Five-layer coextrusion plastic pipe forming die

A pipe forming and co-extrusion technology, which is applied in the field of plastic forming molds, can solve the problems that it is difficult to continue to plasticize the wall thickness of the pipe billet, and the problems such as confluence lines and unevenness will be generated, so as to achieve uniform thickness without eccentricity, uniform distribution and good effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

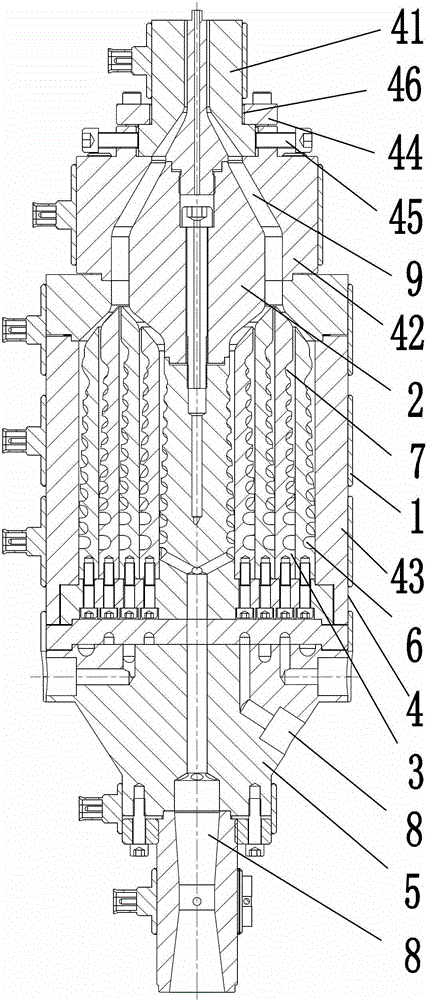

[0018] as attached figure 1 Shown: a five-layer co-extruded plastic pipe forming mold, including a core mold 2, four sleeve molds 3 coaxially sleeved outside the lower part of the mold core, an outer mold 4 sleeved outside the core mold 2 and sleeve mold 3, and a shunt Device 5 and heating device.

[0019] The outer circumference of the lower part of the mandrel 2 and the outer circumference of the sleeve mold 3 both have one or more spiral grooves 6 and a choke ring 7 communicating with the upper end of the helical groove 6, the depth of the choke ring 7 is greater than that of the helical groove 6 The thread depth; the shape of the outer circumference of the spiral groove 6 of the mandrel 2 and the cover mold 3 is a truncated cone shape with a large end at the lower end; the thread depth of the lower end of the spiral groove 6 is greater than the thread depth of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com