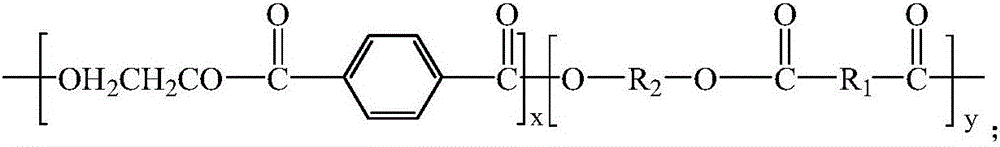

Aromatic polyester-aliphatic polyester block copolymerized ester fiber and purpose thereof

An aromatic polyester and polyester block technology, applied in the field of aromatic polyester-aliphatic polyester block copolyester fibers, can solve the problems of shrinkage, weakened crystallization ability, poor dimensional stability of copolyester fibers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

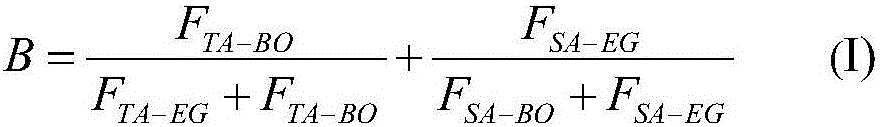

Method used

Image

Examples

Embodiment 1

[0066] The aromatic polyester-aliphatic polyester block copolyester chips were melted through a screw extruder at 280°C and then entered into the spinning assembly at a winding speed of 4200m / min to obtain aromatic polyester-aliphatic polyester block copolyester chips. Segment copolyester fully drawn yarn FDY. Among them, the speed of the heat roller GR1 is 1500 m / min and the temperature is 80°C, and the speed of the heat roller GR2 is 4250 m / min and the temperature is 140°C.

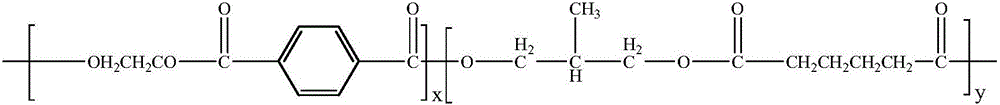

[0067] Aromatic polyester-aliphatic polyester block copolyester is formed by polycondensation of ethylene terephthalate oligomer with a degree of polymerization of 6 and polymethylpropylene adipate polyol with a number average molecular weight of 2000 , wherein the mass ratio of ethylene terephthalate oligomer and polymethylpropylene adipate polyol is 100:10, the intrinsic viscosity of the copolyester chip is 0.72dL / g, and the melting point is 229°C, The glass transition temperature is 71°C, the hue b ...

Embodiment 2

[0071] The aromatic polyester-aliphatic polyester block copolyester chips were melted through a screw extruder at 270°C and then entered into the spinning assembly at a winding speed of 3800m / min to obtain aromatic polyester-aliphatic polyester block copolyester chips. Segment copolyester fully drawn yarn FDY. Among them, the speed of the heat roller GR1 was 1200 m / min and the temperature was 72°C, and the speed of the heat roll GR2 was 3850 m / min and the temperature was 130°C.

[0072] Aromatic polyester-aliphatic polyester block copolyester is composed of ethylene terephthalate oligomer with a degree of polymerization of 2 and polysuccinate-1,2-propylene glycol with a number average molecular weight of 300 Alcohol polycondensation, in which the mass ratio of ethylene terephthalate oligomer and polysuccinate-1,2-propylene glycol ester polyol is 100:10, and the intrinsic viscosity of copolyester chips is 0.75dL / g, the melting point is 226°C, the glass transition temperature ...

Embodiment 3

[0076] The aromatic polyester-aliphatic polyester block copolyester chip is melted by a screw extruder at 300°C and then enters the spinning assembly, and the winding speed is 5200m / min to obtain an aromatic polyester-aliphatic polyester block Segment copolyester fully drawn yarn FDY. Among them, the speed of the heat roller GR1 was 1800 m / min and the temperature was 90°C, and the speed of the heat roll GR2 was 5250 m / min and the temperature was 160°C.

[0077] Aromatic polyester-aliphatic polyester block copolyester is composed of ethylene terephthalate oligomer with a degree of polymerization of 1 and polytrimethylpentanediol sebacate with a number average molecular weight of 1000 Alcohol polycondensation, wherein the mass ratio of ethylene terephthalate oligomer and polytrimethylpentanediol sebacate polyol is 100:3, and the intrinsic viscosity of copolyester chips is 0.62dL / g, the melting point is 250°C, the glass transition temperature is 77°C, the hue b value is 1, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com