Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

147results about How to "Reduce emissions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tail gas-recycled sulfur recovery method

ActiveCN101274750AReduce emissionsImprove solvencyDispersed particle separationSulfur preparation/purificationChemistryNitrogen gas

The invention relates to a method for tail gas recycling sulphur recovery. The method of the invention comprises the steps that external acidic gas is blended with inert gas to reduce the concentration to 2 to 5 percent; after being treated with condensate separation, the mixed gas is heated to 200 to 220 DEG C and blended with air, the oxygen content of which is calculated and which is heated to 200 to 220 DEG C, to react after entering a catalytic oxidation reactor; the gas after the reaction enters a condenser to condense the sulphur; the condensed gas-liquid mixture is treated with the separation of liquid sulfur and gas by a sulphur separator and the gas is then discharged after being washed in a washing tower. In addition, the method for tail gas recycling sulphur recovery also comprises the steps that: 1) when a car is previously run and re-run after the system shutdown, the anoxic gas which is blended with the external acidic gas and dilutes and reduces the concentration of the external acidic gas to 2 to 5 percent is nitrogen gas, and after the car is normally run, the anoxic gas is the discharged gas which is pre-calculated and washed in the washing tower. Meanwhile, the method for tail gas recycling sulphur recovery can greatly reduce the exhaust emission amount of the treated tail gas and also reduce the content of surphur in the emitted tail gas.

Owner:江苏晟宜环保科技有限公司

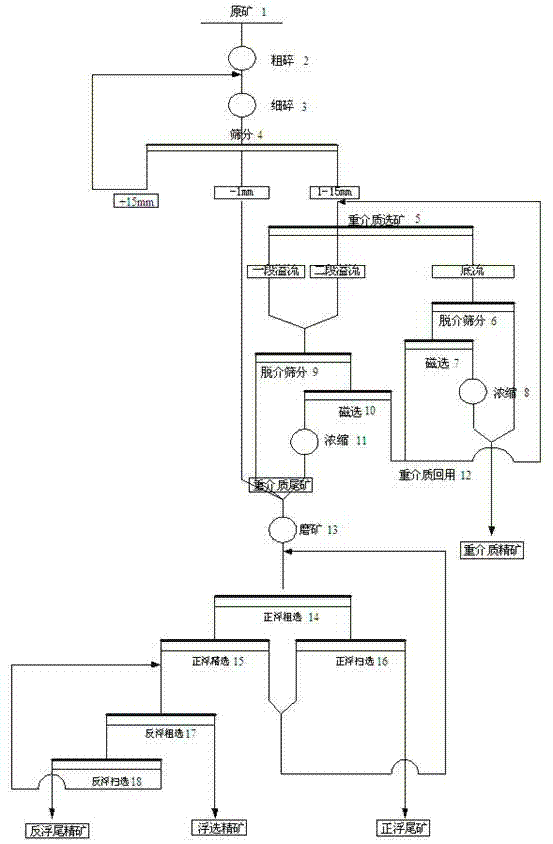

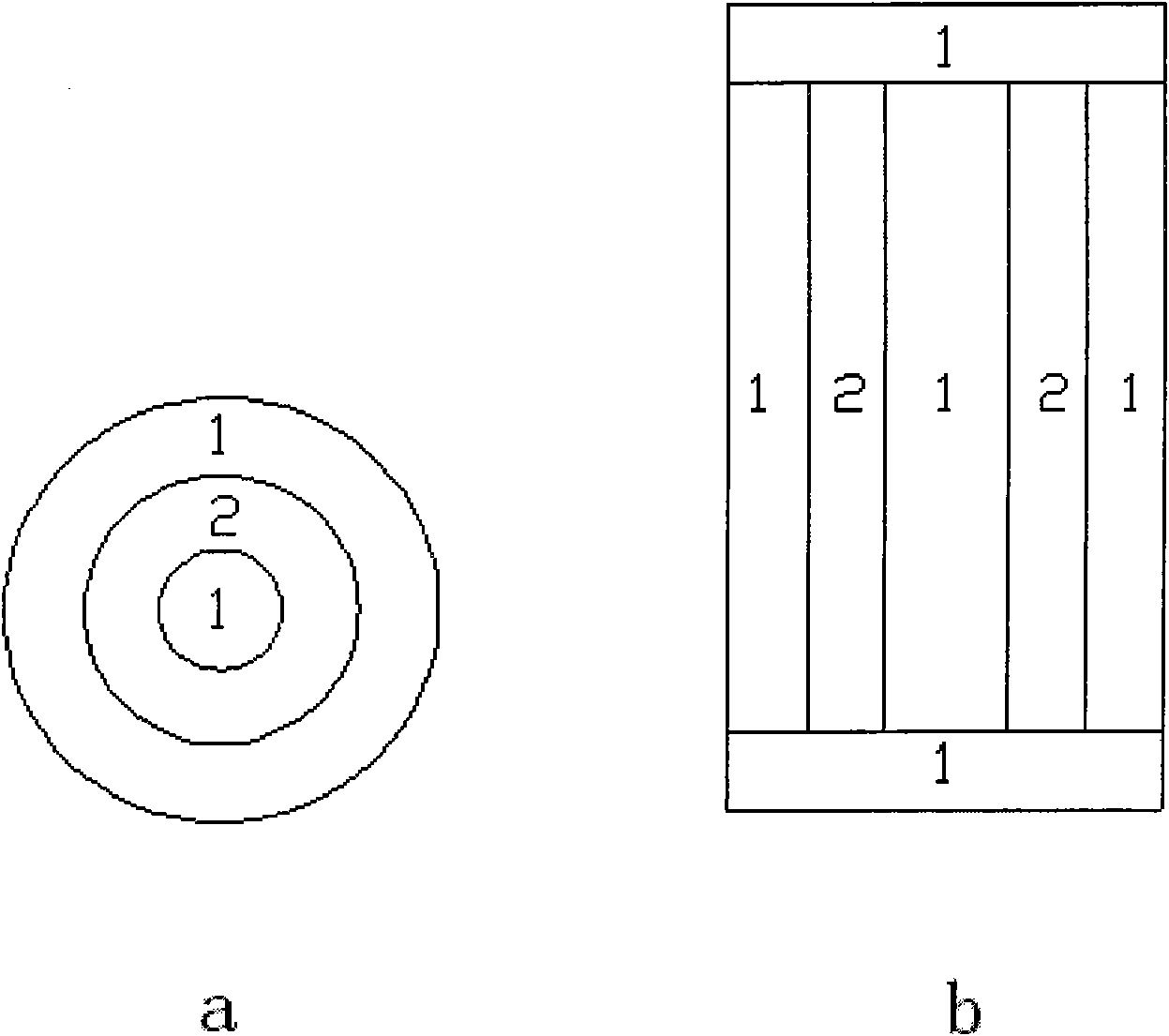

Phosphate dense medium mineral separation and direct-reverse floatation combined technology

The invention belongs to the technical field of phosphate mineral separation, and perpendicularly relates to a phosphate dense medium mineral separation and direct-reverse floatation combined technology. The technology comprises a phosphate ore coarse particle dense medium mineral separation technology and a direct-reverse floatation technology of levigation of dense medium tailings discharged through a dense medium separation technology. According to the dense medium mineral separation technology, the phosphorus raw ore is broken to coarse particles suitable for dense medium mineral separation, dense medium ore concentrate and dense medium tailings are separated through the dense medium mineral separation technology, the dense medium tailings are ground to the granularity suitable for floatation so that direct floatation and reverse floatation can be conducted, after flotation is completed, the floatation concentrate, the direct floatation tailings and the reverse floatation tailings are obtained, and after the floatation concentrate is combined with the dense medium concentrate, a finished phosphate concentrate product is obtained. According to the phosphate dense medium mineral separation and direct-reverse floatation combined technology, the discharging amount of the tailings after phosphate dense medium mineral separation is reduced, the use rate of phosphate resources is improved, and the maximized use of the phosphate resources of the low level is particularly achieved.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

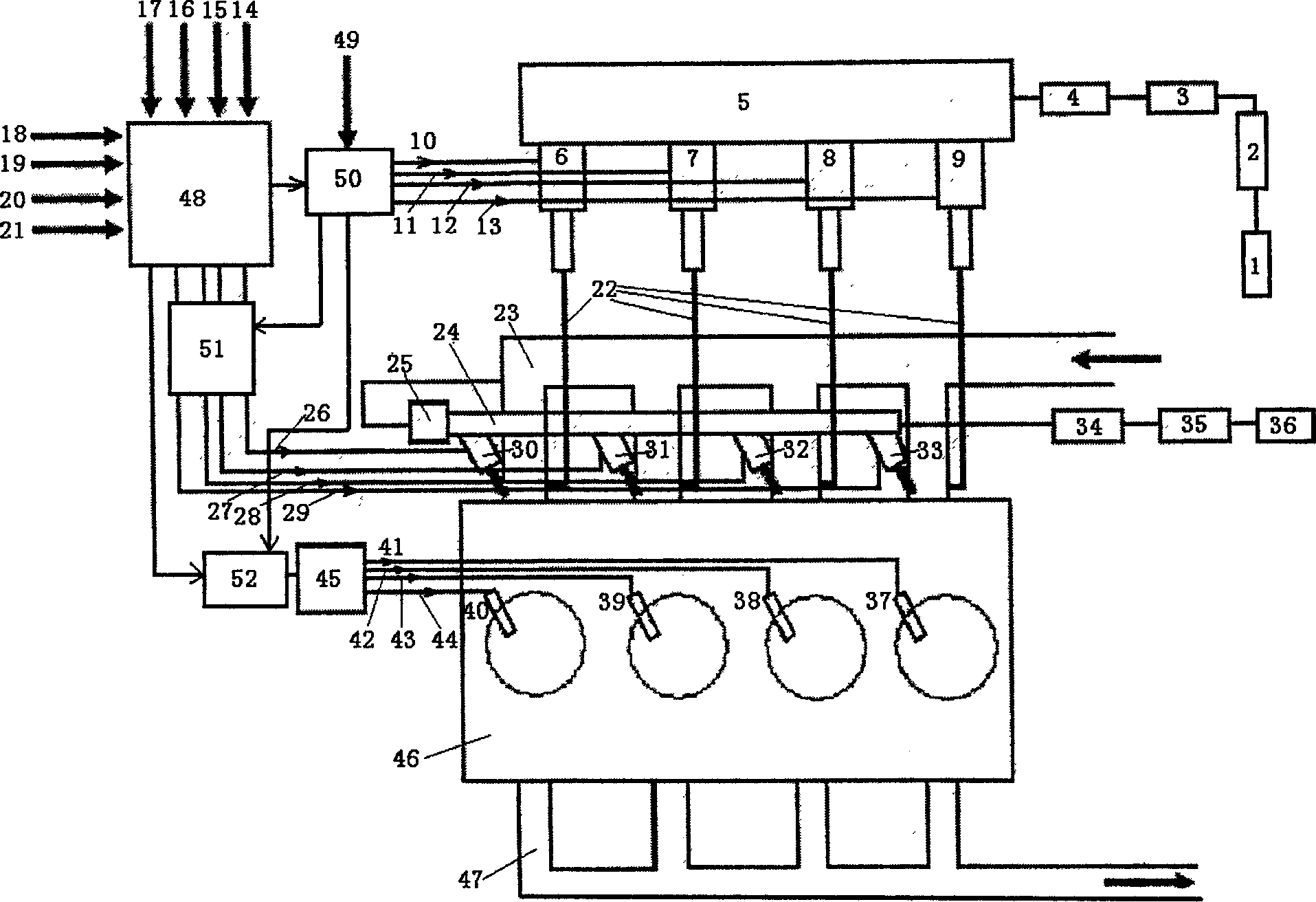

Hydrogen gasoline mixed fuel engine and its control method

ActiveCN1904329AReduce emissionsEasy to startElectrical controlMachines/enginesMixed fuelElectronic control unit

The invention relates to a hydrogen-gasoline mixed fuel engine and its control method, which mainly includes an electric control gasoline injection and ignition system and an electric control hydrogen injection and ignition system. The electric control hydrogen injection and ignition system includes a hydrogen injection and ignition control unit, a fuel injection pulse width control module and an ignition angular advance control module. The fuel injection pulse width control module is disposed between the electronic control unit and the fuel nozzle controlled by the hydrogen injection and ignition control unit. The ignition angular advance control module is disposed between the electronic control unit and the ignition module controlled by the hydrogen injection and ignition control unit.

Owner:BEIJING UNIV OF TECH

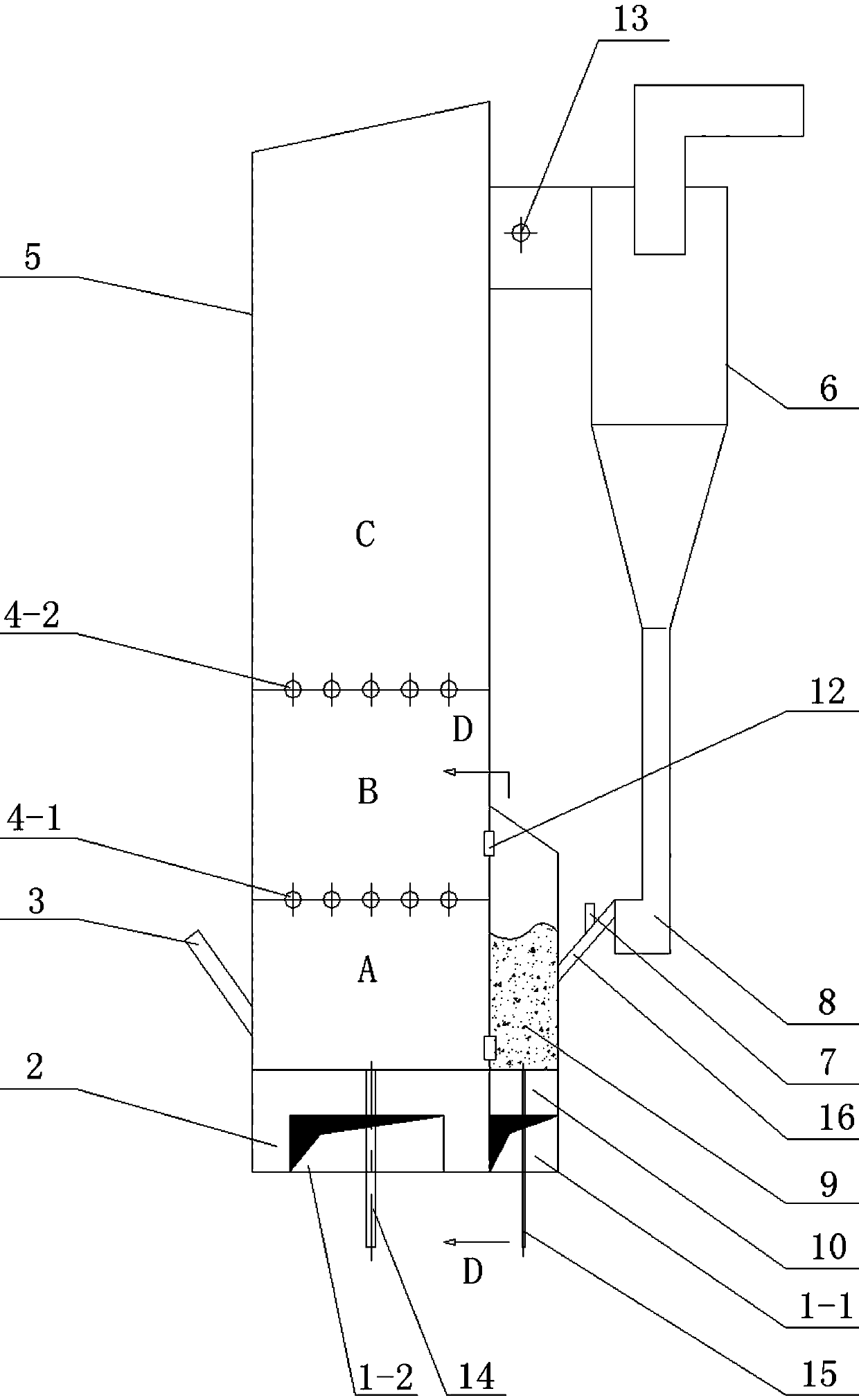

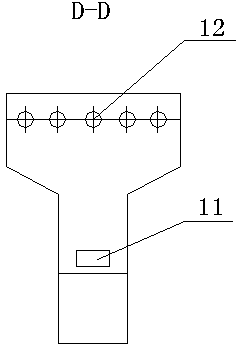

Device and method for controlling NOx of circulating fluidized bed by coupling air staging and fuel staging

