Permanent magnetic ring component and manufacturing method thereof

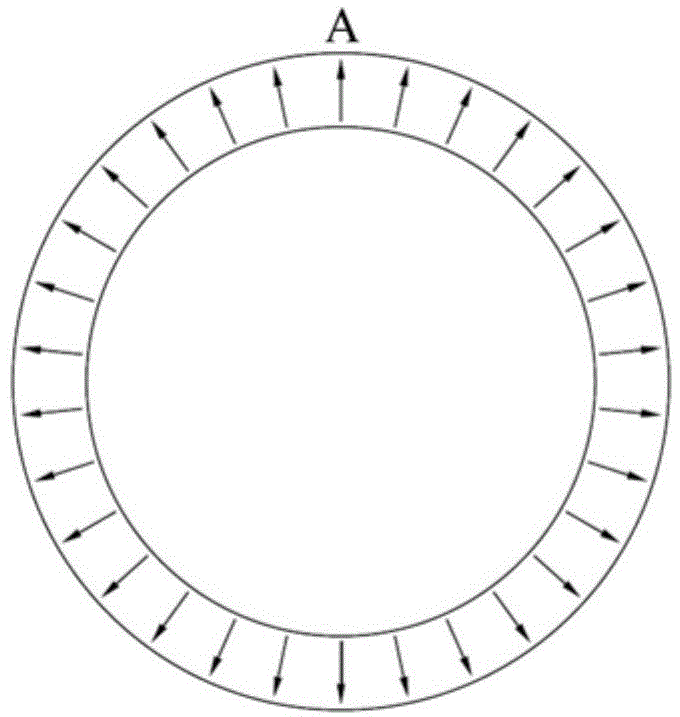

A permanent magnet ring and component technology, which is used in the manufacture of inductors/transformers/magnets, magnetic materials, magnetic objects, etc., can solve the problems of low uniformity and low performance of permanent magnet ring components, and achieve good structural symmetry and solve the Difficult machining problems, reducing the effect of centroid offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The preparation method of the above-mentioned permanent magnetic alloy material is a powder metallurgy process, and the process includes alloy smelting→dry or wet powder making→high magnetic field orientation molding→protective atmosphere sintering and gradient heat treatment→obtaining rare earth-cobalt-based permanent magnets that meet the requirements of radiation orientation. magnetic alloy material.

[0046] The specific preparation method of the rare earth-cobalt-based permanent magnet alloy material required for the permanent magnet ring assembly of the permanent magnet torque device of the present invention comprises the following steps:

[0047] a) Prepare alloy raw materials according to the composition of alloy components, and melt and cast ingots;

[0048] b) After the alloy ingot is coarsely crushed, it is jet-milled into powder under a protective atmosphere, and the particle size of the powder is 3.5-5 μm;

[0049] c) The powder is formed by magnetic field...

Embodiment 1

[0060] The permanent magnetic alloy preparation process method of embodiment 1 is: the alloy raw material composition (by weight) is Sm: 25%, Co: 49%, Cu: 5%, Zr: 2.8%, Fe: 18.2% smelting ingot, After the alloy ingot is coarsely crushed, it is milled into a powder of about 5 μm in a protective atmosphere, and the powder is oriented by a strong magnetic field greater than 1.5T. A lubricant is added during the forming process. After further cold isostatic pressing, sintering and tempering heat treatment are carried out. The heat treatment system is sintering temperature 1205°C for 1 hour, then solution treatment at 1175°C for 4 hours, rapid cooling to room temperature, tempering treatment at 840°C for 12 hours, controlled temperature cooling to 400°C and rapid cooling to room temperature. The results of testing the performance indicators of permanent magnet materials at room temperature show that remanence Br=11.1kGs, coercive force Hc=17.8kOe, and the prepared rare earth-cobalt-...

Embodiment 2

[0063] The permanent magnetic alloy preparation process method of embodiment 2 is: alloy raw material composition (by weight) is Sm: 24.2%, Co: 52.0%, Cu: 3.0%, Zr: 3.8%, balance Fe melting ingot, alloy After the ingot is coarsely crushed, it is milled into a powder of about 3.5 μm in a protective atmosphere, and the powder is oriented by a strong magnetic field greater than 1.5T. A lubricant is added during the forming process. After further cold isostatic pressing, sintering and tempering heat treatment are carried out. The heat treatment system is sintering temperature at 1210°C for 35 minutes, then solution treatment at 1195°C for 2 hours, rapid cooling to room temperature, tempering treatment at 840°C for 5 hours, controlled temperature cooling to 400°C and rapid cooling to room temperature. The performance index results of permanent magnet materials were tested at room temperature, remanence Br=10.6kGs, coercive force Hc=19.6kOe.

[0064] The prepared rare earth-cobalt-b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com