Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

89results about How to "Improve high-speed performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Photoresist stripper composition

InactiveUS20050287480A1Improve high-speed performanceLower resistanceSemiconductor/solid-state device manufacturingDetergent compounding agentsResistDevice material

(Problem) It is to provide a stripper having excellent ability to suppress corrosion or damage to the copper wiring or the low-k film, and having excellent photoresist residue removability after ashing. (Solution) The invention provides a photoresist stripper composition characterized in containing salts of at least two different inorganic acids, surfactants and a corrosion inhibitor for metal, and having a pH in the range of 3-10; and a process for preparation of semiconductor devices characterized in that the photoresist residues generated during the preparation of semiconductor devices which employs copper or a copper-dominant alloy as the material for wiring is stripped using said photoresist stripper.

Owner:DONGWOO FINE CHEM CO LTD

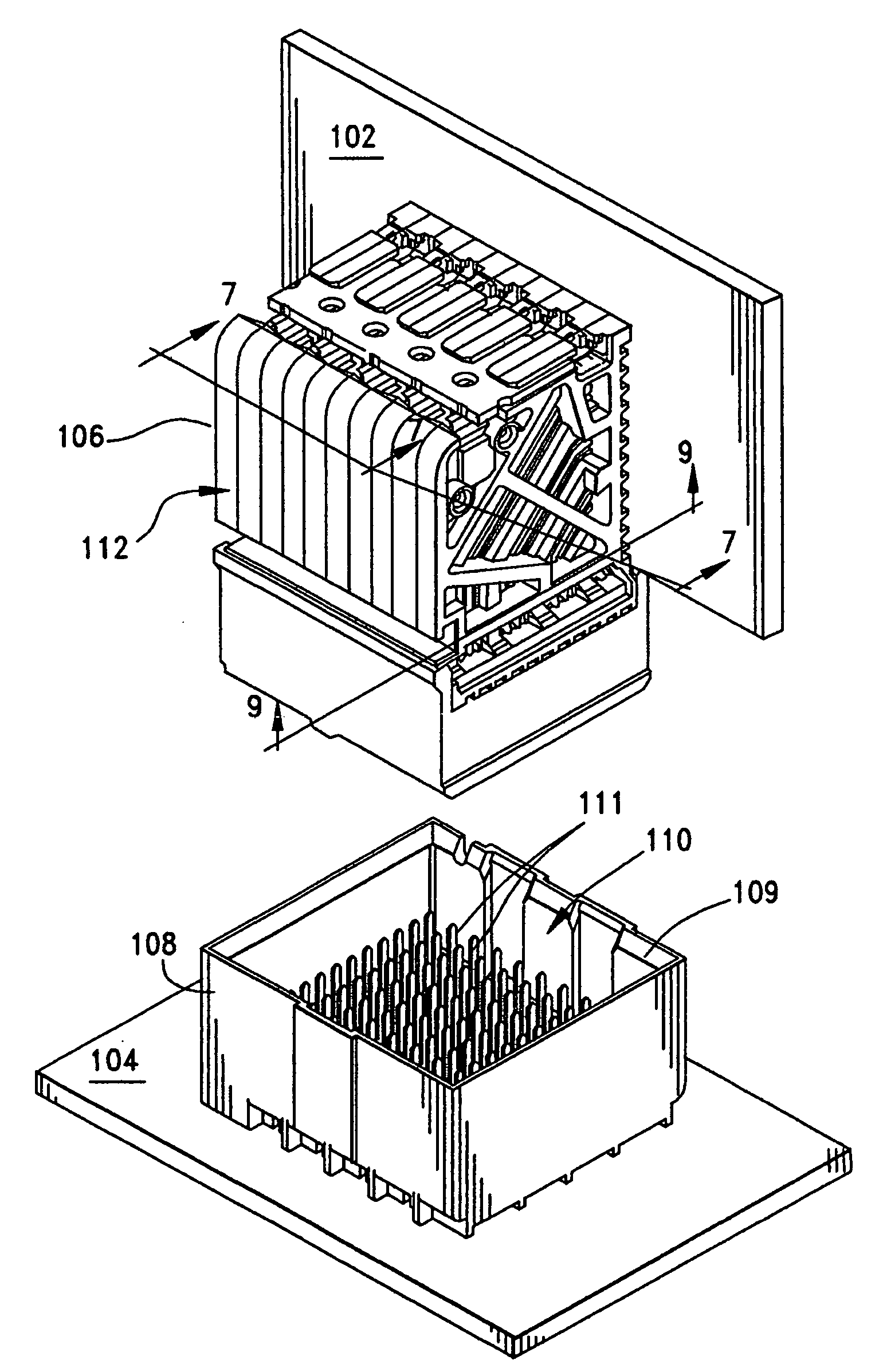

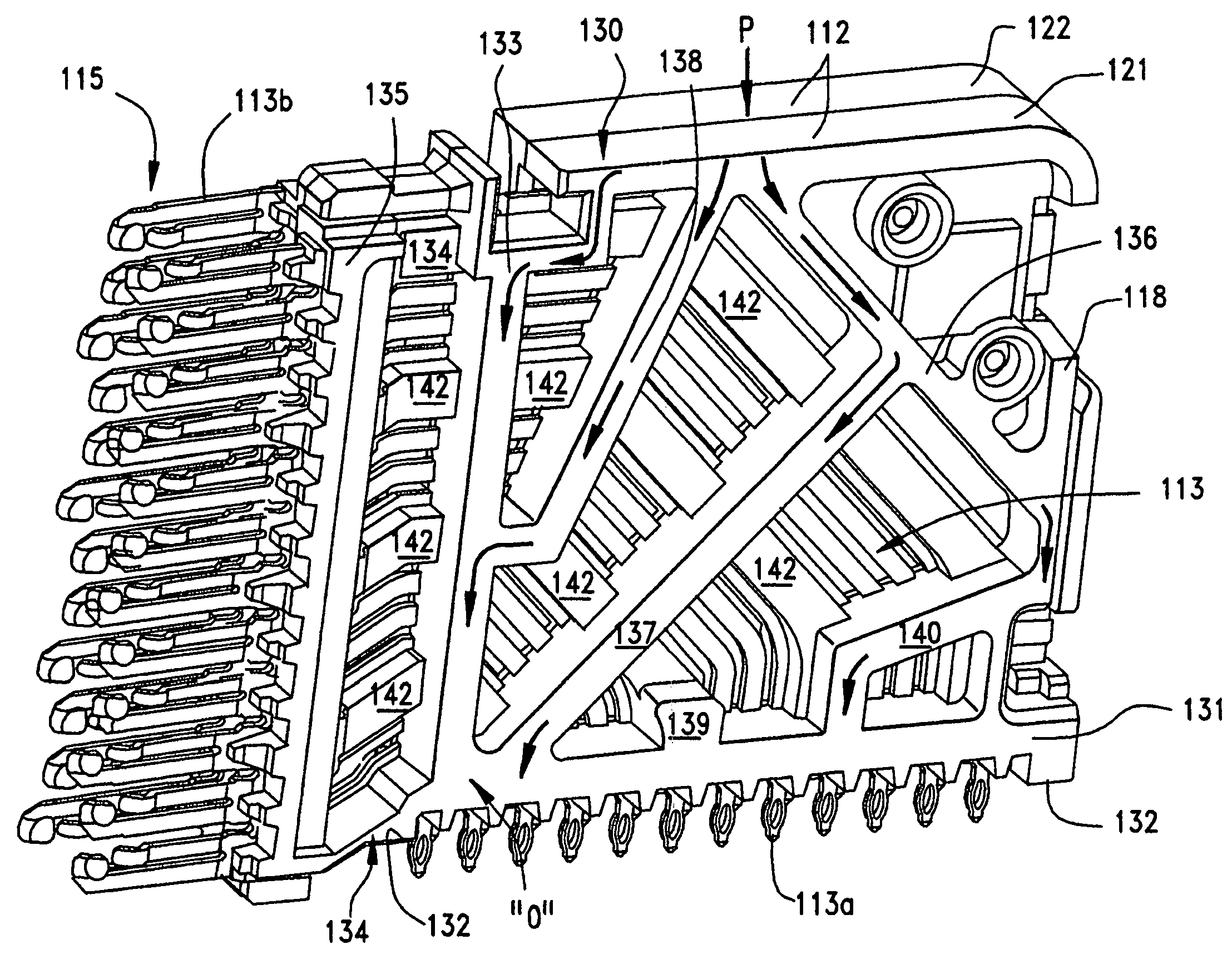

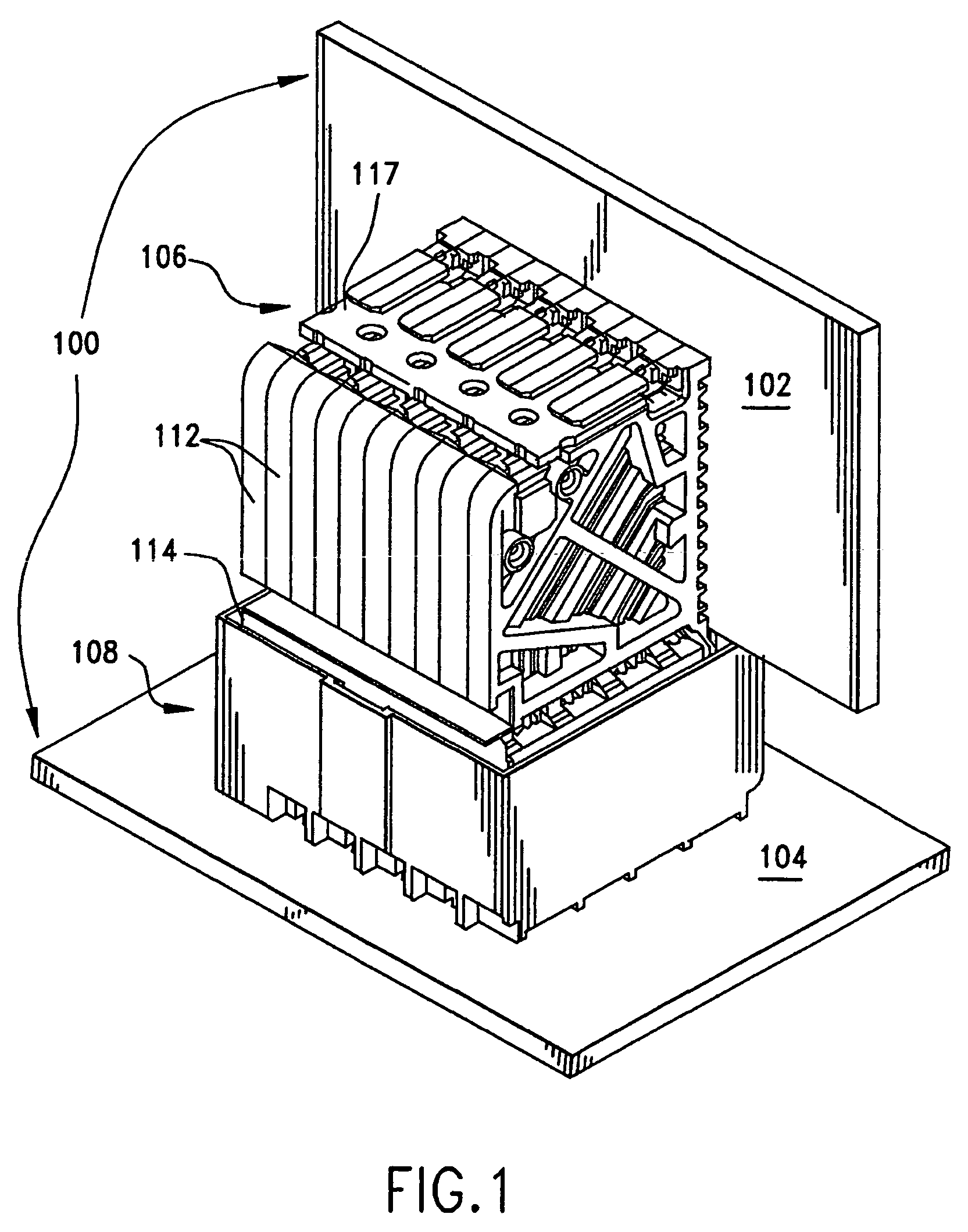

Short length compliant pin, particularly suitable with backplane connectors

ActiveUS20090011642A1Reduce crosstalkGuaranteed uptimeElectrically conductive connectionsTwo-part coupling devicesBackplaneShort length

An electrical connector having a plurality of connector units each having a pair of columns of edge coupled differential signal pairs separated by a ground shield terminal. The ground shield terminals each face a different signal pair of terminals in an adjacent column. Notwithstanding the different size and configurations of the ground and signal terminals, the terminals have mounting tail portions that are disposed in a uniform array different from the arrangement of the body portions of the terminals of the connector unit. The mounting tail portions are of a reduced length which benefit the electrical performance of the connector where it meets its supporting circuit board.

Owner:MOLEX INC

Production method for dedicated steel ball for bearing of high-speed high-precision numerical control machine tool

InactiveCN103008994AImprove manufacturing precisionExtend your lifeSpherical surface grinding machinesFurnace typesNumerical controlCarbon potential

The invention discloses a production method for a dedicated steel ball for a bearing of a high-speed high-precision numerical control machine tool. The method comprises the following steps of steel ball cold heading, namely machining blank by sleeve cutting, shaping, cold heading multi-station and high-speed cold heading ways; rough machining by adopting a macrocyclic light bulb technology; performing controllable atmosphere quenching, cold treatment and tapering treatment by adopting a continuous drum furnace, automatically controlling carbon potential; surface strengthening by adopting a frequency conversion speed adjusting multi-beating-plate structure; hard grinding by adopting a ceramic sand wheel to perform macrocyclic process to machine; after primary grinding, adopting double-roller sorting; after fine grinding, performing photoelectric eddy current test; performing ultra-fine grinding machining after aging treatment; and performing photoelectric detection after ultra-fine grinding. The diameter variation of the steel ball which is machined and produced by the method provided by the invention is less than 0.07 micron, the roundness is less than 0.05 micron, the spherical error is less than 0.05 micron, the surface roughness Ra is less than 0.07 micron, the variation of the diameter of the ball lot is less than 0.09 micron, and the bearing dmn value of the steel ball after being sleeved is more than 2.5*10<6> mm*r / min.

Owner:SHANDONG DONGE STEEL BALL GRP

Short length compliant pin, particularly suitable with backplane connectors

ActiveUS7727017B2Reduce crosstalkGuaranteed uptimeElectrically conductive connectionsTwo-part coupling devicesDifferential signalingElectrical performance

An electrical connector having a plurality of connector units each having a pair of columns of edge coupled differential signal pairs separated by a ground shield terminal. The ground shield terminals each face a different signal pair of terminals in an adjacent column. Notwithstanding the different size and configurations of the ground and signal terminals, the terminals have mounting tail portions that are disposed in a uniform array different from the arrangement of the body portions of the terminals of the connector unit. The mounting tail portions are of a reduced length which benefit the electrical performance of the connector where it meets its supporting circuit board.

Owner:MOLEX INC

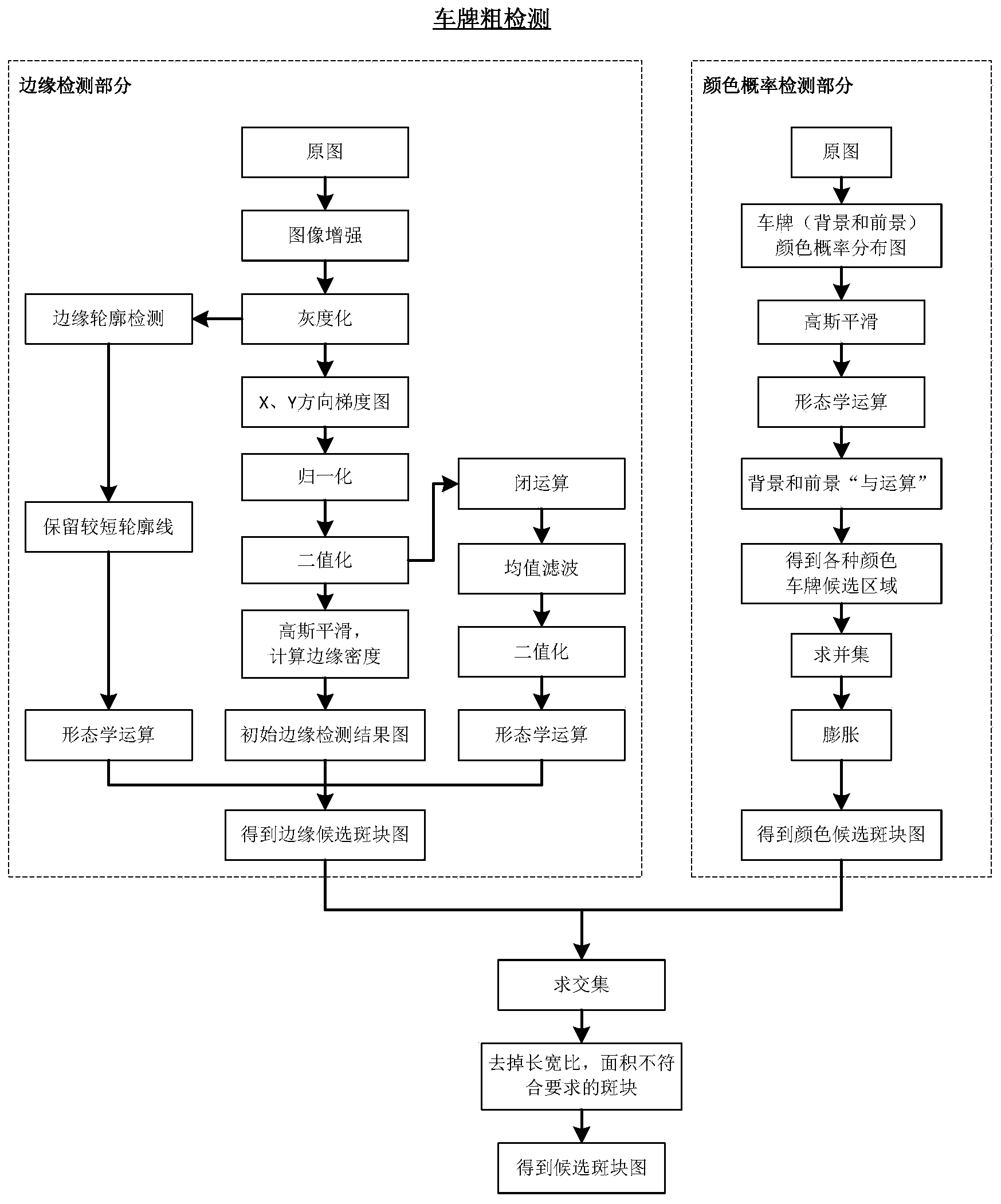

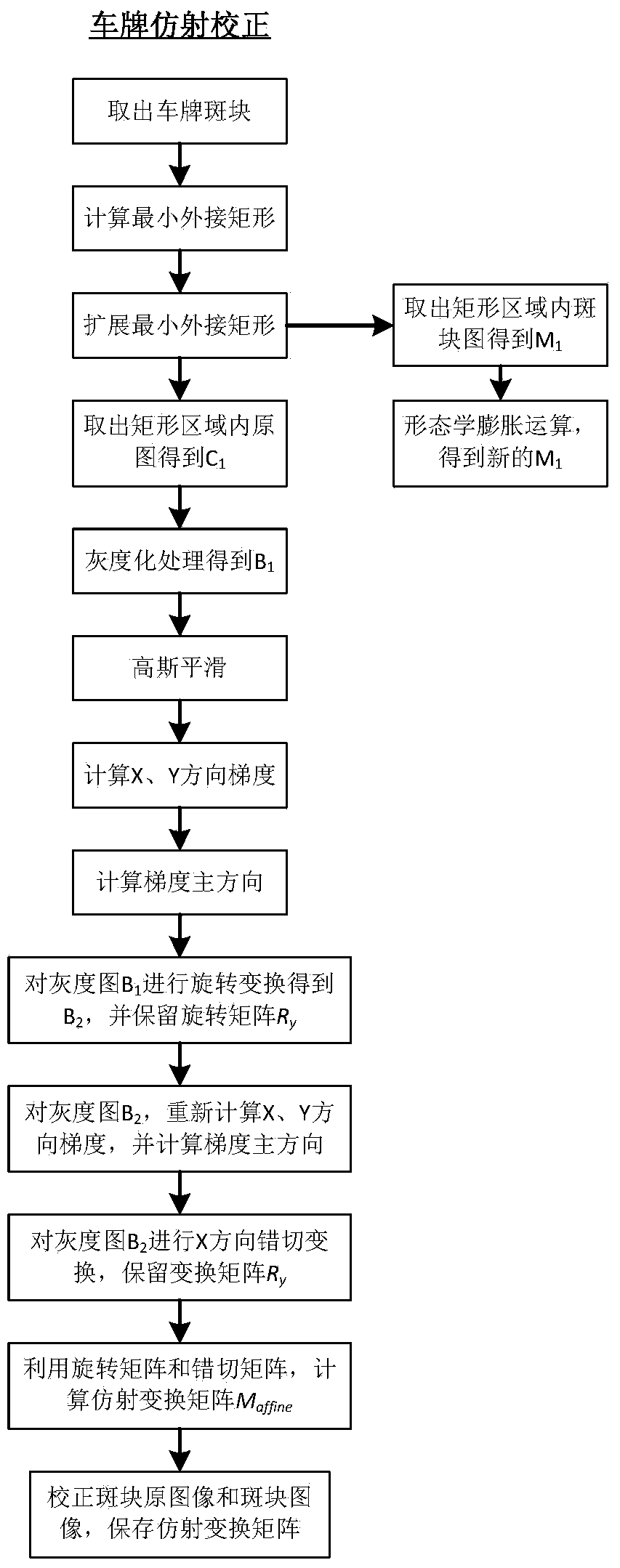

Multi-scale license plate precise locating method based on affine correction

ActiveCN103793708APrecise positioningSolve the positioning problemCharacter and pattern recognitionPattern recognitionBack calculation

The invention discloses a multi-scale license plate precise locating method based on affine correction. Firstly, candidate license plate plaques are detected by using texture information and color features of license plates, then affine correction is carried out on each candidate license plate, an energy function is defined to accurately locate the positions of the license plates, noise is removed, and the positions of license plates in original images are obtained through back calculation. According to the multi-scale license plate precise locating method based on the affine correction, the license plates can be accurately located from multi-scale images in a complex environment, high robustness, accuracy and high-speed performance are achieved, and the omission rate of the license plates is close to zero. The affine correction is uniquely introduced, the license plate locating problem brought by view angles of the images is well solved, and a basis is established for the accurate locating of the license plates. Meanwhile, the energy function is originally defined to evaluate and accurately locate the license plates, more deep information beneficial to the locating of the license plates is used in the method, and the locating of the license plates is made to be more accurate, more stable and more reliable.

