Novel fabric and weaving method thereof

A new type of fabric and technology, applied in the field of velvet, can solve the problems of heavy weight, affecting the dryness and smoothness of the velvet back, and the lack of elegant velvet feeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

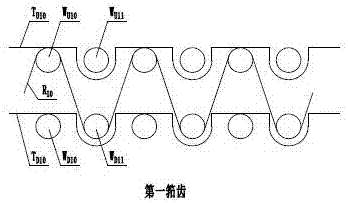

[0070]When one side is a plain weave with one up and one down, and one side is a V-shaped consolidated pile, the upper warp yarns include the tenth warp yarn T of the upper layer U10 , the upper eleventh warp T U11 , the lower warp yarns include the tenth warp yarn T of the lower layer D10 11th warp yarn T of the lower layer D11 , the pile warp yarn includes the tenth pile warp yarn R 10 11th cashmere warp yarn R 11 , the upper layer weft yarn includes the upper layer tenth weft yarn W U10 , the upper eleventh weft W U11 , the lower layer weft yarn includes the lower layer tenth weft yarn W D10 , the eleventh weft yarn W of the lower layer D11 The weaving method that one side is the plain weave of one up and one down, and one side is the velvet two shuttles one cycle of V-type consolidated fluff comprises the following steps:

[0071] First the upper tenth warp yarn T U10 and the lower tenth warp yarn T D10 and the tenth pile warp yarn R 10 Pass through the first ree...

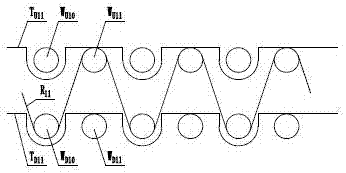

Embodiment 2

[0081] When one side is two up and one down twill weave, and one side is V-shaped consolidated fluff, the upper layer warp yarn includes the upper layer twenty-first warp yarn T U21 , the upper twenty-second warp T U22 , the upper twenty-third warp T U23 , the lower layer of warp yarns includes the lower layer of the twenty-first warp yarn T D21 22nd warp yarn T of the lower layer D22 23rd warp yarn T of the lower layer D23 , the pile warp yarn includes the twenty-first pile warp yarn R 21 , Twenty-second pile warp yarn R 22 , twenty-third cashmere warp yarn R 23 , the upper layer weft yarn includes the upper layer twenty-first weft yarn W U21 , the upper twenty-second weft yarn W U22 , the upper twenty-third weft W U23 , the lower layer weft yarn includes the lower layer twenty-first weft yarn W D21 , the 22nd weft yarn of the lower layer W D22 , The twenty-third weft yarn W of the lower layer D23 The weaving method that one side is the twill weave with two upper a...

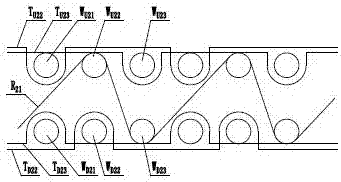

Embodiment 3

[0095] When one side is three up and one down twill weave, and one side is W-shaped consolidated fluff, the upper layer warp yarn includes the upper layer 31st warp yarn T U31 , the upper thirty-second warp T U32 , the upper thirty-third warp T U33 , the upper thirty-fourth warp T U34 , the lower layer warp yarns include the lower layer thirty-first warp yarn T D31 , Lower layer thirty-second warp T D32 , Lower layer thirty-third warp T D33 , Lower layer thirty-fourth warp T D34 , the pile warp yarn includes the thirty-first pile warp yarn R 31 , Thirty-second pile warp yarn R 32 , Thirty-third cashmere warp yarn R 33 , Thirty-fourth cashmere warp yarn R 34 , the upper layer weft yarn includes the upper layer thirty-first weft yarn W U31 , the upper thirty-second weft yarn W U32 , the upper thirty-third weft W U33 , the upper thirty-fourth weft yarn W U34 , the upper thirty-fifth weft yarn W U35 , the upper thirty-sixth weft W U36 , the upper thirty-seventh weft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com