Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

83results about How to "Reduce weaving cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Raschel blanket and production method thereof

InactiveCN101476209AReduce weaving costIncrease productivityWarp knittingHeating/cooling textile fabricsYarnSingle fibre

The invention provides a raschel carpet and a producing method thereof which relates to a raschel carpet produced by a single neilbed tricot machine that terylene is used as raw material. The method includes steps as follows: using 83-333dtex terylene low elastic net yarn as a felted yarn raw material and 56-111dtex terylene FDY as a bottom yarn for knitting on a weft knitting fur machine, thermal finalization; fluffing on front; terylene dyeing or printing; post treatment and front lustre finishing; shearing; reverse surface fluffing; and thermal finalization. The carpet is knitted by using the single neilbed tricot machine and the produced grey cloth needs not slitting that lead to increase productive efficiency greatly and reduce knitting cost. The felted head yarn of the knitted grey cloth is an extensive yarn, fibre in the yarn is fully washed into single fibre state in post treatment. The carpet provided by the invention has characteristics of super soft, filling power, better warmth retention property and exquisite style.

Owner:TAICANG SHUMEITE TEXTILE

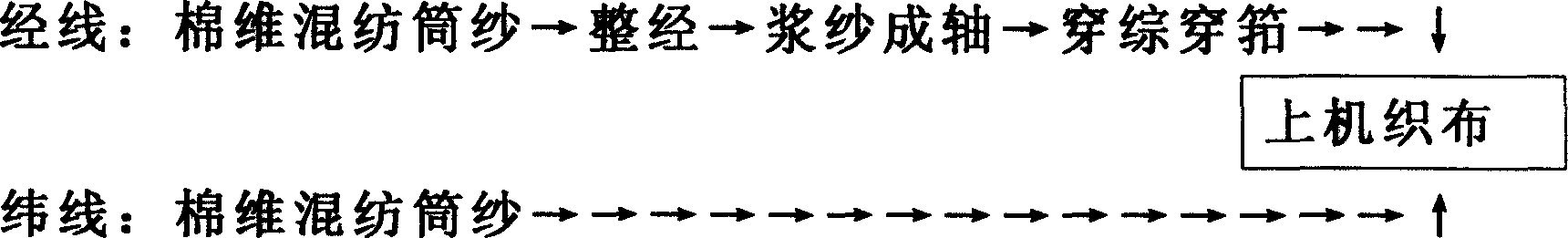

Cotton fiber fabric and manufacture technology thereof

The invention relates to a cotton textile and relative production, wherein it is characterized in that: its transverse line and longitudinal line use the cotton yarn mixed by cotton fiber and soluble vinylon fiber, while the mass between them is 70-85:15-30; and the production comprises: spinning the cotton yarn, warping, sizing, drying, spinning blank cloth, and following treatment. The inventive product is flexible, with wet adsorption, and high yield.

Owner:马伟华

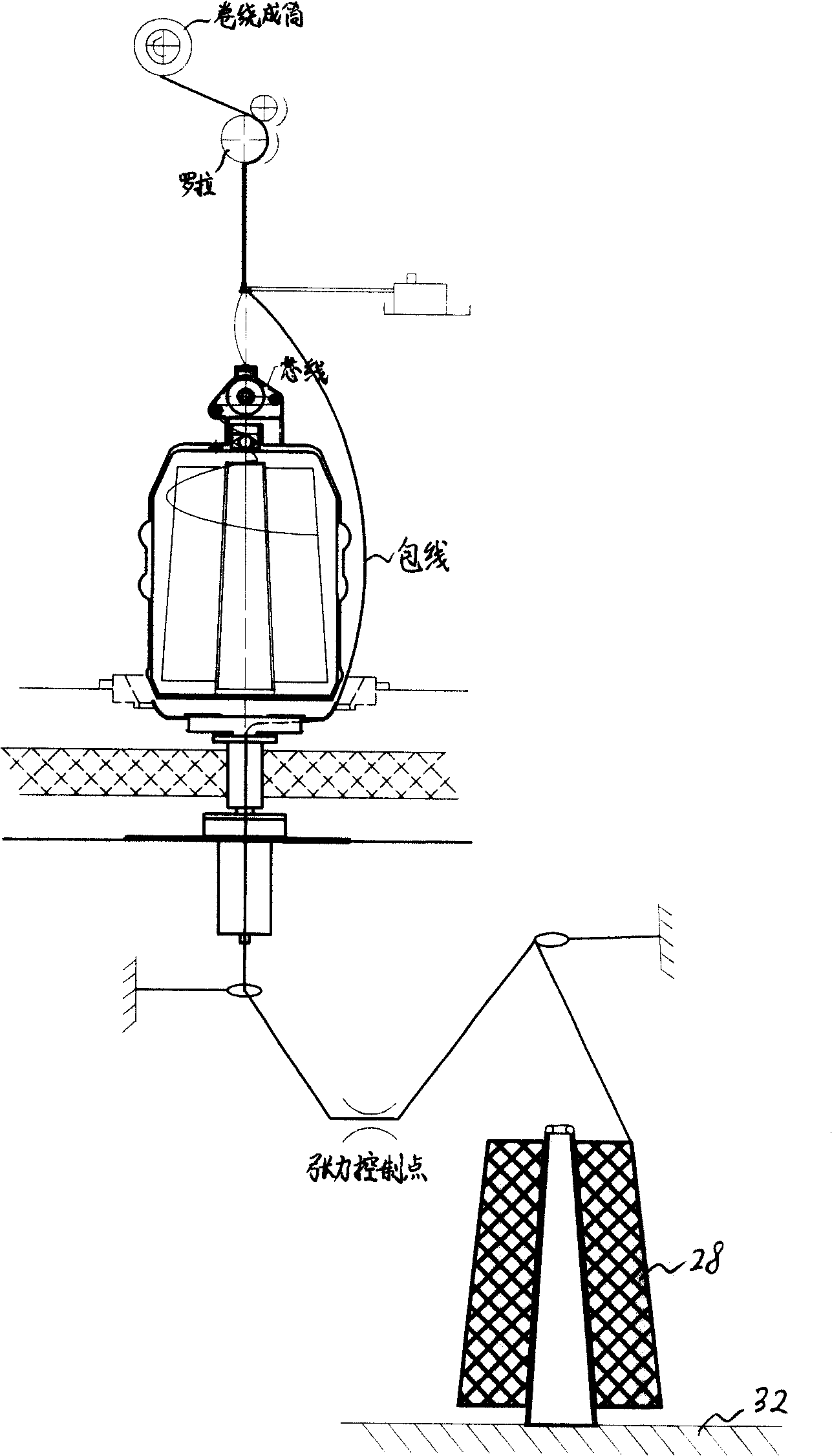

Direct twisting type twisting technique

The invention discloses a direct twisting technique which is applicable to industrialized direct twisting of combination twisting, in particular to the direct twisting of fine denier yarns of embroidery thread, nylon, polyester, rayon and sewing thread. The procedures of the invention are that: on a twisting machine, a first tube of yarn is directly up-drawn; a second tube of the yarn driven by a spindle rotates around the first tube; two tubes of the yarns are twisted together at the circumrotation finial; the yarns are wound into finished products of core-spun yarns. After being stranded by the direct twisting technique, the single yarn has no twist, thereby the strain of the two strings of silk can be easily controlled to obtain satisfying strength.

Owner:北京市文化科技融资租赁股份有限公司

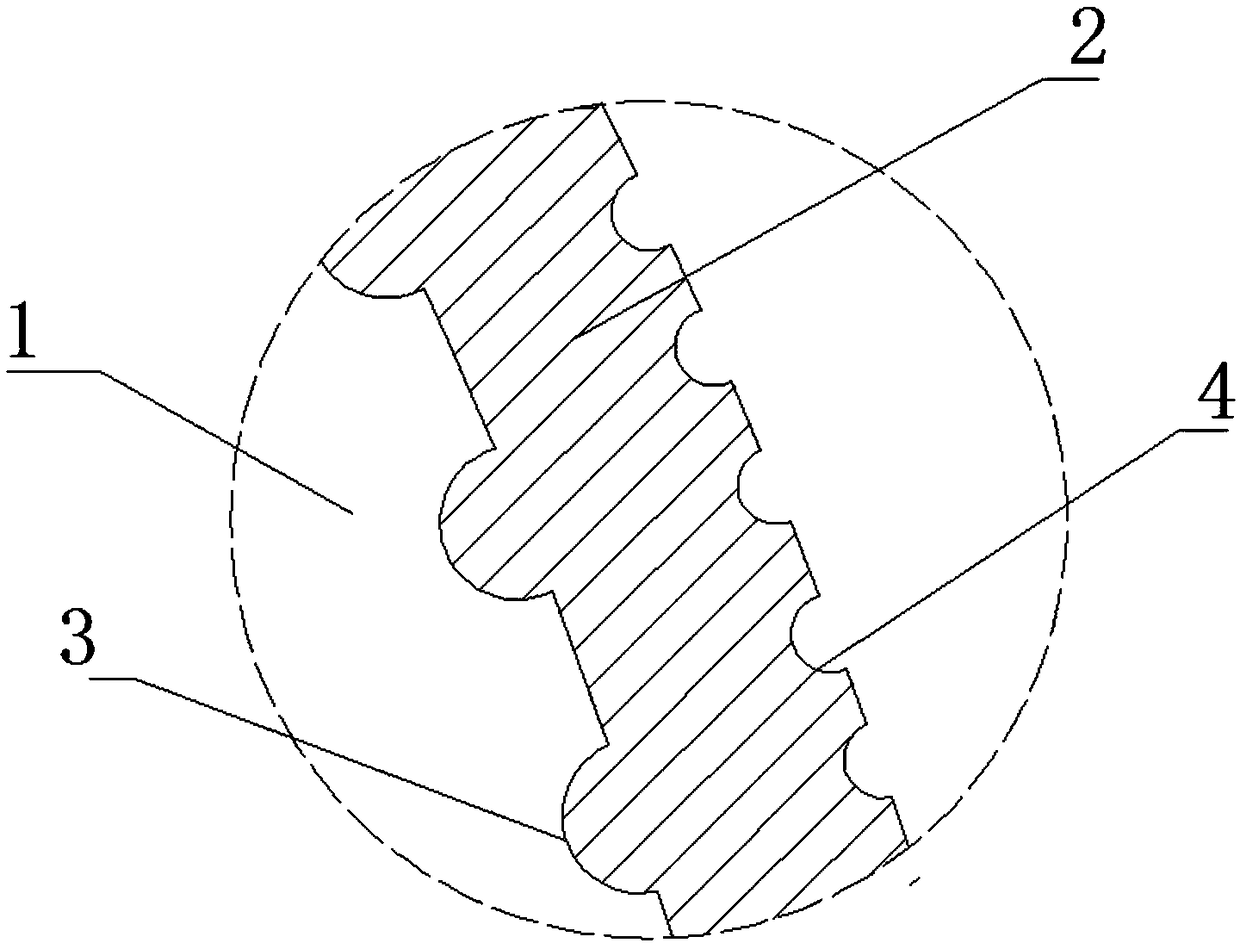

Gear with texturing coating

ActiveCN109236982AEnhanced resistance to peelingImprove damage effectPortable liftingGear lubrication/coolingCoated surfaceMechanical wear

The invention provides a gear with a texturing coating, and relates to the technical field of mechanical transmission. The gear comprises a gear body and a coating adhering to the gear body, multiplefirst micro pits are uniformly distributed on the surface of the gear body, multiple texturing regions are distributed on the surface of the coating, and each texturing region comprises multiple second micro pits. The gear with the texturing coating is prepared by a processing method which comprises the steps that one, the first micro pits are processed on the gear to obtain a texturing gear; two,the surface of the texturing gear is coated with the coating to obtain a coating gear; three, the second micro pits are processed on the surface of the texturing coating gear to obtain a gear with atexturing coating. According to the gear with the texturing coating, the friction abrasion of the surface of the gear is reduced by part of the texturing coating, and the mechanical wear resisting performance and service life of the gear with the texturing coating are improved.

Owner:XIAMEN UNIV OF TECH

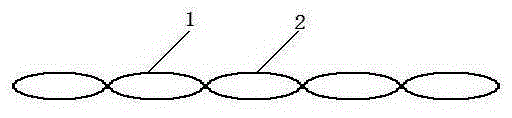

Composite filaments of dacron positive ion dyeable filaments and common dacron filaments

InactiveCN105297227AReduce weaving costThe color effect is natural and gorgeousYarnChemistryFilament yarn

The invention discloses composite filaments of dacron positive ion dyeable filaments and common dacron filaments. The composite filaments are constituted by the dacron positive ion dyeable filaments and the common dacron filaments, wherein each dacron positive ion dyeable filament is a 55dtex / 72f positive ion dyeable dacron total draft filament, each common dacron filament is a 90 dtex / 72f common POY composite modified filament, a strand of the dacron positive ion dyeable filaments and a strand of the common dacron filaments are adopted, the strand of common dacron filaments are fed into a first roller of a draw-textured-yarn machine and subjected to thermal stretch, false twist deformation and formation, then the strand of dacron positive ion dyeable filaments are fed through a zero-roller of a false twist deformation draw-textured-yarn machine and subjected to false twist deformation through a filament guiding device, and the two strands of filaments are combined in front of a third roller of the draw-textured-yarn machine and then enter a jet nozzle for being twined and composited into the composite filaments.

Owner:TAIXIN CHEM FIBER CHINA CO LTD

Method for producing multiaxial mixed braided fabric

The invention discloses a method for producing multiaxial mixed braided fabric. The method includes the steps that first, zero-degree warps of the first layer are prepared; second, zero-degree warps of the second layer to zero-degree warps of the N layer are prepared, wherein N is a natural number and is larger than or equal to two; third, wefts of the (N+1) layer to wefts of the (N+N) layer are prepared, wherein the angle between any layer of the wefts and a workbench of a warp knitting machine ranges from -90 degrees to +90 degrees, and the wefts at the same angle have one or more layers and are made of the same material or different materials; fourth, bundling lines are prepared; fifth, the materials prepared from the first step to the fourth step are laid down and mixed, so that the multiaxial mixed braided fabric is obtained; sixth, cutting and winding are carried out. By the adoption of the method, uniform distribution and thickness consistency of fibers in all areas of the mixed braided fabric can be guaranteed, composite material performance and cost designability can be achieved, and production cost is lowered.

Owner:NEWTRY COMPOSITE

Plisse crepe lattice fabric production technology

ActiveCN107488927ASolve the impossible to weave puzzleReduce weaving costHeating/cooling textile fabricsDry-cleaning apparatus for textilesEngineeringDyeing

The invention discloses a plisse crepe lattice fabric production technology which is characterized by comprising the following steps: evenly winding first warps and second warps on a warp beam through a warping technology, wherein warps include the first warps and the second warps, and the first warps and the second warps have different warp tensions; utilizing a single warp beam weaving technology to weave gray fabric of the plisse crepe lattice fabric; finishing through a later dyeing and finishing technology to enable the shell fabric to not only form grid shape distribution Plisse crepe lattice fabric with a unique style, but also have good all-side stretch touch of shell fabric. According to the seersucker grid shell fabric production technology disclosed by the invention, the technologies of warping, re-beaming, weaving, desizing, scouring, bleaching and the like are innovated, so that the problem that single warp beam weaving cannot weave plisse crepe is solved.