Owner:WUHAN UNIV

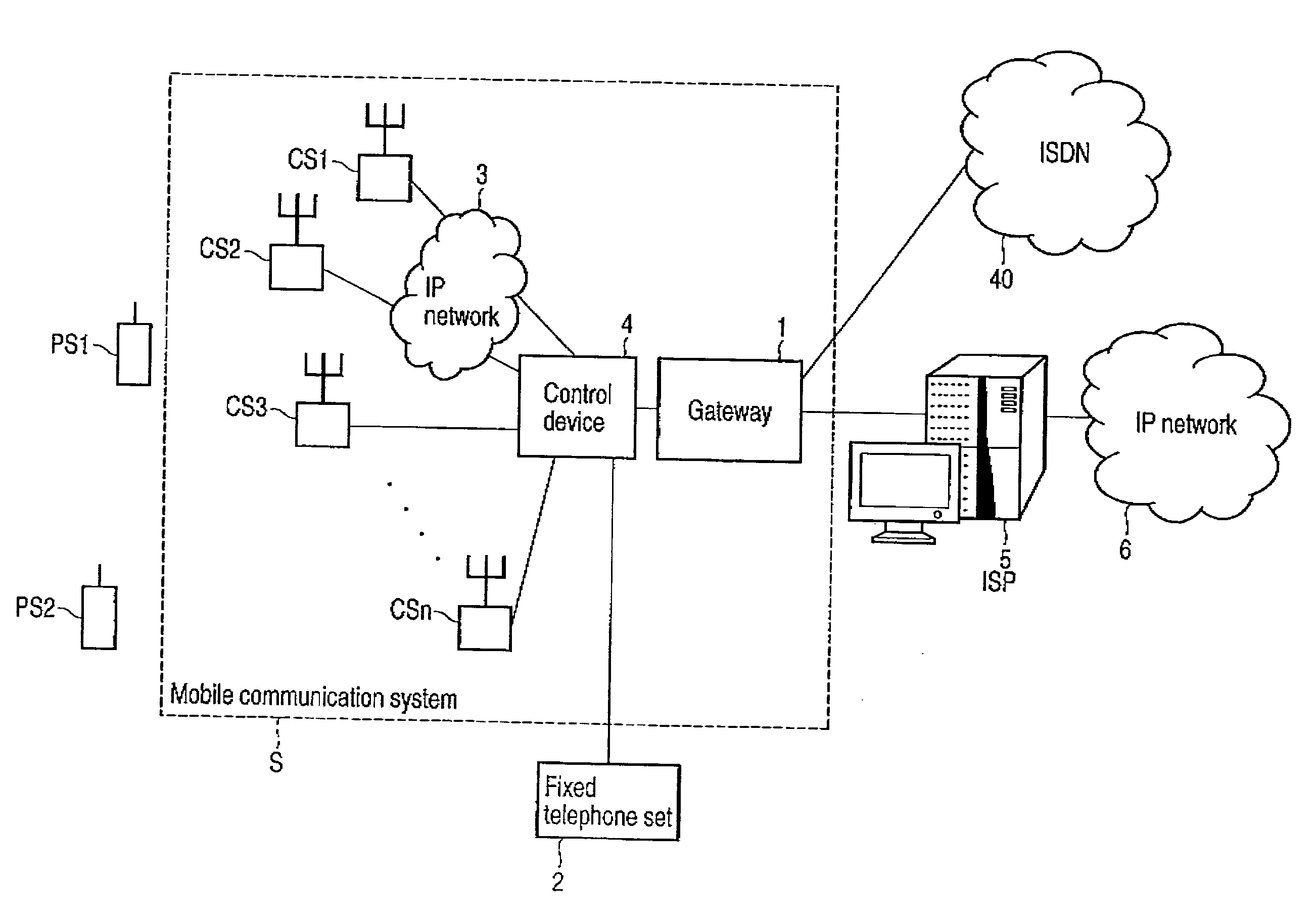

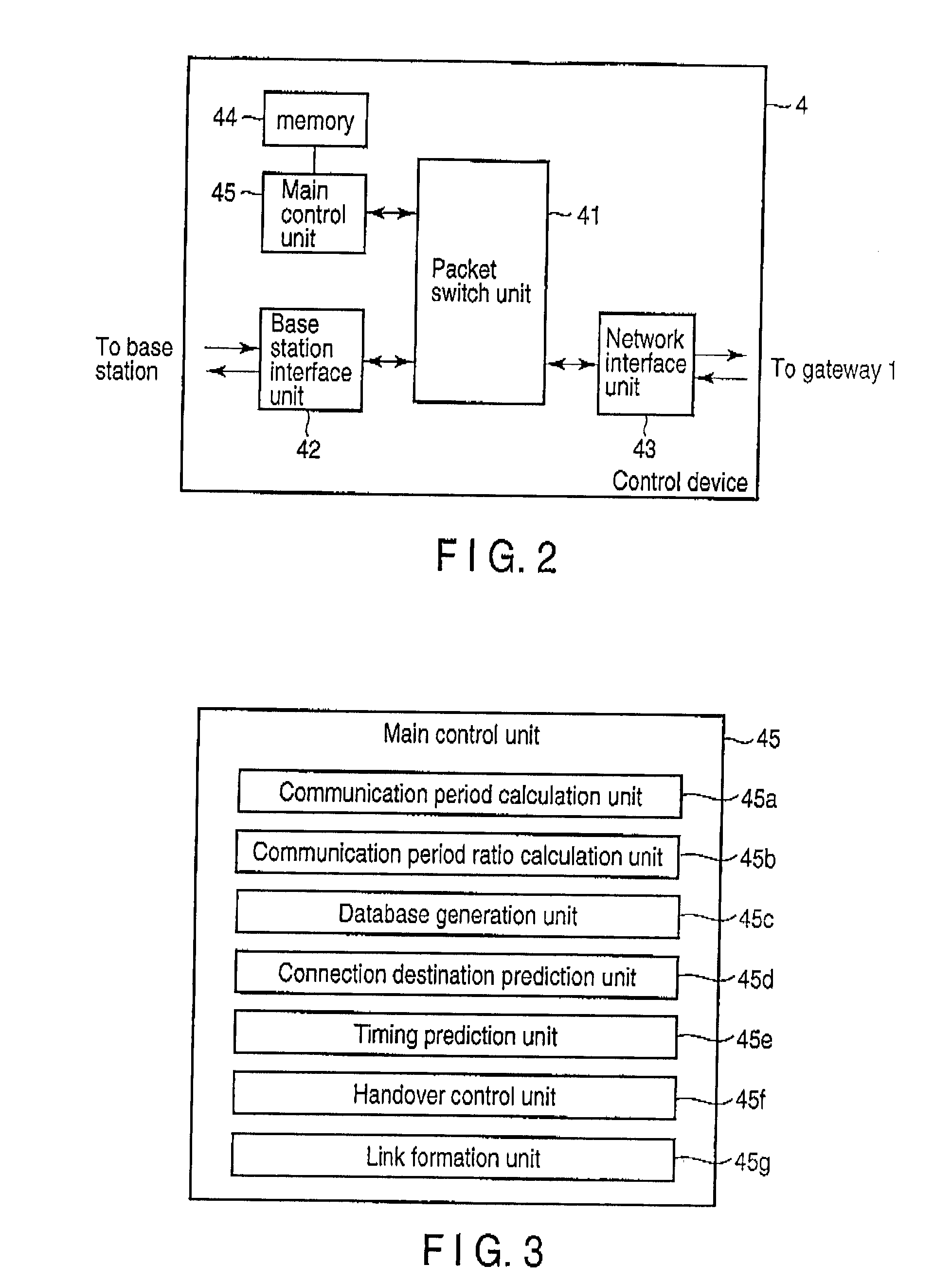

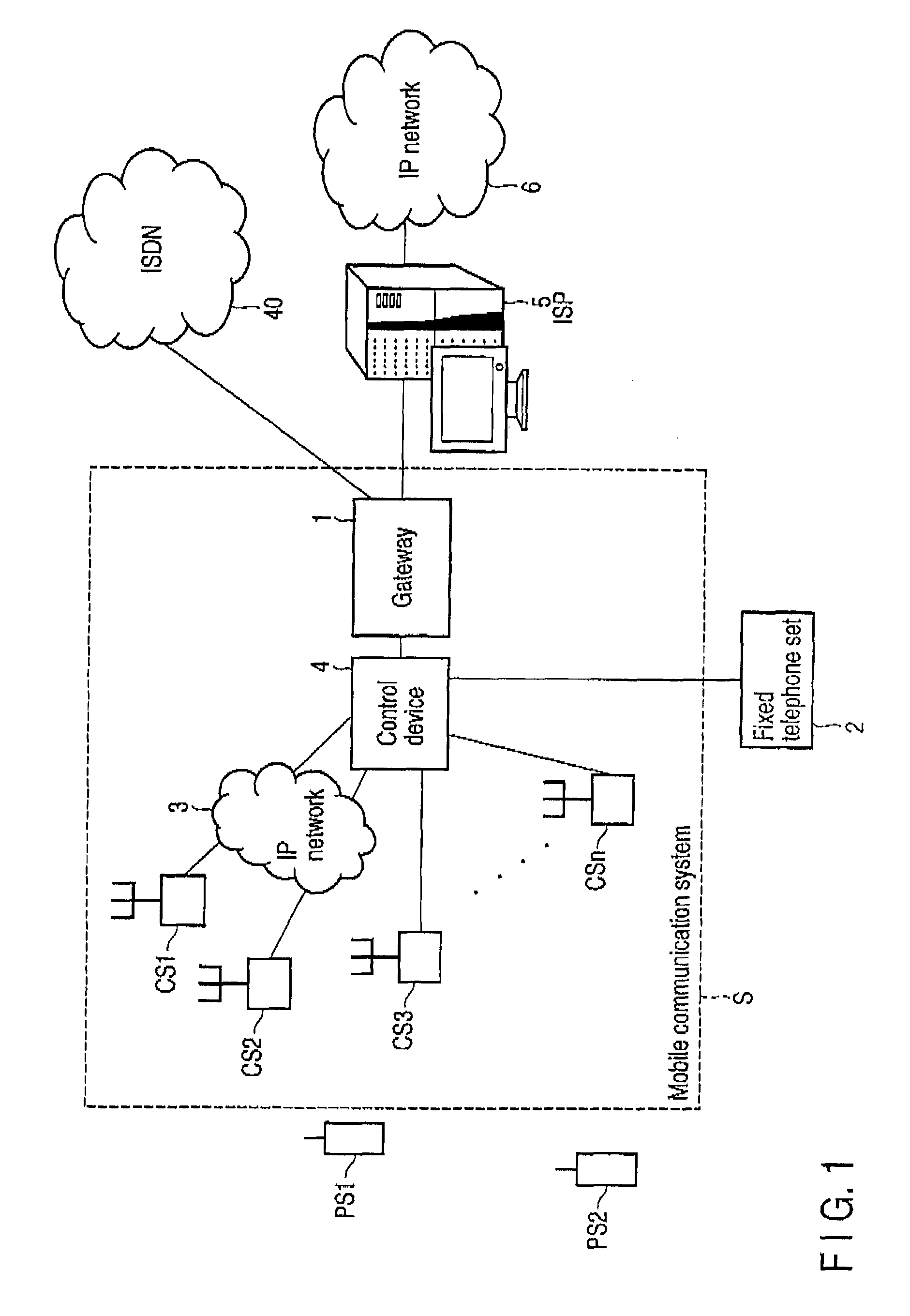

Mobile communication system, its control device, handover control method, and mobile terminal

InactiveUS20100020764A1SpeedLow costWireless commuication servicesMobile communication systemsHandover

According to one embodiment, a mobile communication system includes base stations each forming a wireless zone for wirelessly accommodating mobile terminals, and a control device accommodating the base stations. The control device includes a construction module, a prediction module and an instruction module. The construction module constructs a database regarding a history of handovers by the mobile terminals. The prediction module predicts a base station of the next connection destination of a mobile terminal being in communication and timing of a handover to the base station of the next connection destination on the basis of the database. The instruction module instructs the handover to the predicted base station to the mobile terminal being in communication before the timing comes.

Owner:KK TOSHIBA

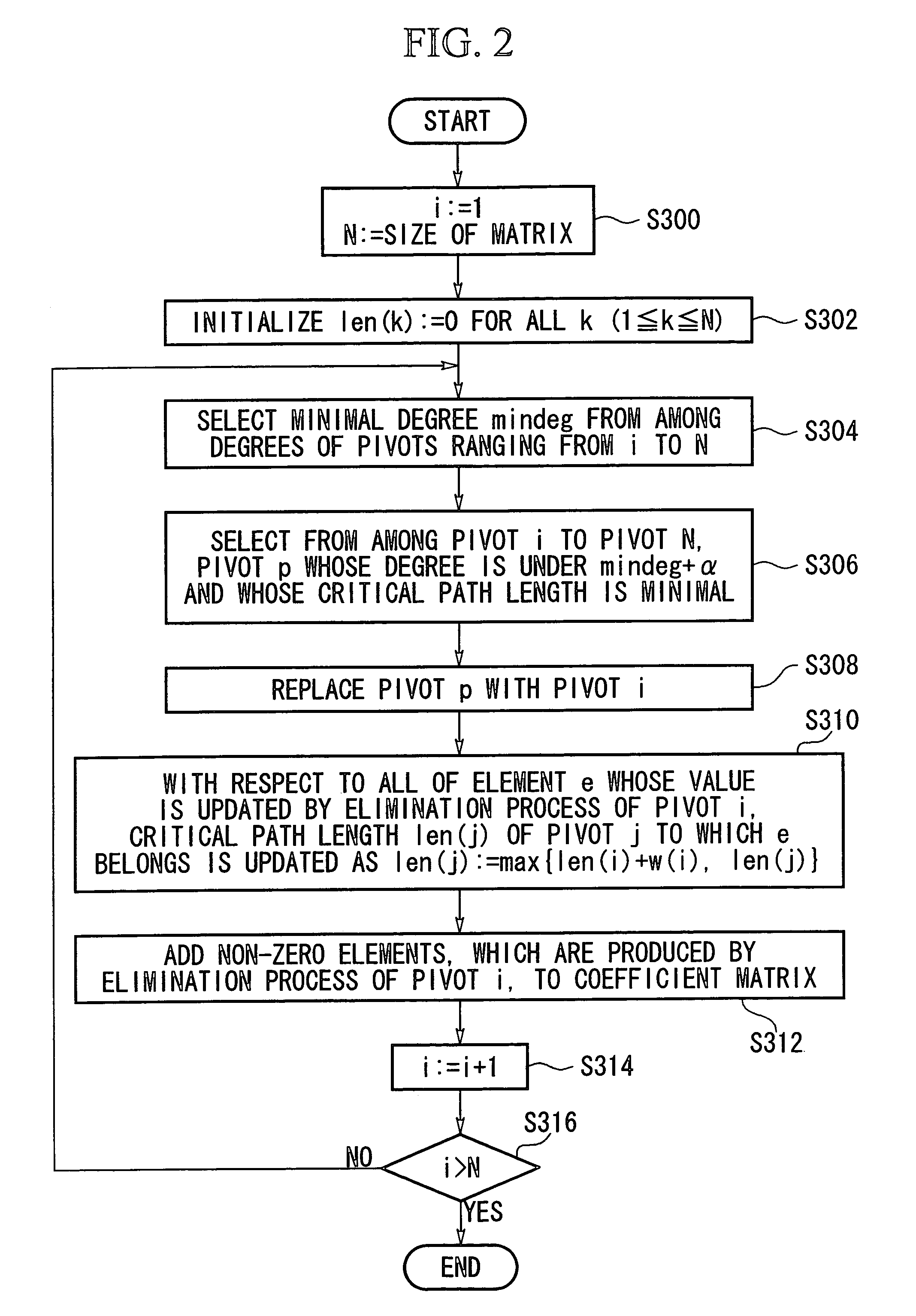

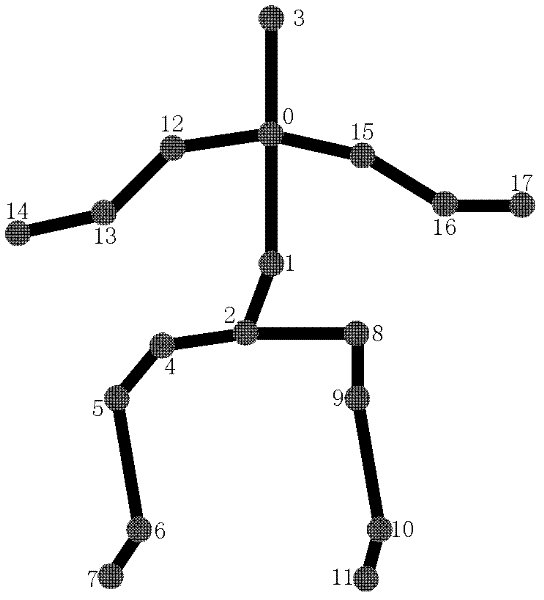

Method and apparatus for matrix reordering and electronic circuit simulation

InactiveUS7089159B2High-speed performanceImprove high-speed performanceAmplifier modifications to reduce noise influenceAnalogue computers for electric apparatusPath lengthSimultaneous equations

A matrix reordering method performs reordering of elements of a coefficient matrix created based on coefficients of linear simultaneous equations whose solutions are to be produced by parallel processing of processors of a computer in accordance with Gaussian elimination. Herein, degrees corresponding to numbers of non-zero elements are calculated with respect to all pivots included in the coefficient matrix. Then, a first pivot whose degree is under a threshold (mindeg+α) is selected from among the pivots of the coefficient matrix, while a second pivot whose critical path length is minimum is also selected from among the pivots of the coefficient matrix. Replacement of elements is performed between the first pivot and second pivot to complete reordering with respect to the first pivot. In addition, non-zero elements, which are newly produced by the Gaussian elimination of the first pivot, are added to the coefficient matrix. If a degree or a parameter of the first pivot is under a threshold (β), reordering is performed on a partial matrix whose elements are not eliminated and are selected from among the elements of the coefficient matrix in accordance with the nested dissection method, so that non-zero elements, which are newly produced by the Gaussian elimination of the partial matrix, are added to the coefficient matrix. Because the critical path length can be reduced as compared with conventional techniques, it is possible to considerably reduce a total processing time of the parallel processing to secure high-speed performance of the Gaussian elimination.

