Toggle rod type injection molding machine mold closing mechanism

A mold clamping mechanism and injection molding machine technology, applied in the field of polymer material machinery, can solve problems such as large frictional resistance, single material, and inability to fully lubricate guide sleeves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

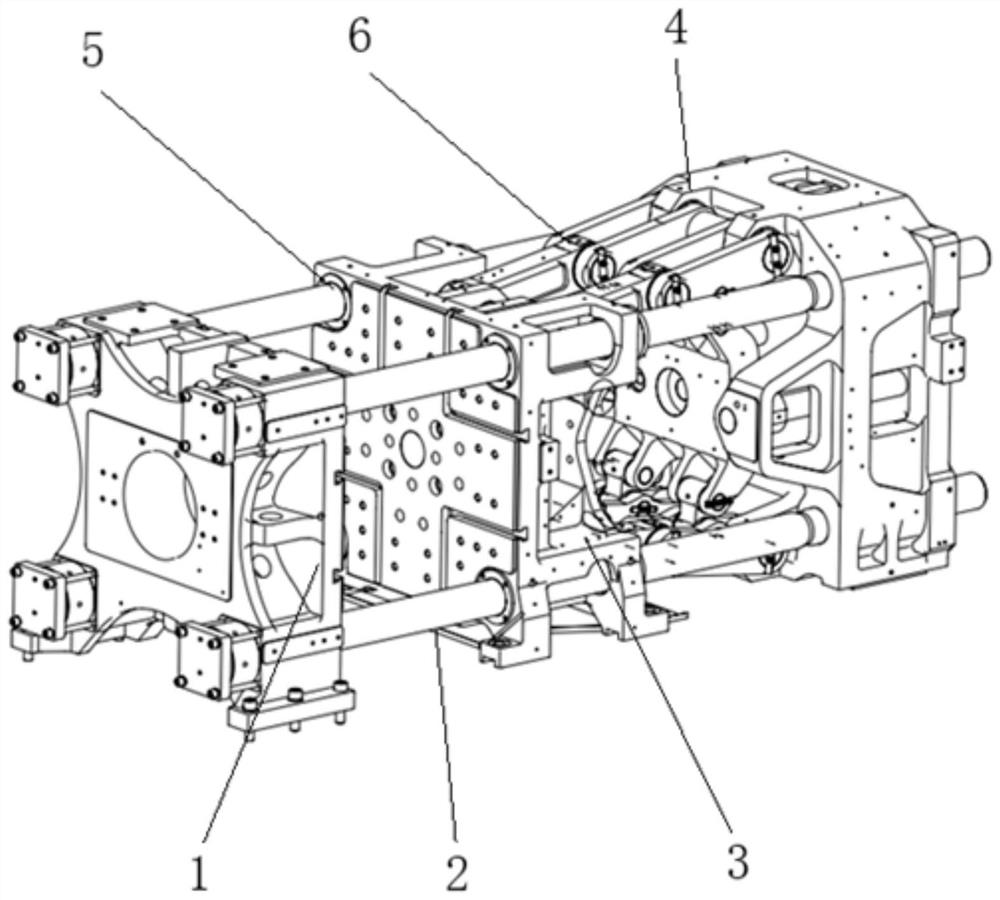

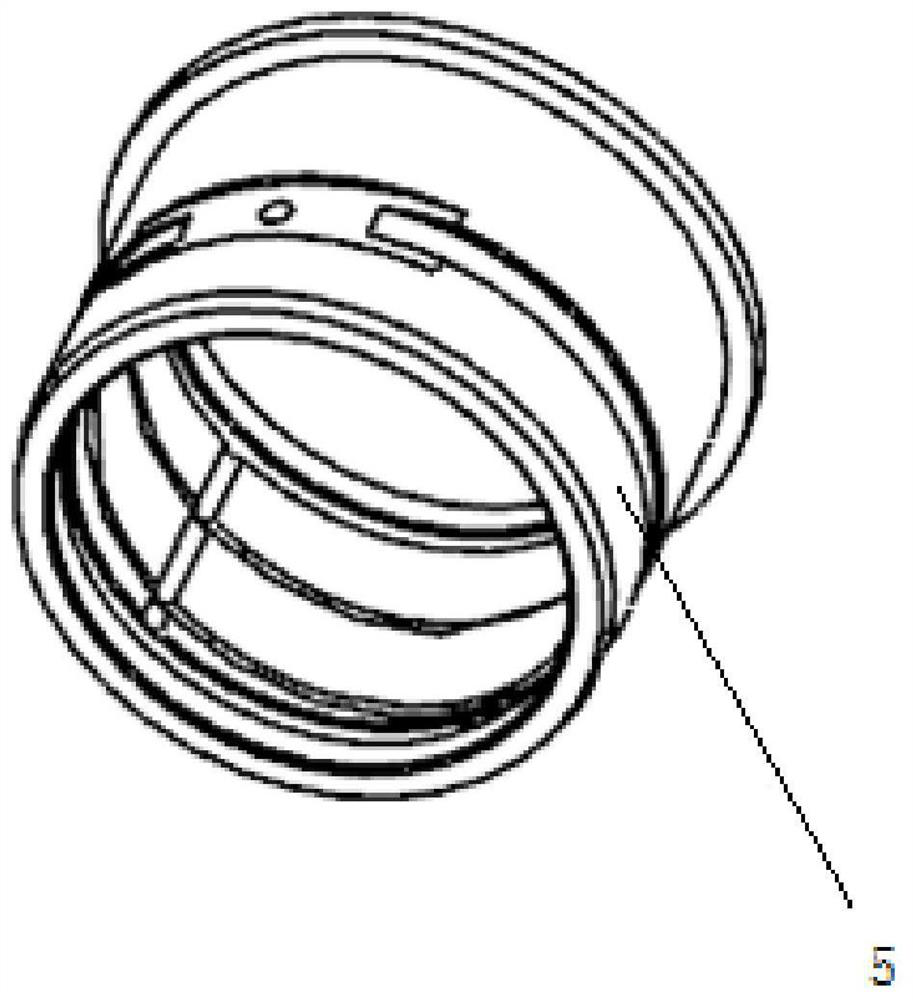

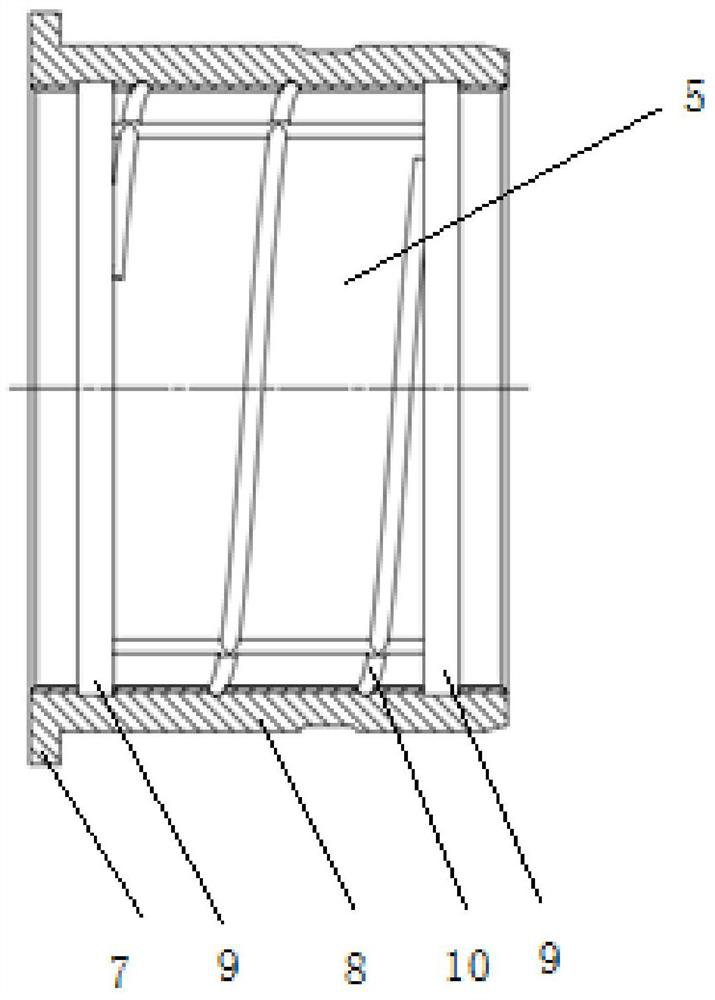

[0018] The clamping mechanism of the toggle type injection molding machine of the present invention, such as figure 1 As shown, in addition to the front template 1, the movable template 3, the rear template 4, the toggle mechanism 6 and the four pull rods 2 included in the mold clamping mechanism of the existing toggle-type injection molding machine, the toggle-type injection molding machine is closed Die mechanism also includes a kind of mold shifting guide sleeve 5, and mold shifting guide sleeve 5 is installed in the two ends of four tie rod holes of movable formwork. In the mold clamping mechanism of the existing toggle-type injection molding machine, the mold is installed between the front template 1 and the movable template 3, the toggle mechanism 6 is installed between the movable template 3 and the rear template 4, and the mold adjustme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com