Method for preparing tire through wavy zero belt

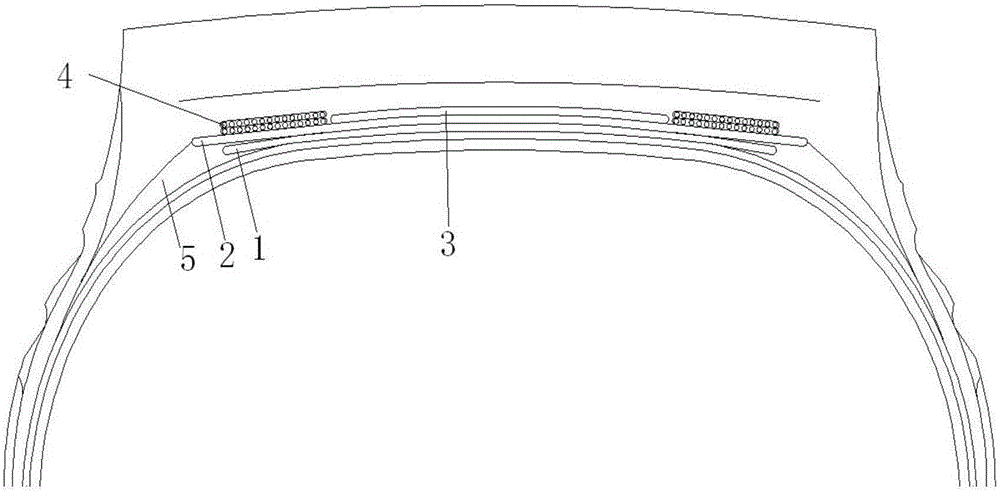

A wave-shaped and belt-shaped technology, which is applied to the reinforcement layer of pneumatic tires, tire parts, tires, etc., can solve the problems of large tension difference between the middle and side parts of the pneumatic belt layer, easy to produce abnormal wear, and high material cost. To achieve uniform distribution in the circumferential direction, reduce cost and tire weight, and achieve the effect of overall flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

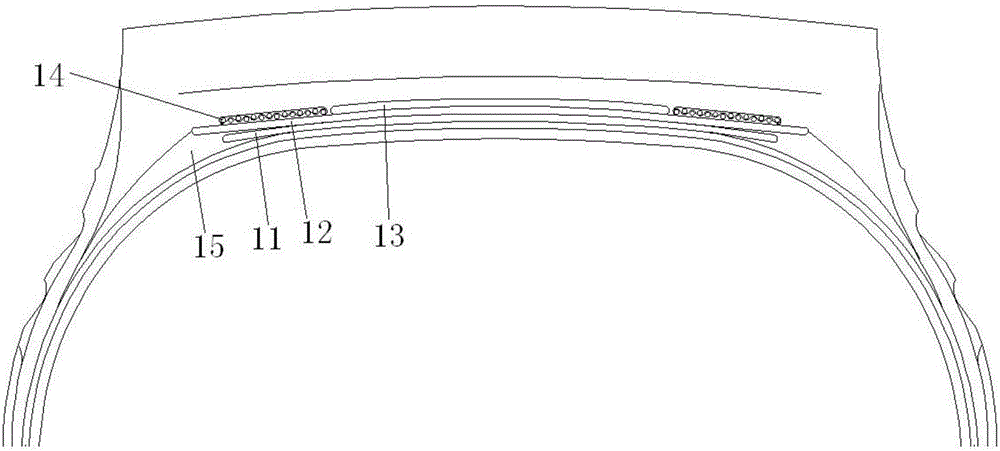

[0021] A belt structure of an inflatable all-steel radial tire, the belt structure is composed of a No. 1 belt 11, a No. 2 belt 12, a No. 3 belt 13, a wave-shaped zero-degree belt 14, a shoulder Pad glue 15 forms.

[0022] A method for preparing a tire using a wave-shaped zero-degree belt, the specific steps of which are:

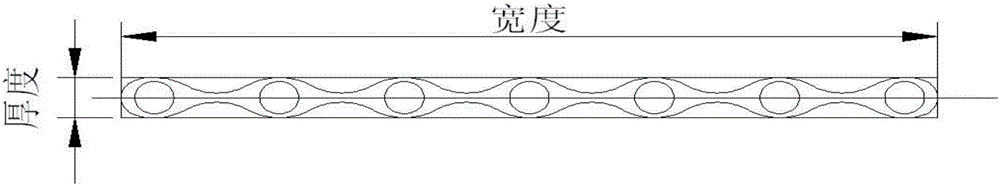

[0023] (1) Preparation of wavy belt strips: design a special extrusion die, and extrude wavy belt strips with a lower density than conventional zero-degree belt layers;

[0024] (2) Coiling of wavy belt strips: the extruded wavy zero-degree belt layer is wrapped with a plastic film with good fresh-keeping effect and coiled;

[0025] (3) Belt layer bonding: according to the normal belt structure method, the first, second, and third layer of belt layers are centered;

[0026] (4) Wave-shaped zero-degree belt winding: wind the first layer of wave-shaped belt at the corresponding belt layer position, and use the winding machine to form an angle of 0°-2° with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com