Owner:CHINA TEXTILE ACAD JIANGNAN BRANCH

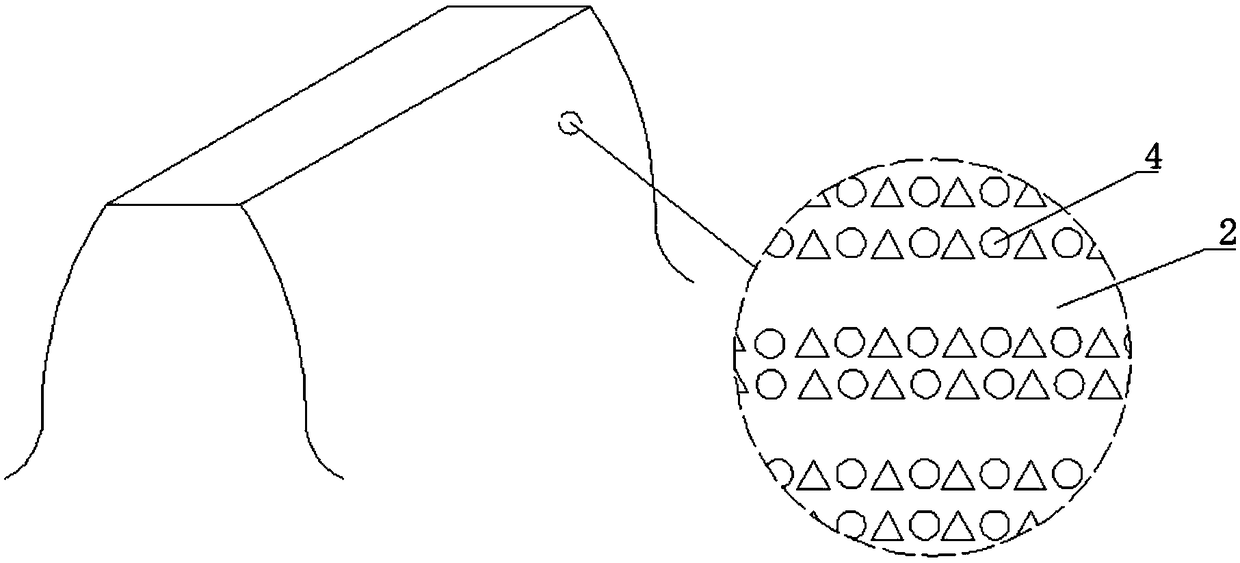

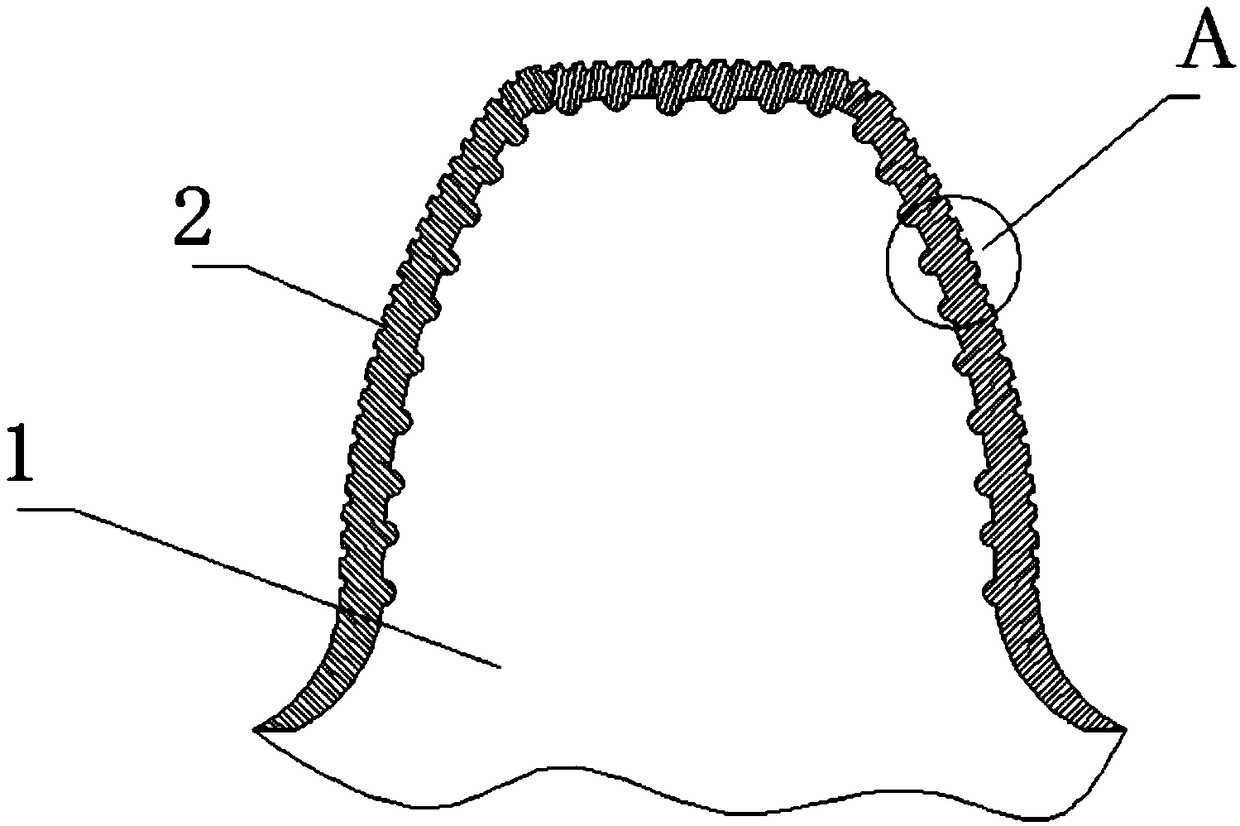

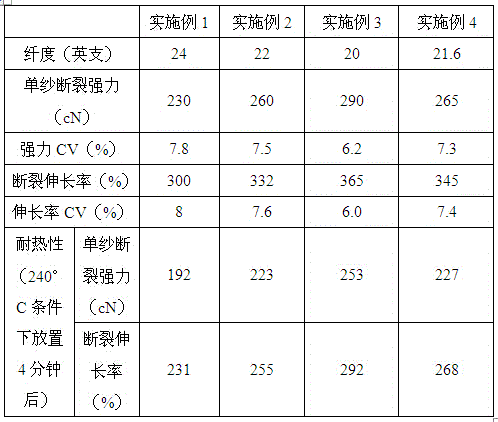

Integral annular three-dimensional fabric and weaving method thereof

The invention discloses an integral annular three-dimensional fabric and a weaving method thereof. The fabric is in a completely integral three-dimensional yarn interweaving structure, and is not laminated or lapped; the yarns inside an xoy plane where the annular direction and the radial direction of the fabric are positioned and the yarns in z direction are all in the states of extension, wherein the yarns inside the xoy plane can be orientated at any angle according to design requirements, and no interweaving point is formed among each layer of yarns; the yarns in z direction are vertical to the yarns inside the xoy plane, and are interweaved with the yarns inside the xoy plane so that each layer of yarns are restricted into an integral annular three-dimensional fabric. The weaving method comprises the following steps of: (1) designing and preplacing a steel pipe array; (2) penetrating and inserting a steel sheet; (3) threading the yarns inside the xoy plane; (4) and leading the yarns in z direction to replace all steel pipes till the integral annular three-dimensional fabric is weaved completely.

