Forming method of fiber-reinforced silicon dioxide ceramic composite material

A ceramic composite material and fiber-reinforced technology, which is applied to ceramic molding machines, unloading devices, manufacturing tools, etc., can solve the problems of affecting the performance of composite materials, wasting manpower and material resources, and slow glue flow out, so as to achieve low cost and reduce impact , Improving the effect of impregnation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

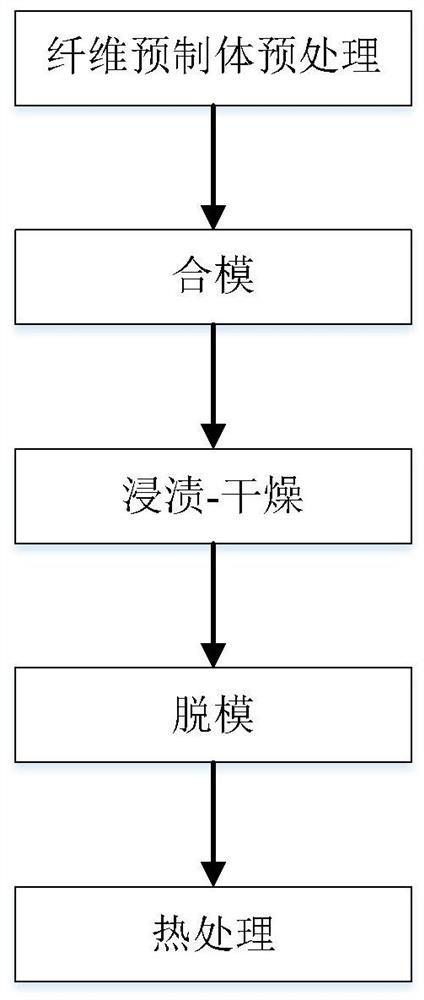

[0034] S1. Fiber preform pretreatment: the fiber preform is placed in a muffle furnace, heated to 500° C. for pretreatment, and the pretreatment time is 2 hours to obtain a fiber preform from which the sizing agent has been removed.

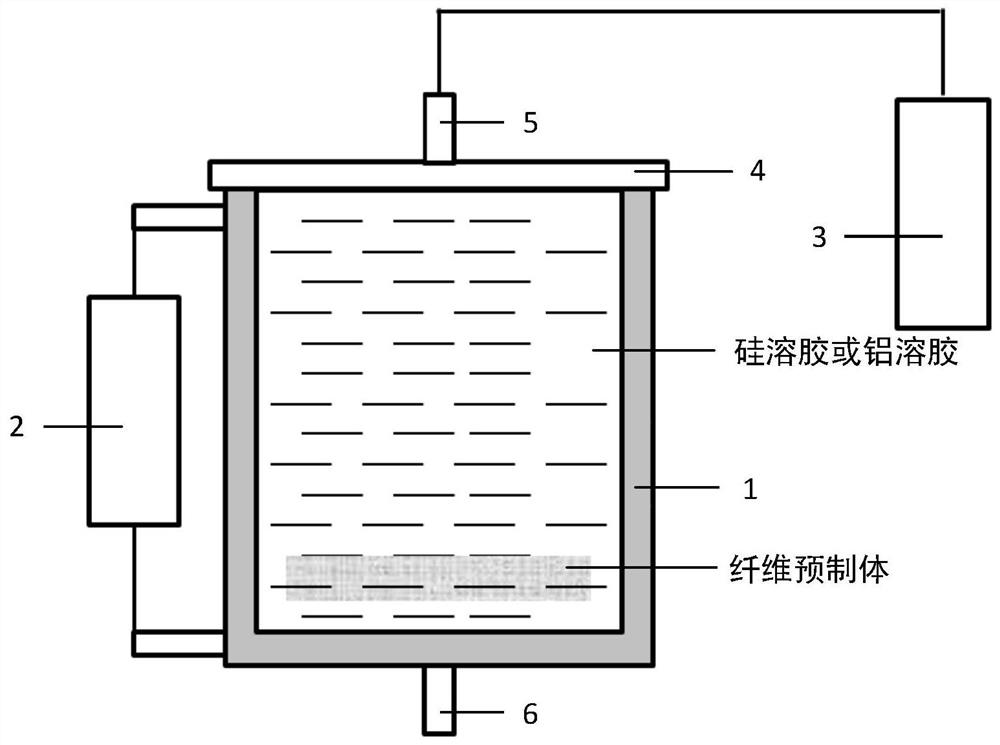

[0035] S2. Mold closing: place the fiber prefabricated body in the tank body of the vacuum impregnation-drying integrated molding device, connect each component to the tank body, turn on the vacuum pump, and remove the air inside the tank body.

[0036] S3. Impregnation-drying: inject silica sol into the tank, keep it for 20 hours, open the upper and lower valves of the tank, discharge all the sol inside the tank, set the temperature control program, and make the tank rise at a rate of 3°C / min Raise the temperature to 180°C and keep it warm for 20 hours to dry the fiber-reinforced ceramic flat body.

[0037] S4. Densification: Repeat the dipping-drying process 8 times to uniformly densify the fiber-reinforced ceramic flat plate.

[0038] S5, dem...

Embodiment 2

[0041]S1. Fiber preform pretreatment: the fiber preform is placed in a muffle furnace, heated to 600° C. for pretreatment, and the pretreatment time is 0.5 h to obtain a fiber preform from which the sizing agent has been removed.

[0042] S2. Mold closing: place the fiber prefabricated body in the drying tank body of the vacuum impregnation-drying integrated molding device, connect each component to the tank body, turn on the vacuum pump, and remove the air inside the tank body.

[0043] S3. Impregnation-drying: inject aluminum sol into the tank, keep it for 24 hours, open the upper and lower valves of the tank, discharge all the sol inside the tank, set the temperature control program, and make the tank heat up at a rate of 5°C / min Raise the temperature to 200°C and keep it warm for 18 hours to dry the fiber-reinforced ceramic flat body.

[0044] S4. Densification: Repeat the dipping-drying process 7 times to uniformly densify the fiber-reinforced ceramic flat plate.

[0045...

Embodiment 3

[0048] S1. Fiber preform pretreatment: the fiber preform is placed in a muffle furnace, heated to 400° C. for pretreatment, and the pretreatment time is 1 hour to obtain a fiber preform from which the sizing agent has been removed.

[0049] S2. Mold closing: place the fiber prefabricated body in the tank body of the vacuum impregnation-drying integrated molding device, connect each component to the tank body, turn on the vacuum pump, and remove the air inside the tank body.

[0050] S3. Impregnation-drying: inject silica sol into the tank, keep it for 2 hours, open the upper and lower valves of the tank, discharge all the sol inside the tank, set the temperature control program, and make the tank rise at a rate of 3°C / min Raise the temperature to 120°C and keep it warm for 24 hours to dry the fiber-reinforced ceramic flat body.

[0051] S4. Densification: Repeat the impregnation-drying process 6 times to uniformly densify the fiber-reinforced ceramic flat plate.

[0052] S5, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com