Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

262results about "Dobbies" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

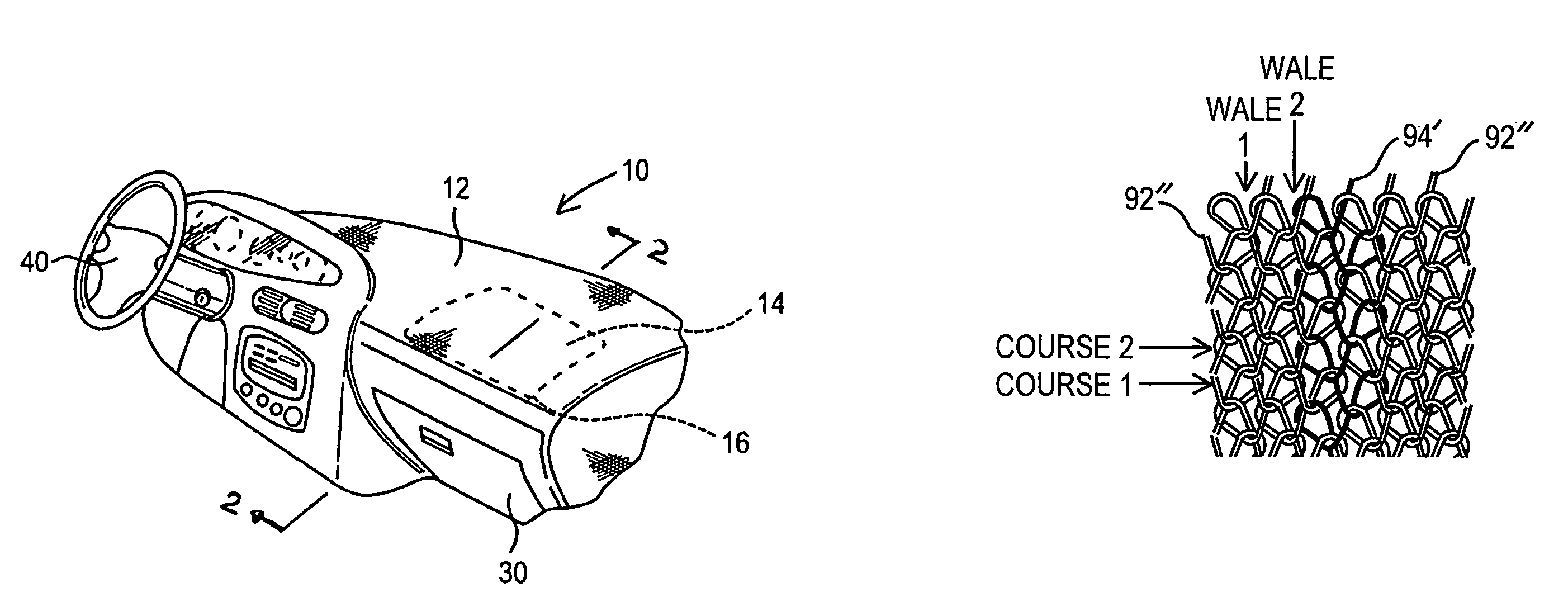

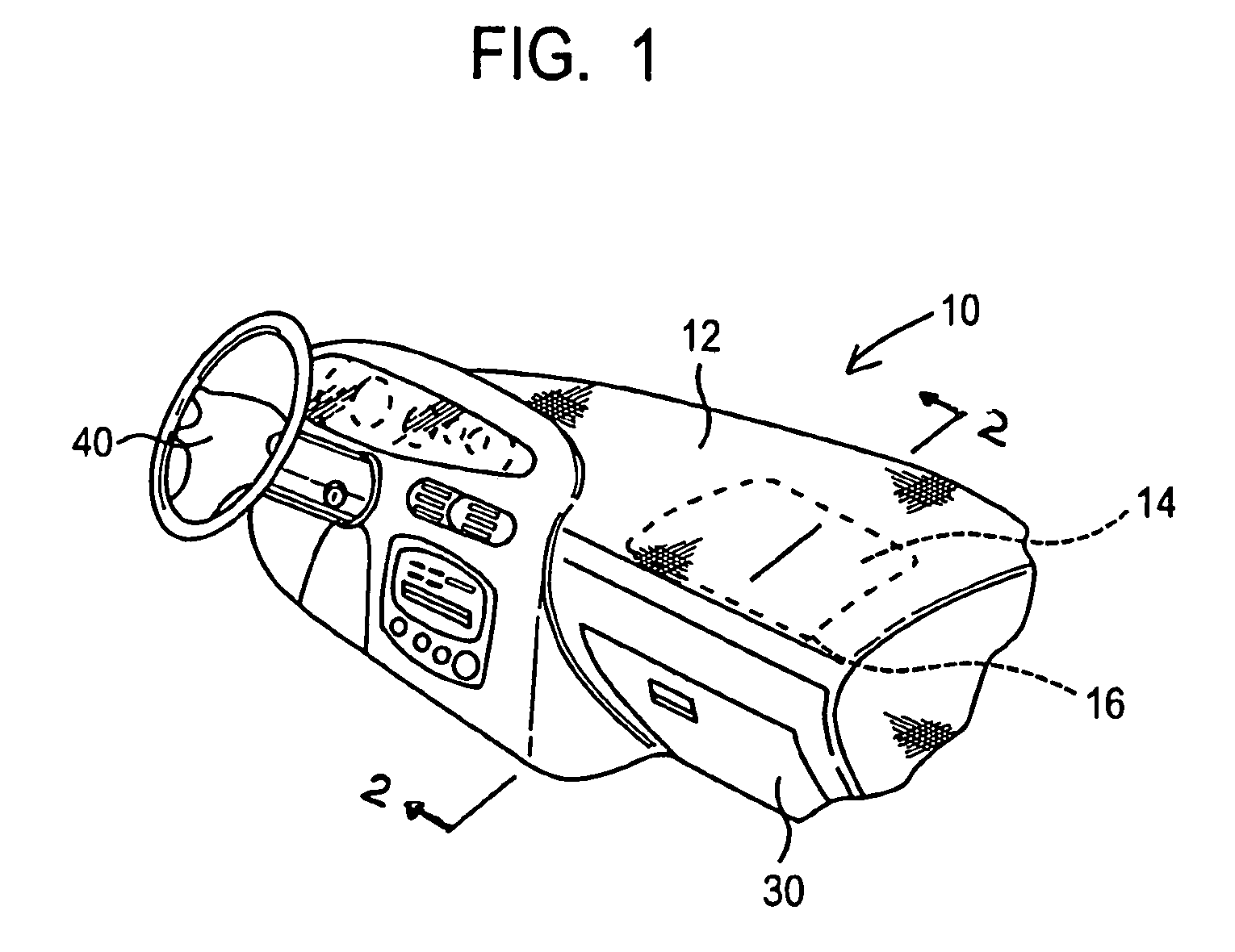

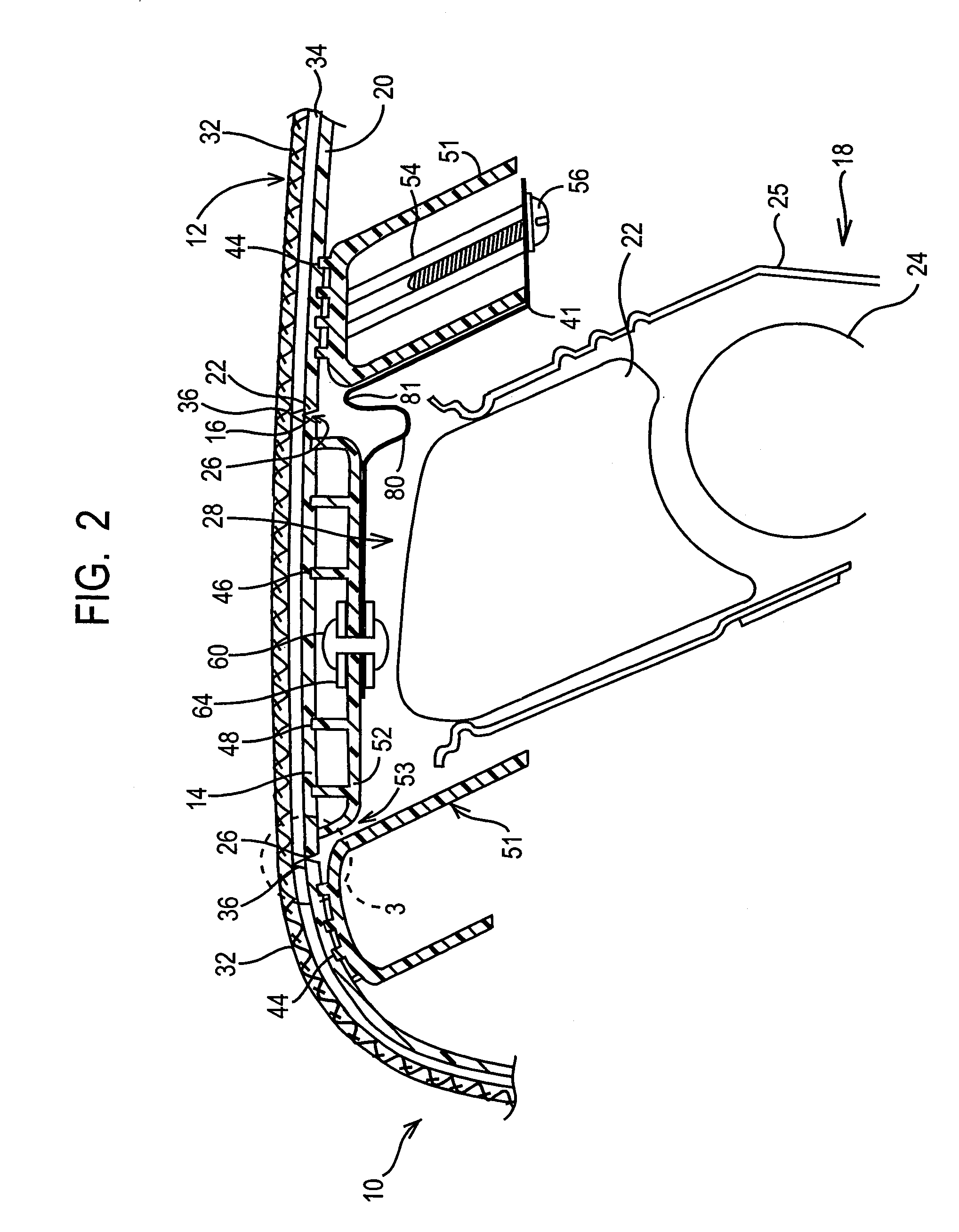

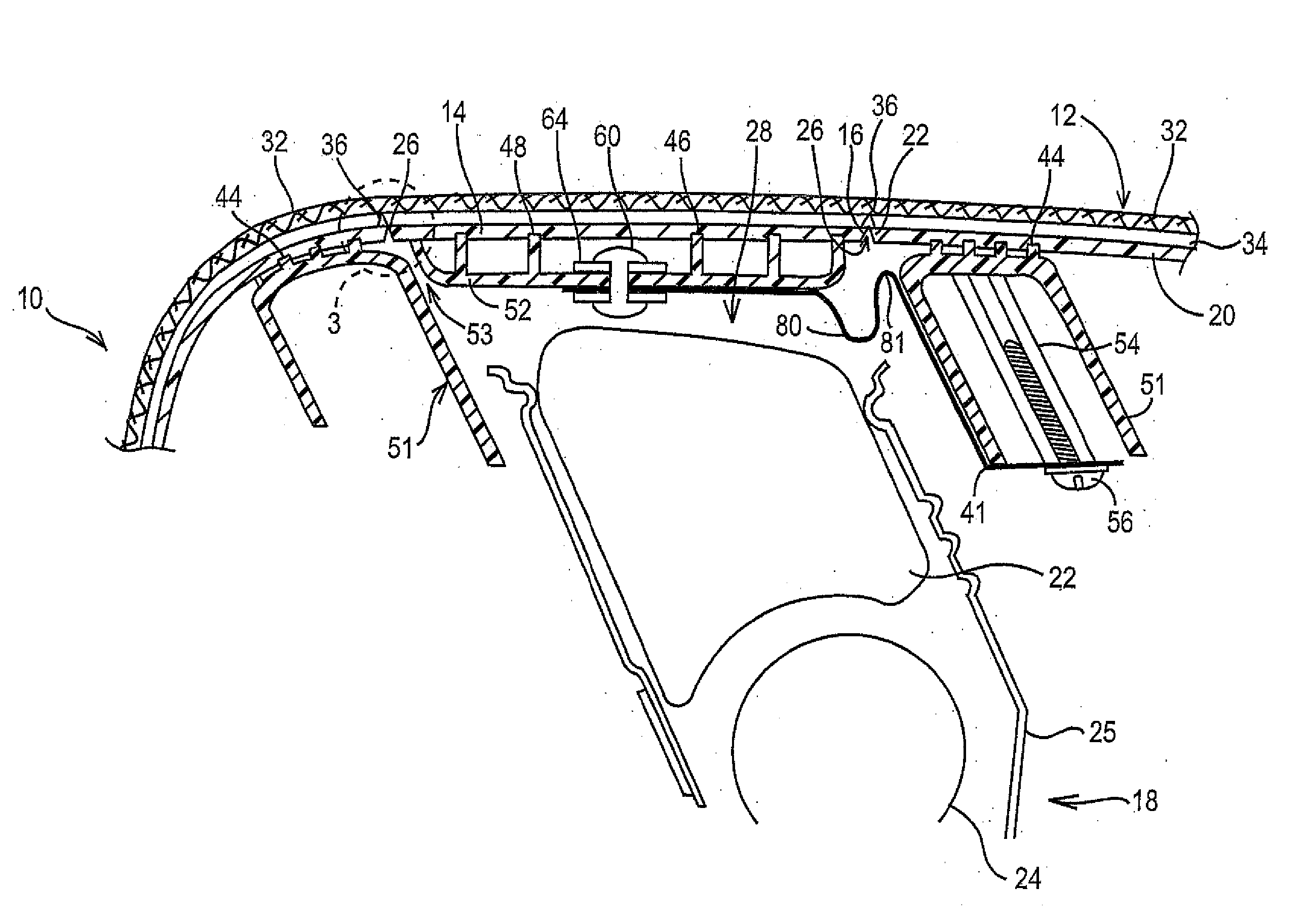

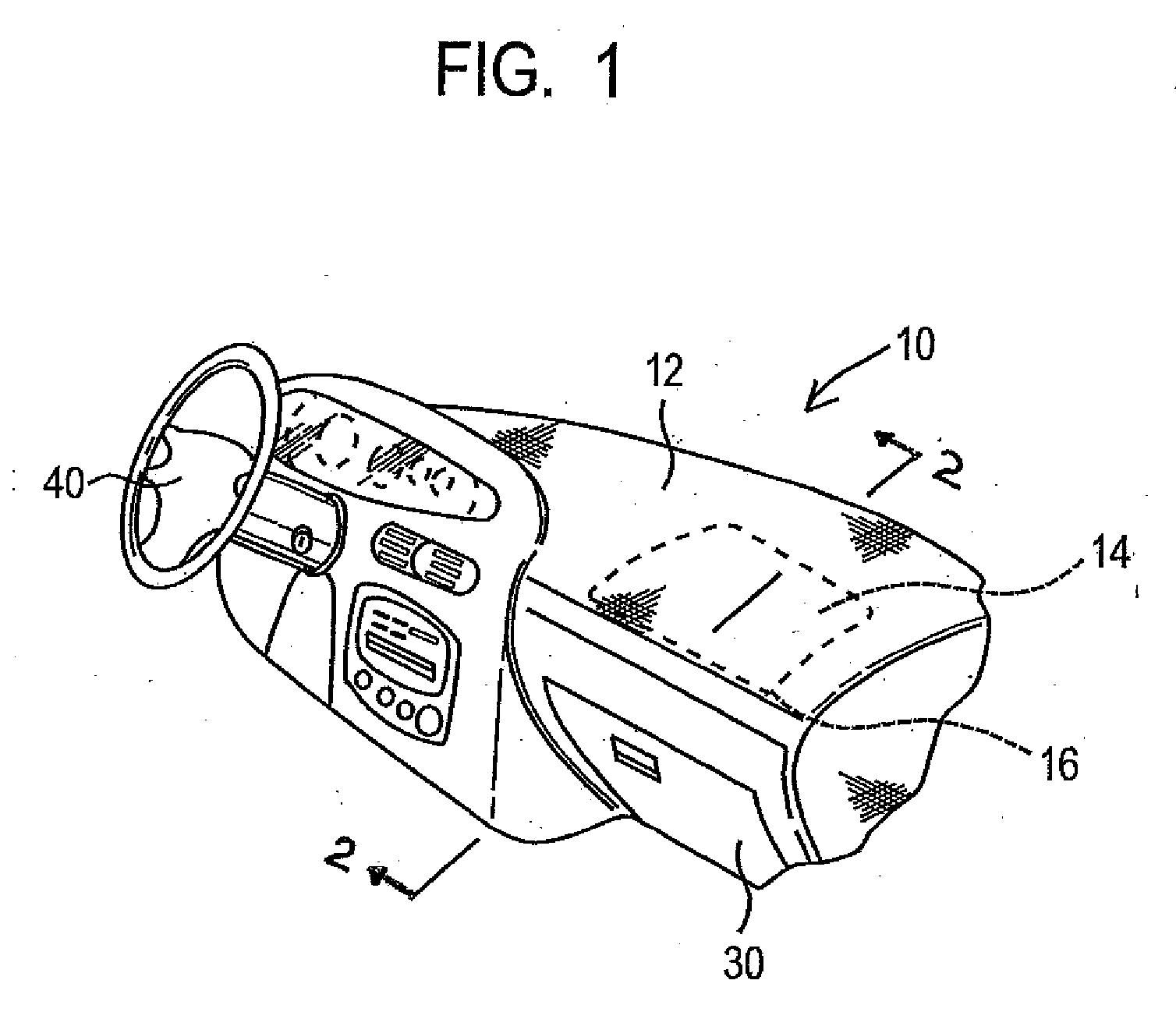

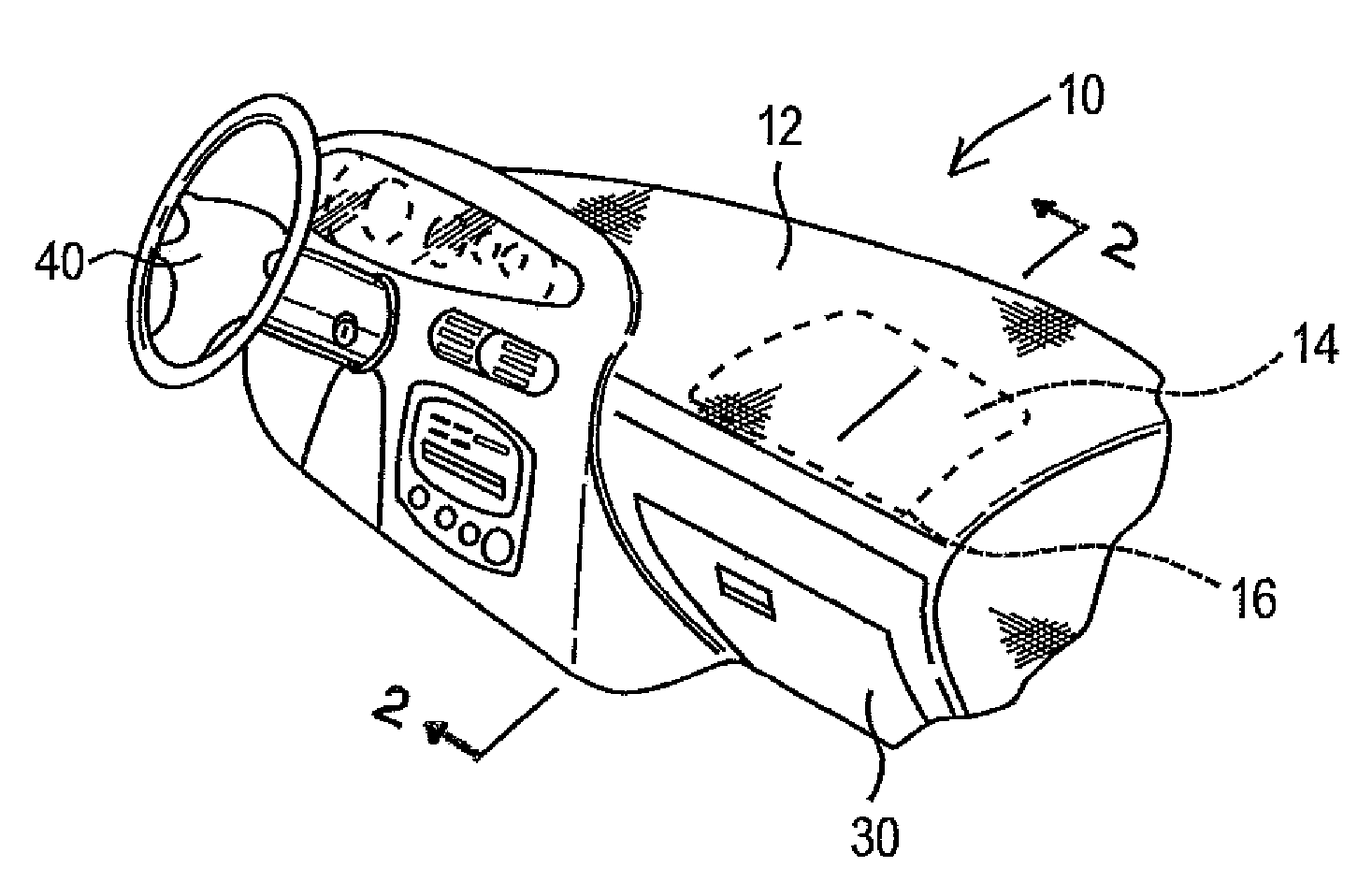

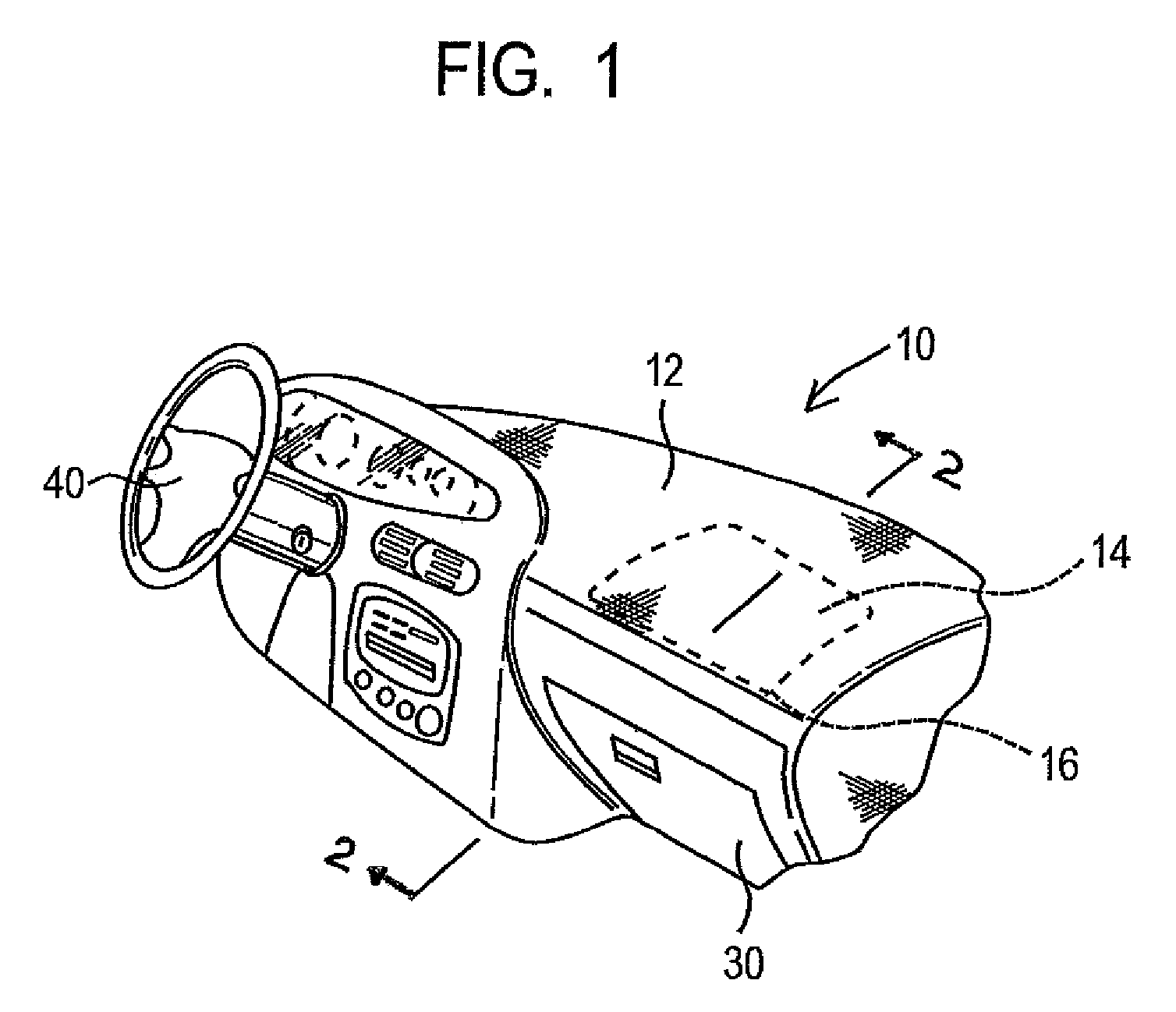

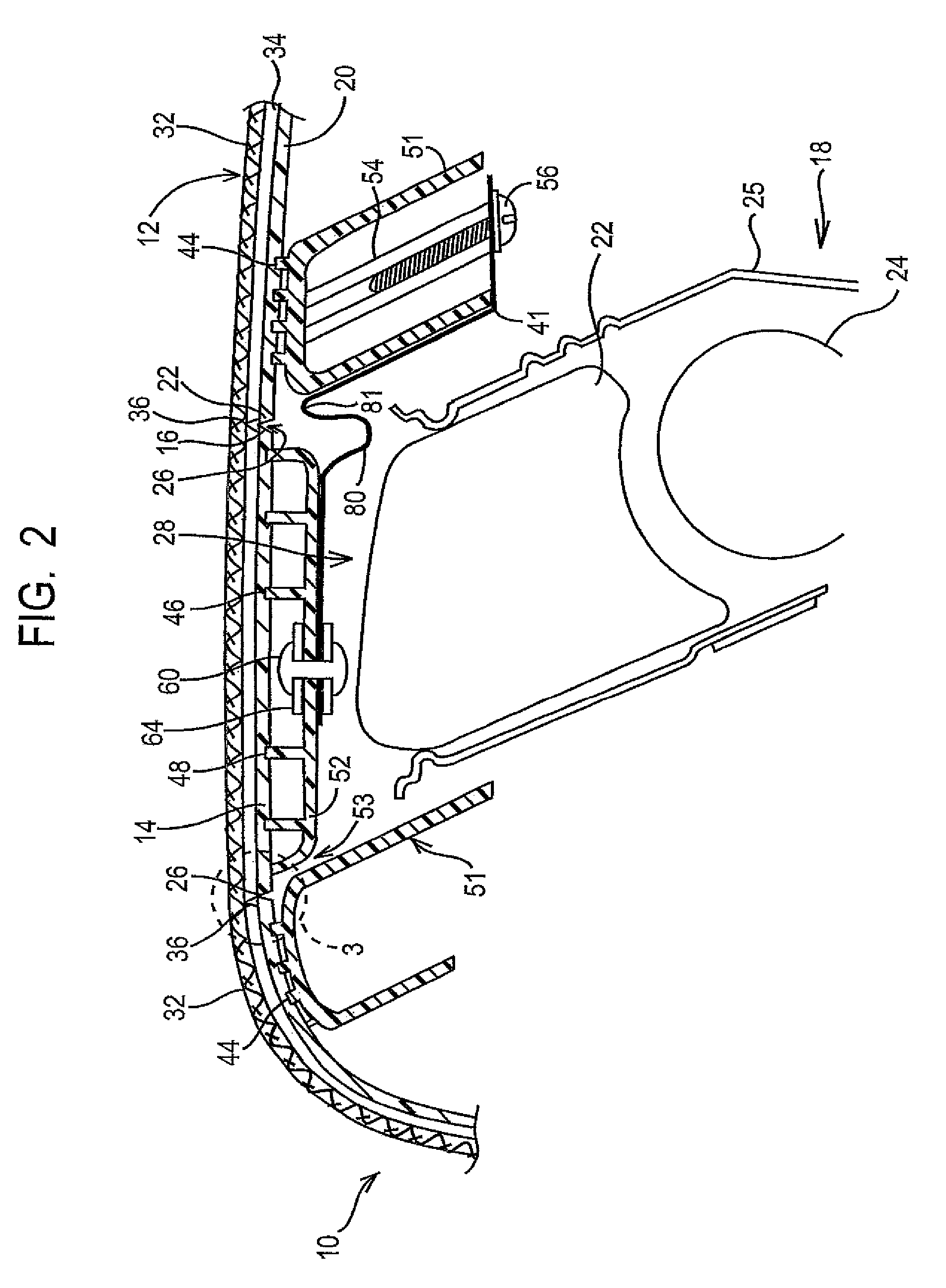

Pre-weakening of fabric covered airbag doors

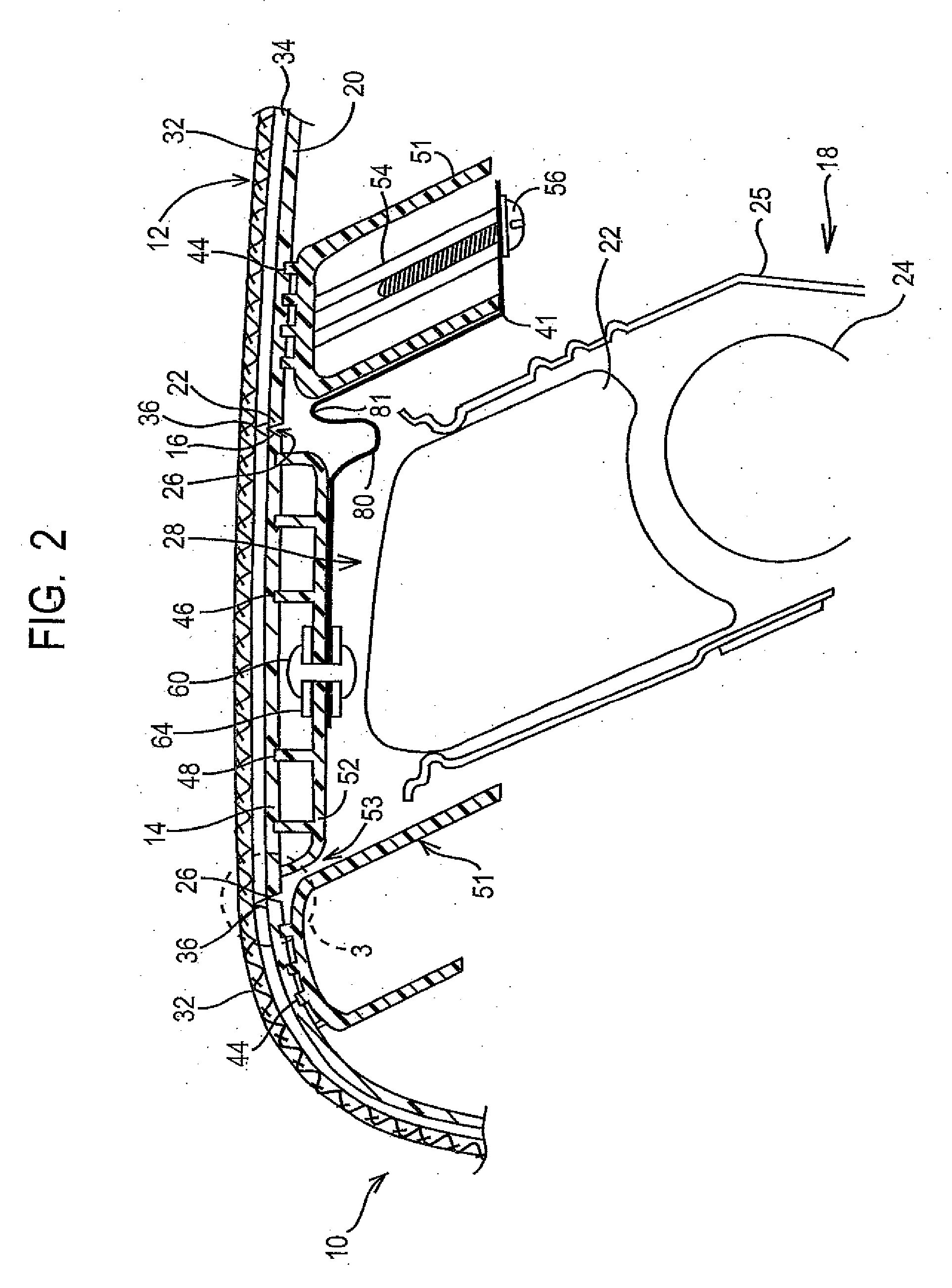

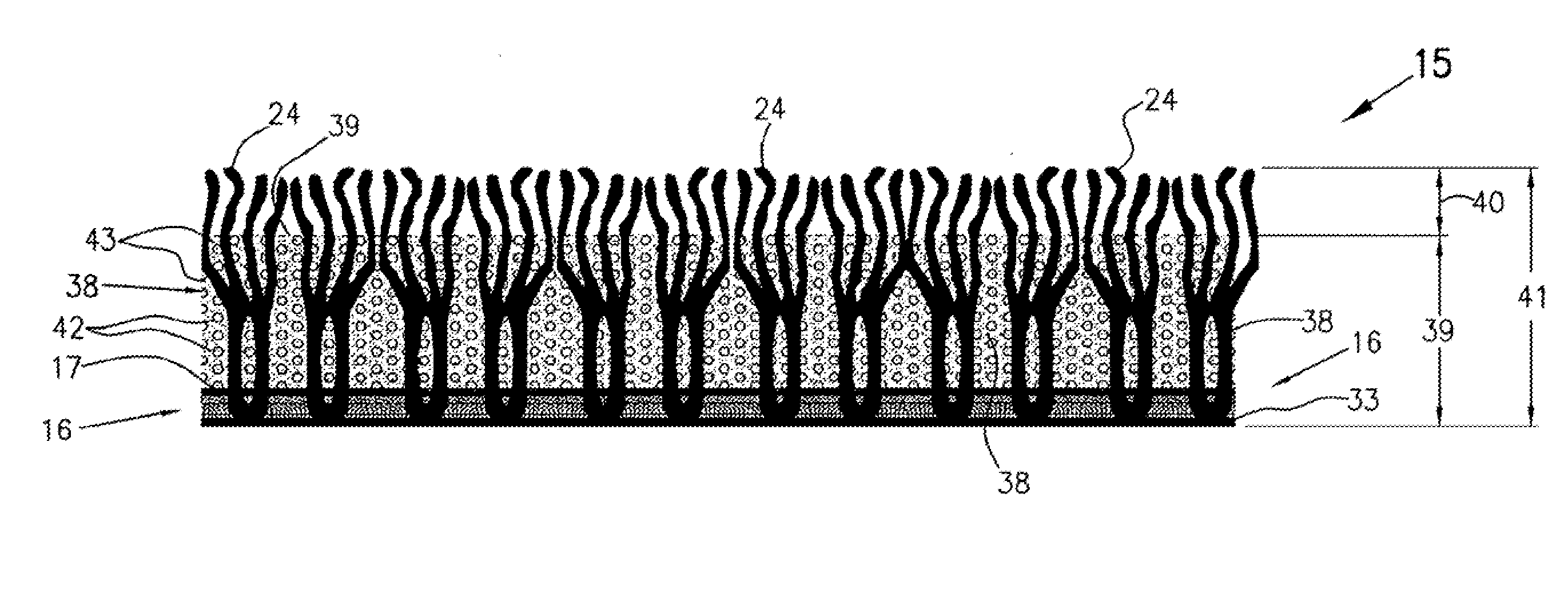

A variety of embodiments are disclosed, in both apparatus and method form, that relate to the use of fabric material in the manufacture of an air bag deployment system. In addition, fabric weakening is disclosed according to a technique that does not result in physical alteration of the fabric. This invention therefore includes an air bag cover for an air bag safety system for a vehicle comprising a fabric outer layer having a frontside and a backside and a substrate containing an opening wherein the opening has a periphery. The substrate is preferably formed by low pressure molding, wherein the fabric outer layer overlies the opening in the substrate, and wherein the fabric outer layer is weakened at a location that is adjacent or overlies the substrate opening periphery.

