Baffle plate reinforced fluidized bed external catalyst cooler

A technology of external heat extractor and baffle plate, which is applied in fluidized bed heat exchangers, catalytic cracking, indirect heat exchangers, etc., can solve the problems of poor fluidization state, axial radial temperature, etc., and achieve circumferential radial distribution Uniform, enhanced heat transfer process, easy renovation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

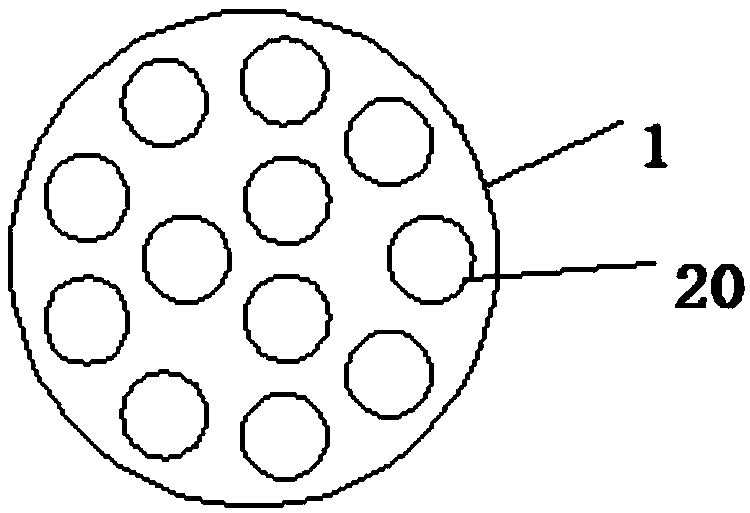

Image

Examples

Embodiment 1

[0044] Such as image 3 As shown, in this embodiment, the baffle 3 adopts a partial conical structure, and the partial conical baffle is a 1 / 4 to 2 / 3 conical panel, and the corresponding cone angle α of the partial conical baffle is 60° to 60°. 150°, the radius R1 of the bottom of the part of the conical baffle is 80% to 95% of the radius of the shell side (the shell side is the inner space of the shell 1 except the wall thickness and heat insulation and wear-resistant layer), and the thickness δ is 3 to 15mm ( Such as image 3 As shown in c); the baffles 3 are helically distributed in the casing 1 along the length direction of the vertical tube bundle 2, and the distance H between adjacent baffles 3 is 150-500mm (such as image 3 shown in a and 3b); by adjusting the spacing H between the baffles 3, the connection form of the adjacent baffles 3 can be adjusted, and according to the influence of the baffles 3 on the flow of the catalyst in the housing 1, considering the relati...

Embodiment 2

[0046] Such as Figure 4 As shown, in this embodiment, the baffle 3 has a partial conical frustum structure. The bottom radius R2 and top radius R3 of the table baffle are respectively 80% to 95% and 15% to 45% of the radius of the shell section, and the thickness δ is 3 to 15mm (such as Figure 4 As shown in c), the baffles 3 are distributed symmetrically and staggered along the length direction of the vertical tube bundle 2 in the shell 1, and the distance H between adjacent baffles 3 is 150-500mm (such as Figure 4 shown in a and 4b); by adjusting the spacing H of the baffles 3, the connection form of the adjacent baffles can be adjusted, that is, whether to overlap, when the spacing H of the adjacent baffles 3 is small, the adjacent baffles 3 Whether they are overlapped or not, the baffles 3 are tightly connected to the vertical tube bundles 2. In this embodiment, the adjacent baffles 3 are non-overlapped. On the basis of part of the conical baffle 3 making the catalyst ...

Embodiment 3

[0048] Such as Figure 5 As shown, in this embodiment, the baffle 3 has an elliptical fan-shaped structure, the central angle β of the elliptical fan-shaped baffle can be 45° to 180°, and the minor axis length a is 80% to 95% of the radius of the shell side section , the length of the major axis b is 1 to 3.85 times the length of the minor axis a, and the thickness δ is 3 to 15 mm (such as Figure 5 As shown in c); the baffles 3 are helically distributed or symmetrically staggered along the length direction of the vertical tube bundle 2 in the shell 1, and the distance H between two adjacent elliptical fan-shaped baffles is 150-500mm (such as Figure 5 a and 5b), the connection form of adjacent baffles can be adjusted by adjusting the spacing H of the baffles 3, that is, whether they are overlapped or not. In this embodiment, the baffles are in a non-overlapped form. The baffle makes the catalyst add spiral flow or radial cross-flow flow on the basis of the axial flow, and ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com