Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Improve axial rigidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

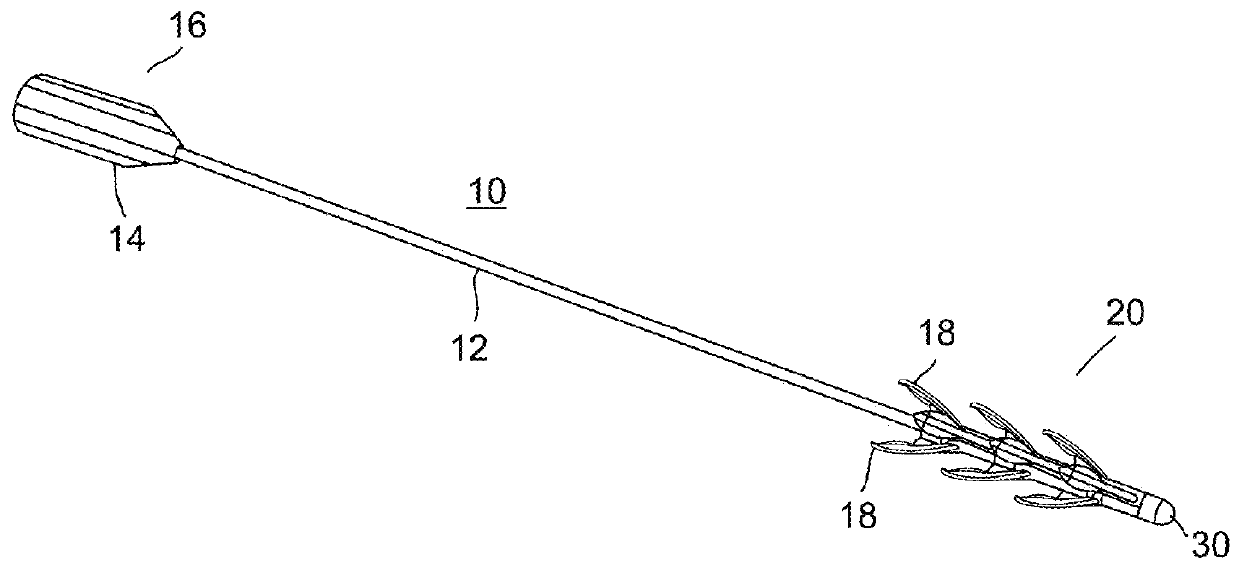

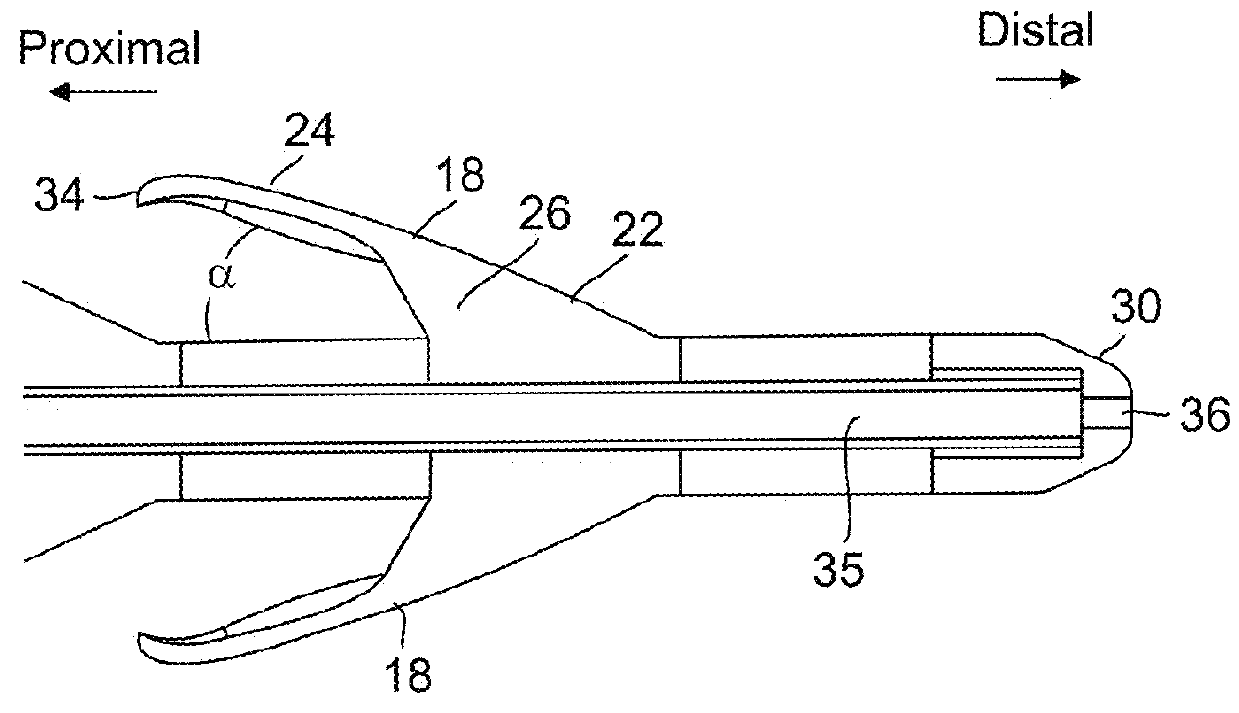

