Novel rotor

A rotor, a new type of technology, applied in the direction of magnetic circuit rotating parts, electrical components, electromechanical devices, etc., can solve the problems that pure aluminum cannot bear the rotation of the rotor and the low efficiency of the motor, so as to solve the problem of low motor efficiency, reduce motor loss, and stabilize The effect of maintaining the rotation of the rotor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

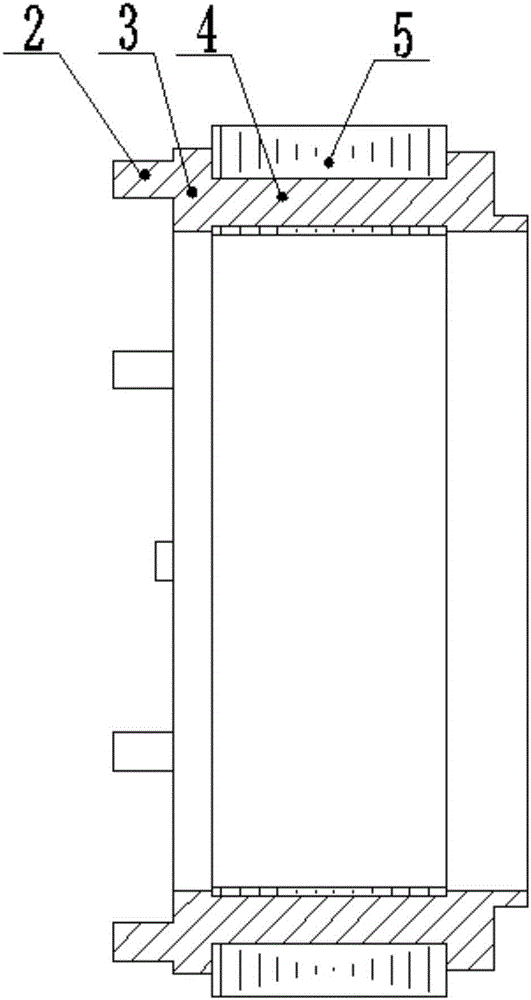

[0016] A new type of rotor, such as Figure 1-3 As shown, it includes an end cover 1, an end ring 3, a guide bar 4 and a rotor core 5. The rotor core 5 is provided with an end ring 3 and a guide bar 4. The end ring 3 and the guide bar 4 are integrally formed. The end cover 1 is connected with the end ring 3, the end cover 1 is a steel end cover 1, the end ring 3 is a pure aluminum end ring 3, the guide bar 4 is a pure aluminum guide bar 4; the end cover 1 is provided with a shaft sleeve 6. There is a rotating shaft inside the sleeve 6, and the rotating shaft drives the rotor to rotate through the sleeve 6 on the end cover 1. Since the end cover 1 is made of steel, the end cover 1 can withstand the rotation of the rotor. Since the end ring 3 and the guide bar 4 are pure Made of aluminum, pure aluminum has the effect of improving motor efficiency and reducing motor loss compared with traditional silicon aluminum.

[0017] The left end of the end cover 1 and the end ring 3 is co...

Embodiment 2

[0020] Same as embodiment 1, the difference is that the end cover 1 is made of silicon aluminum. Since the end cover 1 is made of silicon aluminum, the end cover 1 can withstand the rotation of the rotor, and the number of riveting columns 2 is 6. The number of riveting holes 7 is 6, the inner diameter of the end ring 3 is 60 mm, and the outer diameter of the end ring 3 is 75 mm.

Embodiment 3

[0022] Same as embodiment 1, the difference is that the number of riveting posts 2 is 12, the number of riveting holes 7 is 12, the inner diameter of the end ring 3 is 150 mm, and the outer diameter of the end ring 3 is 210 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com