Owner:NEC ELECTRONICS CORP

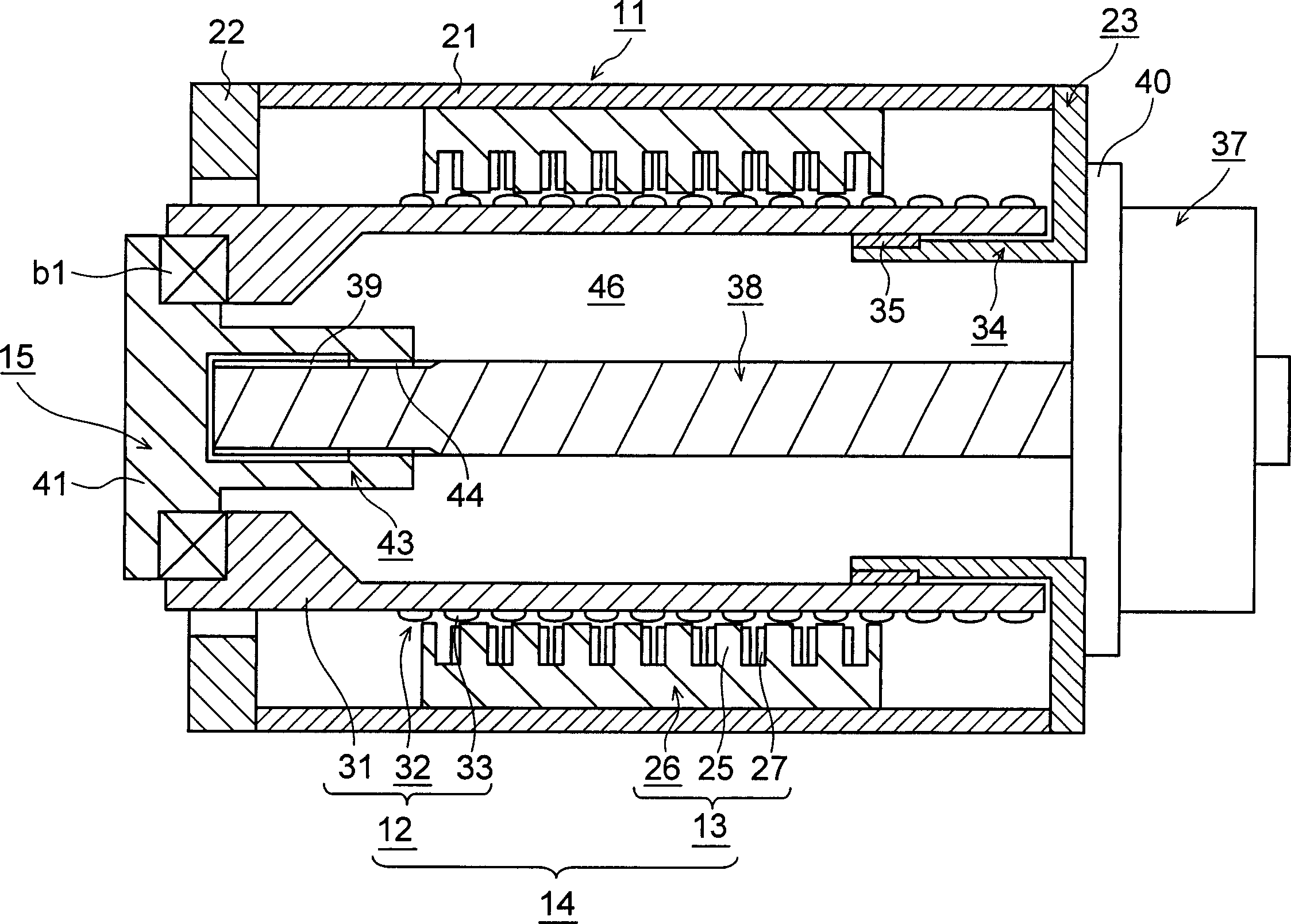

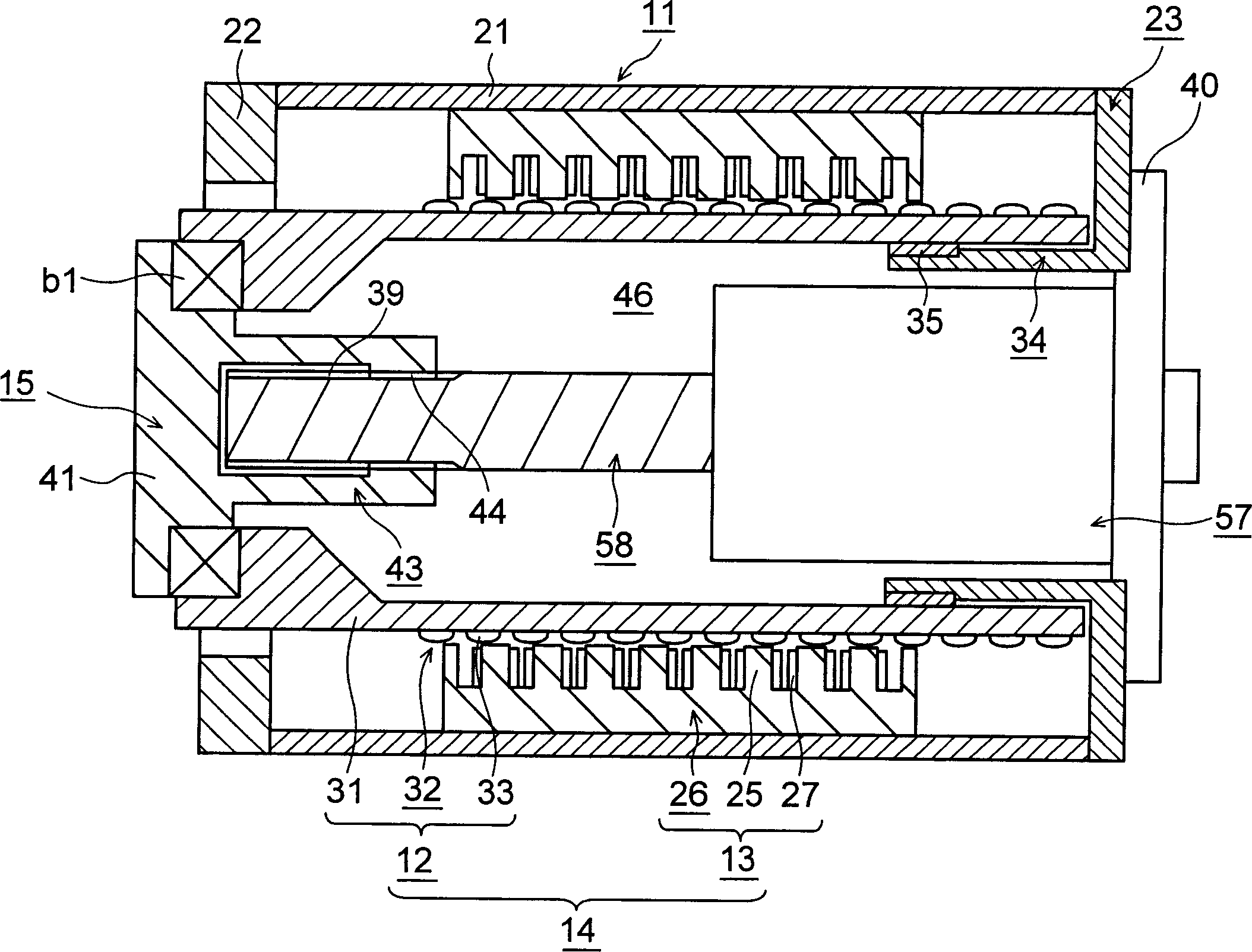

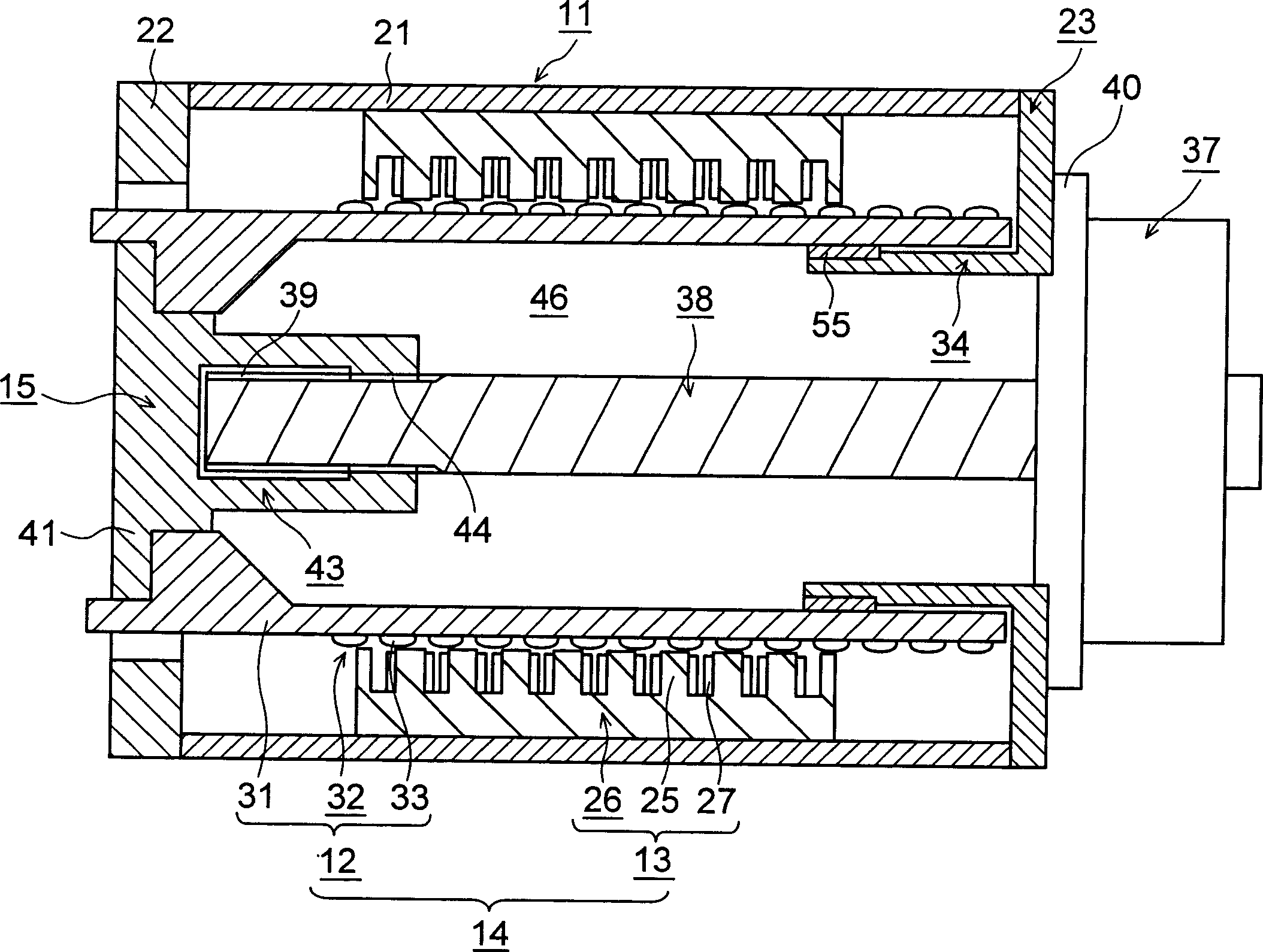

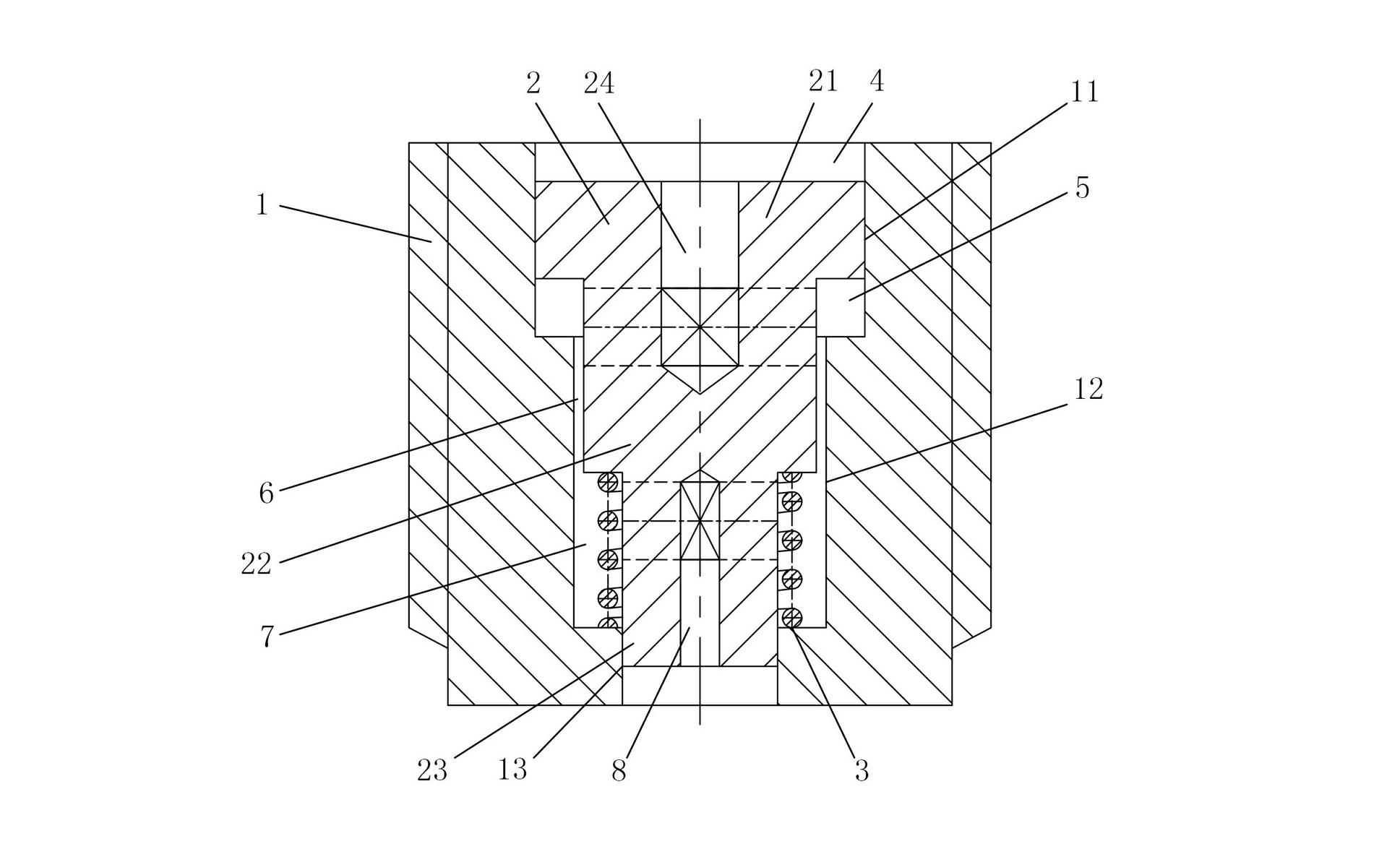

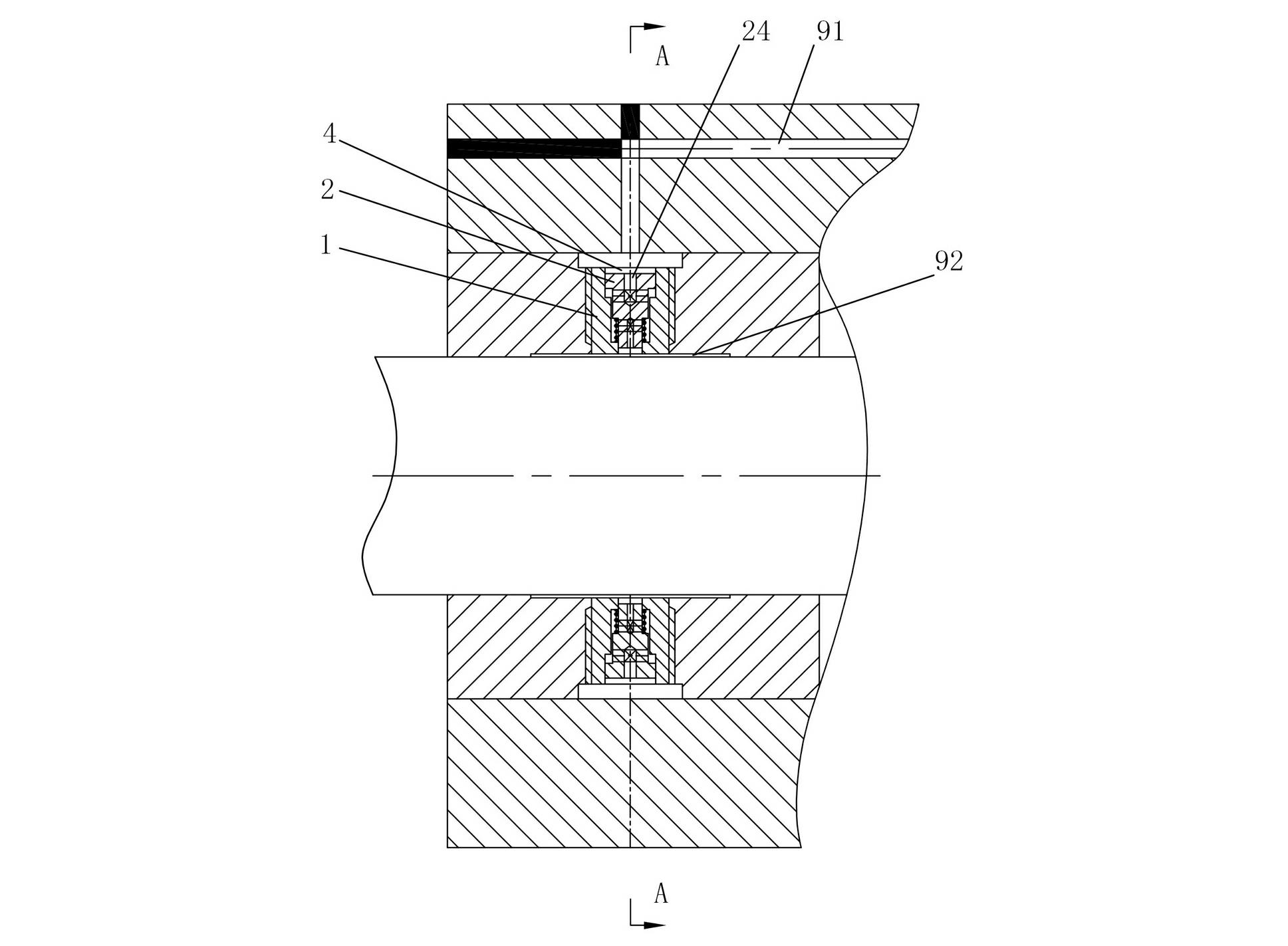

Injection molding machine driving device, injection device and mold clamping device

The object is to provide an injection molding machine driving device capable of generating a large thrust and of continuous drive with a short cycle. It comprises a casing body (11), a cylindrical linear motor (14) provided with a mover (12) disposed in the casing body (11) for advance and retraction and a stator (13) attached to the casing body (11), the linear motor (14) constituting a first drive section, a driven body (15) advanced and retracted together with the mover (12), and a second drive section attached to the casing body (11) and disposed so as to axially overlap the linear motor (14) at least partially. A slight axial increase in the radial dimension makes it possible to sufficiently increase the area of a permanent magnet (23) for the mover (12), thus increasing the capacity of the linear motor (14).