Owner:TIANJIN POLYTECHNIC UNIV

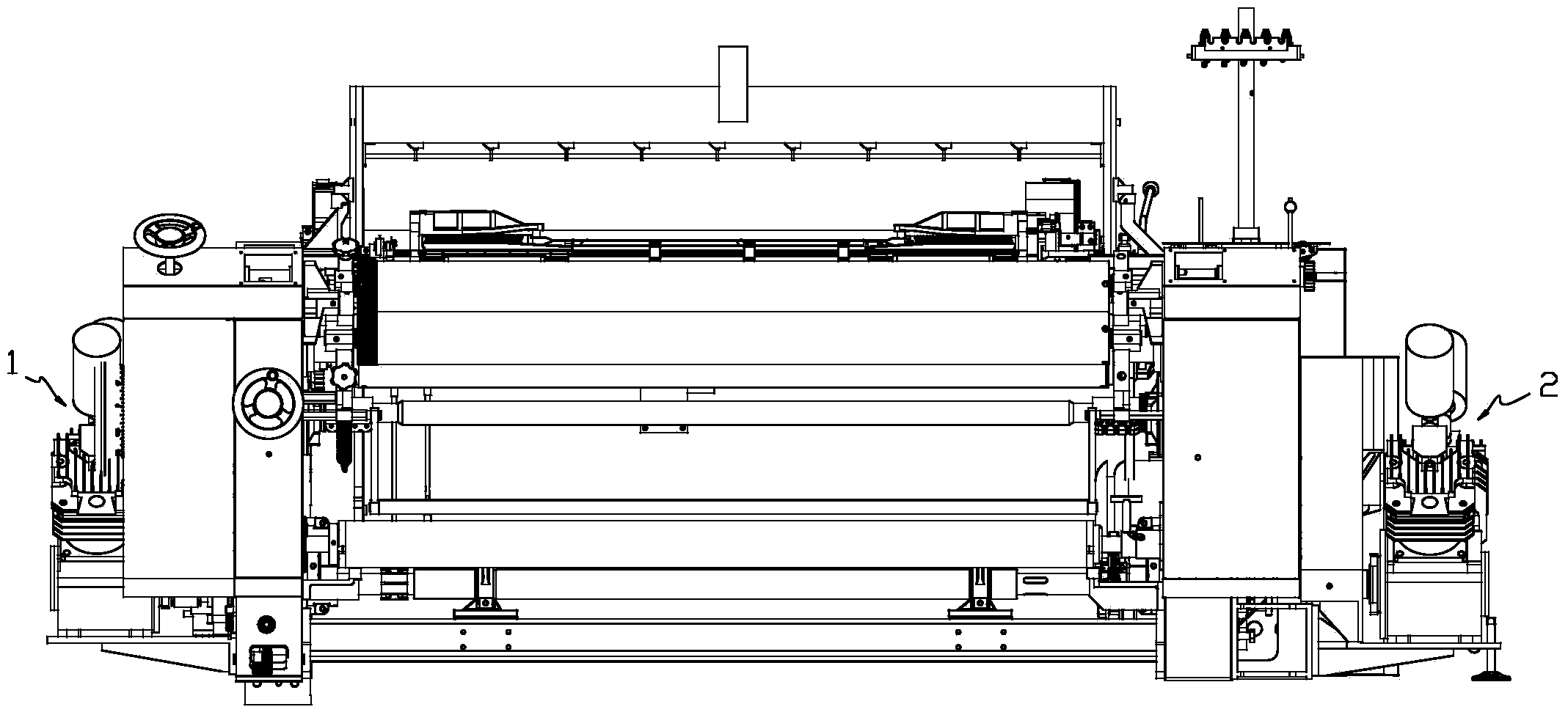

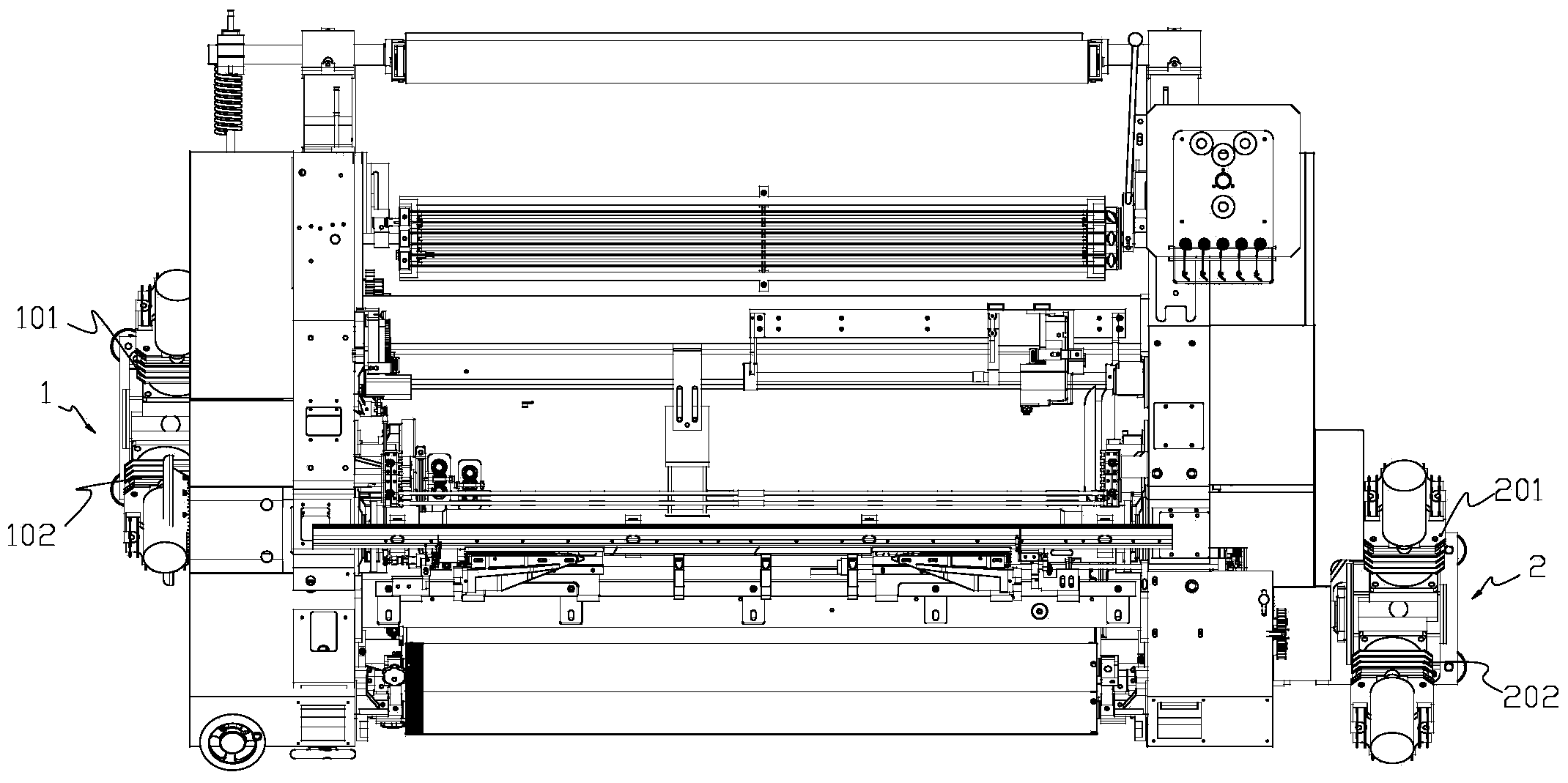

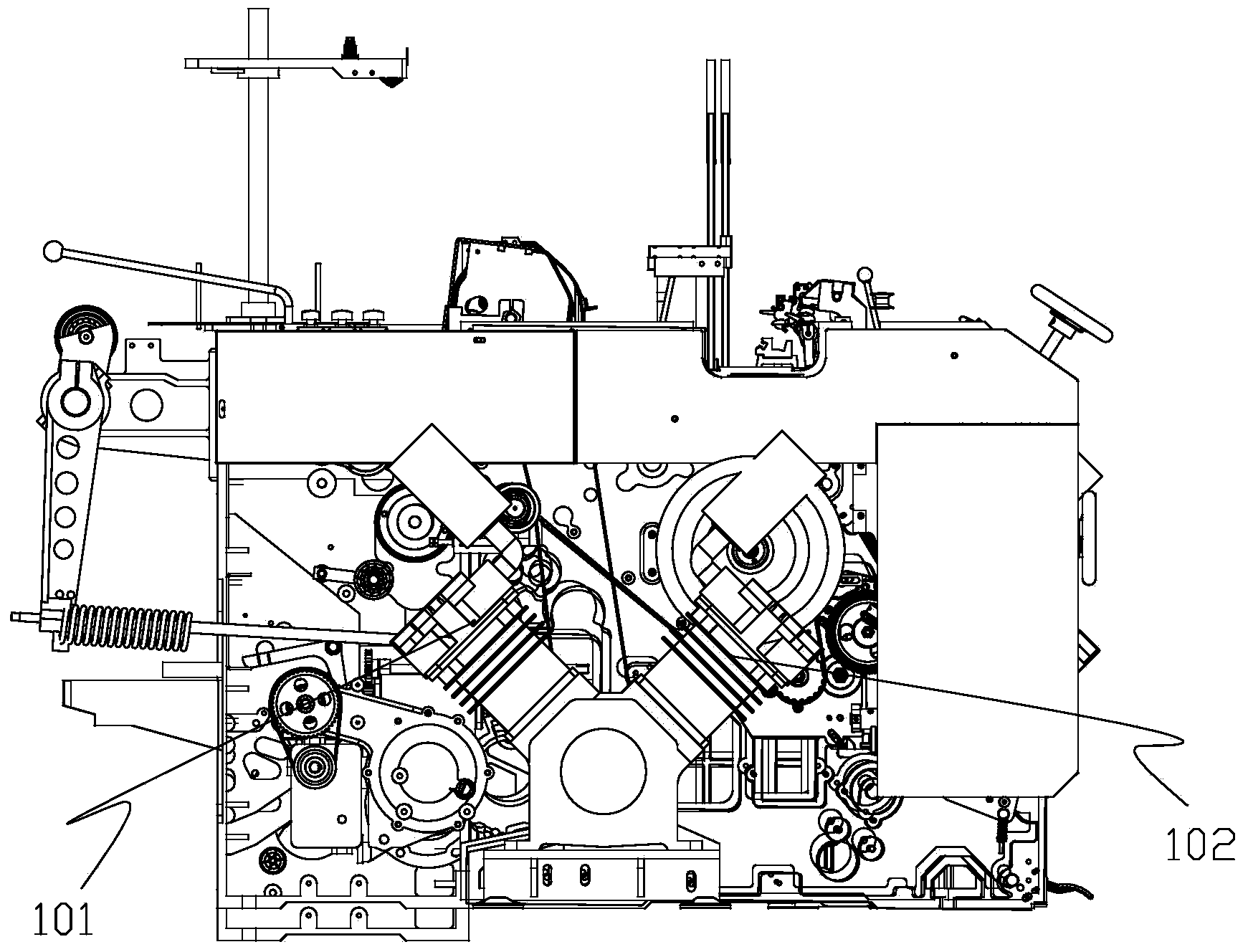

Energy-saving air-jet loom

The invention discloses an energy-saving air-jet loom comprising a frame and an air-jetting-flow weft insertion mechanism. The energy-saving air-jet loom is characterized in that the air-jetting-flow weft insertion mechanism comprises a first air pump, a main nozzle group and an auxiliary nozzle group; the main nozzle group at least comprises one main nozzle, and the auxiliary nozzle group comprises a plurality of auxiliary nozzles arrayed on weft flying lines sequentially; the first air pump is arranged on a wallboard of one side of the frame and comprises a main plunger type cylinder and an auxiliary plunger type cylinder which are connected integrally, and the piston links of the two plunger type cylinders are connected to one crankshaft which is connected to a loom power spindle; the exhausting end of the main plunger type cylinder of the first air pump is connected to the main nozzle through a pipeline, the exhausting end of the auxiliary plunger type cylinder is connected to the auxiliary nozzles in the auxiliary nozzle group through pipelines. By the aid of the energy-saving air-jet loom, weaving cost can be reduced greatly, the problems of high investment, high cost and high energy consumption of a high-grade loom can be solved; in addition, two air pumps can be adopted synchronously, relayed weft insertion can be implemented more effectively, and broad fabric weaving can be implemented.

Owner:QINGDAO TIANYI GROUP RED FLAG TEXTILE MACHINERY

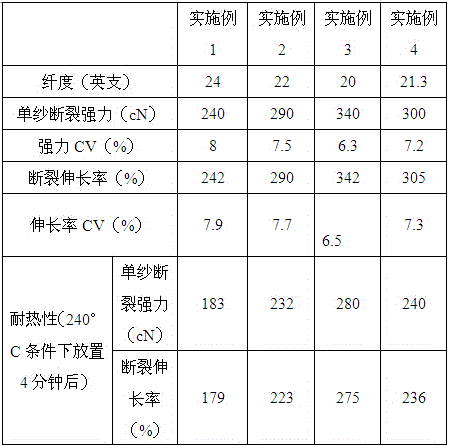

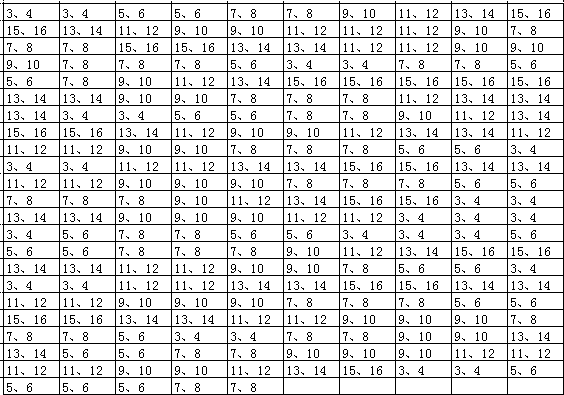

Ring-spun elastic weft yarn used for weaving tyre cord fabric and production process of ring-spun elastic weft yarn

InactiveCN106319712AImprove heat resistancePowerful smallContinuous wound-up machinesYarnBreaking strengthHeat resistance

The invention provides a ring-spun elastic weft yarn used for weaving tyre cord fabric. Fineness of the elastic weft yarn is 22+ / 2 English count. The invention further provides a production process of the ring-spun elastic weft yarn used for weaving tyre cord fabric, wherein the production process comprises the following step: feeding a PA66 undrawn yarn with fineness being 180 + / - 20 dtex. The elastic yarn prepared by the production process has fineness being 22+ / 2 English count, single yarn breaking strength being 290 + / -50 cN, strength CV smaller than 8%, breaking elongation being 290 + / -50%, and elongation CV smaller than 8%. The elastic weft yarn prepared by the production process is good in heat resistance, and strength and extendability loss of the elastic weft yarn is small in thermal treatment processes such as fabric glue impregnation; when the elastic weft yarn prepared by the production process is used for weaving tyre cord fabric, weaving efficiency is high and weft stoppage is less when a jet weaving machine is adopted; and weft stoppage is controlled to be less than 5 times on 0.1 million wefts.

Owner:山东合信科技股份有限公司

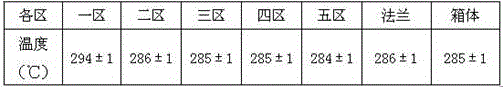

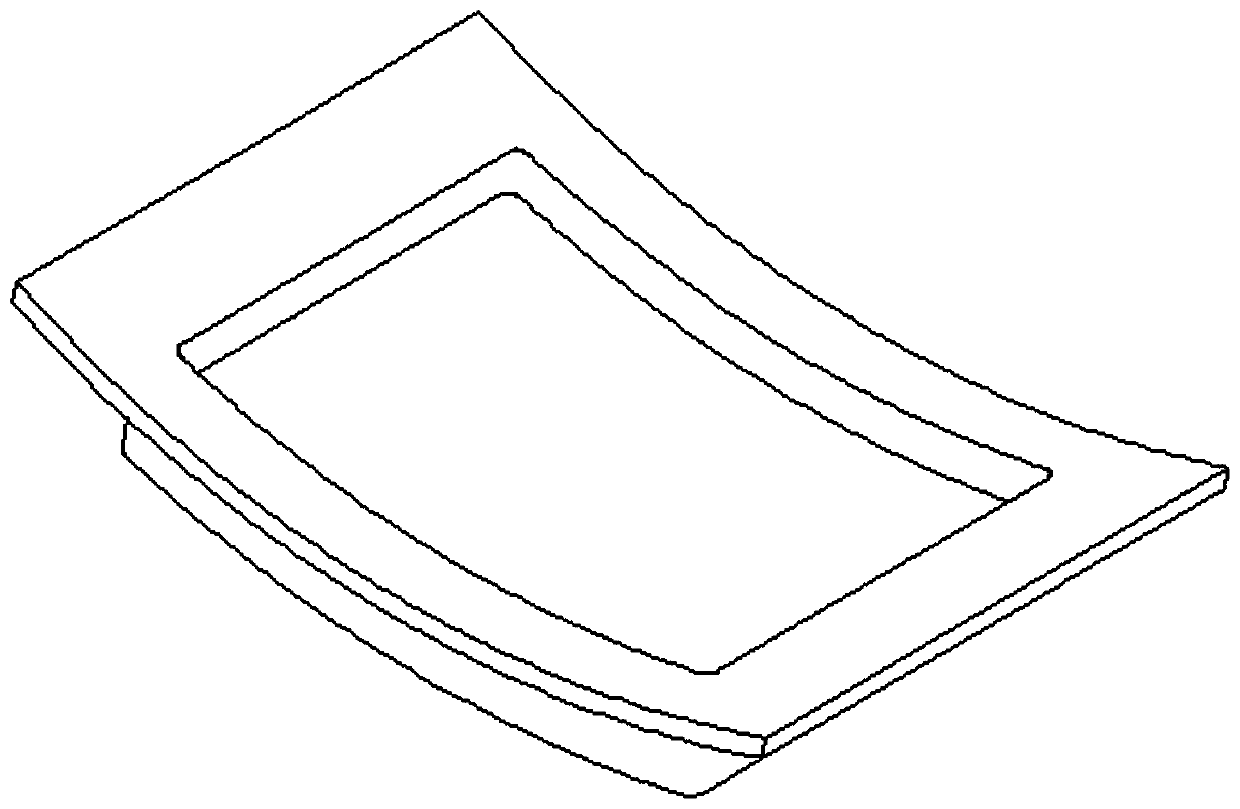

Rapid molding method for special-shaped quartz composite ceramic wave-transmission antenna window

The invention discloses a rapid molding method for a special-shaped quartz composite ceramic wave-transmission antenna window. The method comprises the following steps: 1, removing an impregnating agent at the surfaces of quartz fibers by adopting a combination mode of water steam cooking and oxygen-introducing heat treatment; 2, performing surface treatment on the pre-treated quartz fiber cloth in a silica sol with a low solid content, and performing cutting to obtain a fiber cloth having an equivalent area of 5-100 mm<2>; 3, immersing the fiber cloth piece in a silica sol with a high solid content, performing spreading on a special pressure molding tool, performing pressure molding, performing curing, and performing demoulding; and 4, immersing the pressed blank in a silica sol once, and performing heat treatment at 850 DEG C; and performing processing according to requirements to obtain a design size. The method provided by the invention can realize rapid molding, and has high efficiency, low process costs and uniform materials.

