Dust-laden flue gas classification purification waste heat recovery system and dedusting heat storage and exchange device

A waste heat recovery system and heat exchange device technology, applied in indirect heat exchangers, separation methods, gas treatment, etc., can solve the problems of complex production and processing, unfavorable heat transfer, long production cycle, etc., and achieve reasonable structural design and increase Disturbance of flue gas flow, expansion of heat exchange area, and reduction of heat pipe wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

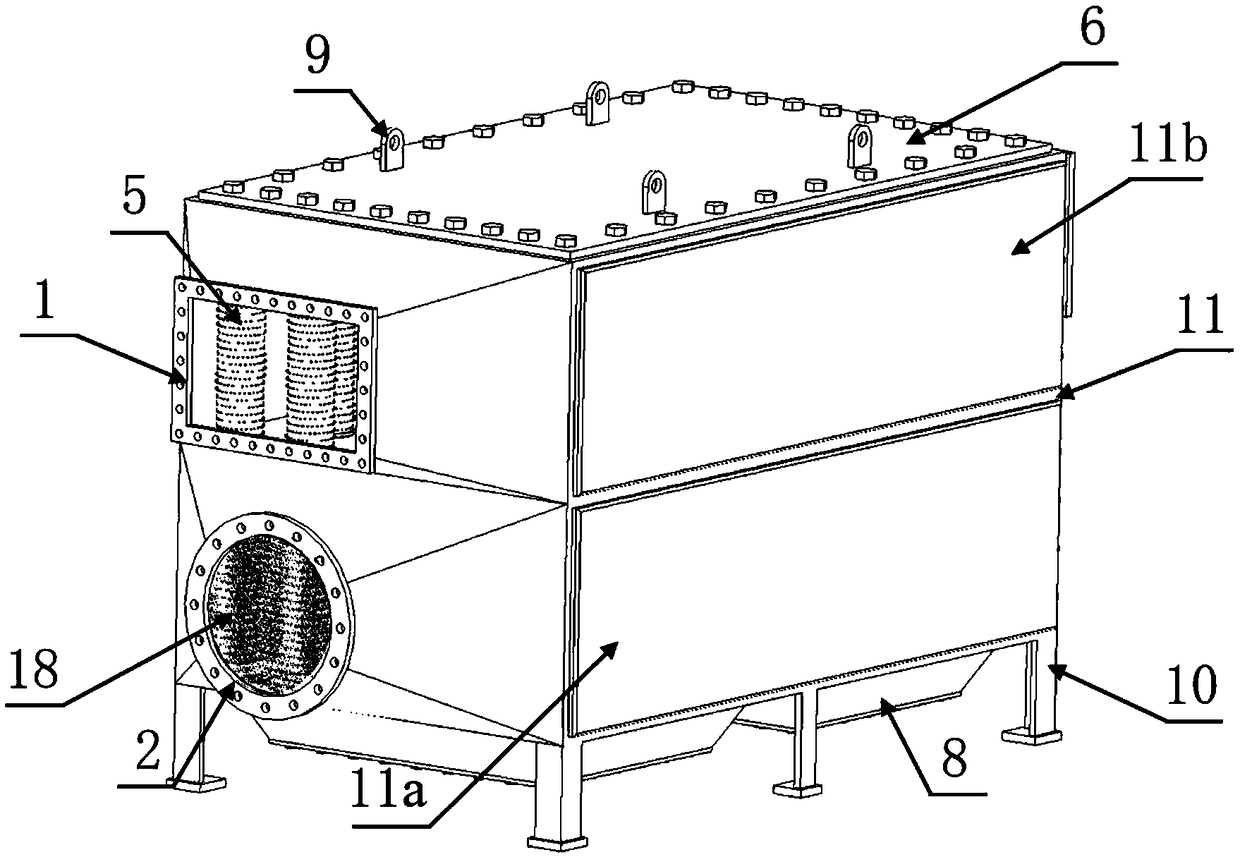

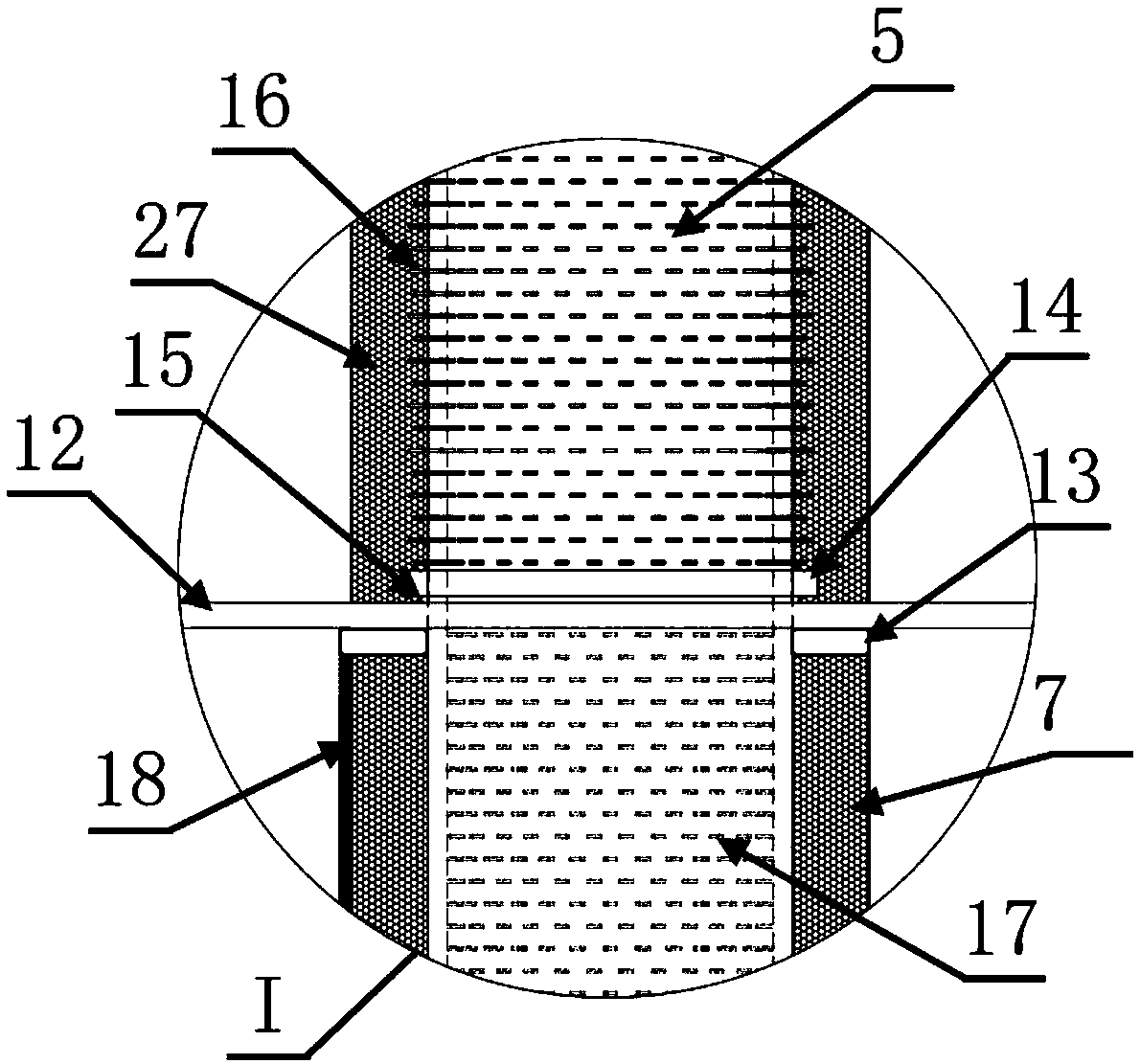

[0033] Embodiment 1: see Figure 1 to Figure 6, a waste heat recovery system for classification and purification of dusty flue gas, comprising a housing 11, the housing 11 is a hollow cuboid structure, a partition 12 is arranged in the middle of the housing 11, and the partition 12 separates the housing 11 into There are two upper and lower chambers, the lower chamber is the flue gas channel 11a, and the upper chamber is the cooling working medium channel 11b; the left end of the flue gas channel 11a is provided with a flue gas inlet 2, and the right end is provided with a flue gas outlet 4, The lower end is provided with a step-shaped dust removal port 8; the left end of the cooling medium channel 11b is provided with a cooling medium outlet 1, and the right end is provided with a first cooling medium inlet 3; Heat exchange device and ash cleaner 28; the dust removal and storage heat exchange device is composed of several dust removal and storage heat exchange units arranged ...

Embodiment 2

