Methanol-modified liquid vehicle clean fuel additive and fuel production process

A clean fuel and additive technology, applied in fuel additives, liquid carbon-containing fuels, fuels, etc., can solve the problems of reducing fuel economy, polluting the environment, costing the environment, and many pollutants, and achieves extended trial periods, low cost, and fuel protection The effect of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

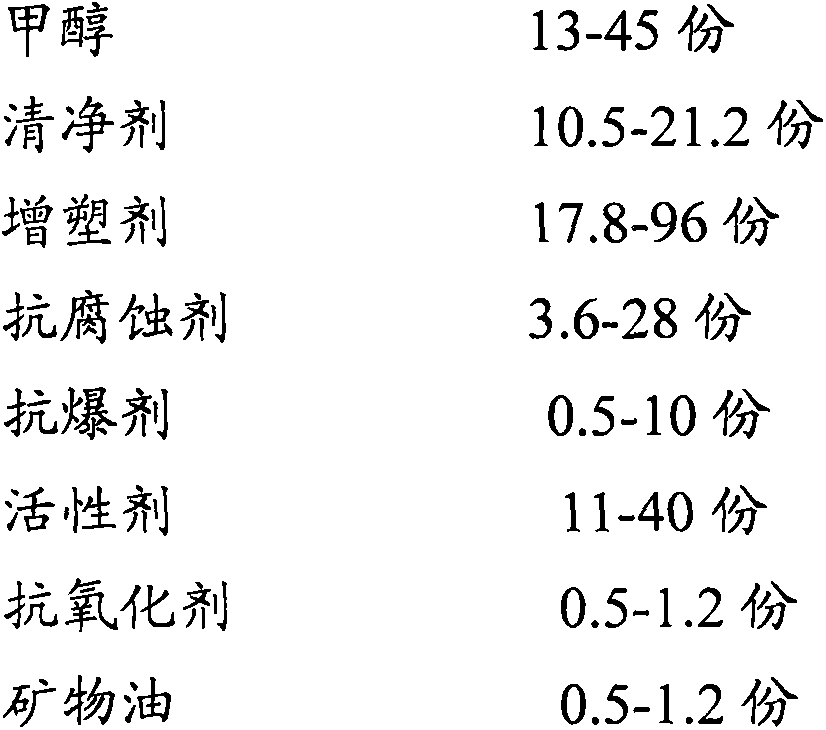

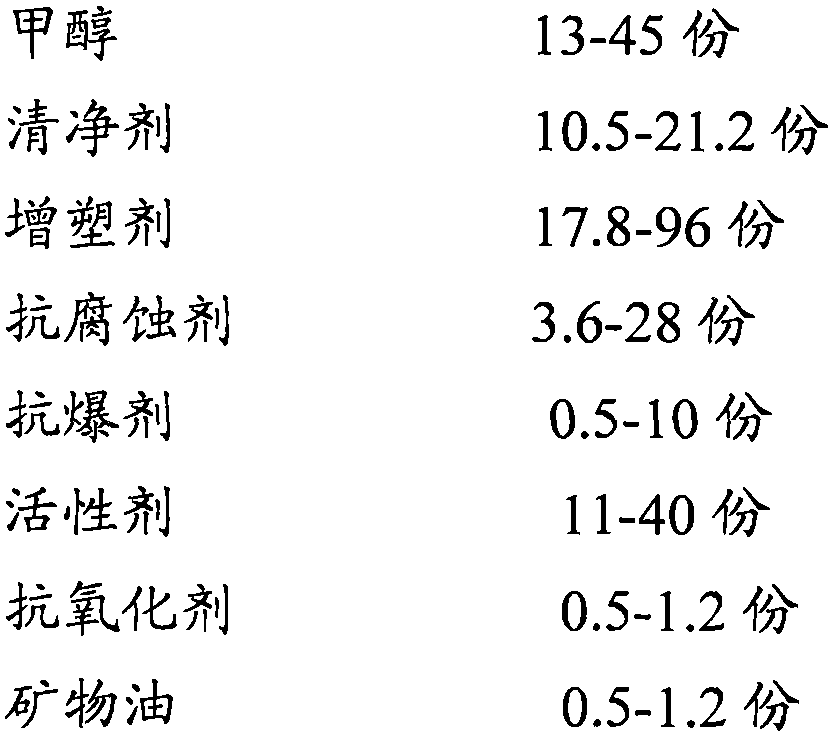

Method used

Image

Examples

Embodiment 1

[0051] 35 parts by weight of methanol from N 1 Fill into the static mixer, then take respectively 12 parts by weight of isopropanol, 5 parts by weight of trimethylbenzene, 0.5 parts by weight of benzotriazole, 0.5 parts by weight of tolyl benzotriazole, 0.8 parts by weight of Butyl octyl diphenylamine, ethylene glycol monobutyl ether of 6 parts by weight, the lower carbon alkane of 20 parts by weight, the bis (2-ethylhexyl) phthalate of 15 parts by weight, the butyl of 15 parts by weight Starting polyoxypropylene ether, 3 parts by weight of polyethylene glycol maleate, 3 parts by weight of nonylphenol polyoxyethylene ether, 0.8 parts by weight of BHT, 0.8 parts by weight of polyisobutylene, 0.8 parts by weight of Mineral oil, 5 parts by weight of 1,2-propanediol and 5 parts by weight of epoxidized soybean oil methyl ester, put it from the top N of the front end of the static mixer 2 Add, fully react with methanol for a period of time, put a certain weight of gasoline from the...

Embodiment 2

[0053] 45 parts by weight of methanol from N 1 Fill into a static mixer, then take 10 parts by weight of isopropanol, 3 parts by weight of trimethylbenzene, 0.3 parts by weight of benzotriazole, 0.2 parts by weight of methylbenzotriazole, 0.1 parts by weight of Butyl octyl diphenylamine, 0.5 parts by weight of ethylene glycol monobutyl ether, 10 parts by weight of lower alkanes, 0.8 parts by weight of bis (2-ethylhexyl) phthalate, 10 parts by weight of butyl Starting polyoxypropylene ether, 1 weight part of polyethylene glycol maleate, 1 weight part of nonylphenol polyoxyethylene ether, 0.5 weight part of BHT, 0.5 weight part of polyisobutylene, 0.5 weight part of Mineral oil, 3 parts by weight of 1,2-propanediol and 3 parts by weight of epoxidized soybean oil methyl ester, put it from the top N of the front end of the static mixer 2 Add, fully react with methanol for a period of time, put a certain weight of gasoline from the top N of the rear end of the static mixer 3 Add,...

Embodiment 3

[0055] 13 parts by weight of methanol from N 1 Fill into the static mixer, then take respectively 20 parts by weight of isopropanol, 15 parts by weight of tetramethylbenzene, 1.5 parts by weight of benzotriazole, 10 parts by weight of tolyl benzotriazole, 1.5 parts by weight of Butyl octyl diphenylamine, 10 parts by weight of ethylene glycol monobutyl ether, 30 parts by weight of lower alkanes, 20 parts by weight of bis (2-ethylhexyl) phthalate, 30 parts by weight of butyl Starting polyoxypropylene ether, 10 parts by weight of polyethylene glycol maleate, 10 parts by weight of nonylphenol polyoxyethylene ether, 1.2 parts by weight of BHT, 1.2 parts by weight of polyisobutylene, 1.2 parts by weight of Mineral oil, 18 parts by weight of 1,2-propanediol and the epoxy soybean oil methyl ester of 18 parts by weight, it is from static mixer front end top N 2 Add, fully react with methanol for a period of time, put a certain weight of gasoline from the top N of the rear end of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com