Adjustable laser coaxial powder feeding nozzle

A coaxial powder feeding and adjustable technology, applied in the field of laser coaxial powder feeding nozzles and laser metal direct manufacturing nozzles, can solve the problems of low powder utilization rate and poor powder convergence effect, so as to improve the cooling effect and promote The effect of powder gathering and avoiding short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

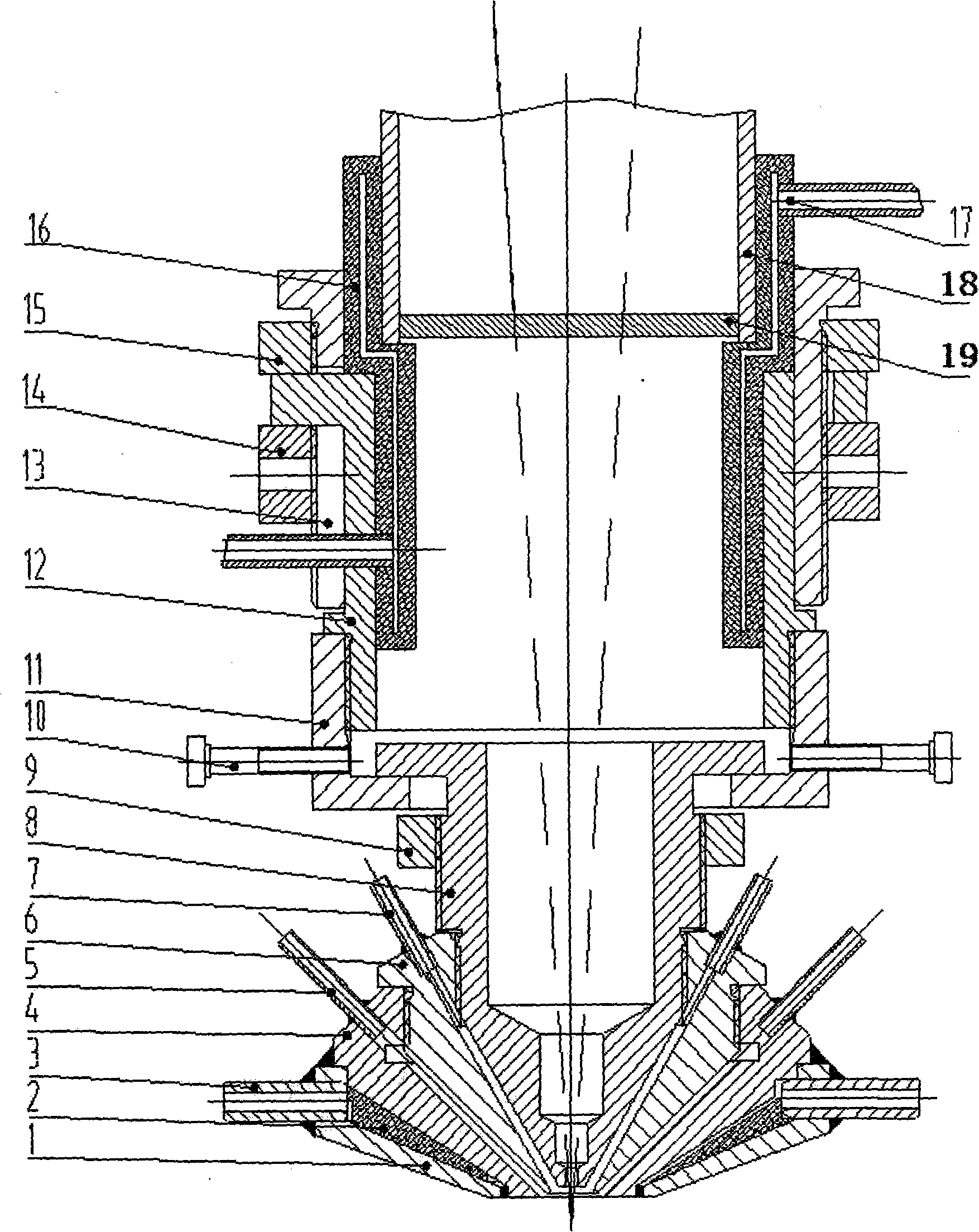

