Aromatic polyester-aliphatic polyester block copolyester fiber and protein fiber fabric

A technology of aromatic polyester and protein fiber, applied in the direction of fabrics, textiles, textiles and papermaking, etc., can solve the problems of decreased regularity, shrinkage, and weakened crystallization ability of macromolecules, and achieve the effect of simplifying the dyeing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Blending wool and 1.8D aromatic polyester-aliphatic polyester block copolyester fiber with a length of 88mm at a mass ratio of 35 / 65, the yarn gauge is 16 S , woven into a knitted fabric with a square meter weight of 240g, and then dyed.

[0071] The dyeing process is as follows: disperse dyes and acid dyes are dyed in one bath under normal pressure, the dyeing pH is 5.0, acid dyes and disperse dyes are added at the same time, the initial dyeing temperature is 30-40°C, the dyeing temperature is 98-100°C, and the dyeing holding time is 30-60min, the heating rate is 1.0-1.5°C / min, the cooling rate after dyeing is 1.2-2.0°C / min, the temperature is lowered to 65°C for drainage, then 80°C soaping once, 80°C hot water washing twice.

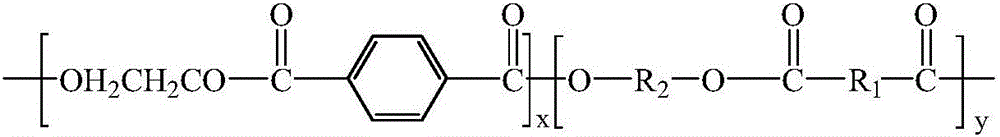

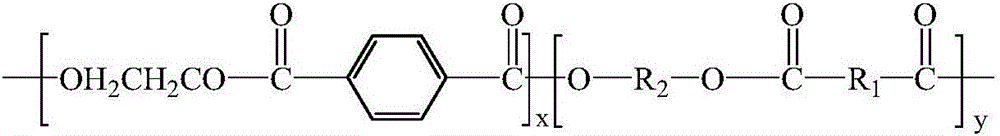

[0072] Aromatic polyester-aliphatic polyester block copolyester is formed by polycondensation of ethylene terephthalate oligomer and aliphatic polydibasic acid glycol ester polyol, and its aromatic polyester-aliphatic The chemical structural fo...

Embodiment 2

[0076] Blending silk and 1.8D aromatic polyester-aliphatic polyester block copolyester fiber at a weight ratio of 20 / 80, the yarn gauge is 16 S , woven into a knitted fabric with a square meter weight of 230g, and then dyed.

[0077] The dyeing process is: disperse dyes and acid dyes are dyed in one bath under normal pressure, the dyeing pH is 4.5, acid dyes and disperse dyes are added at the same time, the initial dyeing temperature is 45°C, the dyeing temperature is 90°C, the dyeing holding time is 60min, and the heating rate 1.0-1.5°C / min, the cooling rate after dyeing is 1.2-2.0°C / min, cool down to 60°C to drain, then soap wash once at 70°C, and wash with hot water at 80°C three times.

[0078] The chemical structural formula of aromatic polyester-aliphatic polyester block copolyester:

[0079]

[0080] Among them, 101 For C2 ~ C8 alkylene, R 2 It is C3~C8 alkylene; straight chain aliphatic dibasic acid is succinic acid; side group aliphatic dibasic alcohol is 1,2-pro...

Embodiment 3

[0083] Rabbit fur and 1.8D aromatic polyester-aliphatic polyester block copolyester fiber are blended at a mass ratio of 70 / 30, and the yarn gauge is 16 S , woven into a knitted fabric with a square meter weight of 220g, and then dyed.

[0084] The dyeing process is as follows: disperse dyes and acid dyes are dyed in one bath under normal pressure, the dyeing pH is 4.5, acid dyes and disperse dyes are added at the same time, the initial dyeing temperature is 45°C, the dyeing temperature is 98°C, the dyeing holding time is 55min, and the heating rate 1.0-1.5°C / min, the cooling rate after dyeing is 1.2-2.0°C / min, cool down to 60°C to drain, then soap wash once at 70°C, and wash with hot water at 80°C three times.

[0085] The chemical structural formula of aromatic polyester-aliphatic polyester block copolyester:

[0086]

[0087] Among them, 151 For C2 ~ C8 alkylene, R 2 It is a C3-C8 alkylene group; the straight-chain aliphatic dibasic acid is adipic acid; the side group ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com