Owner:湖北三江航天江北机械工程有限公司

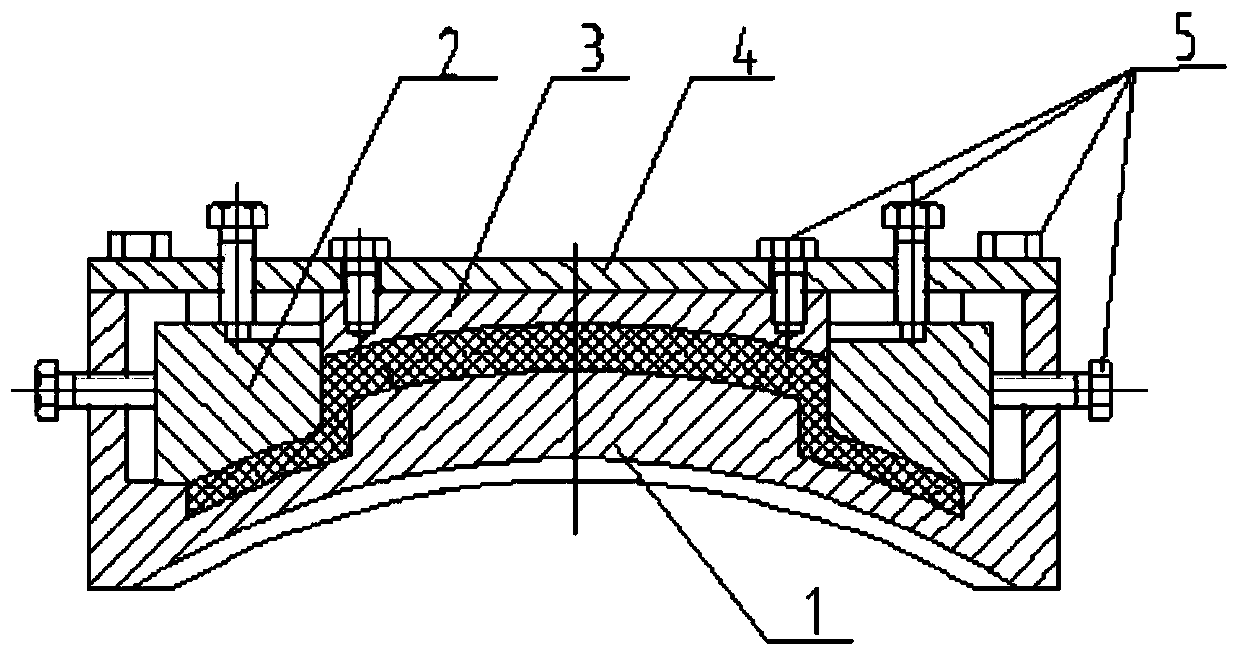

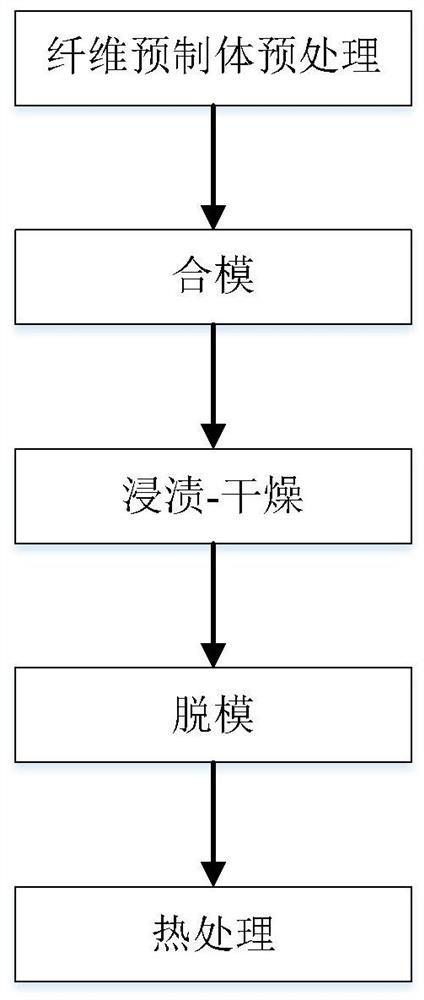

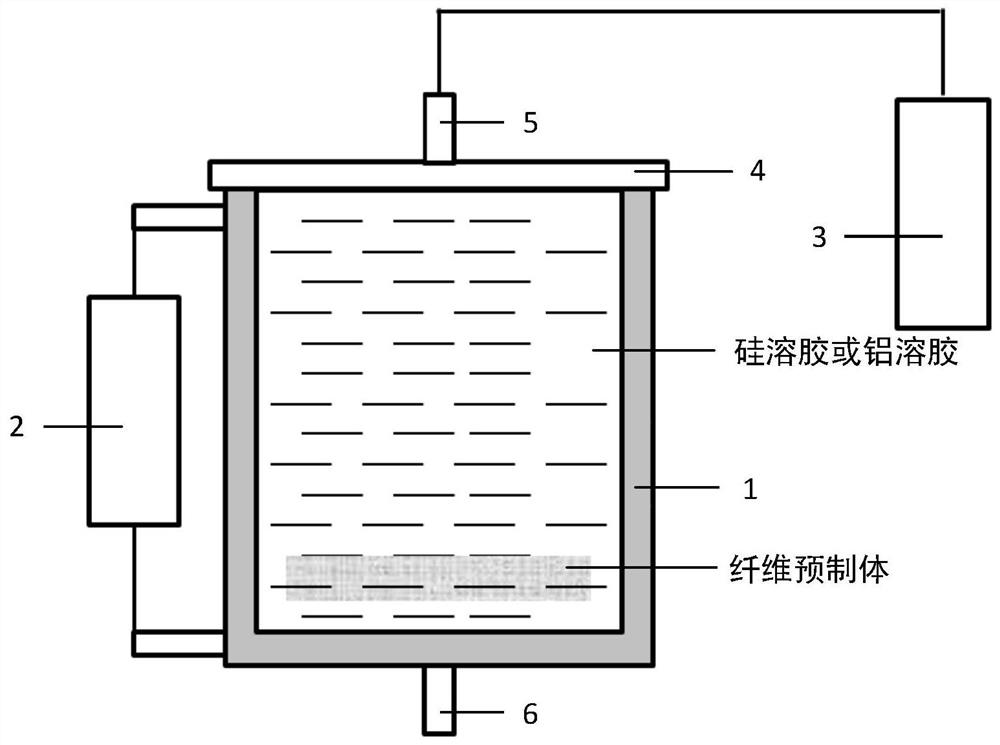

Forming method of fiber-reinforced silicon dioxide ceramic composite material

PendingCN113788695AReduce the impact of uniformityImprove impregnation efficiencyDischarging arrangementCeramic compositeMold removal

The invention discloses a forming method of a fiber-reinforced silicon dioxide ceramic composite material, and relates to the technical field of fiber-reinforced silicon dioxide ceramic composites. A vacuum impregnation-drying integrated forming device is utilized, the fiber-reinforced silicon dioxide ceramic composite material is rapidly formed at a time through the steps of fiber preform pretreatment, mold closing, impregnation-drying, demolding, heat treatment and the like. multiple mold closing and demolding processes are omitted, and the influence of manual operation on the uniformity of the composite material is reduced.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

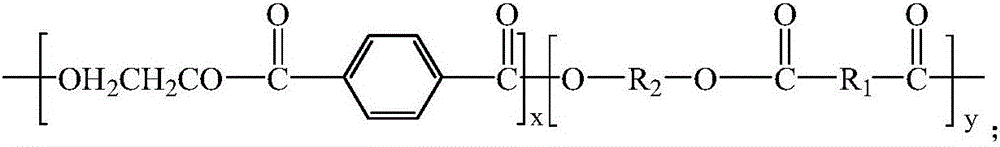

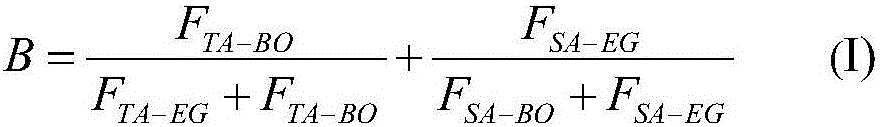

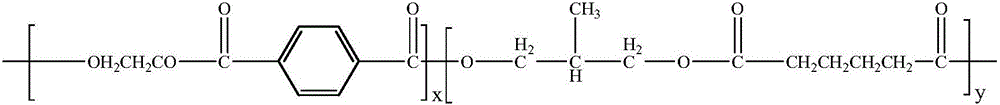

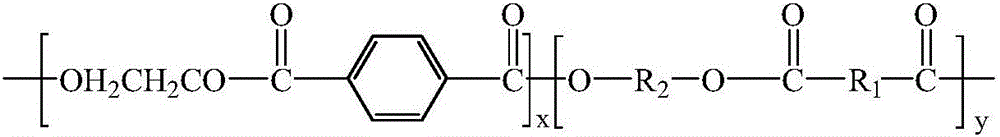

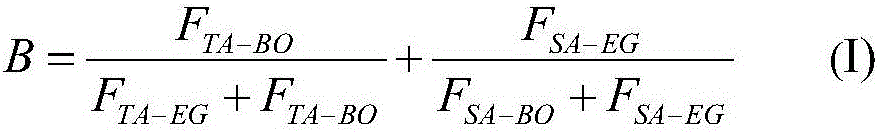

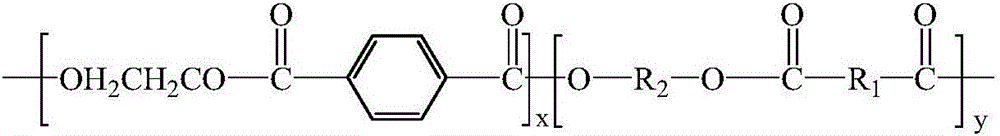

Aromatic polyester-aliphatic polyester block copolymerized ester fiber and purpose thereof

ActiveCN106592001AGood dispersionGood dimensional stabilityMonocomponent copolyesters artificial filamentYarnChemical structureDisperse dye

The invention belongs to the field of textile exploitation, and concretely relates to an aromatic polyester-aliphatic polyester block copolymerized ester fiber. The aromatic polyester-aliphatic polyester block copolyester is composed of polycondensation of an ethylene glycol terephthalate oligomer and fatty group polydiacid dihydric alcohol ester polyol through polycondensation, a chemical structure is shown as a specification, wherein, x is greater than or equal to 100, y is greater than or equal to 25, R1 is C2-C8 alkylene, R2 is C3-C8 alkylene; the randomness degree B of the aromatic polyester-aliphatic polyester block copolyester is 0.05-0.95. The aromatic polyester-aliphatic polyester block copolyester has characteristic of deep color dyeable of a disperse dye under normal pressure, has good size stability, can better mix with natural fiber such as cotton, wool and silk which cannot bear high temperature as well as elastic fiber such as spandex, and the weaving materials with excellent performance and abundant color can be obtained.

Owner:CHINESE TEXTILE ACAD +1

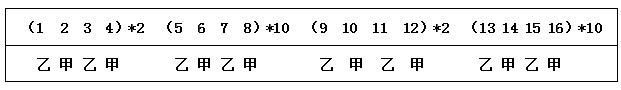

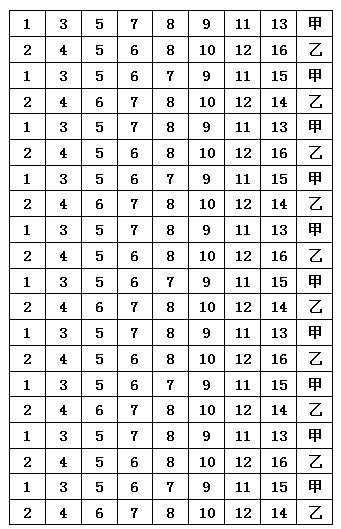

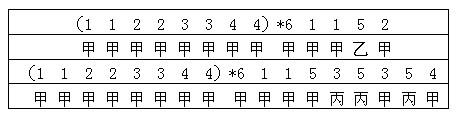

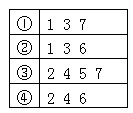

Method for flat bed knitting machine to knit yarn changing plating by single surface of technique face

ActiveCN106032604ASolve the problem of incongruity in the appearance of the structureSave man hoursWeft knittingYarnEngineering

Provided is a method for a flat bed knitting machine to knit a yarn changing plating by a single surface of a technique face. The flat bed knitting machine at least comprises a needle bed. The needle bed is provided with a plurality of latch needles and a plurality of sinkers. A machine head is above the needle bed. The method comprises: arranging a groove and a lug raised portion on the front end of the sinker; controlling the machine head to make knitting operation form a segmented narrowing process, the segmented narrowing process at least comprising a first narrowing section, a second narrowing section, and a delayed narrowing section; feeding a first color yarn and a second color yarn to the flat bed knitting machine; the sinker pushing yarns through the front edge of the lug raised portion during the second narrowing section, to knit a standard plating, and continuing using the standard plating to knit a single-surface fabric; and when the single-surface fabric is knitted to a preset position, controlling the machine head to make the knitting operation form a yarn changing narrowing process additionally, and the sinker picking yarns from joint of the rear edge of the lug raised portion and the groove during the yarn changing narrowing process, and releasing the yarns, to knit the yarn changing plating.

