Auxiliary pressurizing reheating type compressed air energy storage system and method based on double-well structure hot salt well

A technology of compressed air energy storage and well structure, applied in the field of physical energy storage, can solve the problems of no investment value of the energy storage system, low efficiency of the energy storage system, peak shaving and valley filling of the power grid, etc., so as to improve the use efficiency and energy storage. System efficiency, the effect of reducing energy storage and energy consumption and loss, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

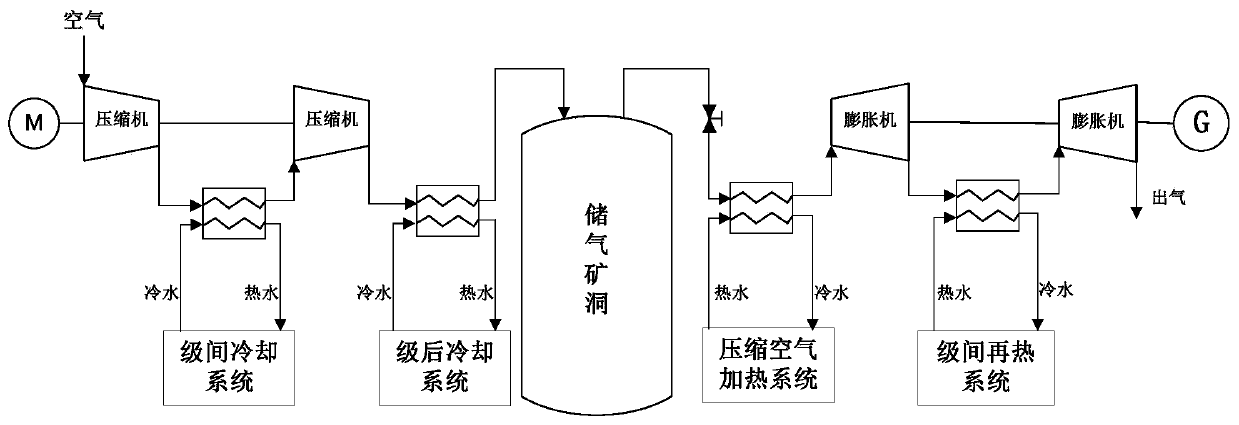

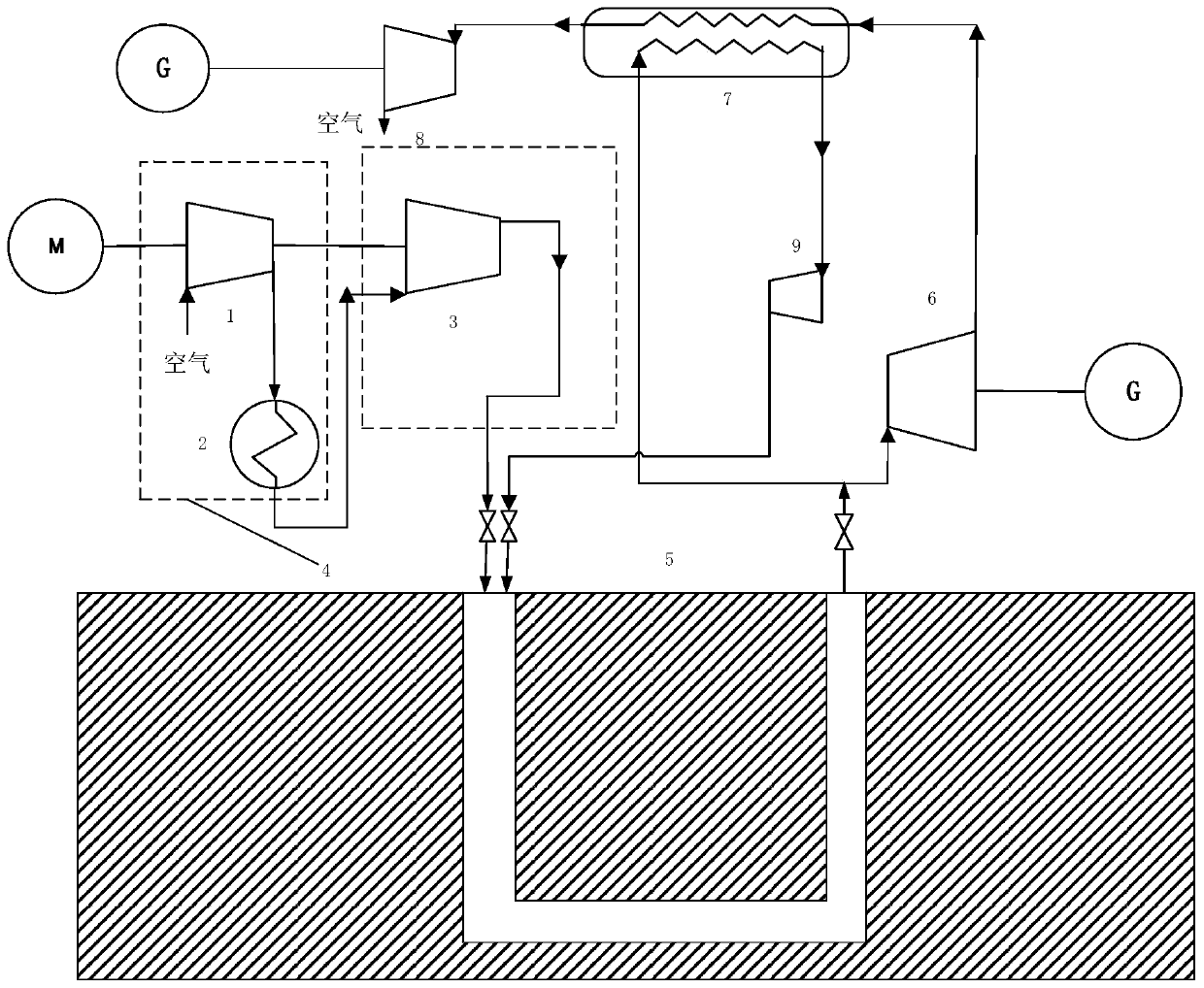

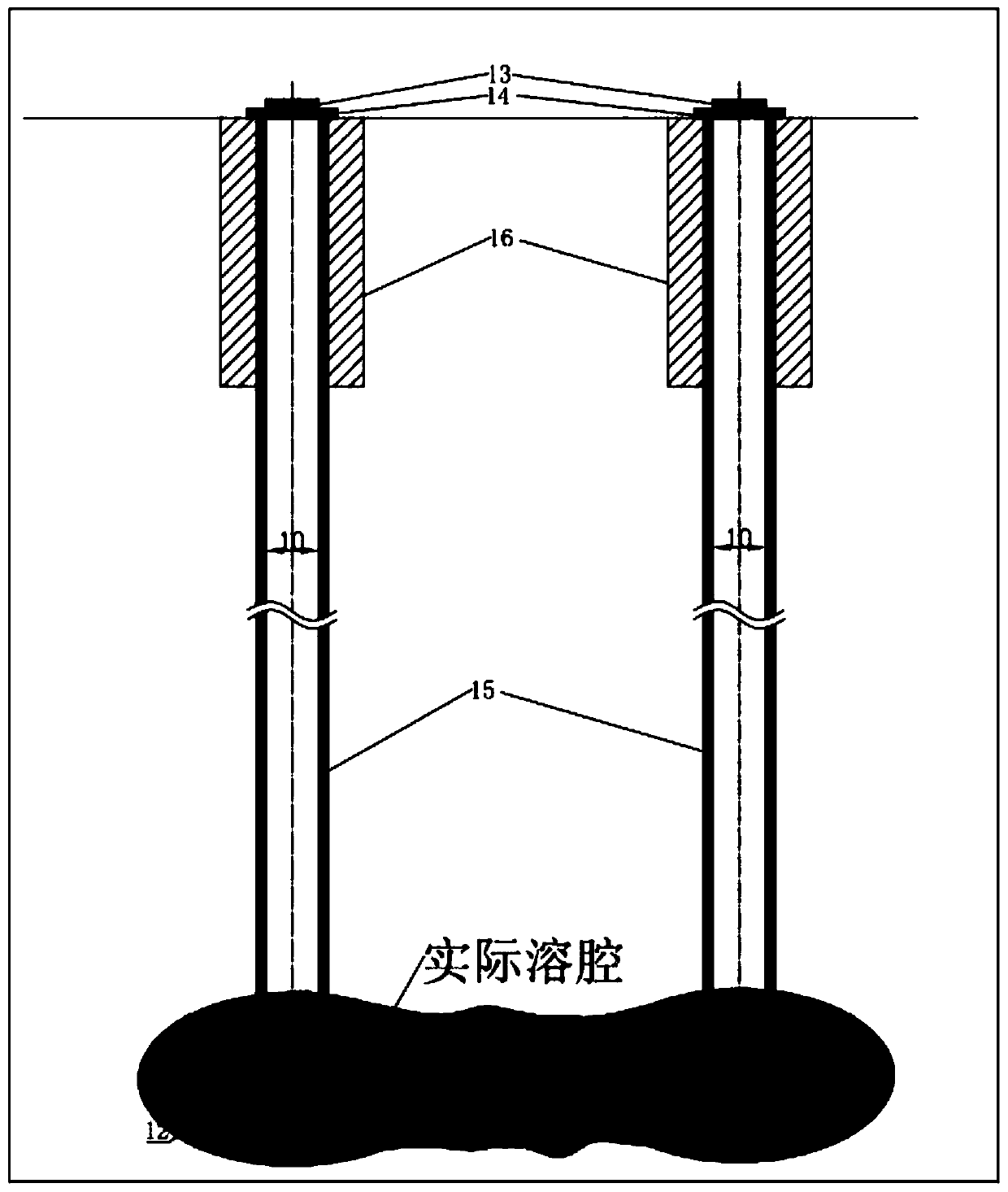

[0045] The present invention is based on the auxiliary pressurization and reheating compressed air energy storage system of hot salt wells with double well structure, including a compressor connected to a motor M through a coupling, a water pump, and several expanders connected to a generator G; wherein, the low-pressure compressor The section is provided with a cooler 2, and the high-pressure compression section adopts a circulation compression device 3, and the exhaust port of the circulation compression device 3 is connected with the entrance of the underground salt well 5; Primary power generation; the airflow from the high-pressure expander 6 passes through the heat exchanger 7 and then enters the low-pressure expander 8 to expand and perform work for secondary power generation; the outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com