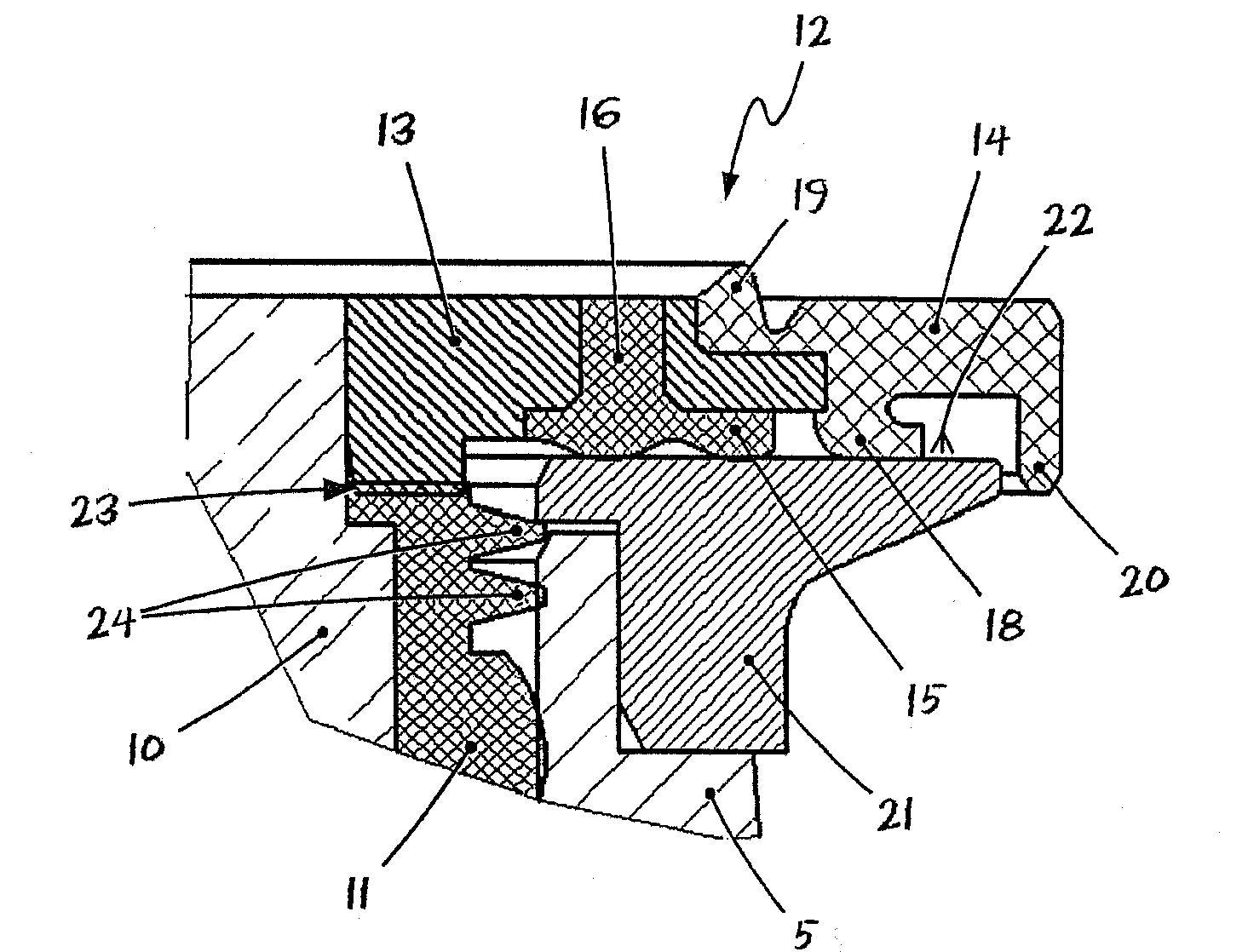

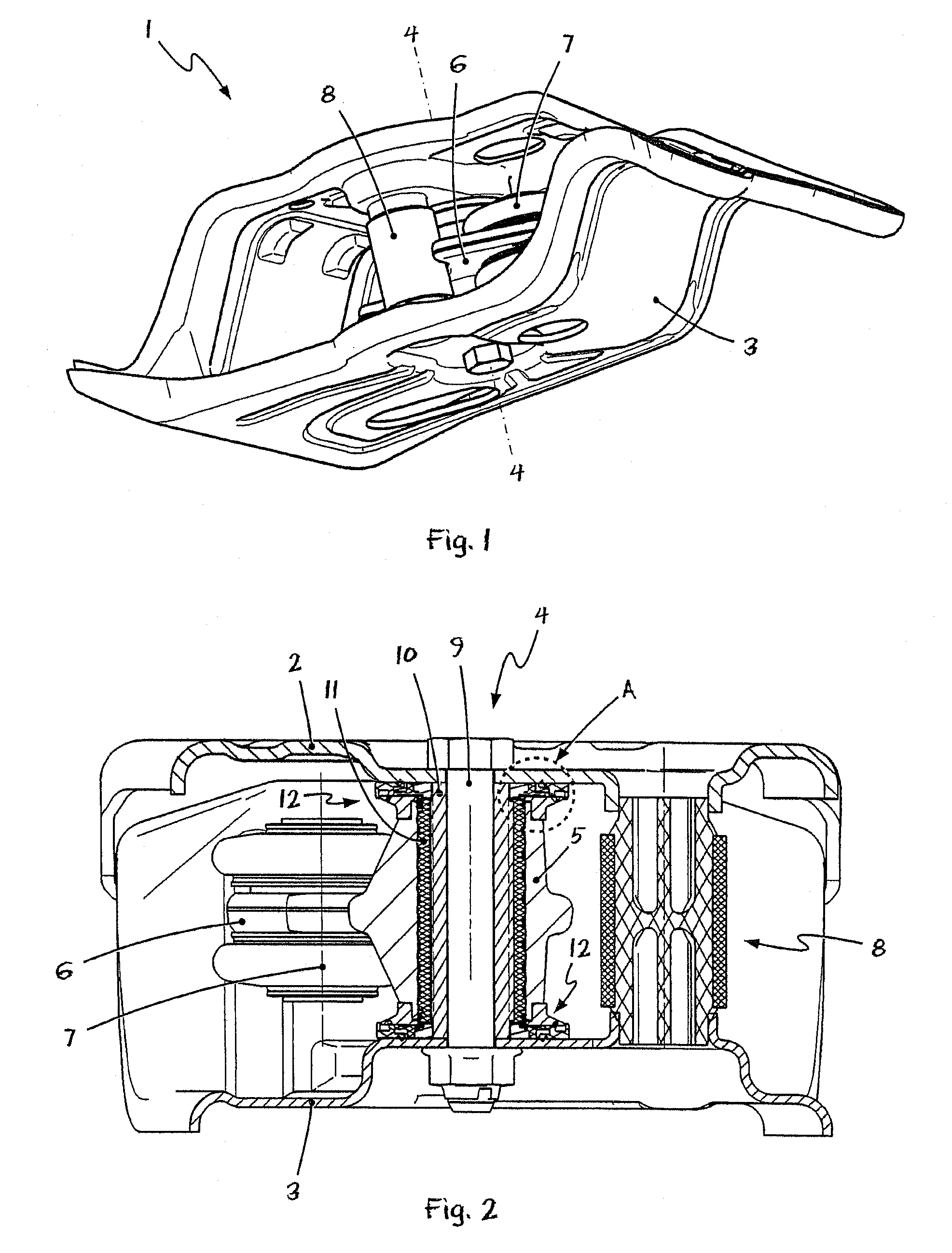

