rotor, adopts the design of the chamber with a variable cross-section to adapt to the change of the flow rate of the steam in the flow process, and makes the steam flow in each inlet channel. The flow velocity distribution of the cross-section tends to be uniform, reducing the pressure and temperature loss of the inlet steam, and improving the efficiency of the steam turbine; by rationally arranging the steam guide vanes, the distribution of the inlet steam in the circumferential direction tends to be uniform, and the impact of the inlet steam on the rotor is reduced. The steam flow force improves the safety and stability of the unit operation.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com