A uniform steam inlet/admission device for a steam turbine

A technology of steam turbine and steam intake, applied in the direction of machine/engine, mechanical equipment, engine components, etc., can solve the problems of lack of steam flow guide vanes, steam intake loss, loss, etc., to improve safety and stability, circumferential distribution Uniform, uniform flow velocity distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

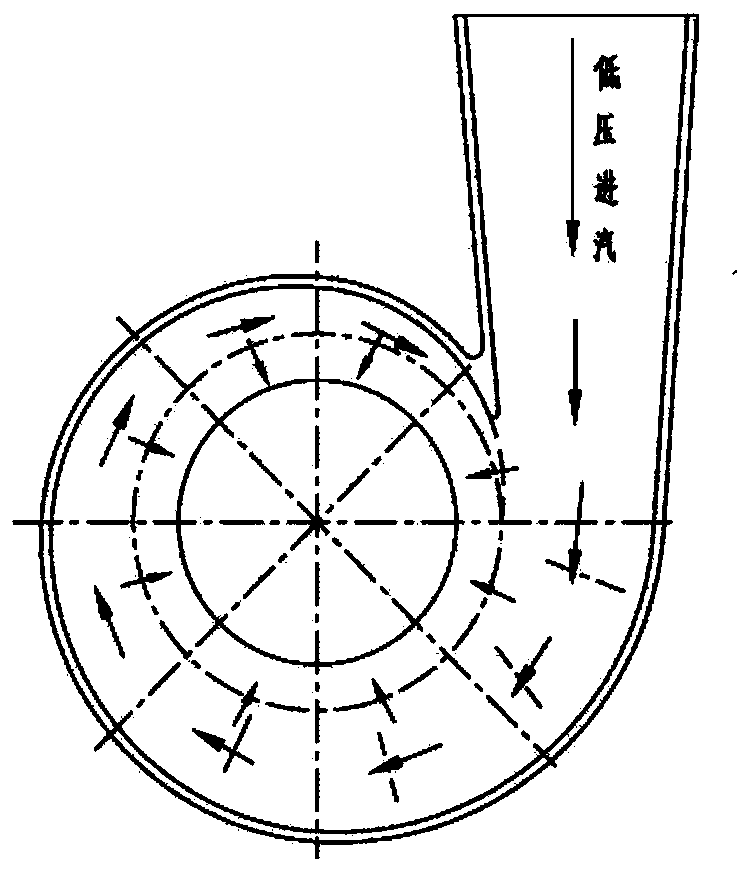

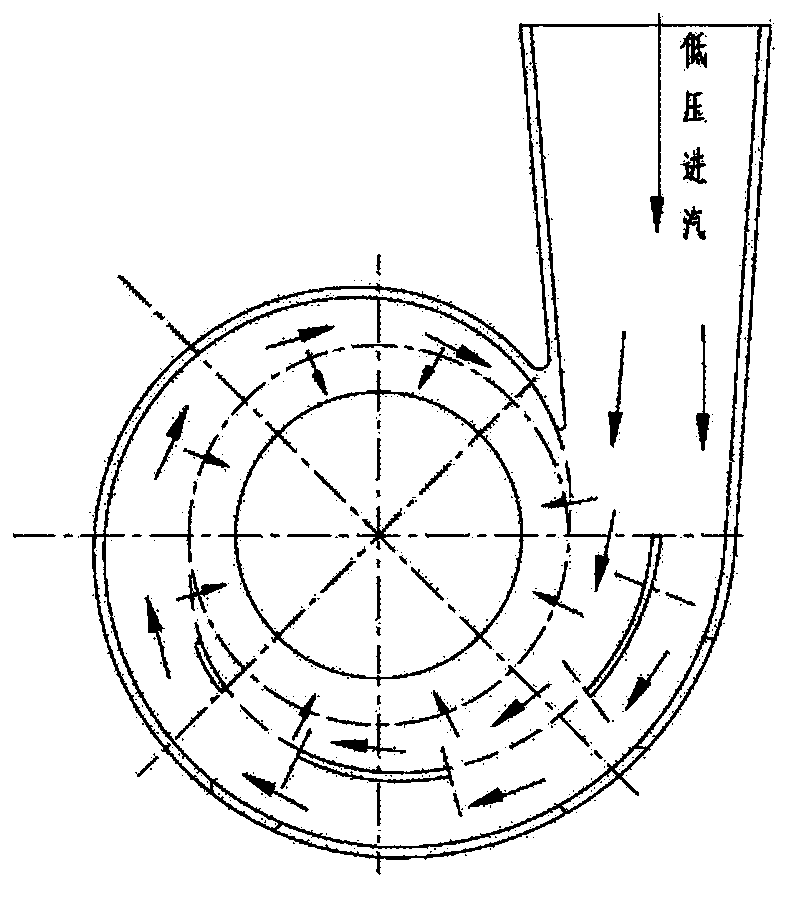

[0032] see Figure 4 to Figure 7 , a uniform steam inlet / admission steam device for a steam turbine provided by the present invention includes an annular steam inlet flow channel casing and an inlet steam pipe casing 1 communicating with the steam inlet flow path casing; wherein, the The steam inlet channel 5 of the steam channel housing is arranged axially symmetrically, and the cross-sectional area of the steam inlet channel 5 decreases monotonically along the direction of the steam inlet flow, and the steam inlet pipe housing 1 communicates with the largest cross-sectional area of the steam inlet channel 5 , and a number of steam guide vanes 4 are arranged axially symmetrically on the inner wall of the steam inlet channel 5 of the steam channel housing.

[0033]Specifically, the air flow guide vane 4 includes a first air flow guide vane, a second air flow guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com