ActiveCN104879748AGuaranteed combustion efficiencyReduce emissionsFluidized bed combustionEmission preventionAutomotive engineeringBurning out

The invention relates to a device and a method for controlling NOx discharge of a circulating fluidized bed by coupling air staging and fuel staging, and belongs to the technical field of circulating fluidized beds. According to the device and the method, the fuel staging and the air staging are combined, fuel gas generated by the circulating fluidized bed is taken as reburning gas, so that the cost is low, and the NOx discharge during running process of the circulating fluidized bed is effectively reduced. A vaporizing chamber and an air chamber of the vaporizing chamber are arranged outside the rear wall of a furnace body, a fuel gas inlet communicated with the furnace body and the vaporizing chamber is formed in the rear wall of the furnace body, a burn-out area outlet of the furnace body is communicated with a cyclone separator, the bottom of the cyclone separator is communicated with the vaporizing chamber through a return valve and a connecting pipe. Secondary fuel is added to a material inlet, and is mixed with a high-temperature circulating material in the vaporizing chamber to obtain a mixed material; air is supplied to the vaporizing chamber from the bottom of the vaporizing chamber, the mixed material is fluidized, the generated fuel gas enters the furnace body, a reburning area with a reducing atmosphere is formed at the upper end of a main combustion area, and NOx generated in the main combustion area is reduced into N2. The device and the method are used for controlling the NOx discharge of the coal-fired circulating fluidized beds.

Owner:HARBIN INST OF TECH

Method for reclaiming gold and silver in tailings after roasting-cyaniding of gold concentrate

ActiveCN101942566AReduce emissionsSmall footprintProcess efficiency improvementWater contentOre concentrate

The invention belongs to the technical field of hydrometallurgy, in particular to a method for reclaiming gold and silver in tailings after roasting-cyaniding of gold concentrate. The method comprises the following steps: drying the tailings until the water content of the tailings is not higher than 10 percent by weight; adding desulfurizing agent and reducing agent to reduce for 10 to 30 hours at the temperature between 900 and 1,200 DEG C; discharging after the tailings are isolated from air and cooled; crushing the tailings subject to impurity removal by separation; carrying out acid-leaching the crushed metal iron powder to obtain ferrous solution; and extracting the gold and silver noble metals in the acid-leaching residue. The method has simple process and low requirement on raw materials, reclaims the valuable elements in the tailings with low production cost, not only reclaims the metal iron, but also effectively reclaims the gold, silver and other noble metals, reduces tailing pollution, and avoids resource waste.

Owner:HENAN ZHONGYUAN GOLD SMELTERY

Method for comprehensively utilizing titanium white waste acid

ActiveCN104178632AReduce energy consumption and material consumptionReduce emissionsSilicaTitanium dioxideSolid phasesBrown iron oxide

The invention discloses a method for comprehensively utilizing titanium white waste acid, and belongs to the field of waste treatment. According to the method, waste acid produced by the titanium white industry is used as a raw material, valuable metal elements such as vanadium are extracted from converter vanadium slag by adopting a pressure acid leaching manner, namely a pressure leaching process is performed after the titanium white waste acid is mixed with the crushed and ground converter vanadium slag, valuable elements such as vanadium and scandium in the converter vanadium slag enter a leachate in the pressure leaching process, and the metal elements such as vanadium and scandium are respectively extracted from the leachate after the leachate is extracted and separated; the main component of the leaching slag is silicon dioxide, the leachate is neutralized by lime to serve as a raw material for cement industry or used for preparing silicon carbide in a reduction manner; and SO2 and SO3 are recovered from the raffinate in a manner of direct pyrolysis, and main solid-phase components obtained by pyrolysis include chromium oxide, manganese oxide and iron oxide which can be used as raw materials for smelting alloy. By virtue of the method, efficient utilization of the valuable elements in the titanium white waste acid and the converter vanadium slag can be realized, and the method is an environment-friendly method for comprehensively utilizing the titanium white waste acid.

Owner:NORTHEASTERN UNIV

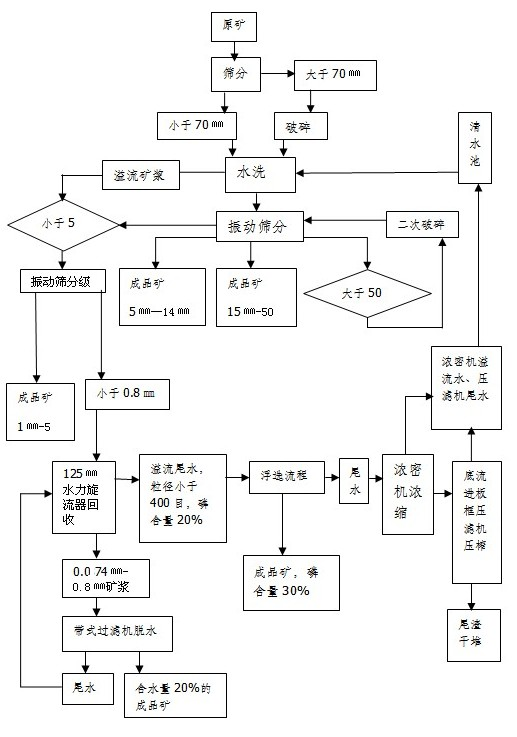

Combined technology of phosphorite scrubbing and direct floatation and reverse floatation

ActiveCN102489385AReduce emissionsImprove return water utilizationFlotationFiltration circuitsChemistrySodium silicate

The invention relates to combined technology of phosphorite scrubbing and direct floatation and reverse floatation. After the scrubbing technology, raw ores enter the rough, fine and scavenging direct floatation and the reverse floatation technology, and the dosage of roughing medicament of the direct floatation is: 3.8-4.2kg / t of inhibitor sodium silicate, 2.05-3kg / t of collector fatty acid soapand 5-6kg / t of modifier industrial alkali. 0.5-0.7kg / t of collector fatty acid soap is added in the scavenging process, the floatation temperature ranges from 15 DEG C to 25 DEG C, and accordingly fine phosphorite is obtained. The combined technology combines the phosphorite scrubbing technology and the direct floatation and reverse floatation technology, thereby not only reducing discharge volume of scrubbed gangue but also improving return water utilization ratio. Simultaneously, middle-level and lower-level phosphorous resources are utilized maximumly, and compared with single floatation technology, the combined technology can remarkably reduce beneficiation cost and improve utilization ratio of resources.

Owner:云南三明鑫疆磷业股份有限公司

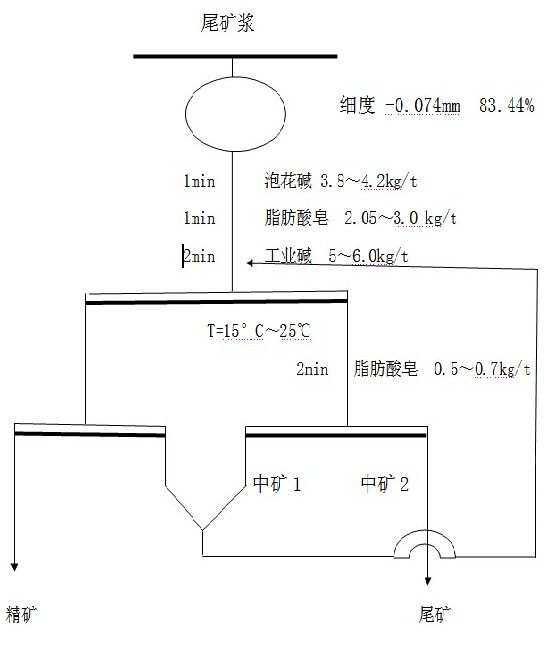

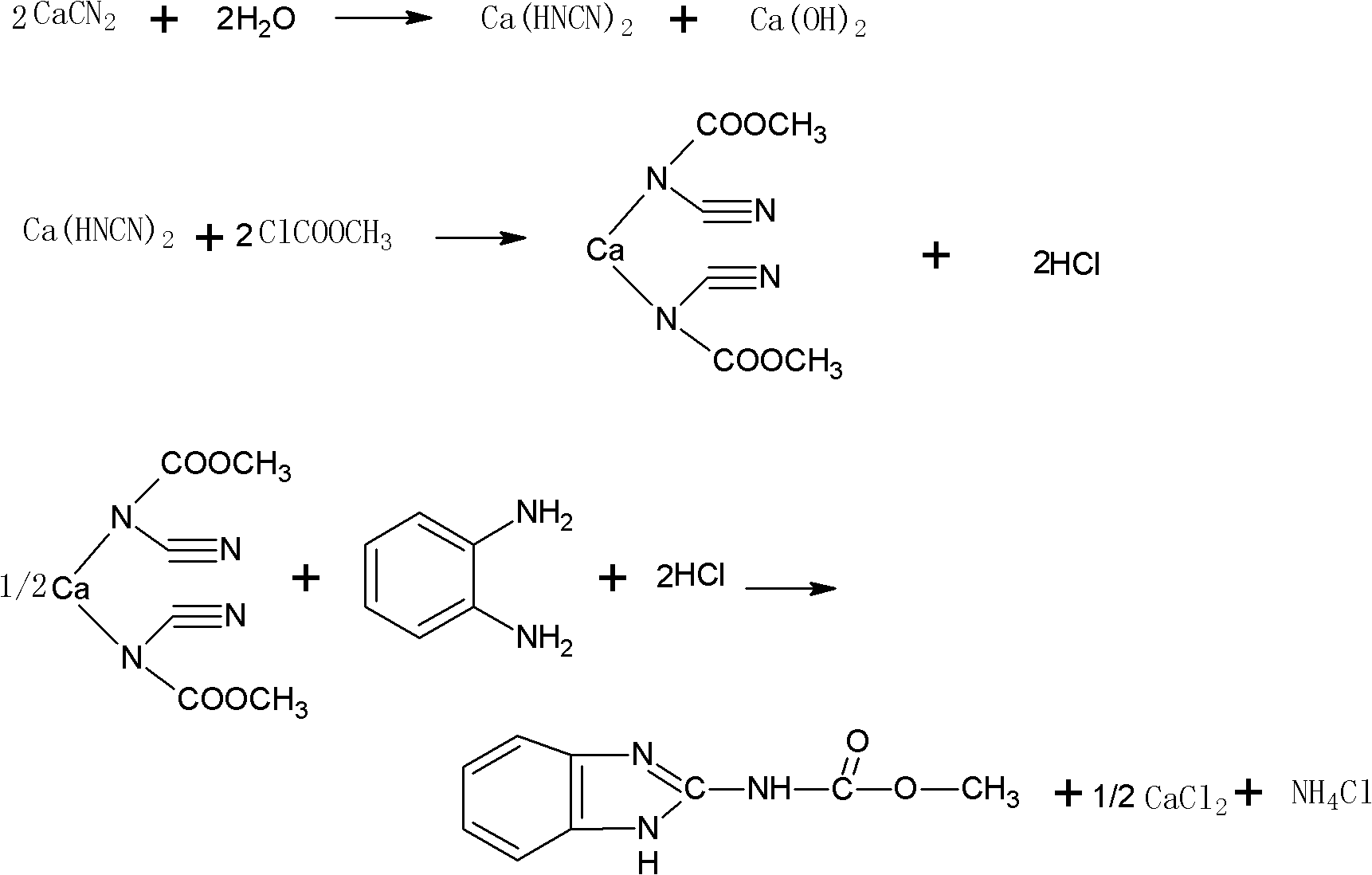

Preparing method for synthesizing sanmate from calcium cyanamide

The invention relates to a preparing method for synthesizing sanmate from calcium cyanamide, in particular to the preparing method for synthesizing the sanmate and generating single-cyanamide water solution from the calcium cyanamide through hydrolytic decalcification. The process flow in the preparing method disclosed by the invention comprises the following steps: 1. hydrolytic decalcification work procedures; 2. amination work procedures; and 3. condensation work procedures and the like. Auxiliary steps such as acid regulation work procedures, exsolution work procedures, cooling work procedures and the like are also included between the hydrolytic decalcification work procedures and the amination work procedures. In the sanmate preparing process, the preparing method disclosed by the invention has high yield, the quantity of generated three-wastes is decreased, consumed raw materials are reduced through being compared with that of the traditional process, the environment protection treatment cost is reduced, and good economic benefits and social benefits are realized.

Owner:XINYI AGRI CHEM PLANT JIANGSU PROV

Prepn of wet sludge carbonizing adsorbent

InactiveCN1973995AReduce emissionsAvoid secondary pollutionOther chemical processesChemistryActivated carbon

The present invention relates to the preparation process of wet sludge carbonizing adsorbent. The wet sludge carbonizing adsorbent is prepared with sludge from city sewage treating yard as main material, and through adding activator, such as zinc chloride solution, etc. commonly used in preparing active carbon to activate sludge, drying the activated sludge, pyrolytically carbonizing in a high temperature carbonizing furnace with water steam as protecting gas, cooling, washing, and stoving. Preparing adsorbent with sludge can reduce secondary pollution, lower adsorbent preparing cost and result in obvious environment benefit and economic benefit.

