Event or exhibition carpet with solid multilobal fibre

A multi-lobal, carpet technology, applied in the direction of carpet, carpet, fiber treatment, etc., can solve the problems of reducing the strength and hardness of the carpet, reducing the carpet, etc., to achieve good wrinkle and deflection, weight reduction, high fiber-fiber friction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0144] The nonwoven fabric is manufactured with 4.4 dtex trilobal fibers and 6.7 dtex round fibers (preferably made of polypropylene or polyester, for example). Both fibers have the same coverage distance when observed under the microscope. For 4.4 dtex trilobal fibers, the coverage distance (distance of solid material fibers) is almost equal to that of 6.7 dtex linear mass density circular cross-section fibers.

[0145] For each fiber, a 5-layer nonwoven was constructed using the following parameters:

[0146] ·The first needle board: 75 needles / cm from top to bottom 2 , puncture depth 11.5mm, 4500 needles / m at the entrance, 7000 needles / m at the exit, needle type 15x18x36 3,5R222G3037.

[0147] ·Second needle board: 100 needles / cm from bottom to top 2 , puncture depth 11mm, the whole board 7000 needles / meter, needle type 15x18x36 3,5R222G3037.

[0148] ·Third needle board: 100 needles / cm from top to bottom 2 , the puncture depth is 8mm, the whole board is 7000 needles / m...

no. 2 approach

[0165] In other embodiments, samples fabricated as described in Embodiment 1 were combined using three different backing methods:

[0166] 1. Pre-coated backing

[0167] 2. Full bath resin backing

[0168] Precoated Backing Embodiments

[0169] A suspension of latex and chalk in water was applied by a kiss roll system at a weight of 300 g / m 2 The circular needle felt and the weight is 260g / m 2 and 210g / m 2 The hairiest side of the trefoil needle felt. Fibers can be made from polypropylene. The suspension density was set at 1200 g / l. The carpet then passes through a first oven at 140°C followed by a second oven at 120°C. After that, cut off the edges of the carpet and cut the remaining 4 meter wide carpet into two parts with a width of about 2 meters.

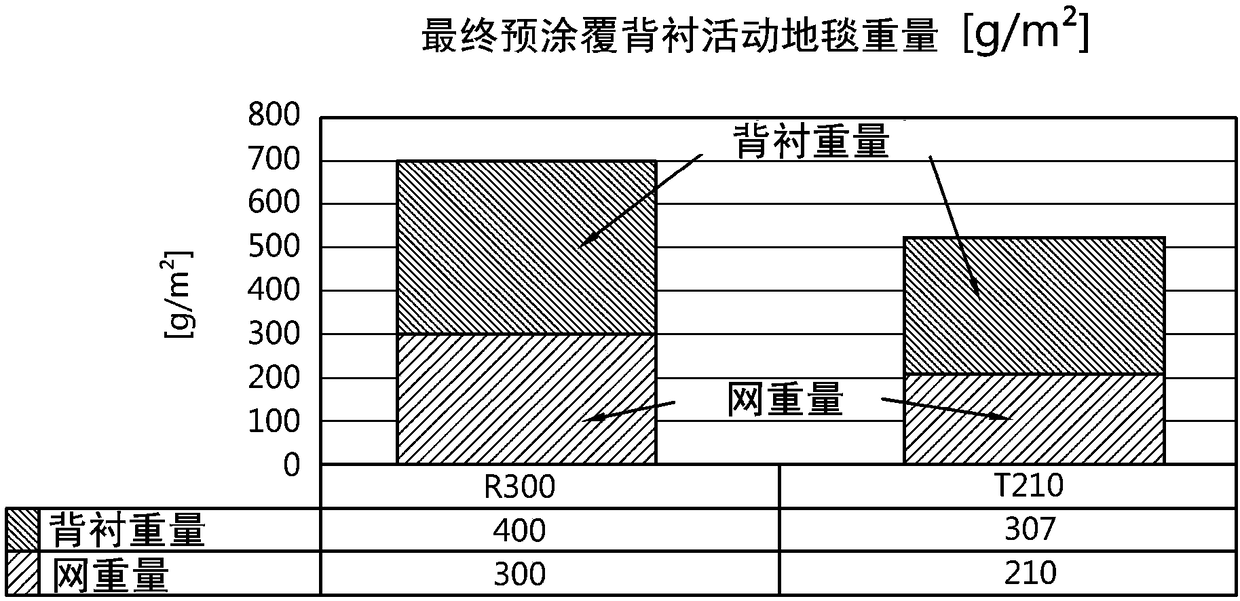

[0170] The following carpets were backed and final roll weights observed (Table 2 - performed on 4m wide carpet)):

[0171]

[0172] Table 2

[0173] Polypropylene trefoil rugs pick up less chalk-latex suspension th...