Owner:SUMITOMO HEAVY IND LTD

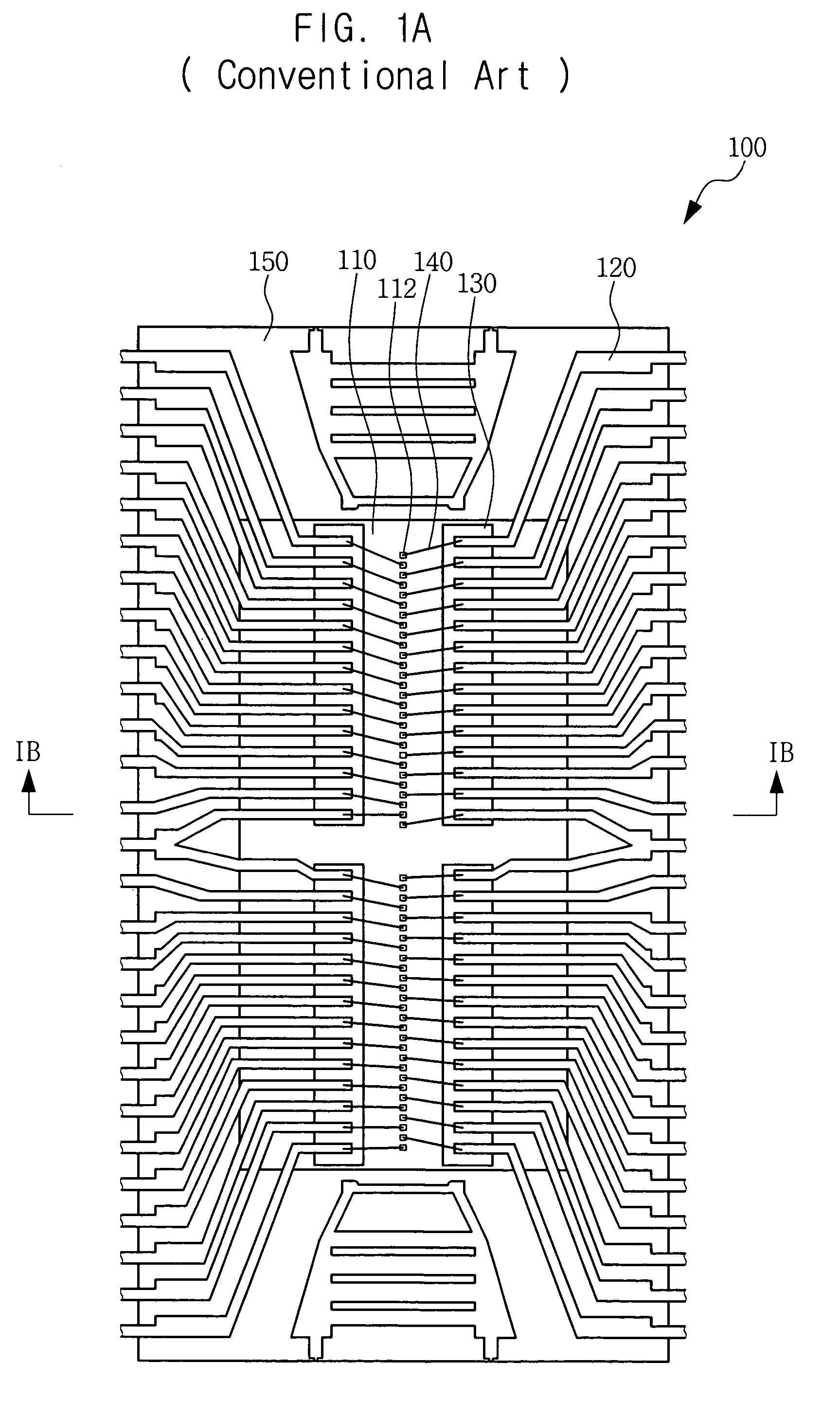

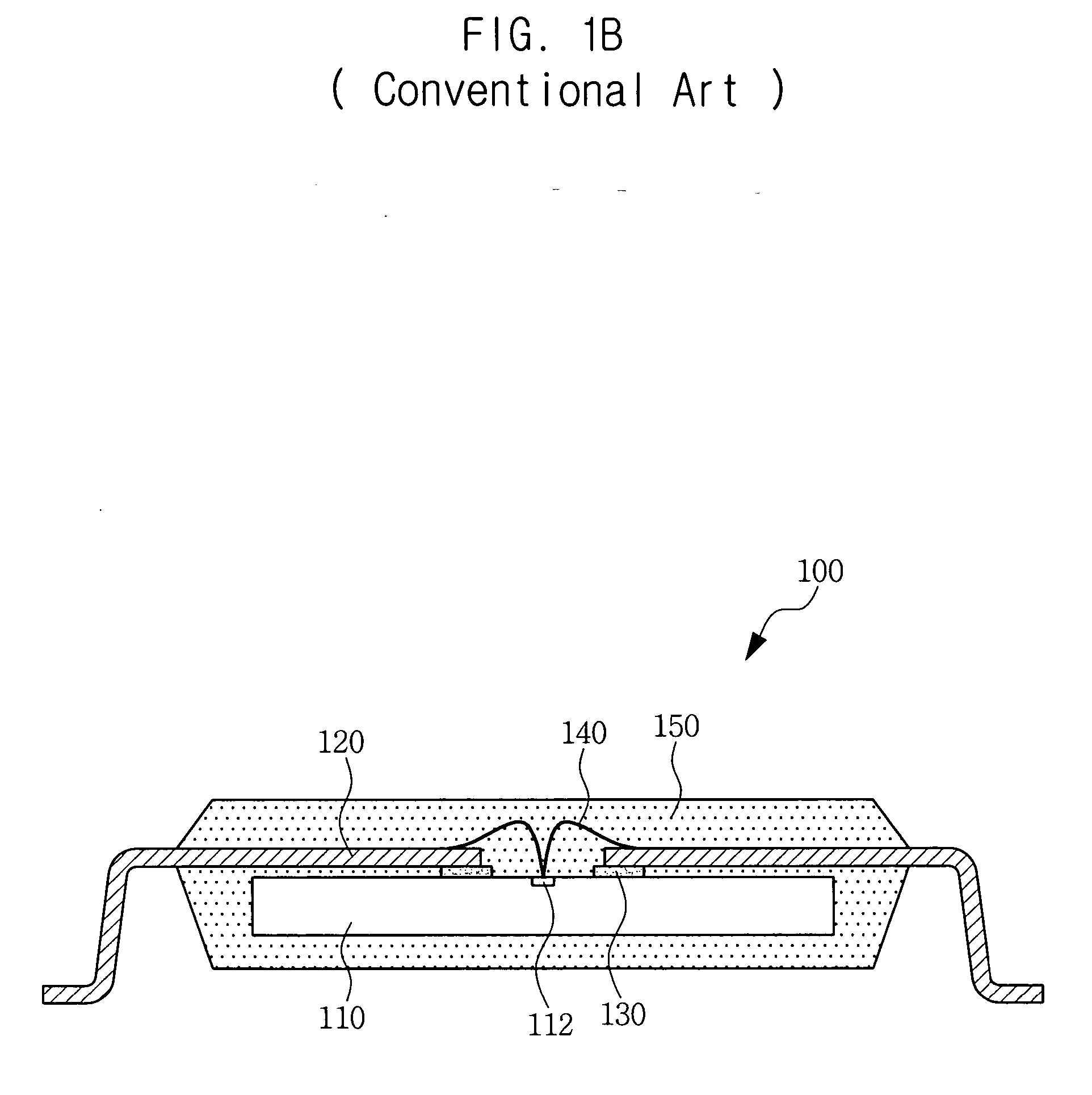

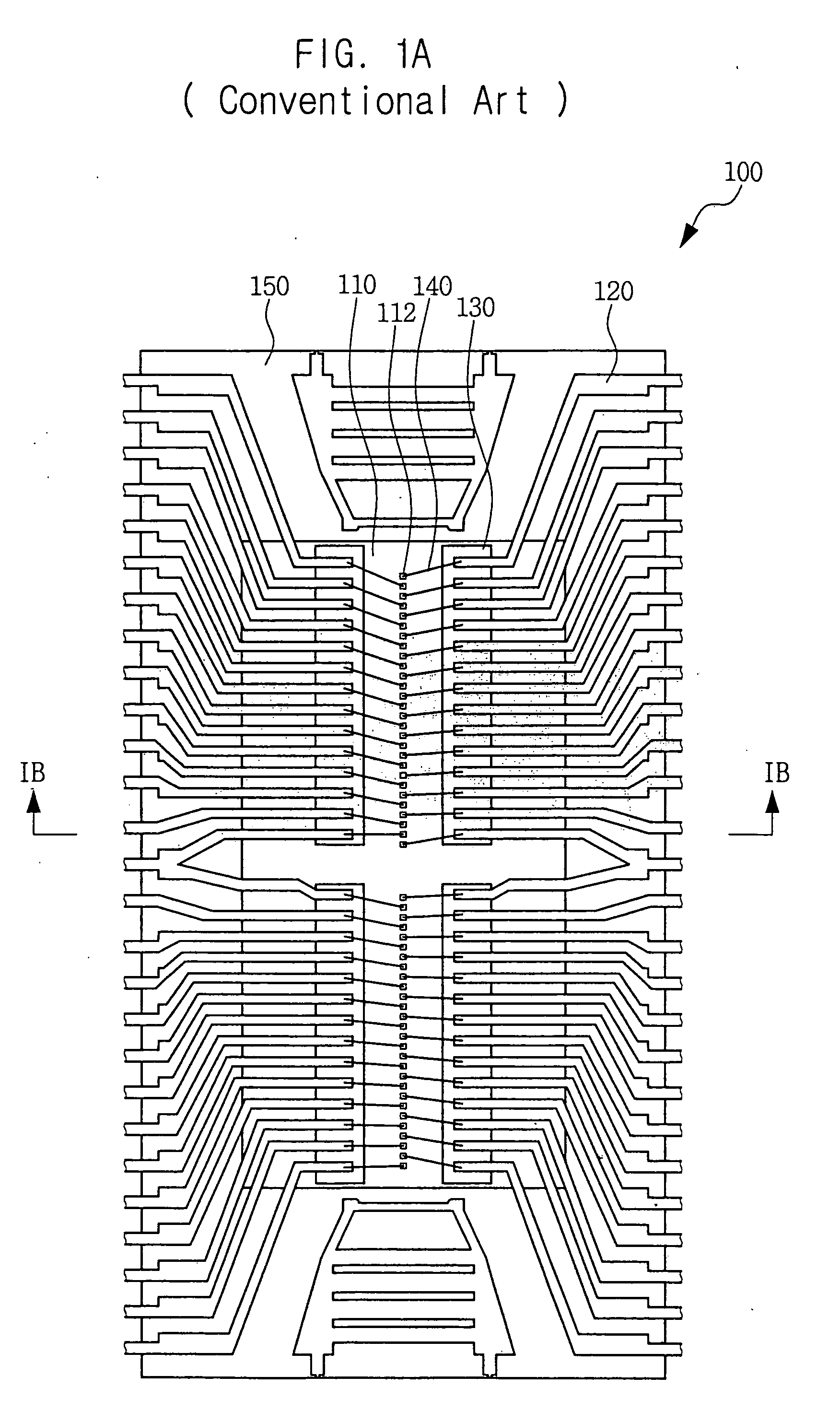

Leadframe package with dual lead configurations

InactiveUS20070040247A1Function increaseImprove performanceSemiconductor/solid-state device detailsSolid-state devicesCapacitanceSemiconductor chip

The invention provides a variety of leadframe packages in which signal connections and fixed voltage connections are configured differently to improve the relative performance of the connections relative to their assigned function. The signal connections incorporate one or more configurations of signal lead and corresponding signal bonding wires that tend to reduce the relative capacitance of the signal connectors and thereby improve high speed performance. The fixed voltage connections incorporate configurations of fixed voltage leads and fixed voltage bonding wires that will tend to reduce the inductance of the fixed voltage connector and reduce noise on the fixed voltage connections and improve power delivery characteristics. The configurations of the associated signal and fixed voltage connections will tend to result in signal connections that include signal leads that are shorter, narrower and / or more widely separated from the active surface of the semiconductor chip than the corresponding fixed voltage leads.

Owner:SAMSUNG ELECTRONICS CO LTD

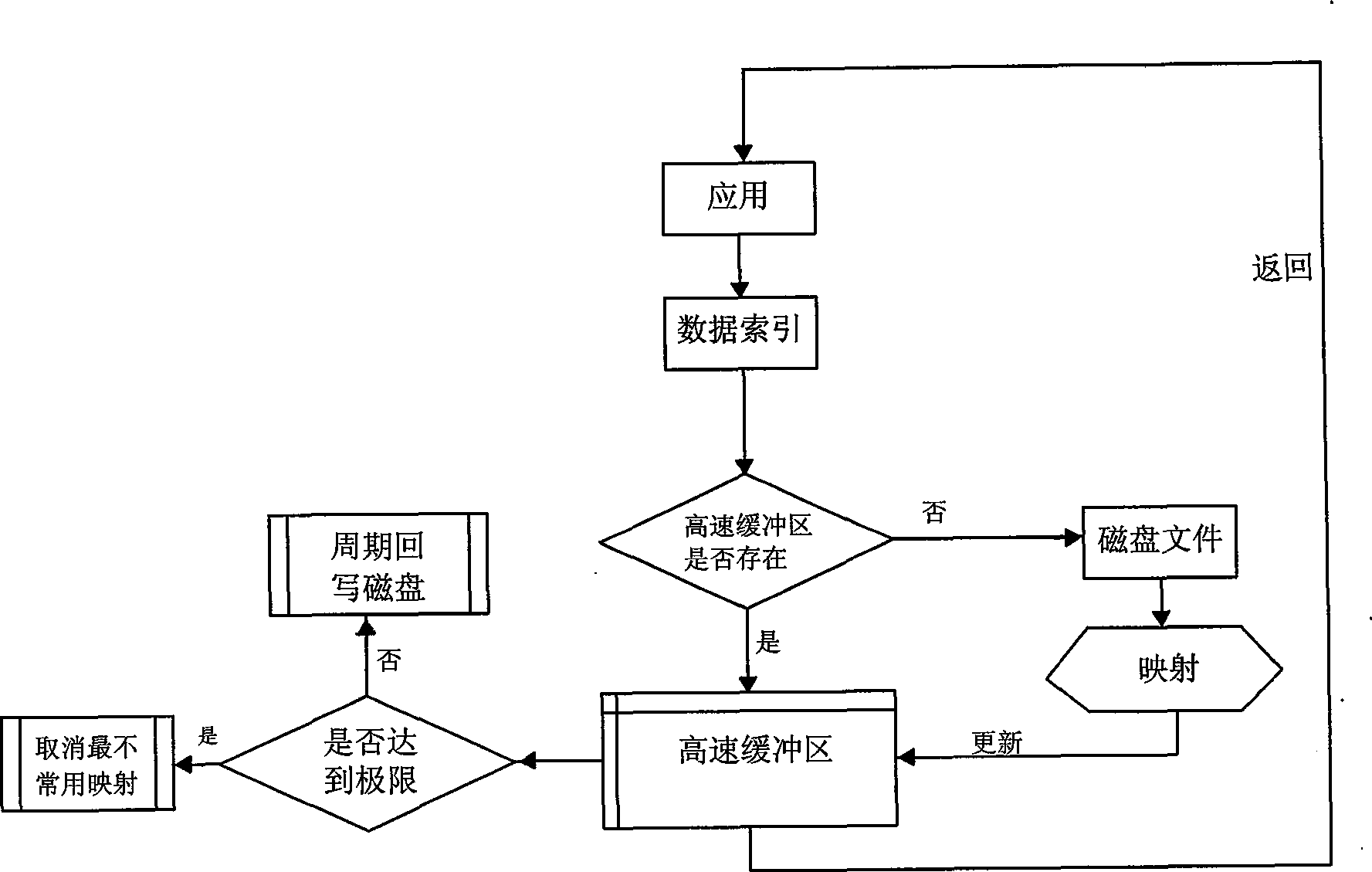

High-speed concurrent access method for power system large data files across platform

ActiveCN101520797AConvenienceImprove high-speed performanceMemory adressing/allocation/relocationSpecial data processing applicationsAccess methodElectric power system

The invention discloses a high-speed concurrent access method for power system large data files across a platform, which is characterized in that a cache management system capable of carrying out the unified management on all data files when a system runs and is responsible for interaction with actual disk files is set; the data files are processed in a memory-mapped file mode; the cache management system concurrently maps each portion of the data files to the minor address space in a data-processing service process one by one by using a method that the data files are divided into fixed block memory-mapped files; and the cache management system sets a high-speed buffer area which does not re-load loaded data accessing once more, thereby enhancing the efficiency and the speed of access. The high-speed concurrent access method of the power system large data files across the platform can meet the convenience, the rapidity and the reliability of an application program to the concurrent access of the large data files through the interaction of the common cache management system and the actual disk files.

Owner:STATE GRID ELECTRIC POWER RES INST

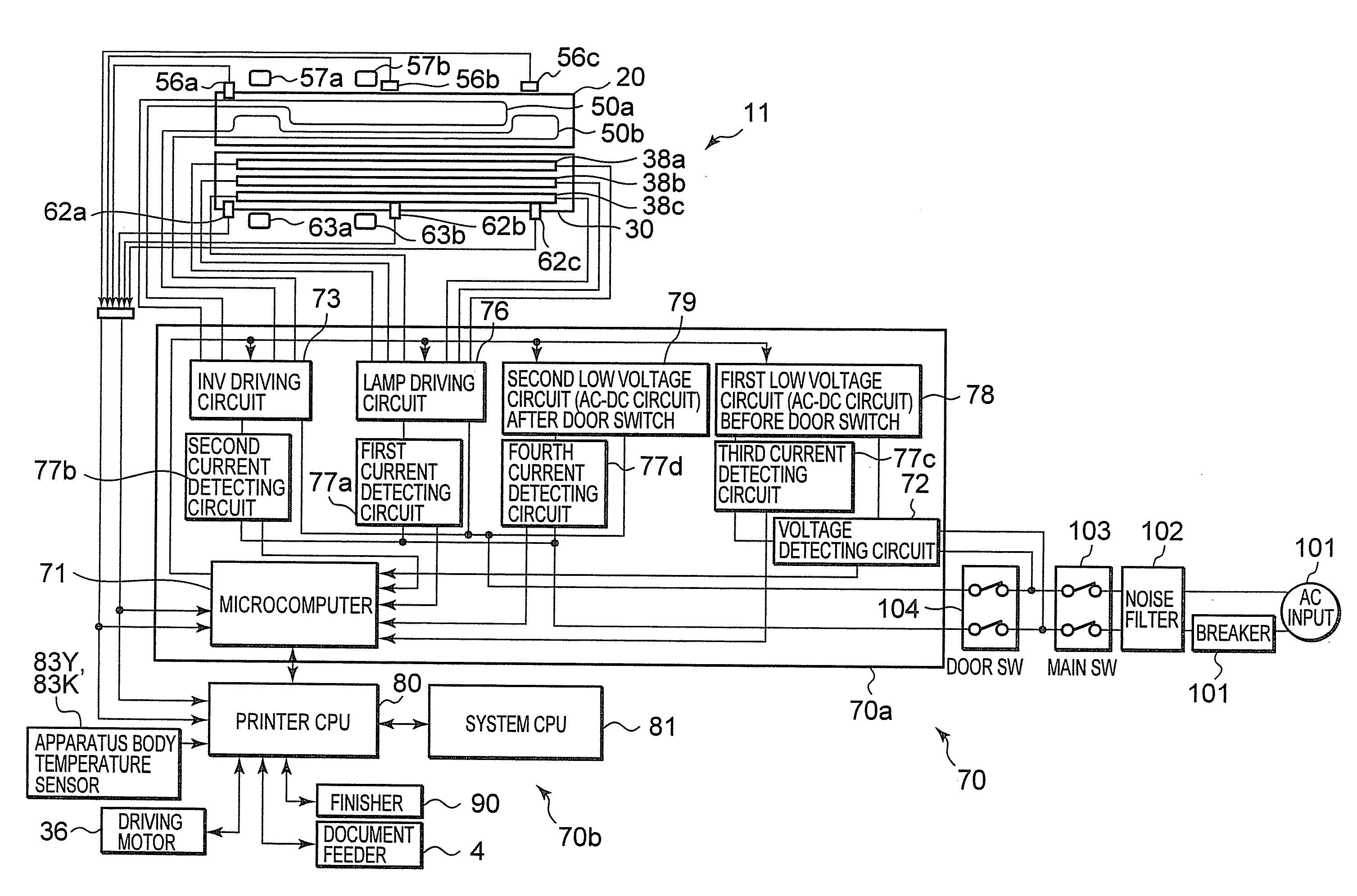

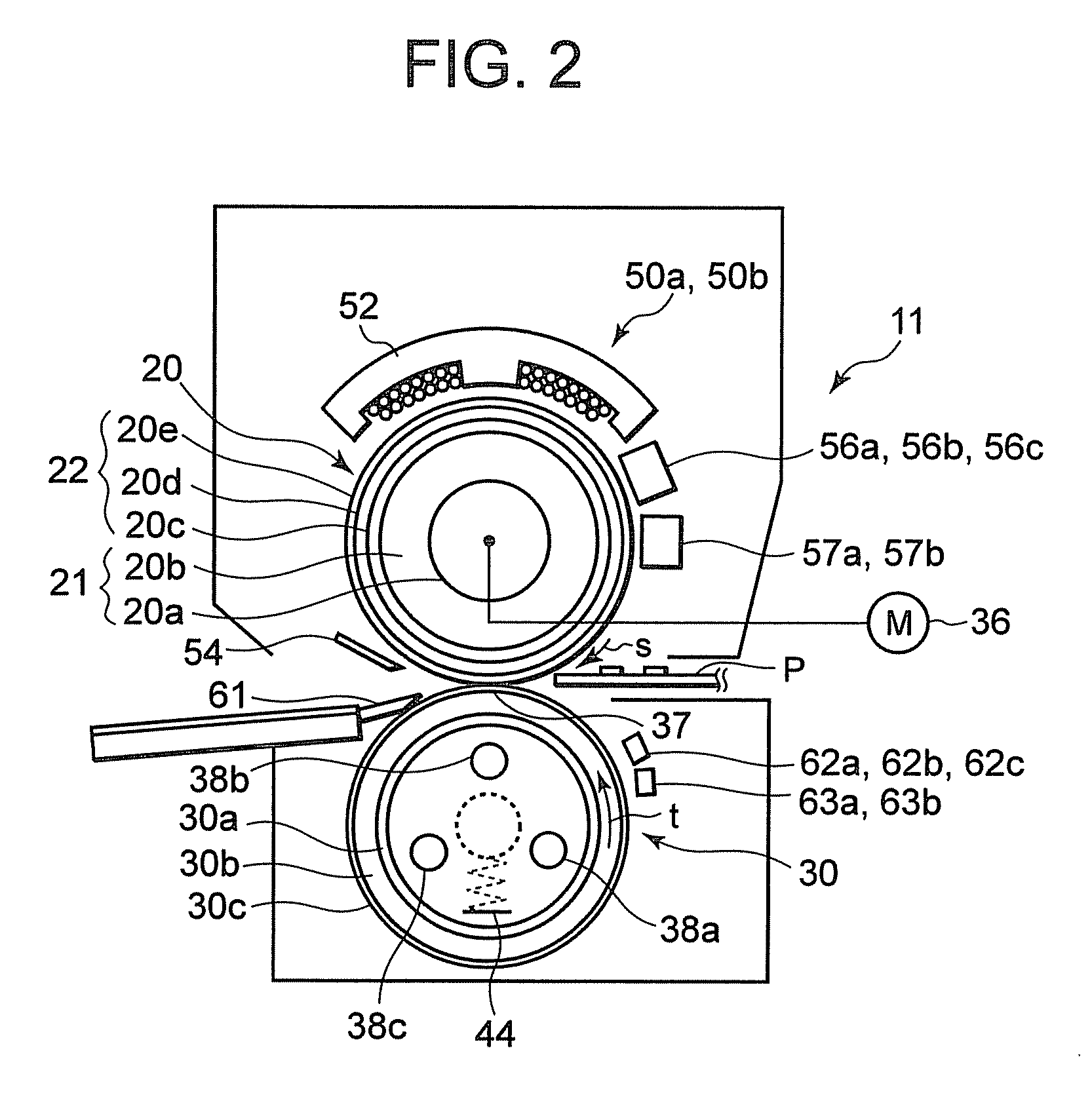

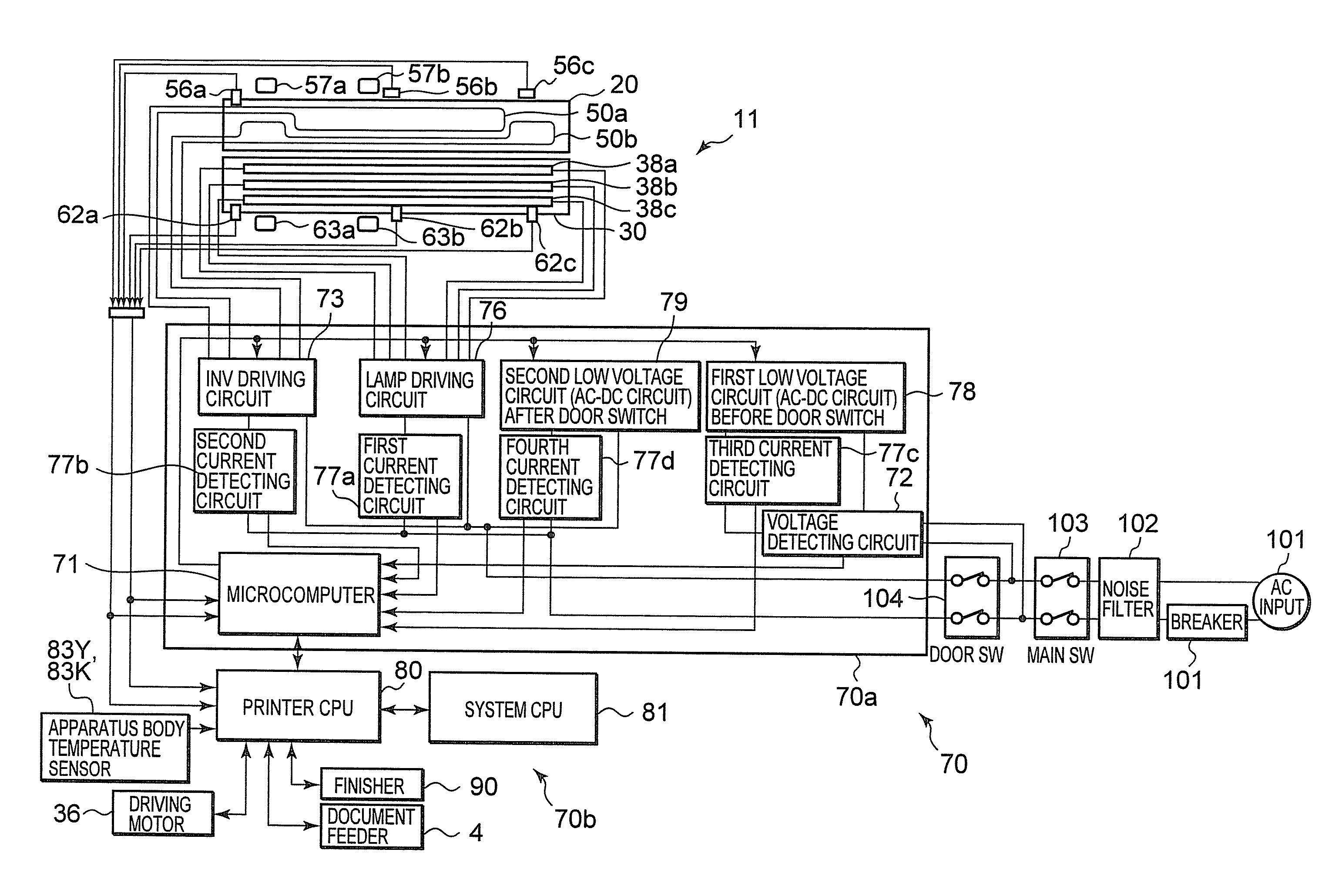

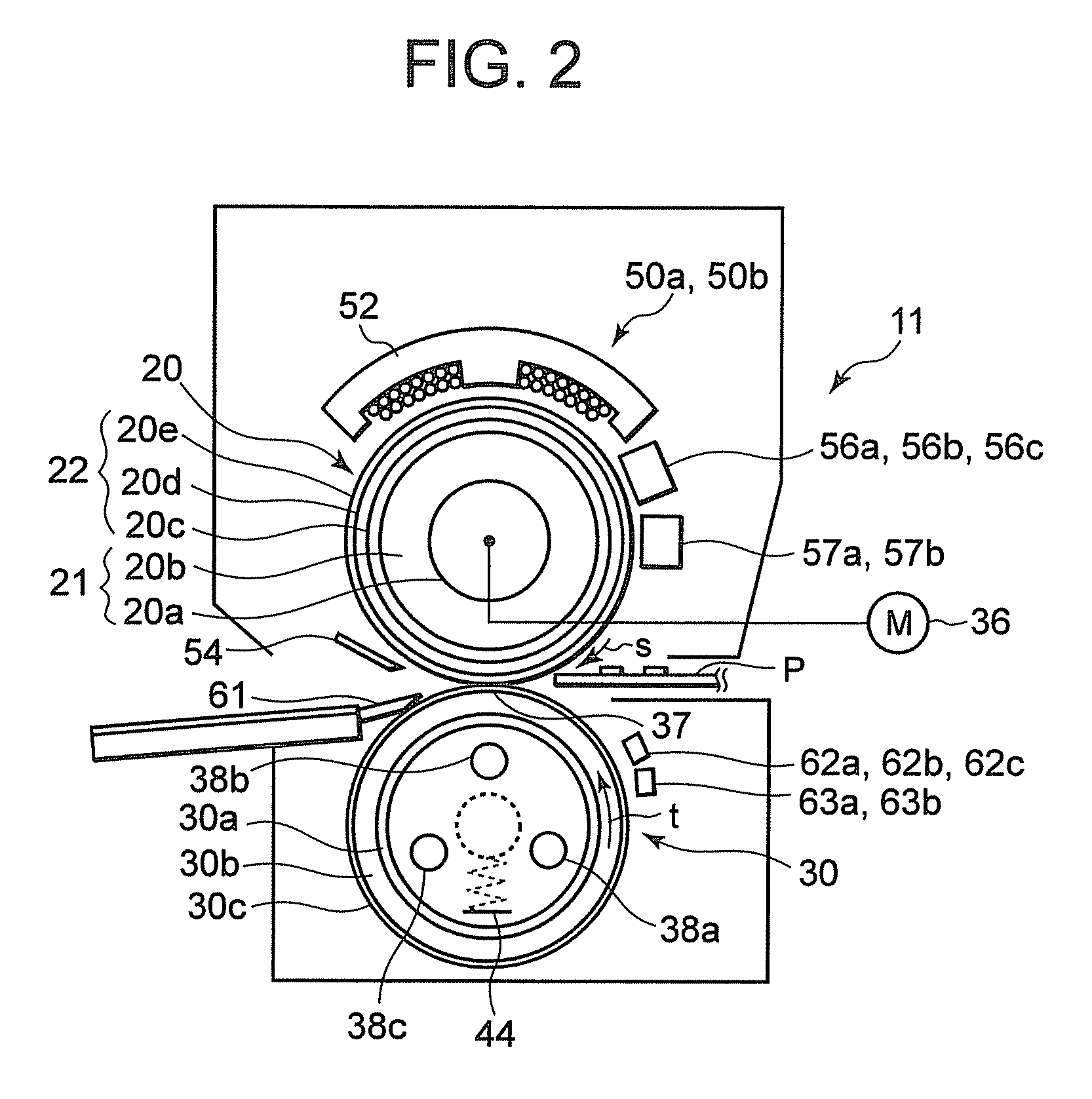

Fixing device for image forming apparatus

InactiveUS20080118263A1Improve high-speed performanceHigh quality imagingElectrographic process apparatusMicrocomputerTemperature control