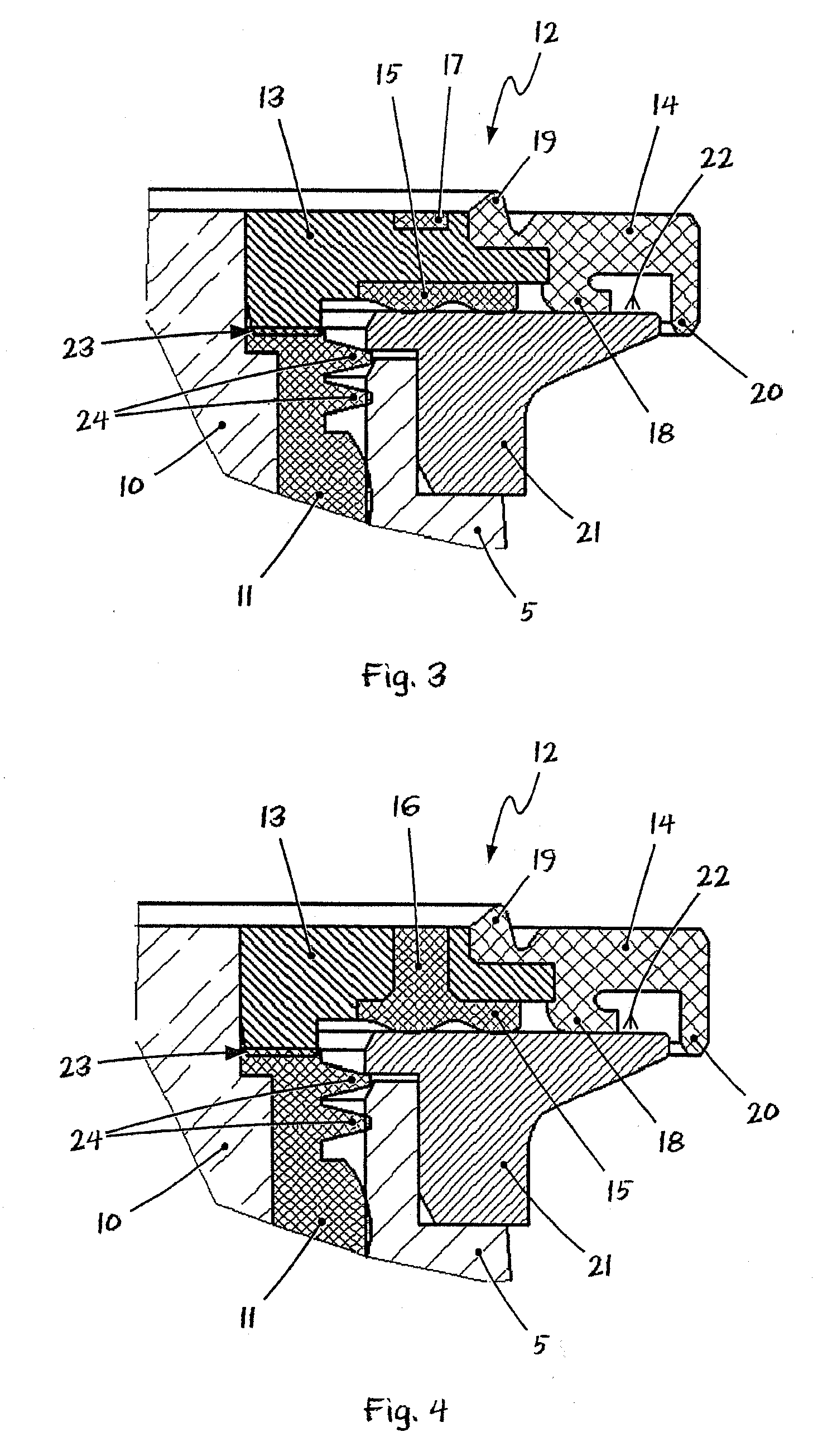

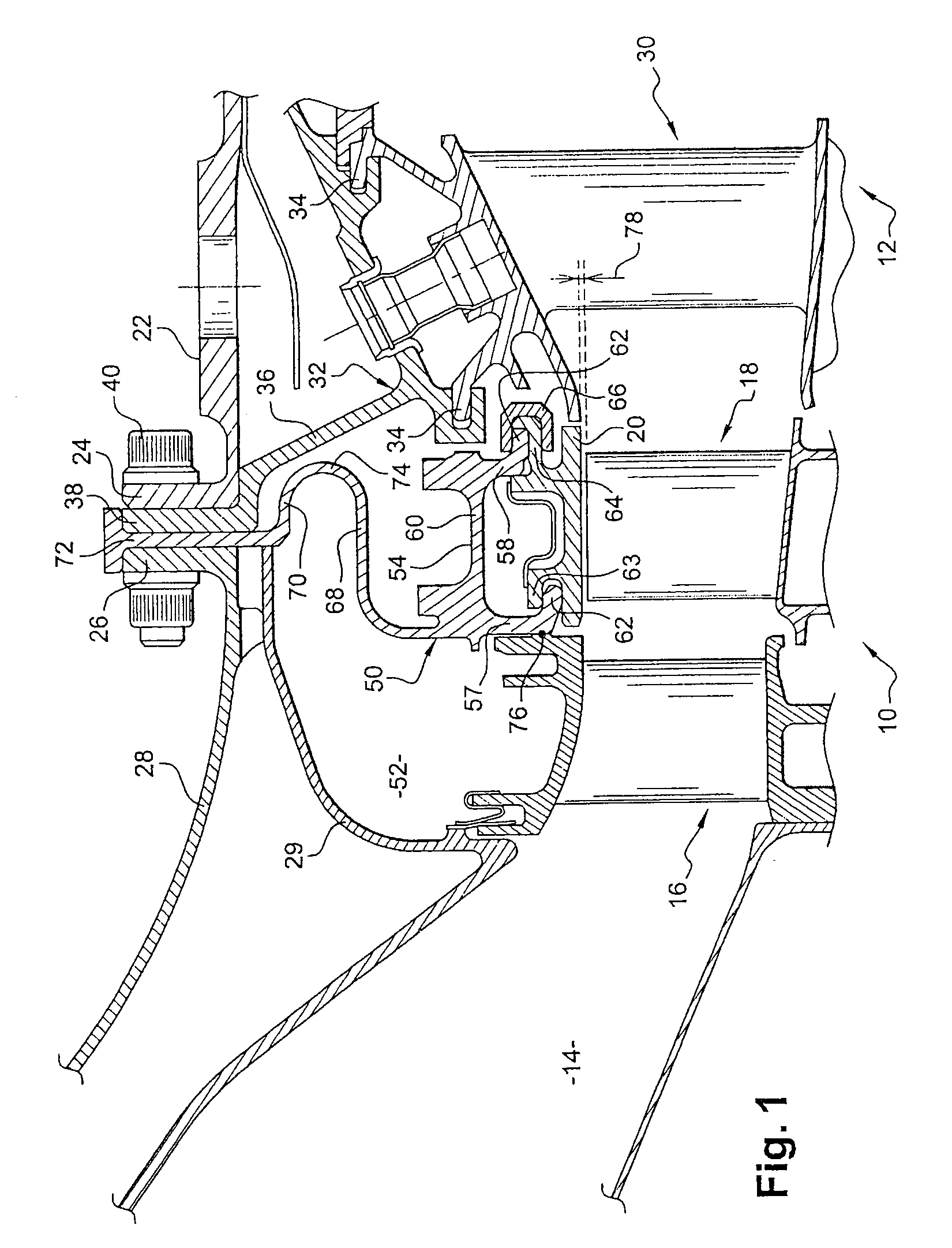

