Differential melt electro-spinning device adopting high-velocity water flow assisted twisting

A technology of melt differentiation and high-speed water flow, applied in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve the problems of twisting failure, fiber suction hole, and inability to adapt well, so as to ensure uniformity anti-adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

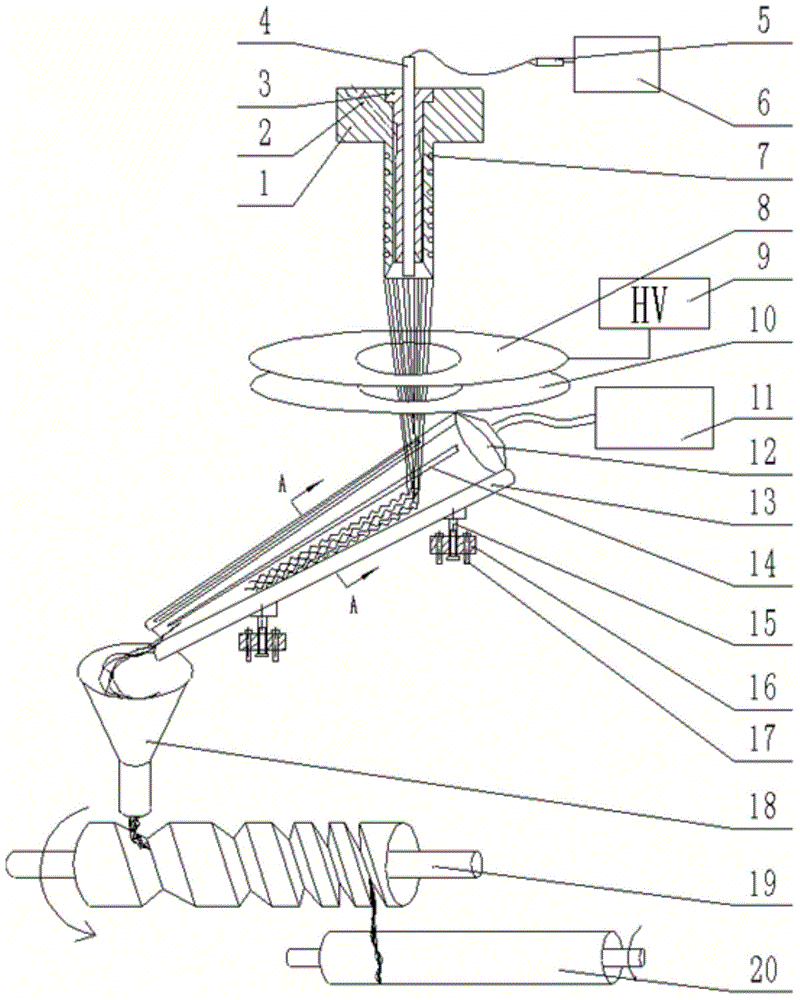

[0020] The present invention proposes a melt differential electrospinning device with high-speed water flow assisted twisting, such as figure 1 As shown, it mainly includes: nozzle outer cylinder 1, material flow channel 2, nozzle mandrel 3, air duct 4, heat gun 5, air compressor 6, heating ring 7, hole electrode plate 8, electrostatic generator 9, Hole insulating plate 10, water pump 11, water inlet channel 12, annular water tank 13, annular water flow channel 14, adjusting screw 15, adjusting screw fixing block 16, fixing screw 17, twisting funnel 18, grooved roller 19 and collecting roller 20. The outer cylinder 1 of the nozzle and the mandrel 3 of the nozzle are connected coaxially through the positioning of the boss. The rod 3 is connected and fixed by interference fit, the heating ring 7 is covered on the outer surface of the nozzle outer cylinder 1, and heats the nozzle outer cylinder and the nozzle mandrel, and the plastic enters the nozzle outer cylinder 1 and the noz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com