A fixing device according to an embodiment of the present invention includes a microcomputer that exclusively performs temperature control for the fixing device. The microcomputer periodically calculates electric power that can be supplied to the fixing device. The microcomputer detects the temperature of the fixing device and the temperature in a printer unit and feedback-controls electric power supplied to the fixing device.

Owner:KK TOSHIBA +1

IPSecVPN (Internet Protocol Security Virtual Private Network) realizing system and method based on NetFPGA (Net Field Programmable Gate Array)

ActiveCN102065021AImprove processing speedRealize forwarding functionNetworks interconnectionData streamControl layer

The invention relates an IPSec VPN (Internet Protocol Security Virtual Private Network) realizing system and method based on a NetFPGA (Net Field Programmable Gate Array), wherein a control layer of a router is additively provided with an IKE (Internet Key Exchange) module, a security relation database mapping module and a security policy database, and a key management module is used for dynamically managing the key, the security relation and the security policy; and a forward layer is additionally provided with two independently designed IPSec input and output process modules in the originalNetFPGA standard router architecture by sufficiently utilizing the modularization reusable idea of a NetPGA development board. The scheme of the invention can realize the route forward function of the data flow in a hardware manner, and can also realize the great mass of calculation functions required by the IPSecVPN in a hardware manner, such as safe detaching / packing load and completeness authentication; in addition, the invention can effectively make a compromise on the data flow forward performance and the IPSec protocol processing performance.

Owner:北京地平线轨道技术有限公司

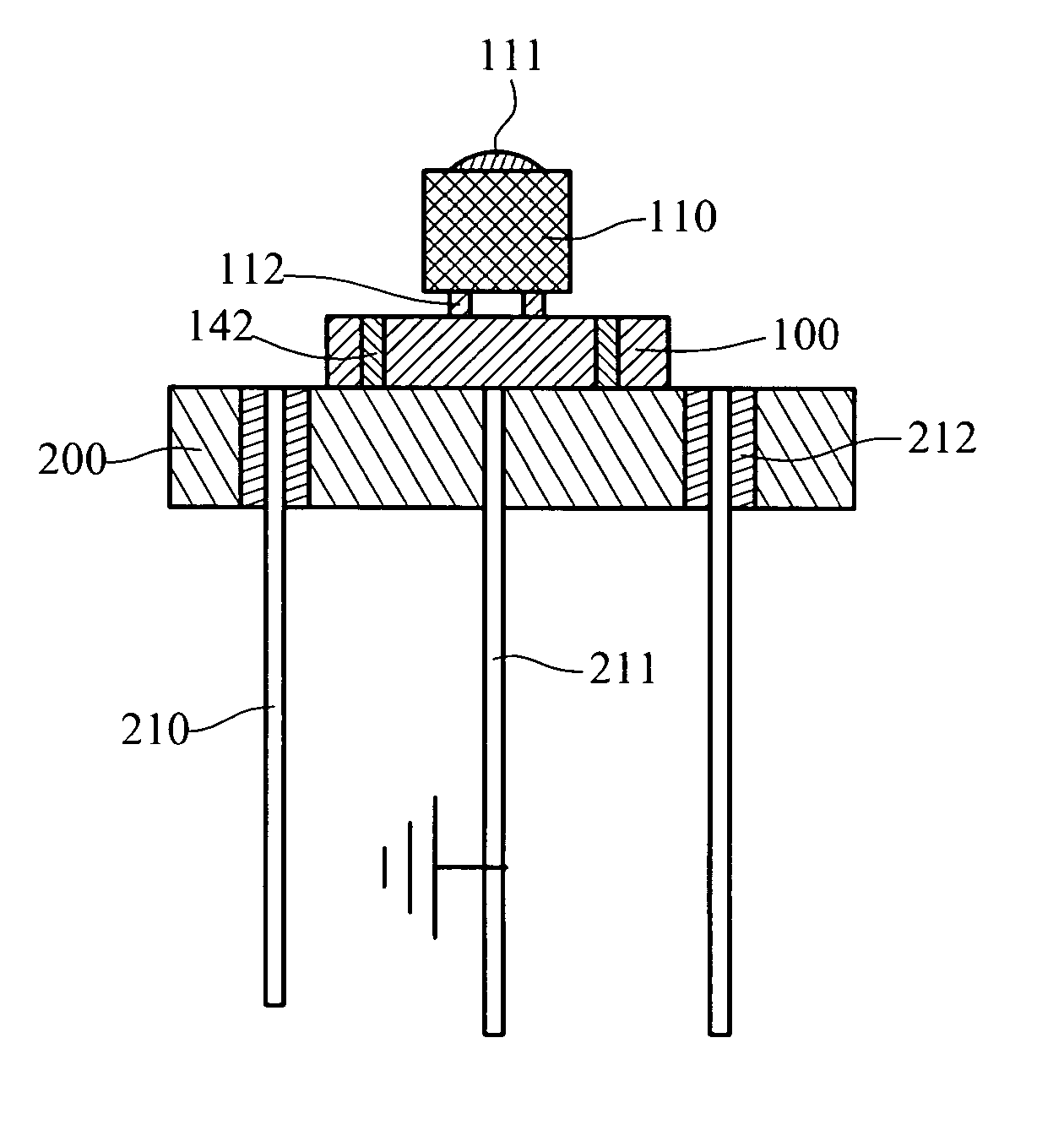

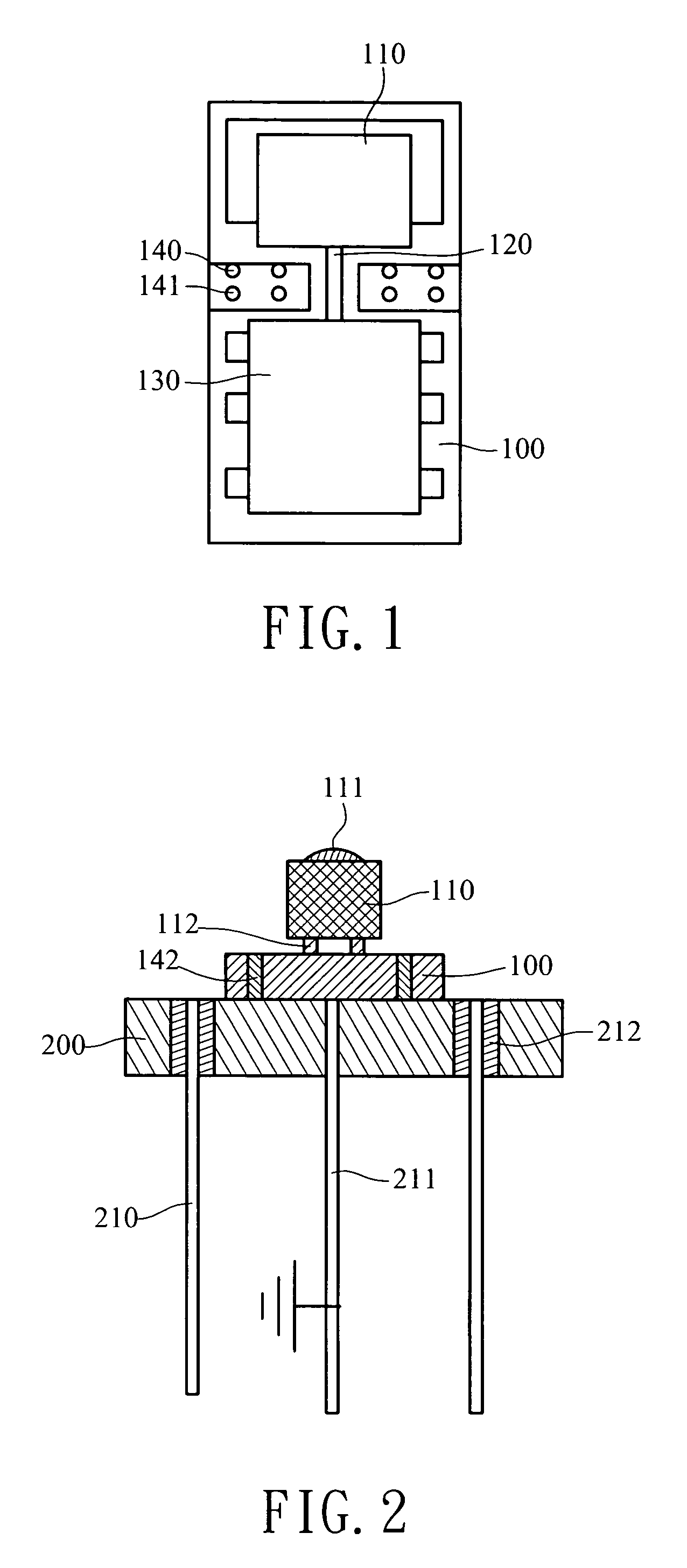

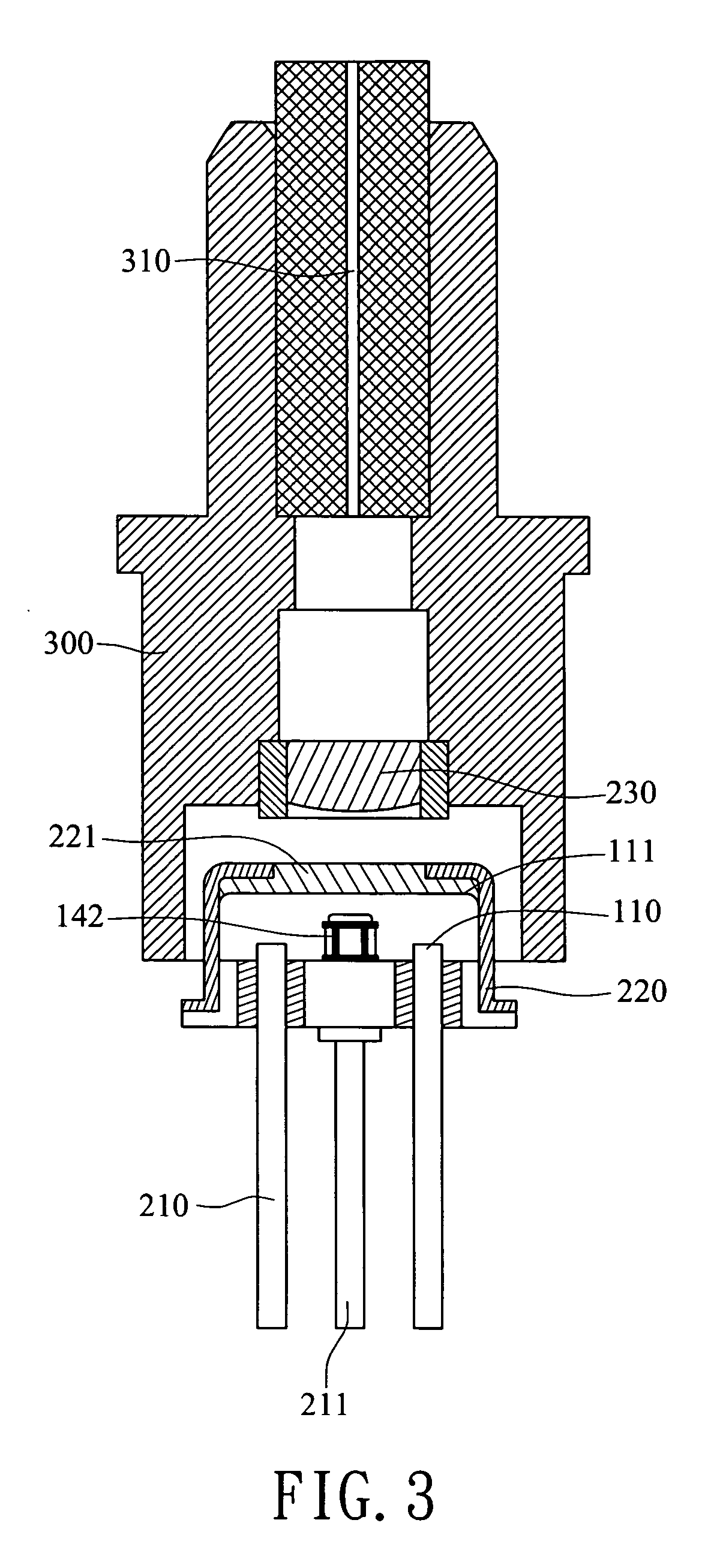

Receiver optical subassembly

InactiveUS20050121736A1Effective alignmentImprove performanceSolid-state devicesOptical light guidesAudio power amplifierEngineering

A receiver optical subassembly for transforming received optical signal into electrical signal includes at least a ceramic substrate, a photo receiver and a transimpedance amplifier. There are high-speed traces formed on the substrate. The positive and negative pads of the photo receiver are coplanar and connected to the traces without wire bonding so as to reduce the parasitic impedance effect and improve the high-speed performance of the optical subassembly. The transimpedance amplifier is electrically connected to the traces via flip chip, wire bonding or other methods. The photo receiver and the transimpedance amplifier are connected via the high-speed traces formed on the substrate.

Owner:IND TECH RES INST

Method and device for capturing movement based on framework and partial interpolation

ActiveCN102306390APrevent frame lossIncreased accuracy and high speedAnimationThree dimensional modelPoint cloud

The invention provides a method and a device for capturing movement based on a framework and a partial interpolation. The method comprises the following steps of: reconstructing a first three-dimensional partial model and a second three-dimensional partial model and extracting a first framework of the first three-dimensional partial model and a second framework of the second three-dimensional partial model; interpolating the first framework and the second framework to obtain an intermediate framework between the first framework and the second framework; solving a deformation distance field between the first thee-dimensional partial model and the second three-dimensional partial model and interpolating a point cloud on the deformation distance field to form a three-dimensional model sequence through which the first three-dimensional partial model is transited to the second three-dimensional partial model; and filtering and reconstructing the point cloud of the three-dimensional model sequence to obtain a finally closed partial three-dimensional model sequence. The method for capturing the movement based on the framework and the partial interpolation of the embodiment of the invention has the advantages of quick capture and high precision. The device has the advantages of high precision and simple structure.

Owner:TSINGHUA UNIV

Leadframe package with dual lead configurations

InactiveUS20090230520A1Function increaseImprove performanceSemiconductor/solid-state device detailsSolid-state devicesCapacitanceSemiconductor chip

The invention provides a variety of leadframe packages in which signal connections and fixed voltage connections are configured differently to improve the relative performance of the connections relative to their assigned function. The signal connections incorporate one or more configurations of signal lead and corresponding signal bonding wires that tend to reduce the relative capacitance of the signal connectors and thereby improve high speed performance. The fixed voltage connections incorporate configurations of fixed voltage leads and fixed voltage bonding wires that will tend to reduce the inductance of the fixed voltage connector and reduce noise on the fixed voltage connections and improve power delivery characteristics. The configurations of the associated signal and fixed voltage connections will tend to result in signal connections that include signal leads that are shorter, narrower and / or more widely separated from the active surface of the semiconductor chip than the corresponding fixed voltage leads.

Owner:LEE JONG JOO +1

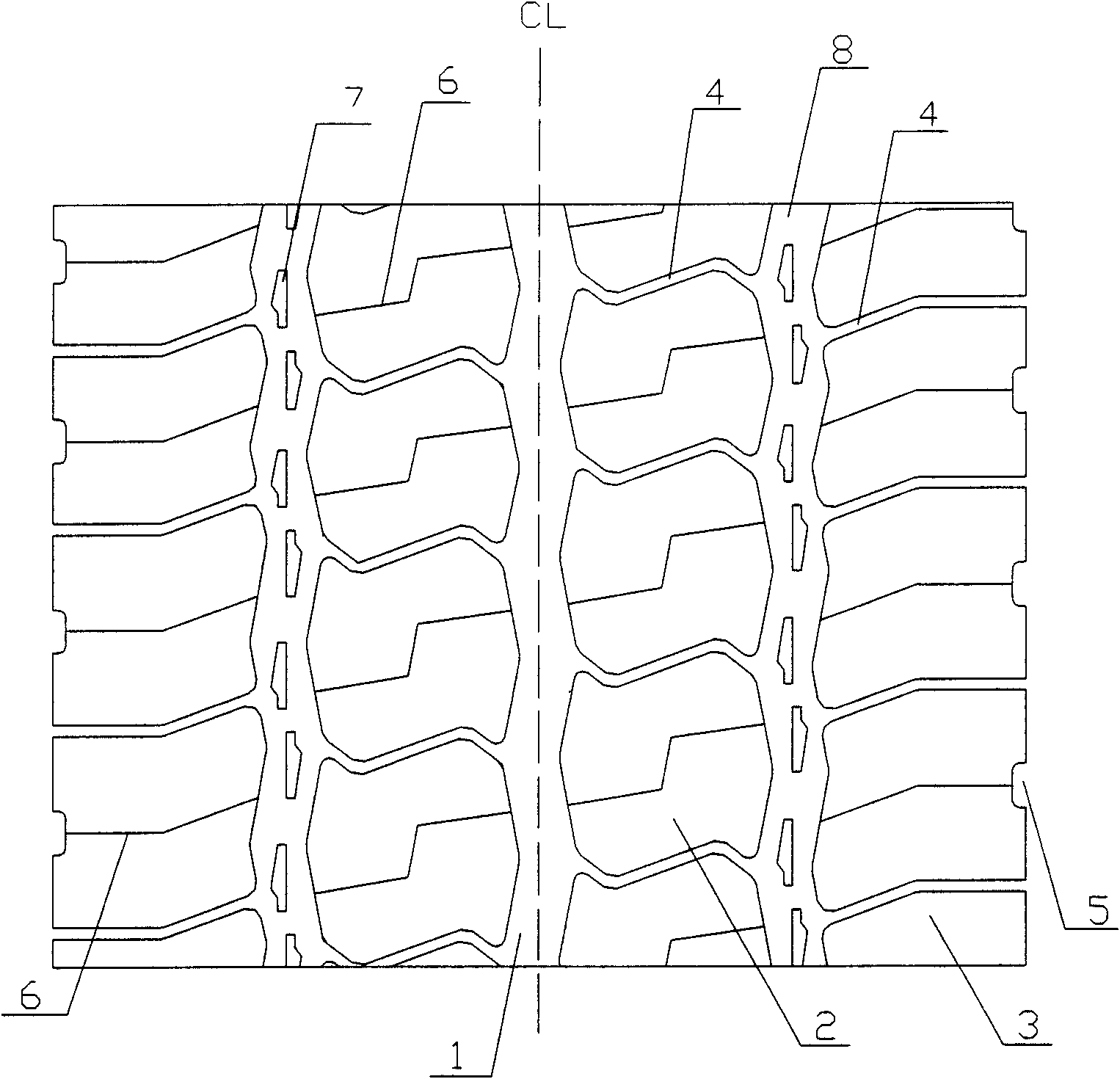

Truck tyre tread

ActiveCN101618664AAvoid eccentric wearImprove maneuverabilityTyre tread bands/patternsEngineeringTruck

The invention relates to an auto tyre structure, in particular to a tread pattern structure for a tyre of a truck. The truck tyre tread comprises a central vertical circumferential pattern groove arranged on the center position of the tyre tread, namely the center line of the tyre tread, wherein the central vertical circumferential pattern groove equally divides the tyre tread into two eudipleural parts, the left side and the right side of the central vertical circumferential pattern groove are provided with lateral pattern blocks and shoulder pattern blocks in turn regularly from inside to the outside, the lateral pattern blocks and the shoulder pattern blocks are spaced by the vertical circumferential pattern groove, and the groove bottom of the vertical circumferential pattern groove is provided with a bulge which is connected with the two side walls of the circumferential pattern groove; and two adjacent lateral pattern blocks and two adjacent shoulder pattern blocks are spaced by a transverse pattern groove respectively. The tyre tread of the truck tyre adopts mixed patterns and has sufficient braking force, good maneuverability, and elegant appearance.