Owner:COLLINS & AIKMAN AUTOMOTIVE CO INC

Rotary type multi-arm shedding mechanism

Owner:常熟纺织机械厂有限公司

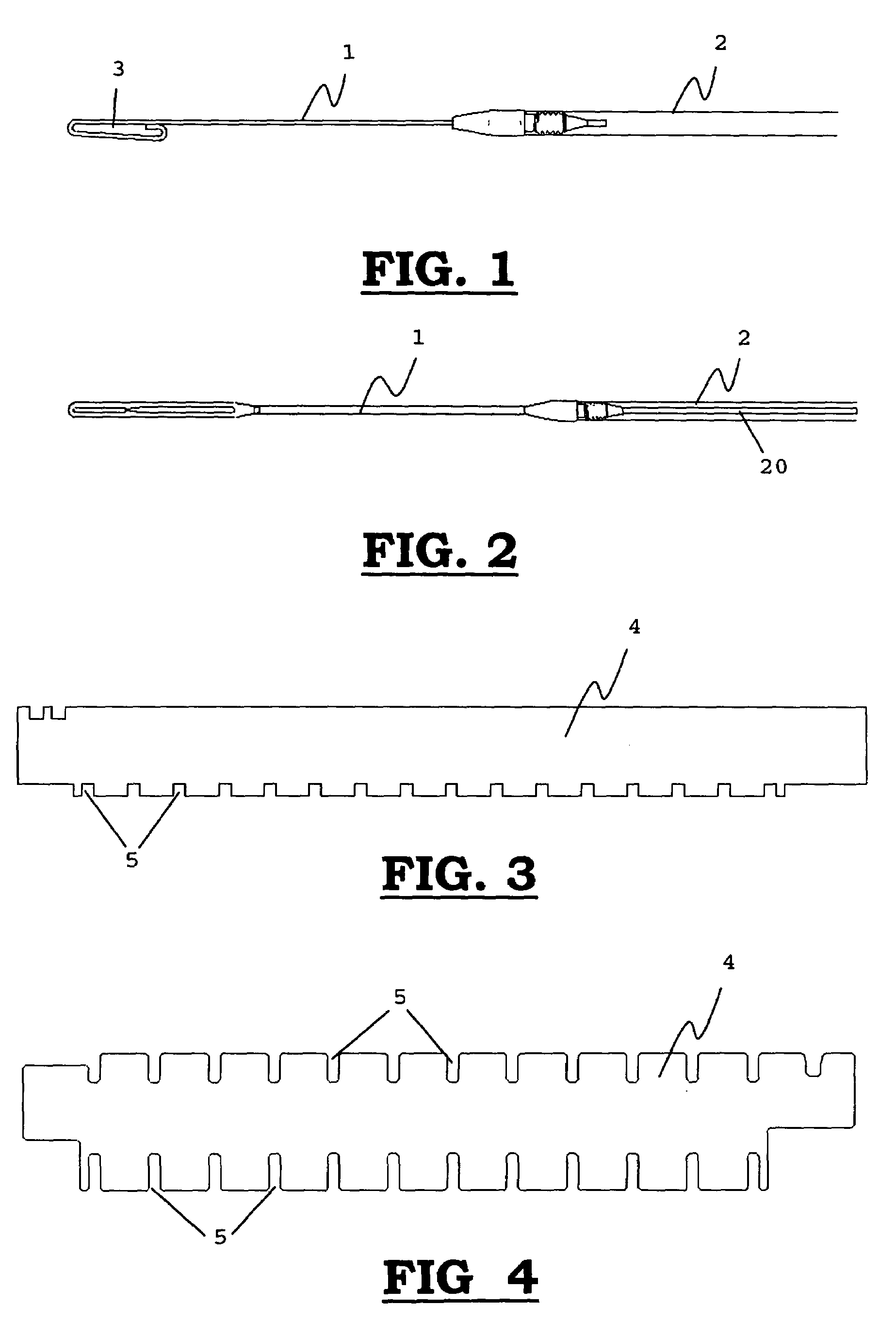

Pre-Weakening Of Fabric Covered Airbag Doors

A variety of embodiments are disclosed, in both apparatus and method form, that relate to the use of fabric material in the manufacture of an air bag deployment system. In addition, fabric weakening is disclosed according to a technique that does not result in physical alteration of the fabric. This invention therefore includes an air bag cover for an air bag safety system for a vehicle comprising a fabric outer layer having a frontside and a backside and a substrate containing an opening wherein the opening has a periphery. The substrate is preferably formed by low pressure molding, wherein the fabric outer layer overlies the opening in the substrate, and wherein the fabric outer layer is weakened at a location that is adjacent or overlies the substrate opening periphery.

Owner:COLLINS & AIKMAN AUTOMOTIVE CO INC

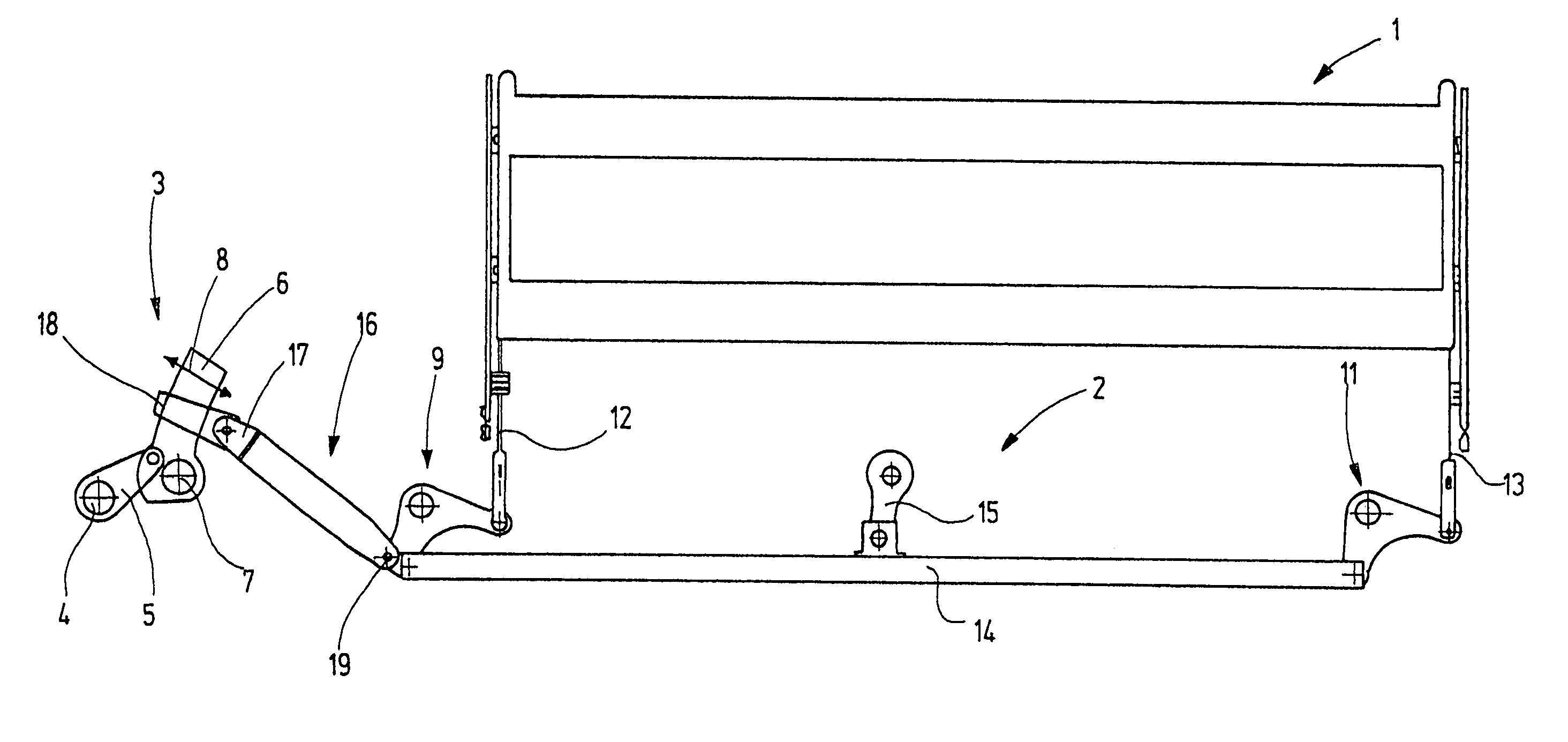

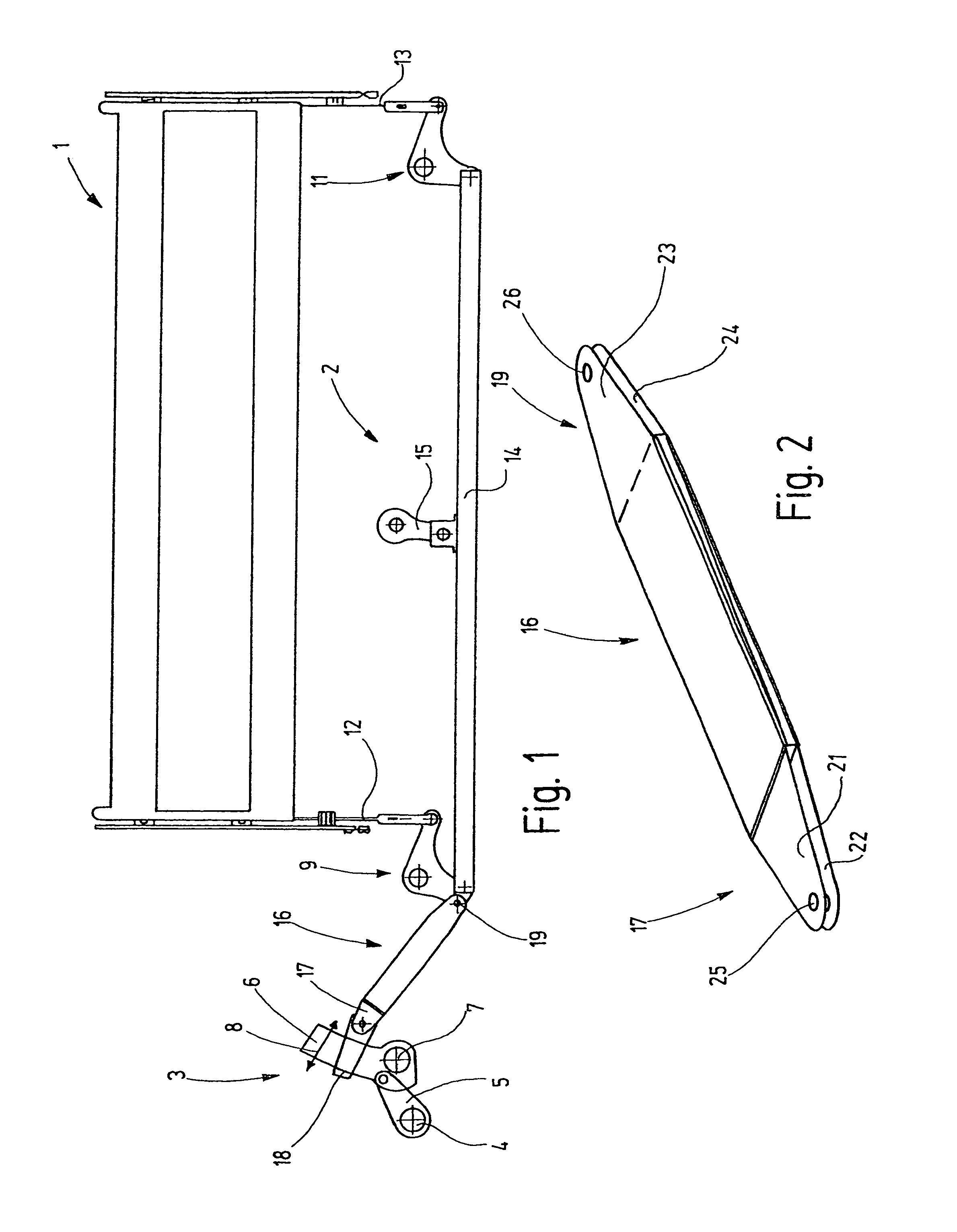

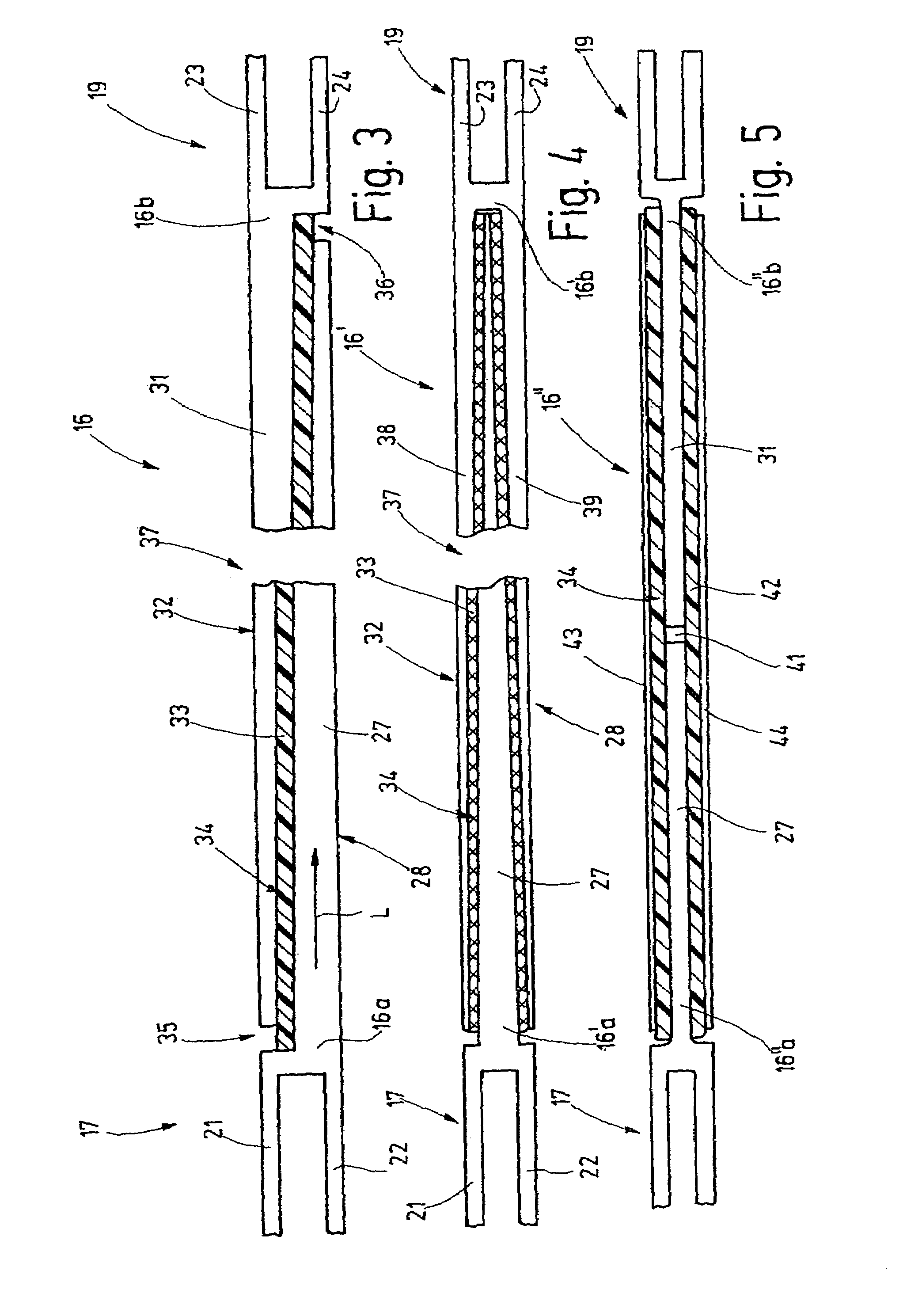

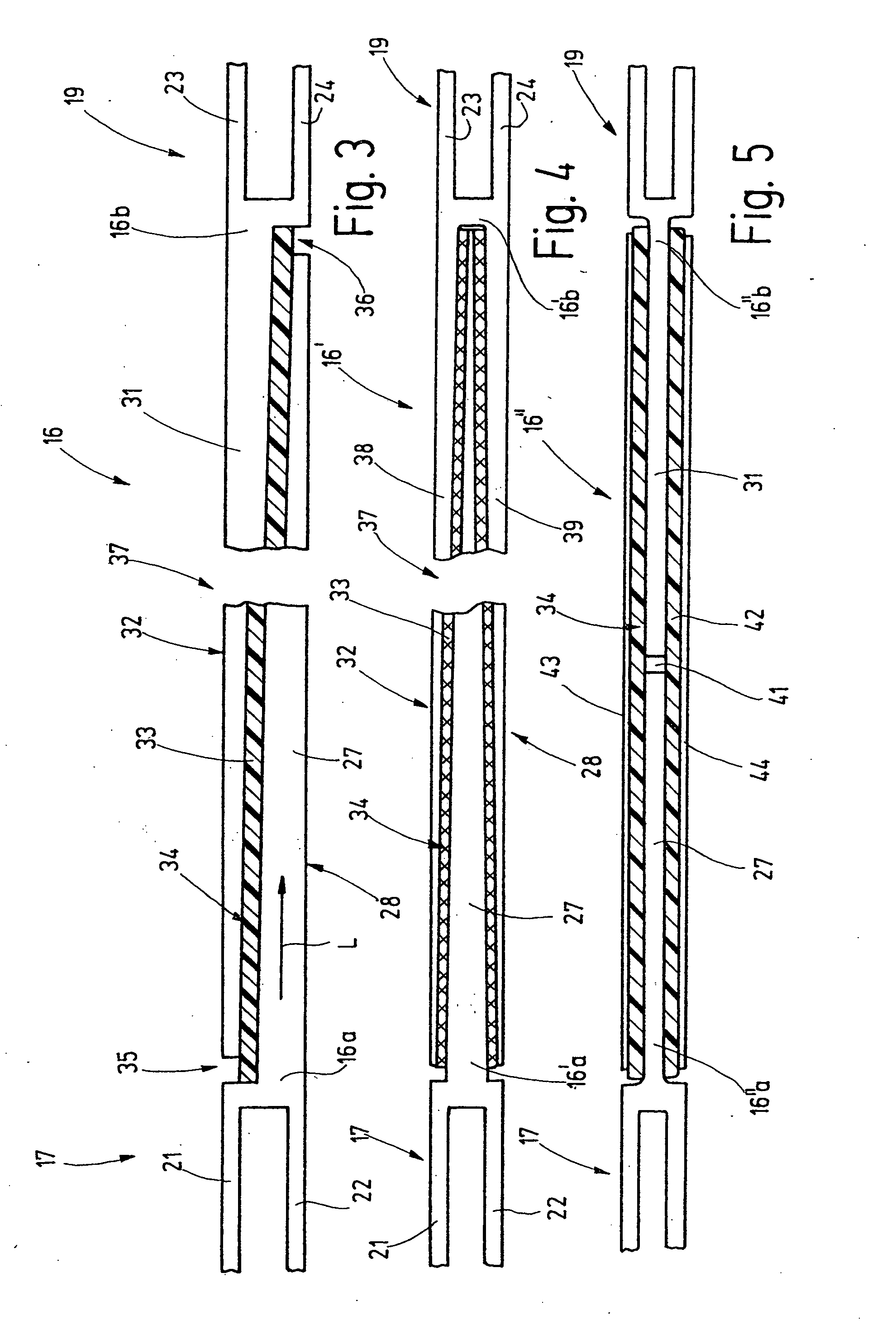

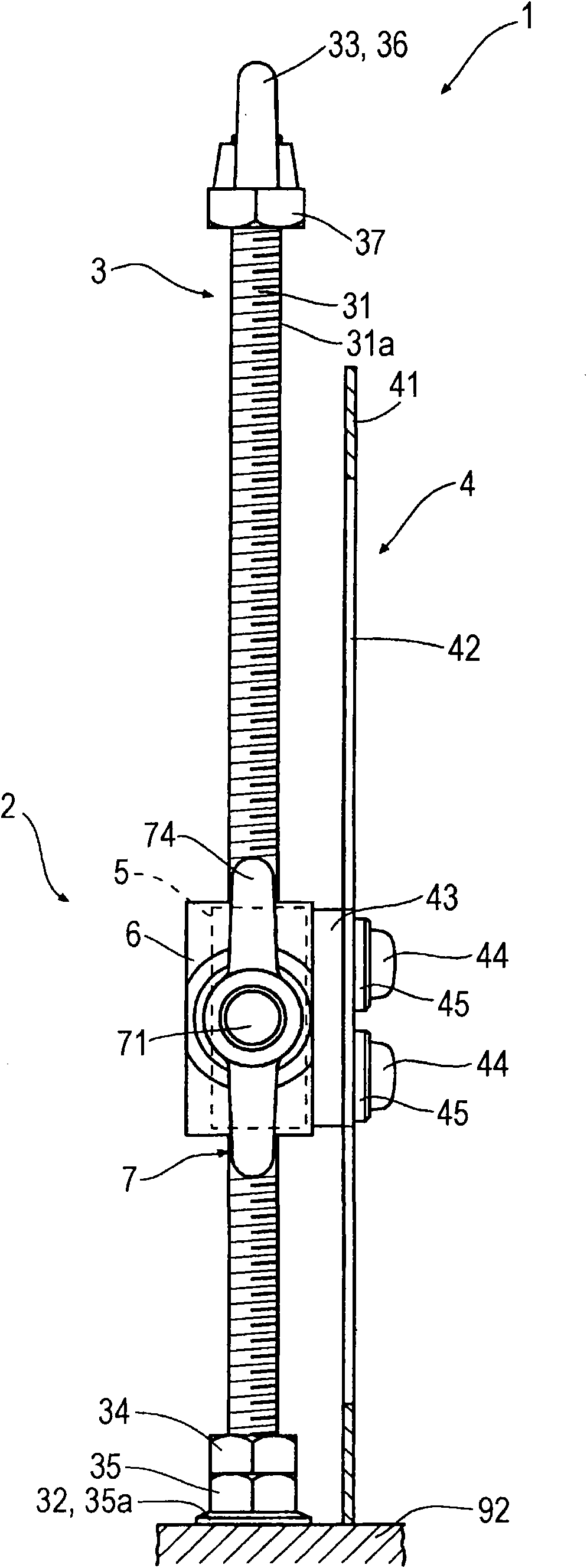

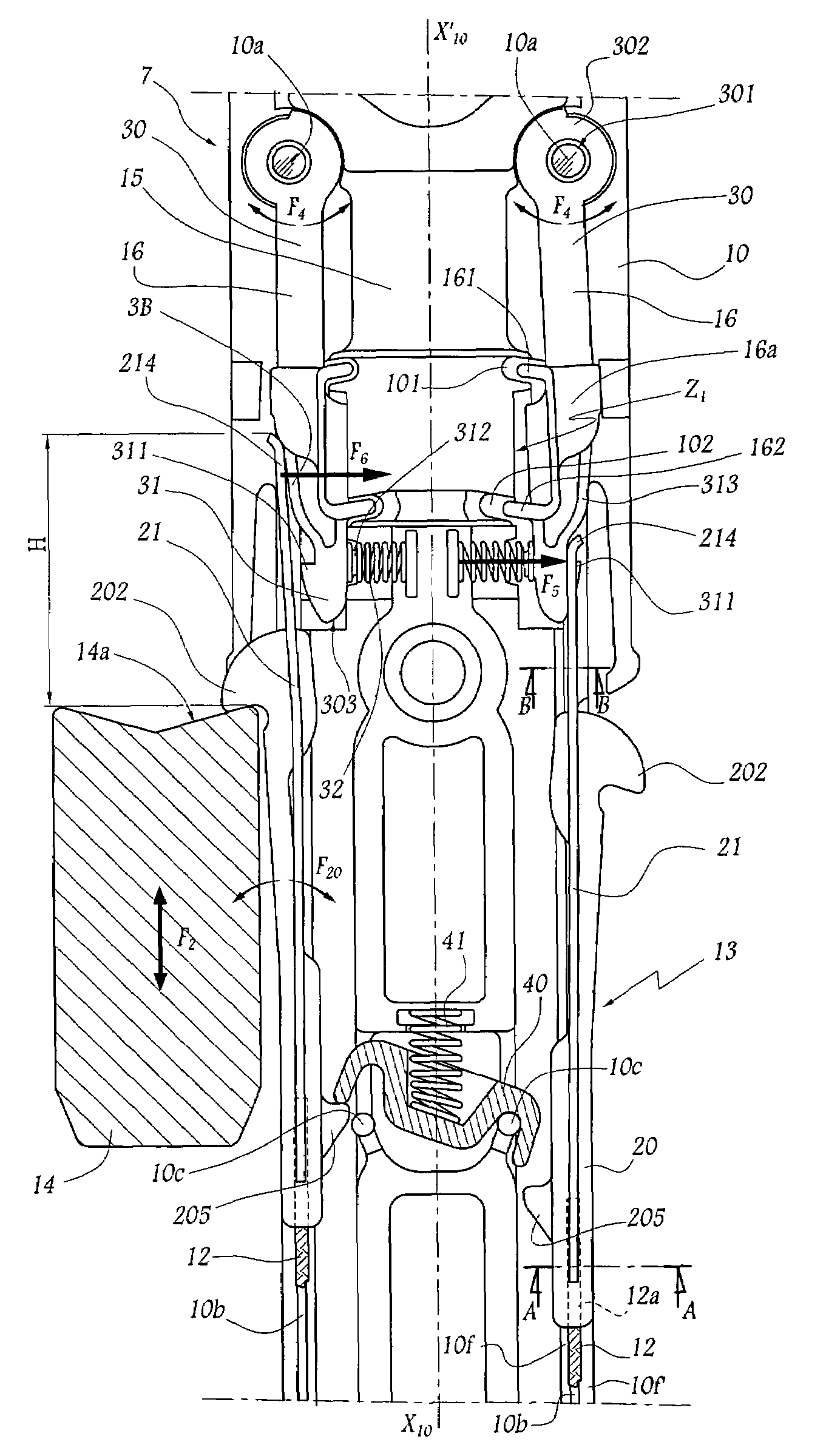

Low-vibration shedding system

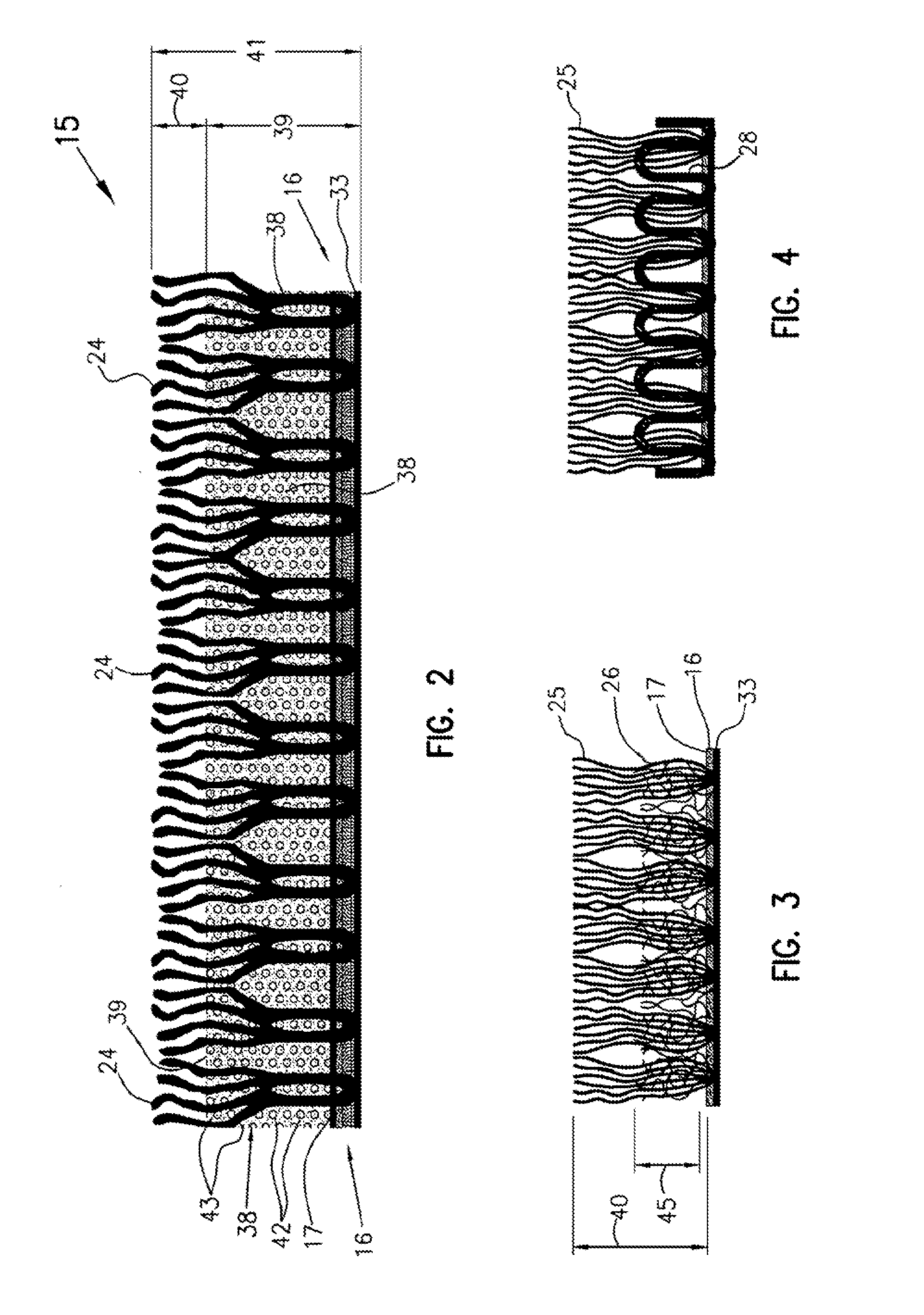

A novel rod linkage for driving a heddle shaft includes at least one strap (16), which for damping oscillation has a sandwich structure (37) oriented in the longitudinal direction (L) of the strap assembly (16). The sandwich structure includes at least one rigid element (27), extending in the longitudinal direction, which is joined to one end (17) of the strap assembly (16); a second rigid element (31), likewise extending essentially in the longitudinal direction, which is joined to the other end (19); and a two-dimensional damping element (34), again extending in the longitudinal direction, disposed between the first two. The element (34) exclusively effects the mechanical connection of the two parts (16a, 16b) of the strap assembly (16). Preferably, no additional connecting elements, such as rivets, screws, or other rigid connections, between the rigid elements (27, 31) are provided. Preferably, the rigid elements (27, 31) are embodied as wedges pointing in opposite directions, which thus define a wave resistance that varies in opposite directions in the longitudinal direction. This wave resistance brings about an intentional coupling misadaptation with respect to the oscillation transmission. The element (34) disposed between them damps the oscillations additionally, so that the strap assembly (16) transmits driving motions like a filter and destroys or absorbs interfering oscillations.