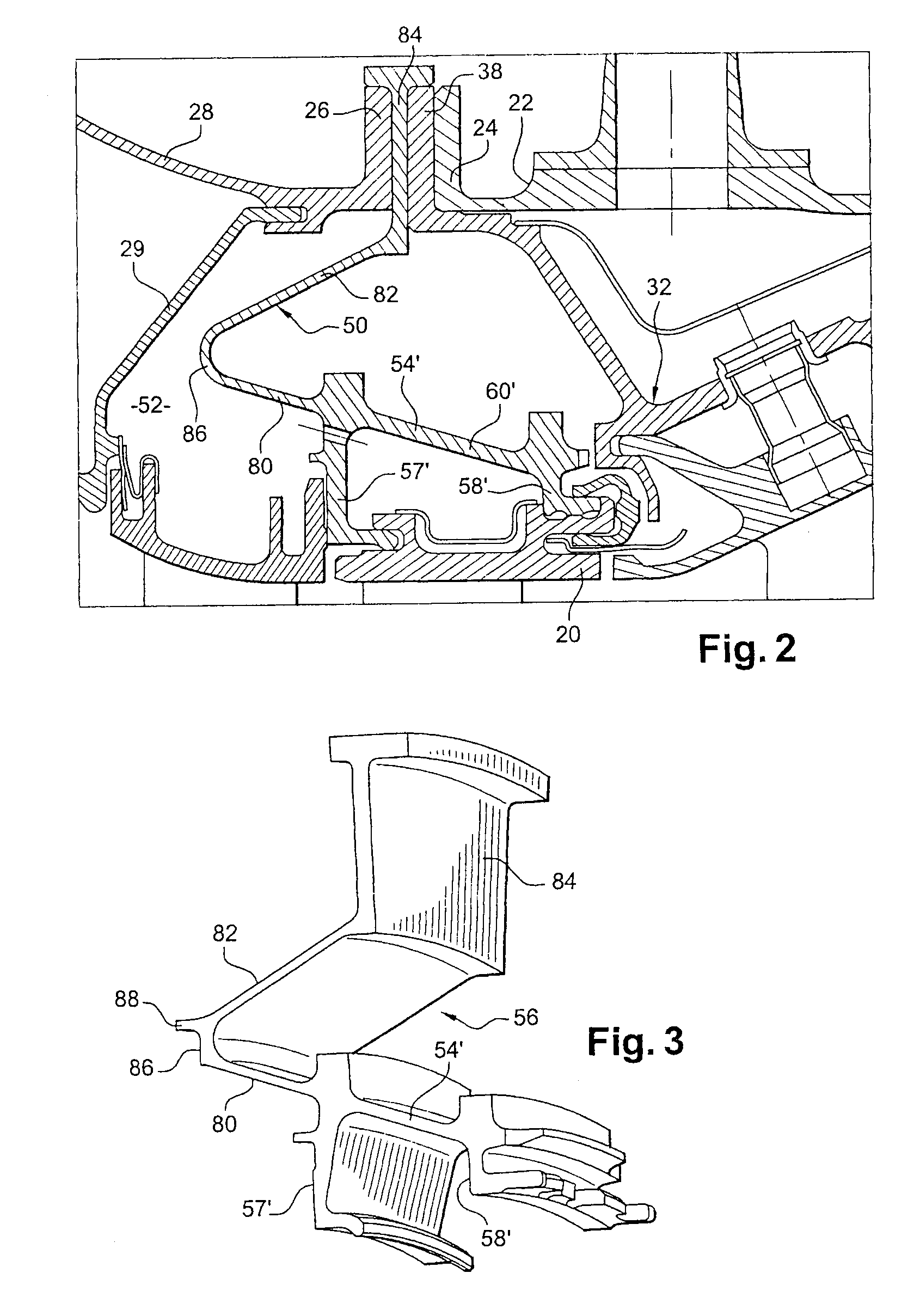

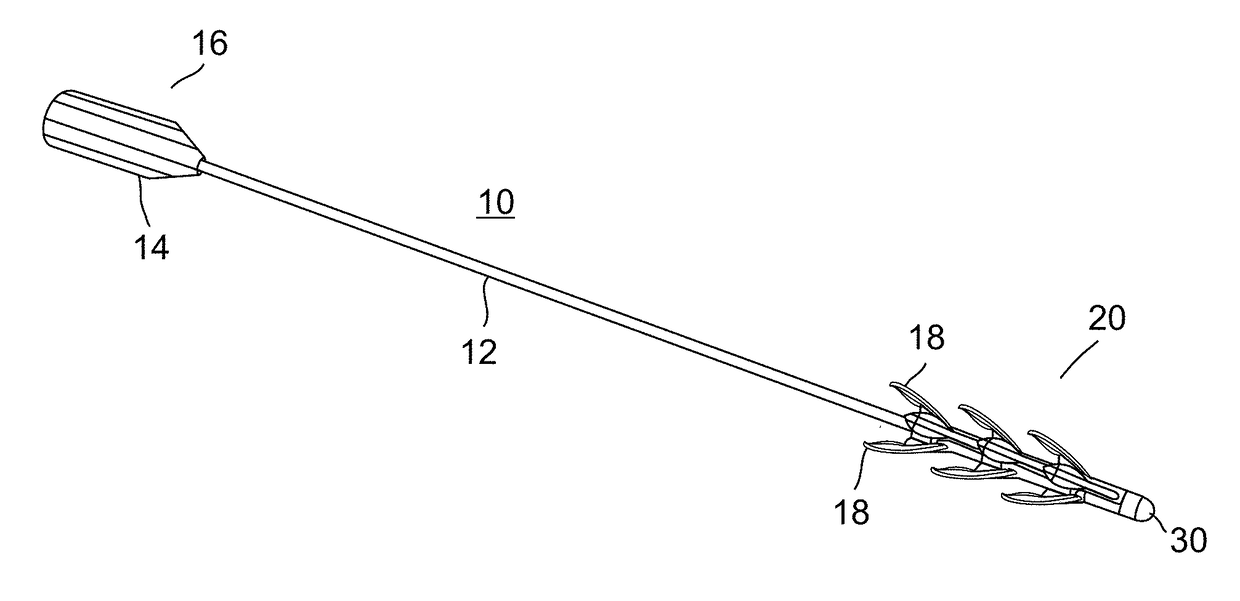