Owner:QINGDAO YELLOWSEA RUBBER

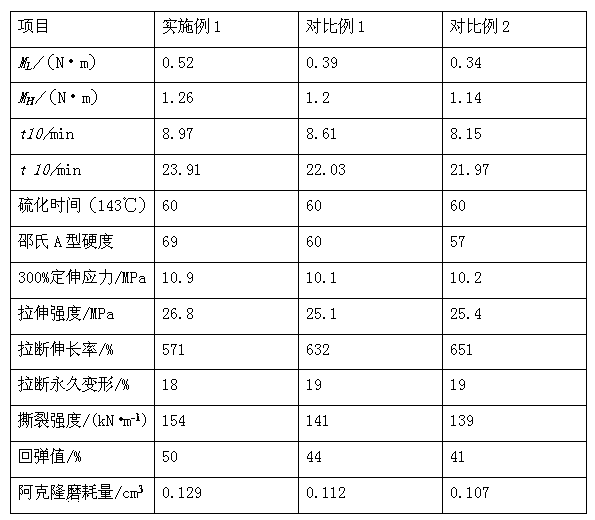

Radial tire crown rubber for high-speed passenger car

The invention provides radial tire crown rubber for a high-speed passenger car, and belongs to the technical field of tire manufacture and particularly relates to automotive tire crown rubber. The automotive tire crown rubber comprises the following components: solution polymerized styrene-butadiene rubber, butadiene rubber, white carbon black, carbon black, sulfur, aromatic hydrocarbon, nano-zinc oxide antiager, high abrasion furnace black, silane coupling agent, scorch retarder, gas carbon black, accelerant, stearic acid and anti-reversion agent, wherein the particle size of the white carbon black is 400-600 meshes, and the white carbon black is smashed in a superfine manner. With the adoption of the formula with the components in parts by weight, the tire crown rubber has the advantages of excellent wear resistance, high rubber hardness, high stress at definite elongation and tear strength, good wet slip resistance, and also relatively good wear resistance performance, and both the endurance quality and the high speed performance of the finished product tire reach a relatively high level.

Owner:SHANDONG YONGTAI CHEM GROUP

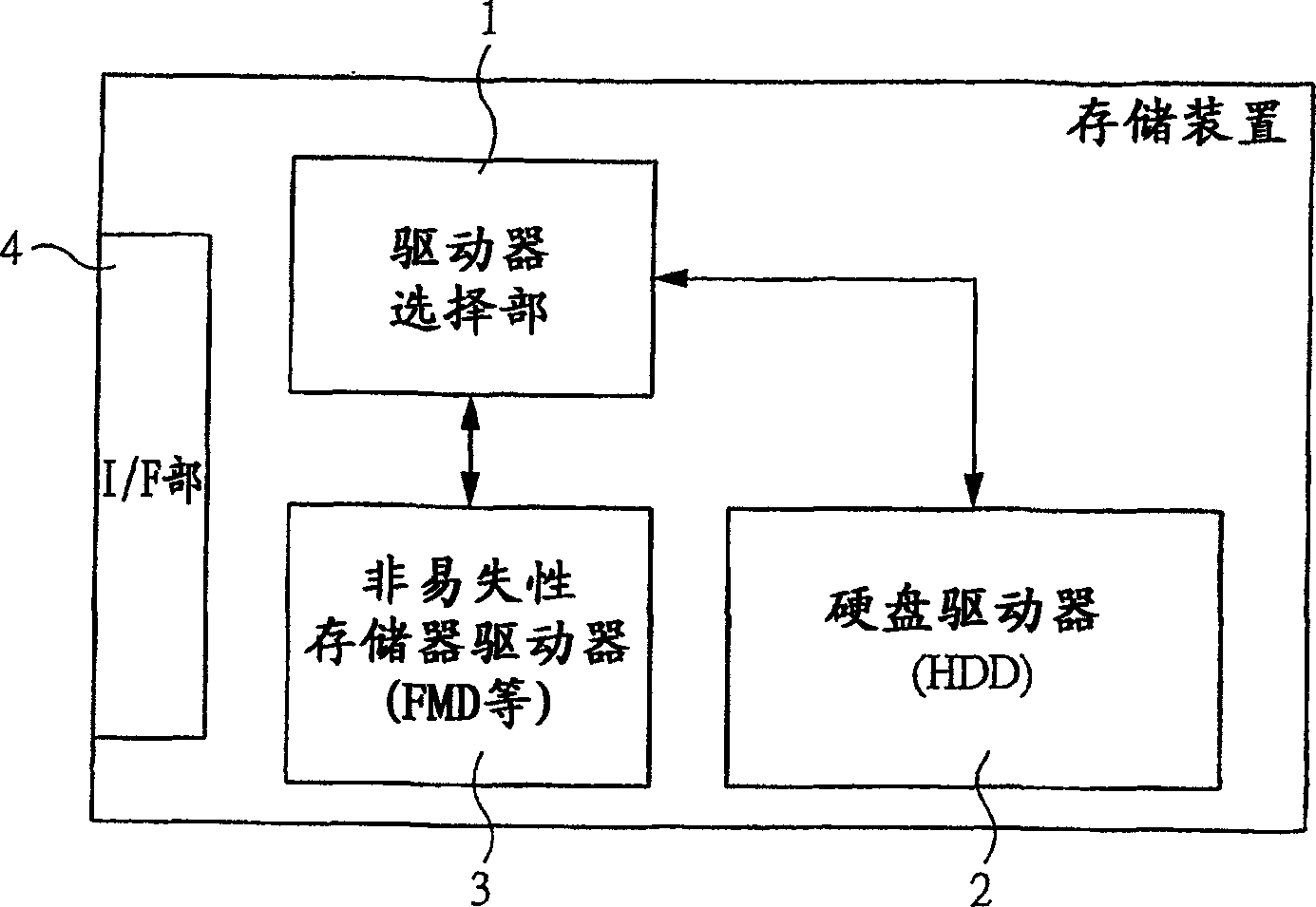

Storage device and storage system

InactiveCN101187849AImprove reliabilityImprove high-speed performanceInput/output to record carriersMemory systemsHard disc driveNon-volatile memory

Owner:HITACHI ULSI SYST CO LTD

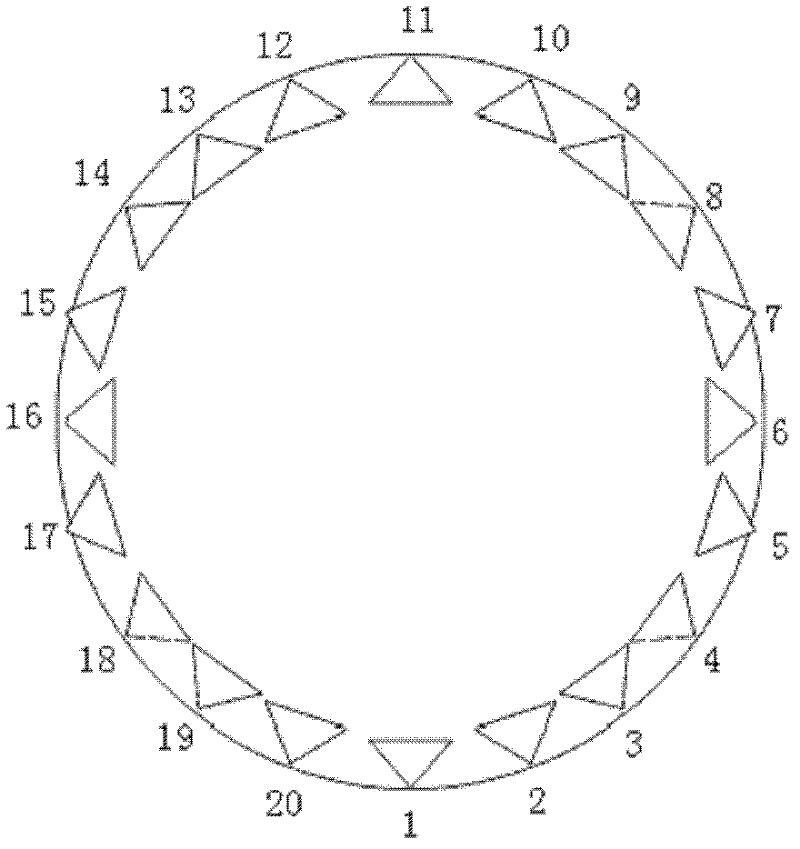

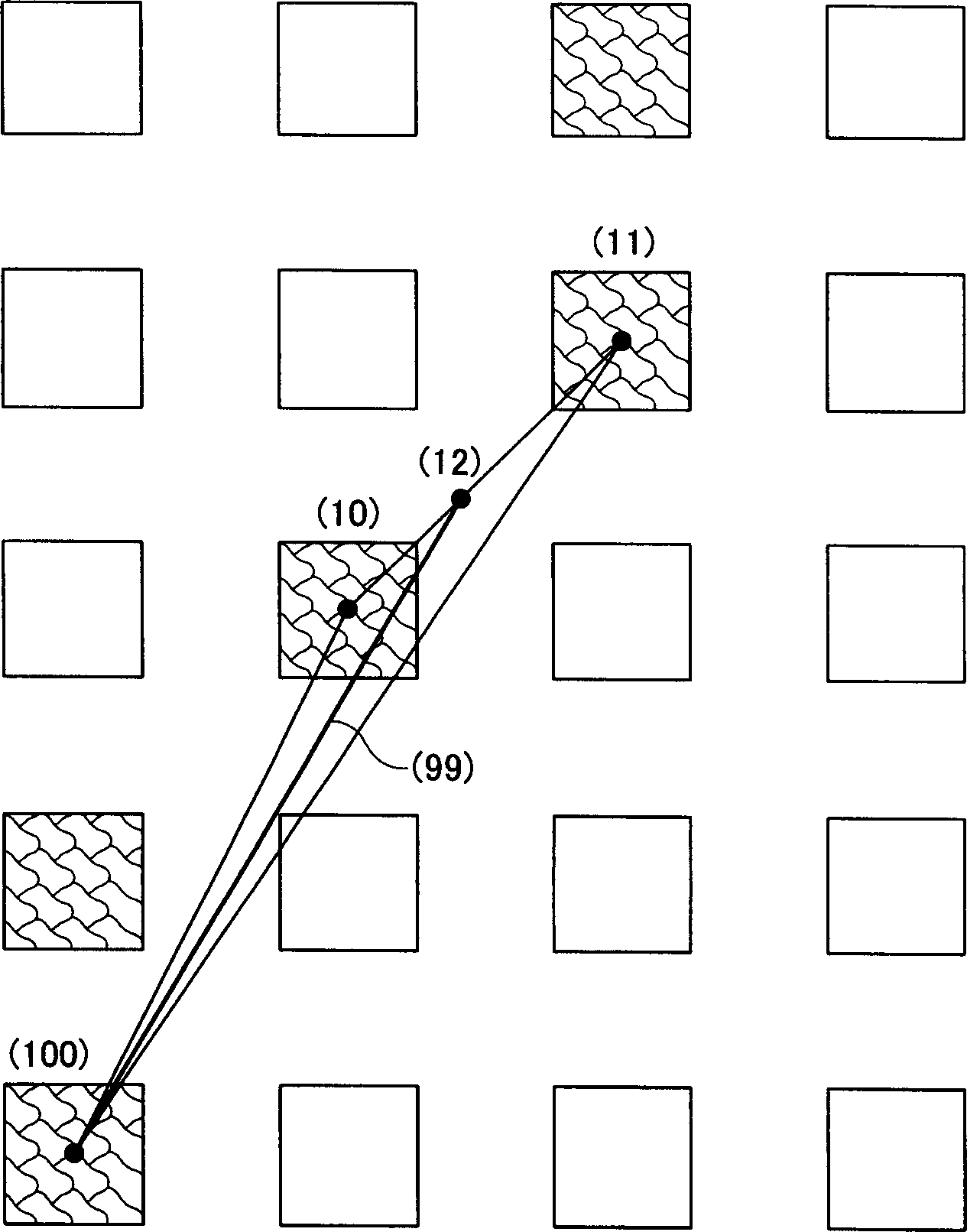

Curve identifying system

InactiveCN1410941AIncrease the scope of applicationLow costCharacter and pattern recognitionFingerprintRecognition system

The invention discloses the curve recognition system possible to apply to the recognition of human fingerprints. The main technical points of the invention are as follows. The method of recognizing in local and fraction is utilized to process image information. The important elements of the curve image such as the shape, gradient and the position can be expressed in concise data. The chords sampled in the curve with equal interval express the curve. Thus, curve can be expressed, stored, restored and compared by using few memory capacities. The shape of object can be recognized by the device with the invention being provided. The invention can be used as the personal id instead of keys, locks, checking tickets etc.