Owner:GROZ BECKERT KG

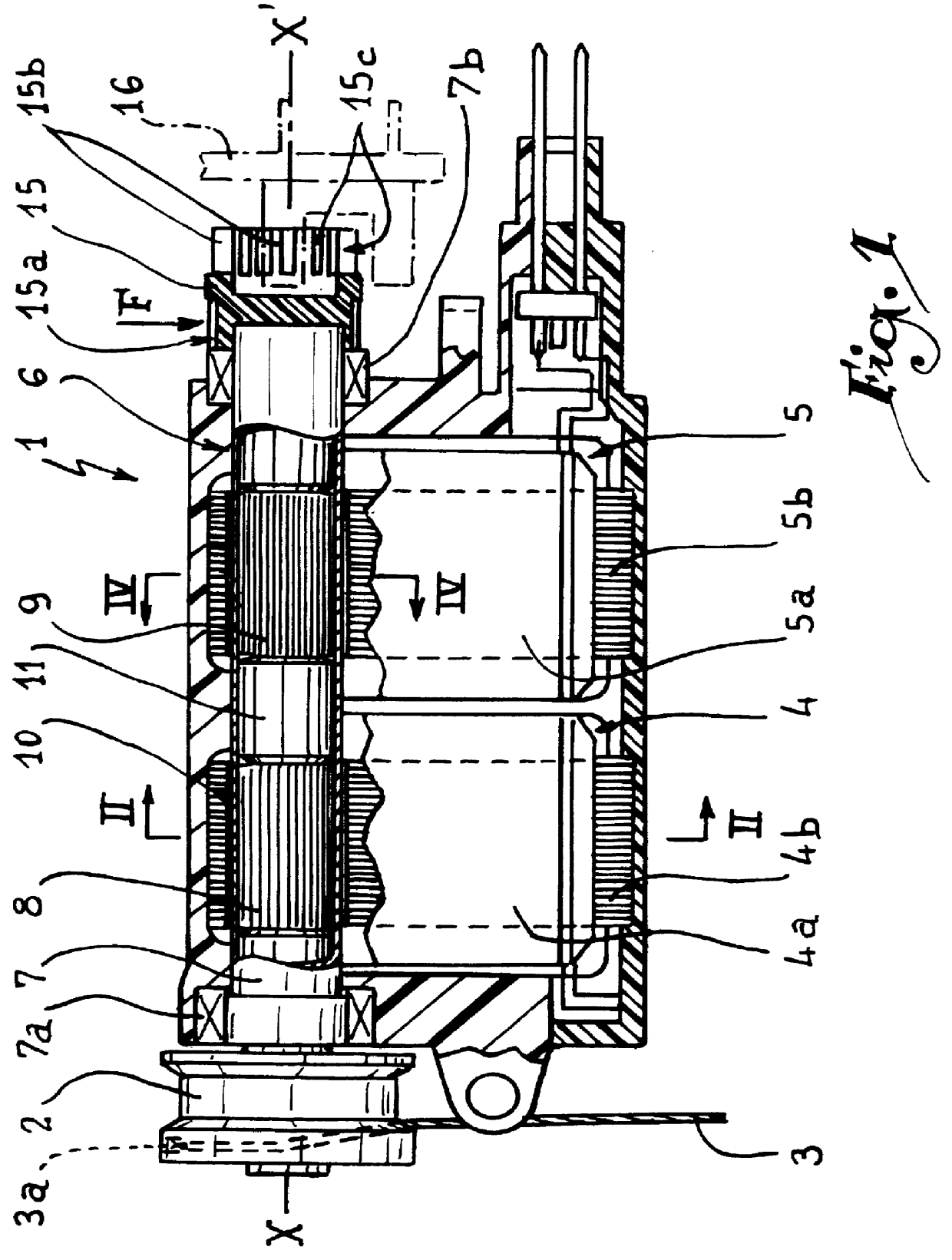

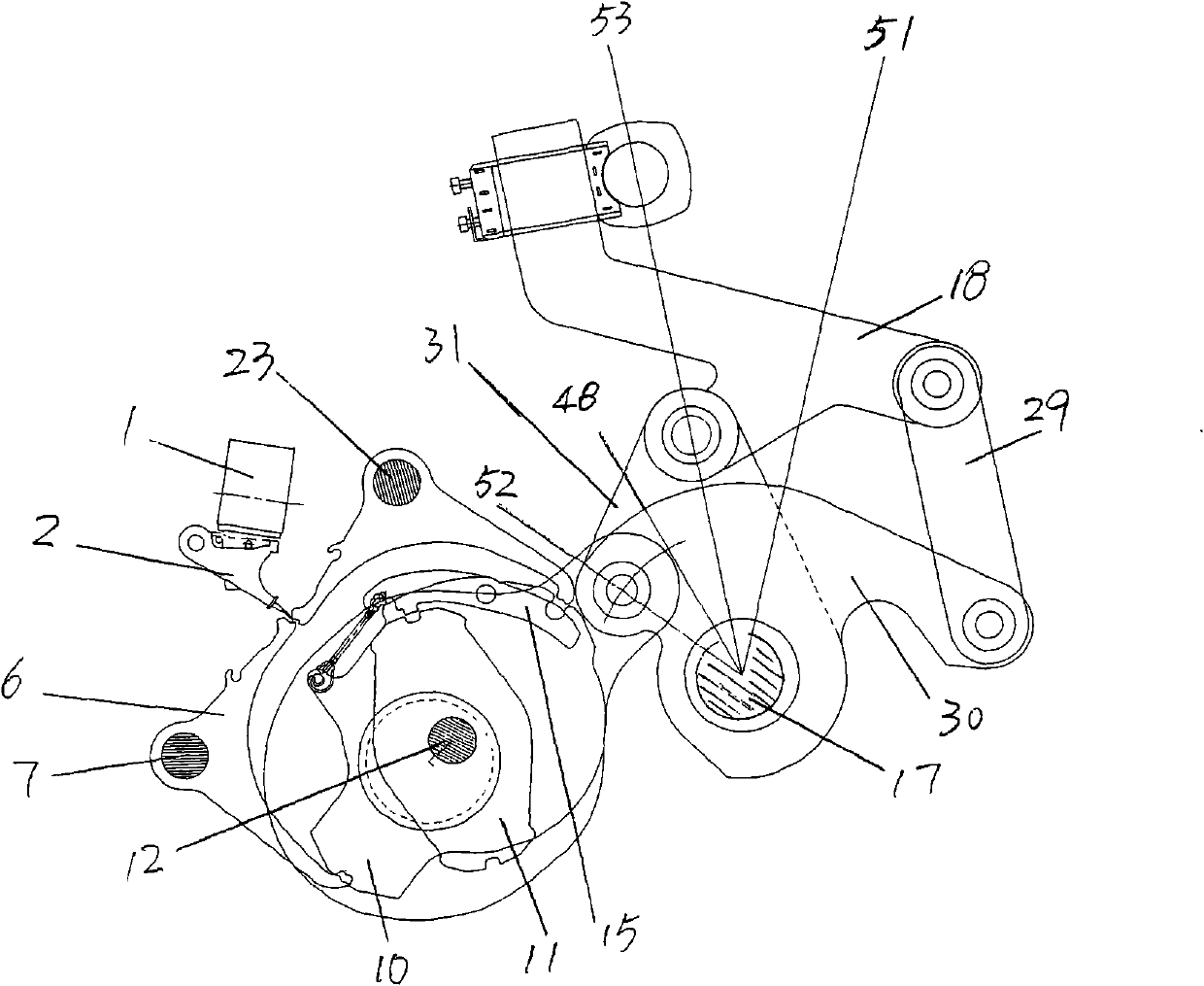

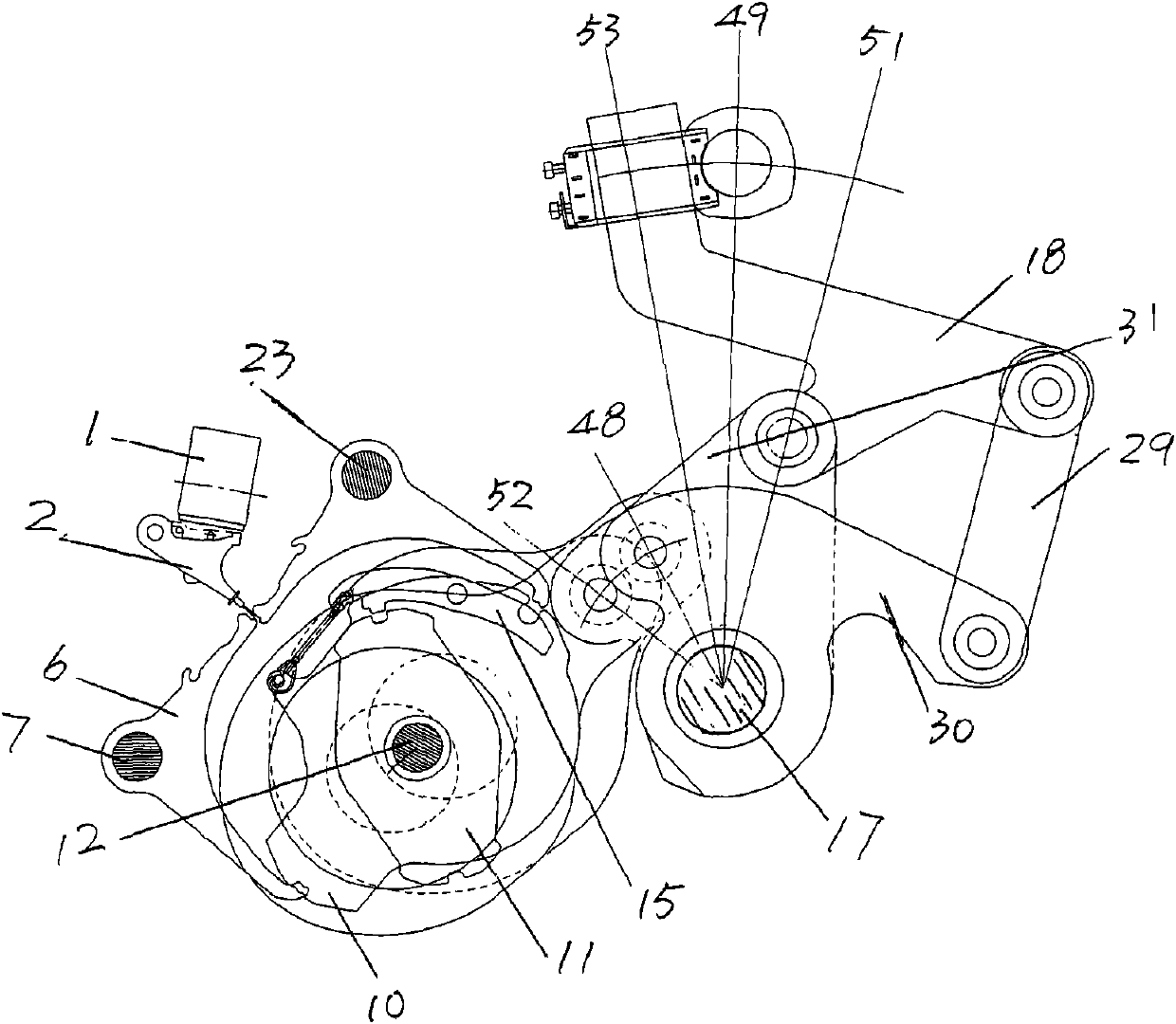

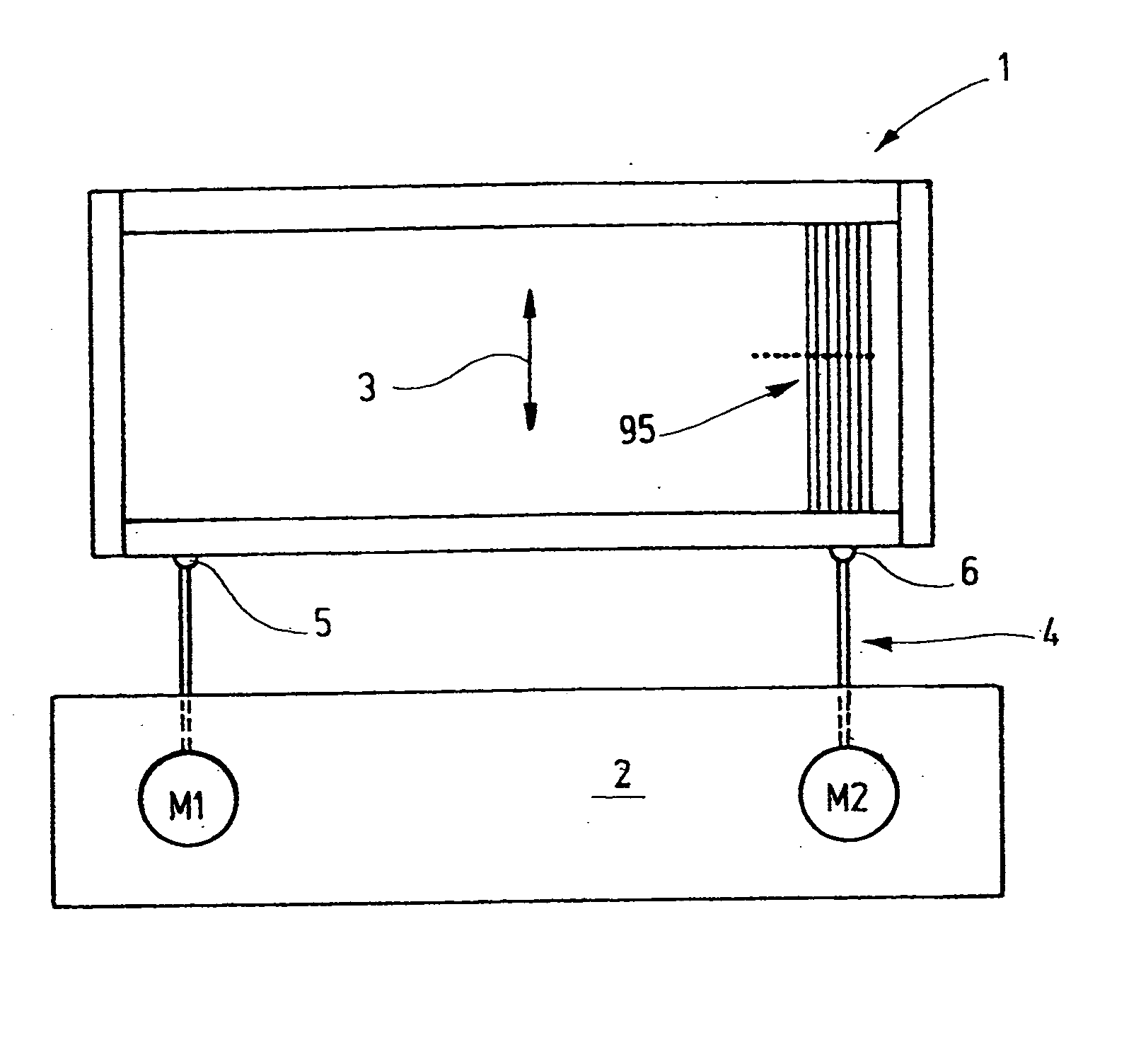

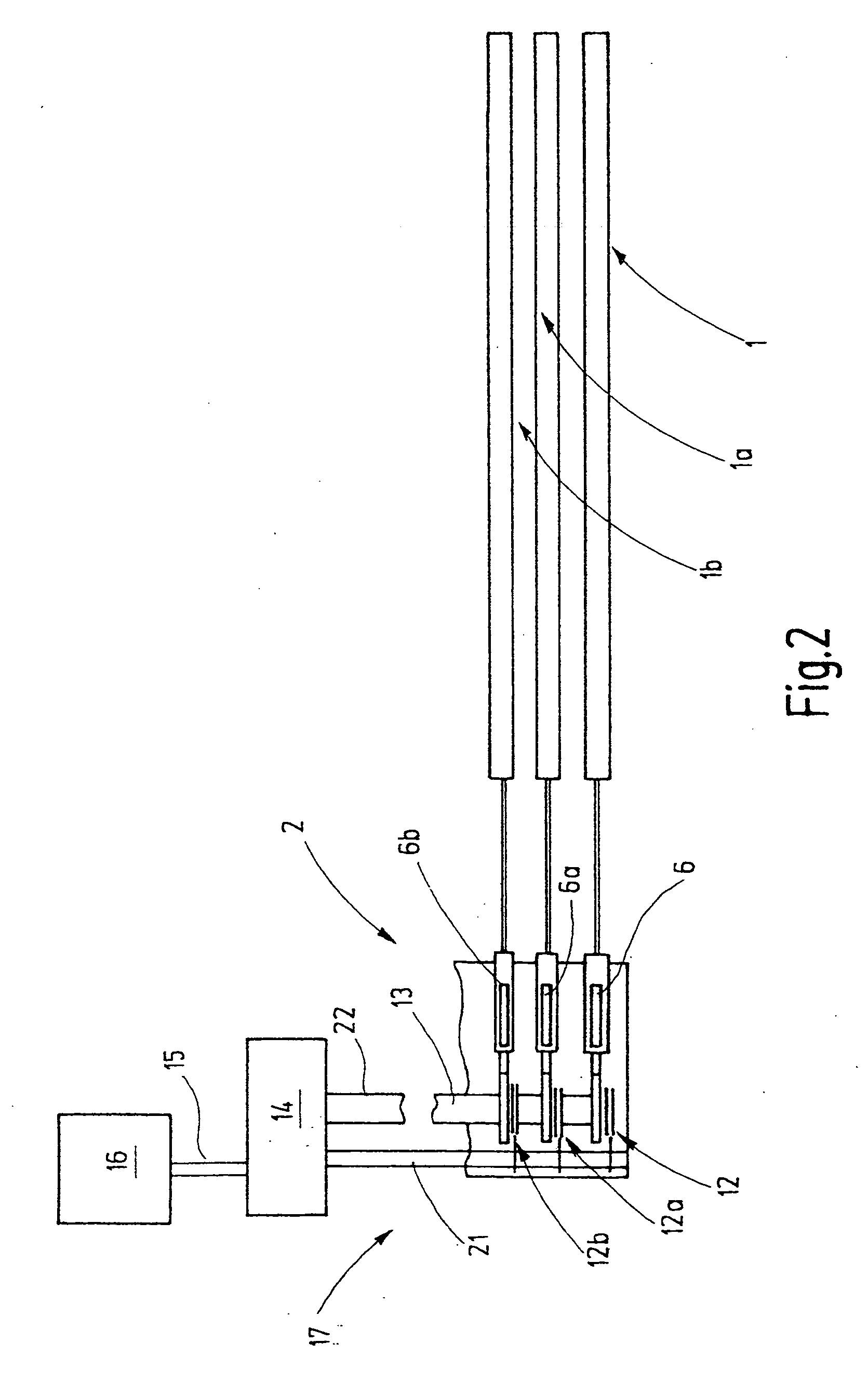

Drive mechanism for shed forming components of a loom

The heald shafts of a power loom are driven by electric D.C. or A.C. motors which have a external rotor or an armature connected to the respective heald shaft through two articulated couplings, for example snap locks, and a push-pull rod. The motors receive control signals from a computerized controller for reversing the motion direction of the external rotor or armature. The stators of the motors are rigidly mounted on a fixed axis secured to the loom frame.

Owner:LINDAUER DORNIER GMBH

Pre-weakening of fabric covered airbag doors

A variety of embodiments are disclosed, in both apparatus and method form, that relate to the use of fabric material in the manufacture of an air bag deployment system. In addition, fabric weakening is disclosed according to a technique that does not result in physical alteration of the fabric. This invention therefore includes an air bag cover for an air bag safety system for a vehicle comprising a fabric outer layer having a frontside and a backside and a substrate containing an opening wherein the opening has a periphery. The substrate is preferably formed by low pressure molding, wherein the fabric outer layer overlies the opening in the substrate, and wherein the fabric outer layer is weakened at a location that is adjacent or overlies the substrate opening periphery.

Owner:COLLINS & AIKMAN AUTOMOTIVE CO INC

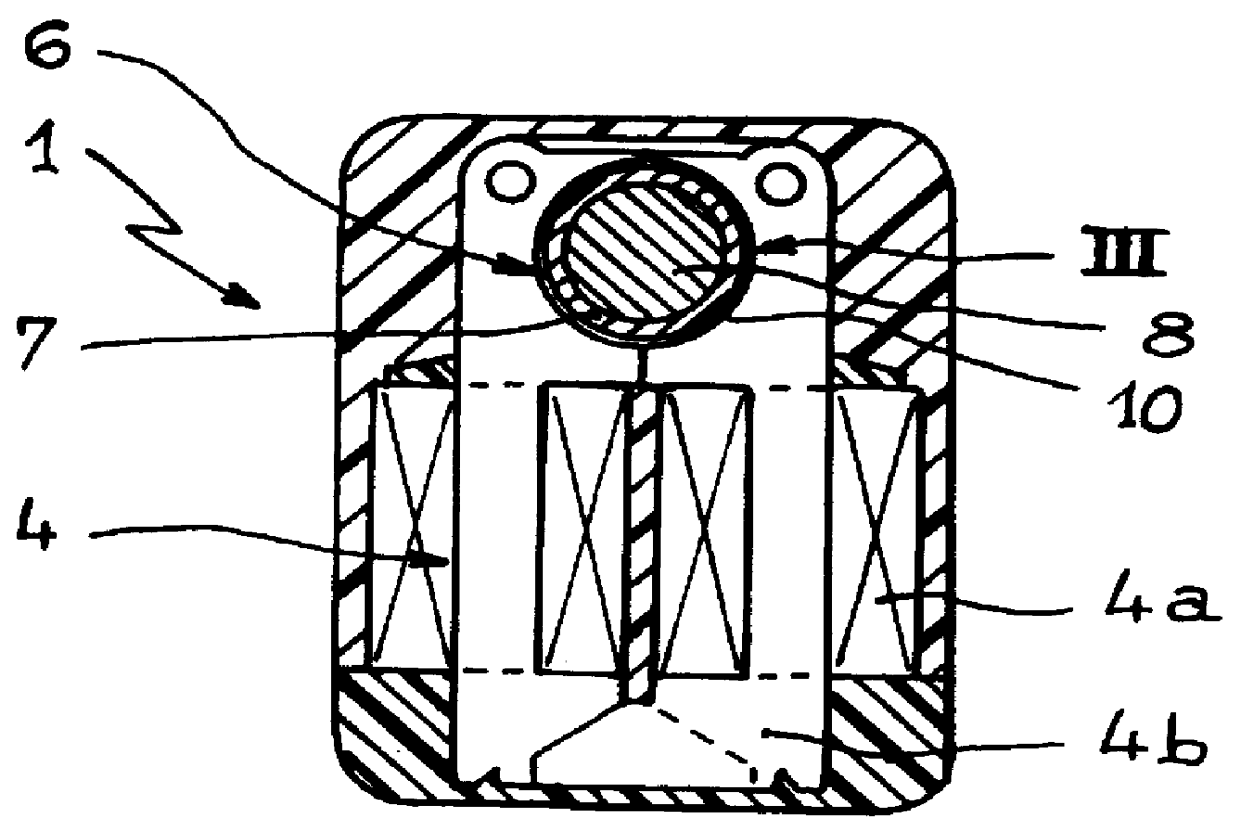

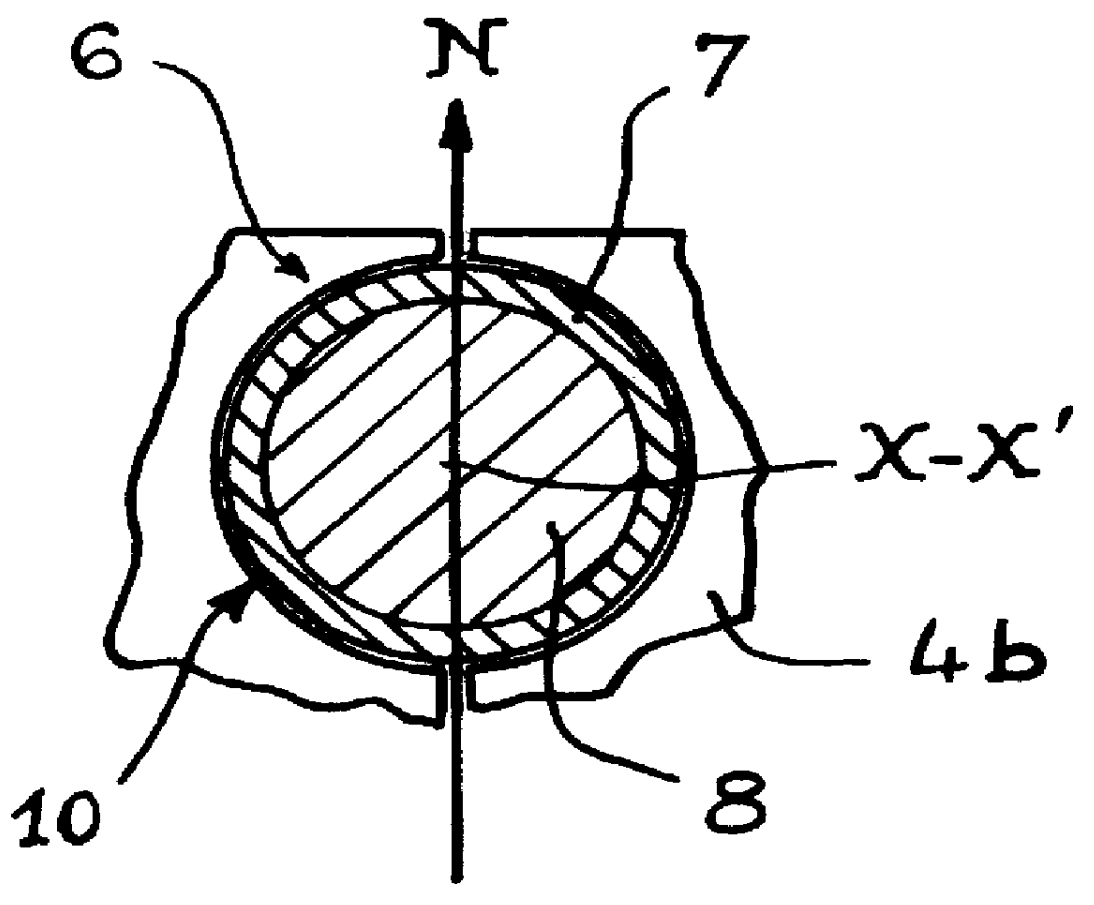

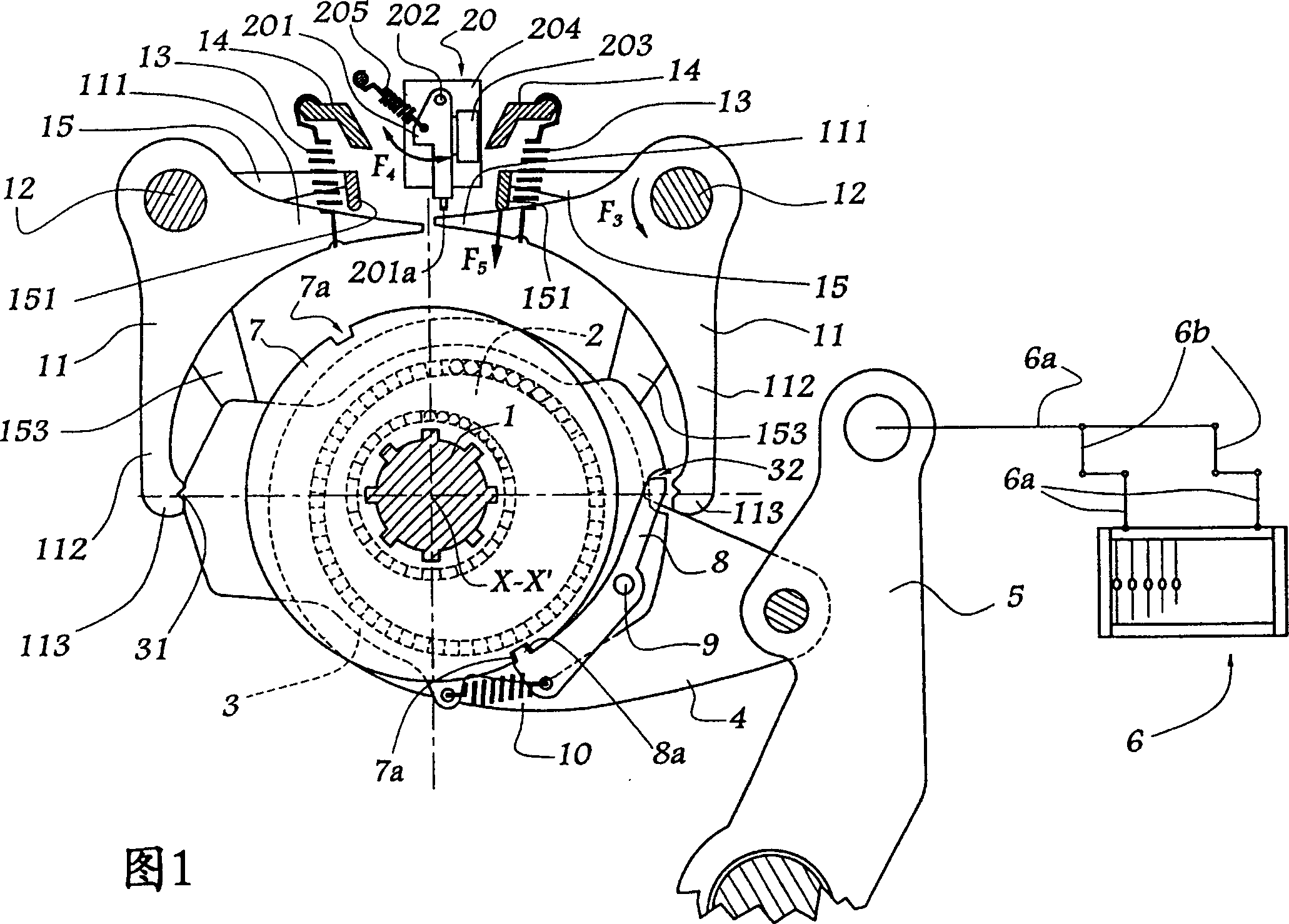

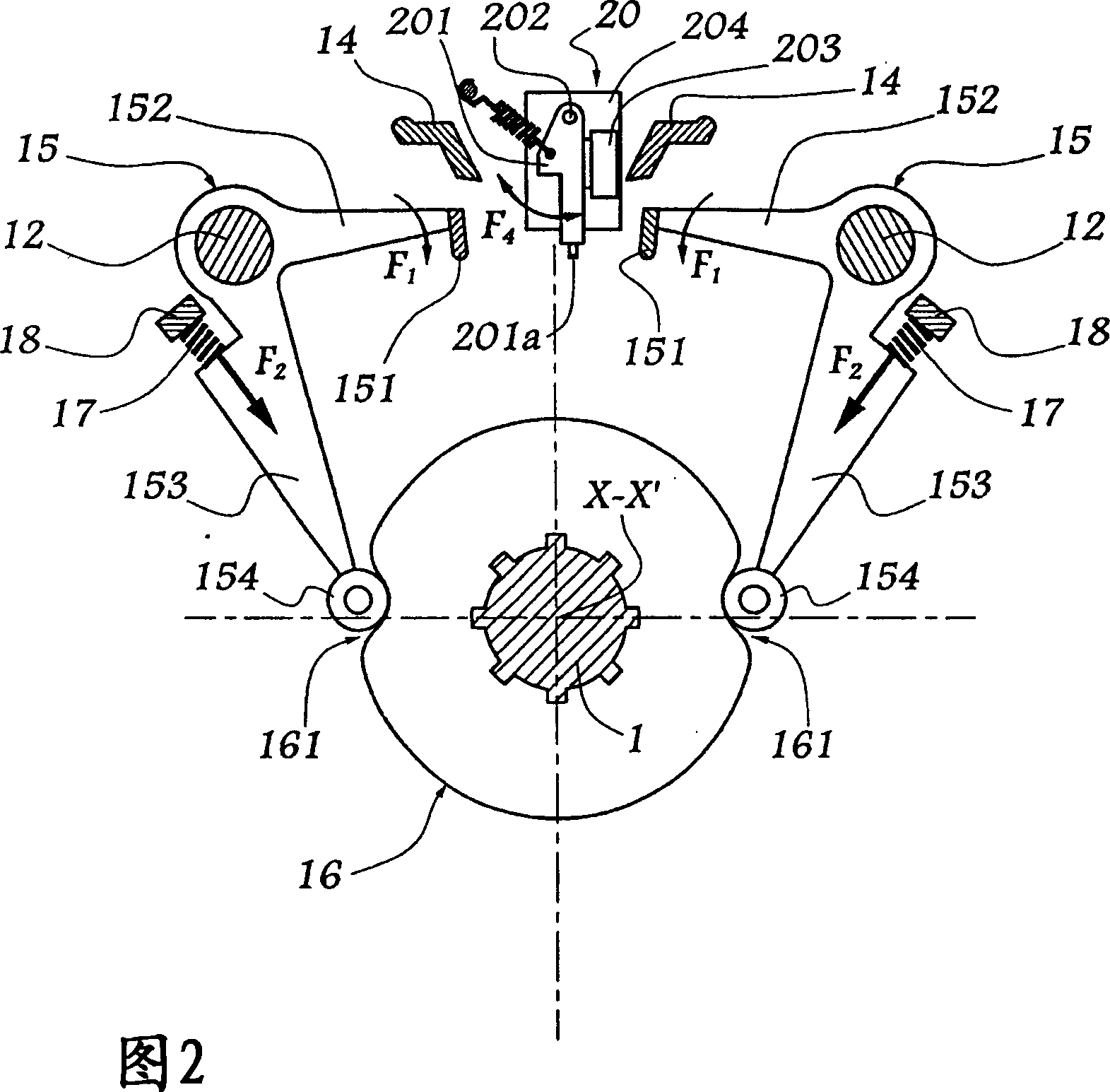

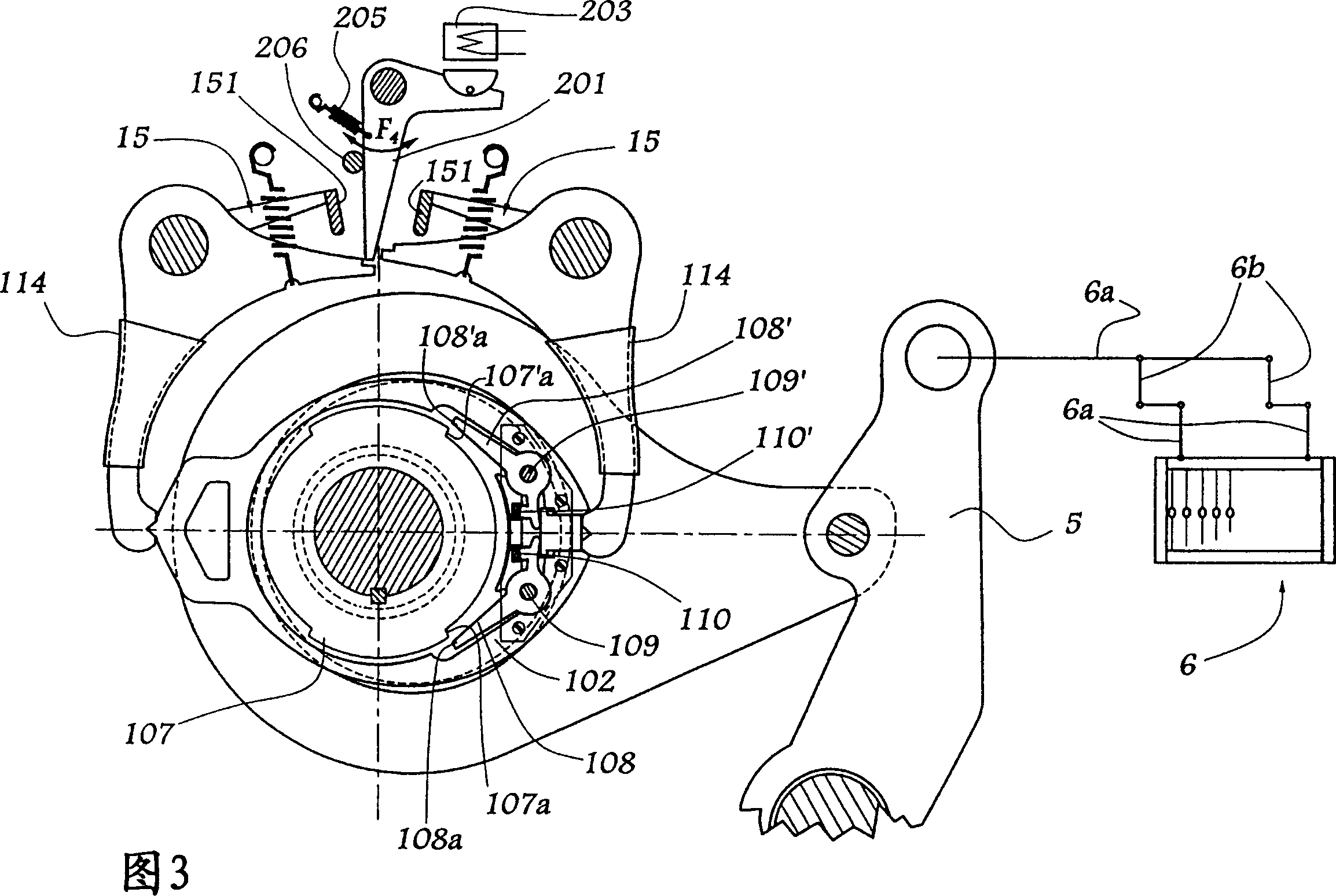

Electrical rotating actuator for forming a weaving loom shed

InactiveUS6105630AEasy to manufactureReduce the overall diameterJacquardsDobbiesElectrical polarityEngineering

An electrical rotating apparatus for controlling a harness cord associated with the shed of a weaving loom which includes an actuator including a rotor and a stator. The rotor is formed of at least two permanent magnets which are mounted within a tube so as to be spaced axially with respect to one another and wherein a plurality of stator elements are also provided offset axially relative to an axis of rotation of the rotor such that each of the plurality of rotors corresponds with a separate one of the plurality of stators. The polarities of one or the other of the permanent magnets or the stator elements are offset angularly relative to the axis of rotation.

