Damping rotating body and damper

A technology of rotating body and damper, which is applied in the direction of liquid shock absorber, shock absorber, shock absorber, etc., can solve the problem of increasing the inventory of damping rotating body, identifying and managing the number of production molds, increasing the production cost of damper, and reducing shell The oil storage capacity of the body cavity and other issues can be improved to improve the rotation stability and precision, improve the service life and reduce the installation steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

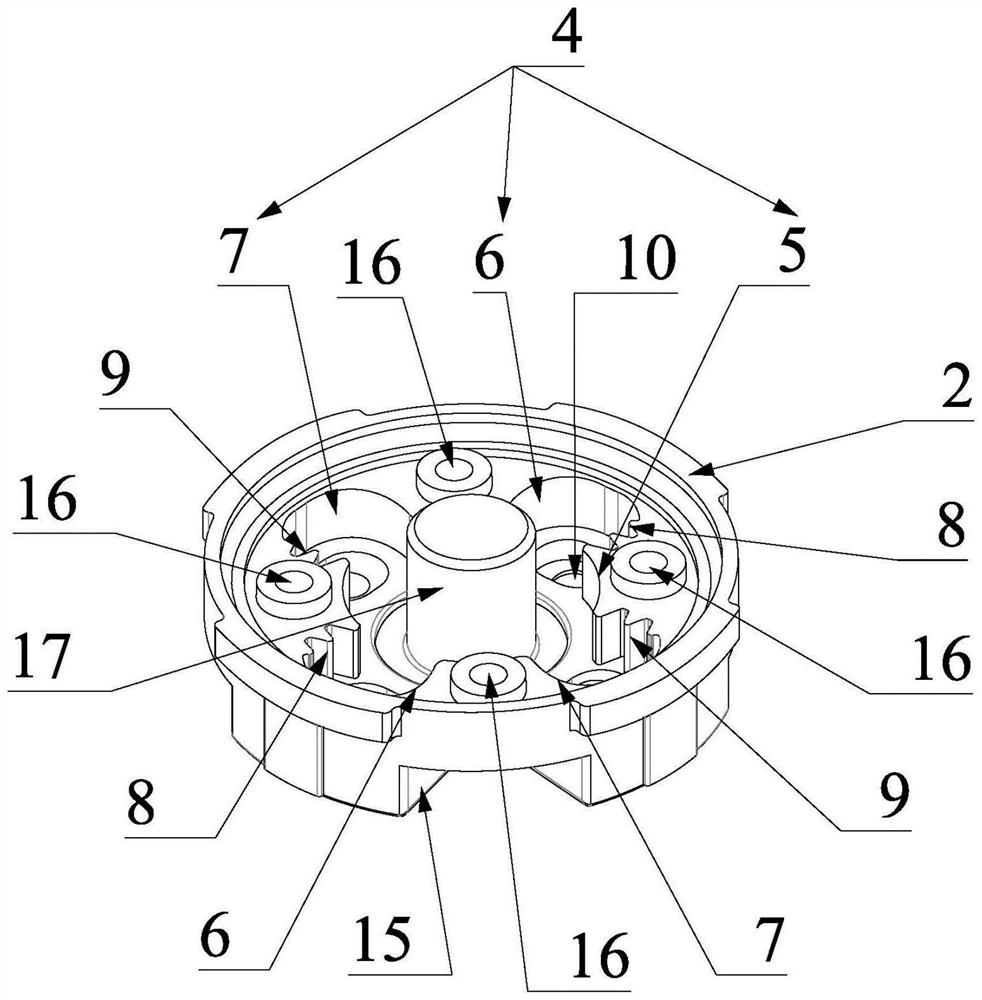

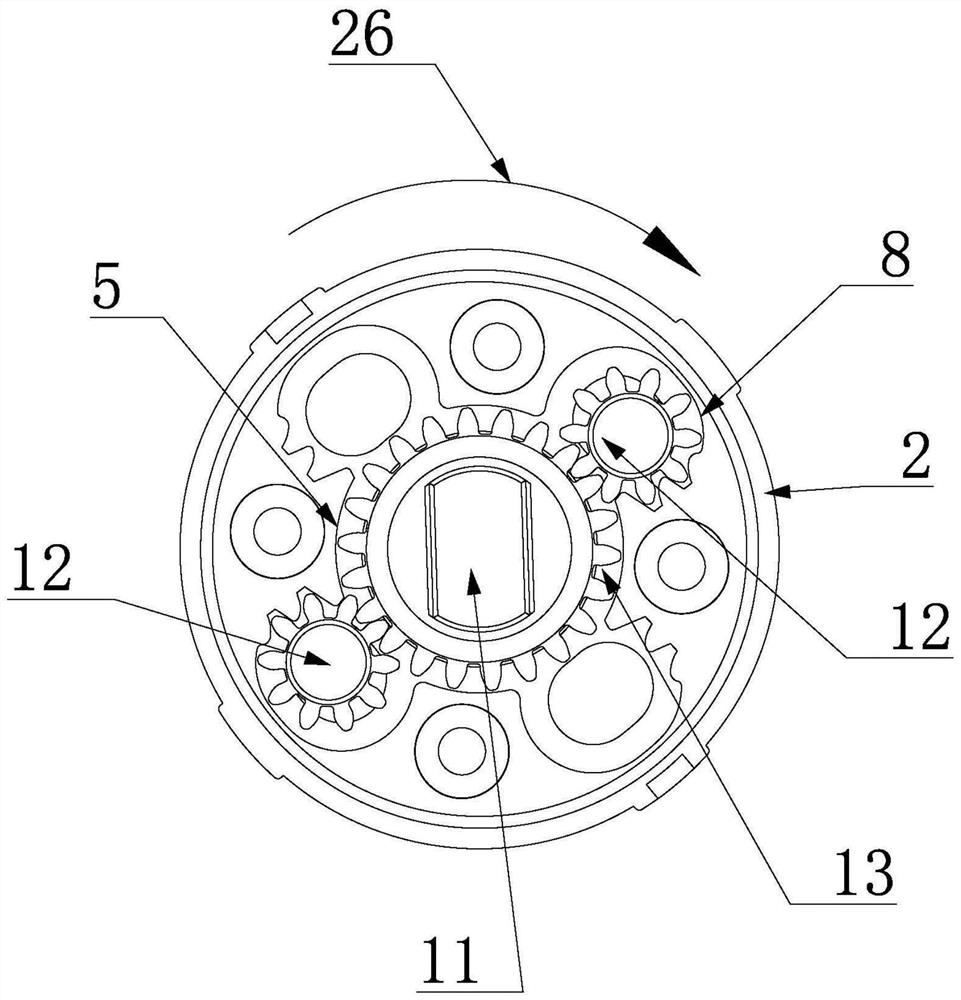

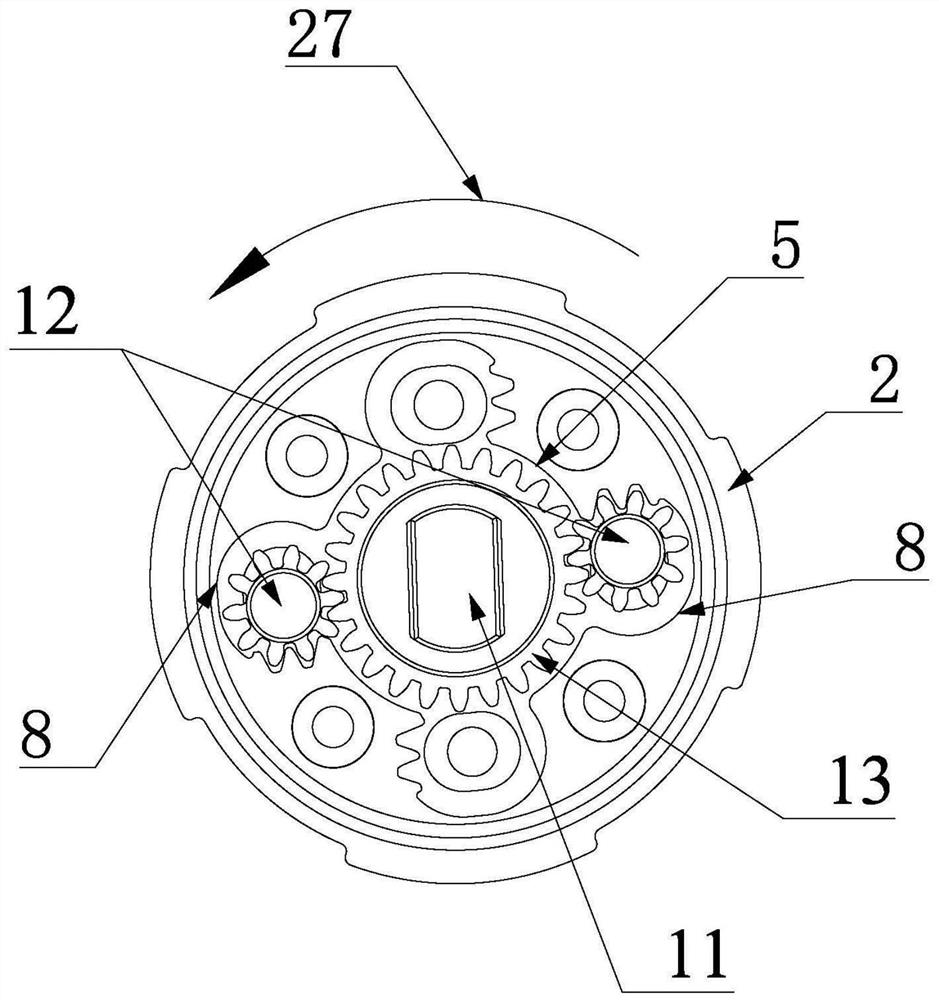

[0035]This embodiment provides a damping rotating body 1, such asFigure 1 ~ 4As shown in this embodiment, the damping rotating body 1 includes a rotating body 2 and a slot cover 3, and the rotating body 2 is used to arrange a gear rendrone on one side surface of the rotary body 2. 