[0046] Embodiment 2: A dust-removing storage heat-exchange device used in a waste heat recovery system for classification and purification of dust-laden flue gas. Unit composition; the dust removal storage heat exchange unit includes a metal foam block 7, a filter screen 18 and several three-dimensional fin heat pipes 5; the three-dimensional fin heat pipes 5 are arranged side by side in the longitudinal direction, and each three-dimensional fin heat pipe 5 is inserted into the foam metal block 7 In the middle; the outside of the left end of the metal foam block 7 is provided with a stainless steel filter screen 18; the upper end of the three-dimensional rib heat pipe 5 passes through the partition plate 12 and enters the cooling medium channel 11b, and extends upwards as the heat pipe condensation section 20; The three-dimensional rib heat pipe 5 in the flue gas channel 11a is used as the heat pipe evaporation section 20; the inside of the three-dimensional rib heat pipe 5 is ...

Embodiment 3

[0054] Example 3, the method of using the waste heat recovery system for the classified purification of dusty flue gas to recover the waste heat of dusty flue gas is as follows: industrial dusty flue gas flows into the flue gas channel from the flue gas inlet 2, and flows through the first stage dust removal storage In the heat exchange unit, the fly ash particles with larger particle size are removed by the large-pore filter screen and the metal foam block, and the flue gas transfers heat to the metal foam block with large specific heat capacity and the three-dimensional rib heat pipe. Afterwards, the flue gas passes through the multi-stage dust removal and storage heat exchange unit successively, and the fly ash particles in the flue gas are removed by the filters 18 of each level and the metal foam block, and the waste heat of the flue gas is evaporated and absorbed by the working fluid in the evaporation section of the heat pipe, and finally The purified low-temperature flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com