Owner:STAUBLI FAVERGES SA

Low-vibration shedding system

InactiveUS20050051228A1Good oscillation absorptionImprove axial rigidityWeft knittingDobbiesCouplingEngineering

A novel rod linkage for driving a heddle shaft includes at least one strap (16), which for damping oscillation has a sandwich structure (37) oriented in the longitudinal direction (L) of the strap assembly (16). The sandwich structure includes at least one rigid element (27), extending in the longitudinal direction, which is joined to one end (17) of the strap assembly (16); a second rigid element (31), likewise extending essentially in the longitudinal direction, which is joined to the other end (19); and a two-dimensional damping element (34), again extending in the longitudinal direction, disposed between the first two. The element (34) exclusively effects the mechanical connection of the two parts (16a, 16b) of the strap assembly (16). Preferably, no additional connecting elements, such as rivets, screws, or other rigid connections, between the rigid elements (27, 31) are provided. Preferably, the rigid elements (27, 31) are embodied as wedges pointing in opposite directions, which thus define a wave resistance that varies in opposite directions in the longitudinal direction. This wave resistance brings about an intentional coupling misadaptation with respect to the oscillation transmission. The element (34) disposed between them damps the oscillations additionally, so that the strap assembly (16) transmits driving motions like a filter and destroys or absorbs interfering oscillations.

Owner:GROZ BECKERT KG

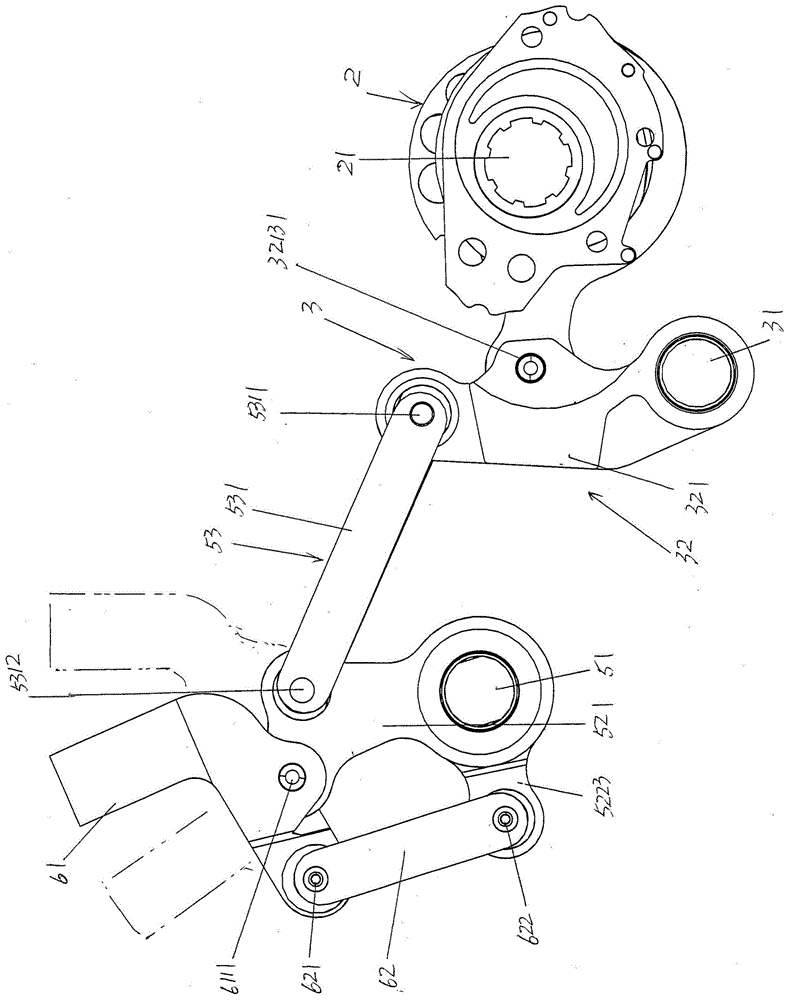

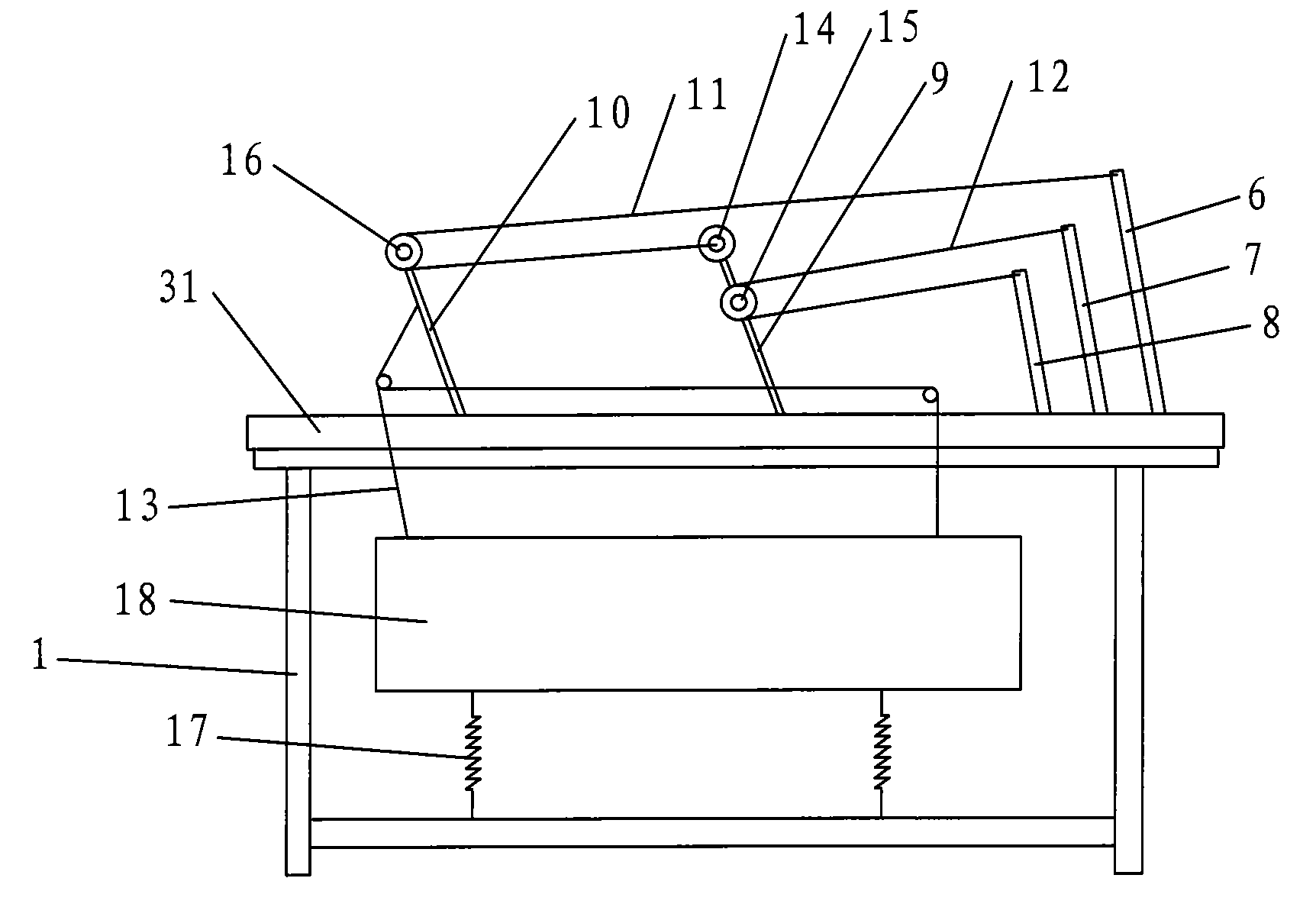

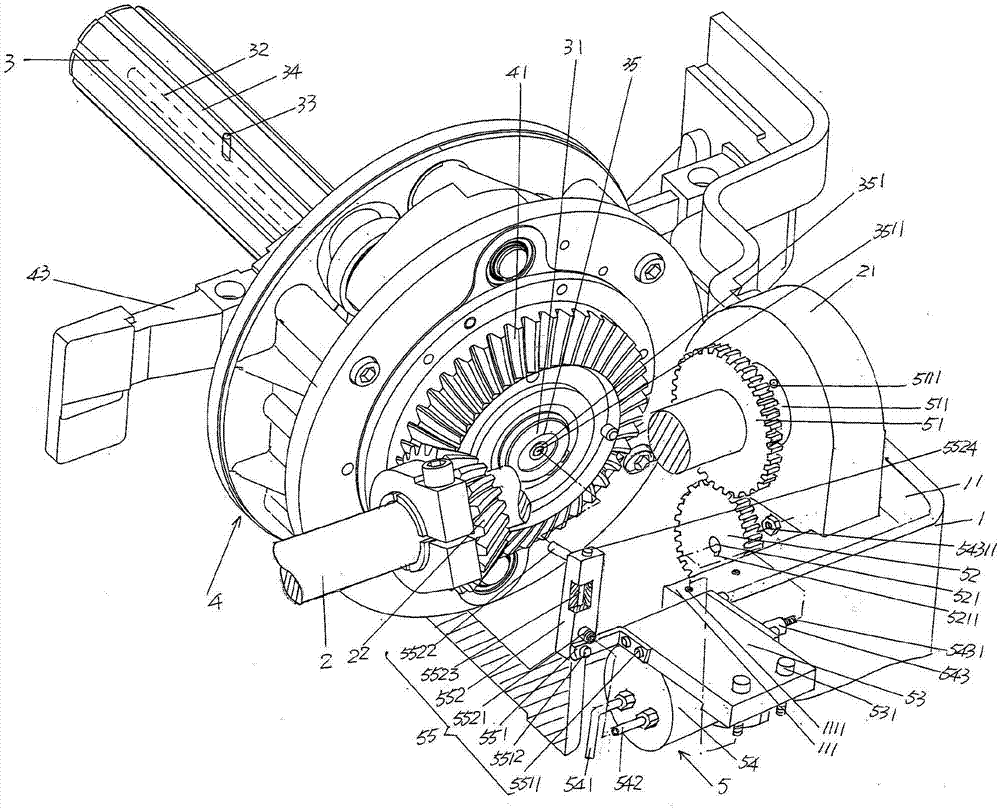

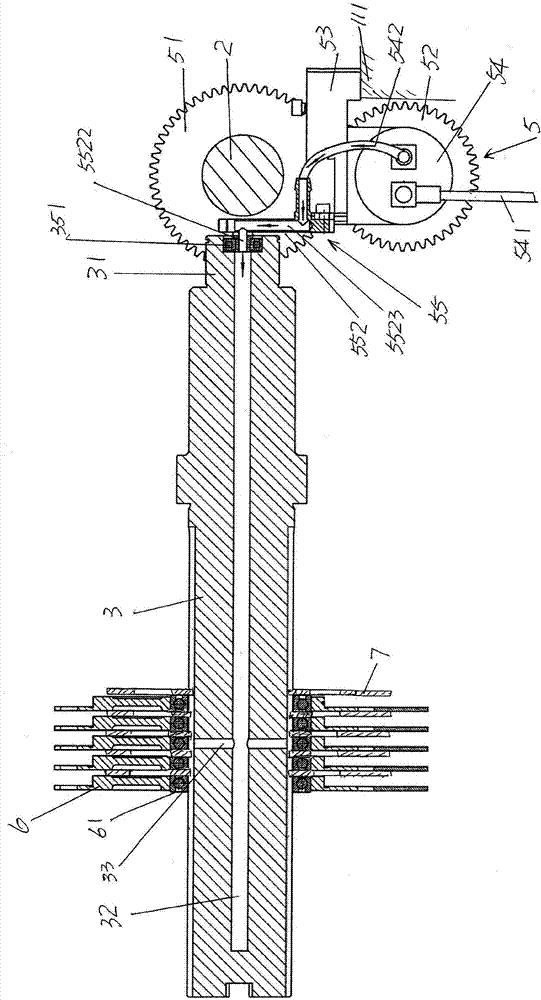

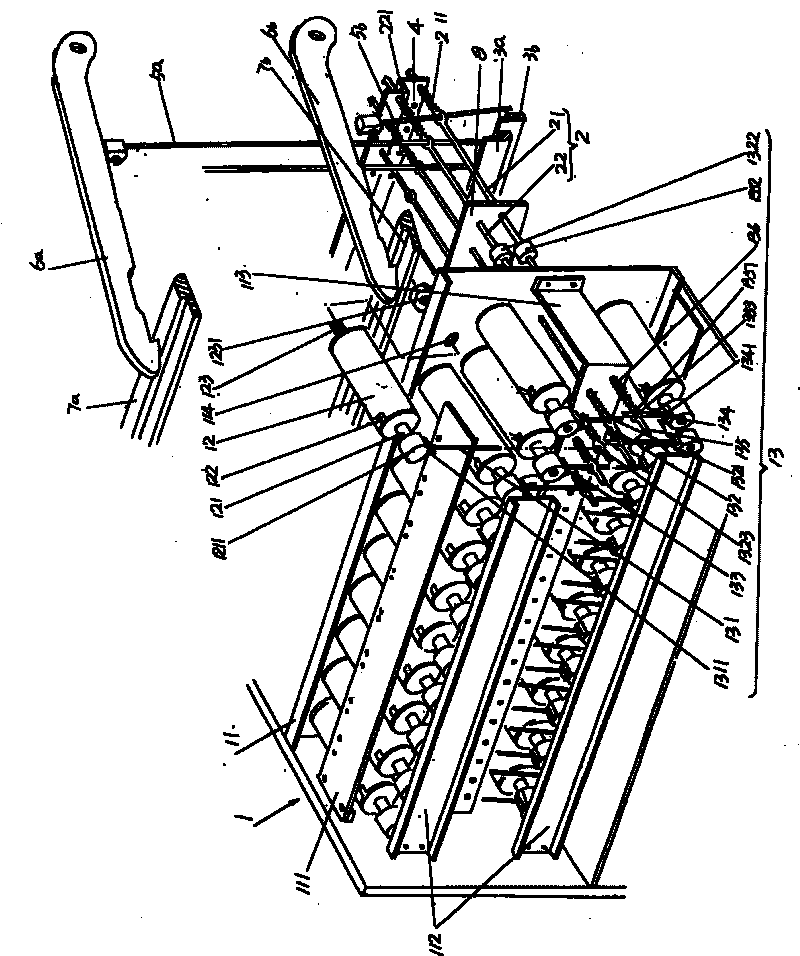

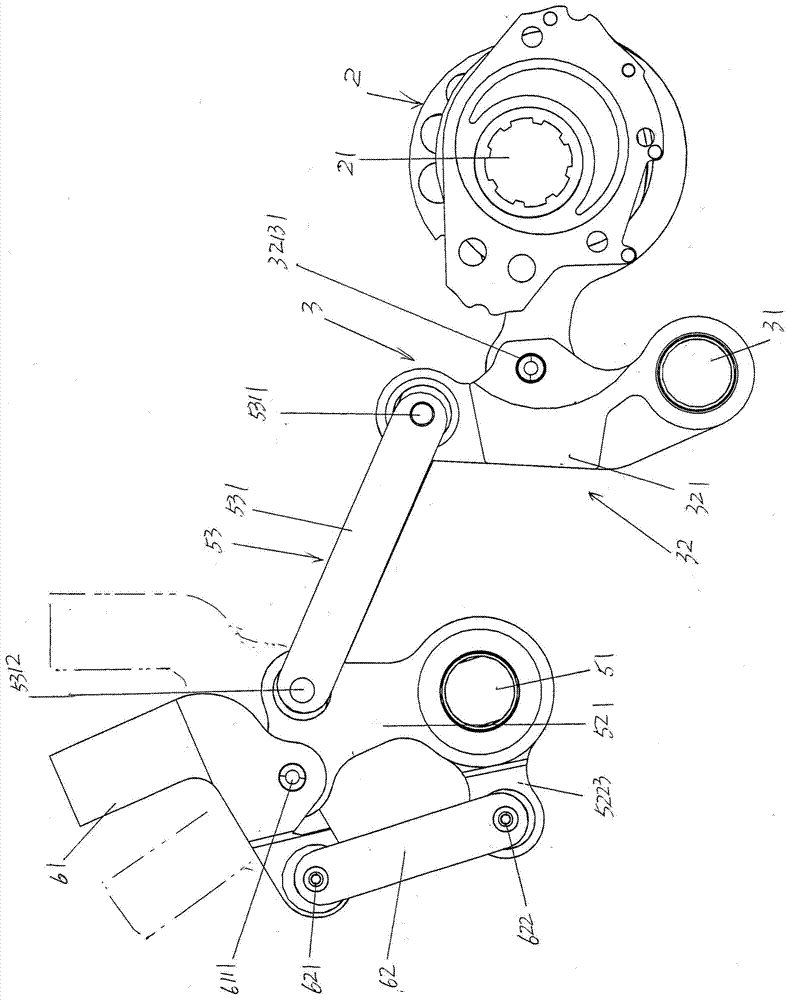

Three opening device of rotary electronic dobby

ActiveCN105442138BSatisfy the requirement of three shed openingSave resourcesDobbiesEngineeringMechanical engineering

The invention provides a three-shed device of a rotary electronic dobby and belongs to the technical field of textile machinery. The rotary electronic dobby comprises a tank body, a heald lifting arm driving mechanism and a heald lifting arm mechanism, wherein the heald lifting arm driving mechanism is arranged in a tank body cavity of the tank body through a spindle; the heald lifting arm mechanism is arranged in the position, corresponding to the left side of the heald lifting arm driving mechanism, in the tank body cavity of the tank body through a heald lifting arm shaft and is connected with the heald lifting arm driving mechanism. The three-shed device comprises a pair of supporting seats, a swing arm mechanism and a heald frame three-shed heald lifting blade mechanism, wherein the supporting seats correspond to each other and are fixed with one side, opposite to the tank body cavity of the tank body, of the left tank wall when in a state perpendicular to the left tank wall of the tank body; the swing arm mechanism is supported between the pair of supporting seats and is connected with the heald lifting arm mechanism; the heald frame three-shed heald lifting blade mechanism is connected with the swing arm mechanism. The three-shed device of the rotary electronic dobby has the following advantages: resources are saved, and the requirement for three sheds of a loom for weaving pile warp fabric is met; the integral structure is concise, and the rotary electronic dobby in the prior art can be subjected to addition improvement, so that economic cheapness can be reflected.

Owner:常熟纺织机械厂有限公司

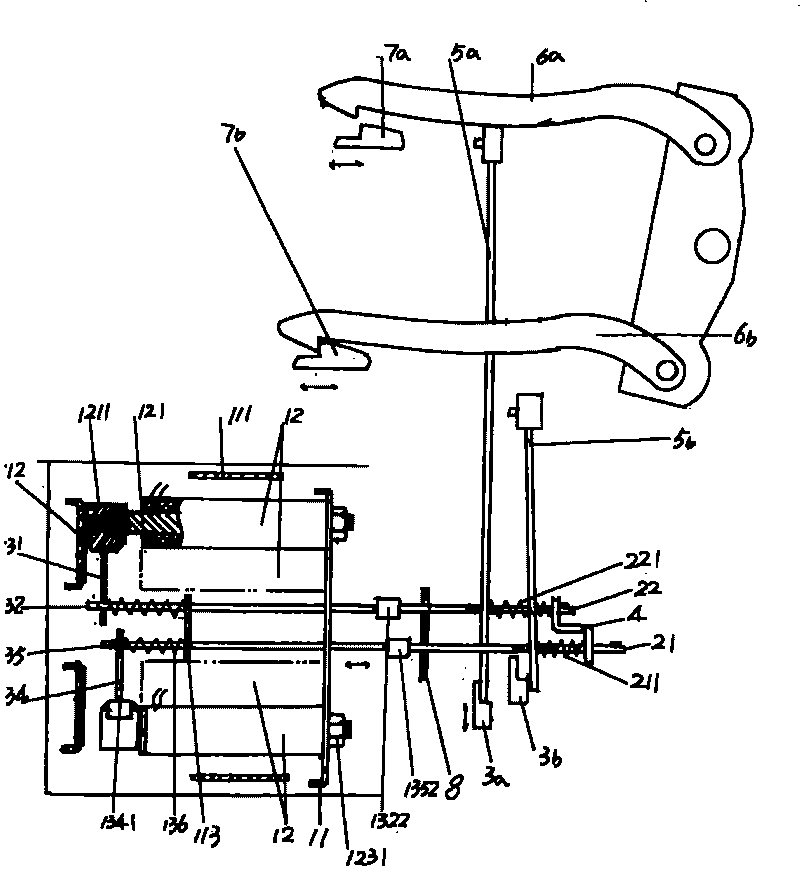

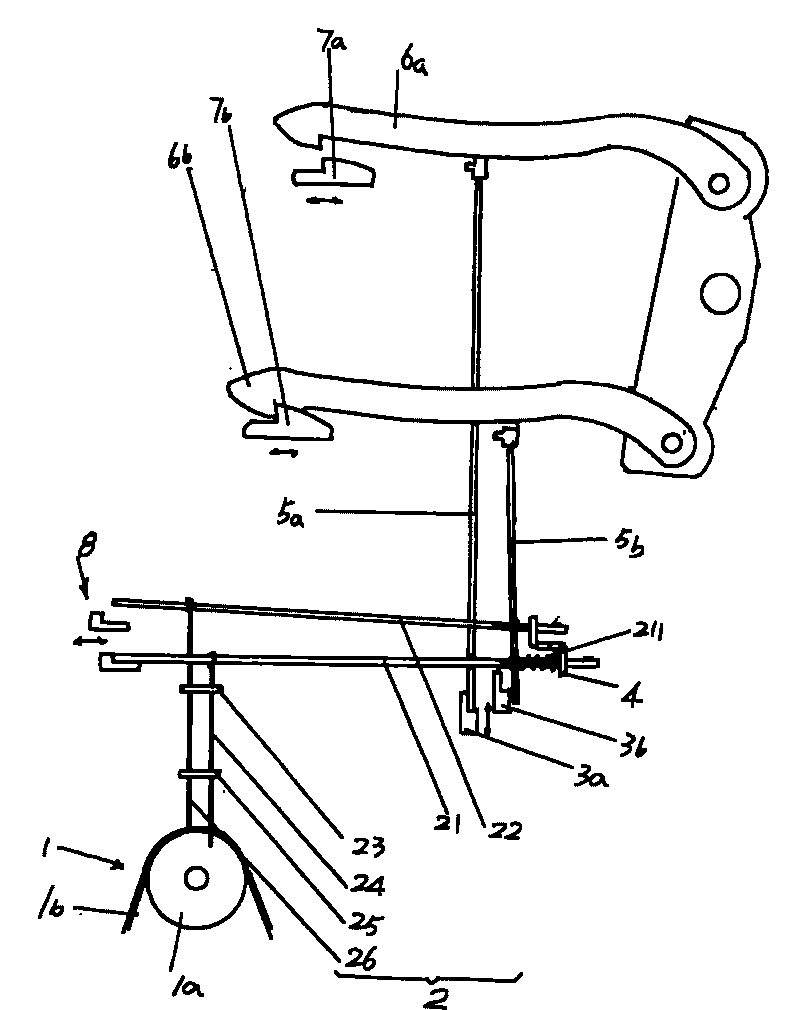

Three-shed shedding mechanism for rotary electronic dobby

ActiveCN101709525BMeet three weaving shed requirementsSimple structureDobbiesMachineIndustrial engineering

The invention relates to a three-shed shedding mechanism for a rotary electronic dobby, belonging to the technical field of the textile machinery.The rotary electronic dobby comprises a splined main shaft, and the three-shed shedding mechanism comprises one pair of signal device and a heald lifting device, wherein the heald lifting device comprises a heald lifting arm and a heald lifting arm shaft and is connected with the signal device. The three-shed shedding mechanism is characterized in that the heald lifting device also comprises a rear oscillating disc connecting base, a front oscillating disc connecting rod, a front oscillating disc and a rear oscillating disc. Due to the adoption of the technical scheme, the three-shed shedding mechanism can meet the requirement of shedding three weaving sheds for weaving double-layer textile by a weaving machine. The three-shed shedding mechanism has simple structure and low manufacturing and modifying cost.

Owner:常熟纺织机械厂有限公司

Method for producing imitation jacquard pattern by adopting dobby machine

The invention provides a method for producing an imitation jacquard pattern by adopting a dobby machine, comprising the following steps of: carrying out gradually advancing method combination on a warp arrangement sequence of original yarns by taking an original small figure as a blueprint, that is to say, advancing one digit number by taking every N numbers, and orderly gradually advancing till circulation is finished, wherein N is a multiple to be amplified in a warp direction; also carrying out gradually advancing method combination on a weft arrangement sequence of the original yarns, that is to say, advancing one digit number by taking every M numbers, and orderly gradually advancing till the circulation is finished, wherein M is a multiple to be amplified in a weft direction. The area of the produced imitation jacquard pattern is N*M times larger than that of an original small figure pattern. The method not only has low cost, but also has high efficiency, solves the problem of production of jacquard shell fabrics and can also produce the jacquards with different effects.