4, the gear rendering groove 4 includes a positioning a circle slot 5, a plurality of clockwise arc grooves 6 and a plurality of counterclockwise arc grooves 7, clockwise arc grooves 6, and counterclockwise grooves 7 can preferably be a long arc. The grooves, each clockwise arc groove 6 and each counterclockwise arc groove 7 each can accommodate a card-contact gear 12, and the positioning round groove 5 can accommodate the drive gear 13 that meshes with each of the respective cartridge gear 12, the card connection The gear 12 can rotate the axis of the drive gear 13 in the drive gear 13 or counterclockwise under the drive of the drive gear 13, and each clockwise arc-shaped groove 6 is clockwise clockwise w...

Embodiment 2

[0042]This embodiment provides a damper 25, such asFigure 1 ~ 4As shown in this embodiment, the damper 25 includes a damper housing 19, a housing cover 20, and a damper rotating body 1 in the first embodiment, the housing cover 20 closed the damper housing 19, the housing cover 20 and The damper housing 19 forms the accommodating chamber 21, and the damping rotating body 1 is disposed within the accommodating chamber 21, and a number of clockwise arcuate grooves 6 and several counterclockwise arc grooves 7 are provided on the rotating body 2, each of the various times. The first gear groove 8 capable of engaging the engagement gear 12 is provided on the side wall surface of the engaging gear 12, and each counterclockwise arc-shaped groove 7 is provided on the side wall surface opposite the axis of the positioning round groove 5 axle. Both the side wall surface of the groove 5 axis counterclockwise is provided with the arrangement of the second gear groove 9 that can be engaged with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com