Owner:上海银龙水务设备公司

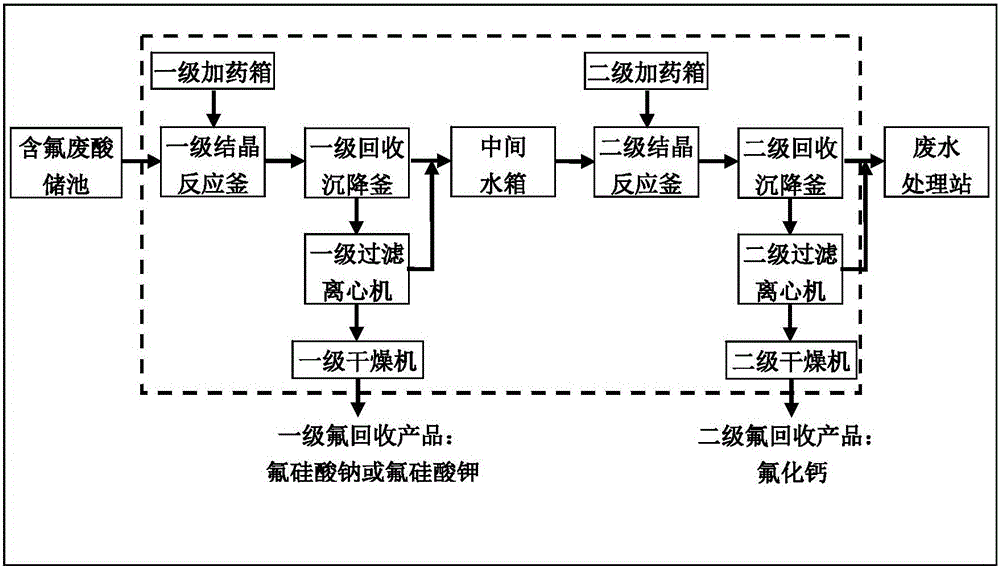

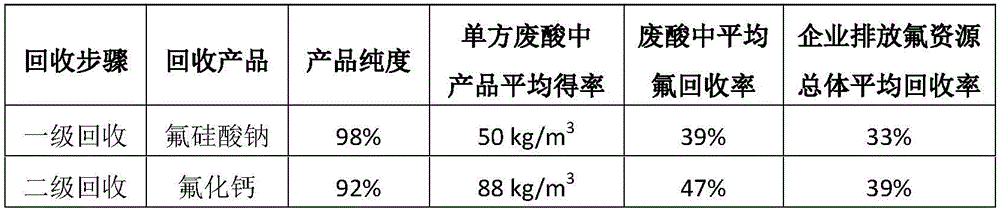

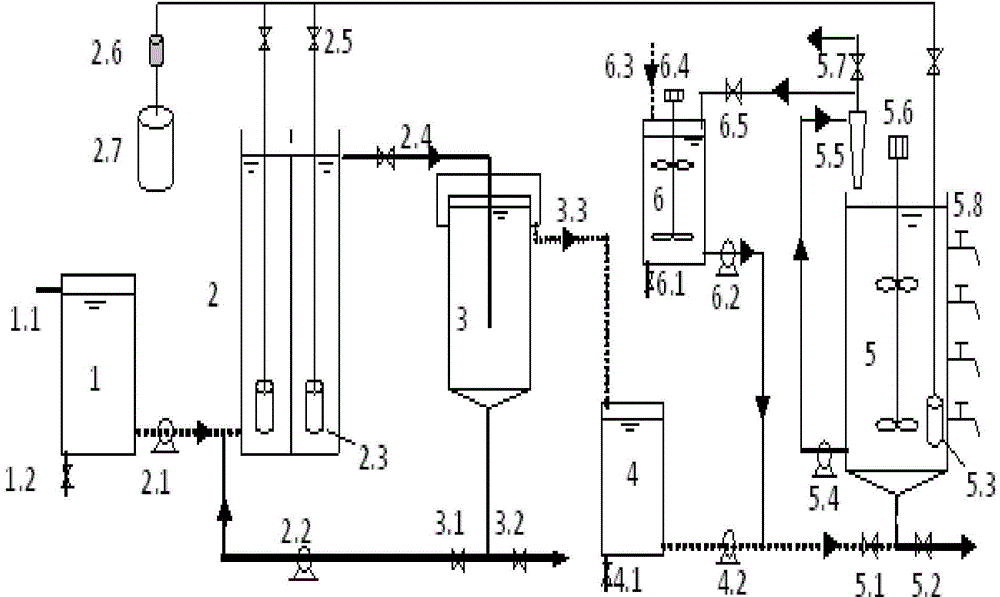

Method and system for recovering fluorine from waste acid produced in thinning production of solar cells or glass

InactiveCN105753211AReduce processing costsReduce emissionsWater contaminantsTreatment involving filtrationChemistryFluoride calcium

The invention discloses a method and a system for recovering fluorine from waste acid produced in thinning production of solar cells or glass and belongs to the technical field of environmental protection. The method comprises the following steps: the waste acid is collected by a production line source; sodium fluosilicate or potassium fluosilicate is obtained through primary fluorine recovery; calcium fluoride is obtained through secondary fluorine recovery; wastewater is treated. The system comprises a fluorine-containing waste acid storage tank, a middle water tank, two stages of fluorine recovery units and a wastewater treatment station, wherein an outlet of the fluorine-containing waste acid storage tank is connected with an inlet of the primary fluorine recovery unit, a waste acid outlet of the primary fluorine recovery unit is connected with an inlet of the middle water tank, an outlet of the middle water tank is connected with an inlet of the secondary fluorine recovery unit, a wastewater outlet of the secondary fluorine recovery unit is connected with the wastewater treatment station, and the two stages of fluorine recovery units are provided with recovery product outlets respectively. With adoption of the method, fluorine resources can be recovered efficiently, and the discharge amount of fluorine-containing sludge and fluorine pollution of the wastewater can be reduced remarkably; with adoption of the system, capacity and quantity of equipment can be reduced, and the production cost can be saved.

Owner:BEIJING GUOHUAN TSINGHUA ENVIRONMENT ENG DESIGN & RES INST CO LTD BEIJING CHINA

Method for realizing autotrophic nitrogen removal of city sewage through symbiosis of flocculent sludge and granular sludge

ActiveCN104529056AAvoid inhibitionReduce emissionsSpecific water treatment objectivesMultistage water/sewage treatmentMunicipal sewageChemistry

The invention discloses a method for realizing autotrophic nitrogen removal of city sewage through symbiosis of flocculent sludge and granular sludge. The city sewage firstly goes into a high-load activated sludge reactor, organic compounds in the sewage are adsorbed to activated sludge, then effluent goes into a flocculent sludge and granular sludge symbiosis autotrophic nitrogen removal reactor through a middle water tank, and synchronous shortcut nitrification anaerobic ammonia oxidation autotrophic nitrogen removal is realized; the autotrophic nitrogen removal reactor allows the mixed sludge to be screened into the granular sludge and the flocculent sludge through arranging a cyclone separator; the sludge age of the flocculent sludge is controlled through daily regular emissions of the flocculent sludge; the flocculent sludge is treated regularly by nitrite, so that increase of nitrite oxidizing bacteria in the flocculent sludge is controlled, and the system stable shortcut nitrification is maintained; through the above measures, the stable shortcut nitrification anaerobic ammonia oxidation autotrophic nitrogen removal of the city sewage is achieved, and the purposes of energy saving and consumption reduction are reached.

Owner:BEIJING UNIV OF TECH

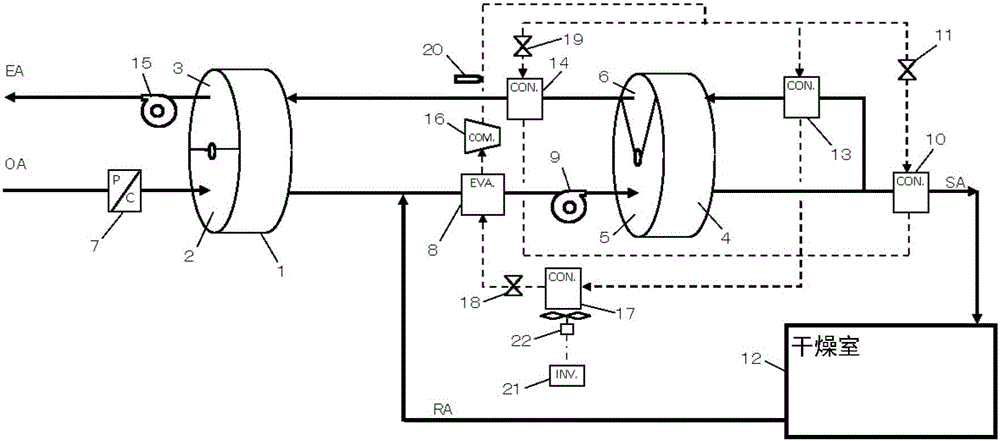

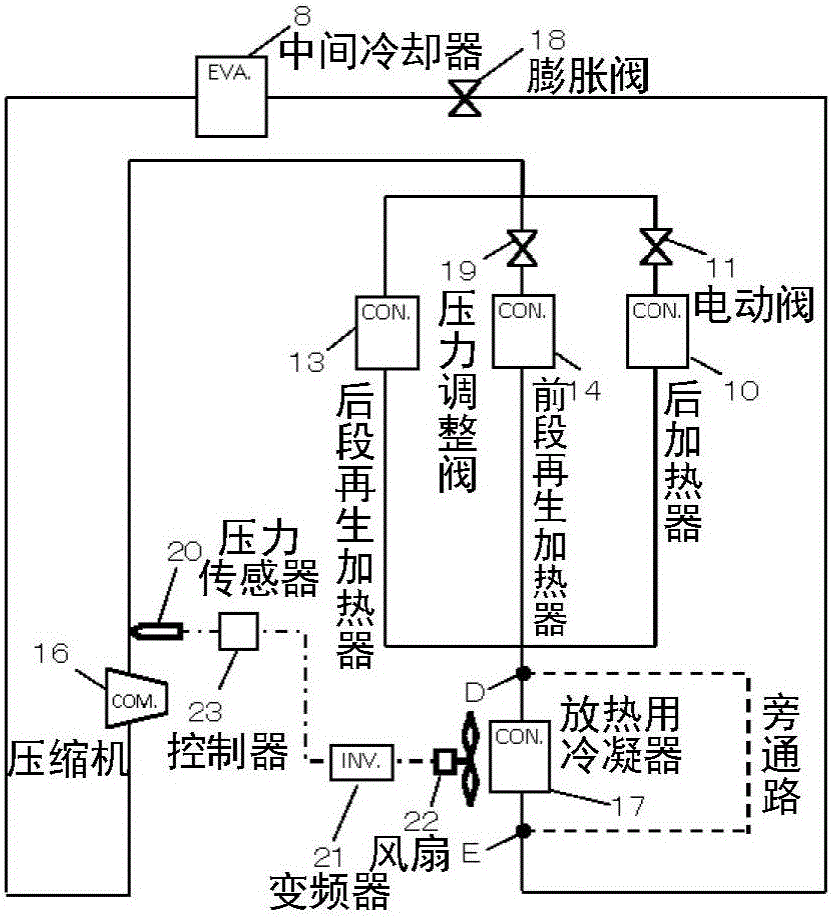

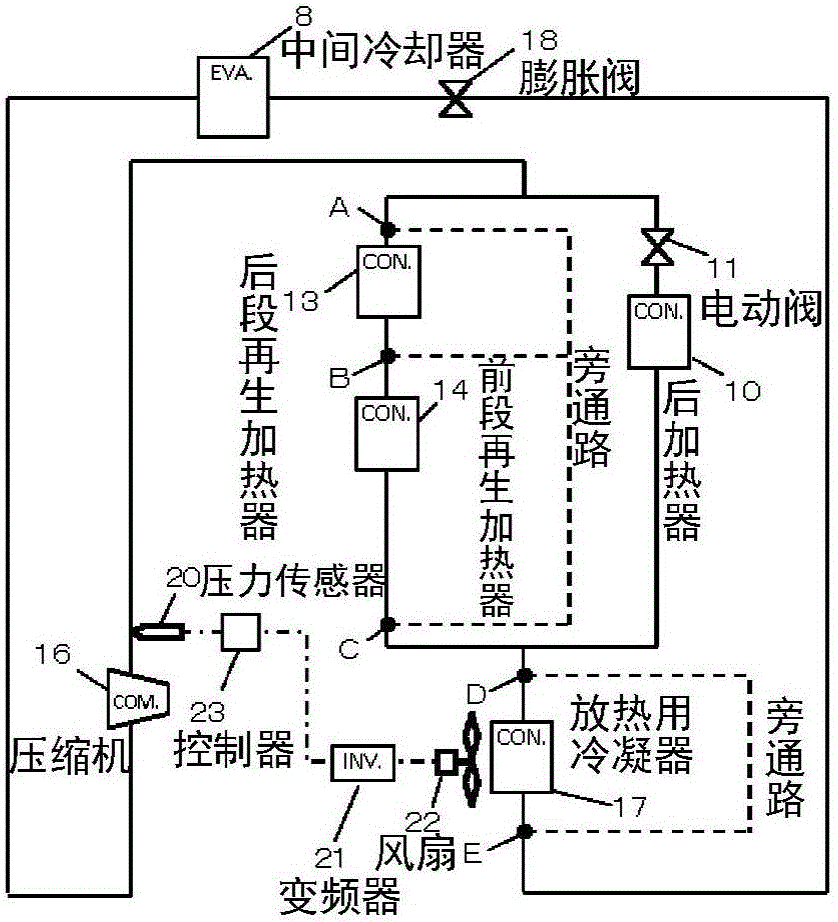

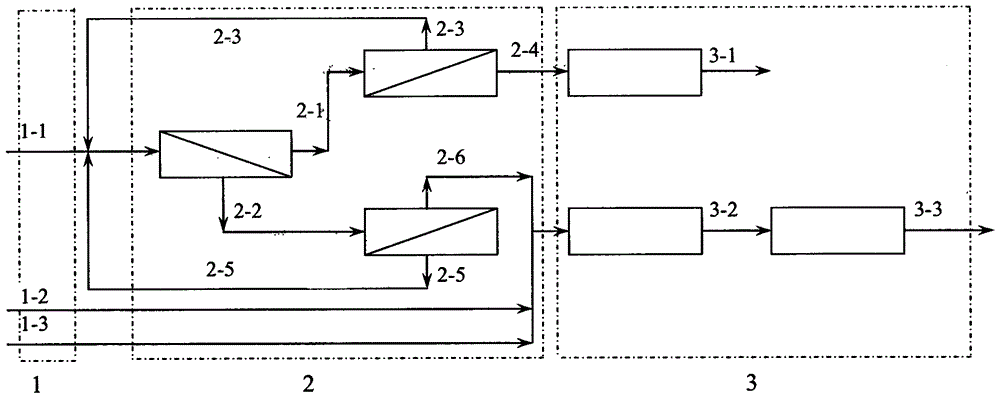

System of low-temperature regeneration, drying and dehumidification for low-dew point drying room

ActiveCN106091175AReduce emissionsEmission reductionMechanical apparatusAir treatment detailsChillerDew point

The invention provides a dehumidification device which applies a heat pump which can supply low-dew point air even if a regeneration temperature is as low as 50 DEG. The device provided by the invention comprises a first dehumidification turning wheel and a second dehumidification turning wheel, wherein an external gas is made to pass an adsorption area of the first dehumidification turning wheel after being cooled and dehumidified by a first cooler, the air which passes the adsorption area of the first dehumidification turning wheel is made to pass a second cooler and an adsorption area of the second dehumidification turning wheel and supplied to a drying room as supply air; and returning air from the drying room is mixed with the air which passes the adsorption area of the first dehumidification turning wheel, the air which passes the adsorption area of the second dehumidification turning wheel is partially shunted, heated by a second heater and then made to pass a regeneration area of the second dehumidification turning wheel, and the air which passes the regeneration area of the second dehumidification turning wheel is heated by a third heater and made to pass a regeneration area of the first dehumidification turning wheel.