Owner:国枝博昭

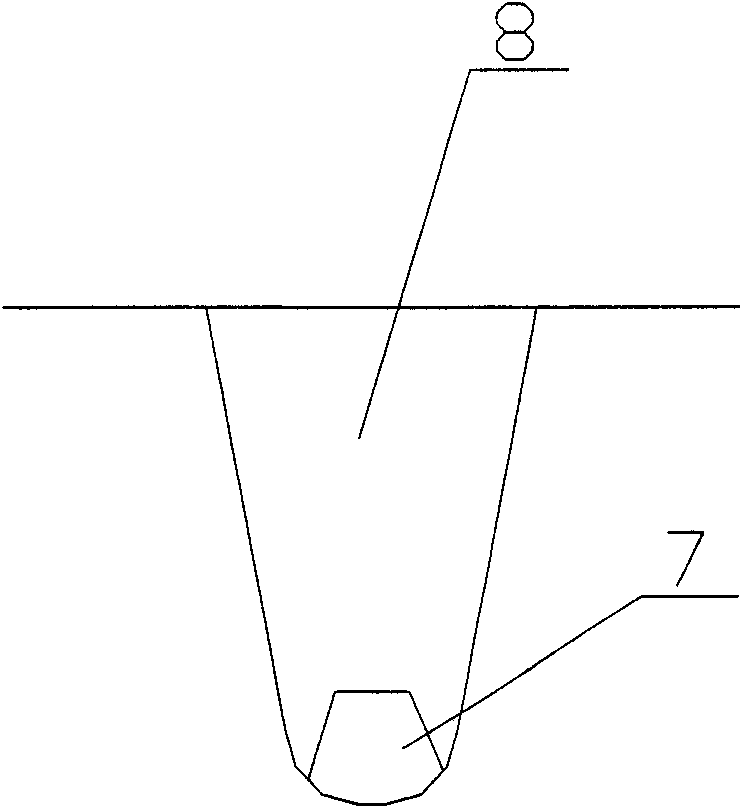

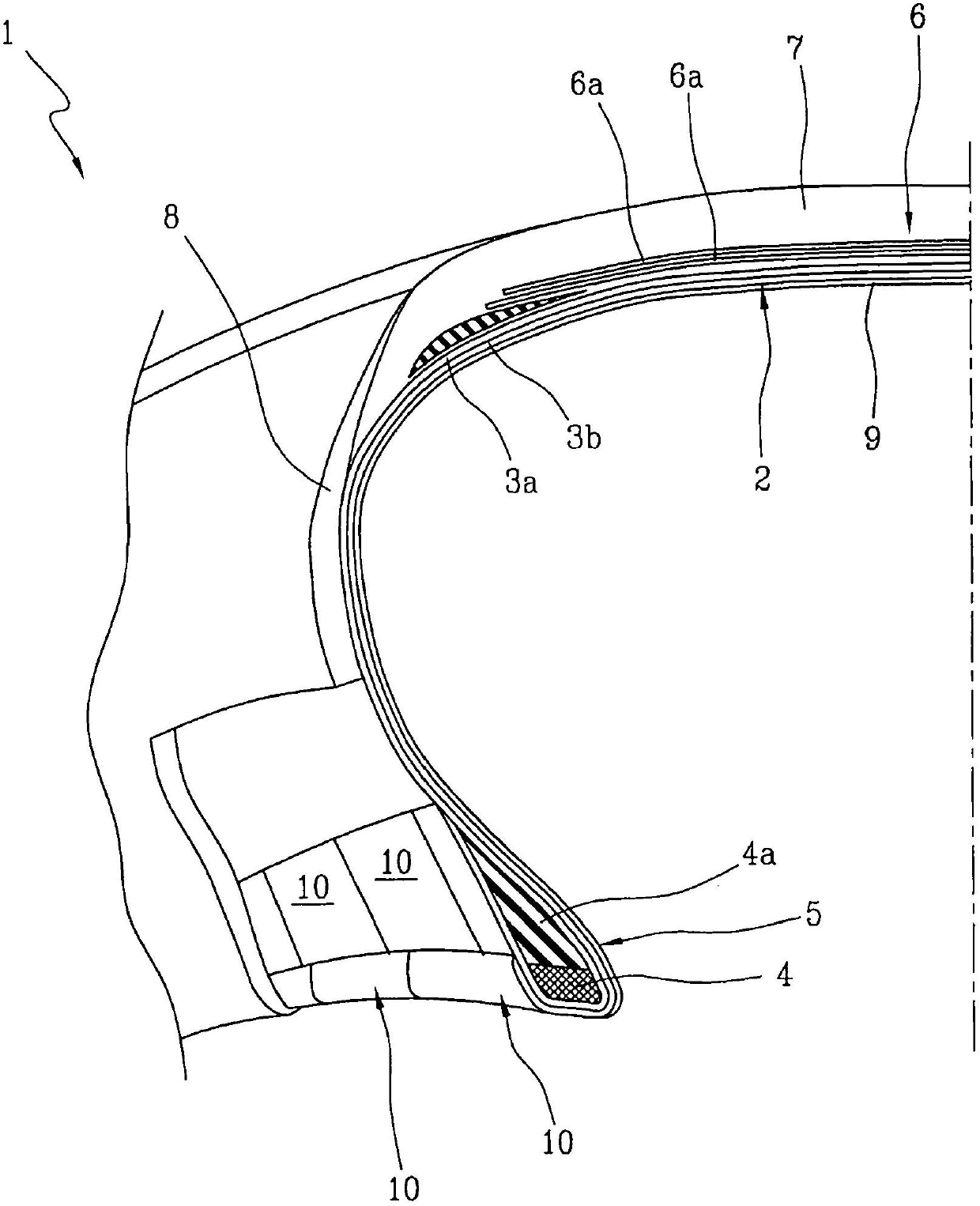

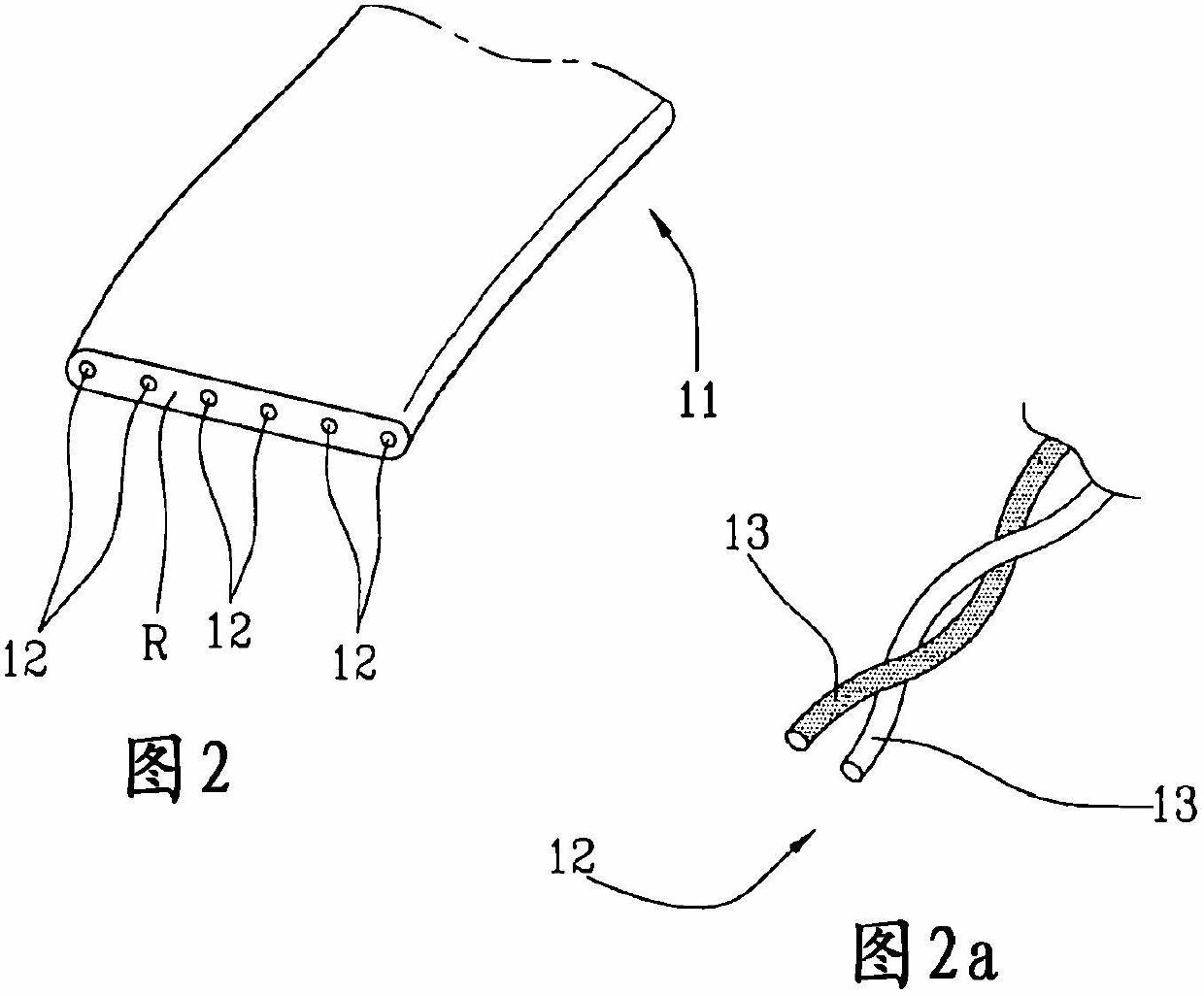

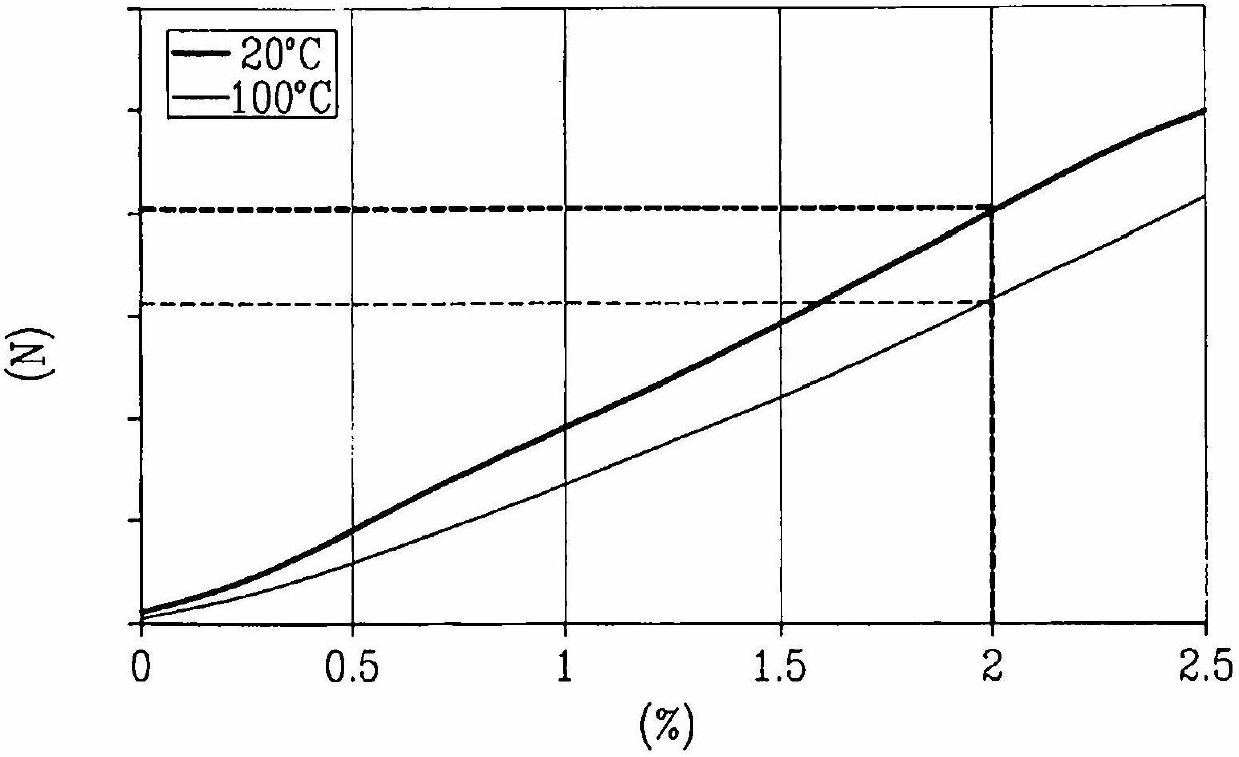

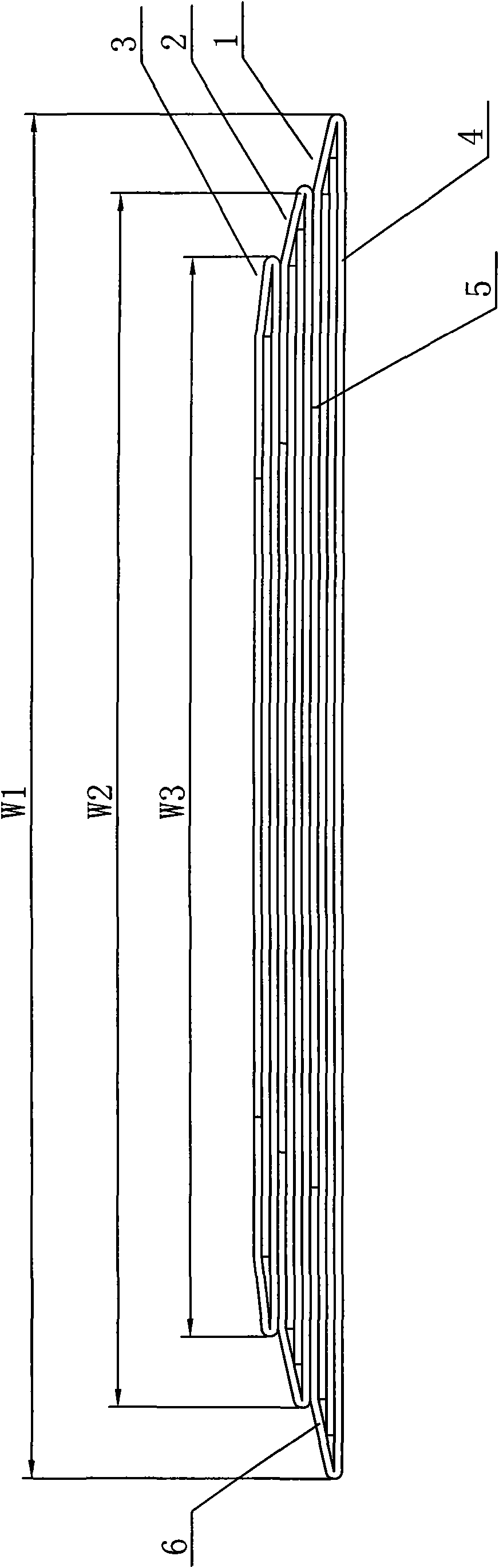

Method of increasing the high-speed performance of a carcass structure in a tyre for vehicle wheels and tyre for vehicle wheels

ActiveCN102666132AMaintain or improve performanceLimit manufacturing costsTyresPneumatic tyre reinforcementsEngineeringFilament yarn

The present invention relates to a method of increasing the high-speed performance of a carcass structure in a tyre for vehicle wheels. The method includes: preparing at least one hybrid yarn (13) and assembling a carcass structure (2) comprising at least one carcass ply (3a, 3b) substantially built on cords (12) comprising the hybrid yarn (13). The hybrid yarn (13) comprises a plurality of filaments (14a, 15a) obtained from a first multi-filament yarn (14) of polyester and a second multi-filament yarn (15) having a decay of the modulus with the temperature lower than 20%. Each of the first multi-filament yarn (14) and second multi-filament yarn (15) comprises a plurality of individual filaments (14a, 15a). The individual filaments (14a) of the first multi-filament yarn (14) are at least partly mixed in proportions of at least 50% with the individual filaments (15a) of said second multi-filament yarn (15).

Owner:PIRELLI TYRE SPA

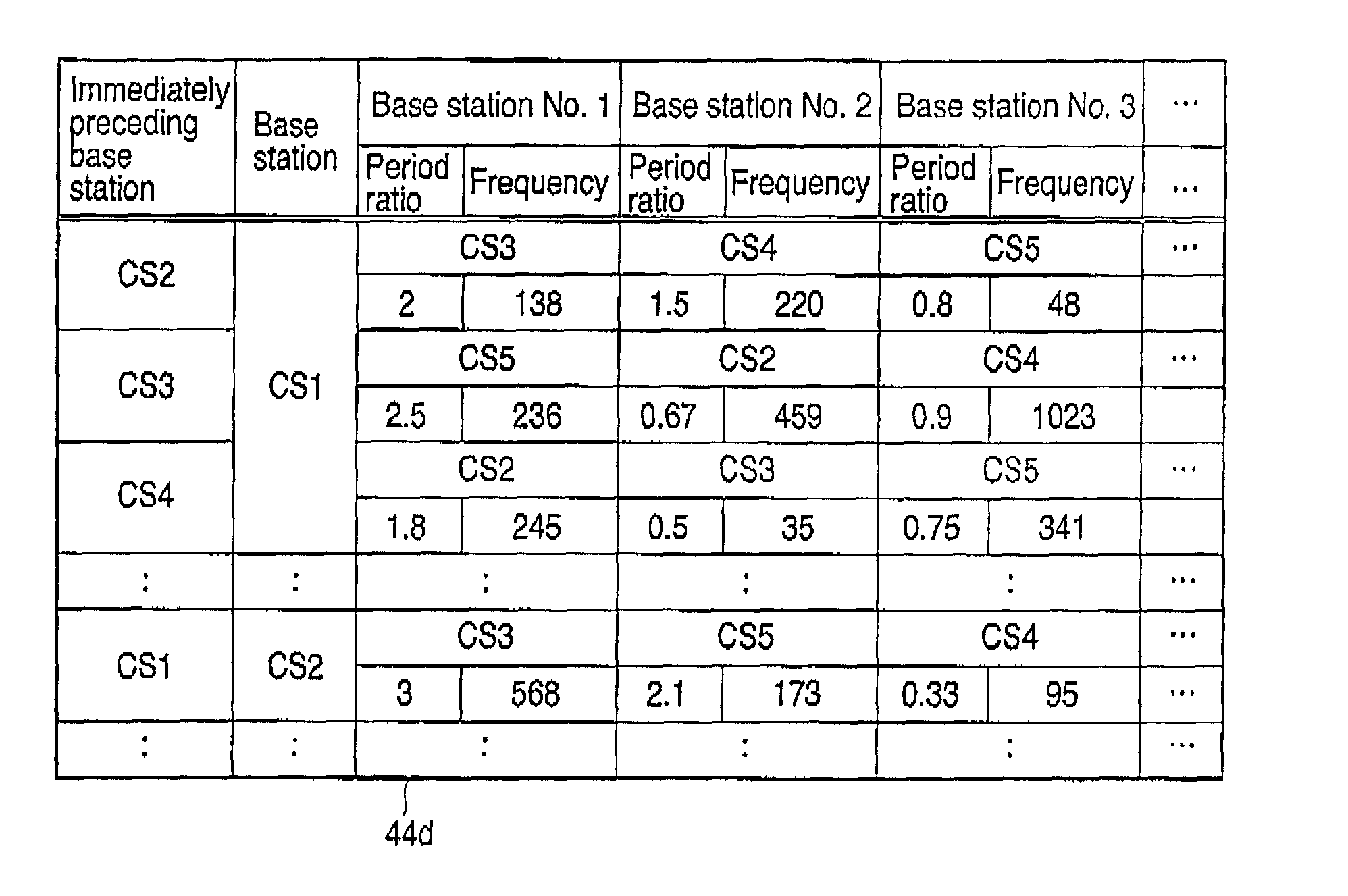

Mobile communication system, its control device, handover control method, and mobile terminal

InactiveUS8218504B2Improve high-speed performanceSpeedError preventionTransmission systemsComputer moduleComputer terminal

According to one embodiment, a mobile communication system includes base stations each forming a wireless zone for wirelessly accommodating mobile terminals, and a control device accommodating the base stations. The control device includes a construction module, a prediction module and an instruction module. The construction module constructs a database regarding a history of handovers by the mobile terminals. The prediction module predicts a base station of the next connection destination of a mobile terminal being in communication and timing of a handover to the base station of the next connection destination on the basis of the database. The instruction module instructs the handover to the predicted base station to the mobile terminal being in communication before the timing comes.