Owner:PAI LUNG MACHINERY MILL CO LTD

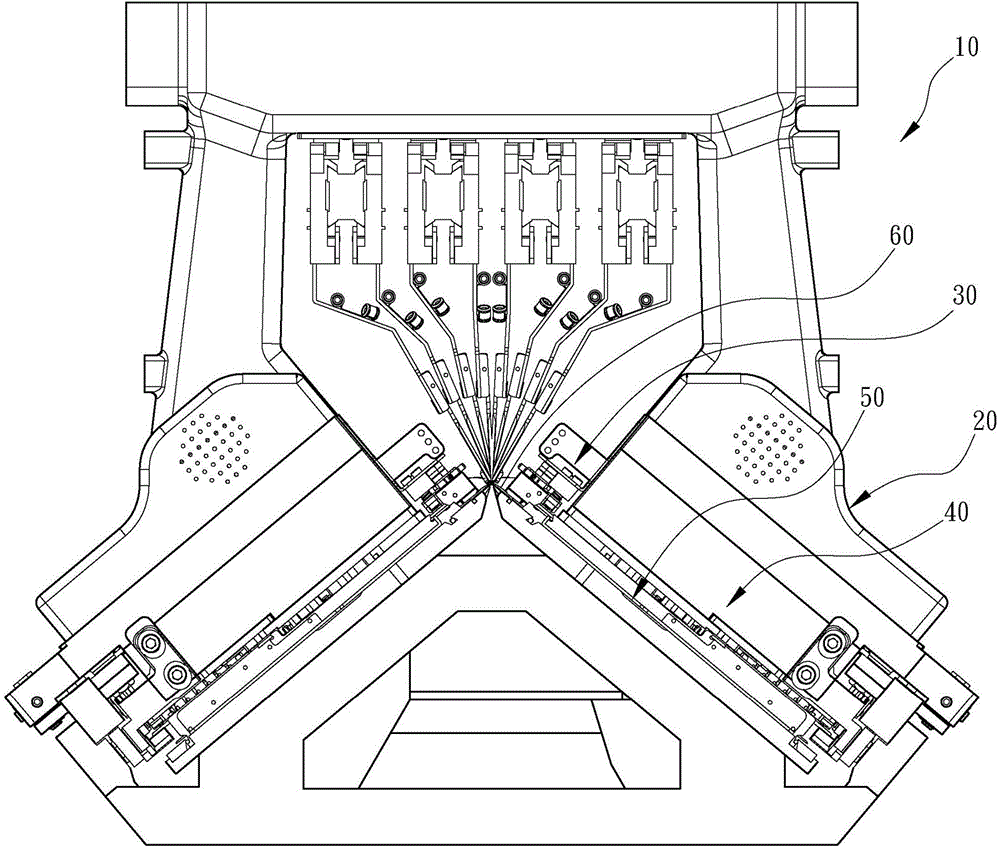

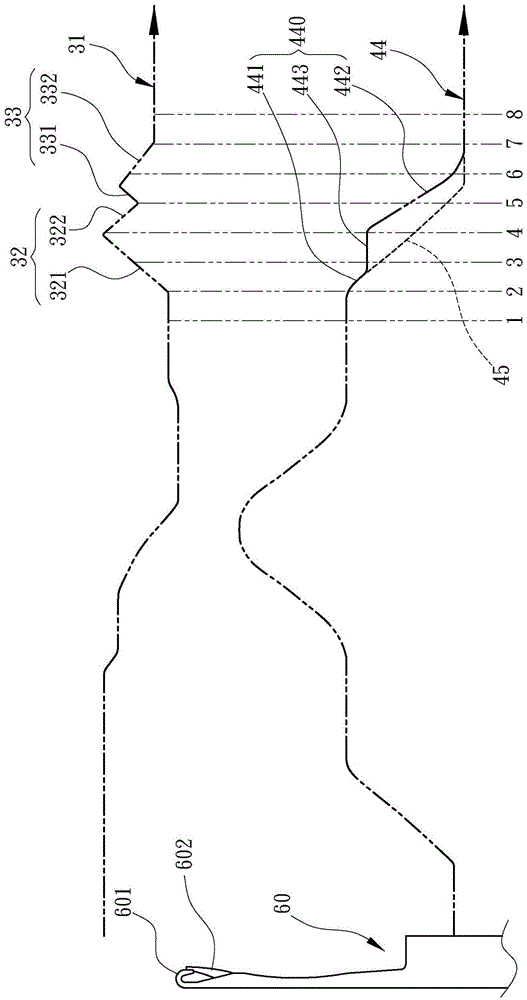

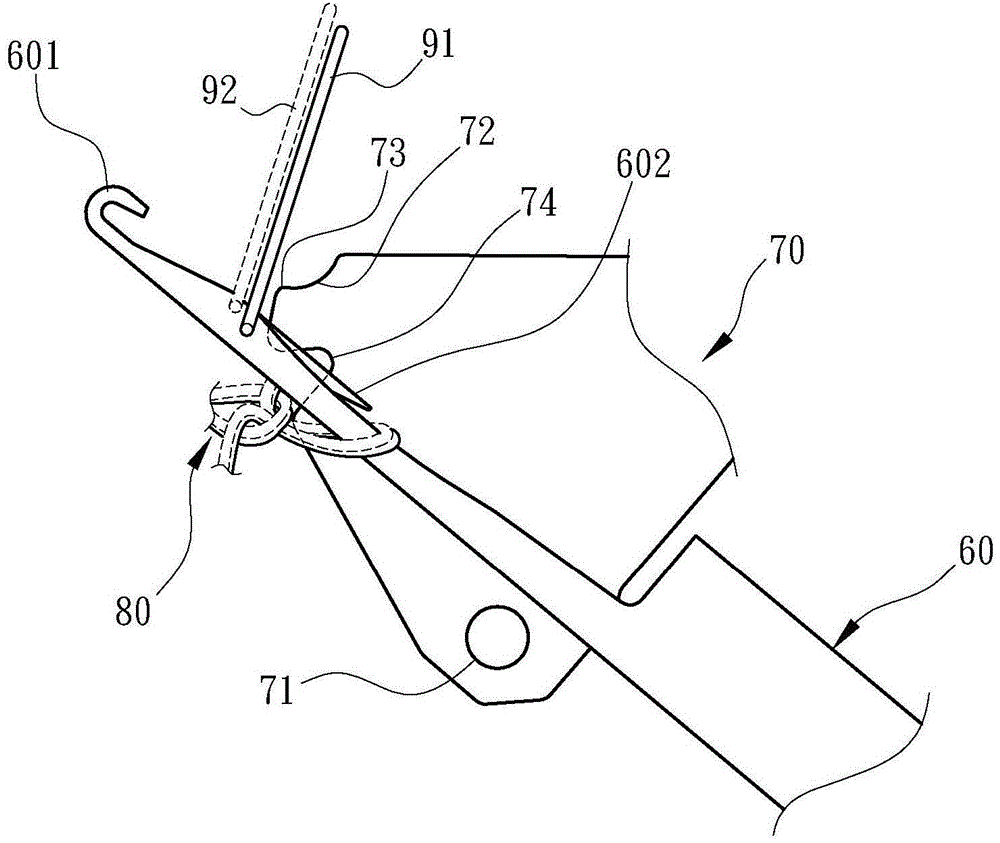

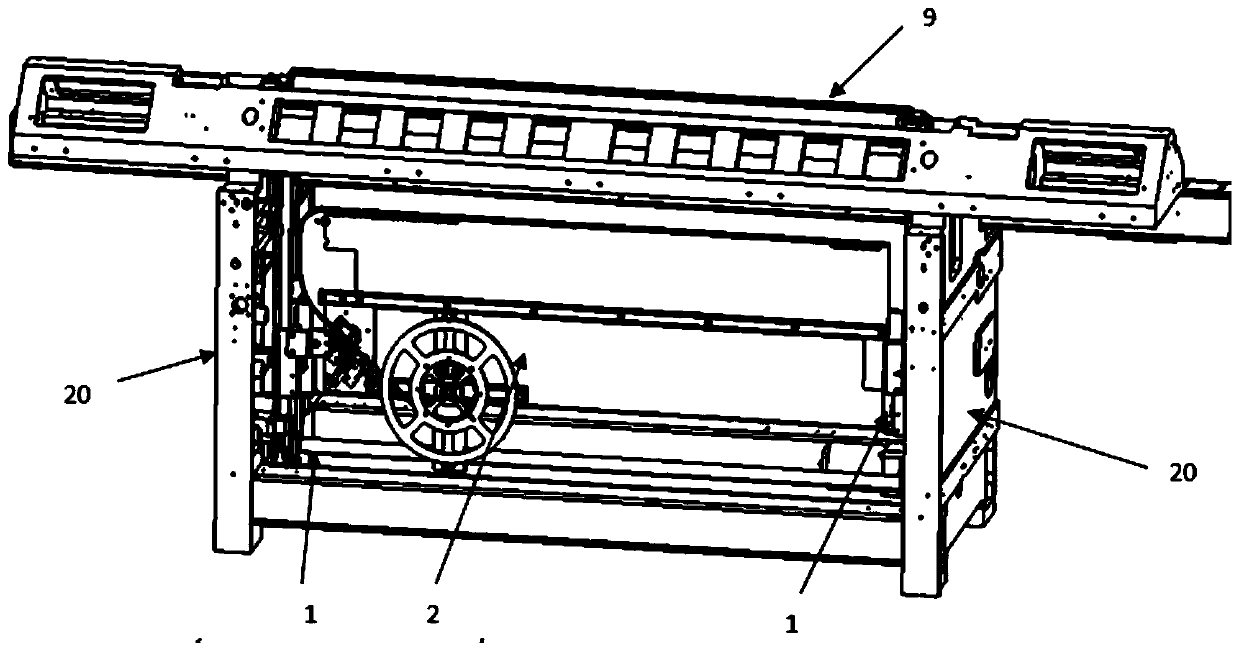

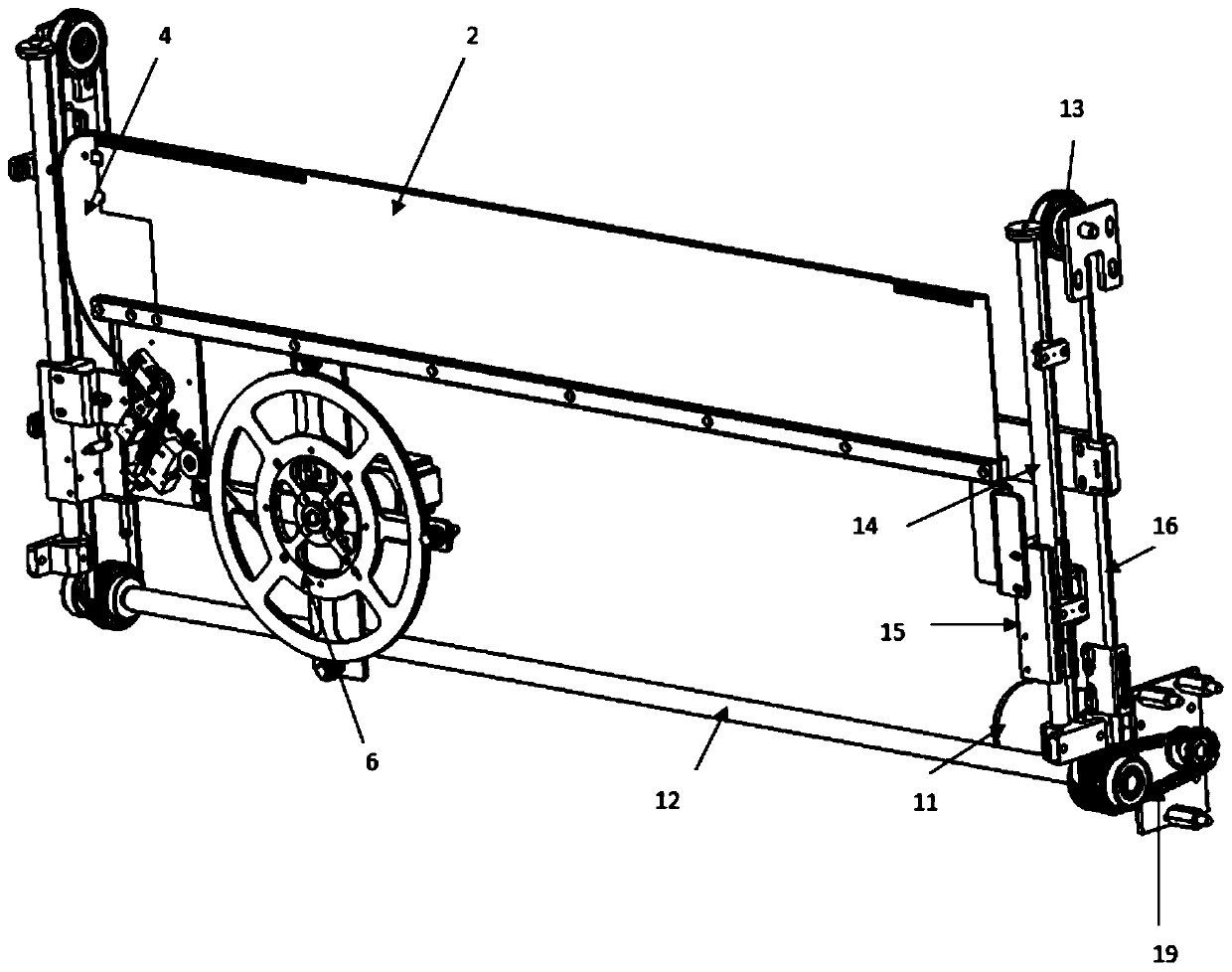

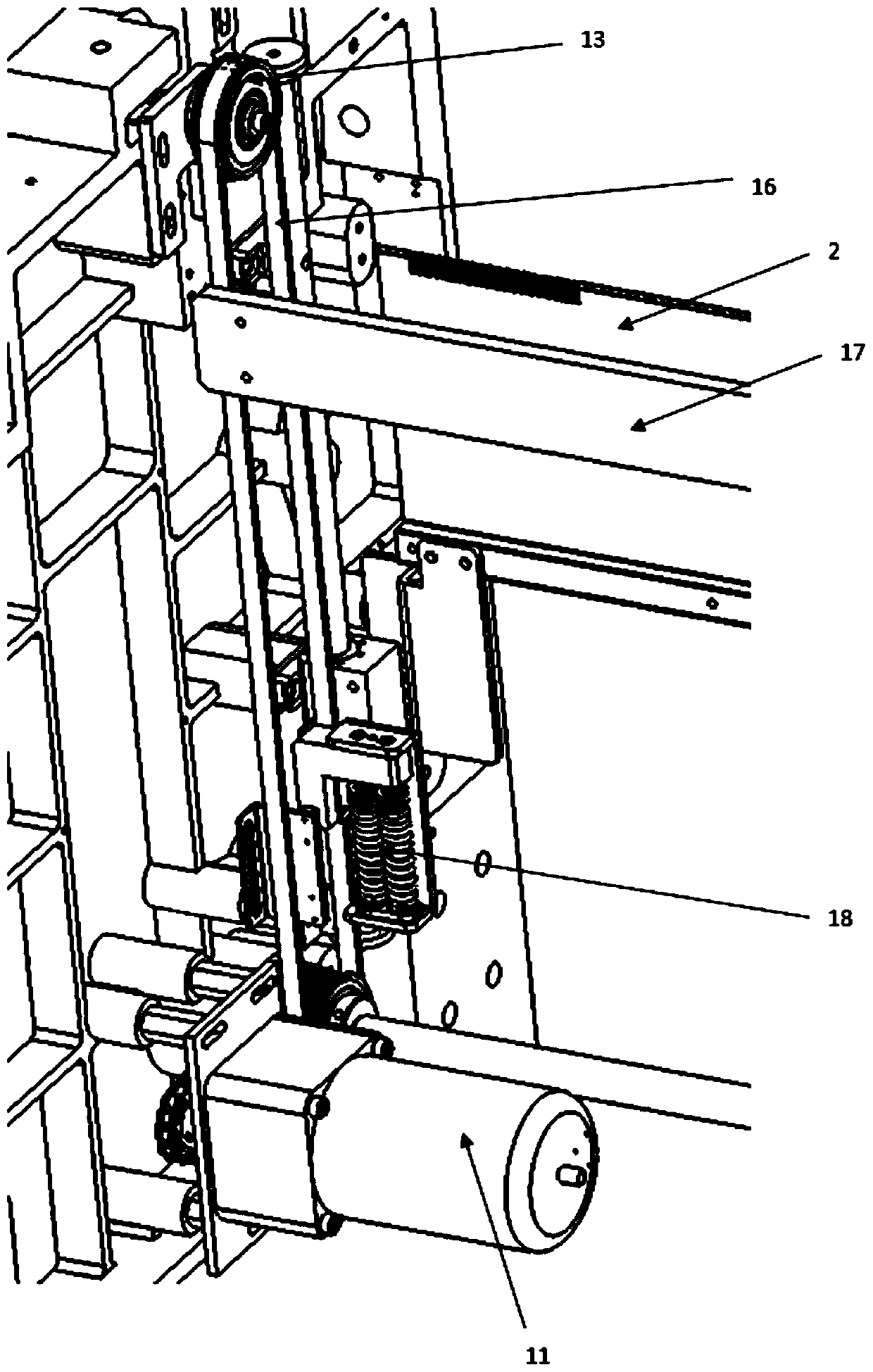

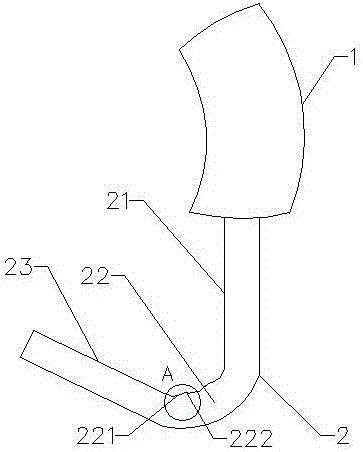

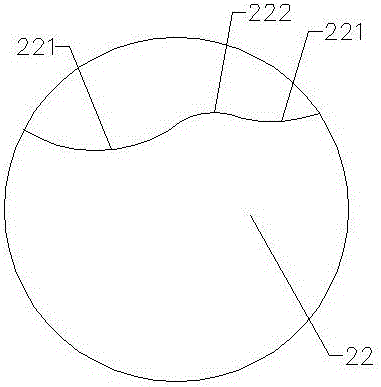

Opening device for automatic threading plate of flat knitting machine

The invention discloses an opening device for an automatic threading plate of a flat knitting machine. The opening device comprises left and right lifting devices, the threading plate and an opening needle. The left and right lifting devices are symmetrically arranged on left and right racks on the two sides of the flat knitting machine; the threading plate is installed on the left and right lifting devices for driving the threading plate to ascend and descend vertically, the opening needle is arranged at the top of the threading plate, a lead plate is installed at the end of one side of the threading plate, and a lead channel allowing a steel wire to penetrate and penetrating into the opening needle is arranged on the lead plate; a steel wire conveying and withdrawing device for conveyingor withdrawing a steel wire is installed below the threading plate, the tip end of the steel wire is located inside the lead channel, a steel wire limiting switch is installed in the middle of the steel wire conveying and withdrawing device, and a limiting block matched with the steel wire limiting switch for limiting is arranged on the steel wire. The steel wire automatically penetrates throughor is disengaged from the opening needle through eh steel wire conveying and withdrawing device and the lead channel, the assembling efficiency is improved, the steel wire limiting switch is arrangedfor controlling the steel wire conveying and withdrawing device to stop pushing of the steel wire, and yarn hanging and disengaging of the automatic opening device are stable.