Owner:SEIBU GIKEN CO LTD

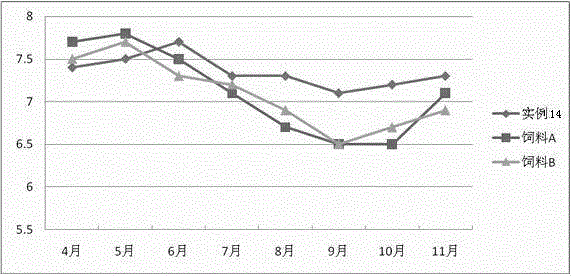

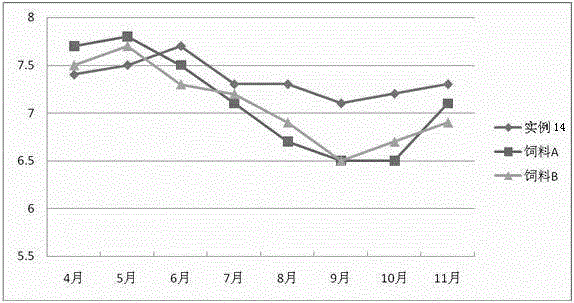

Healthy and environmentally-friendly raw fish puffed mixed feed and production technology thereof

InactiveCN104982677AReduce emissionsAvoid water pollutionAnimal feeding stuffSOYBEAN SEED OILRaw fish

The invention relates to a healthy and environmentally-friendly raw fish puffed mixed feed and a production technology thereof, and belongs to the technical field of aquatic product culture feeds. The feed comprises fish meal, chicken meal, meat and bone meal, shrimp meal, soybean protein concentrate, soybean meal, peanut meal, flour, soybean oil, fish oil, soyabean lecithin oil, fish soluble, yeast extract, beer yeast powder, calcium dihydrogen phosphate, a composite trace element premix, a composite vitamin premix, choline chloride, coated lysine, coated methionine, coated sodium butyrate and carnitine hydrochloride. The h puffed mixed feed can reduce the discharge amount of nitrogen in water and reduce water pollution; and the puffed mixed feed also can promote the healthy and rapid growth of raw fish, reduce the organ-to-body weight ratio and maintain natural body shape, and facilitates healthy and sustainable development of the raw fish breeding industry.

Owner:TONGWEI

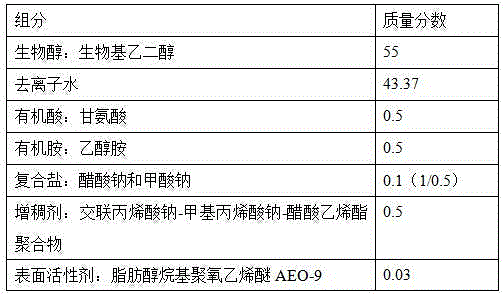

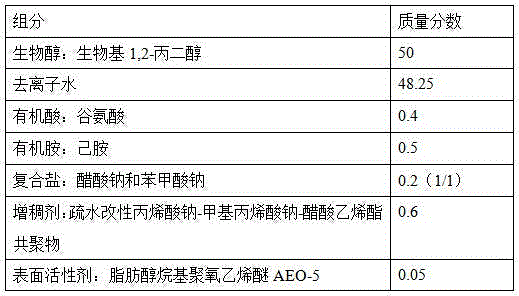

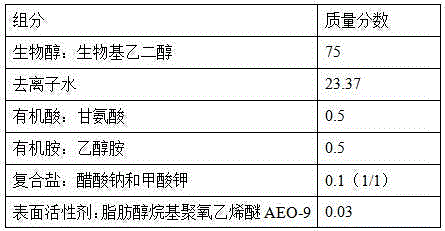

Bio-based alcohol airplane ice removal and prevention liquid and preparation method thereof

ActiveCN104130751AReduce emissionsConducive to resource recyclingOther chemical processesChemistryOrganic acid

The invention relates to a liquid for removal and prevention of ice on the outer surface of an airplane, and especially relates to a bio-based alcohol airplane ice removal and prevention liquid for removing ice, snow and frost staying on the surface of an airplane and a preparation method thereof. The bio-based alcohol airplane ice removal and prevention liquid comprises, by mass, 40-90 parts of at least one bio-based polyol, 0.01-1 part of at least one organic acid, 0.01-1 part of at least one organic amine, 0.01-0.3 parts of a metal organic composite salt, 0.03-0.2 parts of a surfactant and 10-60 parts of deionized water. Through use of bio-based alcohol as a main raw material of a freezing point reduction agent, the problems caused by petrochemical-based alcohol raw material performance difference are solved. The preparation method of the liquid for removal and prevention of ice on the outer surface of an airplane is a novel technology in the field of energy saving and emission reduction. The bio-based alcohol airplane ice removal and prevention liquid can satisfy high material compatibility requirements, has effects of energy saving and emission reduction, substantially reduces a carbon dioxide discharge capacity, is conducive to resource cycle usage and has the characteristics of safety, environmental friendliness and low carbon.

Owner:成都民航六维航化有限责任公司

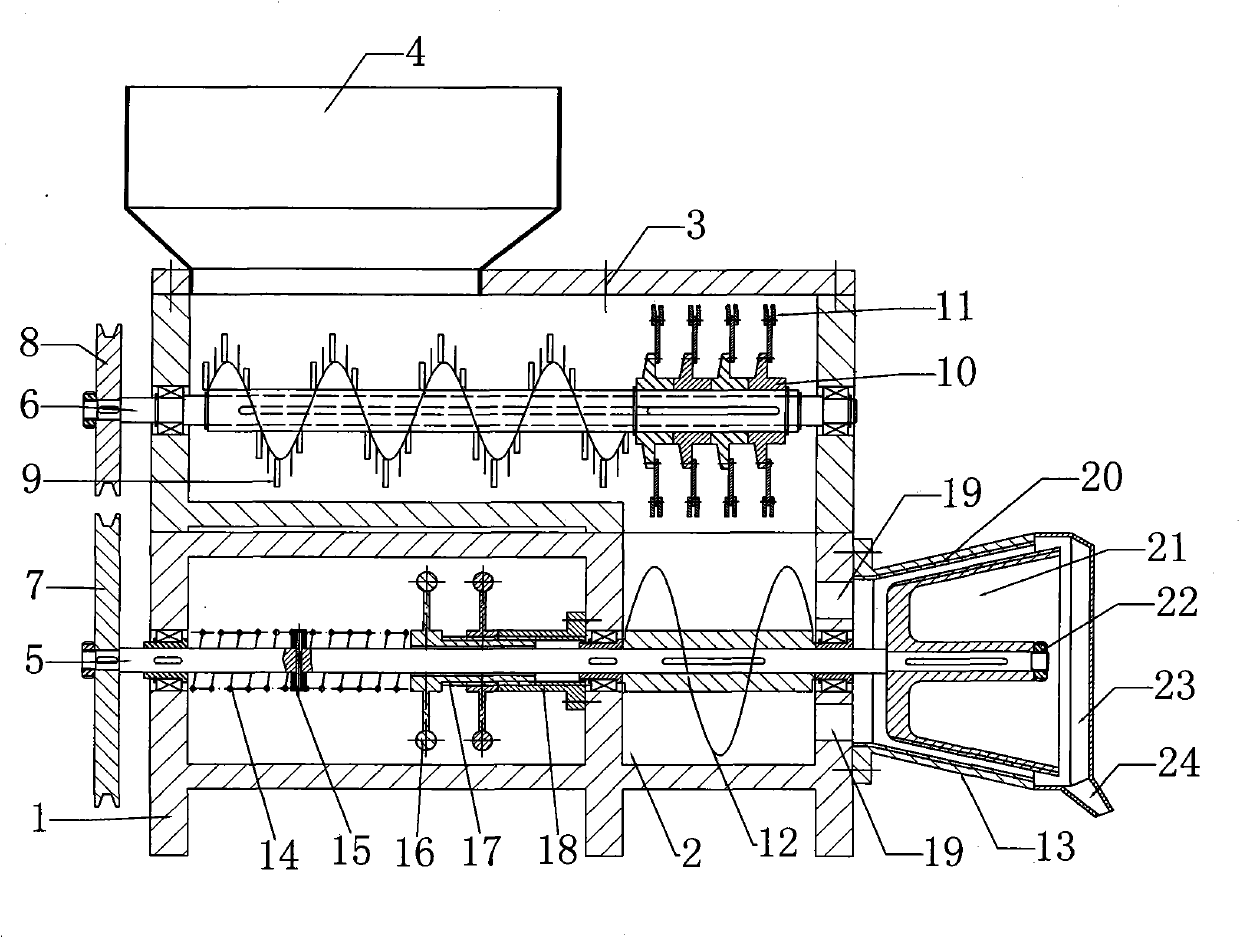

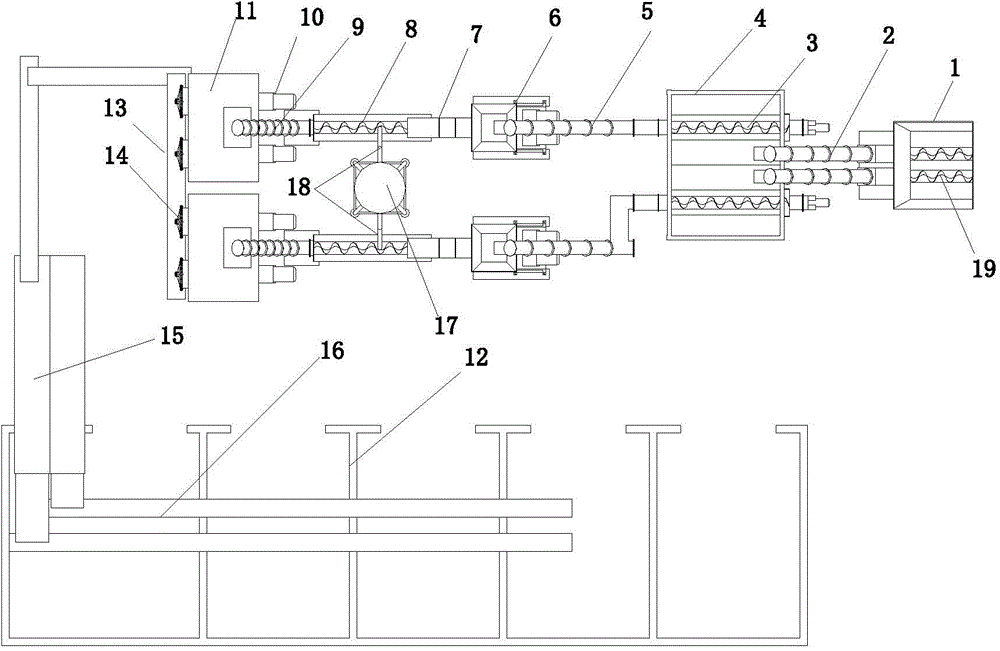

Potato extracted starch refiner

ActiveCN101906168AReduce emissionsReduce power consumptionGrain treatmentsAgricultural engineeringPulley

The invention discloses a potato deep-processing machine, in particular a potato extracted starch refiner. The potato extracted starch refiner comprises a frame, and is characterized in that: a grinding mechanism is arranged on the frame; a crushing mechanism is arranged above the grinding mechanism; a feed hopper is arranged above the crushing mechanism; a main engine shaft and a crushing shaft are arranged inside the grinding mechanism and the crushing mechanism respectively; a main engine wheel and a belt pulley are arranged at the front ends of the main engine shaft and the crushing shaft; the main engine wheel and the belt pulley are connected through a belt; and the main engine shaft is connected with power input. The potato extracted starch refiner can effectively utilize water contained in potatoes and can improve the yield by three to four times compared with the yield of the prior art under the condition of the same power consumption. Therefore, the potato extracted starch refiner can reduce the wastewater discharge and greatly reduce the power consumption, also can grind big potatoes into fine slurry, and can substantially extract the starch from the potatoes completely. Therefore, the starch extraction ratio is greatly improved.

Owner:曹县鲁曹高新材料机械制造有限公司

Method for absorbing and activating carbon dioxide in boiler flue gas and application of method

ActiveCN103007727AReduce emissionsSimplified absorption and activation application processCalcium/strontium/barium carbonatesProductsActivated carbonHigh concentration

The invention discloses a method for absorbing and activating carbon dioxide in boiler flue gas and application of the method. The method comprises the following steps of: 1, replacing cane juice through lime milk with the concentration of 8-15-degree Be for absorbing the carbon dioxide in boiler flue gas and generating by-products of a calcium carbonate solution in the decarbonization process in a two-stage spray packing absorption tower; 2, reacting phosphoric acid and one part of calcium carbonate solution, and generating a monocalcium phosphate solution and high-concentration carbon dioxide gas when the PH is controlled to be less than 3; 3, excessively injecting the high-concentration carbon dioxide gas into the calcium carbonate solution through an ejector, dissolving and activating the calcium carbonate into calcium bicarbonate solution, and controlling the PH to be less than 6; and 4, respectively filling the monocalcium phosphate solution and calcium bicarbonate solution generated in the decarburization and activation processes in the steps 2 and 3 into a storage box for later use. The method has the advantages of reducing the retention time of the cane juice in the carbon absorption process and saving the investment, along with high absorption rate and the like.