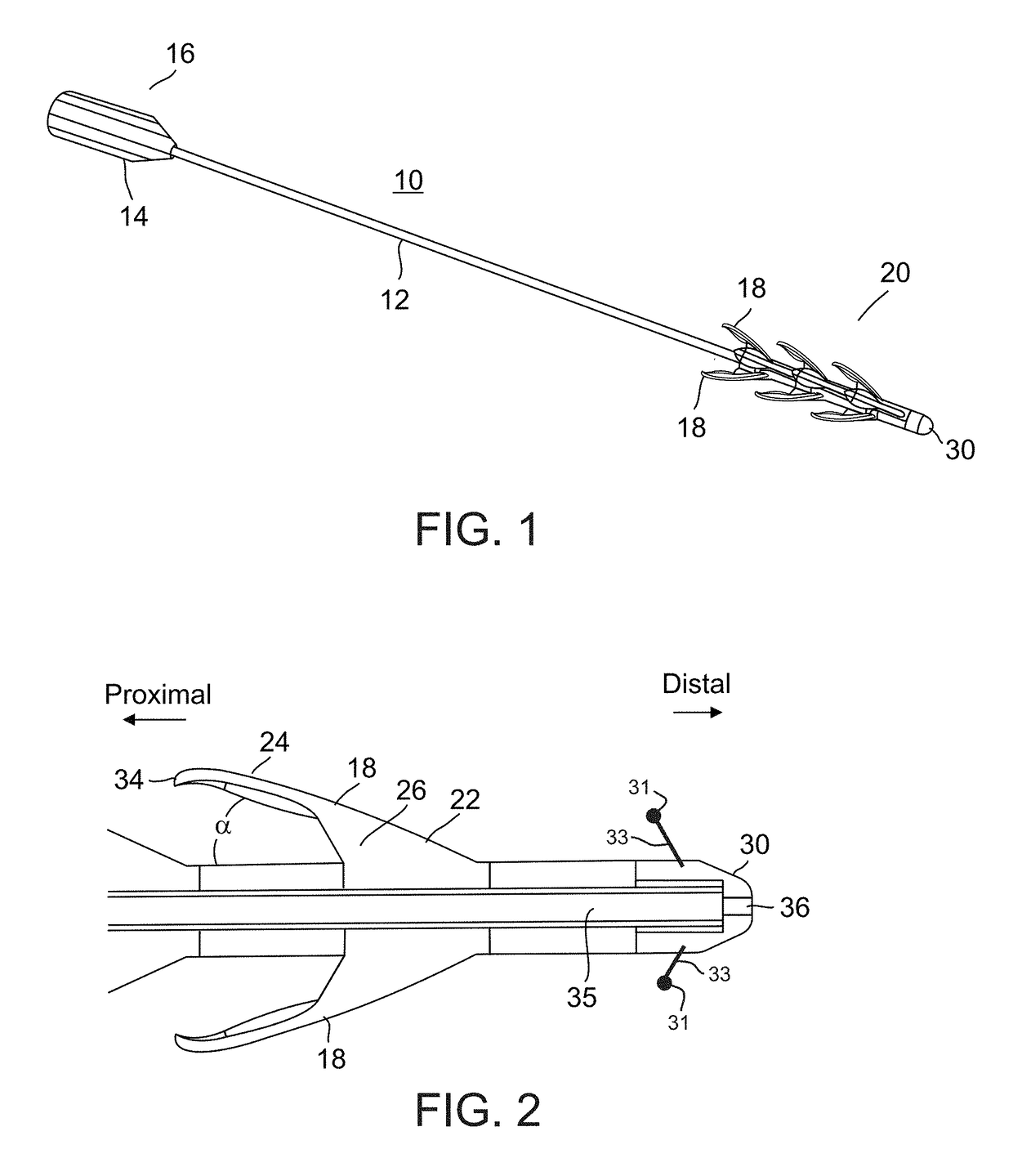