Owner:福州华冠针纺织品有限公司

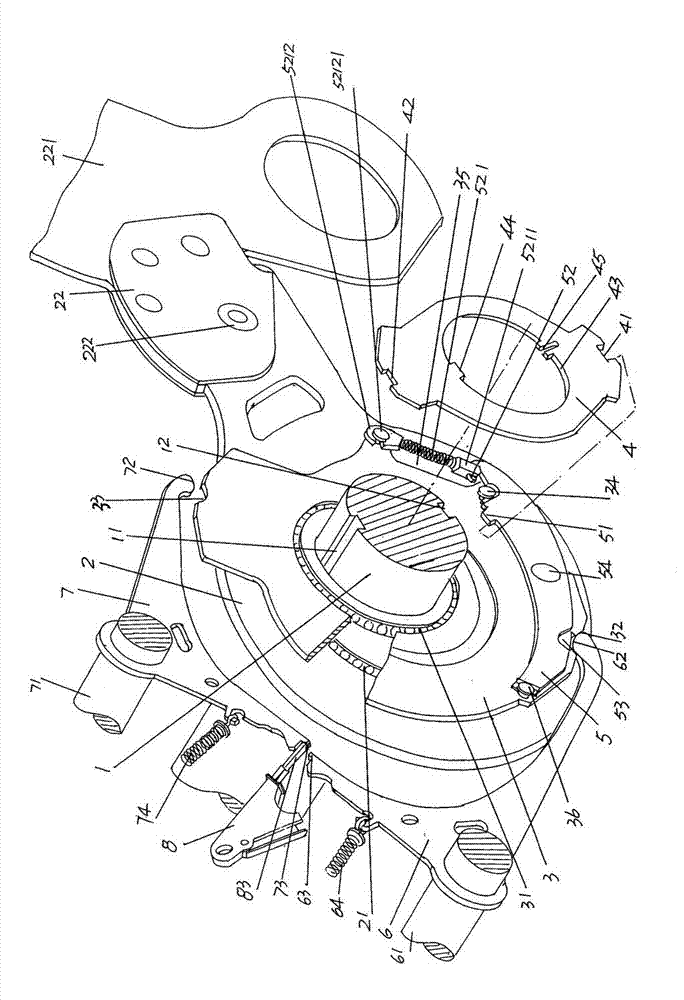

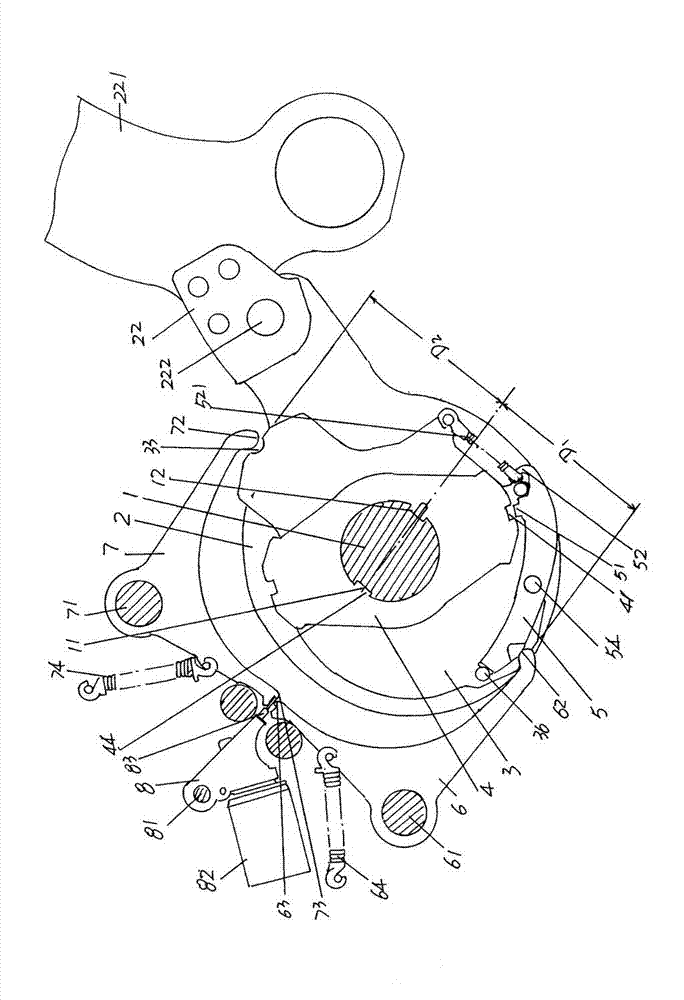

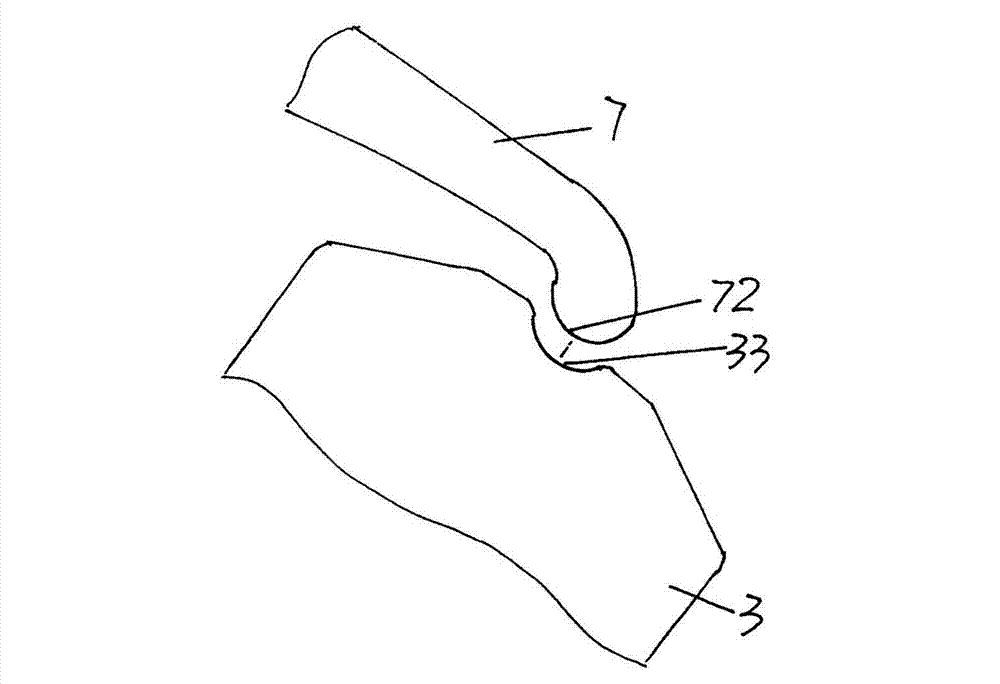

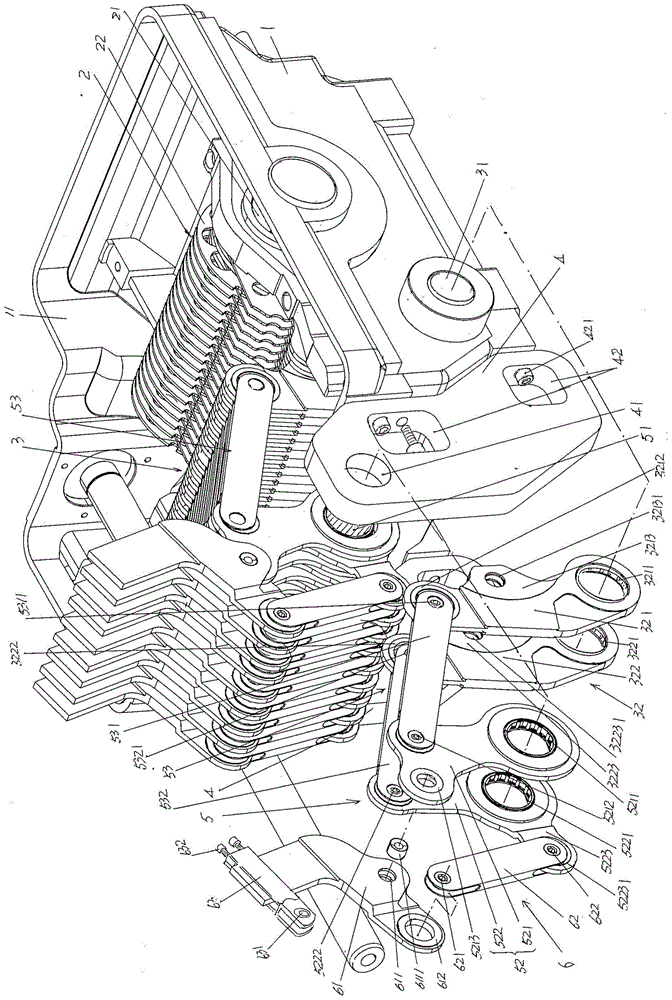

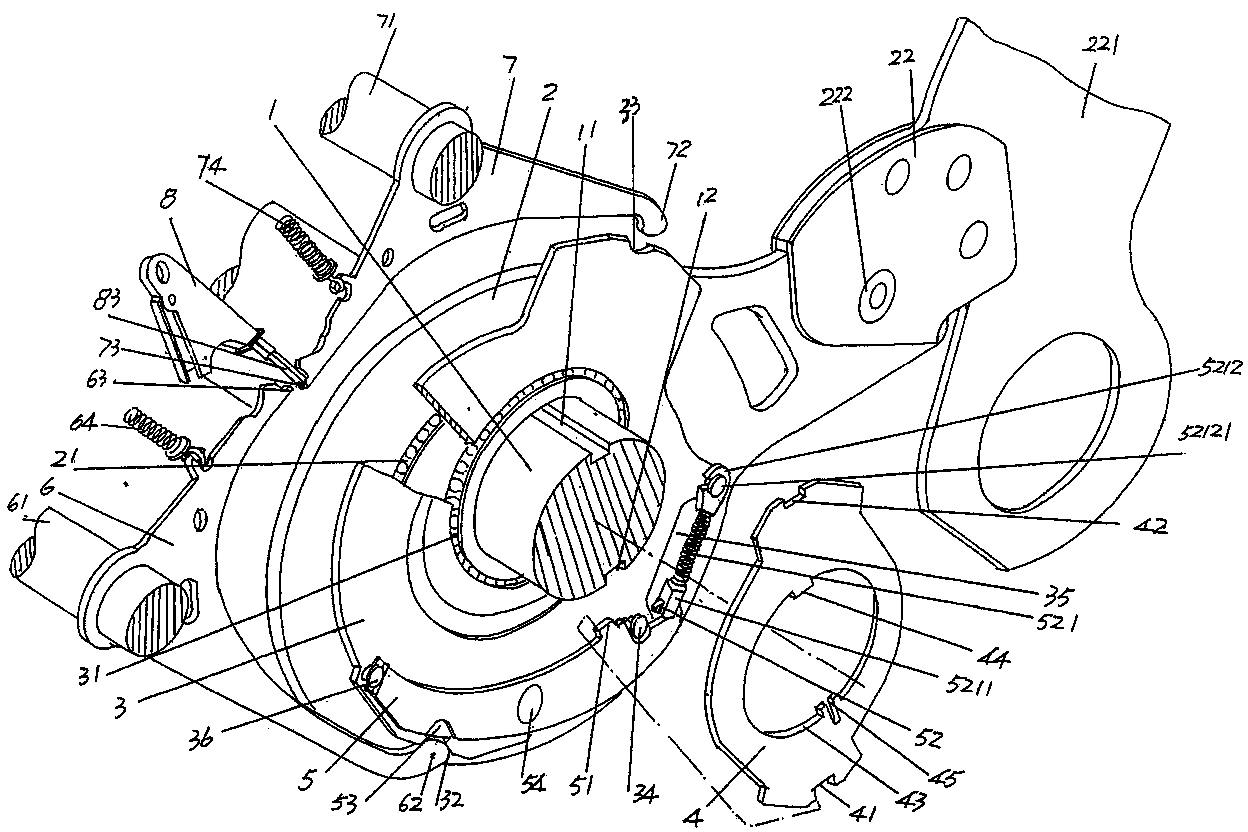

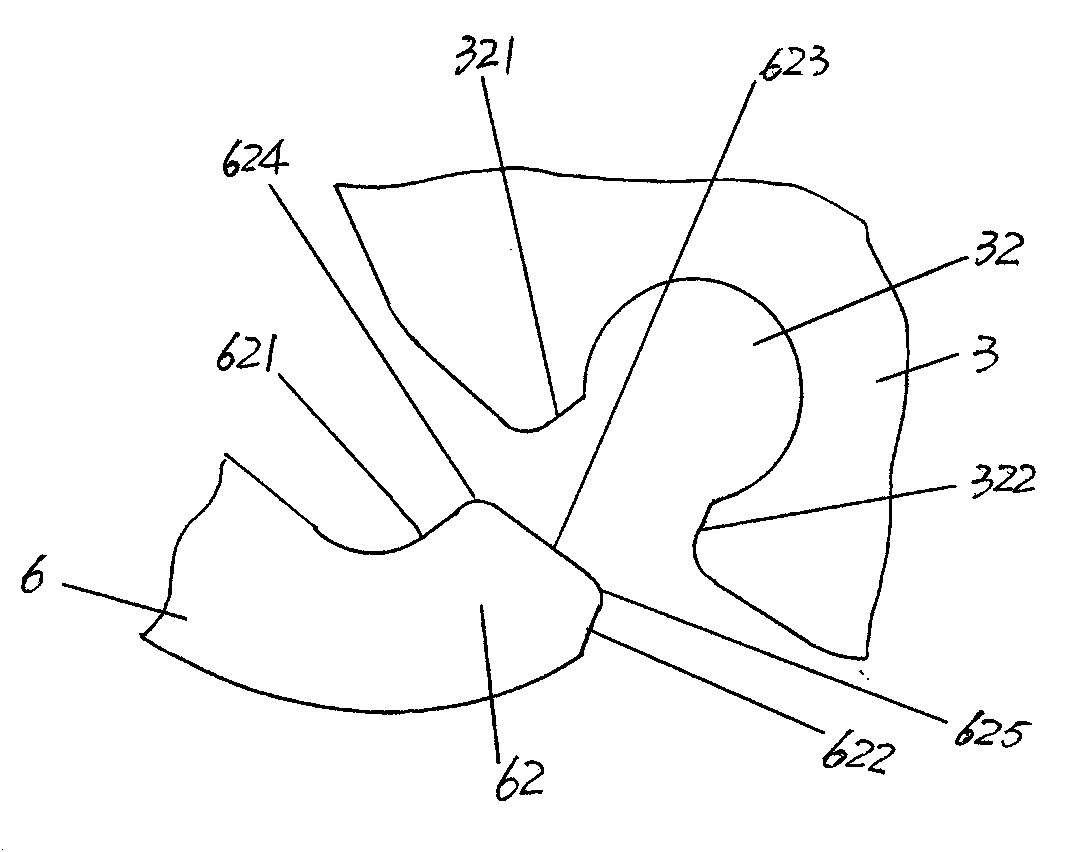

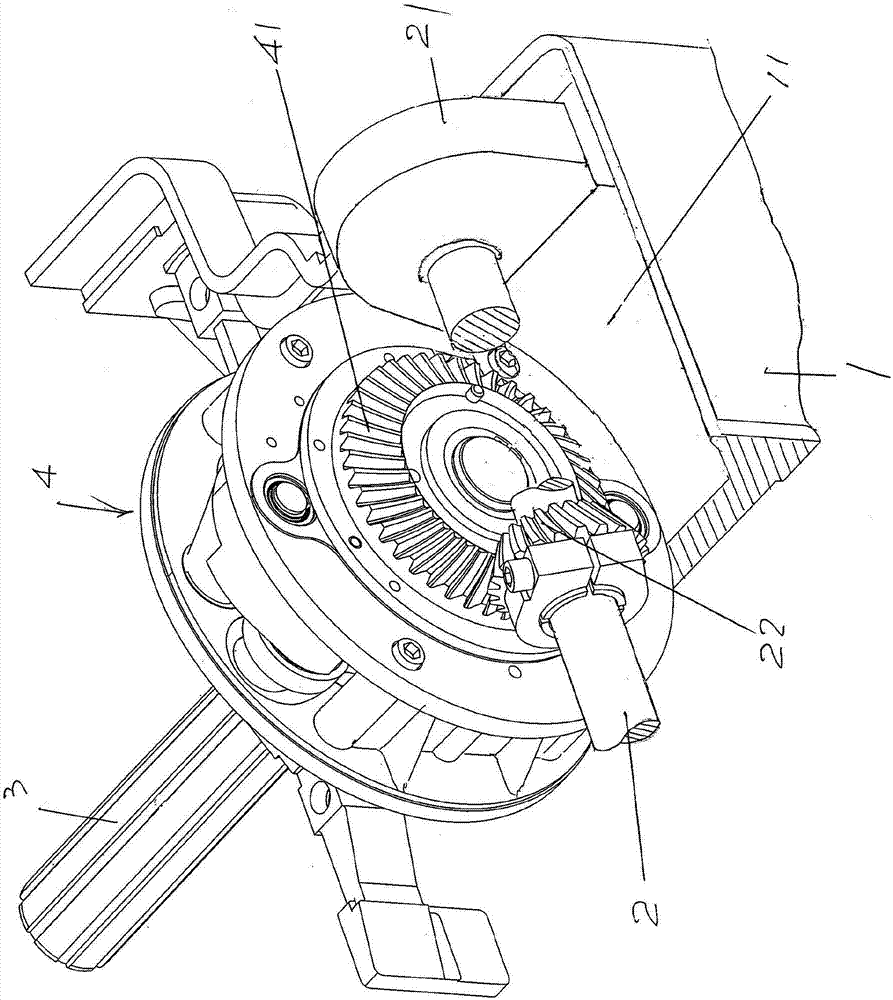

Selecting and comprehensively actuating mechanism for rotary type dobby opening device

ActiveCN102995212BInertial kinetic energy reductionReliable lockingDobbiesEngineeringMechanical engineering

The invention relates to a selecting and comprehensively actuating mechanism for a rotary type dobby opening device and belongs to the field of textile machinery. The selecting and comprehensively actuating mechanism provided by the invention comprises a spindle, a swing arm and an eccentric disc, a spline disc, a clutch claw, a first signal swing arm and a second signal swing arm and a magnet absorption swing arm, and the selecting and comprehensively actuating mechanism is characterized in that a first inclined plane and a second inclined plane are formed on the two sides of an opening of a first eccentric disc meshing cavity; a third inclined plane and a fourth inclined plane are formed on the two sides of the opening of a second eccentric disc meshing cavity; a fifth inclined plane and a sixth inclined plane are formed on the two sides of a first swing arm meshing part, and the surface on one side of the first swing arm meshing part forms a first milling plane, a first transition arc surface is formed between the first milling plane and the fifth inclined plane, and a second transition arc surface is formed between the first milling plane and the sixth inclined plane; and a seventh inclined plane and an eighth inclined plane are formed on the two sides of the second swing arm meshing part, and the surface on one side of the second swing arm meshing part forms a second milling plane, a third transition arc surface is formed between the second milling plane and the seventh inclined plane, and a fourth transition arc surface is formed between the second milling plane and the eighth inclined plane. The selecting and comprehensively actuating mechanism provided by the invention has the advantages that locking is reliable and energy consumption is saved.

Owner:常熟纺织机械厂有限公司

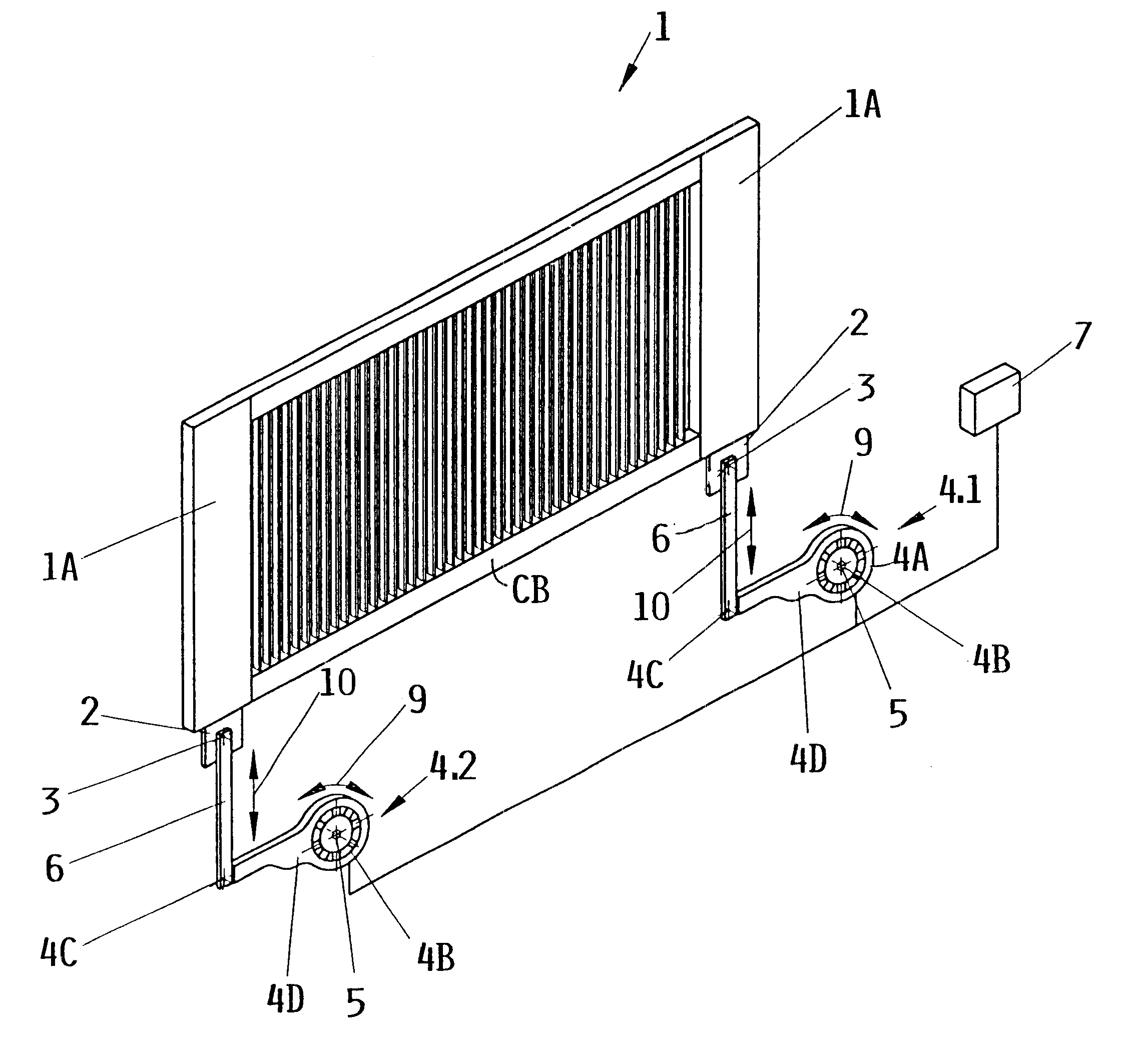

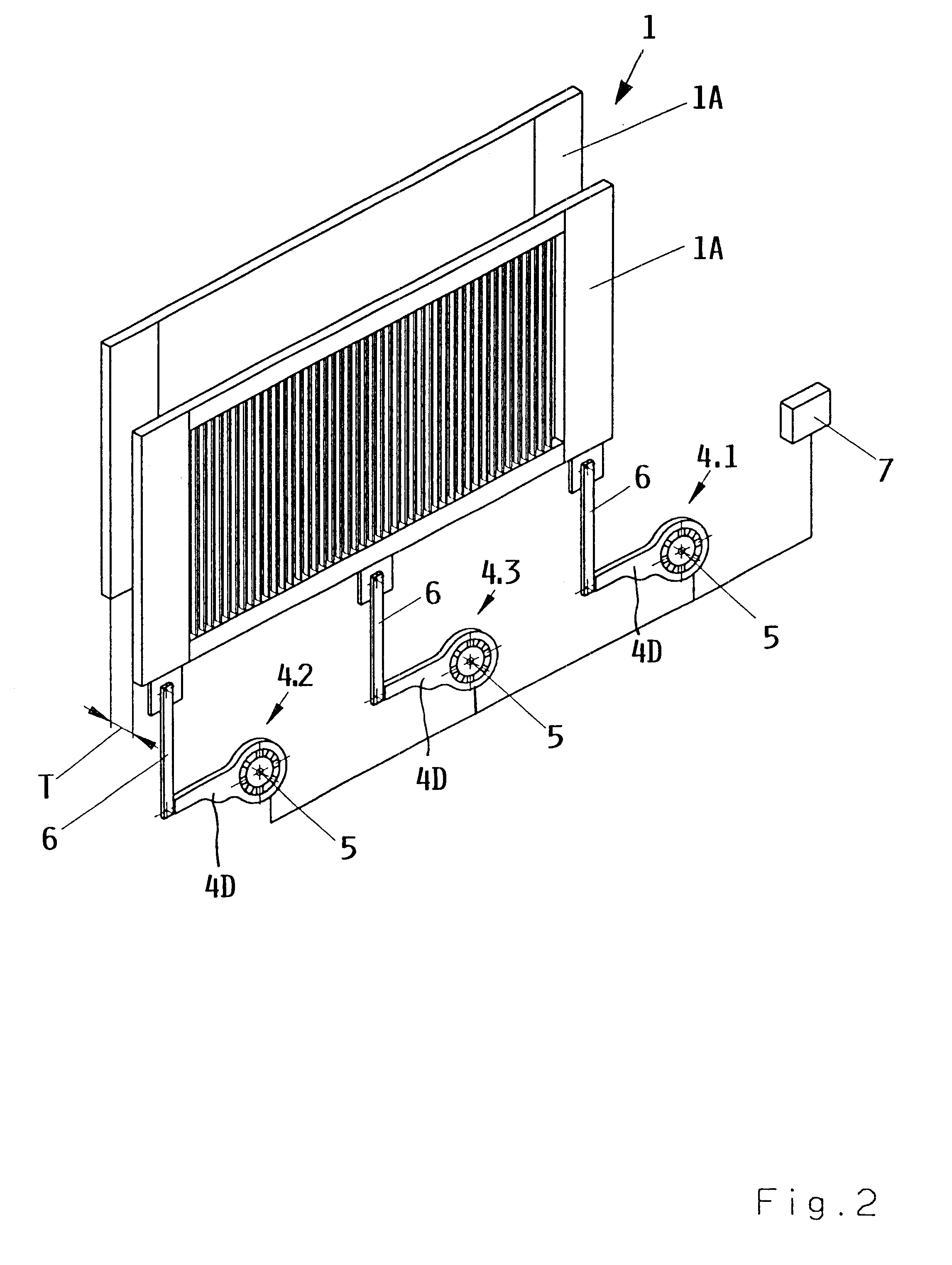

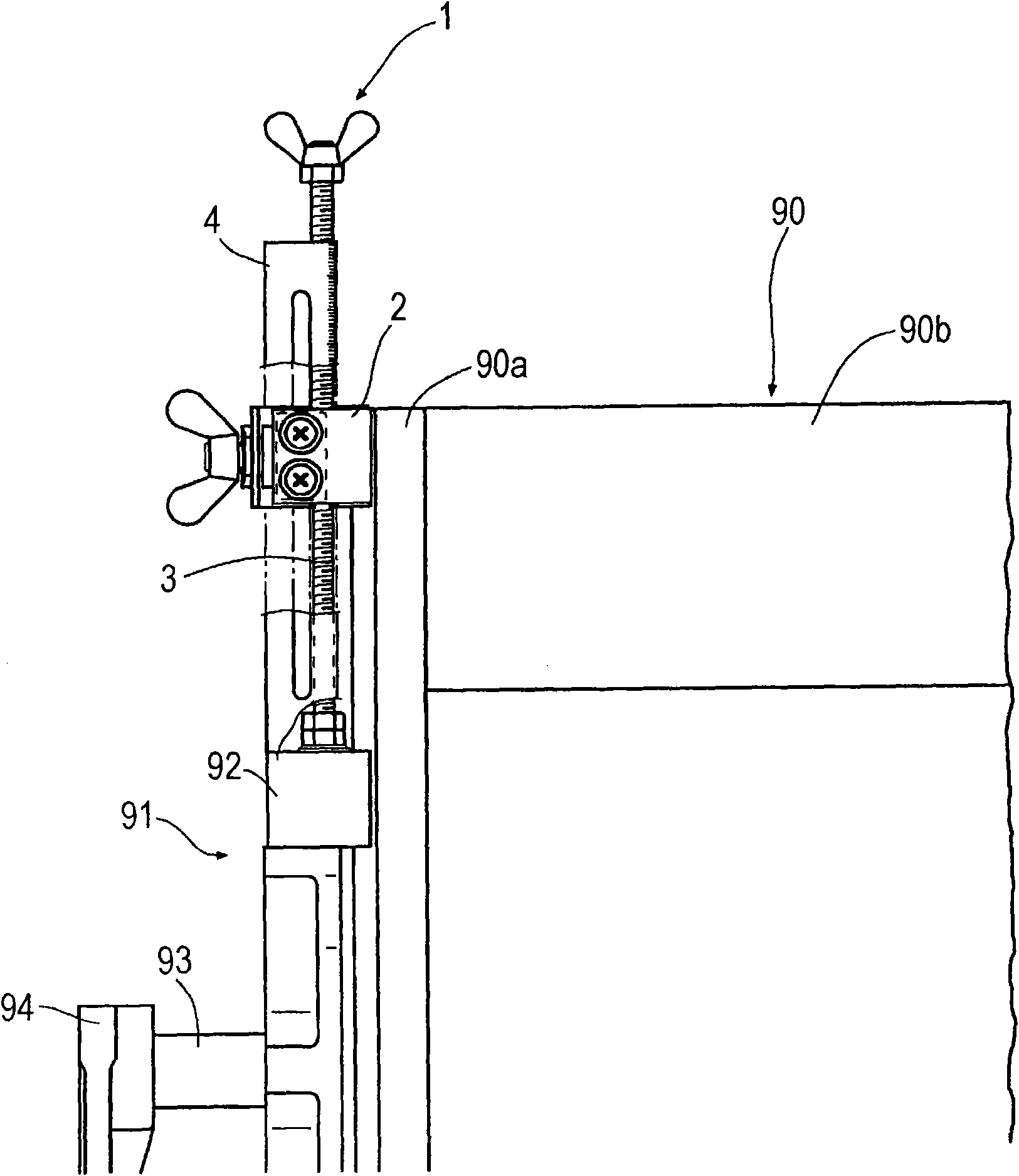

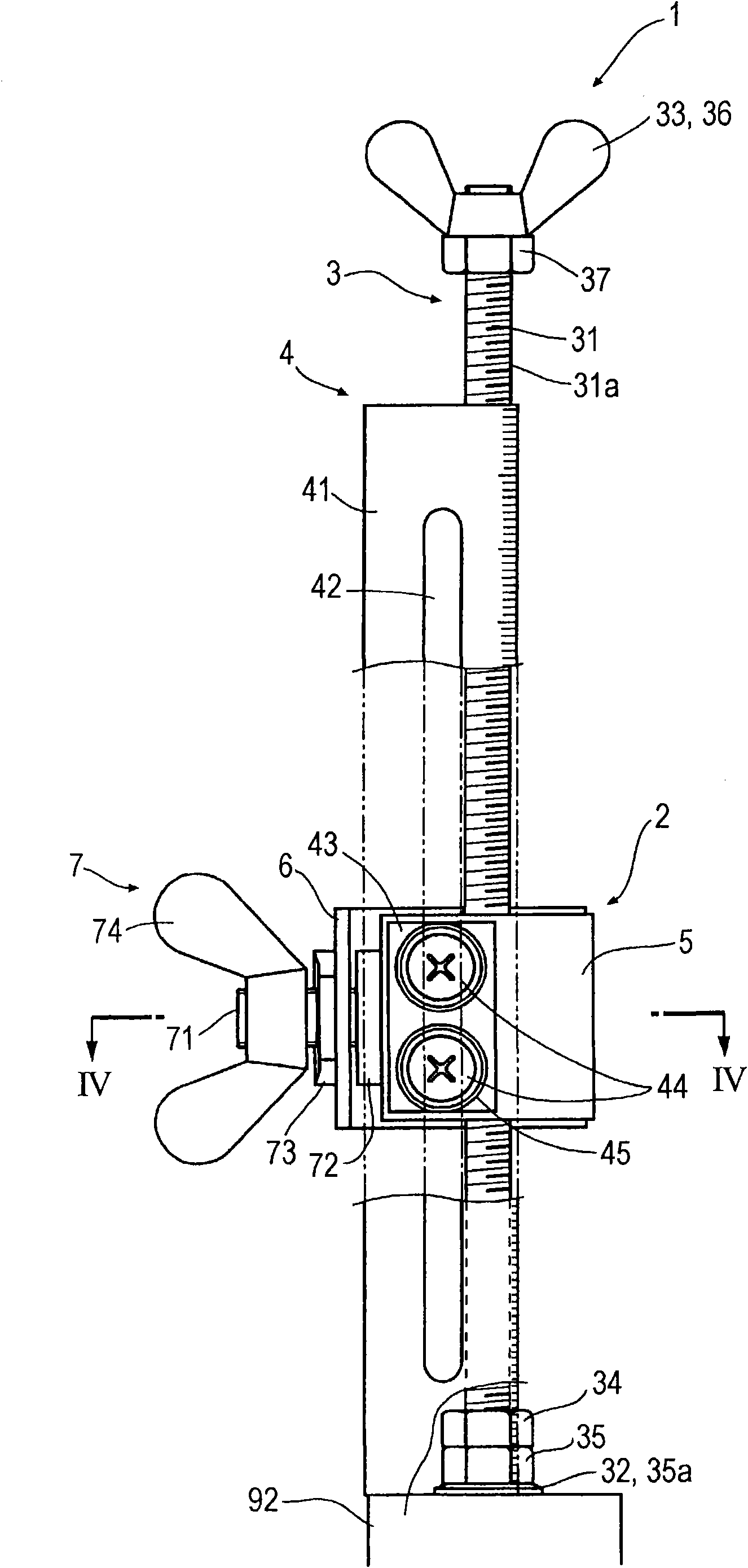

Device for attaching return springs in a harness of a Jacquard weaving machine

On the one hand, the invention relates to a device for exerting a return force on at least one harness element of the harness of a Jacquard weaving machine, comprising at least one return spring (2) provided with means of attachment (1) for attaching the return spring (2) to retaining means (4) being immovably provided, said means of attachment (1) being provided with a positioning opening (6) for positioning the means of attachment (1) with respect to the retaining means (4), and a fixing opening (7) for fixing the means of attachment (1) to the retaining means (4), a spring connection (8) being provided between the positioning opening (6) and the fixing opening (7), in such a manner that the means of attachment (1) are able to move from positioning opening (6) to the fixing opening (7) with respect to the retaining means (4), but after having been fixed will be unable to move back from the fixing opening (7) to the positioning opening (6) with respect to the retaining means during operation or transport of the Jacquard machine.On the other hand, the invention relates to a device for immovably installing the retaining means (4) of one or several return springs (2) of a Jacquard weaving machine, the device being provided with at least two fixed installing elements (13) for installing the retaining means (4), the said installing elements (13) being provided with one or several recesses to apply the retaining means (4).

Owner:N V MICHEL VAN DE WIELE

Electric motor drive mechanism for shed forming components of a loom

The heald shafts of a power loom are driven by electric D.C. or A.C. motors which have an external rotor or an armature connected to the respective heald shaft through two articulated couplings, for example snap locks, and a push-pull rod. The motors receive control signals from a computerized controller for reversing the motion direction of the external rotor or armature. The stators of the motors are rigidly mounted on a fixed axis secured to the loom frame.

Owner:LINDAUER DORNIER GMBH

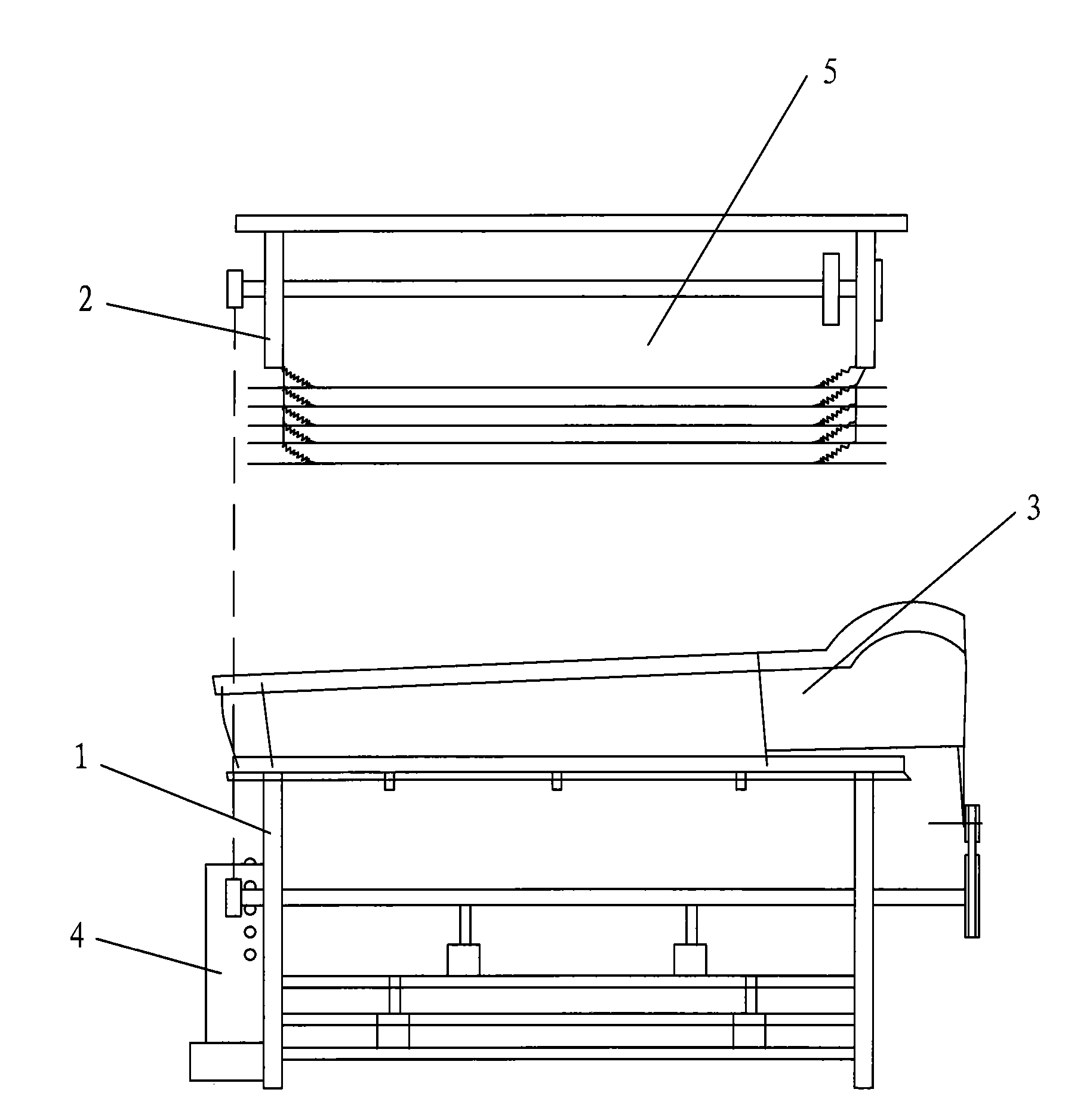

Shaft drive system for power loom shafts

A novel shaft gear for harmonious engagement and disengagement of individual heddle shafts and for deriving their motion from the rotary motion of a single input shaft has a coupling system with two input elements. While one of the input elements serves to drive the output element of the coupling system permanently, the other input element serves solely to synchronize the output element briefly with the first input element. The switchover takes place in the brief synchronous phases, in selected angular regions that correspond to the top or bottom reversal point of the heddle shaft. For the switchover, such novel shaft drive mechanisms do not require any stoppage of motion for the input shaft or the shaft drive mechanism.