Owner:GUANGXI NANNING HUAXIN SUGAR IND TECH

Method for producing limestone powder and aluminium ammonium sulfate using heat-engine plant desulfurized gypsum and fly ash

InactiveCN101497455AReduce emissionsReduce manufacturing costCalcium/strontium/barium carbonatesAluminium sulfatesAmmonium sulfateGreenhouse gas

The invention discloses a method for producing limestone powder and aluminum ammonium sulfate from desulfurized gypsum and fly ash of thermal power plants. The method comprises the steps of: (1) paste mixing and impurity removal of the desulfurized gypsum; (2) absorption and reaction of gypsum paste and ammonia gas and carbon dioxide gas; (3) solid-liquid separation of an ammonium sulfate solution and a calcium carbonate solid; (4) concentration and crystallization of the ammonium sulfate solution; (5) mixing of the fly ash and ammonium sulfate; (6) production of clinker of the fly ash; (7) dissolution of reaction clinker of the fly ash; (8) multi-stage settling separation and fine filtration of a mixed liquid of aluminum sulfate and aluminum ammonium sulfate; (9) adjustment of pH value of an aluminum sulfate solution; (10) crystallization and recrystallization of the aluminum ammonium sulfate; (11) ammonia replacement and ammonia supplement of a ferric ammonium sulfate solution; and 12) filtration and washing of ferric hydroxide. The method combines the treatment of the desulfurized gypsum with the treatment of the fly ash to produce the aluminum ammonium sulfate and the limestone powder. During the production, carbon dioxide in flue gas can be absorbed, so that the discharge amount of carbon dioxide greenhouse gas can be reduce effectively; the supplement amount of synthetic ammonia is only one fourth of that of the prior method; and the production cost is greatly reduced.

Owner:李睿德

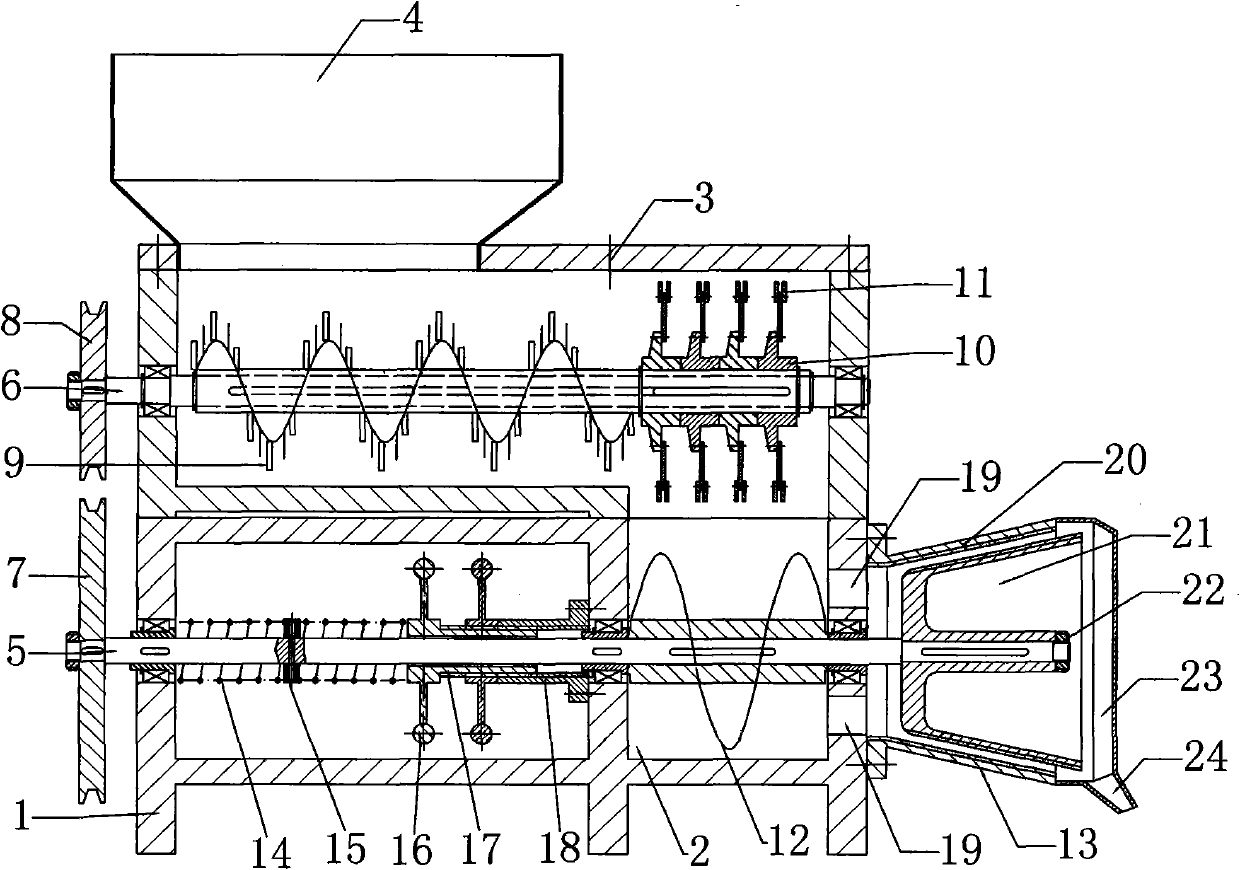

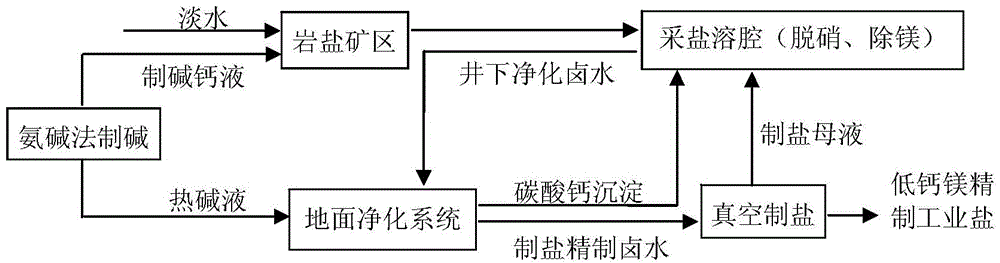

Method for preparing refined salt low in calcium and magnesium by utilizing underground denitration process

ActiveCN103979579AReduce emissionsReduce production energy consumptionAlkali metal chloridesCalciums magnesiumMagnesium

The invention discloses a method for preparing refined industrial salt low in calcium and magnesium by utilizing an underground denitration process. The method disclosed by the invention comprises the following steps: (1), injecting alkali production calcium liquid in a well and extracting brine; (2), underground removing sulfate radicals and magnesium; (3), surfacely removing calcium; (4), producing salt in vacuum; and (5), returning salt production mother liquid in the well and denitrating. The content of calcium and magnesium in industrial salt produced by the method disclosed by the invention is less than or equal to 0.05%, and therefore, the content of calcium and magnesium is far less than that in industrial salt produced by the traditional methods.

Owner:江苏苏盐井神股份有限公司 +1

Treatment method of wastewater generated during citric acid preparation and preparation method of citric acid

InactiveCN102219286AReduce consumptionReduce emissionsWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentChemistryCalcium salts

The invention provides a treatment method of wastewater generated during citric acid preparation, wherein the wastewater contains citric acid, mixed acids, organic pigments, calcium salts and fermentation residues, and the treatment method comprises the step of carrying out membrane filtration on the wastewater, wherein the membrane has a pore size of 0.1-0.6 mu m. Using the treatment method of wastewater generated during citric acid preparation provided by the invention can improve the recycling efficiency of wastewater, effectively reduce the consumption of raw water, facilitate energy conservation and emission reduction and reduce the production cost of citric acid; and the treatment method is simple and easy for industrial production.

Owner:COFCO BIOTECHNOLOGY CO LTD

Wastewater split-flow separation and quality-based treatment utilization process method

ActiveCN105776670AReduce emissionsSimple processingTreatment involving filtrationWater/sewage treatment bu osmosis/dialysisChemistryHigh concentration

The invention relates to a wastewater split-flow separation and quality-based treatment utilization process method. Wastewater is subjected to split-flow into high-concentration waste liquid and low-concentration clean water; the low-concentration water is simply pretreatmented, and is subjected to reverse osmosis separation into fresh water and concentrated water; the resource utilization of fresh water is realized; the quality-based treatment is performed for utilizing concentrated water, so that the wastewater treatment realizes reduction, harmlessness and recycling. The defects of complexity, long flow process, great consumption, serious secondary pollution and the like of the existing wastewater treatment process are overcome. The process method is suitable for treatment and utilization of various kinds of low-salinity industrial wastewater and municipal domestic sewage.

Owner:路林茫

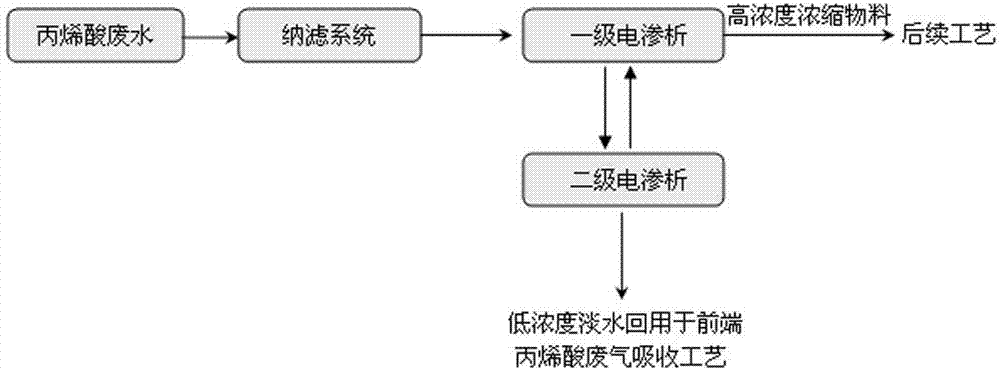

Process for recycling acrylic wastewater

ActiveCN104773882AHigh yieldReduce emissionsMultistage water/sewage treatmentChemistryNanofiltration

The invention provides a process for treating acrylic wastewater through a membrane process. The process for treating the acrylic wastewater comprises the following steps: 1) performing nanofiltration system treat (NF); 2) performing two-stage electroosmosis system (ED) treatment, introducing concentrated outlet water which passes through the electroosmosis system into a follow-up rectifying process or a high-pressure reverse osmosis process, and recycling fresh outlet water into an acrylic acid absorption tower for being recycled as absorbed water. The process disclosed by the invention can be used for comprehensively treating the acrylic wastewater without causing environmental load, and can be used for recycling the acrylic wastewater.

Owner:HANGZHOU BLUETEC ENVIRONMENTAL TECH

Novel medical waste disposal method and novel medical waste disposal device

InactiveCN104475429AReduce emissionsReduce concentrationSolid waste disposalBiofuelsRefuse-derived fuelMedical treatment

The invention discloses a novel medical waste disposal method and a novel medical waste disposal device. After the medical waste is disposed by the method, the aims of disinfection and sterilization are achieved and a refuse-derived fuel is also produced so as to realize volume reduction, quantity reduction, energy regeneration and harmlessness; the device comprises a feed bin, wherein the feed bin is sequentially connected with a large storage bin, a material crusher, a material dryer, a conveyor, a small storage bin and an extrusion forming machine; a lime tank is arranged on the side surface of the conveyor; and multiple levels of conveying mechanisms are arranged at the lower part and side surface of the extrusion forming machine. According to the method and the device, the medical waste can be made into the refuse-derived fuel to achieve the aims of harmlessness, volume reduction, quantity reduction and energy regeneration in the medical waste disposal; and moreover, the discharge of HCL can be reduced during combustion, and the concentration of doxin is reduced so as to reduce environmental pollution while the value of medical waste in energy regeneration is improved.

Owner:杭州运邦环保技术有限公司

Tape base paper and production method thereof

InactiveCN102041744AReduce energy consumptionReduce emissionsSpecial paperReinforcing agents additionHydrogen peroxideFiber

The invention provides tape base paper and a production method thereof. As for the tap base paper, the fracture length is more than or equal to 6.0km; the tensile strength is more than or equal to 1.5kN / m; the moisture content is within the range of 7-10%; the tightness is more than or equal to 0.62g / cm<3>; the wet strength is more than or equal to 0.33kN / m; and the whiteness is within the range of 17-25%. The production method of the tape base paper comprises the following steps: carrying out low-energy consumption displacement cooking, oxygen-alkali delignification and hydrogen peroxide bleaching processes on a wood fiber raw material to produce micro-bleaching pulp, wherein the whiteness of the bleached pulp is 19-27%, the beating concentration of the bleached pulp is 2.5-4.5%, the beating degree of the bleached pulp is 26-32 degree SR, and the wet weight of the bleached pulp is 10.5-15g; and the pulp is formed by beating, degritting, adding a wet strength agent, carrying out fine screening with a pressurized screen, forming on a mesh, squeezing, drying, reeling, rewinding, and packaging.