Owner:NINGBO CIXING

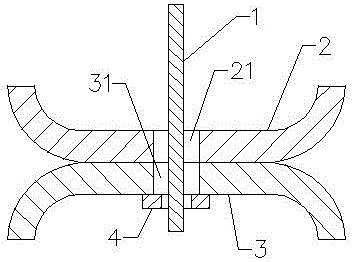

Convenient-to-disassemble type assembling mechanism for yarn splitting device

A convenient-to-disassemble type assembling mechanism for a yarn splitting device relates to the technical field of textile and comprises a yarn storing bobbin, a yarn storing bobbin dustproof cover and the yarn splitting device. The upper end of the yarn storing bobbin is covered by the yarn storing bobbin dustproof cover, the yarn splitting device comprises a core rod and a yarn splitting dustproof cover, the yarn splitting dustproof cover is in a barrel shape and covers the core rod, and assembling devices are respectively manufactured on the yarn storing bobbin dustproof cover and the yarn splitting dustproof cover, the yarn splitting device is detachably arranged on the yarn storing bobbin dustproof cover through the assembling devices, the assembling devices on the yarn storing bobbin dustproof cover are arranged at the two radial ends of the yarn storing bobbin dustproof cover, and the assembling devices are in a drawn clamping-connection mode through clamping connection convex ribs and clamping-connection grooves. The yarn splitting device can be conveniently clamped with and disassembled from the yarn storing bobbin dustproof cover. When the rotating direction of the yarn storing bobbin is changed, the yarn splitting device is disassembled from one side of the yarn storing bobbin dustproof cover and is assembled to the assembling devices on the other side of the yarn storing bobbin dustproof cover, and then the yarn splitting device is quick to assemble and disassemble. After startup or yarn breaking in the halfway, yarns can be quickly wound on the yarn storing bobbin and a yarn splitting sleeve. Thus, work time is saved, the work efficiency is improved, and the weaving cost is reduced.

Owner:DONGGUAN JINFU HARDWARE MACHINERY +1

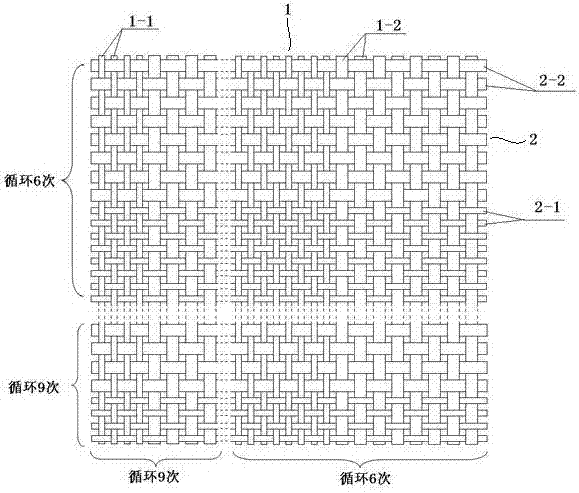

Weaving method of plaid fabric

InactiveCN102493080AReduce the failure rateReduce weaving costWoven fabricsProcess engineeringIndustrial engineering

The invention discloses a weaving method of a plaid fabric, the fabric is formed by interweaving warps and wefts, wherein the warps comprise warps A and warps B, the wefts comprise wefts A and wefts B, the arrangement of the warps is one warp B and one warp A, and the arrangement of the wefts is one weft A and one weft B; and during the warp pacing process, one weft B is paced, a heald frame is skipped to the next turn, then one warp A is paced, and the process is circulated and repeated. Through adopting the technical scheme, patterns are formed through the variation of the fabric weaving structure, the subsequent printing and dyeing of the design and color are not required, the production process is short and simple, so the reject ratio of finished products is benefited to being reduced, and the production efficiency is improved; and the weaving method is not limited by the environmental bearing capacity, and can be used for volume production.

Owner:苏州市凯灵织造厂

Novel fabric and weaving method thereof

The invention provides a novel fabric and a weaving method thereof and belongs to the technical field of textile. According to the weaving method, the novel fabric of which one side is clothing fabric and the other side is velvet is formed by interweaving and cutting piles. The weaving method comprises the steps that one side is one up one down tabby, and the other side is V-shaped consolidation-method velvet woven by the weaving method of two shuttles as a cycle; one side is two up one down twill, and the other side is V-shaped consolidation-method velvet woven by the weaving method of three shuttles as a cycle; one side is three up one down twill, and the other side is W-shaped consolidation-method velvet woven by the weaving method of eight shuttles as a cycle; one side is five heddle satin, and the other side is W-shaped consolidation-method velvet woven by the weaving method of ten shuttles as a cycle. According to the novel fabric and the weaving method thereof, the technical problems in the prior art are solved that one side is the clothing fabric, the other side is velvet fabric and velvet roots are exposed, or a group of warps or wefts are added to overcome velvet root exposure, and thus the fabric is thick, and not light, thin and soft in hand feel as the velvet is supposed to be.

Owner:ZHEJIANG INNOVATION TEXTILE CO LTD

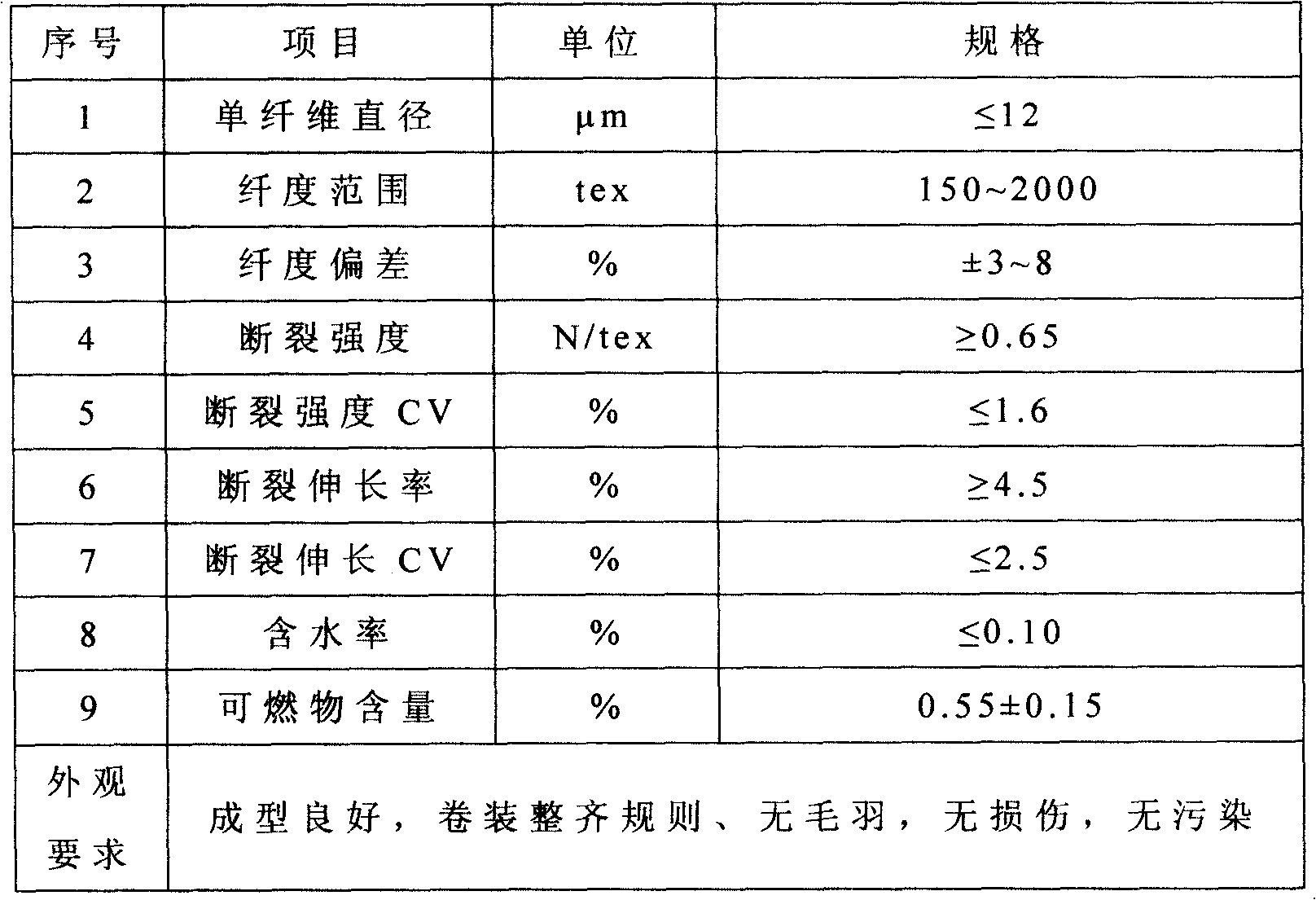

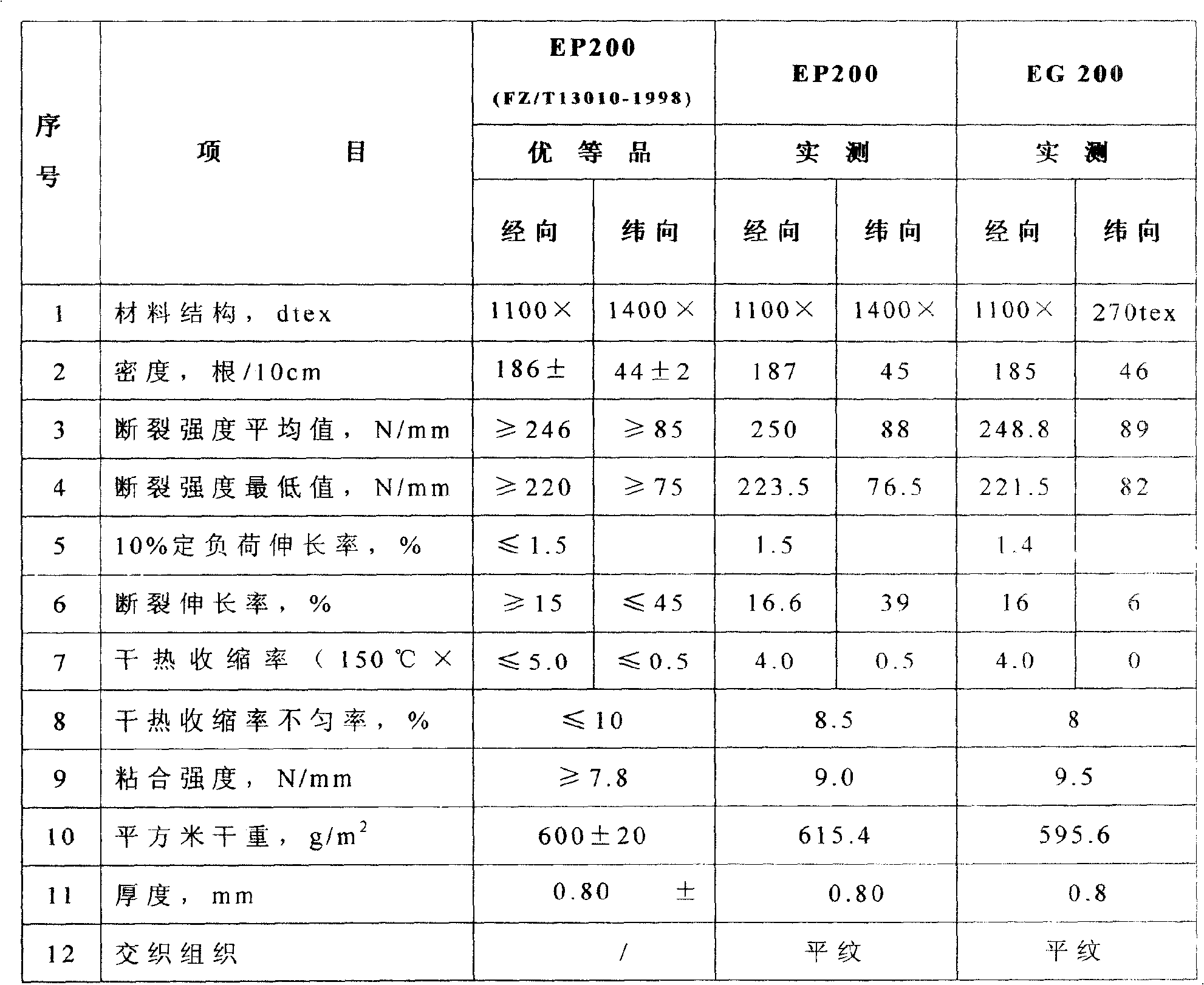

Dacron glass fiber dipped canvas and its preparation method

InactiveCN100447332CImprove heat resistanceGood dimensional stabilityWoven fabricsGlass fiberPolyester

The invention provides a polyester glass fiber dipped canvas and a preparation method thereof. Silk is woven into canvas. The single fiber diameter of glass fiber filaments in weft direction is ≤12μm. The glass fiber is a modified glass fiber filament, based on the total weight of the modified glass fiber filament, it consists of: SiO 2 : 50%~56%, Al 2 o 3 : 12%~16%, B 2 o 3 : 6%~9%, MgO: 2%~4%, CaO: 16%~20%, Na 2 O or / and K 2 O: 0.15% to 0.4%, Fe 2 o 3 : 0.1%~0.4%, TiO 2 or / and ZrO 2 : 0~0.1%, F 2 : 0.1% to 0.3%. The raw material cost is low, the preparation process is simple and reasonable, and the product has high heat resistance and dimensional stability.

