Vertical air-cooled pulverized coal burner capable of realizing continuous slag tapping

A technology of pulverized coal burner and liquid slag discharge, which is applied to burners, burners, combustion methods and other directions of burning powder fuel, can solve the problems of restricting the commercialization of the technology, slag sticking to the wall, serious heat dissipation of the slag port, etc. Achieve the effect of avoiding wall solidification, uniform distribution, and ensuring continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

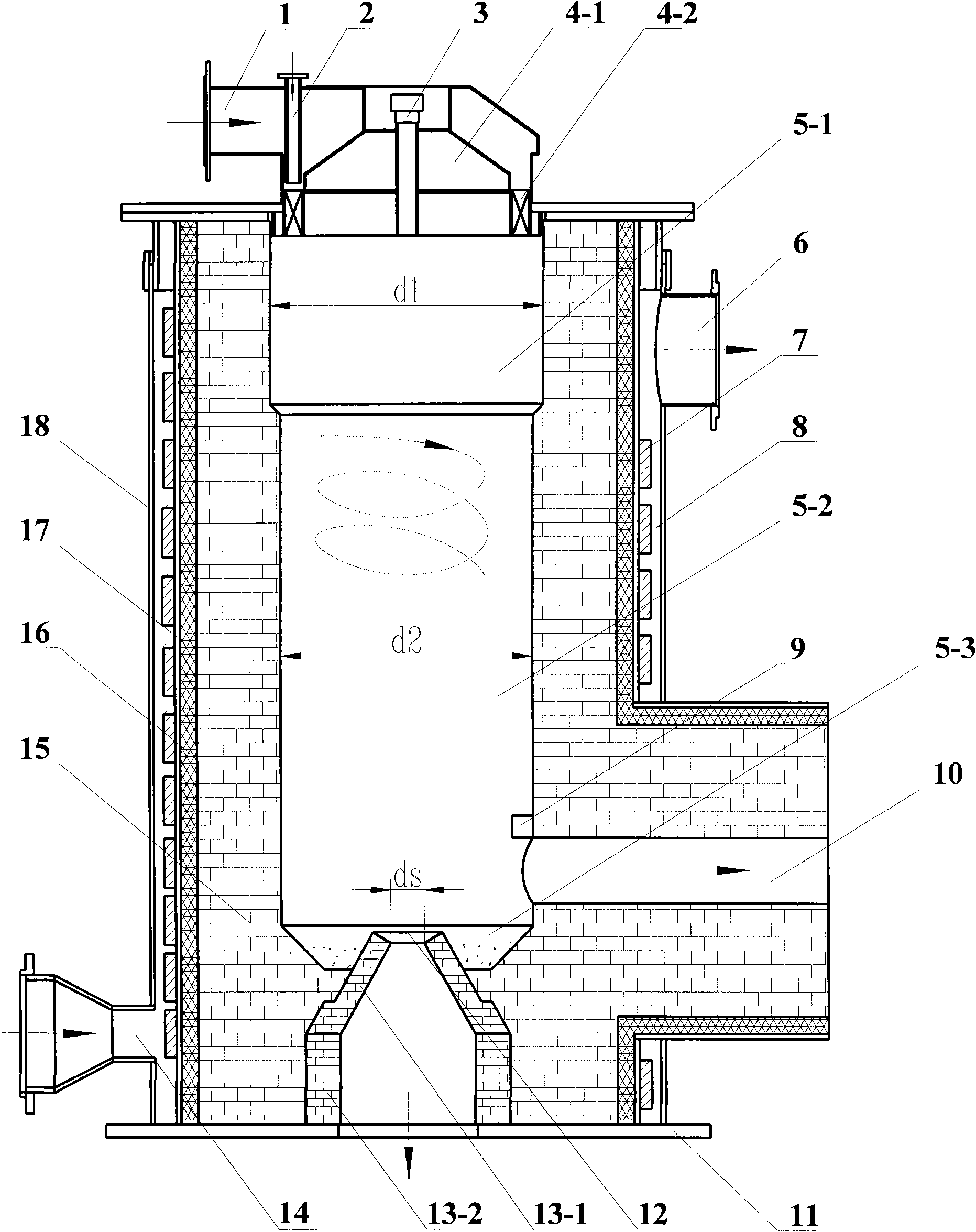

[0031] see figure 1 As shown, a vertical air-cooled pulverized coal burner that can realize continuous liquid slagging includes secondary air pre-swirling chamber 4, combustion chamber 5, slagging chamber 13, and cooling air chamber 8 that are vertically connected in sequence. Including the inlet end face arranged on the top of the combustion chamber 5 and the outlet end face of the lower side wall, the inlet end face is respectively provided with a secondary air inlet 1, a fuel inlet 2 and an ignition port.