Owner:YONGZHOU XIANGJIANG PAPER CO LTD

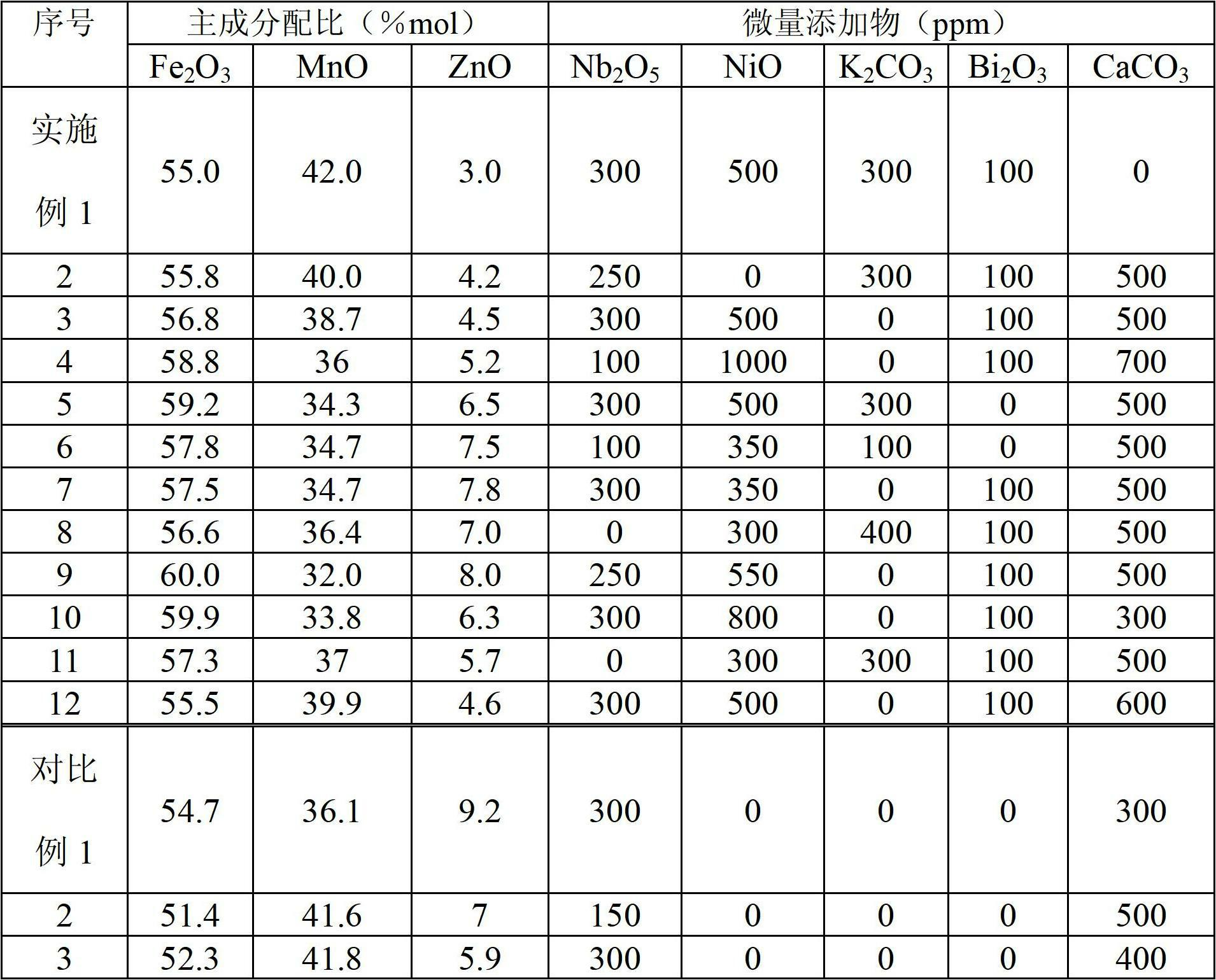

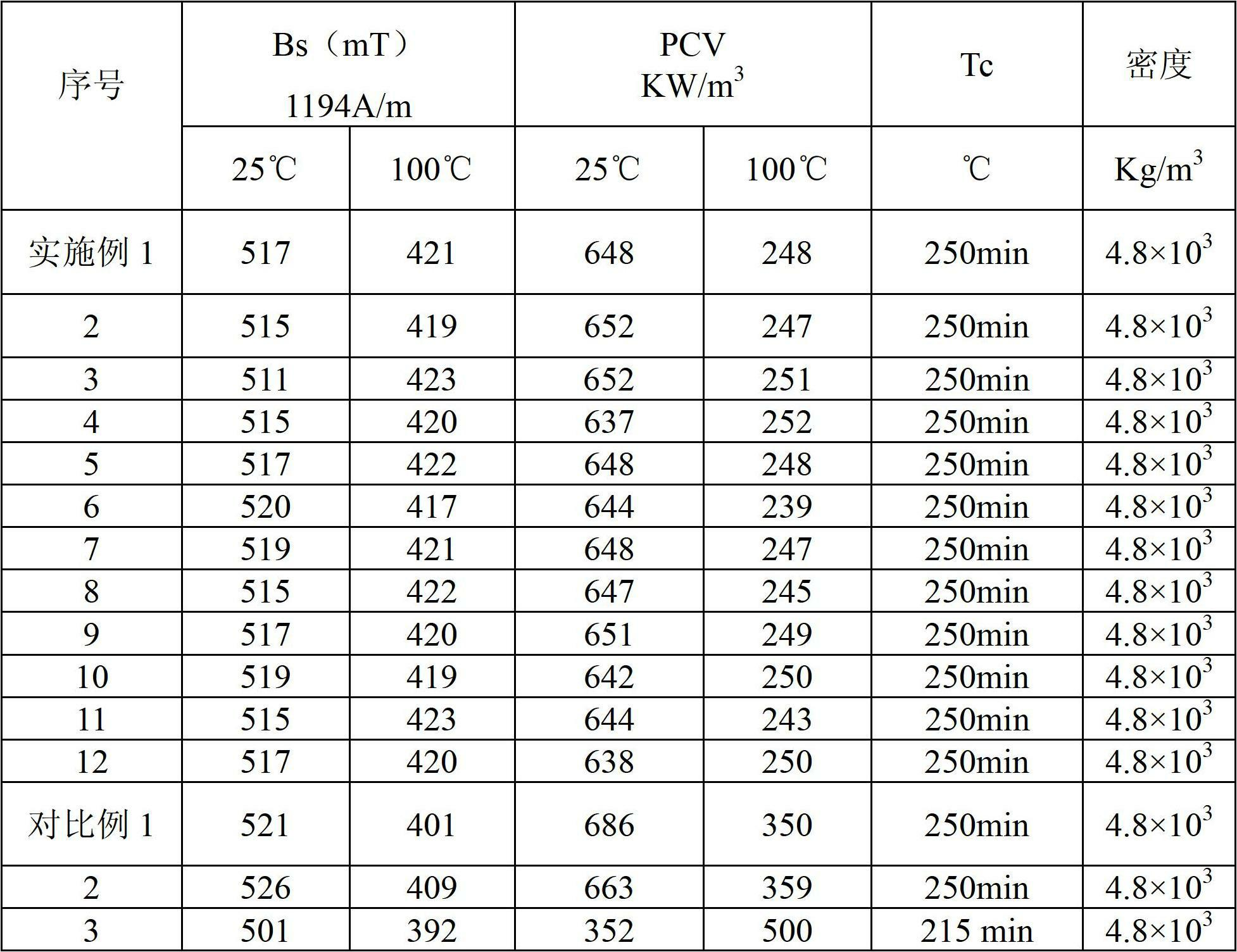

Method for preparing Mn-Zn soft magnetic power ferrite core material

InactiveCN102674821ALow calorific valueReduce emissionsInorganic material magnetismMagnetic corePower loss

The invention relates to a method for preparing a Mn-Zn soft magnetic power ferrite core material. The method comprises the following specific implementation process flows of: weighing, mixing, tableting, presintering, crushing, sanding, pulping, spray granulation, pressing and sintering. Compared with the prior art, the method for preparing the Mn-Zn soft magnetic power ferrite core material has the advantages that the heat productivity is reduced, and miniaturization and thinning are realized. Moreover, the Mn-Zn soft magnetic power ferrite core material has high saturation flux density (Bs) and low power loss.

Owner:上海康顺磁性元件厂有限公司 +1

Hot gas flow dissociation dewatering indirect Karl-Fischer-process analysis device

InactiveCN104569113AAccurate measurementReduce emissionsPreparing sample for investigationMaterial electrochemical variablesBuretteVolatile substance

The invention relates to a hot gas flow dissociation dewatering indirect Karl-Fischer-process analysis device which comprises a titration tank, a Karl-Fischer burette, an electrode, a voltameter, an electromagnetic stirrer positioned below the titration tank, a Karl-Fischer titration component composed of waste liquid bottles, a methanol recovery component composed of a minitype gas pump and a methanol coagulator, and a gas heating component, wherein the gas heating component is arranged outside the titration tank and is used for heating the sample so that the sample can release water, and the hot gas flow carries the water into the titration tank. Compared with the prior art, only water and certain specific volatile matters are carried into the burette so as to keep the electrode and electrolysis carrier liquid clean, so that the detection is more accurate, and the electrolysis carrier liquid in the titration tank does not need to be replaced frequently. The methanol coagulator is arranged in the gas phase, so the methanol is recovered by utilizing the pressure difference before and after the gas pump, thereby relieving the environmental pollution and being beneficial to environmental protection.

Owner:SHANGHAI RES INST OF CHEM IND +1

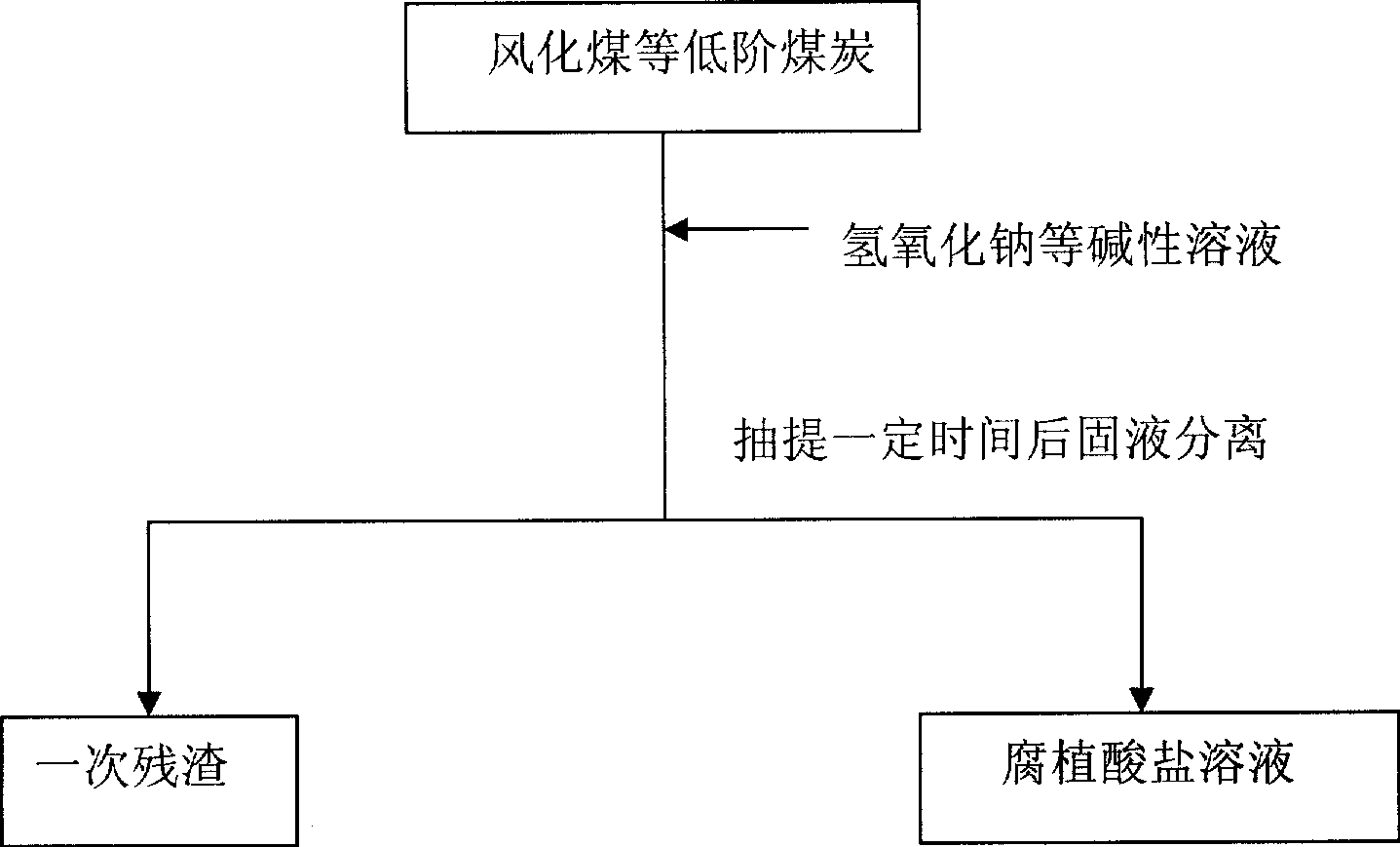

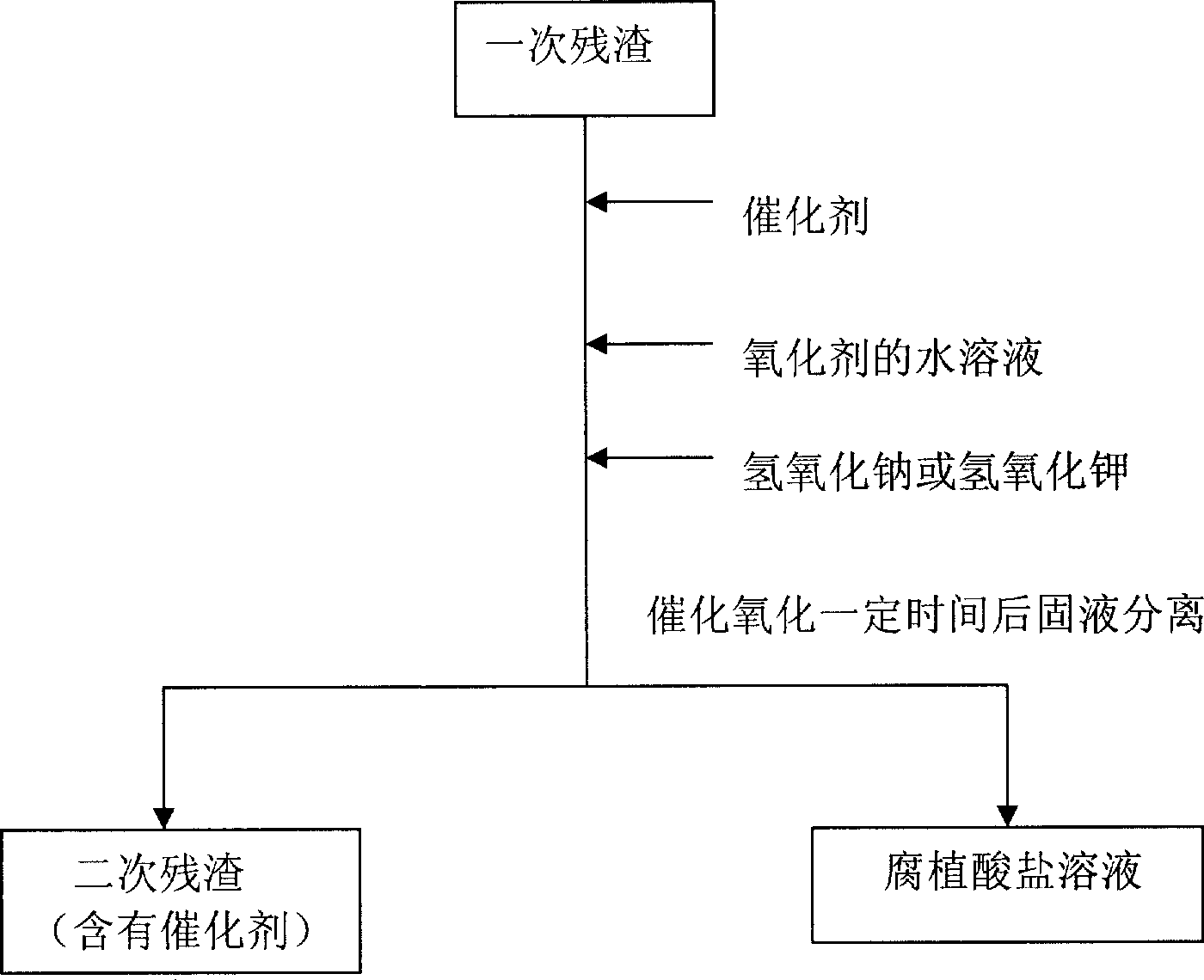

Liquid-phase catalytic oxidation cycle method for preparing humic acid from coal residue

InactiveCN101519415AReduce emissionsProtect environmentOrganic chemistryChemical recyclingHumic acidCoal

