Guide table type oil jet nozzle

A technology of fuel injectors and guide platforms, which is applied in the direction of fuel injection devices, engine components, machines/engines, etc. It can solve the problems of short penetrating distance of umbrella-shaped spray, too thick circumferential distribution of mixed gas, unevenness, etc., and achieve fog Good chemical performance, rapid and perfect combustion, uniform circumferential distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

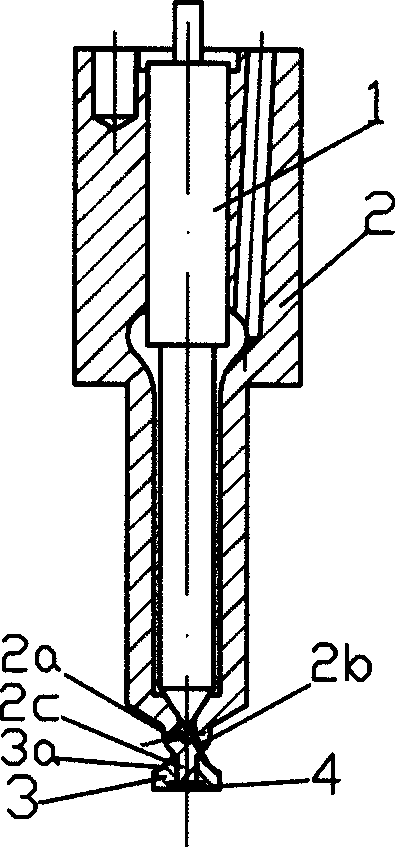

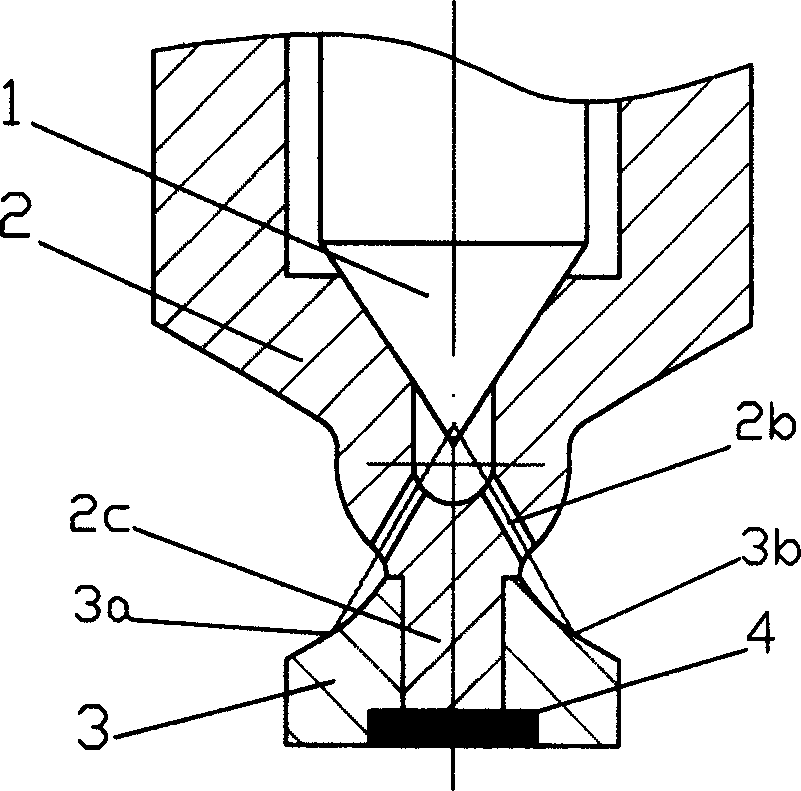

[0013] exist figure 1 , 2 . In the embodiment shown in 3, the guide table type fuel injector is a pair composed of a needle valve (1) and a needle valve body (2). There is a guide table (3) at the head of the needle valve body (2). Hollow guide platform (3) is enclosed within on the cylinder (2c) of needle valve body (2) head, and guide platform (3) is welded on the cylinder (2c) by welding block (4). exist figure 2 Among them, the head of the needle valve body (2) is also provided with 3 upper row of spray holes (2a) and 3 lower row of spray holes (2b), and the lower row of spray holes (2b) is facing the guide platform (3) The conical arc surface (3a). The included angle of the upper row of oil injection holes (2a) is 140 degrees, and the three upper row of oil injection holes (2a) and the three lower rows of oil injection holes (2b) are staggered from each other to form a uniform circumferential distribution. exist image 3 Among them, a row of 6 oil injection holes (2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com