Owner:刘显宝

Aromatic polyester-aliphatic polyester block copolyester fiber and protein fiber fabric

Owner:CHINESE TEXTILE ACAD

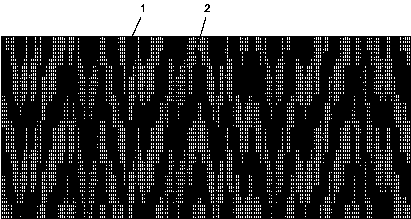

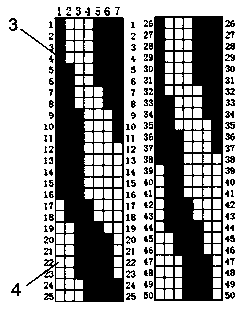

Warp-knitted zebra curtain fabric and manufacture process thereof

InactiveCN110219094AIncreasing the thicknessHorizontal and vertical structure stabilityWarp knittingCurtainsHigh densityEngineering

The invention relates to warp-knitted zebra curtain fabric and a manufacture process thereof, in particular to transverse-type warp-knitted zebra curtain fabric and a manufacture process thereof. Thewarp-knitted zebra curtain fabric and the manufacture process thereof have the advantages that the process is simple, the knitting cost is low, the texture is stable, the curtain fabric is free of looseness and slip, knitted fabrics are ever-changing, and the curtain fabric has many patterns and styles and is attractive and practical. The manufacture process is characterized in that a (Tricot-typeor Raschel-type) warp knitting machine and an electronic translation mechanism are adopted; fine spinning yarns are used for forming chains and meshes, and thick spinning yarns are used for weft insertion and warp insertion; warp knitting of the chains is combined with weft insertion to basically form fabric with high density and thickness, namely shading fabric, and warp knitting of the meshes is combined with warp insertion to basically form light-transmitting fabric with low density and thickness. The shading fabric and light-transmitting fabric are arrayed alternately and segmentally during knitting to form the transverse-type warp-knitted zebra curtain fabric that can be freely switched between a shading mode and a light transmitting mode.

Owner:HAINING KEYUAN WARP

Wear-resistant, soft and skin-friendly glove for knitting

ActiveCN108783675AProtection securityIncrease elasticityGlovesProtective garmentEmulsionPolyvinyl alcohol

The invention mainly relates to the technical field of willow weaving product processing, and discloses a wear-resistant, soft and skin-friendly glove for knitting. The wear-resistant, soft and skin-friendly glove for knitting is prepared from, 62-64 parts of modified butadiene rubber, 21-23 parts of latex, 46-48 parts of nylon fiber, 13-15 parts of medical stone fiber, 7-9 parts of graphene fiber, 6-8 parts of polyvinyl alcohol and 14-16 parts of modified styrene-acrylic emulsion; the provided wear-resistant, soft and skin-friendly glove for knitting is green and healthy, soft and skin-friendly, wear-resistant and scratch-resistant, can effectively protect the hand safety of a weaving worker, the traditional direct contact between the skin and a weaving material and the bacterial infection caused by the fact that the skin is simply bound by directly using woundplast or adhesive tape are changed; the modified butadiene rubber is mixed with the latex, thereby enhancing the processing performance and non-skid performance of the butadiene rubber and improving the soft elasticity and skin-friendly performance of the glove, so that the force can be accurately exerted when the glove is worn, the weaving force is mastered conveniently, and the higher weaving efficiency and quality are maintained.

Owner:阜南县创发工艺品有限公司

Method for weaving polyamide bag fabrics

The invention discloses a method for weaving polyamide bag fabrics. According to the method, a double-jet single-beam loom weaves two kinds of yarns in different thicknesses; two polyamide full draw yarns (FDY) are combined, and added with a 200T / M Z twist to form a warp A, and four polyamide FDY are combined, and added with a 200T / M Z twist to form a warp B; when the warps are put onto a loom, the loom is regulated to make the tension of the warp A and the warp B consistent; and during sectional warping, the tension of the warp A and the warp B are kept consistent. By the technical scheme, after single-beam weaving is performed, the cost is reduced. By the weaving technology, the weaving cost of the bag fabrics is reduced, energy conservation, consumption reduction and emission reduction are facilitated, and the weaving technology accords with a development policy of energy conservation and consumption reduction of China.

Owner:苏州市凯灵织造厂

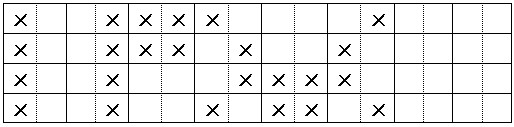

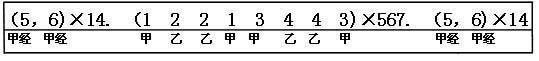

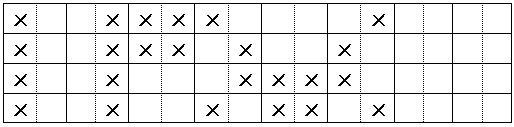

Method and system for knitting applique

ActiveCN103668734AImprove the efficiency of intarsia knittingReduce weaving costWeft knittingS systemEngineering

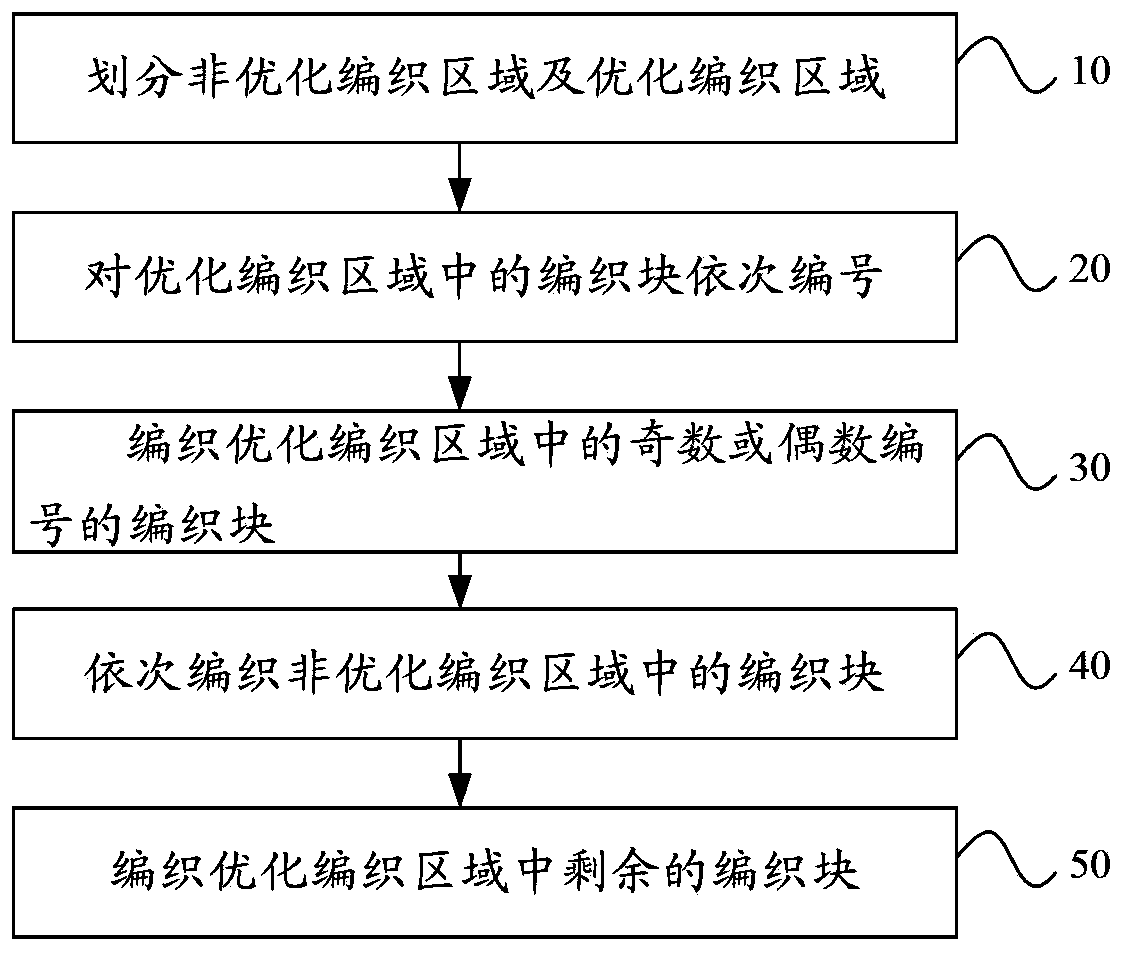

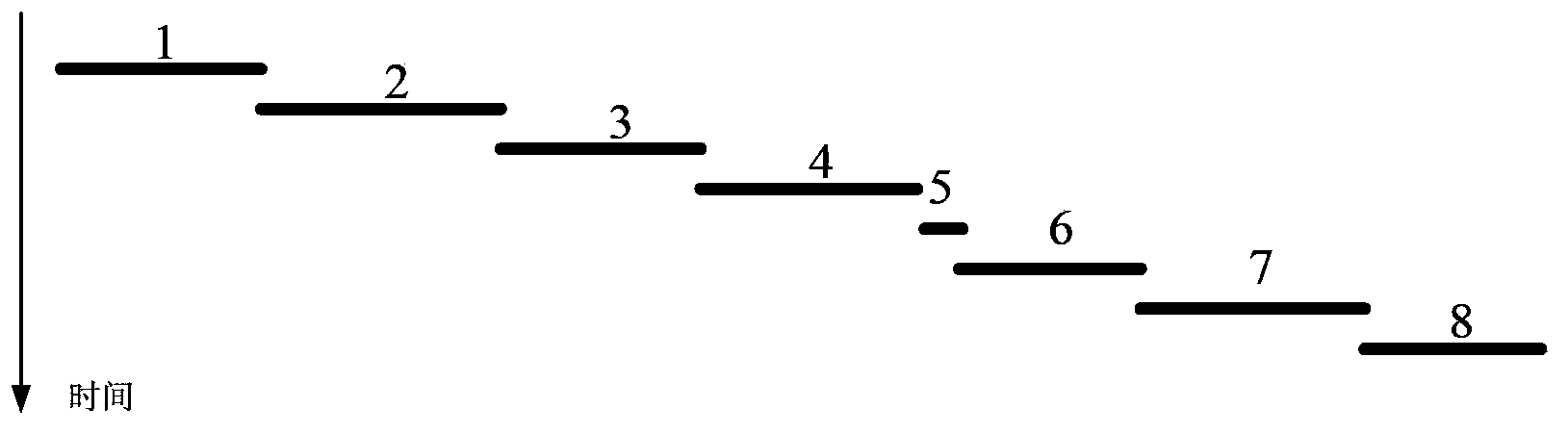

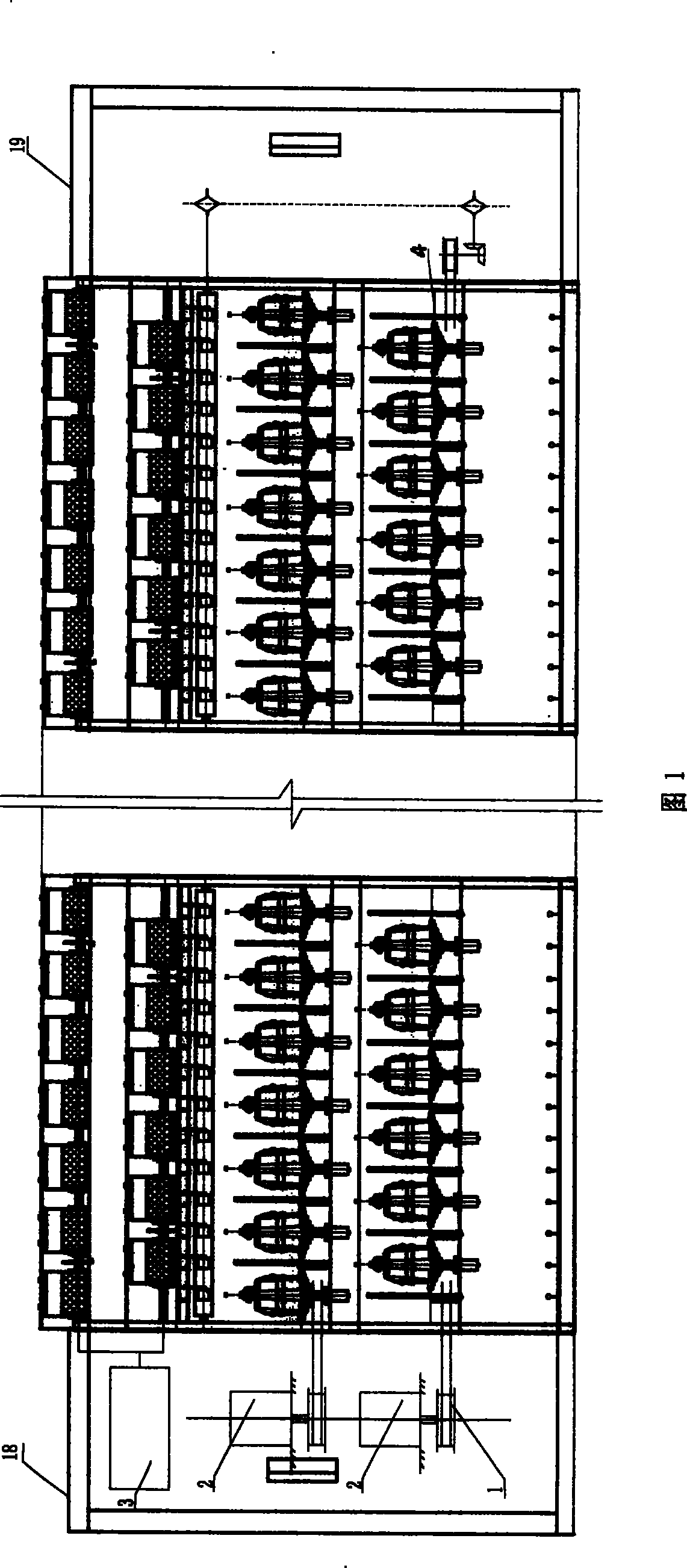

The invention provides a method and system for knitting applique. The method comprises the steps that a non-optimized knitting area and an optimized knitting area are divided out; knitting blocks in the optimized knitting area are numbered in sequence; the knitting blocks with the numbers of odd numbers or even numbers in the optimized knitting area are knitted; the knitting blocks in the non-optimized knitting area are knitted in sequence; the remaining knitting blocks in the optimized knitting area are knitted. The area capable of being optimized can be extracted to the maximum extent, an optimized mode is adopted for knitting to the greatest extent until the area cannot be optimized, then a non-optimized mode is used for knitting, applique knitting efficiency can be improved, and knitting cost can be lowered.