The invention relates to a liquid-phase catalytic oxidation cycle method for preparing humic acid from coal residue after coal humic acid extraction. The method comprises the following steps: putting the residue after the coal humic acid extraction in a reaction container at a room temperature and adding a catalyst with 0.1 per thousand to 10 percent of the quality of the residue; then, adding an oxidizer water solution with the 1 to 20 times of the quality of the residue; stirring to form a suspension and adding sodium hydroxide or potassium hydroxide as required so as to control a pH value to be in a range of 7 to 14; and reacting for 10 mins to 72 hours and stopping stirring; naturally standing or centrifugally separating a humic acid solution and secondary residue which contains the solid catalyst added in the preceding step, separating the humic acid by solid-liquid separation operation and obtaining the secondary residue as well. The invention can similarly carry out circular catalytic oxidation reactions to continuously increase the yield of the humic acid.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

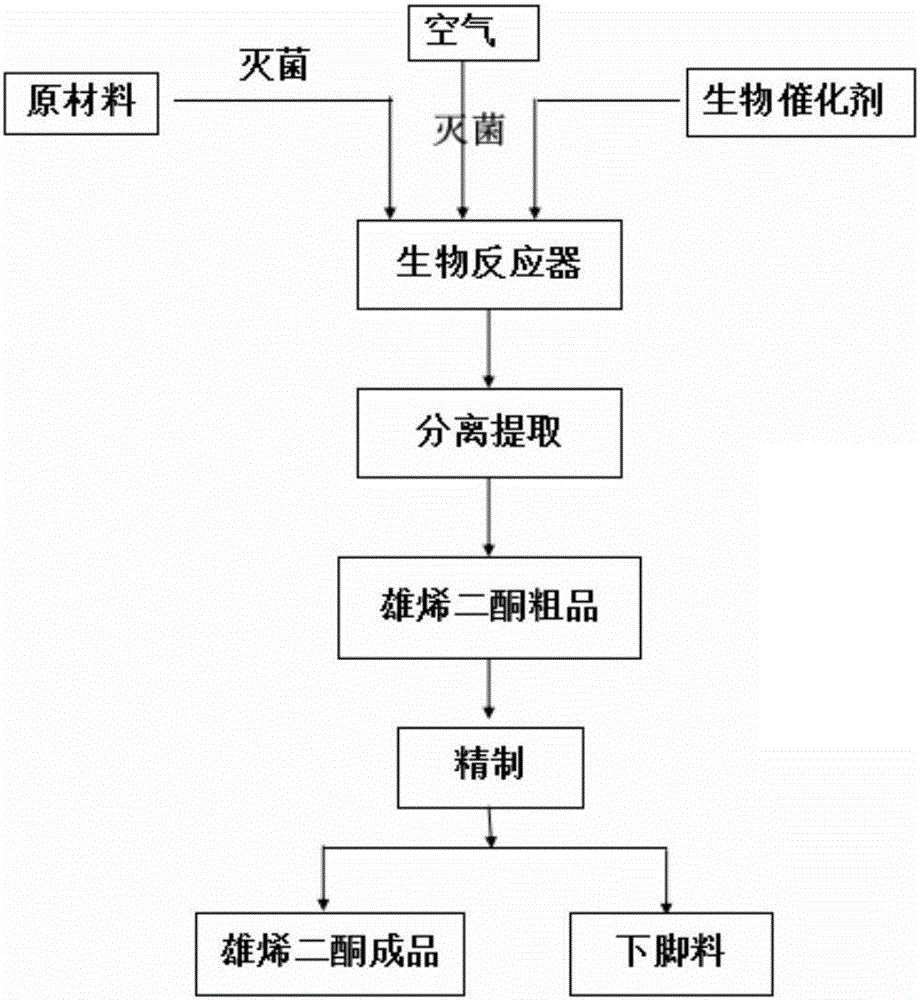

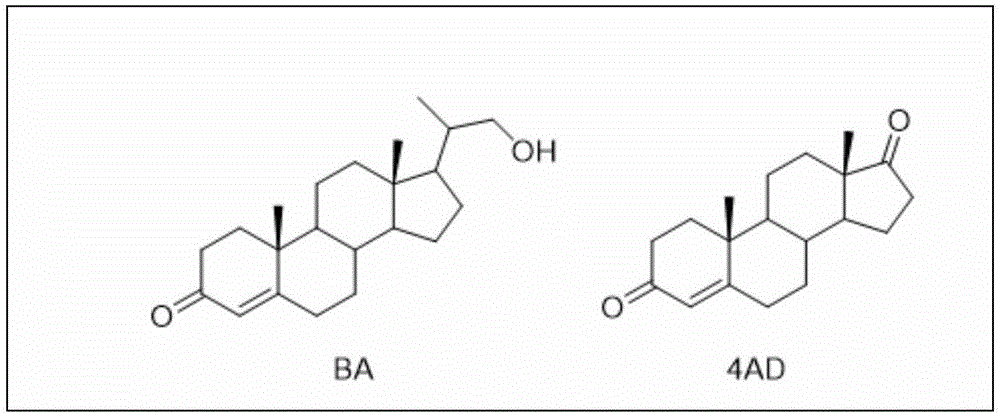

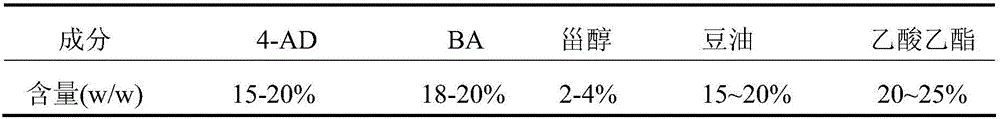

Process for recovering steroids from residues in biological fermentation based androstenedione production

The invention relates to a method for recovering steroids from residues in biological fermentation based androstenedione production. The method includes steps: 1) dissolving solid residues in a solvent, heating and stirring until solubility equilibrium is achieved, filtering lower solids, drying to obtain solid steroids, concentrating supernatant, and removing part of the solvent to obtain clear liquid; 2) slowly adding the solvent into the clear liquid; stirring, standing, and performing liquid separation to remove lower oily substances to obtain upper emulsion; 3) standing the upper emulsion, filtering, and drying filter cakes to obtain the solid steroids; 4) dissolving the lower oily substances into the solvent to obtain clear liquid; 5) repeating the step 2) and the step 3), combining solids obtained each time with the solids obtained at the step 1) and the step 3) to obtain the steroids. The method has advantages that discharging quality of oily residues in biological fermentation based androstenedione production is reduced, environment pollution is relieved, and economic benefits of enterprises are increased.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Lead-acid storage battery polar plate grid

InactiveCN102751505AReduced lead melting processReduce emissionsElectrode carriers/collectorsCopper wireFiber

The invention discloses a lead-acid storage battery polar plate grid, which comprises a grid body, wherein the grid body is formed by a carbon fiber material, positive lead paste is coated on the grid body to form a positive plate; and negative lead paste is coated on the grid body to form a negative plate. The polar plates and polar clusters are connected in a tightening way without use of lead, copper wires are lead out to form a positive electrode and a negative electrode, so that the lead consumption for the storage battery is less, the lead can be saved about 40 to 60 percent compared with that of the traditional lead-acid storage battery; and moreover, in the entire production process, the lead melting steps are reduced, the lead emission is greatly reduced, and the environmental pollution caused by the lead in the production process can be further reduced.

Owner:杨成清

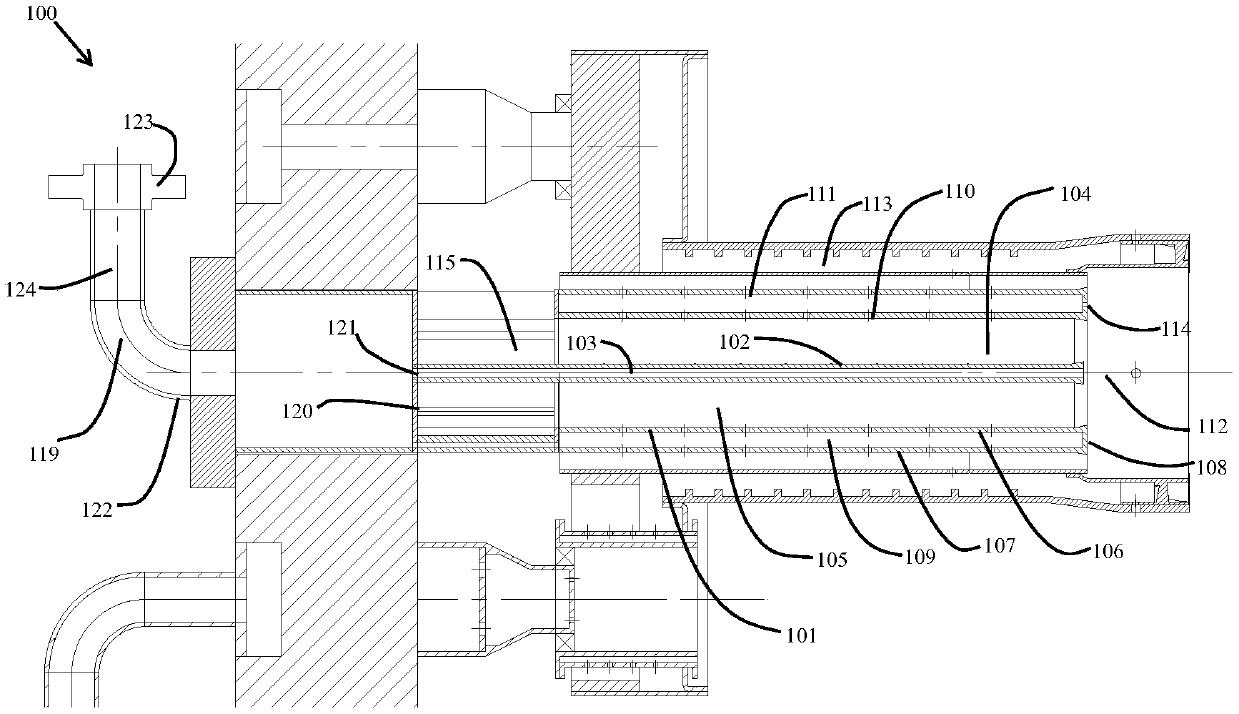

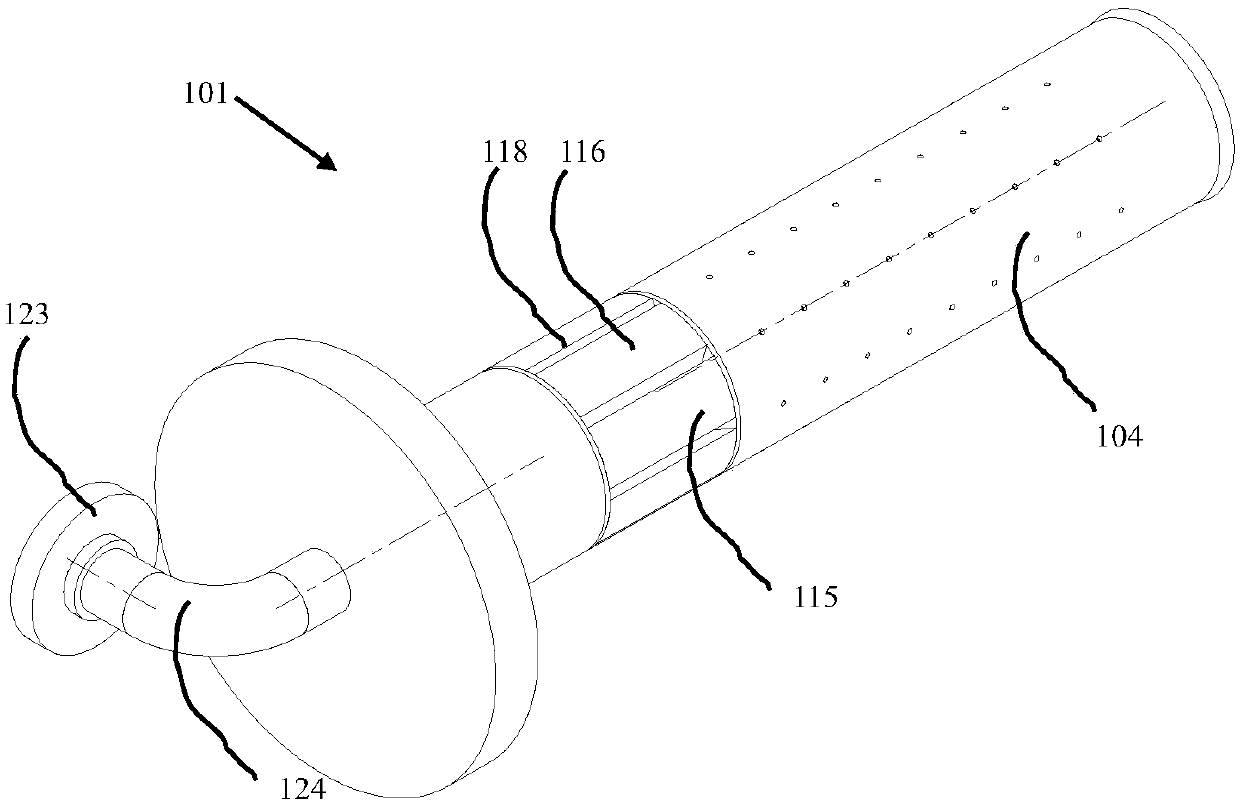

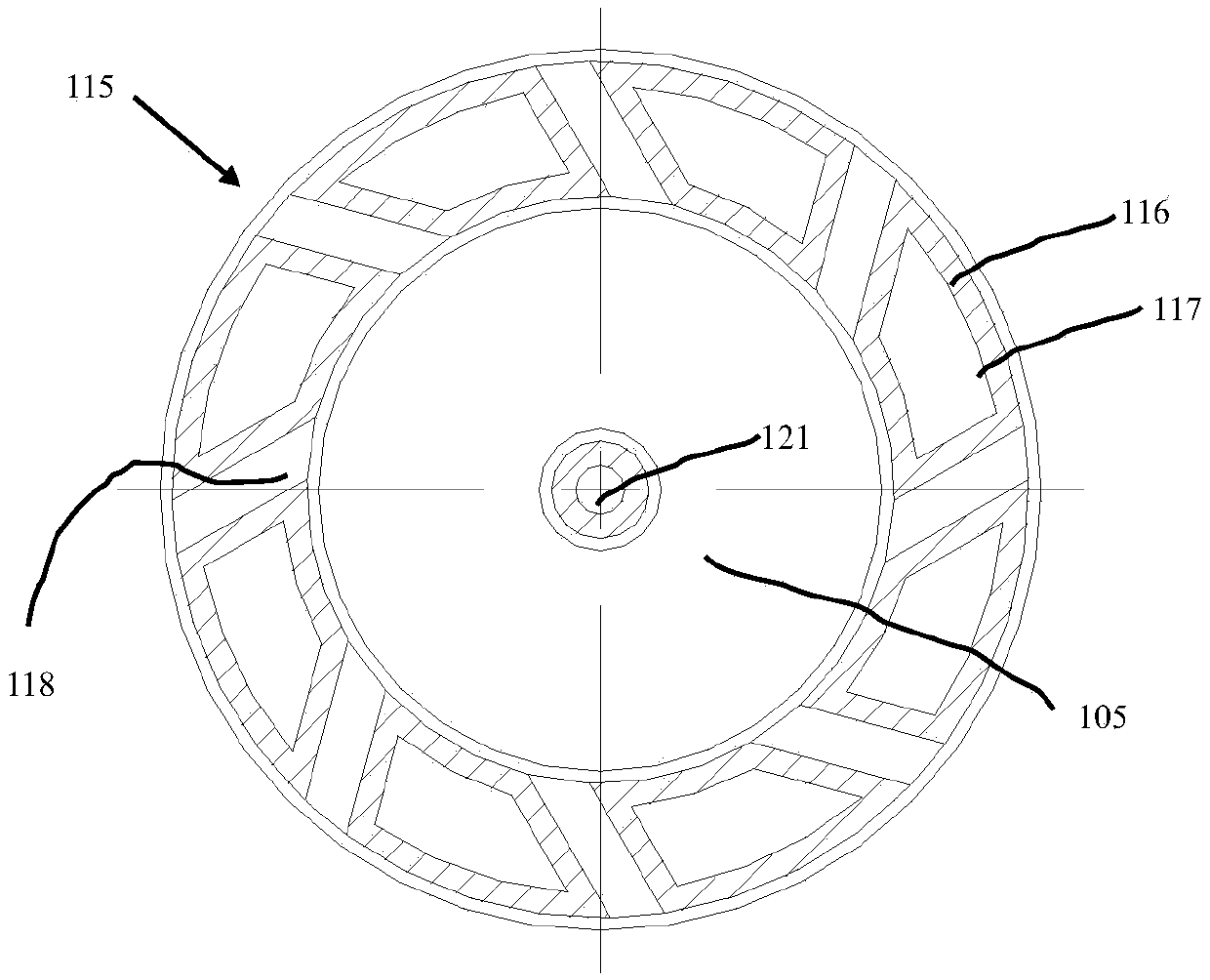

Center fuel nozzle

ActiveCN109654537AEnhanced blending uniformityReduce emissionsContinuous combustion chamberAutomotive engineeringGas turbines

