Method of increasing the high-speed performance of a carcass structure in a tyre for vehicle wheels and tyre for vehicle wheels

A carcass structure and tire technology, applied in the direction of wheels, vehicle parts, tire parts, etc., can solve the problems of difficult man-made fiber performance, detachment, and increased real deformation of the carcass, and achieve the effect of enhancing high-speed performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

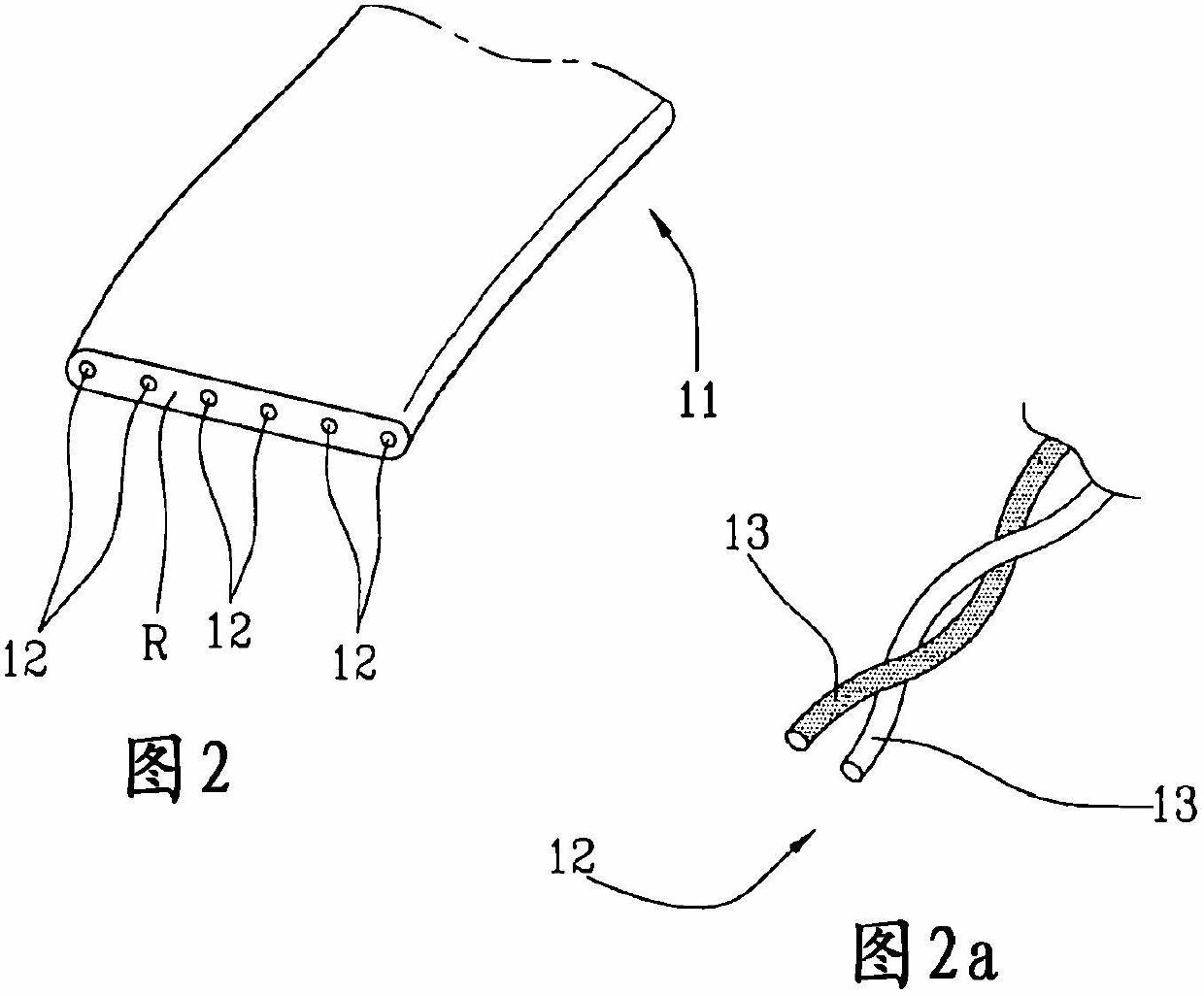

[0131] Three blended yarns according to the invention have been prepared:

[0132] A1- Aromatic polyamide (AR) + polyethylene terephthalate (PET) (aramid 50%)

[0133] A2-aramid+polyethylene terephthalate (aramid 25%)

[0134] A3-aramid+polyethylene terephthalate (aramid 20%)

[0135] And two non-mixed yarns:

[0136] B1-Kevlar 440

[0137] B2-Polyethylene terephthalate 1670

[0138] A1 is a mixed fiber yarn made of aramid (AR) multifilament yarn and polyethylene terephthalate (PET) multifilament yarn; Silk yarn constitutes 50% by weight of the mixed fiber yarn A1.