Owner:BEIJING DAHAO TECH

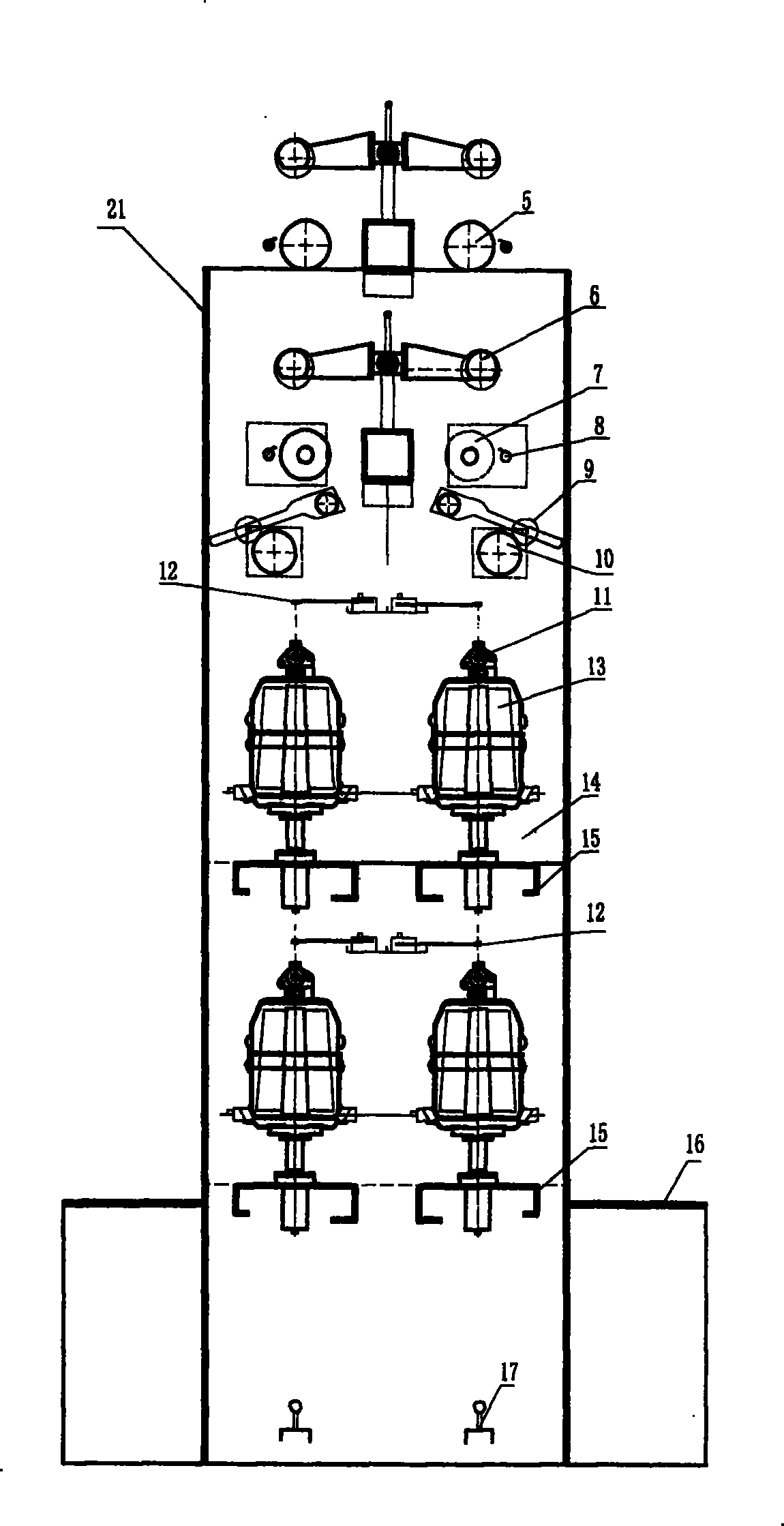

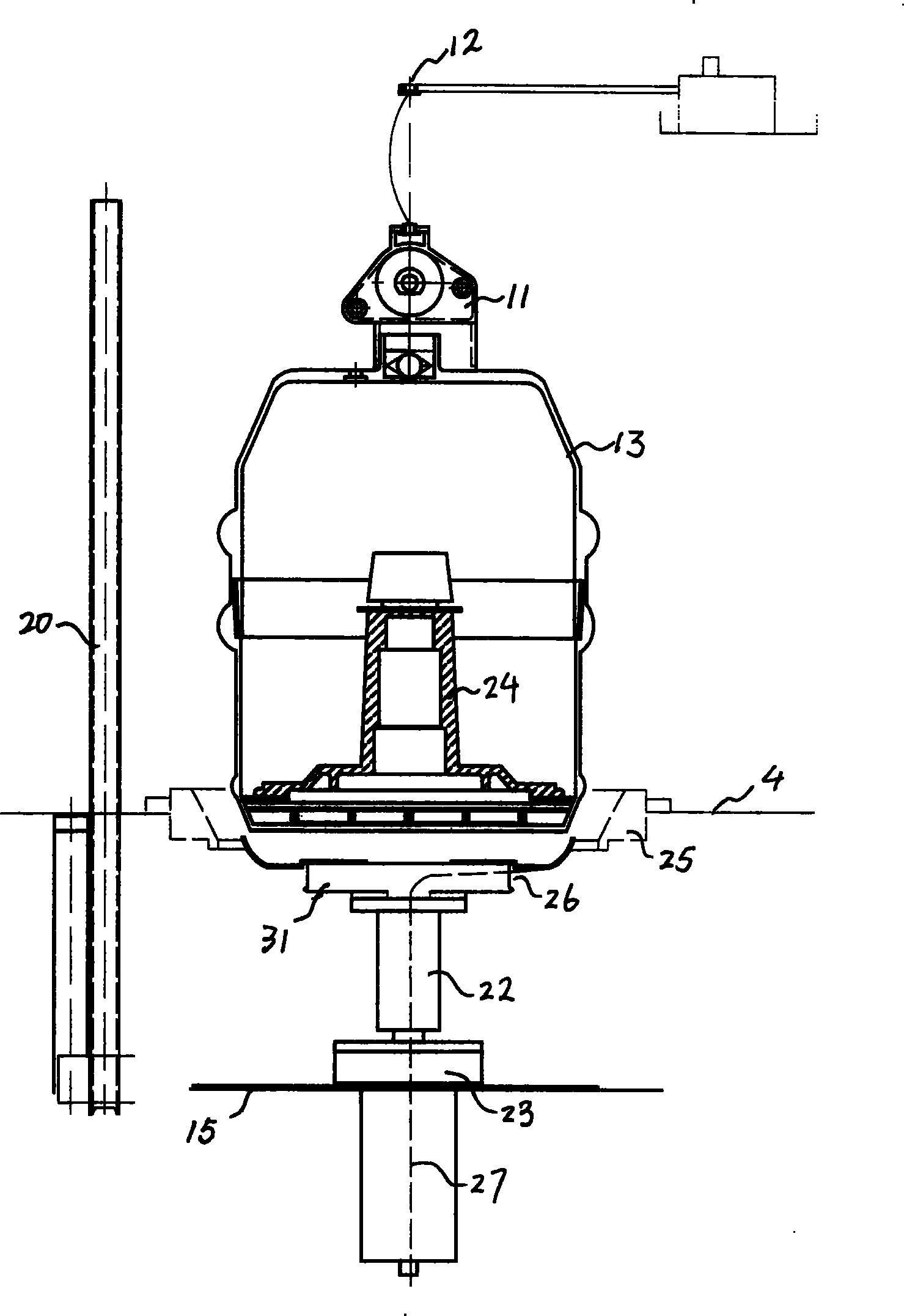

Multipurpose composite direct twisting type twisting machine

ActiveCN101245511BConvenient tension controlSatisfied and strongContinuous wound-up machinesYarnPolyesterYarn

The invention discloses a composite direct twisting machine with multiple functions and is applicable to the twisting of embroidery thread, nylon, polyester, rayon and sewing thread, etc. The machine comprises a frame, a spindle driving device, a spindle module, a tension mechanism, a thread-guiding mechanism, a cylinder yarn forming mechanism and an electronic control mechanism. The direct twisting structure provided by the machine of the invention ensures single yarn to have no twist after stranding. Owing to direct forming of thread, the strain of the two strings of silk can be easily controlled to obtain satisfying strength.

Owner:北京市文化科技融资租赁股份有限公司

Jacquard-like high-figured fabric and method for weaving fabric on dobby machine

InactiveCN108642677AStrong randomnessReduce weaving costDobbiesHeating/cooling textile fabricsWoven fabricYarn

The invention relates to a jacquard-like high-figured fabric and a method for weaving the fabric on a dobby machine and belongs to the technical field of spinning. The fabric comprises a pattern partand a cloth part, upward protrusions arranged at intervals in a roll length direction form the pattern part of the fabric, and the remaining part is the cloth part; the pattern part comprises polygonal-shaped patterns continuously distributed in a width direction, and the width and fluctuation range of polygonal lines are constantly changed; the fabric is interwoven by a group of warp threads andtwo groups of weft threads, one group of the weft threads are high-shrinkage yarn, the other group of the weft threads are low-shrinkage yarn, and the warp threads are low-shrinkage yarn; the patternpart consists of surface-layer texture and inner-layer texture, the surface-layer texture is interwoven by the low-shrinkage yarn in the warp threads and the low-shrinkage yarn in the weft threads, and the inner-layer texture is a weft floating length part formed by the high-shrinkage yarn in the weft threads; the cloth part is formed by interweaving the warp threads and the two groups of weft threads. The pattern part of the fabric presents the polygonal-shaped patterns continuously distributed in the width direction without interruption, and the width and fluctuation range of the polygonal lines are constantly changed, so that the fabric achieves a jacquard-like pattern effect.

Owner:SHANDONG VOCATIONAL COLLEGE OF LIGHT IND

Ring spinning elastic weft with high elongation and production process of ring spinning elastic weft

The invention provides a ring spinning elastic weft with high elongation and a production process of the ring spinning elastic weft with the high elongation. The elastic weft has the fineness being 22 plus or minus 2 S. The production process comprises feeding of PA66 undrawn yarn, yarn spinning and automatic winding, wherein the PA66 undrawn yarn has the fineness being 180 plus or minus 20 dtex; the prepared elastic weft has the fineness being 22 plus or minus 2 S, the single yarn breaking strength being 260 plus or minus 30 cN, the strength CV smaller than 8%, the elongation at break being 330 plus or minus 30% and the elongation CV smaller than 8%. The prepared elastic weft has good heat resistance, and the strength and the extensible performance loss of the elastic weft are small in the heat treatment process of fabric dipping and the like; when the prepared elastic weft is used for weaving radial tire cord fabric, the efficiency is high and little weft stoppage is caused during weaving by the aid of a jet cloth machine; the number of times of weft stoppage of a hundred thousand of weft is 5 or below. The prepared elastic weft can sufficiently keep the texture stability of the cord fabric.

Owner:山东合信科技股份有限公司

Interwoven sun-shading material

ActiveCN104404686AGuaranteed StrengthGuaranteed flame retardant performanceWarping machinesHeating/cooling textile fabricsFiberPolyester

The invention discloses an interwoven sun-shading material, belongs to the technical field of sun shading, and particularly relates to a flame-retarding interwoven fabric coated with polyester fibers or not coated with polyester fibers. The sun-shading material is prepared by adopting a method of interweaving non-coated flame-retarding polyester yarns and coated polyester yarns; the non-coated flame-retarding polyester yarns have the characteristics of being soft and light; the coated polyester yarns is higher in flame resistance and strength; the sun-shading material is specifically produced according to the following steps: step A, warping the coated yarns to form a warp beam; step B, denting the warp beam; step C, weaving by using a weaving machine; step D, shaping. The interwoven sun-shading material disclosed by the invention improves the flexibility of the fabric on the premise of guaranteeing the strength and the flame resistance of the sun-shading material, lowers the weaving cost, improves the efficiency and is beneficial for promotion of products.

Owner:温多利遮阳材料(德州)股份有限公司

Method for weaving vertical-bar bag fabrics

InactiveCN102493082AReduce the failure rateReduce weaving costYarnSwivel-woven fabricsMechanical engineeringIndustrial engineering

The invention discloses a method for weaving vertical-bar bag fabrics. A dobby loom is used for weaving, and the method comprises the following steps of: a) performing sectional warping by using a sectional warping machine, arranging warps according to a process requirement, and drawing the warps to obtain a live axis; b) after the warps are loaded on the axis, regulating the height of a back beam of the dobby arm to be -1-1 lattice; and c) regulating the warp tension to be more than 4,500N to facilitate clear openings during weft spray. By the technical scheme, patterns are formed through structural change of fabric weave, the subsequent printing and dyeing is not required, the production procedure is short and simple, the reject ratio of finished products is reduced and the production efficiency is improved; the method is not limited by the environment bearing capacity, and the fabrics are suitable for volume production; meanwhile, by the weaving method, investment is not required to reform equipment, and the fabrics can be woven on the conventional dobby loom. By the weaving technology, the weaving cost of the bag fabrics is reduced, and energy conservation, consumption reduction and emission reduction are facilitated.

Owner:苏州市凯灵织造厂

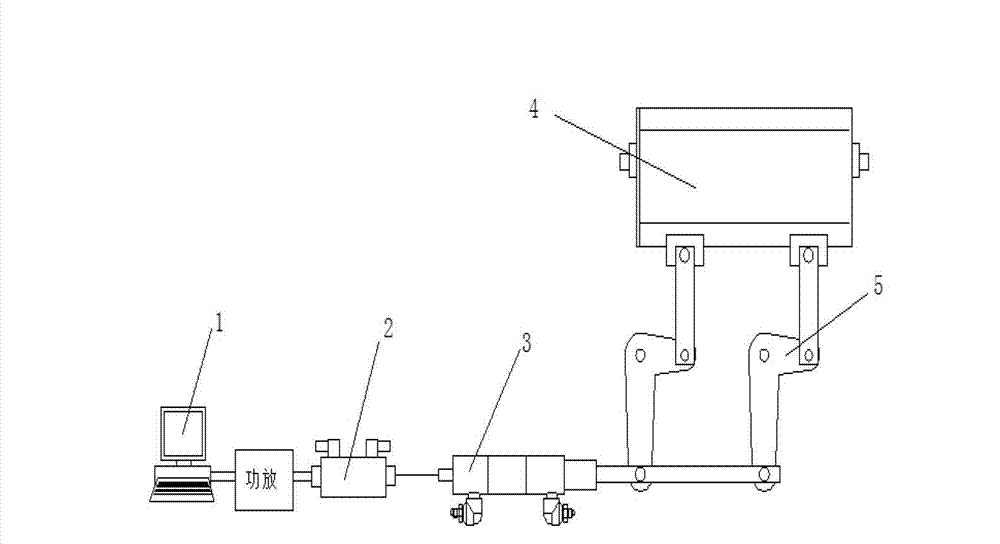

Electric-hydraulic proportional opening device for air jet loom and control method

InactiveCN102899772AImprove performanceImprove labor productivityLoomsOther shedding mechanismAir-jet loomAmplifier

The invention discloses an electric-hydraulic proportional opening device for an air jet loom. The electric-hydraulic proportional opening device for the air jet loom comprises multiple harness frames arranged in parallel, wherein the lower part of each of the harness frames is connected with a lifting driving connecting rod through a connecting rod; the lifting driving connecting rod is connected with a servo cylinder through the connecting rod; the servo cylinder is connected with a proportional servo valve through an oil path; and the proportional servo valve, a power amplifier device and a computer are connected in turn through a circuit. The invention also relates to a control method for the opening device. According to the invention, the adjustment for all the opening parameters is realized by changing preset program parameters by software, the weaving cost is lowered and the labor productivity is increased.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com