The invention belongs to the technical field of turbine engines, and particularly relates to a center fuel nozzle. The center fuel nozzle (101) is arranged in a gas turbine combustion chamber (100), and comprises an on-duty fuel pipe (102), a fuel distributing pipe (104), a rotational flow pipe (115) and an inlet segment (122). According to the center fuel nozzle, the design of a traditional fuelspraying rod is omitted, through an inner fuel hole and an outer fuel hole, multi-point fuel putting is carried out, the mixed uniform degree of fuel and air can be reinforced, the emission amount ofthe combustion chamber can be reduced, the inner fuel hole and the outer fuel hole replace the fuel spraying rod in a pre-mixed channel to prevent back traces, and tempering risks of the combustion chamber are prevented.

Owner:AECC SHENYANG ENGINE RES INST

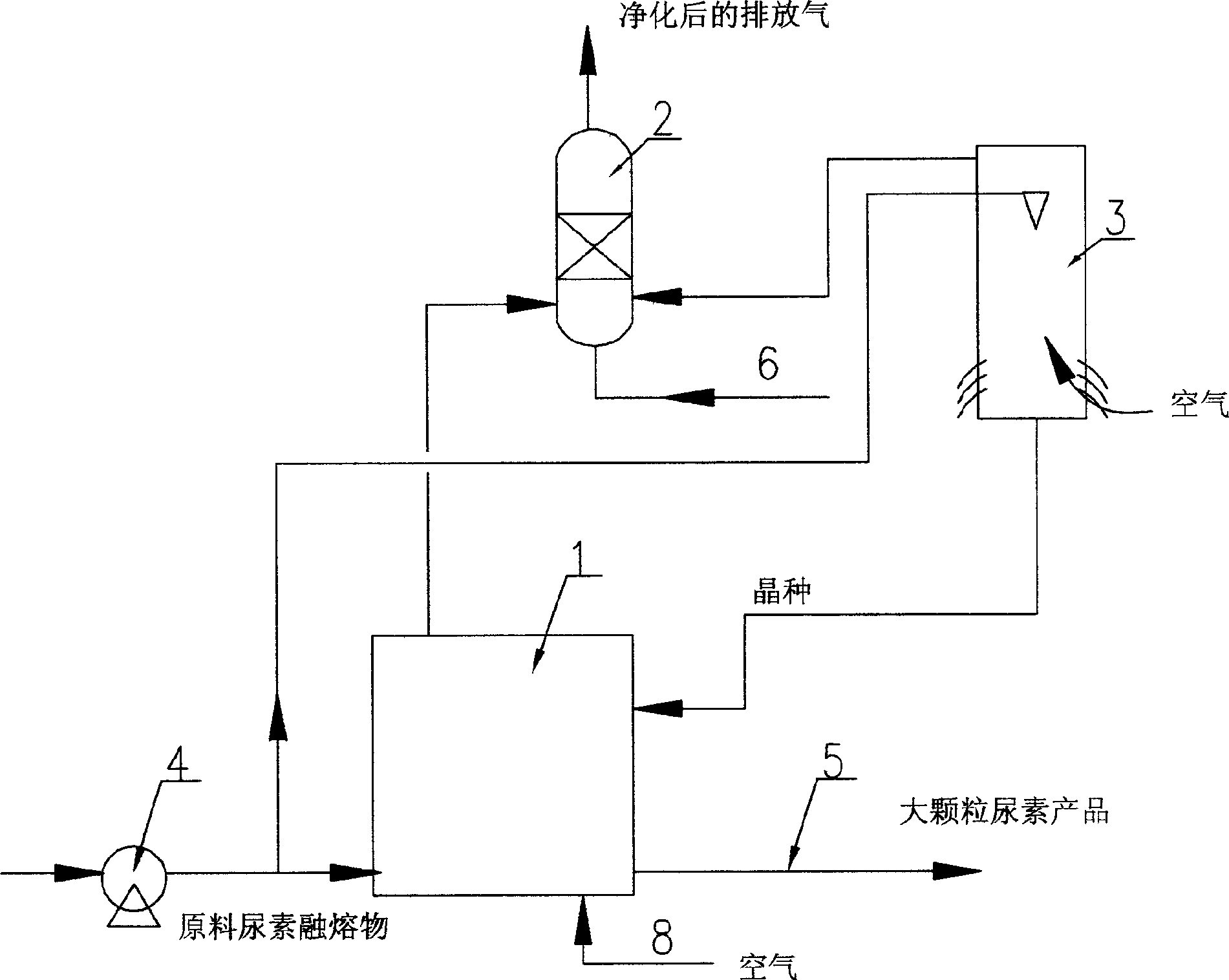

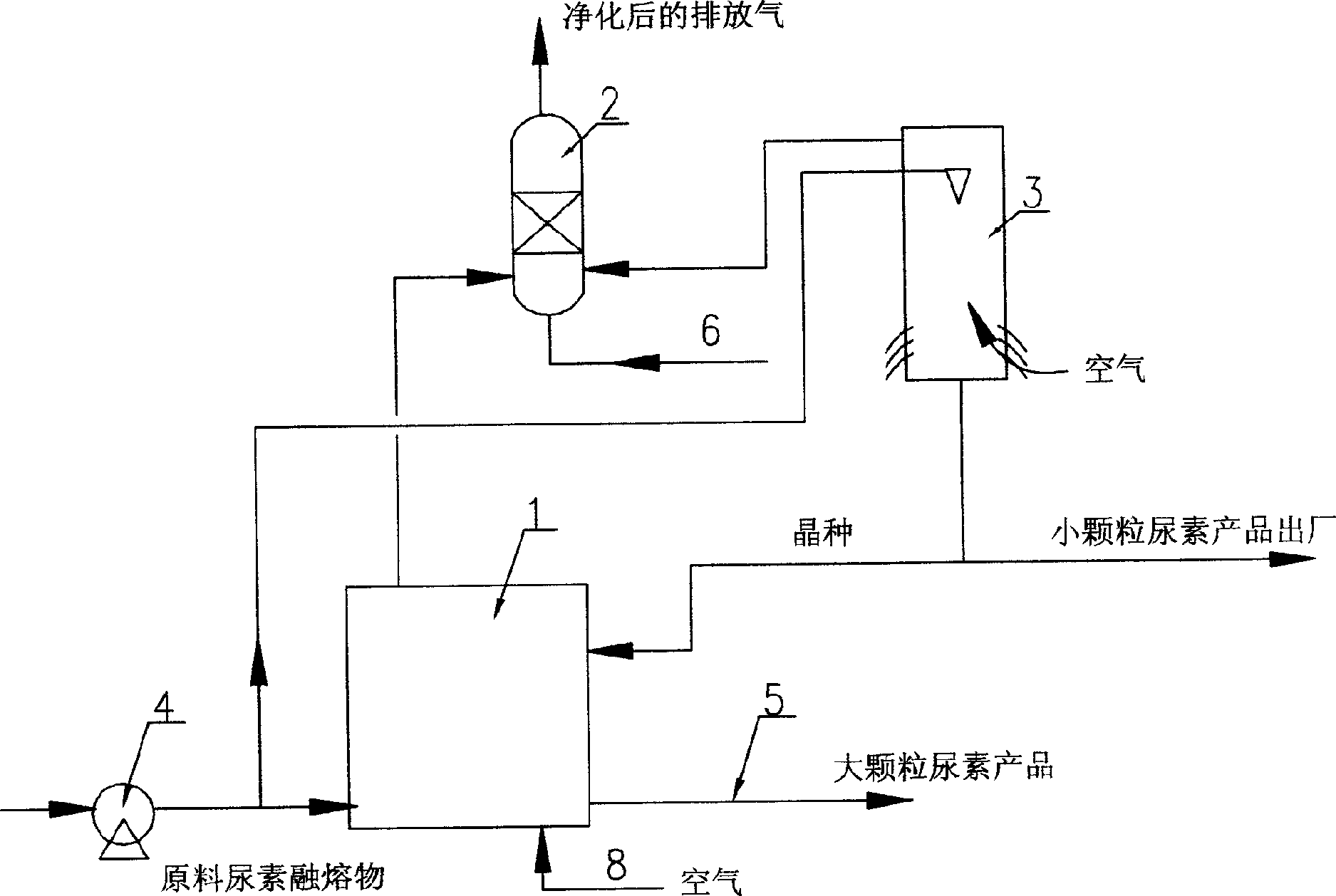

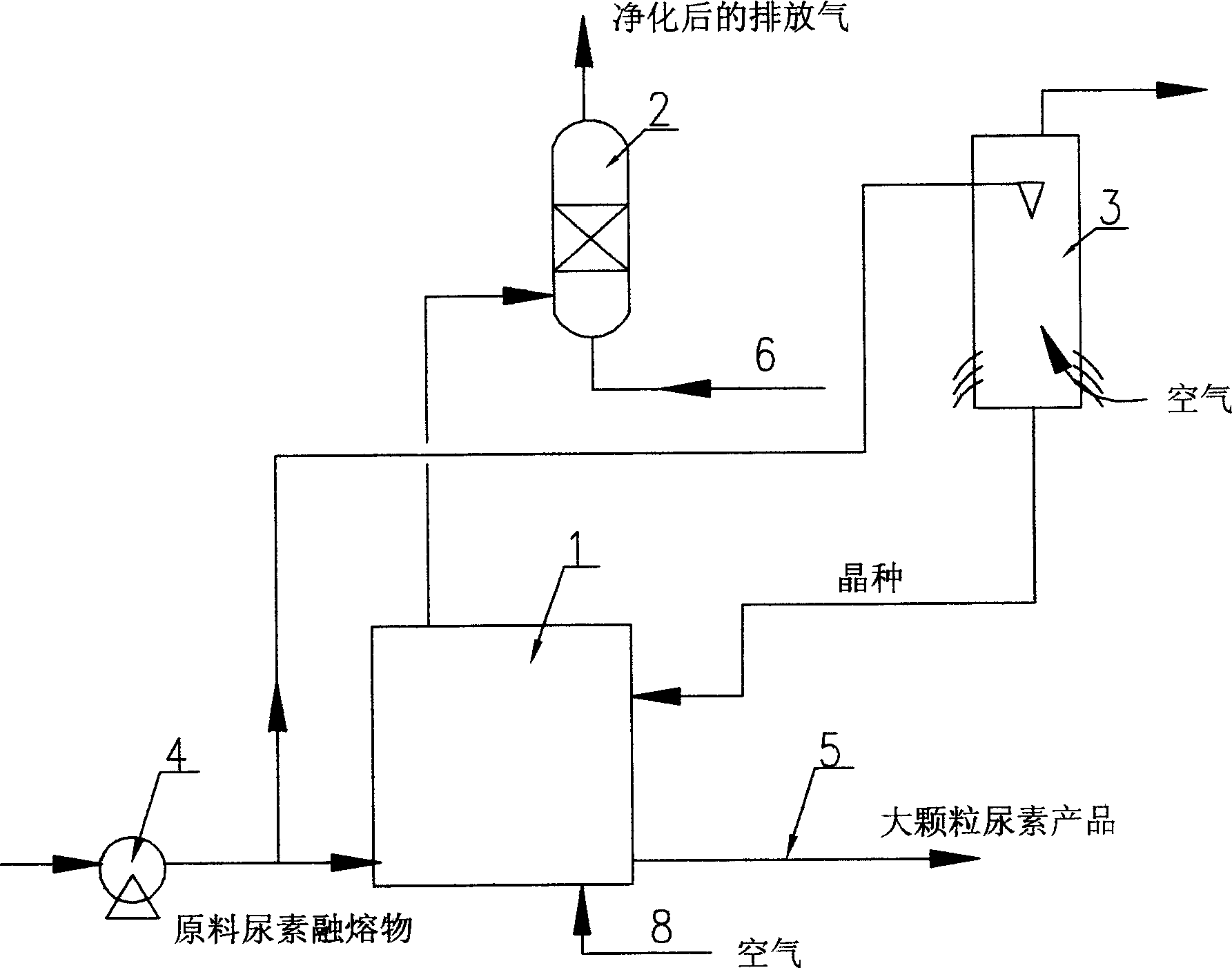

Improved method of purifying gas containing urea dust

InactiveCN1609100AReduce emissionsReduce energy consumptionUrea derivatives preparationOrganic compound preparationPelletizingExhaust gas

The present invention provides one improved method of purifying air containing urea dust through reducing total tail gas exhaust greatly to raise the environment quality around urea plant. The present invention includes the following steps: pelletizing urea of molten urea in double-cylinder fluidized bed large grain urea apparatus; and washing air connecting urea dust in tail gas washing tower or absorbing with molten urea drops moving inversely in the pelletizing tower before exhausting.

Owner:顾大地

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com