Owner:GROZ BECKERT KG

Multilayer cloth multi-shed water jet loom

The invention relates to a multilayer cloth multi-shed water jet loom, which comprises a front rack and a rear rack, wherein a multi-arm mechanism is arranged above the front rack, a heald frame assembly controlled by the multi-arm mechanism is arranged below the front rack, the left side of the front rack is provided with a weft insertion mechanism, and the rear part of the front rack is provided with a ground warp weaving shaft; and a seam warp weaving shaft and a tension compensating device are arranged on the rear rack. The multi-arm mechanism enables warps passing through harness wires in a seam warp heald frame to form six warp positions and five sheds; the weft insertion mechanism can simultaneously jet five wefts in the five sheds up and down, and multilayer cloth of less than or equal to five layers can be woven by weft insertion and battening; and the seam warp weaving shaft and the tension compensating device enable seam warps to be conveyed at a constant speed and subjected to seam warp tension compensation in a single seam warp heald frame so as to meet weaving of the multilayer cloth of less than or equal to five layers with a comparatively complex tissue structure. The multilayer cloth multi-shed water jet loom has the advantages of doubled production efficiency, production variety increment, wide application and the like.

Owner:WUJIANG HENGSHENGLI SPRAY & KNITTING

Heald-frame height adjusting apparatus

InactiveCN101624738AEasy height adjustment workReduce manufacturing costsDobbiesCam shedding mechanismEngineeringMechanical engineering

Owner:TSUDAKOMA KOGYO KK

Electronic dobby with positive lubrication

The invention discloses an electronic multi-arm machine having an active lubrication function. The electronic multi-arm machine comprises a box body, a power input shaft, a spline shaft and a cam driving mechanism. The axial center of the spline shaft is provided with a spline shaft oil-guide channel along a direction parallel to a length direction of the spline shaft. The front end of the spline shaft is provided with an oil inlet seal bearing installation hole. An oil seal bearing is arranged in the oil inlet seal bearing installation hole. The spline shaft oil-guide channel is communicated with an oil inlet seal bearing inner ring hole of the oil inlet seal bearing. The middle of the spline shaft is provided with a spline shaft oil outlet channel. The spline shaft oil outlet channel and the spline shaft oil-guide channel form a cross-staggered relationship and the spline shaft oil outlet channel is communicated with the spline shaft oil-guide channel. An active lubricating oil supplying mechanism is arranged in the position corresponding to the front side of the oil inlet seal bearing inner ring hole in the box body cavity. The active lubricating oil supplying mechanism is connected to an oil path of the oil inlet seal bearing inner ring hole and is transmission-connected to the power input shaft. The electronic multi-arm machine has good whole lubricating effects and helps to prolong service lives of the eccentric plate, eccentric disc bearing and swing arm.

Owner:西安滨田特型机械有限公司

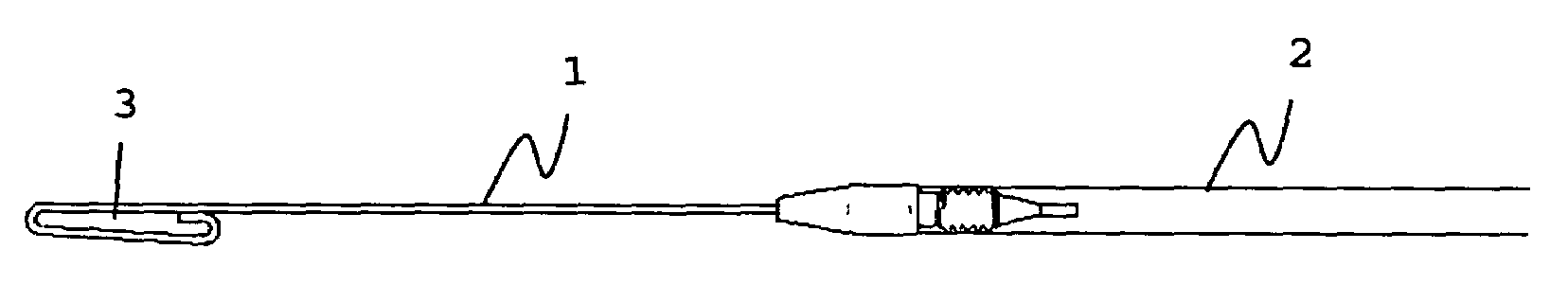

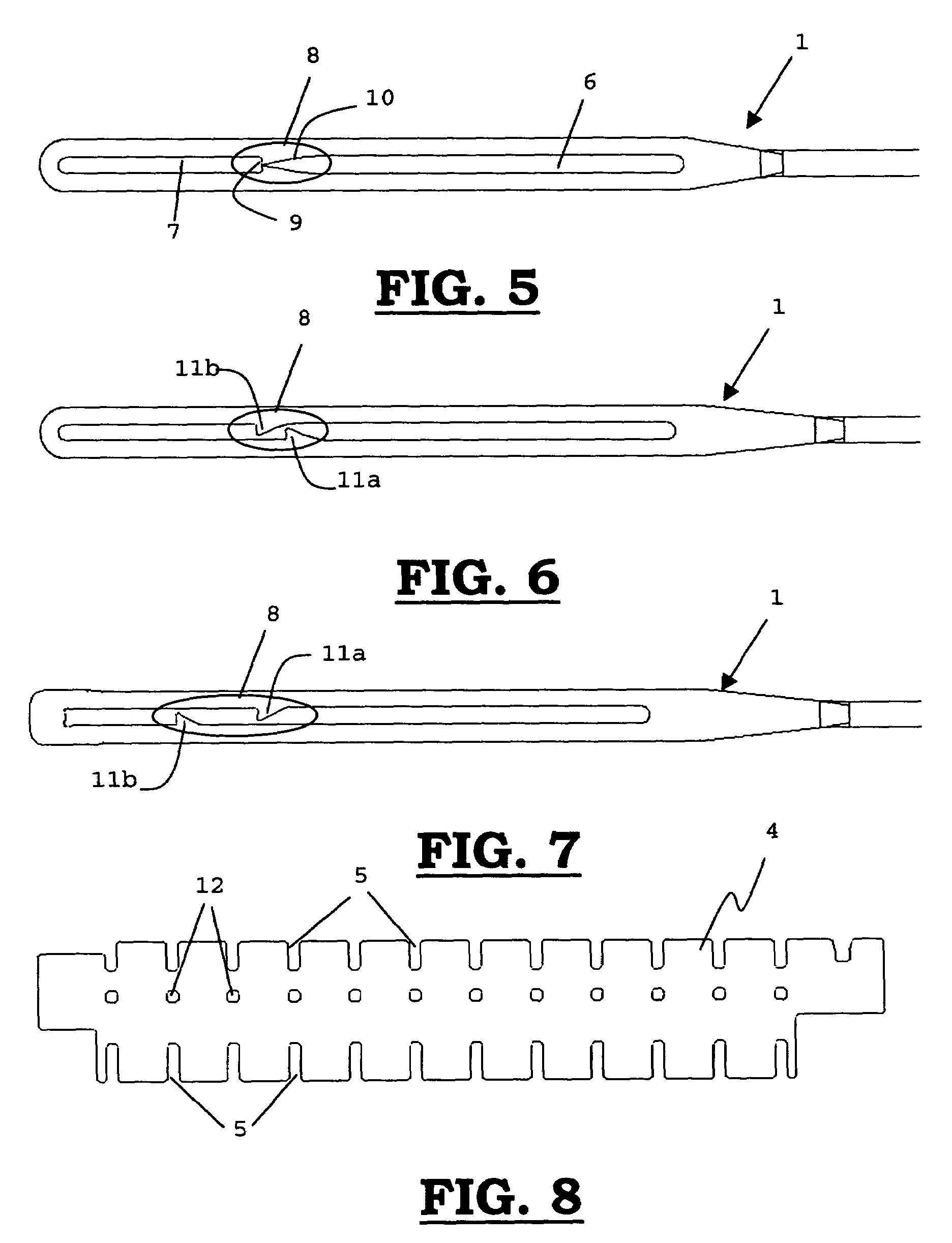

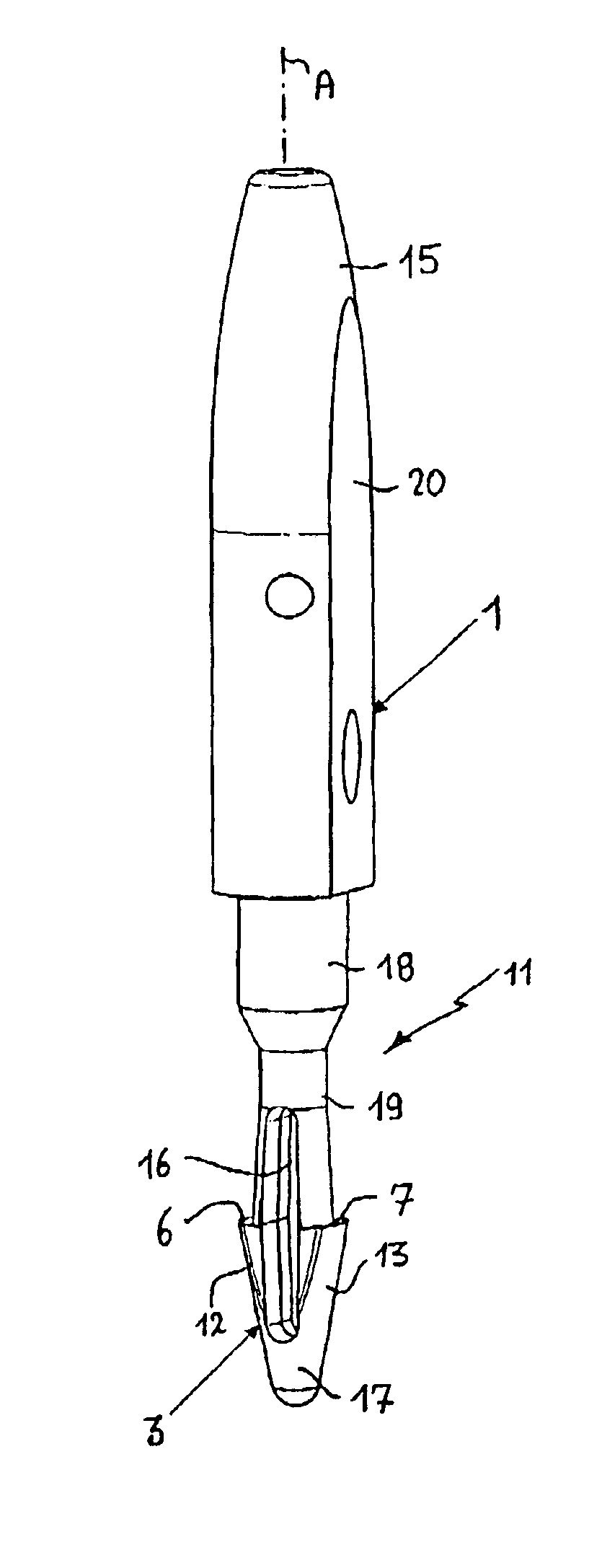

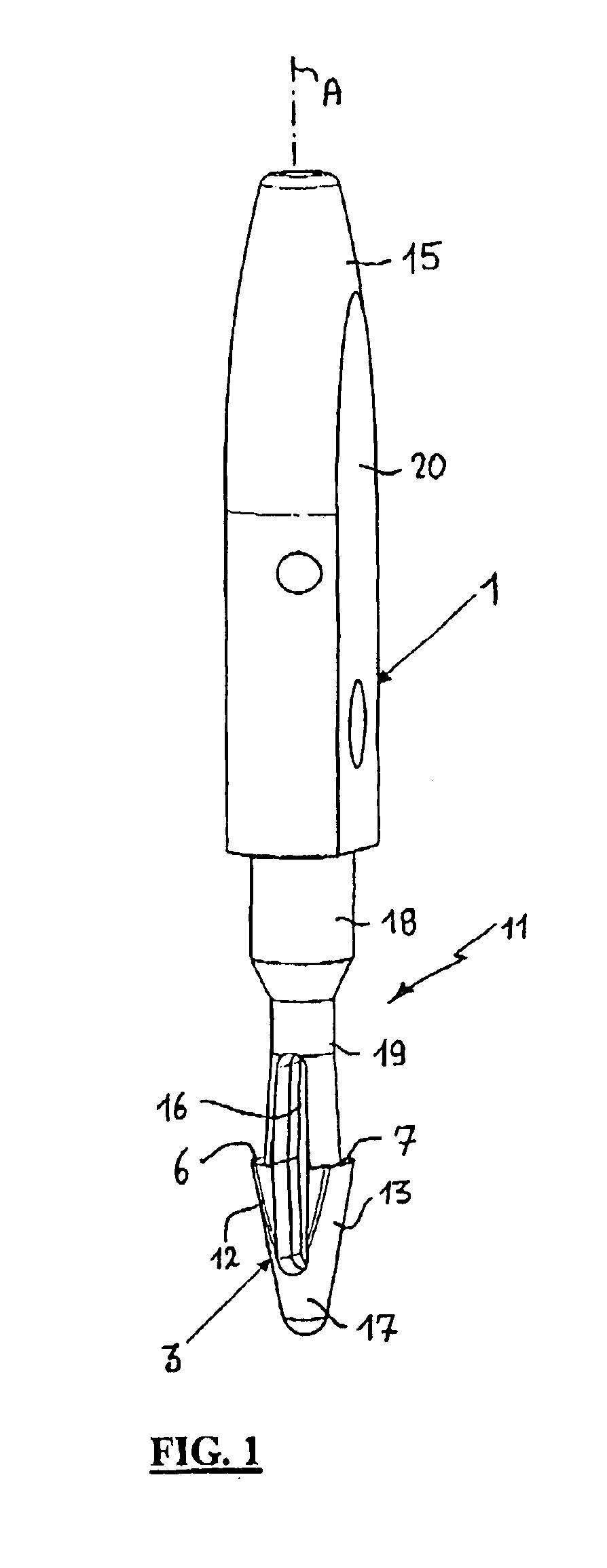

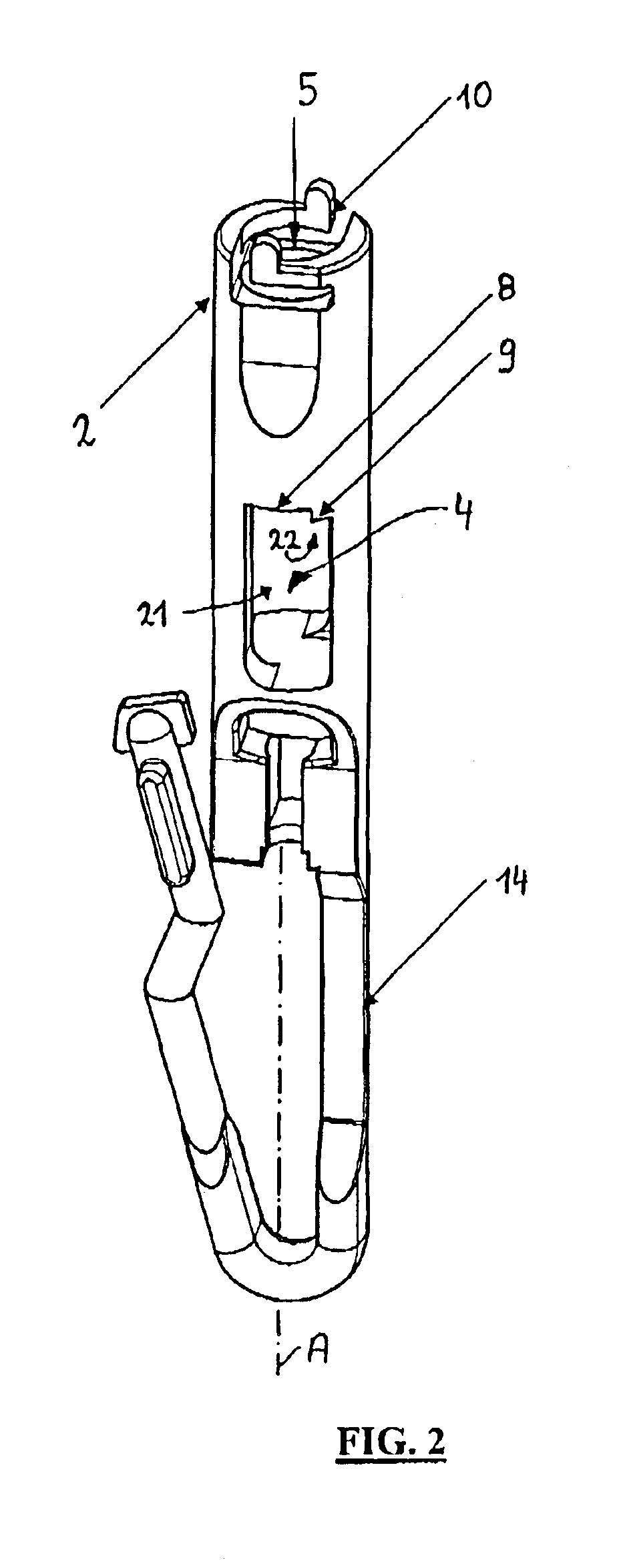

Connecting means for detachably connecting cords of a jacquard machine

A first (1) and a second connecting means (2) which may be connected in a detachable manner in order to connect a first and a second cord, more particularly a lifting cord and a harness cord of a Jacquard machine, the first connecting means (1) comprising an elastically deformable coupling element (3) which may be received in a receiving part (4) of the second connecting means and may be retained in axial direction, the second connecting means (2) comprising a passage (5) through which the coupling element (3), compressed in the radial direction, may be moved to the receiving part (4) and the coupling element (3) in the receiving part (4) having the possibility of adopting a larger radial dimension than is necessary to be moved through the passage (5), so that the coupling element (3) snap-fits in the receiving part (4). In the receiving part (4), the coupling element (3), by rotation around the longitudinal axis (A), may be brought into a disengaging position in which it is not retained.

Owner:N V MICHEL VAN DE WIELE

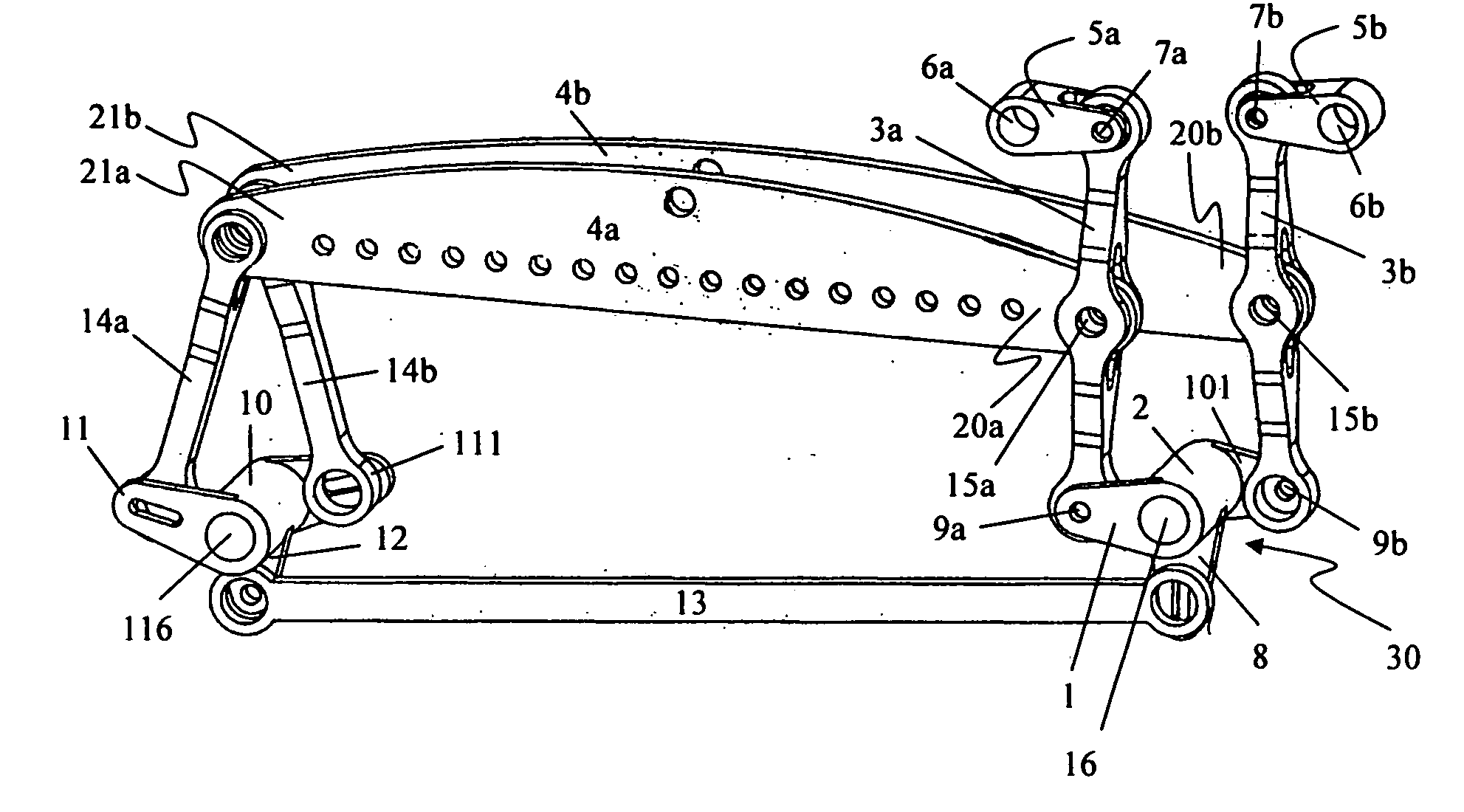

Jacquard machine

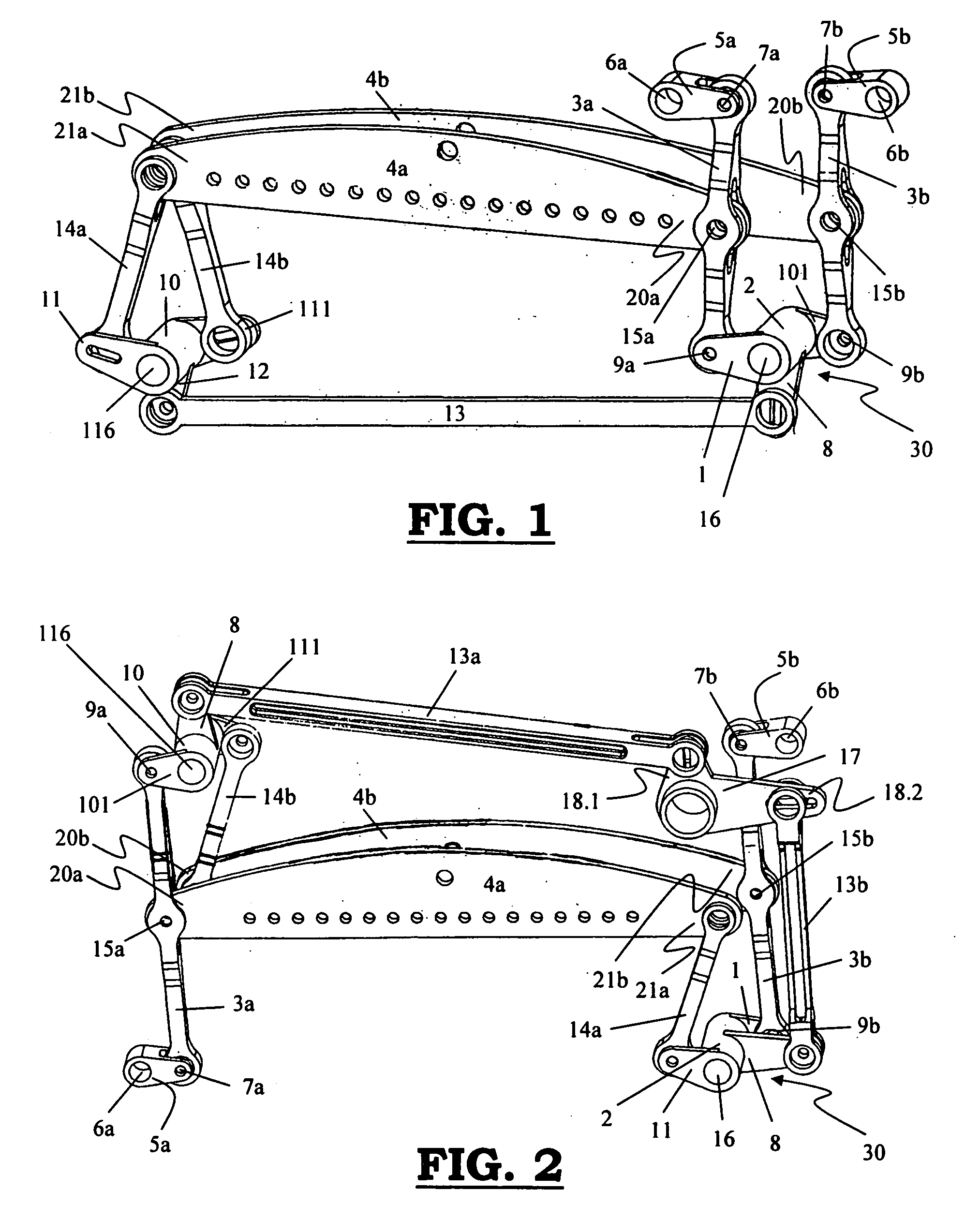

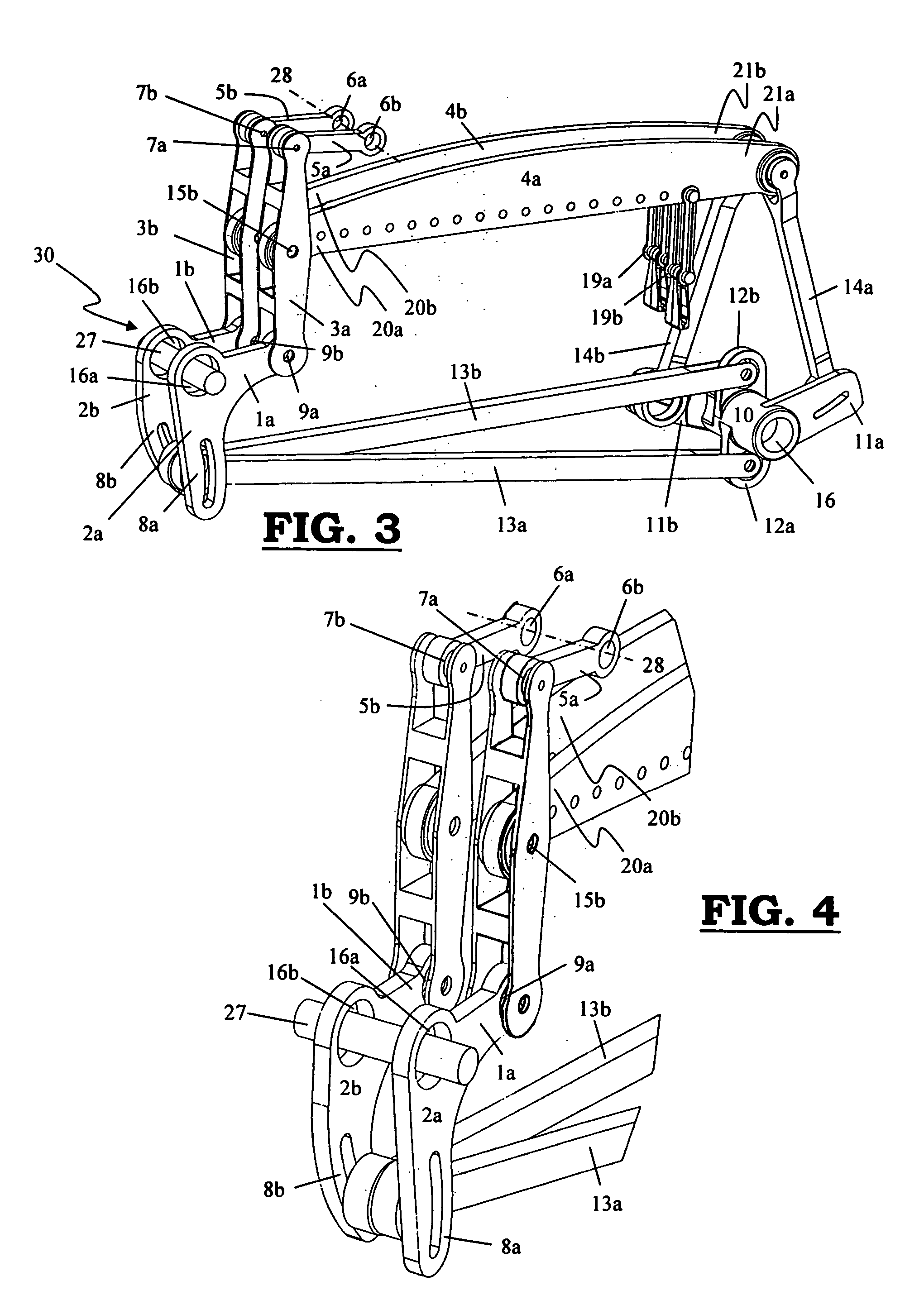

The invention relates to a Jacquard machine, comprising 2 sets of knifes moving up and down in opposition, which each, at each of their extremities, are taken up in separate knife grids (4a, 4b) being driven by a cinematic drive chain (30), and each, at one of their extremities (20a, 20b), being guided into a straight motion by means of a “Watt's linkage” rod system, the height of lift of each of these extremities (20a, 20b) of the knife grids (4a, 4b) being adjustable, and the knife grids (4a, 4b) each at their first extremities (20a, 20b) being linked with at least one first driving lever (2, 2a, 2b, 10) by means of a first linking rod (3a, 3b), and at their second extremities (21a, 21b) being linked with at least a second driving lever (2, 10) by means of a second linking rod (14a, 14b), wherein per knife grid (4a, 4b) one or several elements (1, 101, 1a, 1b, 3a, 3b) of the Watt's linkage rod system are part of the cinematic drive chain (30), and the amplitude of the motion of the said extremity (20a, 20b) of the knife grid (4a, 4b) is adjustable in the cinematic drive chain (30) before the linking point (9a, 9b) between the first rod (1, 101, 1a, 1b) and the third rod (3a, 3b) of the Watt's linkage rod system with respect to the drive motor.

Owner:VAN DE WIELE MICHEL

Time-adjustable warp tension control device of loom

ActiveCN105525422AEasy to adjustIncrease the amount of let-offDobbiesLoomsElectric machineryBack rests

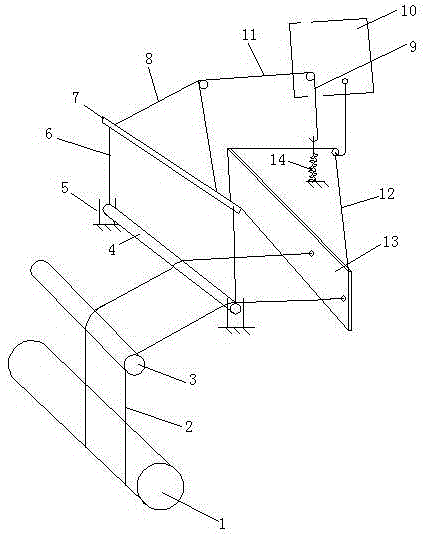

The invention discloses a time-adjustable warp tension control device of a loom. The device comprises a beam, warp, a back rest, a tension rod, a guide groove, a tension rod lifting rope, a guide roller, a guide roller lifting rope, a heald lifting hook, a hoisting arm, a heald lifting arm, a heald lifting rope, a heald and a spring. The device has the simple mechanism and is convenient to adjust, no driving mechanism or motor is added, all that is required is to drive a tension adjusting device by the aid of an idle dobby heald lifting hoisting mechanism of the existing loom in a linkage manner, the dobby heald lifting page number is 14-16, and 2-14 pages are generally used for weaving common three-elementary weave fabric, mini-jacquard and complex fabric.