[0139] Yarn A1 is prepared by feeding aramid (AR) multifilament yarn and polyethylene terephthalate (PET) multifilament yarn to an air-jet texturising device .

[0140] A2 is a mixed fiber yarn made of aramid (AR) multifilament yarn and polyethylene terephthalate (PET) multifilament yarn; Silk yarn constitutes 25% by weight of mixed fiber yarn A2.

[0141] The yarn A2 is prepared by feeding an aramid (AR) multifilament yarn a...

example 2

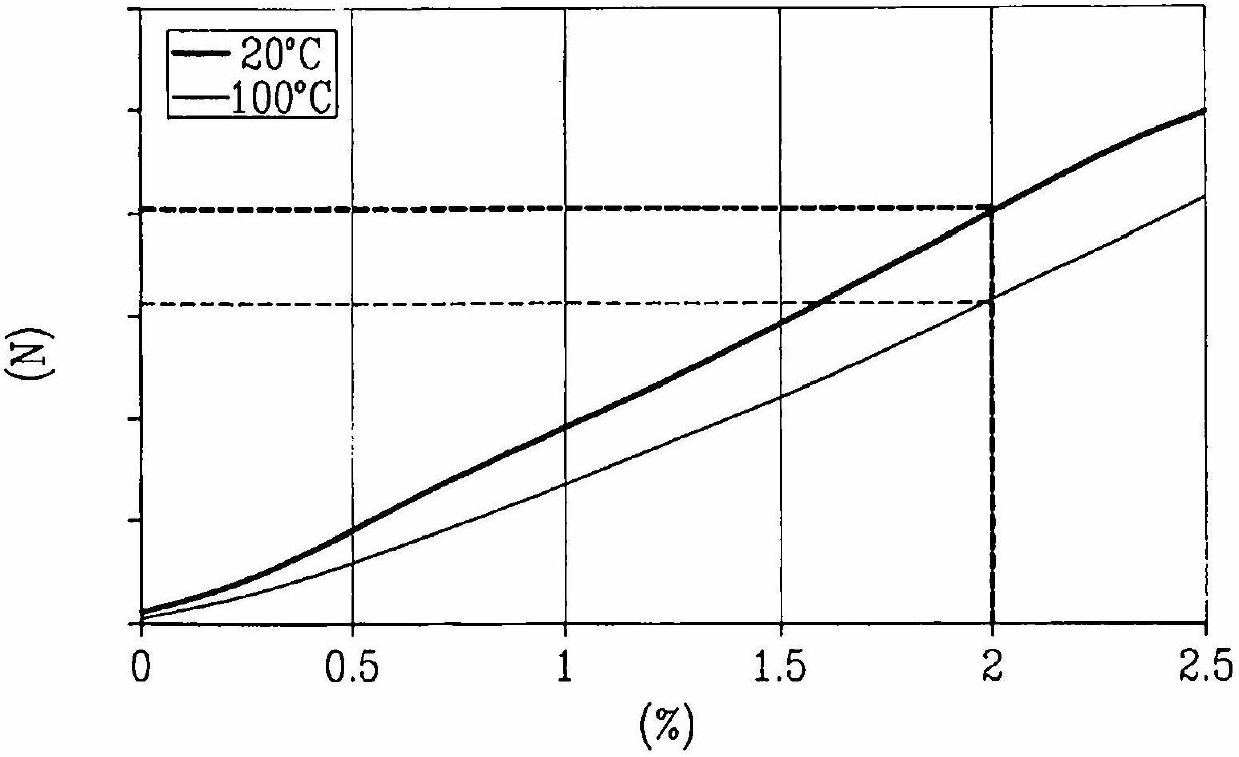

[0149] Figure 7 Shows the traction load (Newtons) as a function of elongation (%) for three cords according to the invention:

[0150] Aramid + polyethylene terephthalate (37%) 1840×2405×405 (made of two kinds of mixed yarn aramid + polyethylene terephthalate (37%) The cord, each blended yarn aramid + polyethylene terephthalate (37%) has a yarn count of 1840 (dtex) and 405 twisting operations per meter);

[0151] Aramid + polyethylene terephthalate (37%) 1840×2305×305 (made of two kinds of mixed fiber yarn aramid + polyethylene terephthalate (37%) For cords, each blended yarn aramid + polyethylene terephthalate (37%) has a yarn count of 1840 (dtex) and 305 twisting operations per meter);

[0152] Aramid + polyethylene terephthalate (20%) 2130×2405×405 (made of two kinds of mixed fiber yarn aramid + polyethylene terephthalate (20%) The cord, each blended yarn aramid + polyethylene terephthalate (20%) has a yarn count of 2130 (dtex) and 450 twisting operations per meter);

[0153] An...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com