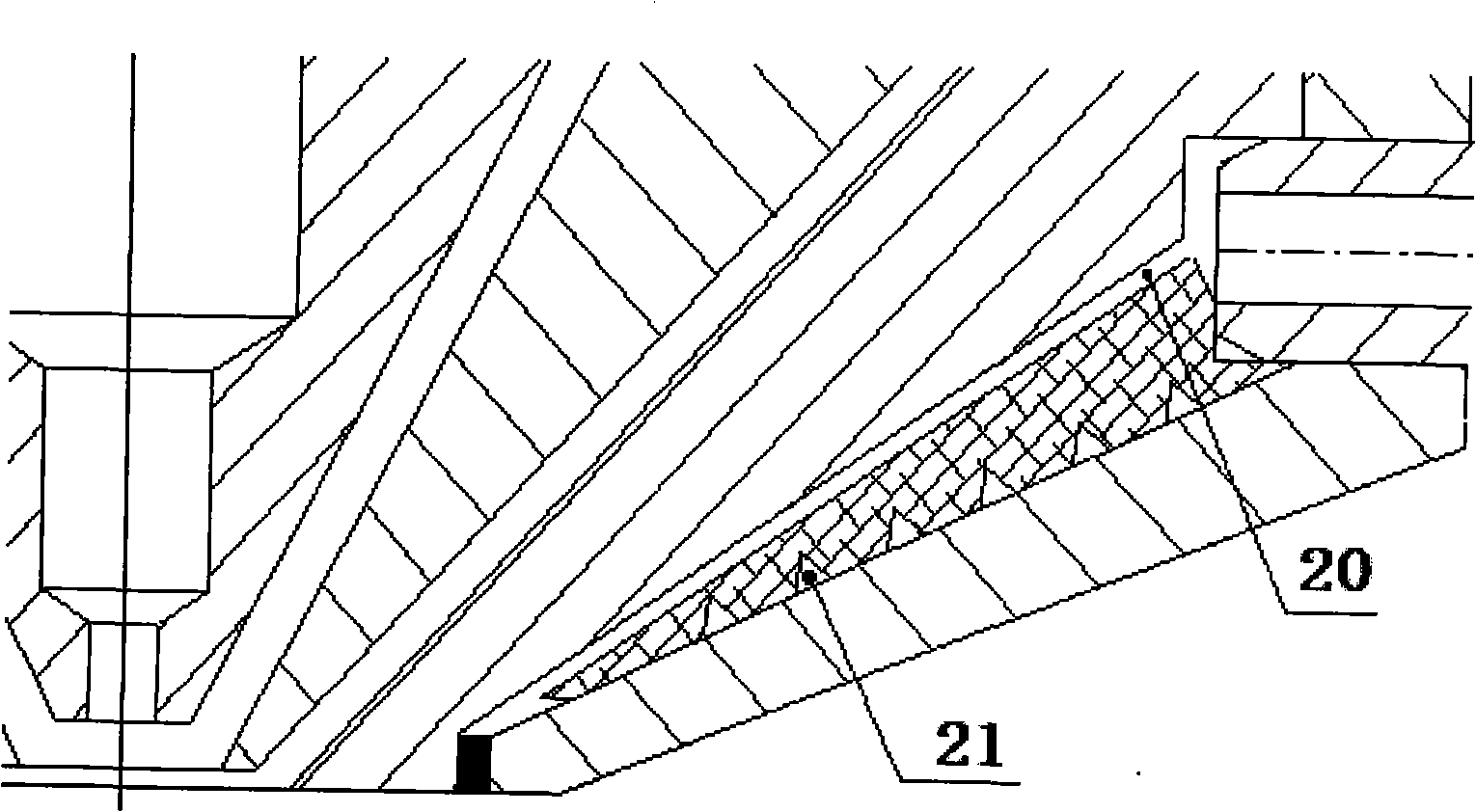

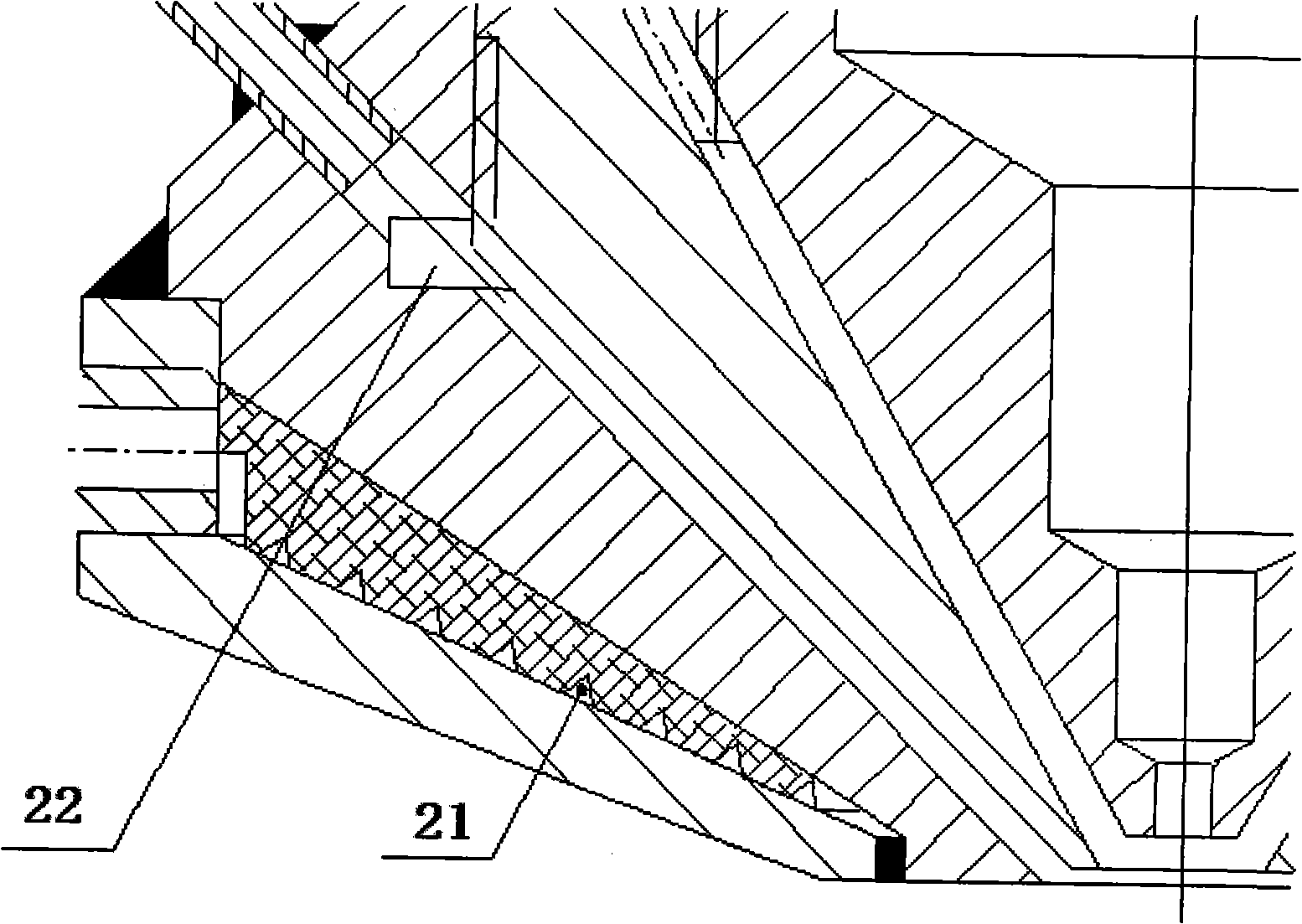

[0024] as attached figure 1 , figure 2 and image 3 As shown, the present invention is characterized in that the lower part of the coaxial powder feeding nozzle is composed of a nozzle water cooling jacket 1, a protective gas jacket 4, a powder cavity cover 6 and a laser cover 8, and the upper part of the coaxial powder feeding nozzle is composed of a centering adjustment base 11. It is composed of lifting inner and outer sleeves 12, 13, protective mirror water cooling sleeve 16 and two threaded clamps. The nozzle water cooling jacket 1 is welded with cooling water inlet and outlet pipes 3 at its cylindrical part. The nozzle water cooling jacket 1 and the protective air jacket 4 form a water cooling chamber. In order to prevent the phenomenon of "short-circuit circulation" of cooling water in the water-cooling chamber, a water-dividing sc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com