Owner:IANGSU COLLEGE OF ENG & TECH

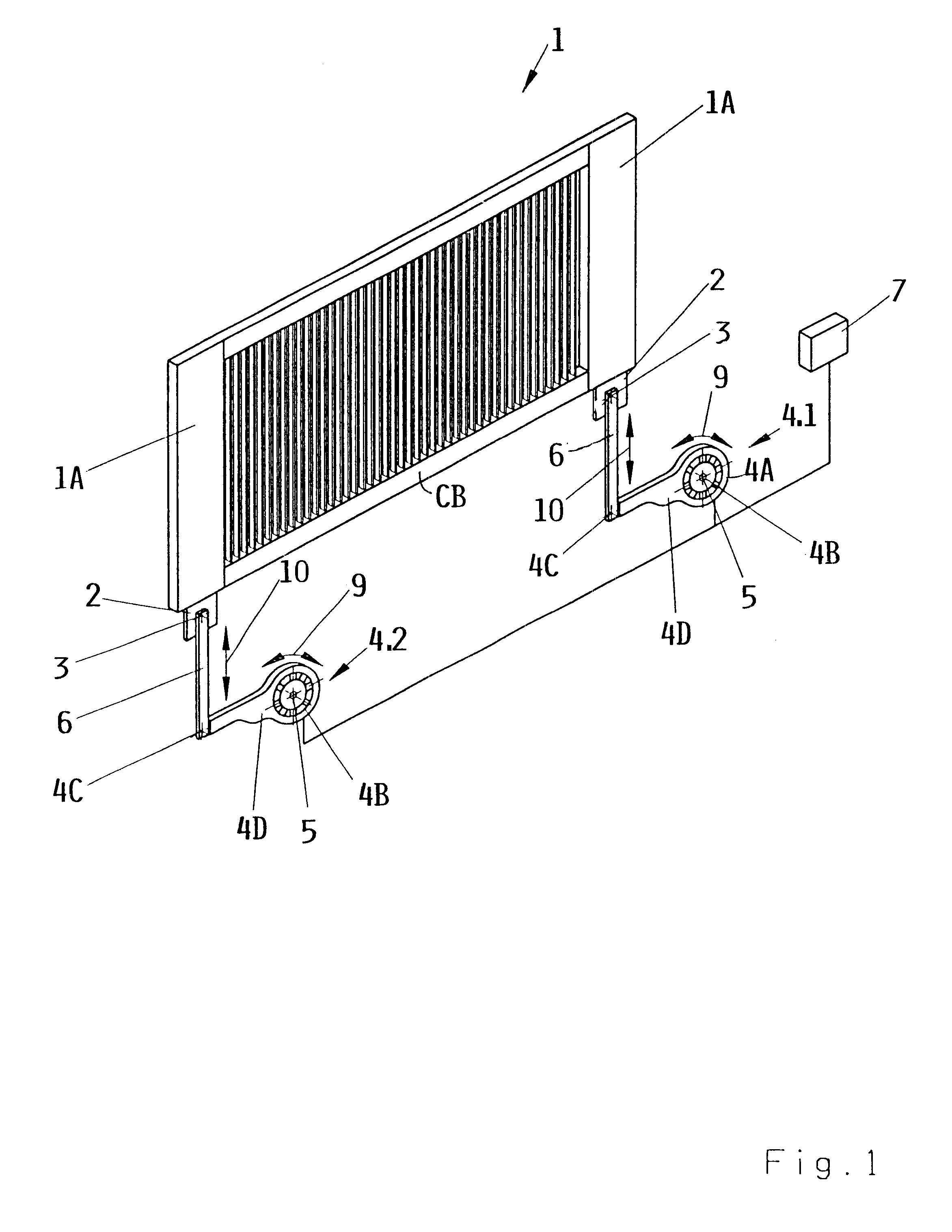

Shed forming mechanism and weaving loom equipped with such a mechanism

Hooks for controlling movement of heddle cords in a Jacquard weaving loom are each displaced by a knife, between a position of top dead center, wherein each hook may be immobilized by a selection device, and a position of bottom dead center. Each hook includes a body provided with a catch that engages a corresponding knife and a metal blade that is relatively movable with respect to portions of the body adjacent the catch and that interacts with the selection device to selectively retain the hook in the top dead position thereof.

Owner:STAUBLI LYON

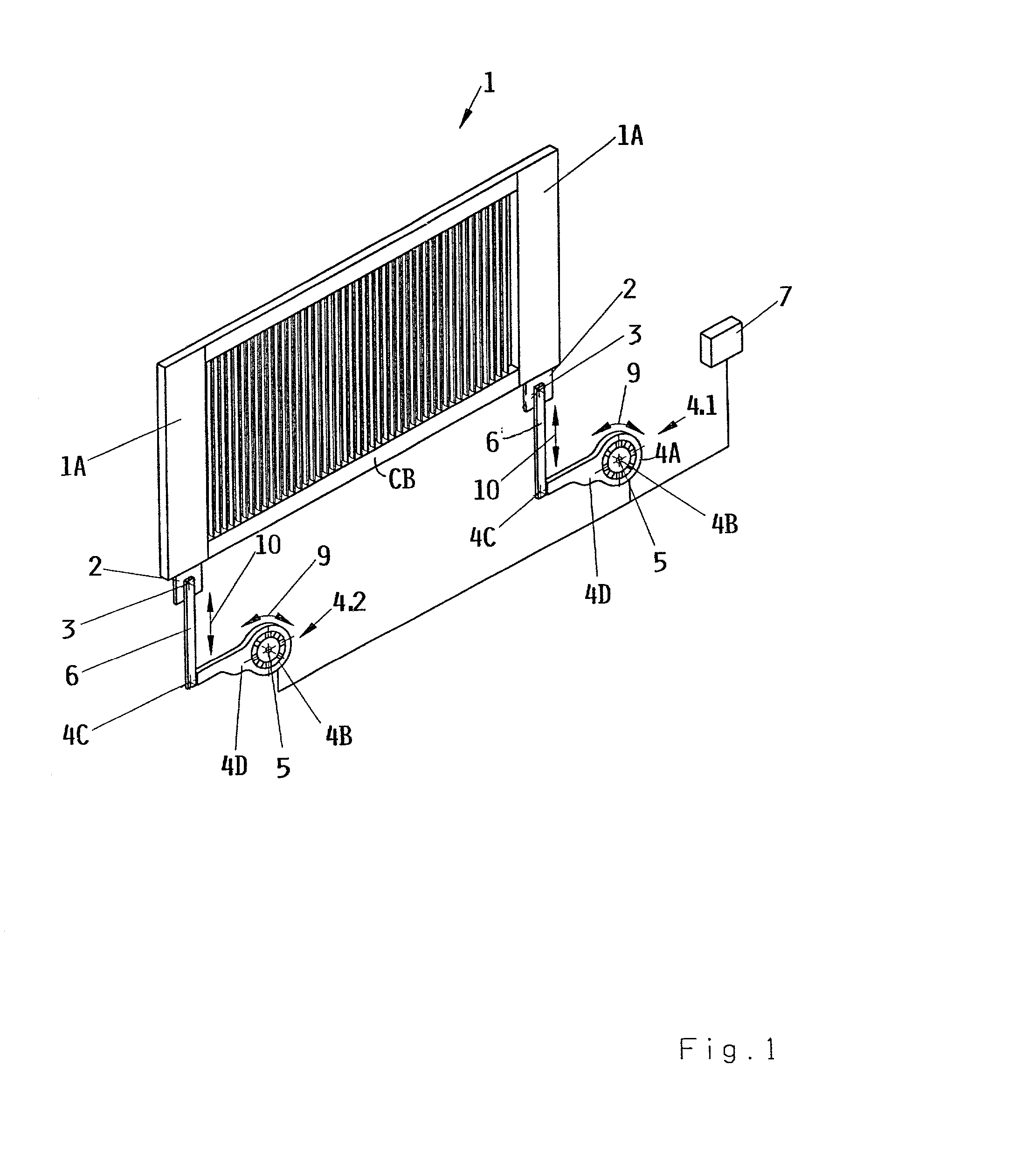

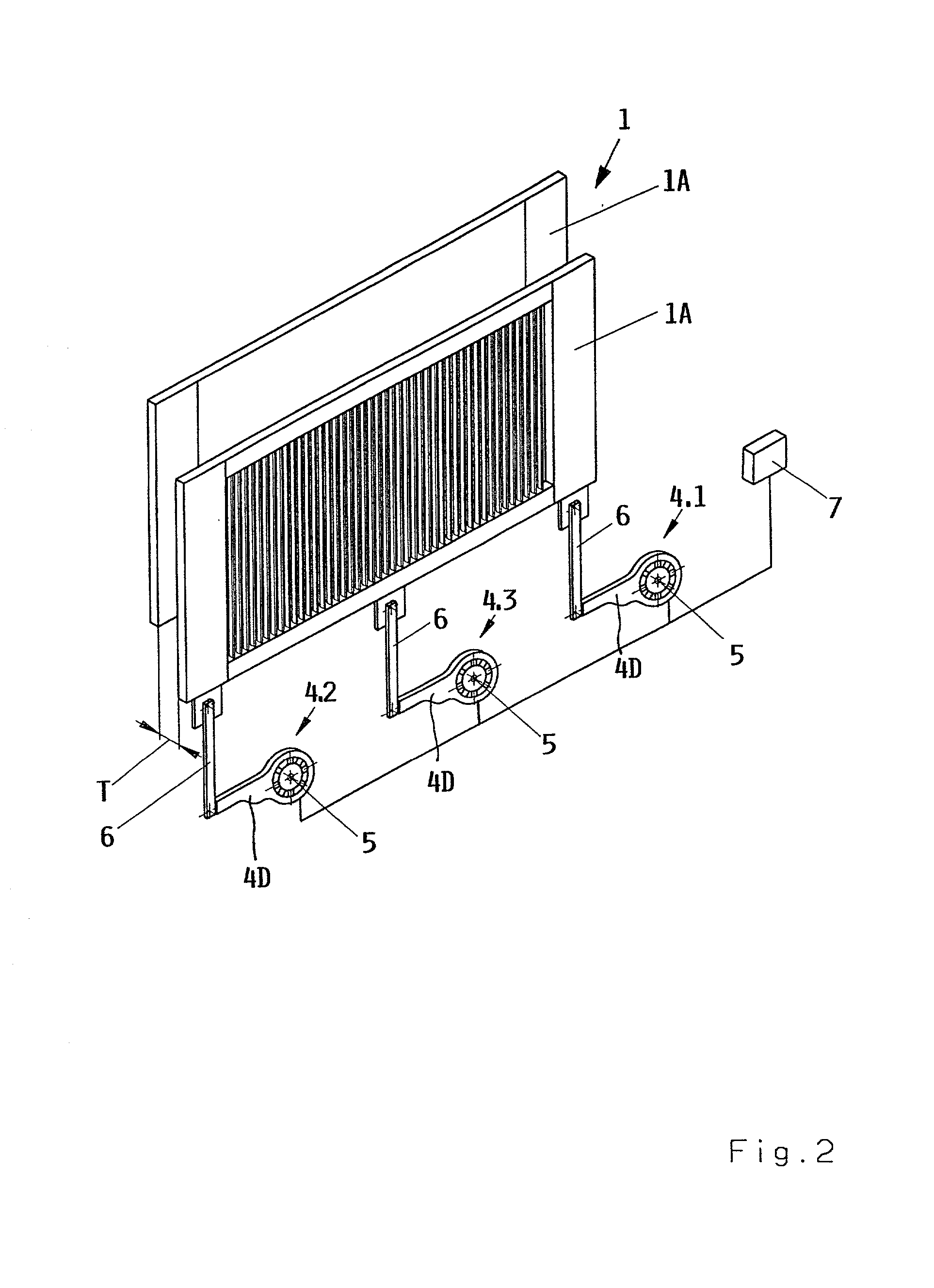

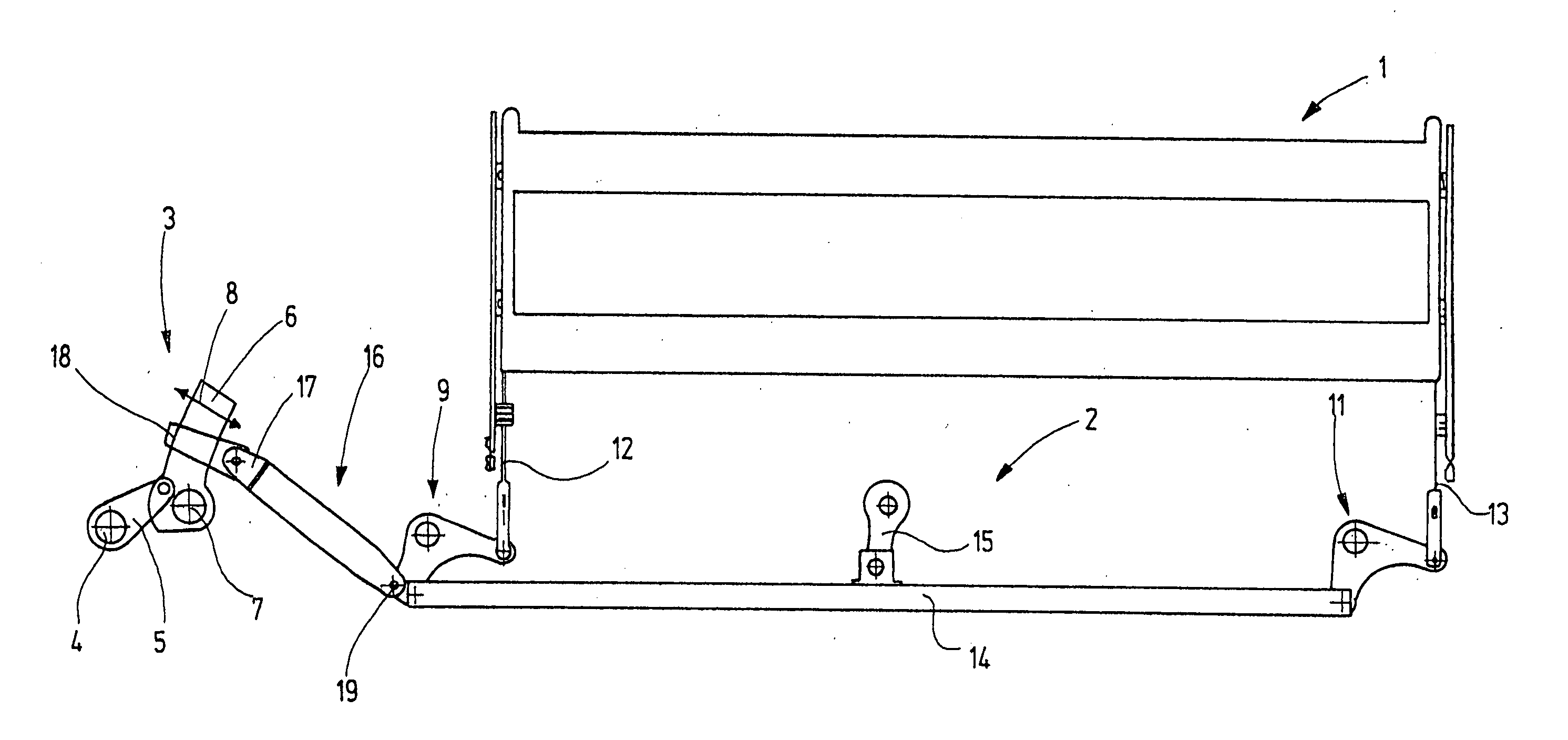

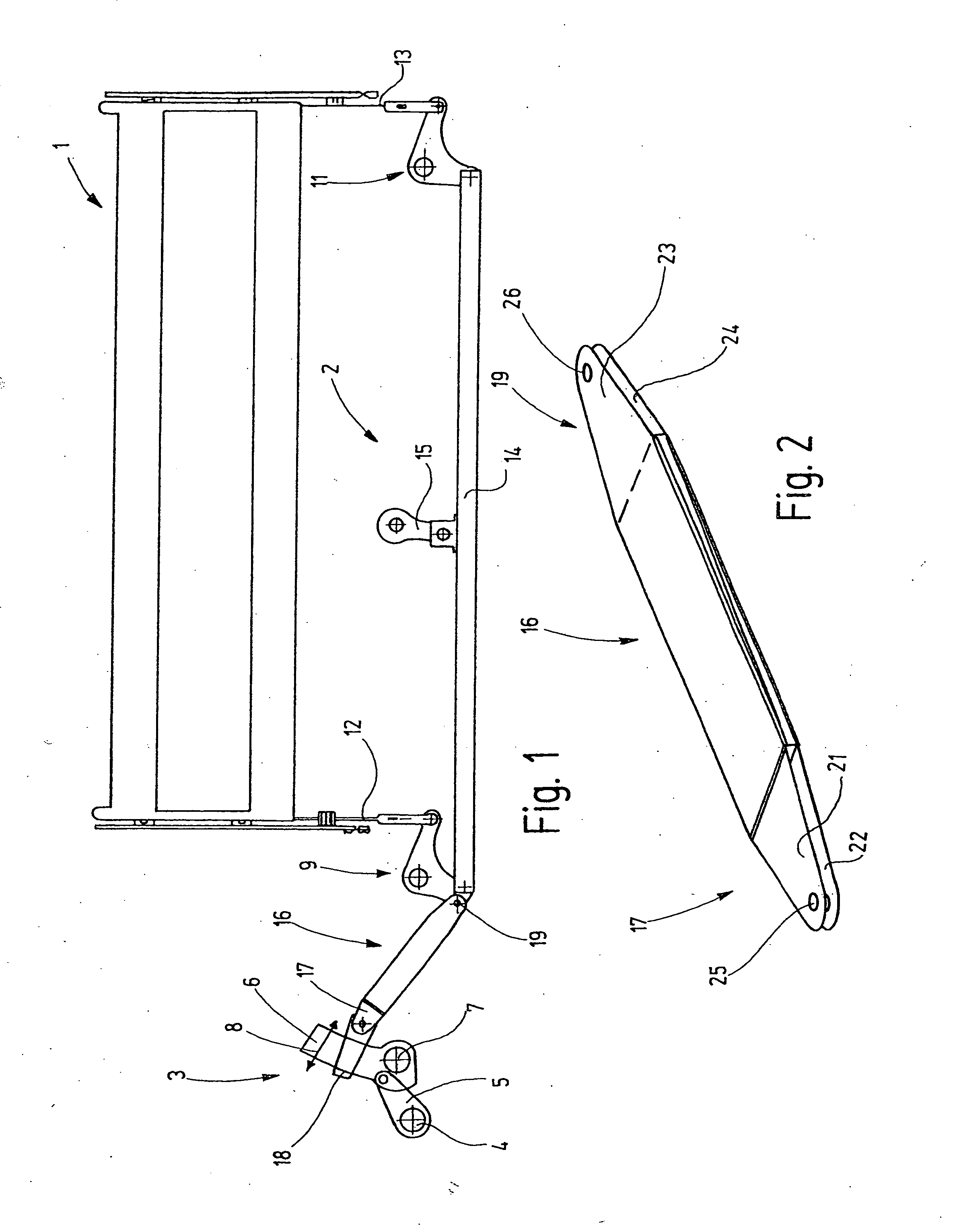

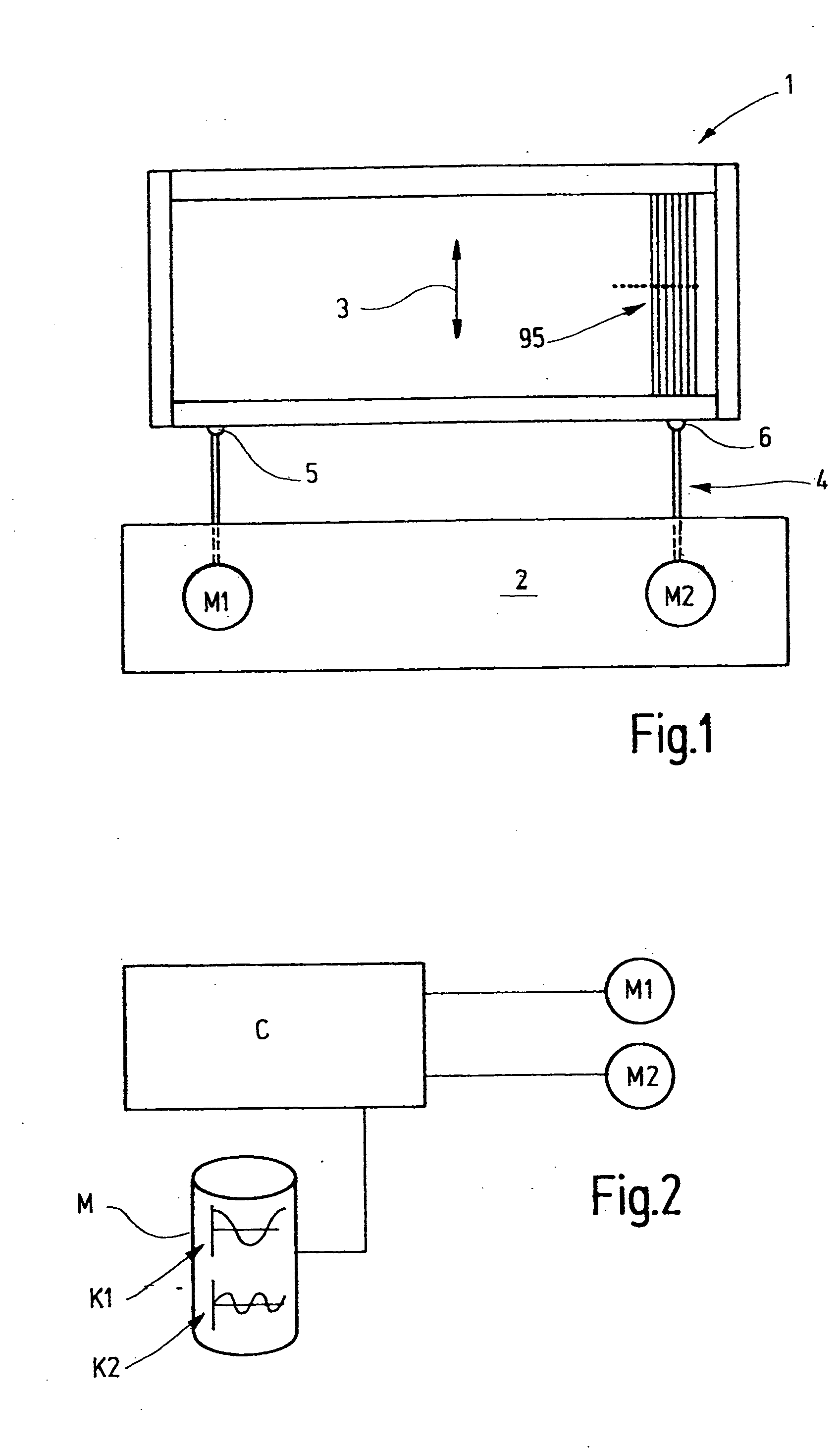

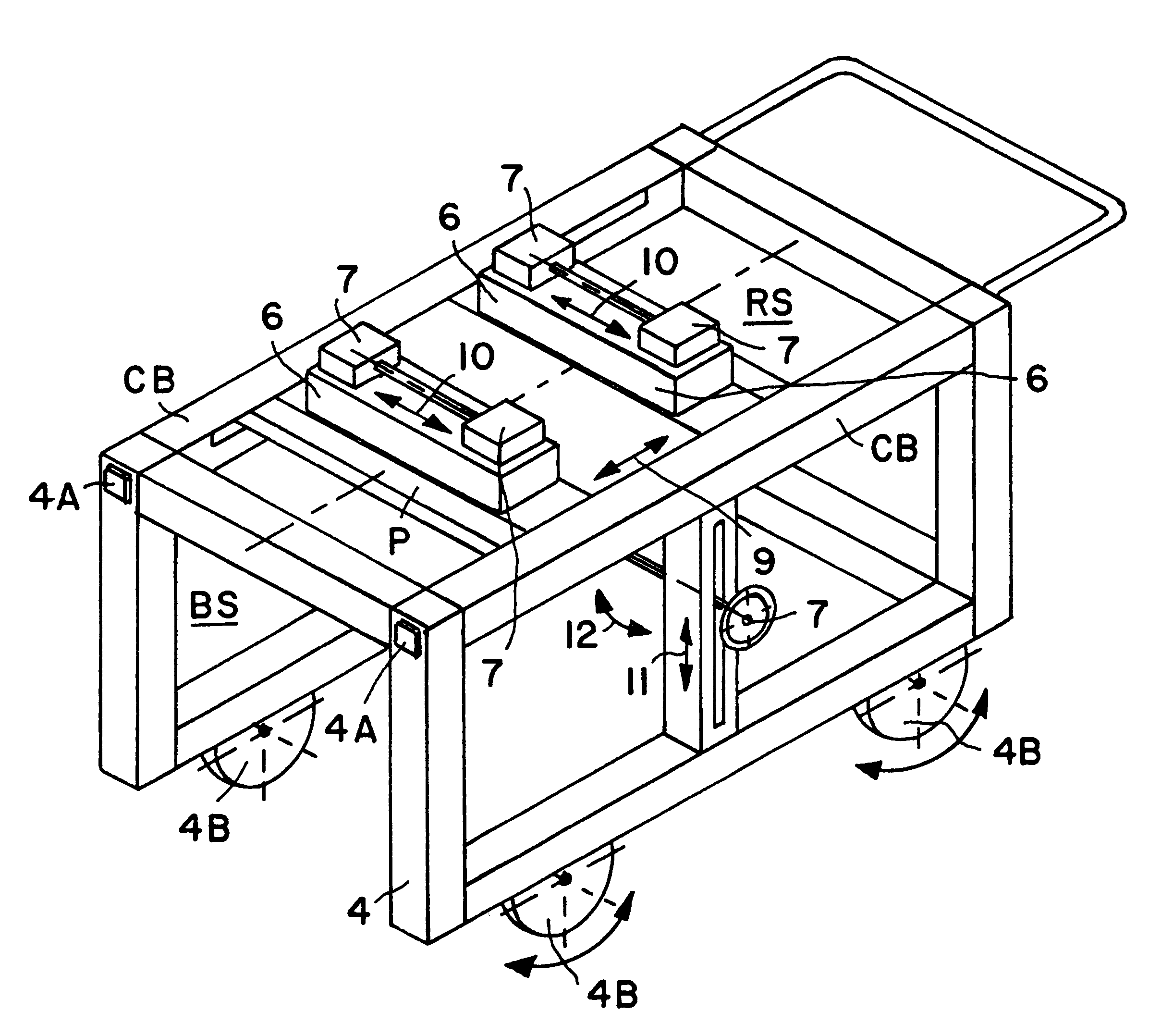

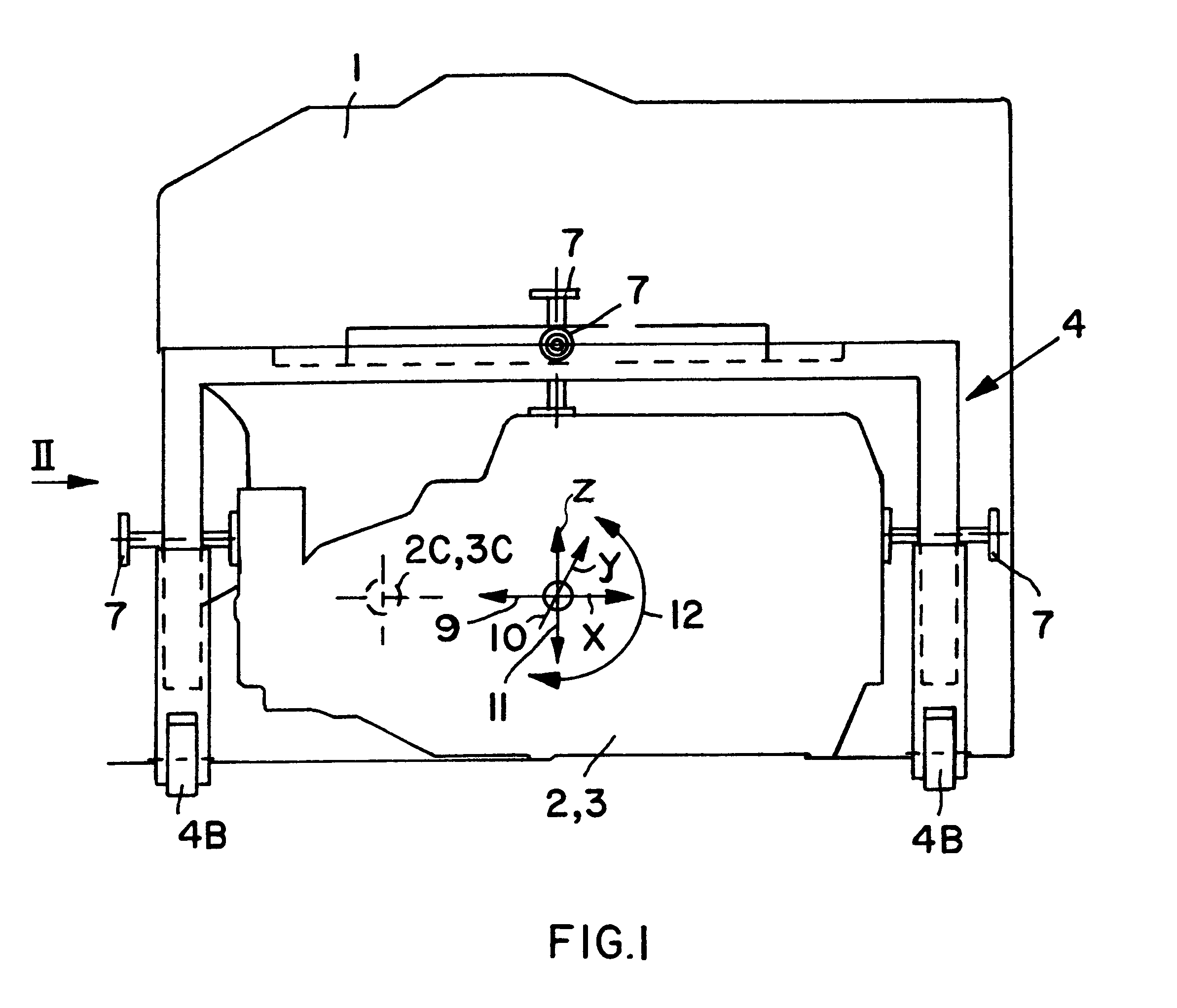

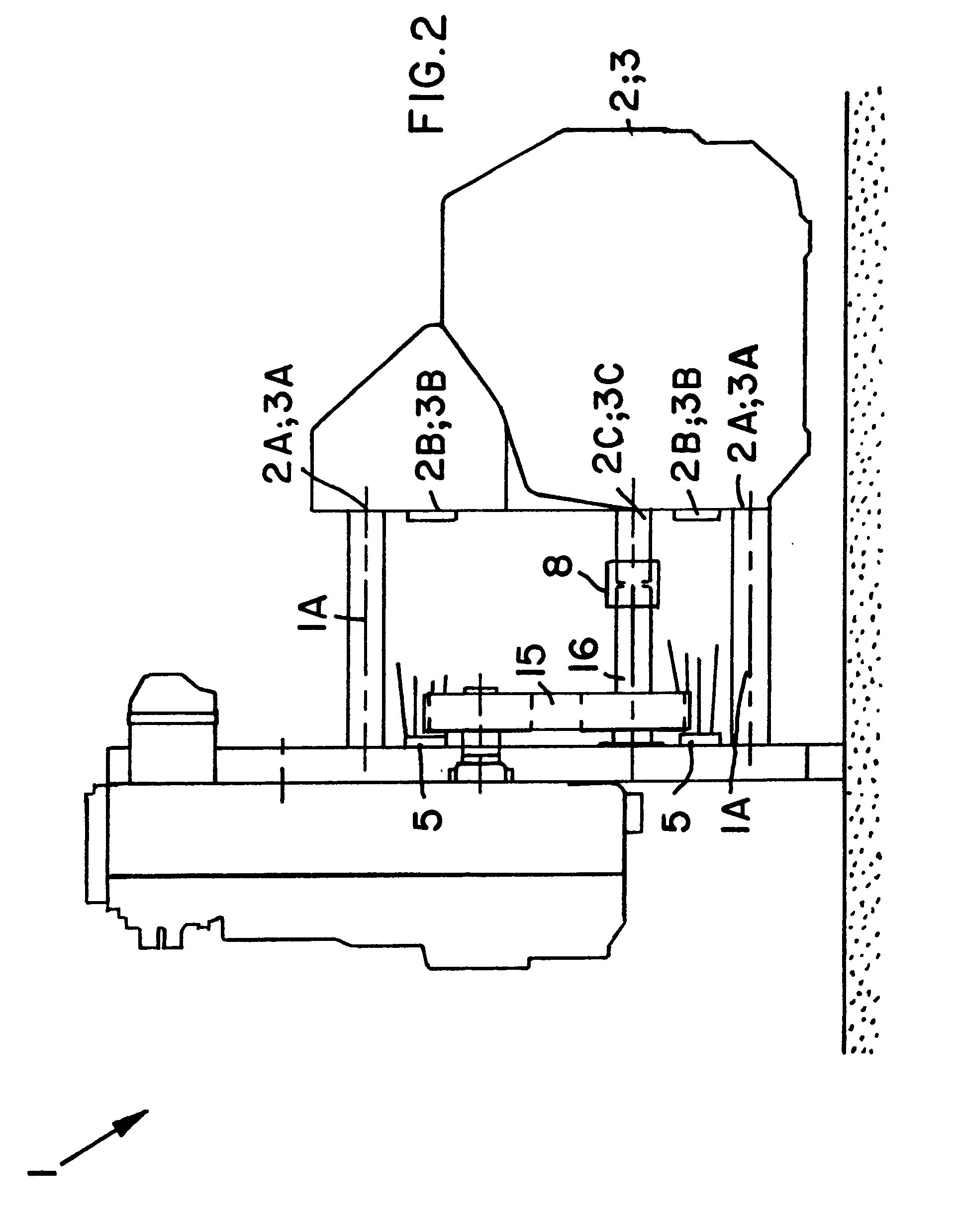

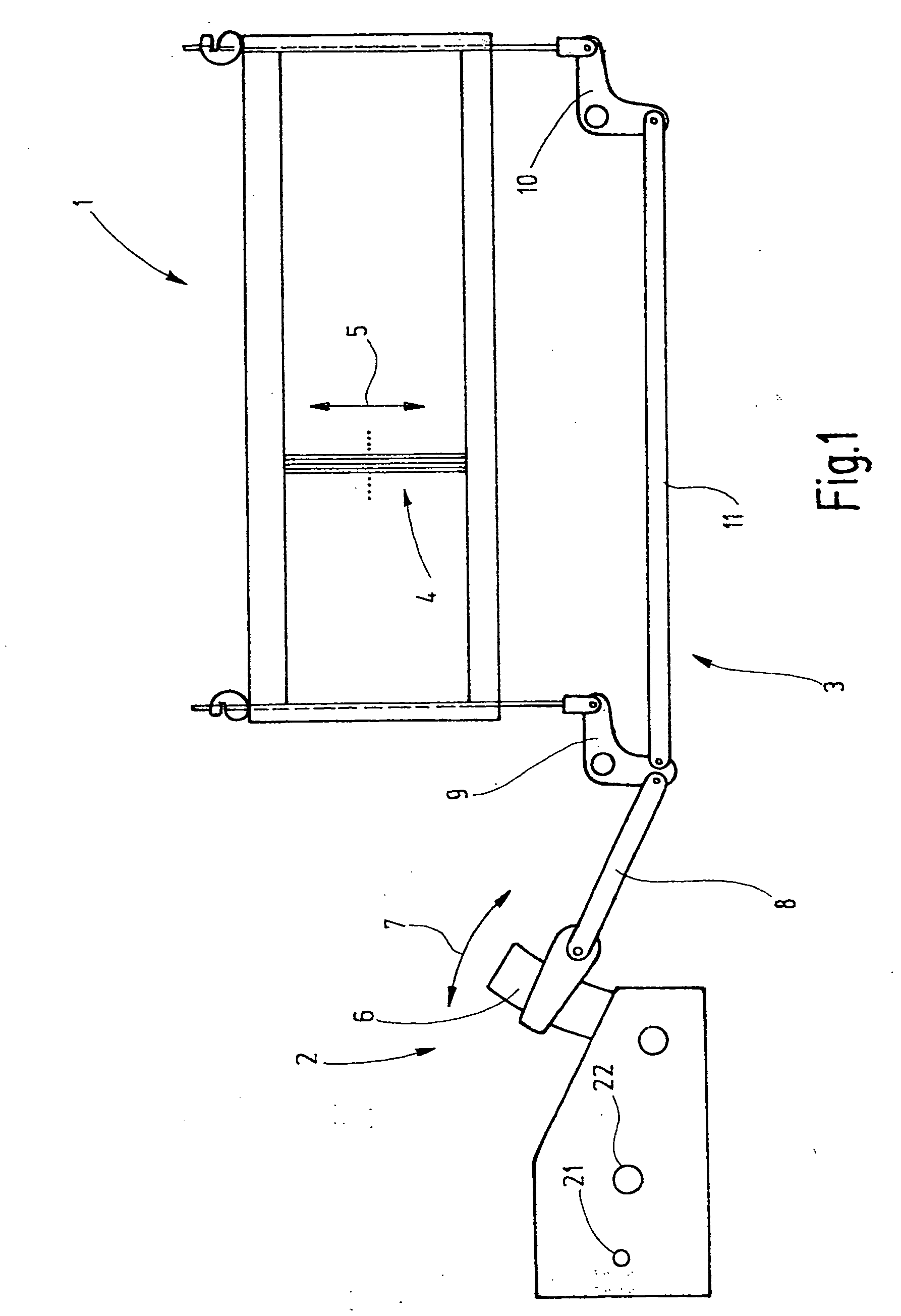

Method and apparatus for rapidly exchanging a shed drive in a heald loom

InactiveUS6230752B1Avoiding and minimizing time-consume adjustment operationQuick exchangeDobbiesLoomsEngineeringCarriage

The shed formed by the warp threads in a loom is changeable by a shed drive that may either be an eccentric drive or a shaft drive. In order to rapidly exchange one shed drive (2) by another shed drive (3) these shed drives are mounted individually in a respective carriage (4). The carriage is constructed for docking in an exchange position next to the loom. An empty first carriage can take up a shed drive currently cooperating with the loom to remove the shed drive from the loom. A second carriage carrying another shed drive can then dock in the exchange position after the second carriage has been removed. The carriage is positionable either manually or automatically in response to distance signals.

