Lead-free welding tin wire and water-soluble welding flux used by same

A lead-free solder, water-soluble technology, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of residual halogen, environmental hazards, non-compliance, etc., to reduce interfacial tension and reduce environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

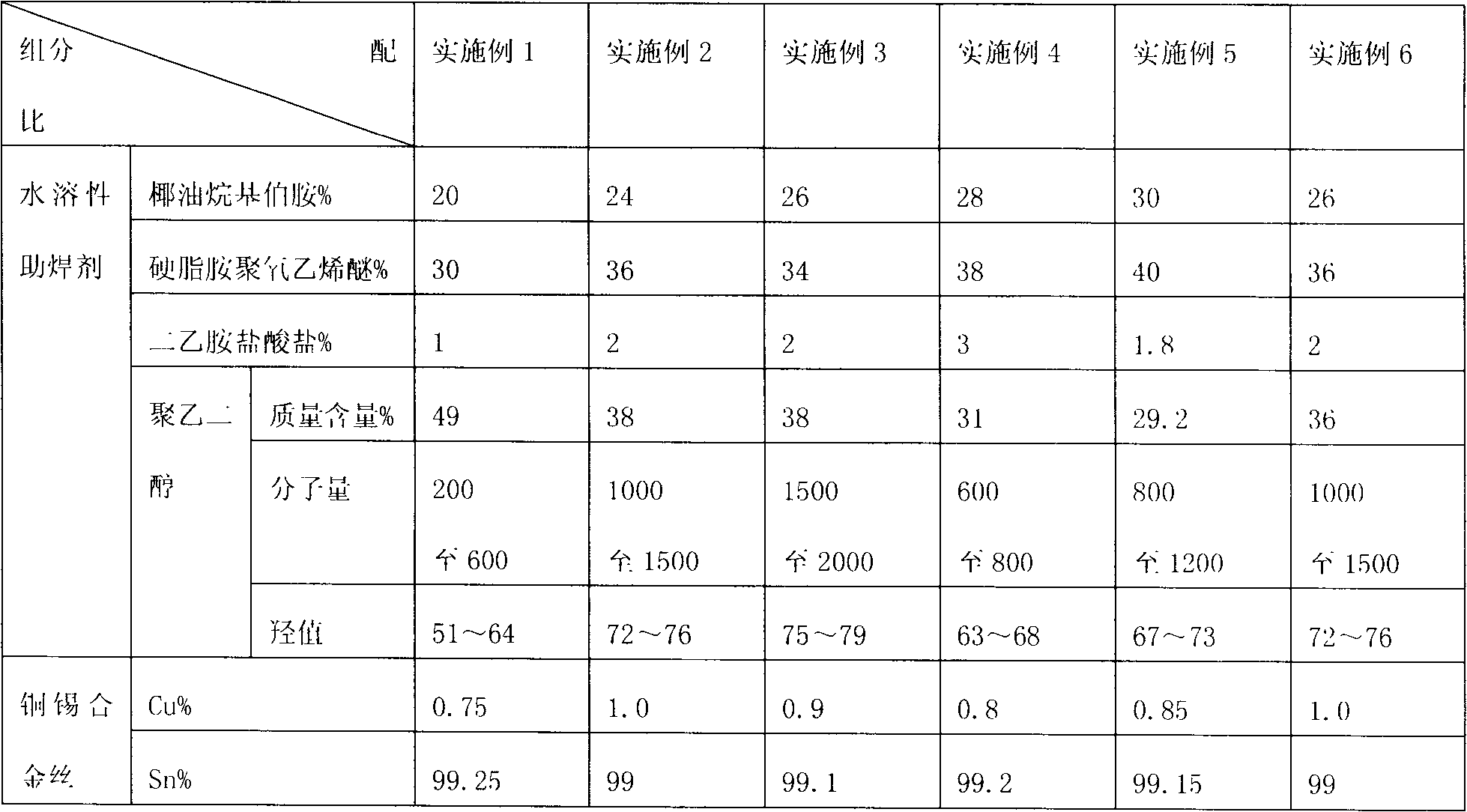

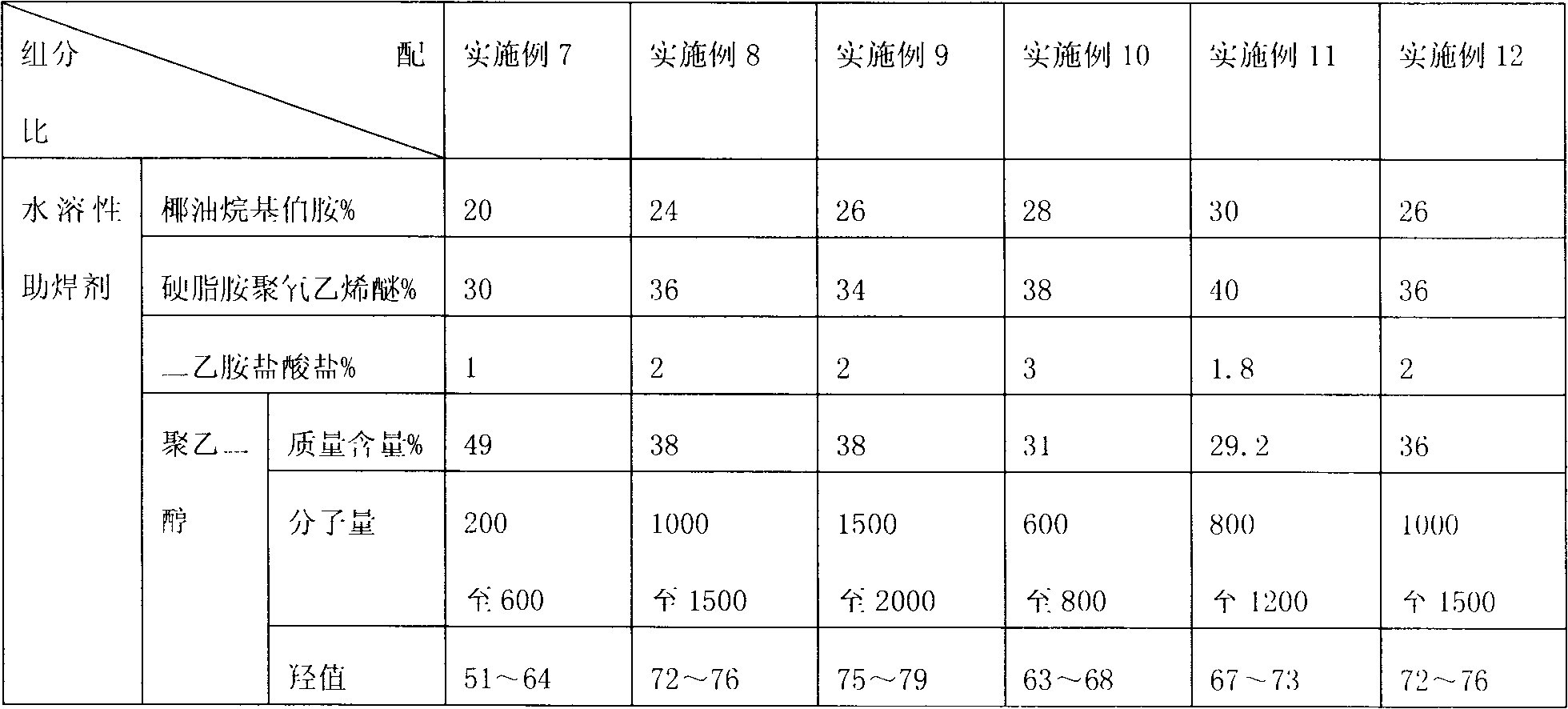

[0056] (Example 1, lead-free solder wire)

[0057] This embodiment is a lead-free solder wire, which includes a copper-tin alloy wire with a cavity and a water-soluble flux arranged in the cavity; the ratio of the copper-tin alloy wire and the water-soluble flux is:

[0058] Water-soluble flux 2.0%;

[0059] Copper tin alloy wire 98%;

[0060] The copper-tin alloy wire includes the following components:

[0061] Cu 0.75%;

[0062] Sn 99.25%;

[0063] The water-soluble flux includes the following components:

[0064] Coconut oil alkyl primary amine 20%;

[0065] Stearylamine polyoxyethylene ether 30%;

[0066] Diethylamine hydrochloride 1%;

[0067] Water-soluble high molecular polymer 49%;

[0068] The above percentages are mass percentages;

[0069] The ammonium salt halide is diethylamine hydrochloride;

[0070] The water-soluble high molecular polymer is polyethylene glycol with a molecular weight of 200 to 600 and a hydroxyl value of 51 to 64.

