Barrier film

A technology of barrier film and barrier layer, which is applied in the direction of electronic equipment, types of packaging items, special packaging items, etc., and can solve problems such as deterioration of physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

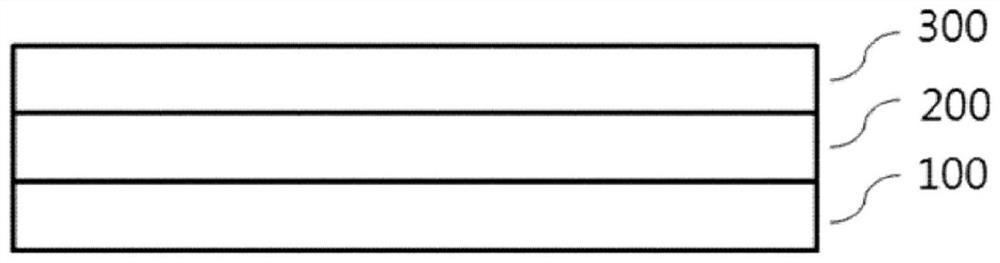

[0128] Production of barrier layers

[0129] A coating solution obtained by dissolving polysilazane in dibutyl ether was applied to a PET (poly(ethylene terephthalate)) film (T600E50, Mitsubishi) having a thickness of 50 μm by a bar coating method , and the obtained coating film was kept at 70° C. for 1 minute and at 130° C. for 2 minutes to form a polysilazane layer with a thickness of about 300 nm.

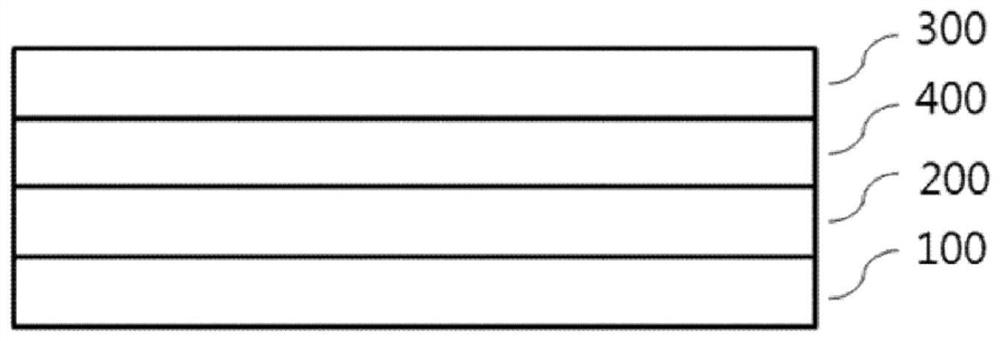

[0130] Production of anti-blocking layers

[0131] Make pentaerythritol triacrylate (PETA, trifunctionality, molecular weight: about 298.291g / mol) and dipentaerythritol hexaacrylate (DPHA, hexafunctionality, molecular weight: about 524g / mol) in a ratio of 8:2 (PETA:DPHA) Weight ratio Dissolved in a solvent (propylene glycol monomethyl ether). Relative to the total weight of 100 parts by weight of PETA and DPHA, by adding 4 parts by weight of a polymerization initiator (Irgacure 127, Ciba) and 0.4 parts by weight of particles (average particle diameter (D50 particle diameter): ...

Embodiment 2

[0136] Example 2: Production of barrier film

[0137] A barrier film was produced in the same manner as in Example 1, except that particles (MX-2000, Soken ) instead of particles with an average particle size (D50 particle size) of 5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com