Owner:LINDAUER DORNIER GMBH

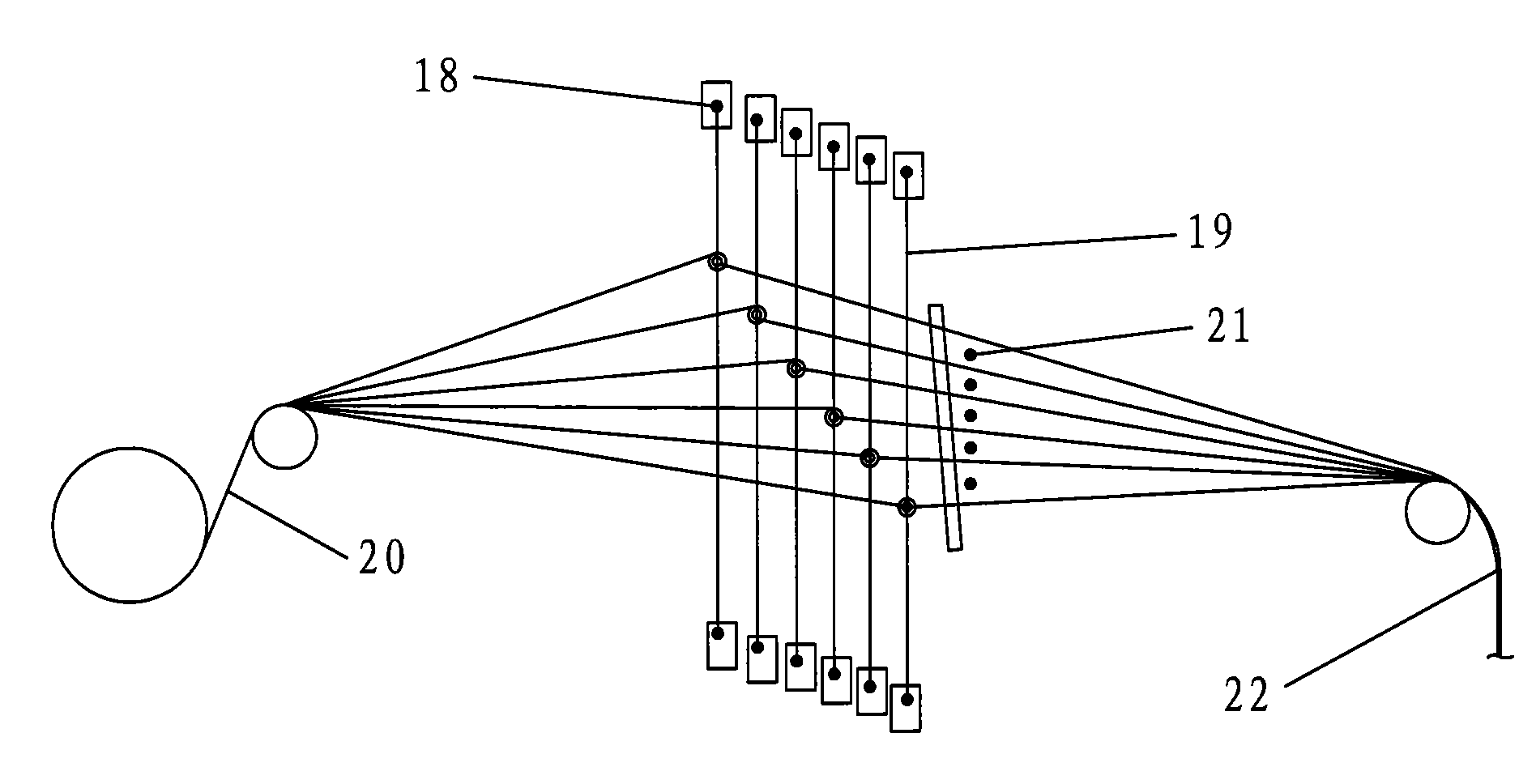

Electronic needle selecting mechanism of passive multi-arm device

ActiveCN101705556AExtended service lifeGuarantee work reliabilityDobbiesEngineeringBiomedical engineering

An electronic needle selecting mechanism of a passive multi-arm device belongs to the technical field of textile machine and comprises a signal supply device and an execution device that consists of a first transverse needle and a second transverse needle; the signal supply device comprises a bracket, a group of electromagnetic valves and a group of transverse needle actuating devices; the amount of the group of the electromagnetic valves is equal to the total amount of the first transverse needles and the second transverse needles; all electromagnetic valves are arranged in the length direction of the bracket and used for actuating the transverse needle actuating devices; the amount of the group of the transverse needle actuating devices is equal to the total amount of the first transverse needles and the second transverse needles; and all transverse needle actuating devices are arranged on the bracket, connected with the electromagnetic valves and matched with the first transverse needles and the second transverse needles, thus actuating the first transverse needles and the second transverse needles. The electronic needle selecting mechanism prolongs the service life of the signal supply device, can ensure working reliability, stability and adaptability of the signal supply device, is beneficial to reducing usage cost, and simplifies the whole structure.

Owner:常熟纺织机械厂有限公司

Three-shed device of rotary electronic dobby

ActiveCN105442138ASatisfy the requirement of three shed openingSave resourcesDobbiesEngineeringMechanical engineering

The invention provides a three-shed device of a rotary electronic dobby and belongs to the technical field of textile machinery. The rotary electronic dobby comprises a tank body, a heald lifting arm driving mechanism and a heald lifting arm mechanism, wherein the heald lifting arm driving mechanism is arranged in a tank body cavity of the tank body through a spindle; the heald lifting arm mechanism is arranged in the position, corresponding to the left side of the heald lifting arm driving mechanism, in the tank body cavity of the tank body through a heald lifting arm shaft and is connected with the heald lifting arm driving mechanism. The three-shed device comprises a pair of supporting seats, a swing arm mechanism and a heald frame three-shed heald lifting blade mechanism, wherein the supporting seats correspond to each other and are fixed with one side, opposite to the tank body cavity of the tank body, of the left tank wall when in a state perpendicular to the left tank wall of the tank body; the swing arm mechanism is supported between the pair of supporting seats and is connected with the heald lifting arm mechanism; the heald frame three-shed heald lifting blade mechanism is connected with the swing arm mechanism. The three-shed device of the rotary electronic dobby has the following advantages: resources are saved, and the requirement for three sheds of a loom for weaving pile warp fabric is met; the integral structure is concise, and the rotary electronic dobby in the prior art can be subjected to addition improvement, so that economic cheapness can be reflected.

Owner:常熟纺织机械厂有限公司

Method of Producing a Woven Artificial Turf

Owner:SHAW CONTRACT FLOORING SERVICES

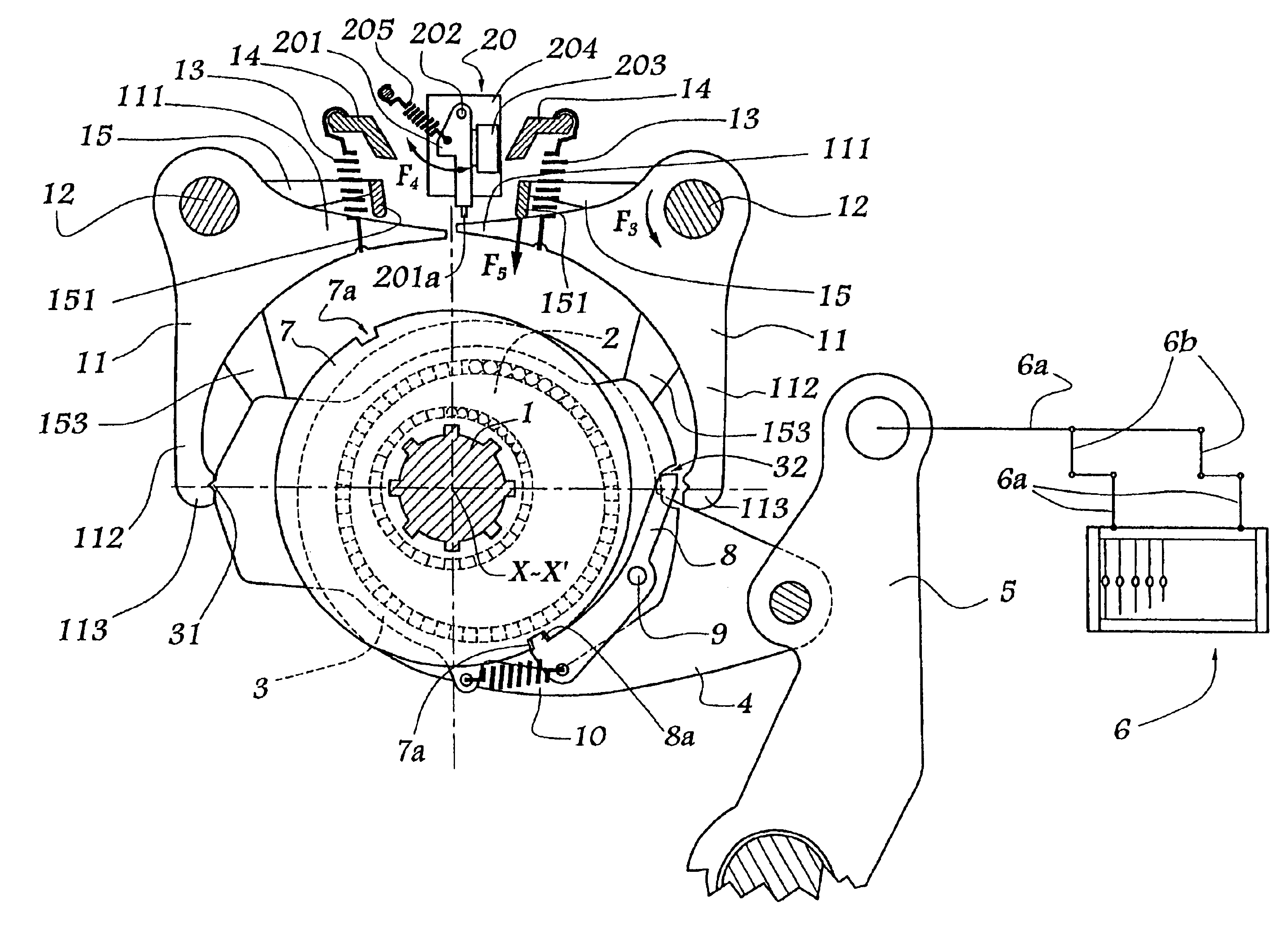

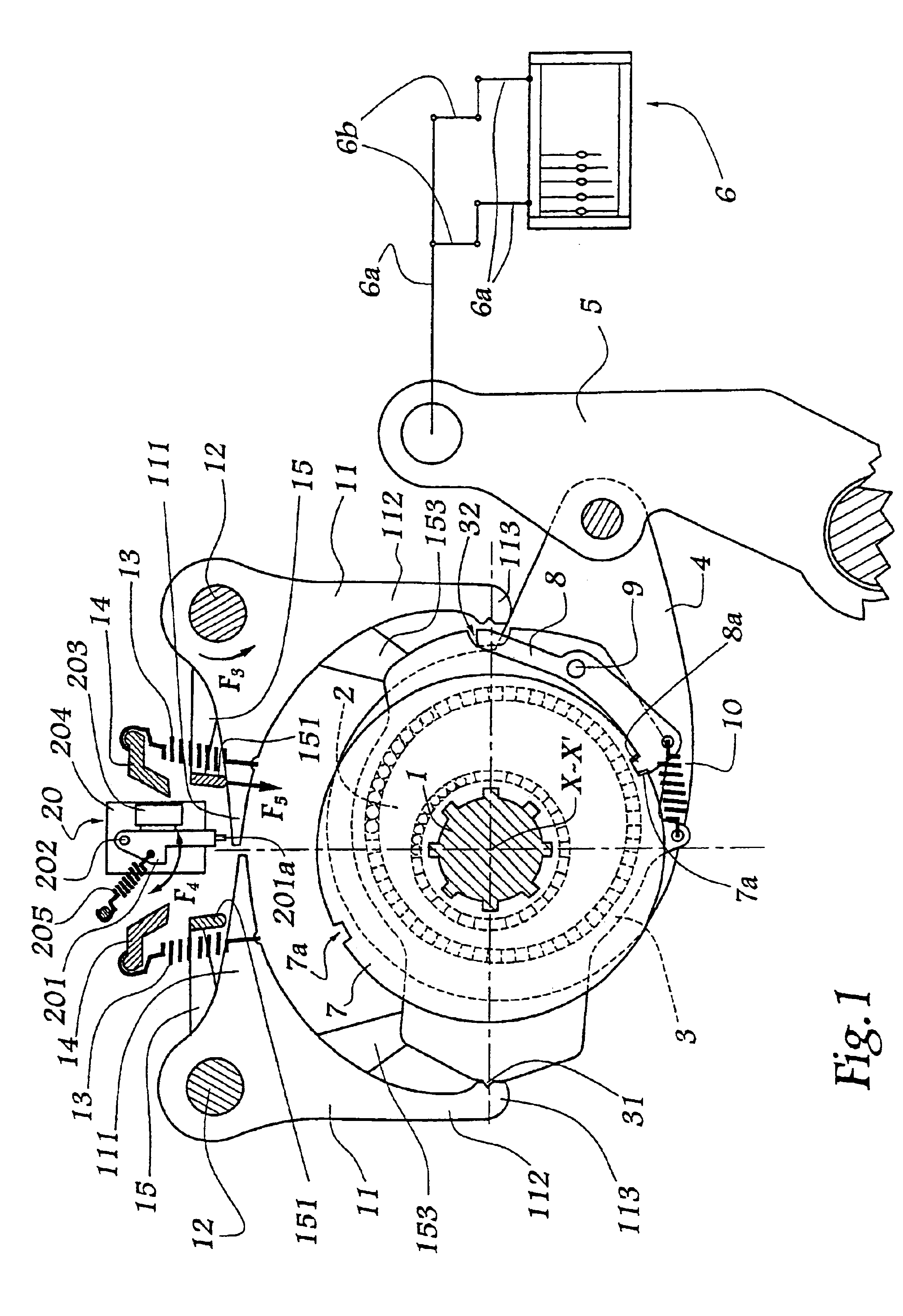

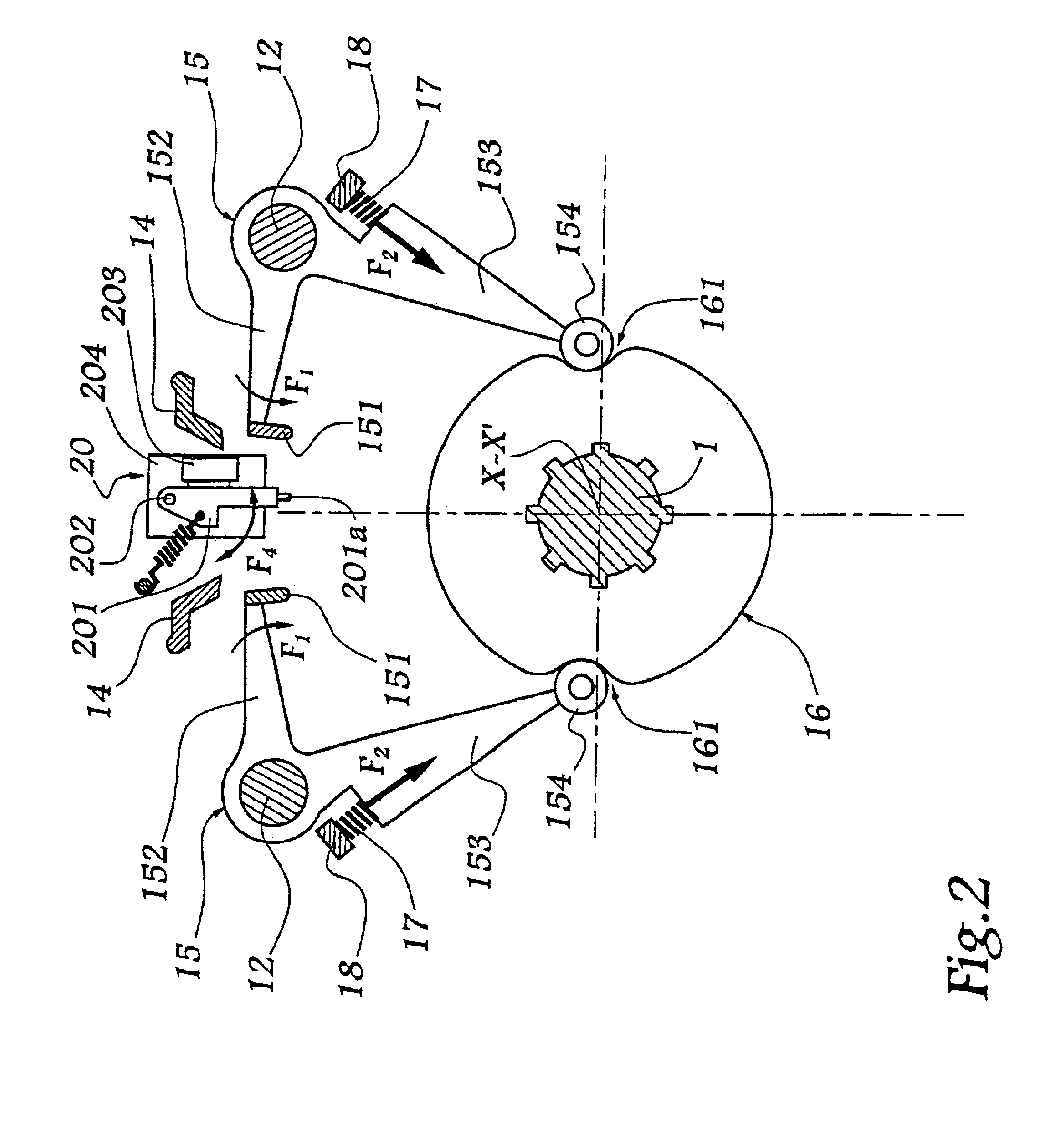

Rotary dobby machine for weaving machine and weaving machine with said rotary dobby machine

InactiveCN1477250ADoes not interfere with angular movementExtend your lifeMechanical apparatusDobbiesEngineeringMechanical elements

Owner:STAUBLI FAVERGES SA

Shaft drive for a power loom

The heddle shaft (1) according to the invention combines a traditional heddle machine (2) with an eccentric toothed gearing to purposely allow the heddle shaft (1) to dwell for longer periods of time in the upper and lower reversing region and to reduce any accelerations that occur. This permits an increase in the weaving speed and / or the weaving widths. For a particularly advantageous embodiment, a coupling device is additionally provided, which gives the heddle shaft (1) a pendulum movement with a stroke ranging from a few millimeters to centimeters during the idle phases, meaning when no sheds are formed. As a result of the pendulum movement of the heddle shaft (1) in the upper or lower reversing region, the acceleration loads on the heddle shaft (1) can be further reduced.

Owner:GROZ BECKERT KG

Flame-retardant union fabric

A flame retardant union fabric obtained by combining (A) 30 to 70% by weight of a fiber comprising as a main component a flame retardant halogen-containing fiber made of a composition comprising 100 parts by weight of an acrylic copolymer of 30 to 70% by weight of acrylonitrile, 30 to 70% by weight of a halogen-containing vinyl monomer and 0 to 10% by weight of a vinyl monomer copolymerizable with them, 10 to 30 parts by weight of an antimony compound and 8 to 30 parts by weight of a zinc stannate compound, with (B) 70 to 30% by weight of a cellulosic fiber. The flame retardant union fabric shows a high flame resistance which passes the M1 class of NF P 92-503 burning test in France even after the post-treatment.

Owner:KANEKA CORP

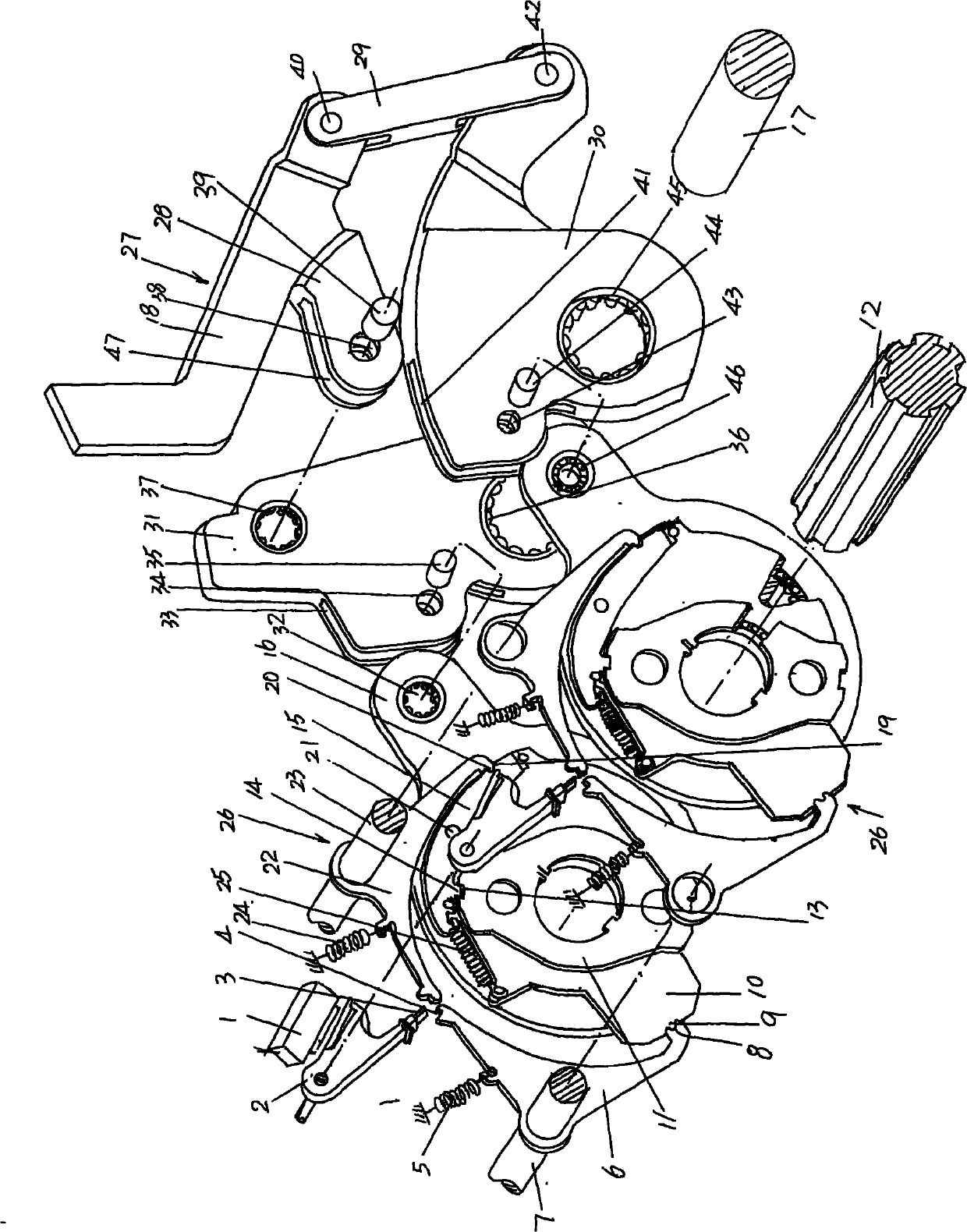

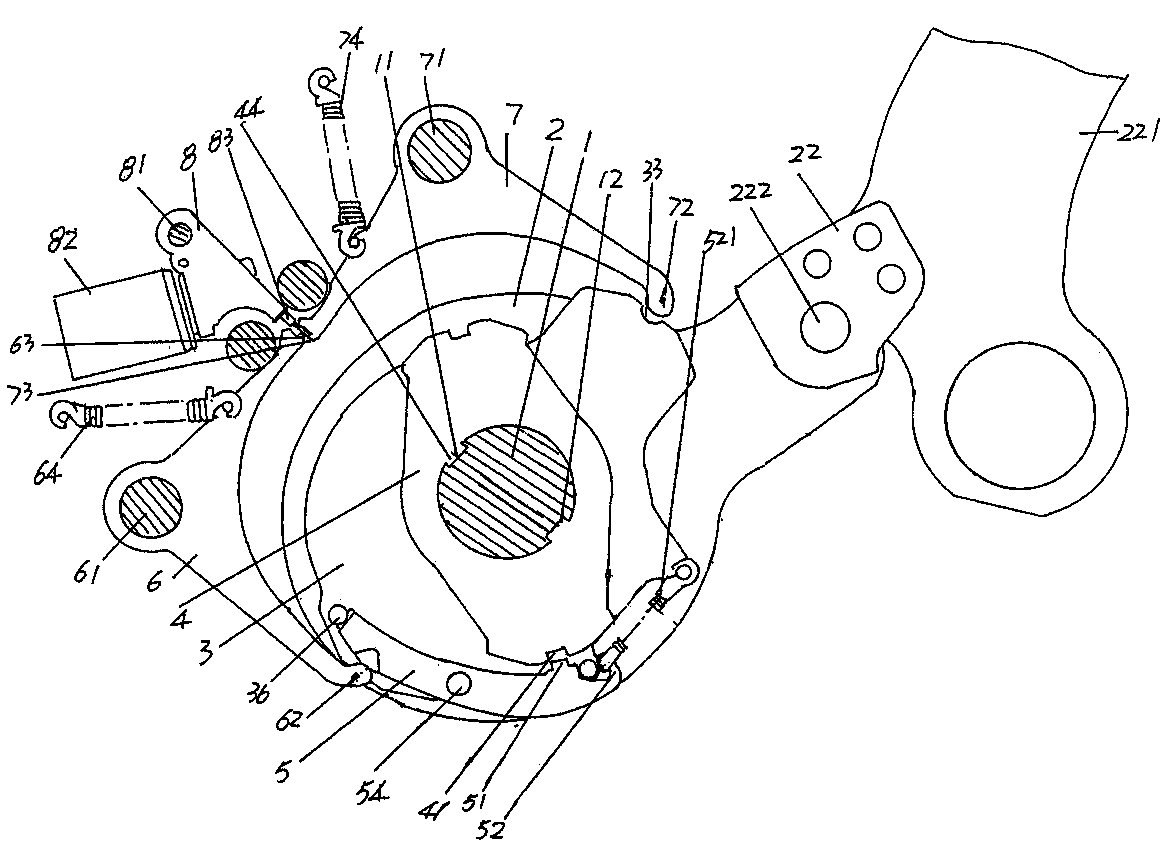

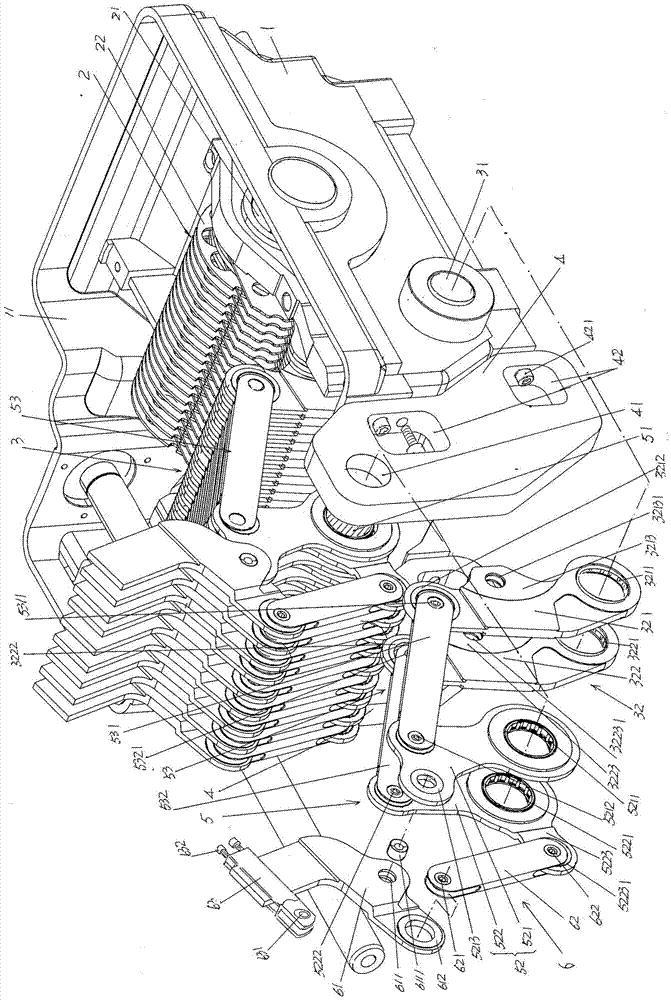

Rotating dobby for weaving loom and weaving loom equipped with such a dobby

ActiveUS6938647B2Without of of premature wearWithout riskMechanical apparatusDobbiesEngineeringMechanical engineering

The dobby according to the invention comprises, at the level of each of its blades, an oscillating piece associated with an actuation element, at least one mobile coupling member borne by the actuation element and two pivoting levers subjected, on the one hand, to the action of a reading device and, on the other hand, to that of elastic means which tend to engage catches of the pivoting levers either with a jamming surface provided on the actuation element, or with the coupling member, while the lever in engagement with the jamming surface is out of range of a selector of the reading device. In addition, mechanical members independent of the reading device are adapted to displace, against the action of the elastic means, a lever whose catch is not in engagement with the jamming surface, with the result that it does not interfere with the angular displacement of the selector.

Owner:STAUBLI FAVERGES SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com