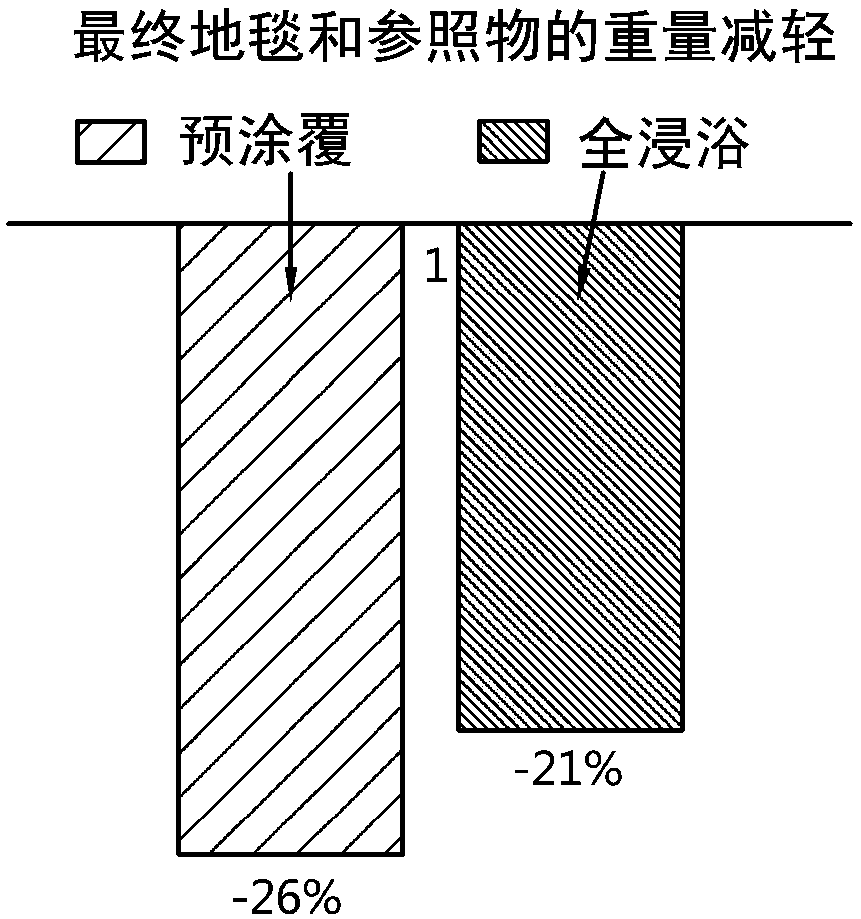

Embodiment approach

[0177] Apply 245g / m using the same settings as the pre-coated backing 2 The wet latex weight is applied to the carpet sample. The latex is pressed through the nonwoven fabric using soft silk to ensure complete impregnation. The carpet width after trimming the edges is exactly 4 meters.

[0178] The following carpets were backed and observed for final roll weight (Table 3):

[0179]

[0180] table 3

[0181] Raised carpets with trelobal fibers showed sufficient stiffness and coverage, especially based on trelobal 210g / m 2 The hardness and coverage of the raised carpet. And the trefoil rug has a pure white color and richness of the rug.

[0182] mechanical result

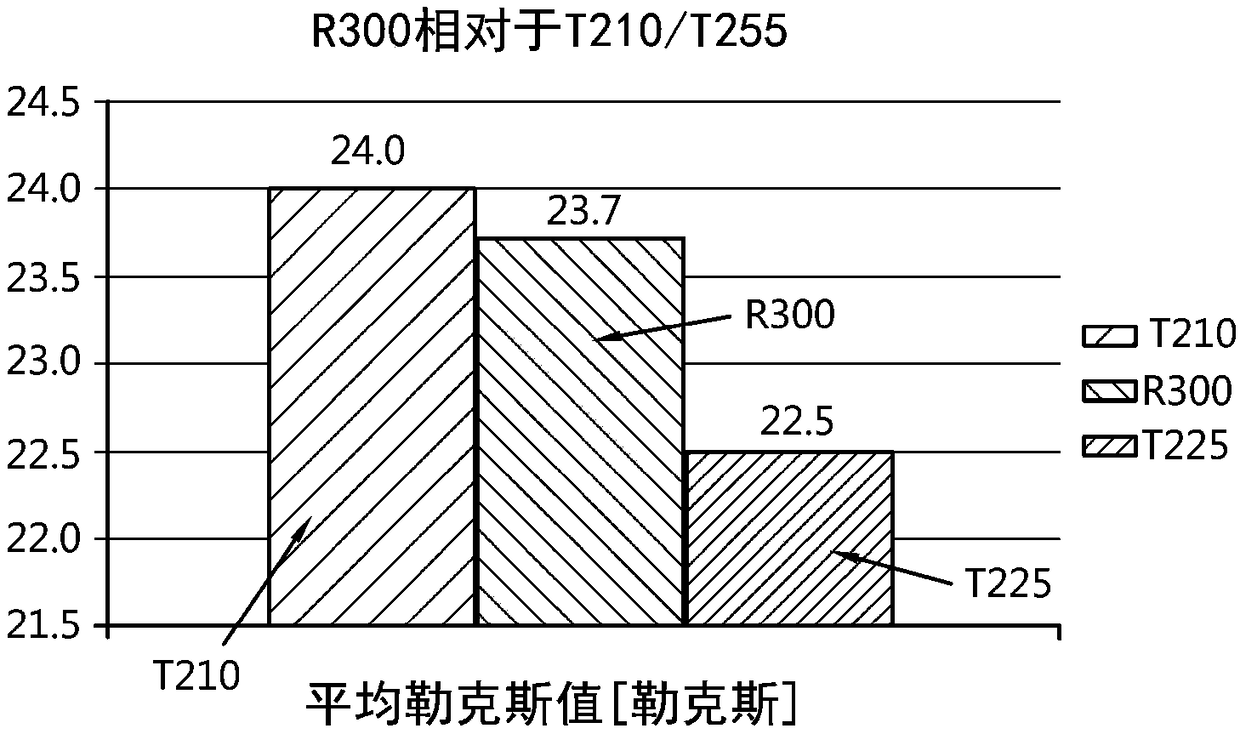

[0183] Compare the following properties of circular cross-section polypropylene fibers with reference to carpets and their trefoil equivalents ( Figure 4 -8).

[0184] Figure 4 A comparative example of modulus is shown for a reference carpet (300) and a precoated embodiment of the invention (T210), showi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com