Owner:KK TOSHIBA

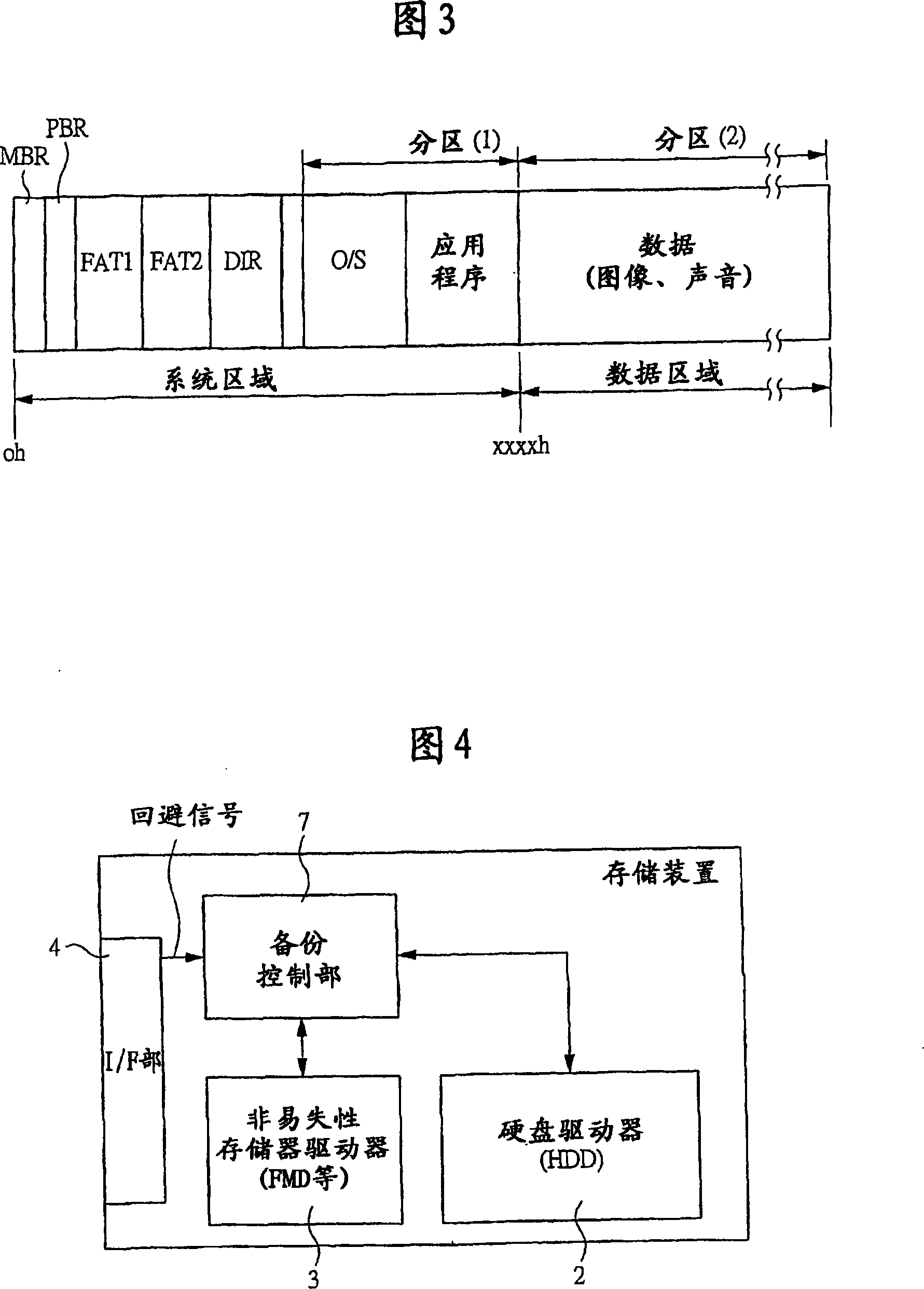

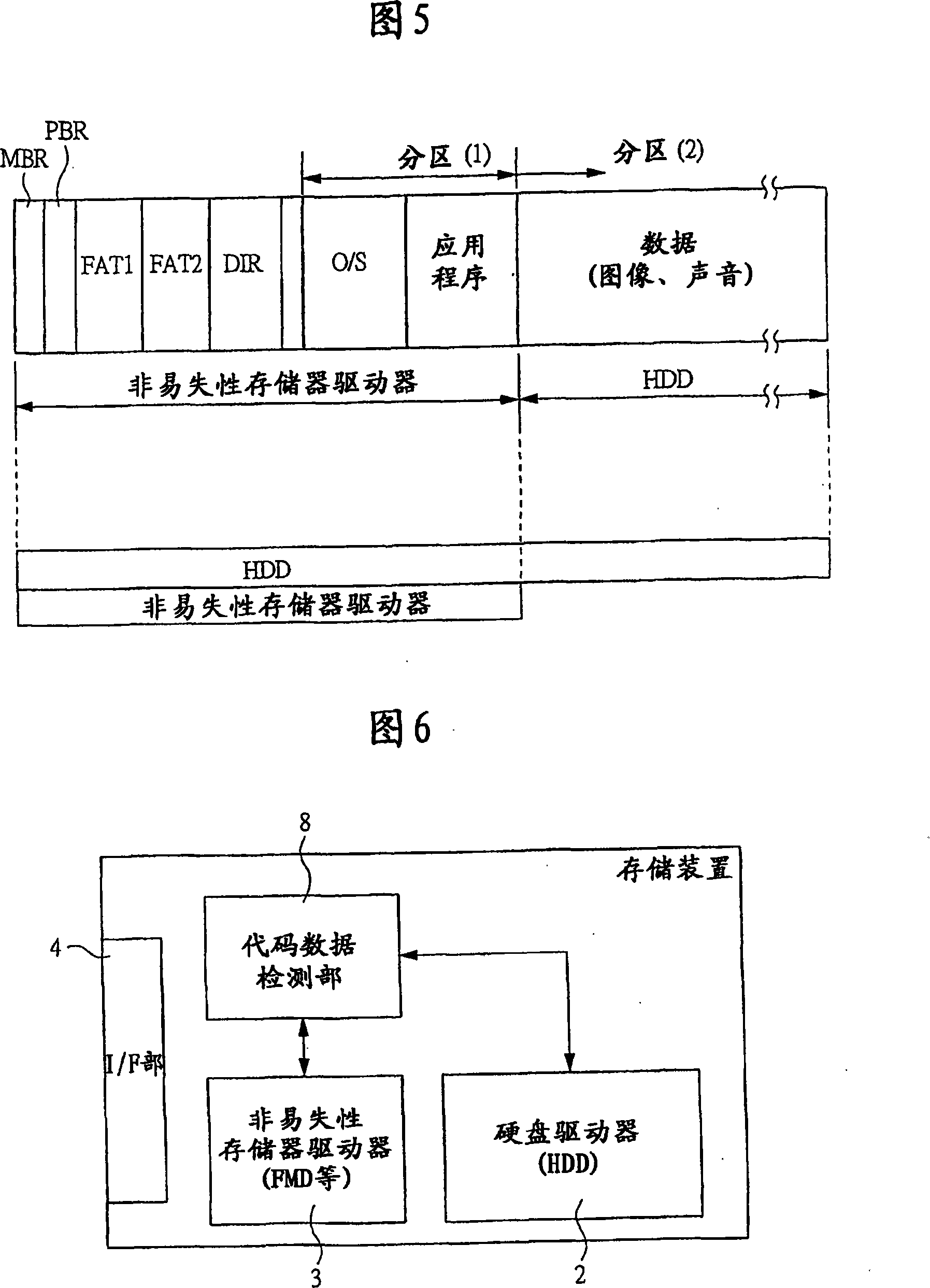

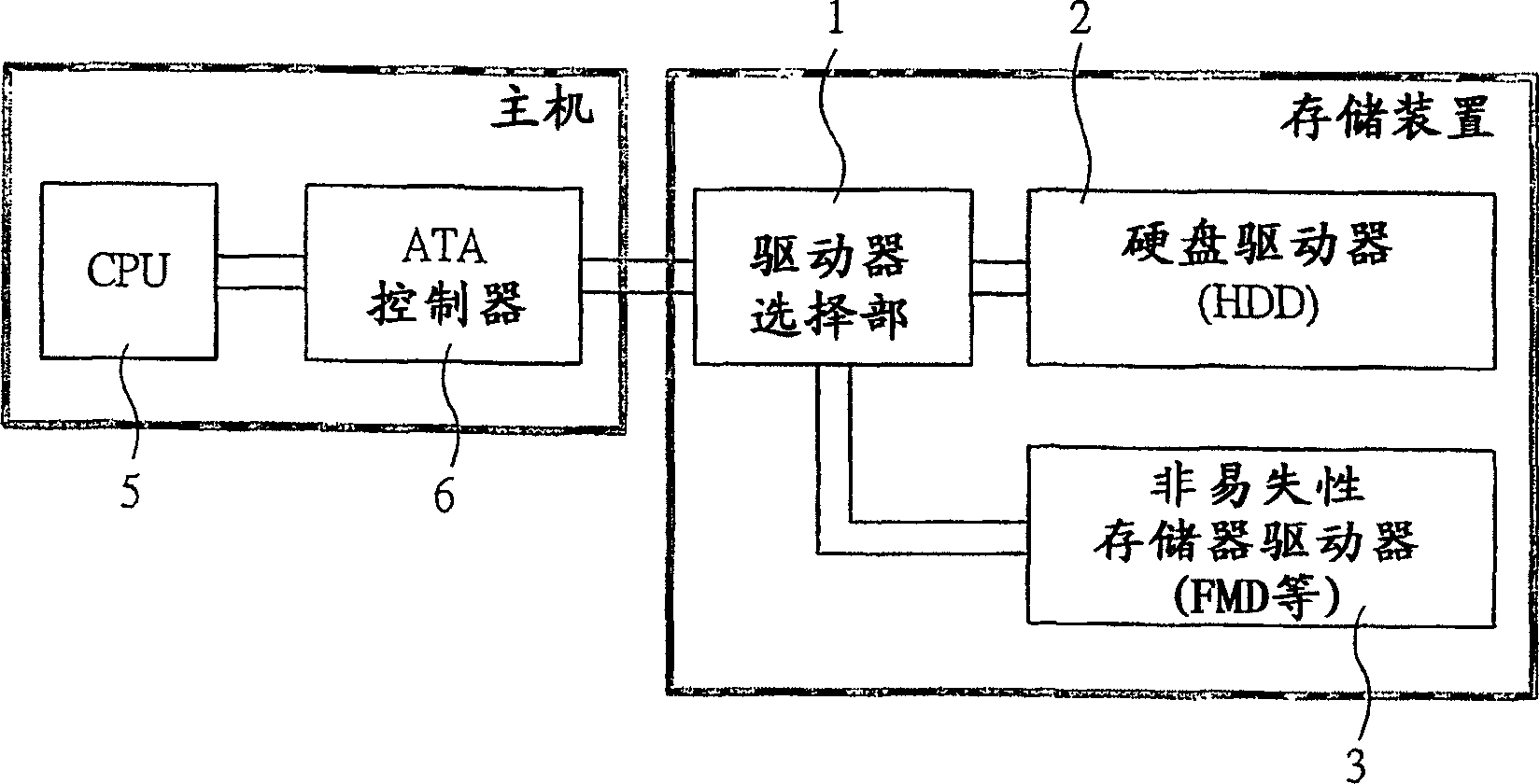

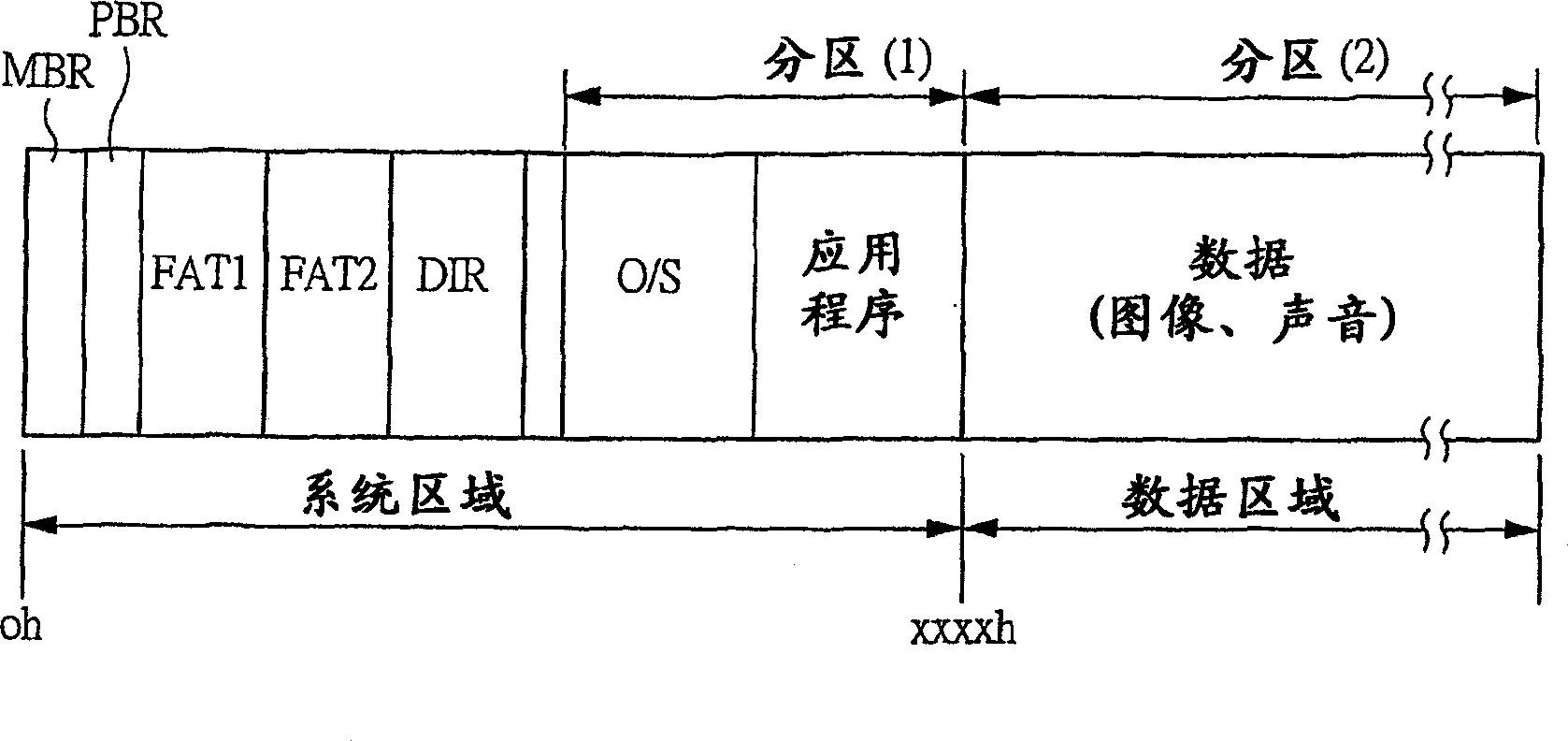

Storage device and storage system

InactiveCN1820244AImprove reliabilityImprove high-speed performanceInput/output to record carriersMemory loss protectionHard disc driveNon-volatile memory

A storage device includes a drive selection section (1), a hard disc drive (HDD) (2), and a non-volatile memory drive (3). When an instruction such as a data I / O instruction is issued from a host such as a CPU (5) and an ATA controller (6) to the hard disc drive (HDD) (2), the drive selection section (1) receives the address value. If the address value is contained in the address space predefined, the non-volatile memory drive (3) is made to execute the instruction. Otherwise, the hard disc drive (HDD) (2) is made to execute the instruction.

Owner:HITACHI ULSI SYST CO LTD

Fixing device for image forming apparatus

InactiveUS7787789B2Improve high-speed performanceAccurately and quickly feedback-controlsElectrographic process apparatusMicrocomputerTemperature control

A fixing device according to an embodiment of the present invention includes a microcomputer that exclusively performs temperature control for the fixing device. The microcomputer periodically calculates electric power that can be supplied to the fixing device. The microcomputer detects the temperature of the fixing device and the temperature in a printer unit and feedback-controls electric power supplied to the fixing device.

Owner:KK TOSHIBA +1

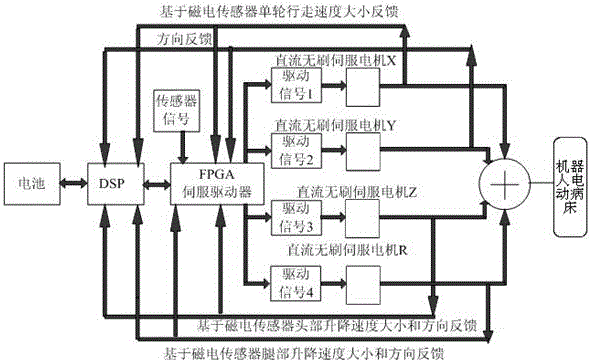

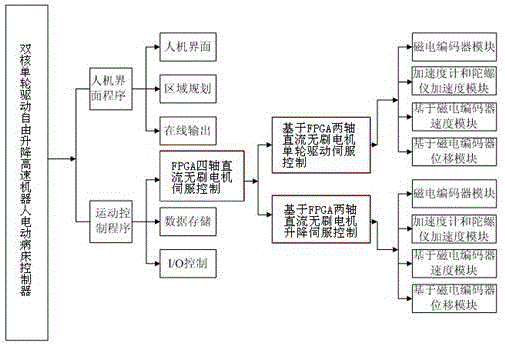

Dual-core and single-wheel drive free lifting high speed robot electric sickbed controller

InactiveCN106074049AImprove high-speed performanceMeet needsProgramme controlComputer controlElectric machineDual core

The invention discloses a dual-core and single-wheel drive free lifting high speed robot electric sickbed controller. The controller comprises a battery, a control panel, a motor X, a motor Y, a motor Z, a motor R and a robot electric sickbed, wherein the control panel adopts a dual-core controller and comprises a DSP and an FPGA; the DSP and the FPGA are in communication connection; and forward moving, the moving speed, the moving direction and lifting motion of the robot electric sickbed are controlled by the motor X, the motor Y, the motor Z and the motor R via magnetoelectricity encoders. The controller has the beneficial effects that the amount of labor and labor intensity of nursing workers or nurses can be reduced; meanwhile, a one-axis electric lifting device is additionally arranged at the head and tail of the robot electric sickbed respectively and has the function of freely lifting the heads, waists and legs of patients; and through combination of various sensors, the robot electric sickbed has various functions and can meet the requirements of the patients for the sickbed under different conditions.

Owner:JIANGSU ROBOBOR ROBOT TECH CO LTD

Built-in variable throttler

A built-in variable throttler comprises a throttler seat, a throttling post and a spring. A stair-step centre hole is arranged on the throttler seat and composed of a big diameter hole, a middle diameter hole and a small diameter hole, the big diameter hole is communicated with the small diameter hole through the middle diameter hole, the throttling post is formed by connecting a big diameter post, a middle diameter post and a small diameter post, the throttling post is installed in the throttler seat, the big diameter post is tightly matched with the big diameter hole, an oil storage chamber is defined by the top end of the big diameter post and the inner wall of the big diameter hole, an oil inlet chamber is formed between the middle diameter post and the big diameter hole, an oil inlet channel for communicating the oil storage chamber and the oil inlet chamber is arranged on the throttling post, a throttling gap communicated with the oil inlet channel is formed between the middle diameter post and the middle diameter hole, an oil collecting chamber is formed between the small diameter post and the middle diameter hole, the small diameter post is tightly matched with the small diameter hole, an output channel communicated with the oil collecting chamber is arranged on the small diameter post, and a spring abuts against and is arranged between the bottom end of the middle diameter post and the bottom end of the middle diameter hole. The built-in variable throttler is simple and compact in structure, and rapid in changing dynamic response of external loads.

Owner:HUNAN UNIV

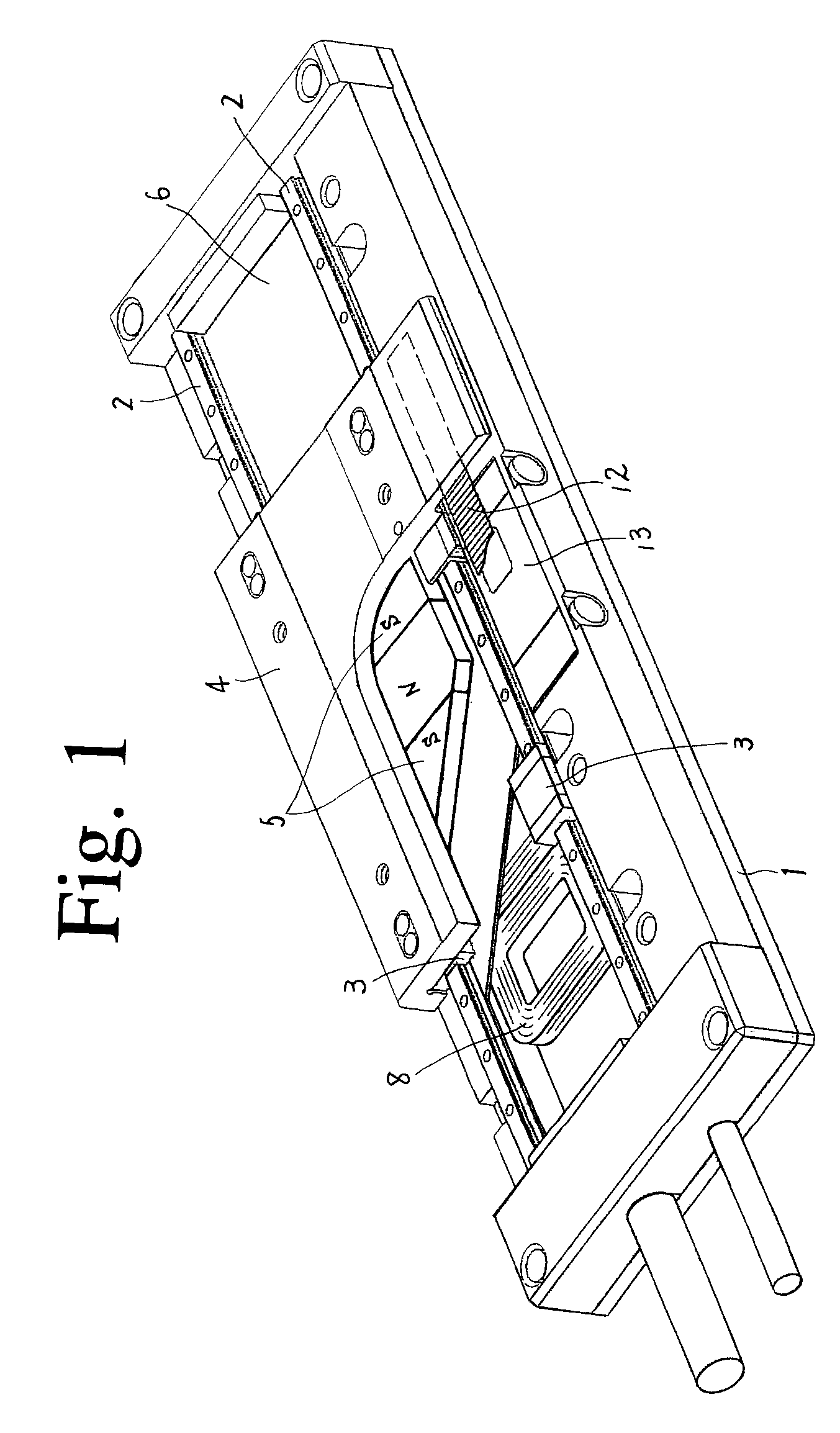

Linear drive system

ActiveUS7498700B2Simple structureImprove performancePropulsion systemsMagnetic tension forceRelative motion

Owner:NIPPON THOMPSON

Meridian aircraft tyre

InactiveCN101638037APrevent peelingImprove stabilityPneumatic tyre reinforcementsAviationLayer group

The invention relates to a meridian aircraft tyre, in particular to a meridian aircraft tyre having a folding edge-belted layer structure. The meridian aircraft tyre comprises a belted layer formed bybonding at least one belted layer group. Curtain lines of the bundle layer and a tyre surface form an included angle of 10 DEG to 20 DEG in a circumferential direction, wherein the belted layer groupis formed by bonding three layers or four layers of belt curtain cloth layers. In the same group of belted layer group, both ends of the bottom belt curtain cloth layer are reversed upwards into turned edges; the turned edges cover both ends of other belt curtain cloth layers except the first belt curtain cloth layer in the belted layer group; the ends of the turned edges are respectively connected with both ends of the first belt curtain cloth layer; and connection positions are within the range of the belt curtain cloth layer or a tyre top layer above the first belt curtain cloth layer. Byadopting the meridian aircraft tyre with the belted layer structure, the bundle layer has good stability and can effectively avoid producing a peeled meridian aircraft tyre between the ends of the curtain lines and glue.

Owner:HAOHUA SOUTH CHINAGUILIN RUBBER

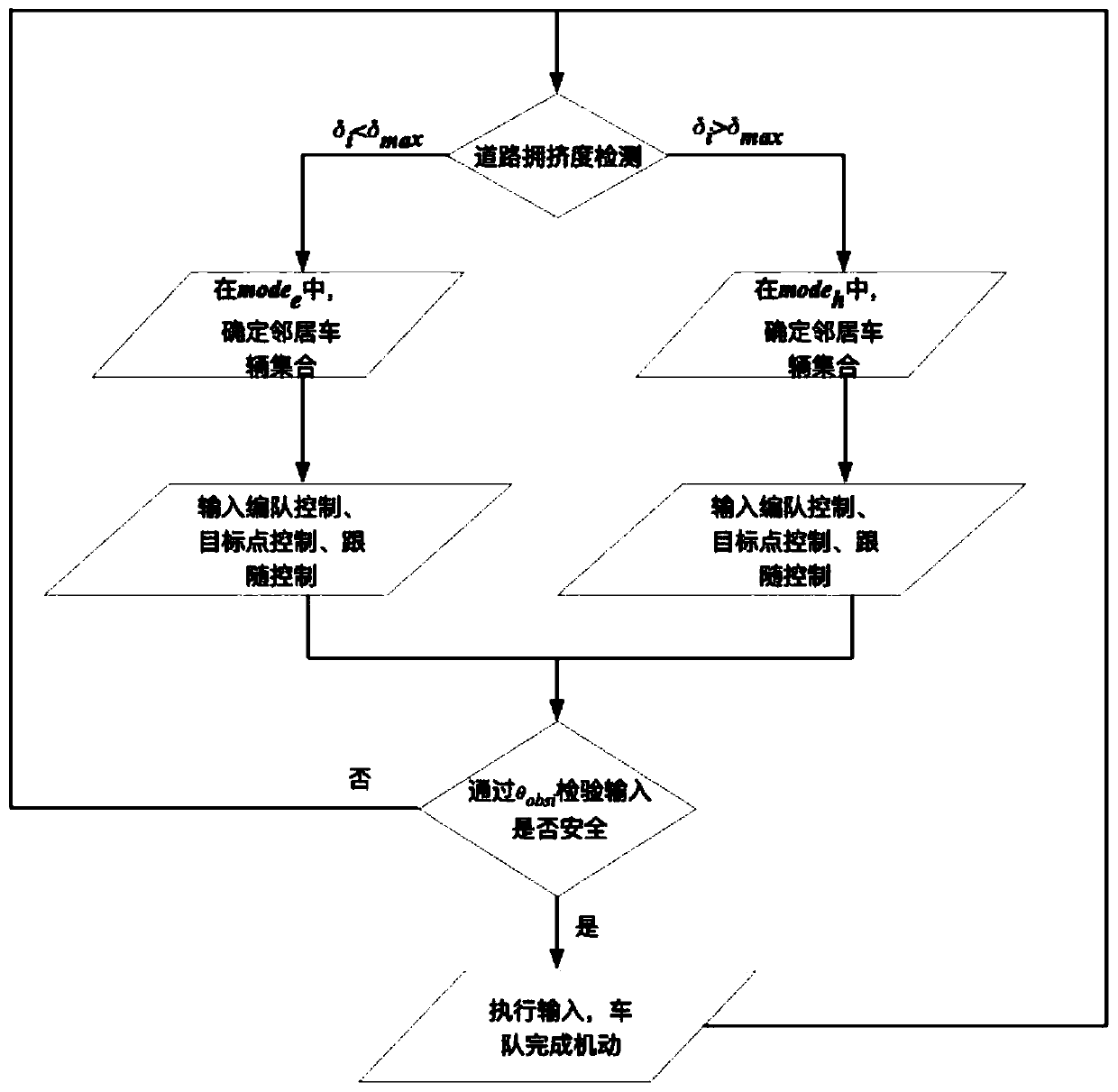

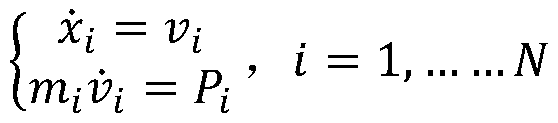

Pigeon-flock-imitating intelligent vehicle formation cooperative adaptive cruise control switching method

ActiveCN111324130AImprove securityImprove high-speed performanceAutonomous decision making processPosition/course control in two dimensionsSimulationControl mode

The invention discloses a pigeon-flock-imitating intelligent vehicle formation cooperative adaptive cruise control switching method. The method comprises the steps that firstly, each individual vehicle calculates a road congestion degree according to the number of obstacle vehicles within a perceptible range of the individual vehicle, and if the congestion degree delta i calculated by all the individual vehicles is larger than a congestion degree threshold value delta max, a motorcade enters a hierarchical control mode modeh; otherwise, the motorcade enters an equal interaction mode modee; then, in a current state, each individual vehicle i in the motorcade marks a neighbor vehicle j within a distance with relatively low communication delay so as to obtain a neighbor vehicle set, then control input is performed, the control input includes a formation control gain, a target point control gain and a following control gain, and the formation control gain, the target point control gain andthe following control gain are all added into a potential field function so as to maintain a function value within a reasonable range; and finally, safety is judged, each individual vehicle judges whether a direction of a control input vector is within the range of the obstacle angle theta avoi or not by calculating obstacle angles occupied by all obstacle vehicles within the perceptible range, and safety of a driving behavior is predicted.

Owner:JIANGSU UNIV

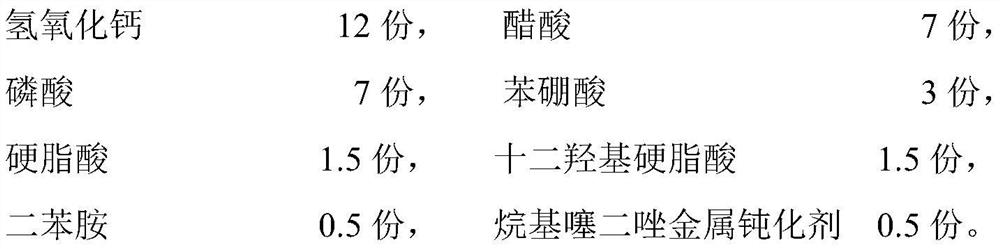

Composite calcium-based lubricating grease and preparation method thereof

ActiveCN111718778AImprove anti-friction and anti-wear effectGood extreme pressure and anti-wear propertiesLubricant compositionCalcium biphosphateCalcium pidolate

The invention relates to novel composite calcium-based lubricating grease and a preparation method thereof. The novel composite calcium-based lubricating grease is prepared from, by weight, 50-80% ofa base liquid, 20-40% of a novel composite calcium-based composite calcium soap thickening agent and 0.1-5% of a function improvement additive. The novel composite calcium-based lubricating grease ischaracterized in that the novel composite calcium-based thickening agent is adopted, a calcium phenylborate-calcium phosphate component is introduced to improve the friction and wear resistance and the antioxidant stability of the composite calcium-based thickening agent and improve the storage hardening problem of the composite calcium-based lubricating grease, and meanwhile, the characteristicsof excellent extreme pressure wear resistance, mechanical stability, water resistance and the like of the composite calcium-based thickening agent are fully utilized, so that the prepared novel composite calcium-based lubricating grease can meet the use requirements of high temperature, high speed, high reliability and long service life of the hub bearing of the heavy-duty vehicle.

Owner:长沙众城石油化工股份有限公司

Full steel radial tire with separated outer belt ply and zero degree belt ply structure

PendingCN108215664AImprove shoulder strengthImprove tire clamping effectPneumatic tyre reinforcementsHeavy duty tyresRadial tireEngineering

The invention discloses a full steel radial tire with a separated outer belt ply and zero degree belt ply structure. The radial tire comprises a three belt plies arranged in the middle of the tire crown and one or two zero degree belt plies arranged on two tire shoulders. Three belt plies comprise an internal belt ply, a middle belt ply, and an outer belt ply, which are arranged on the middle of the tire crown in sequence from inner to outer along the radial direction of the tire crown. Two tire shoulders are both provided with one zero degree belt ply or two zero degree belt plies, which arearranged in sequence along the radial direction from inner to outer. The distance between two radial edges of the outer belt ply and the zero degree belt plies of two tire shoulders is greater than 6mm. The tire has the advantages that the tire can be tightly fastened, the deformation of the edges of the outer belt ply is reduced, the shearing of the zero degree belt plies is relieved, the durability and high speed performance of the radial tire are enhanced effectively, and raw materials such as rubber, steel wire, cords, and the like, can be saved.

Owner:SHANDONG LINGLONG TIRE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com