[0032] A refractory insulation layer 15 is laid on the outer surface of the combustion chamber 5 and the slag discharge chamber 13 and inside the burner, and a heat insulation layer 16 is laid on the outside of the refractory insulation layer 15, and the inner cylinder wall of the burner is arranged on the outside of the heat insulation layer 16. 17 and the outer cylinder wall 18, there is a gap between the inner cylinder wall 17 and the outer cylinder wall 18 and a cool...

Embodiment 2

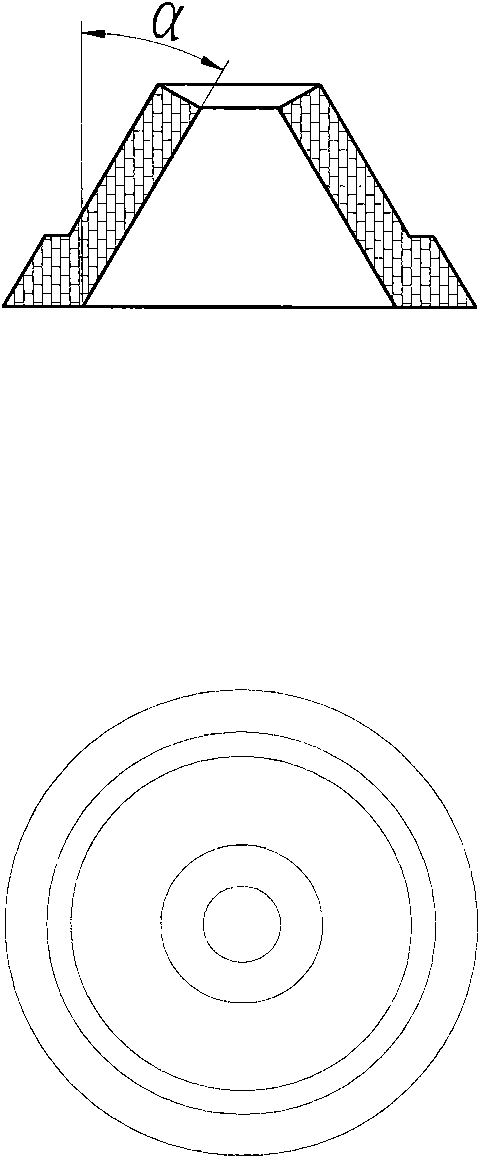

[0042] see Figure 4 As shown, the taper angle α of the diffusion pipe 13-1 is 30°, and the shape of the slag outlet 12 is square. In this embodiment, the diameter d1 of the upper cavity 5-1 is 1.3 times the diameter d1 of the lower cavity 5-2.

[0043] Other structures of this embodiment are the same as those of Embodiment 1, and will not be described in detail here.

Embodiment 3

[0045] see Figure 5 As shown, the taper angle α of the diffusion pipe 13-1 is 30°, and the shape of the slag outlet 12 is oval. In this embodiment, the diameter d1 of the upper cavity 5-1 is 1.5 times the diameter d1 of the lower cavity 5-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com