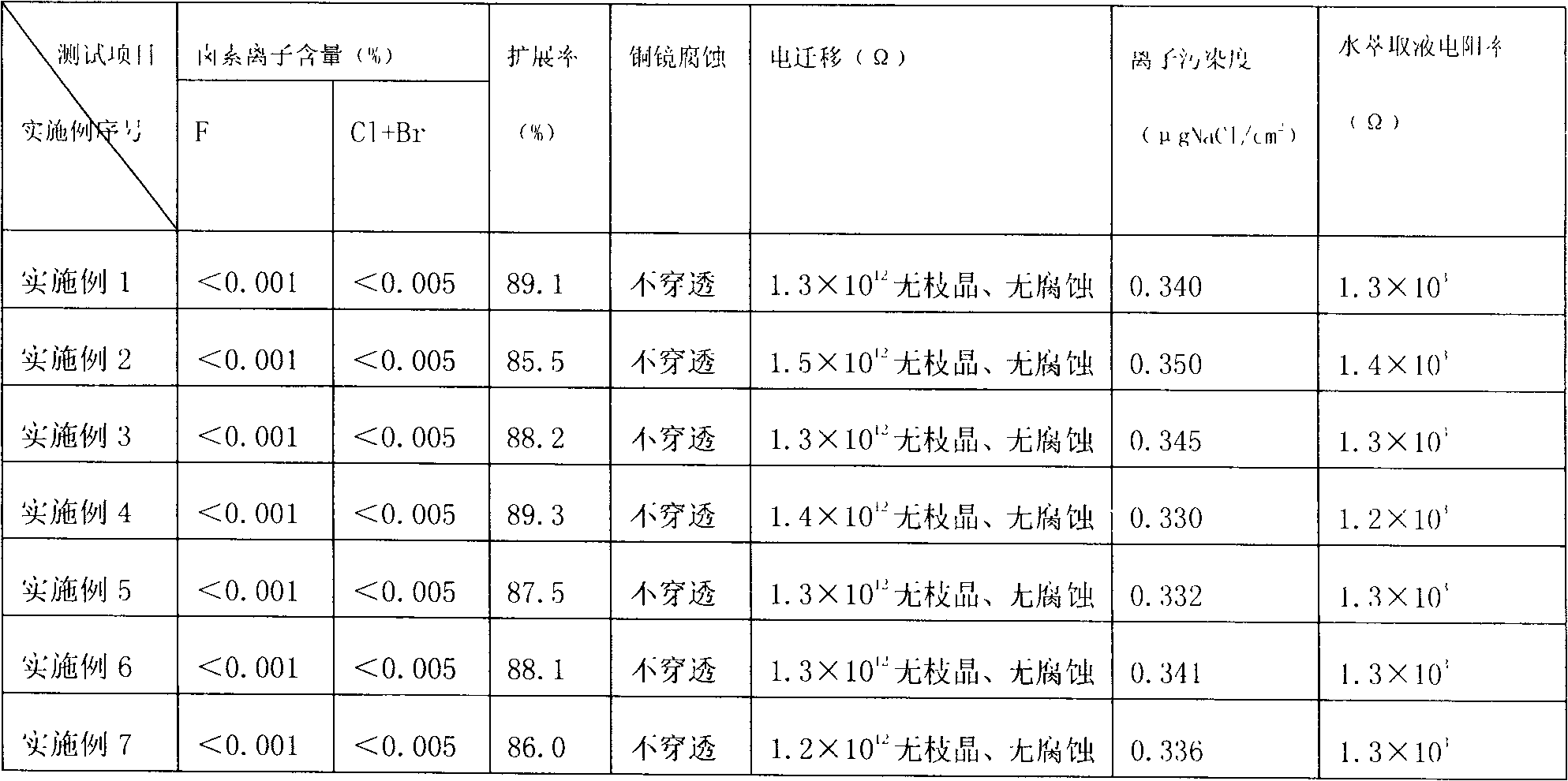

[0071] See Table 1 for the materials and their ...

Embodiment 2

[0072] (Example 2, lead-free solder wire)

[0073] Example 2 is basically the same as Example 1, except that the ratio of the copper-tin alloy wire and the water-soluble flux in this example is:

[0074] Water-soluble flux 2.2%;

[0075] Copper-tin alloy wire 97.8%;

[0076] In addition, the ratio of the water-soluble flux used in this embodiment is different from that in Embodiment 1. The relevant parameters in this embodiment are shown in Table 1.

Embodiment 3

[0077] (Example 3, lead-free solder wire)

[0078] Embodiment 3 is basically the same as embodiment 1, except that the ratio of copper-tin alloy wire and water-soluble flux in this embodiment is:

[0079] Water-soluble flux 2.1%;

[0080] Copper-tin alloy wire 97.9%;

[0081] In addition, the ratio of the water-soluble flux used in this embodiment is different from that in Embodiment 1. The relevant parameters in this embodiment are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com