Vortex chamber combustion system utilizing umbrella-shaped spray

A technology of combustion system and vortex chamber, which is applied in the direction of combustion engine, internal combustion piston engine, machine/engine, etc., which can solve the problem of increased channel flow loss, heat dissipation loss of vortex chamber wall, poor economy and cold start performance, and heat dissipation loss of vortex chamber wall Large and other problems, to achieve the effect of improved cold start performance, small excess air coefficient, and increased power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

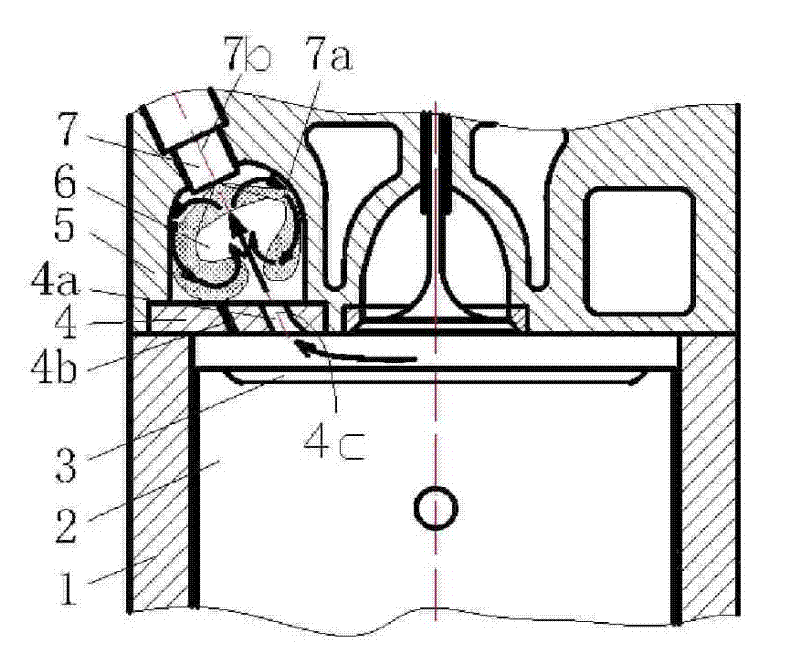

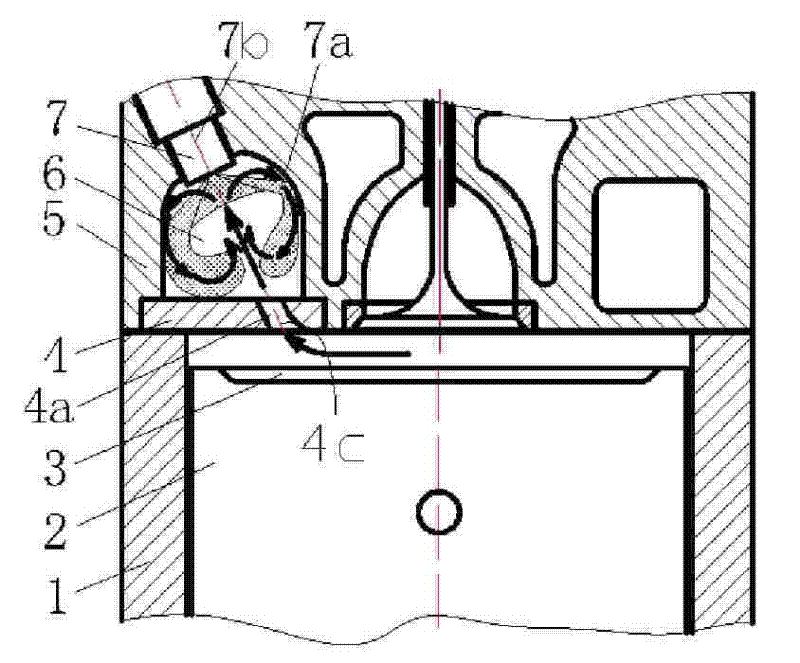

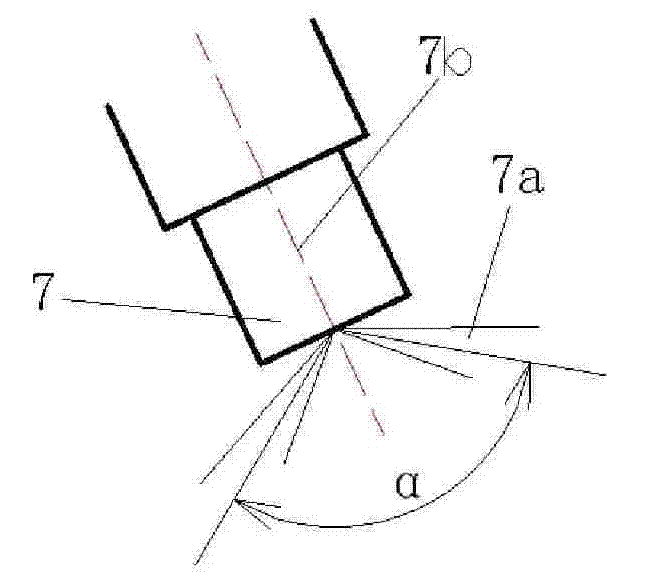

[0014] figure 1 A schematic diagram of a swirl chamber combustion system utilizing an umbrella spray with a start-up hole is shown. The figure mainly shows the main combustion chamber 3, the swirl chamber 6 and the insert 4, and the insert 4 is provided with a main channel 4a and a starting hole 4b connecting the main combustion chamber 3 and the swirl chamber 6. In addition, there is also an umbrella-shaped spray nozzle 7 for spraying umbrella-shaped spray 7a into the swirl chamber 6. The nozzle centerline 7b of the umbrella-shaped spray nozzle 7 overlaps with the channel centerline 4c of the main channel 4a.

[0015] The function of the start-up hole 4b designed on the insert is that during cold start-up, the airflow velocity in the vortex chamber 6 is low, and part of the sprayed oil particles can directly enter the main combustion chamber 3 with relatively high air temperature from the start-up hole 4b. Ignition and combustion in the main combustion chamber 3, or re-enter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com