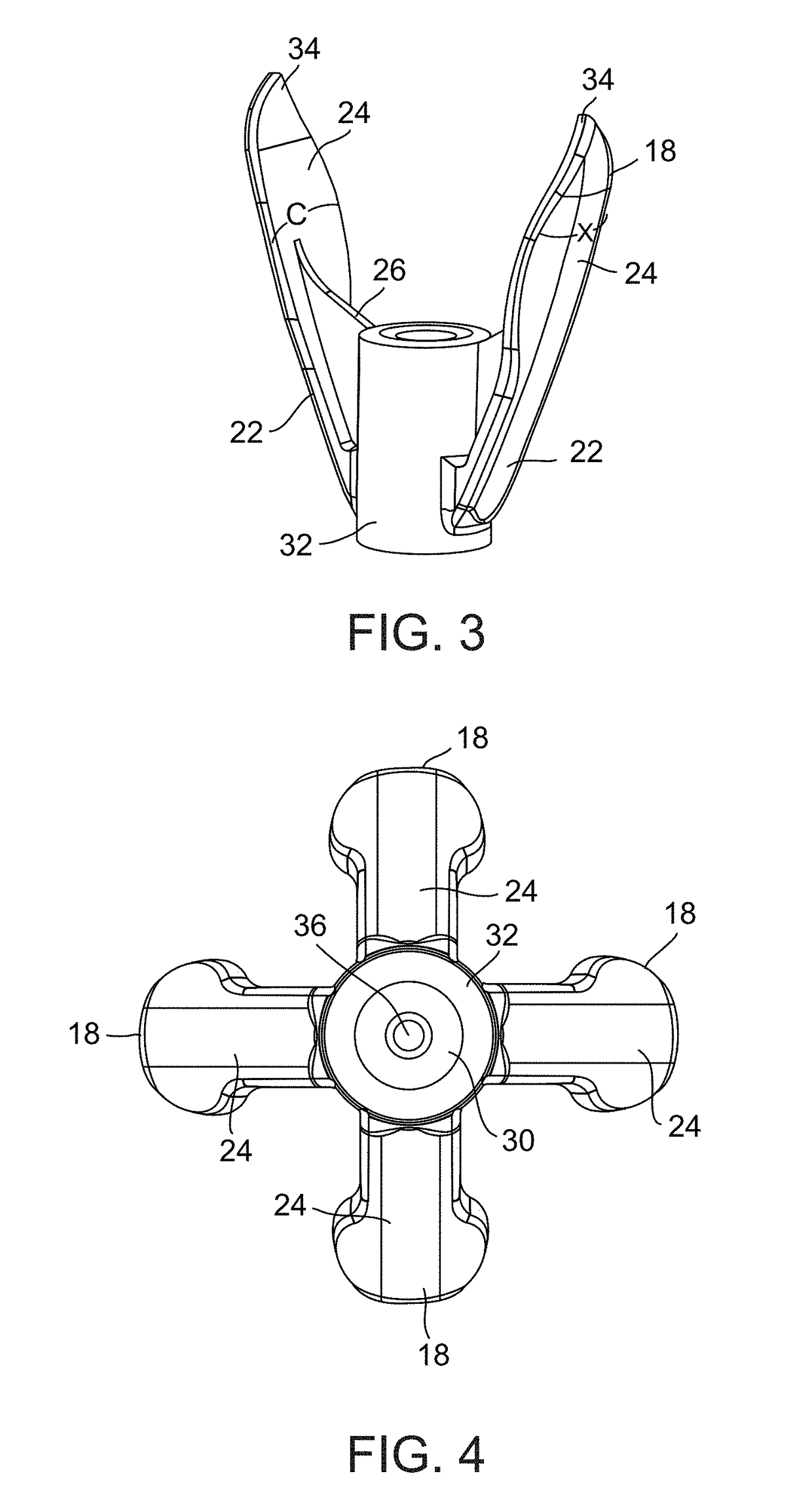

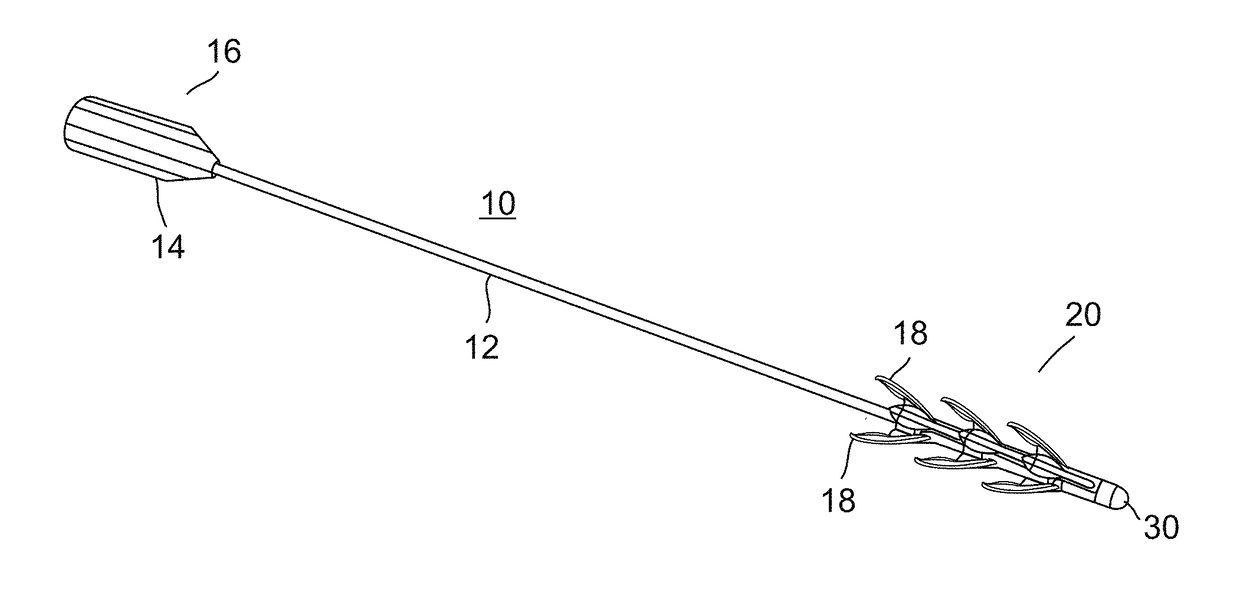

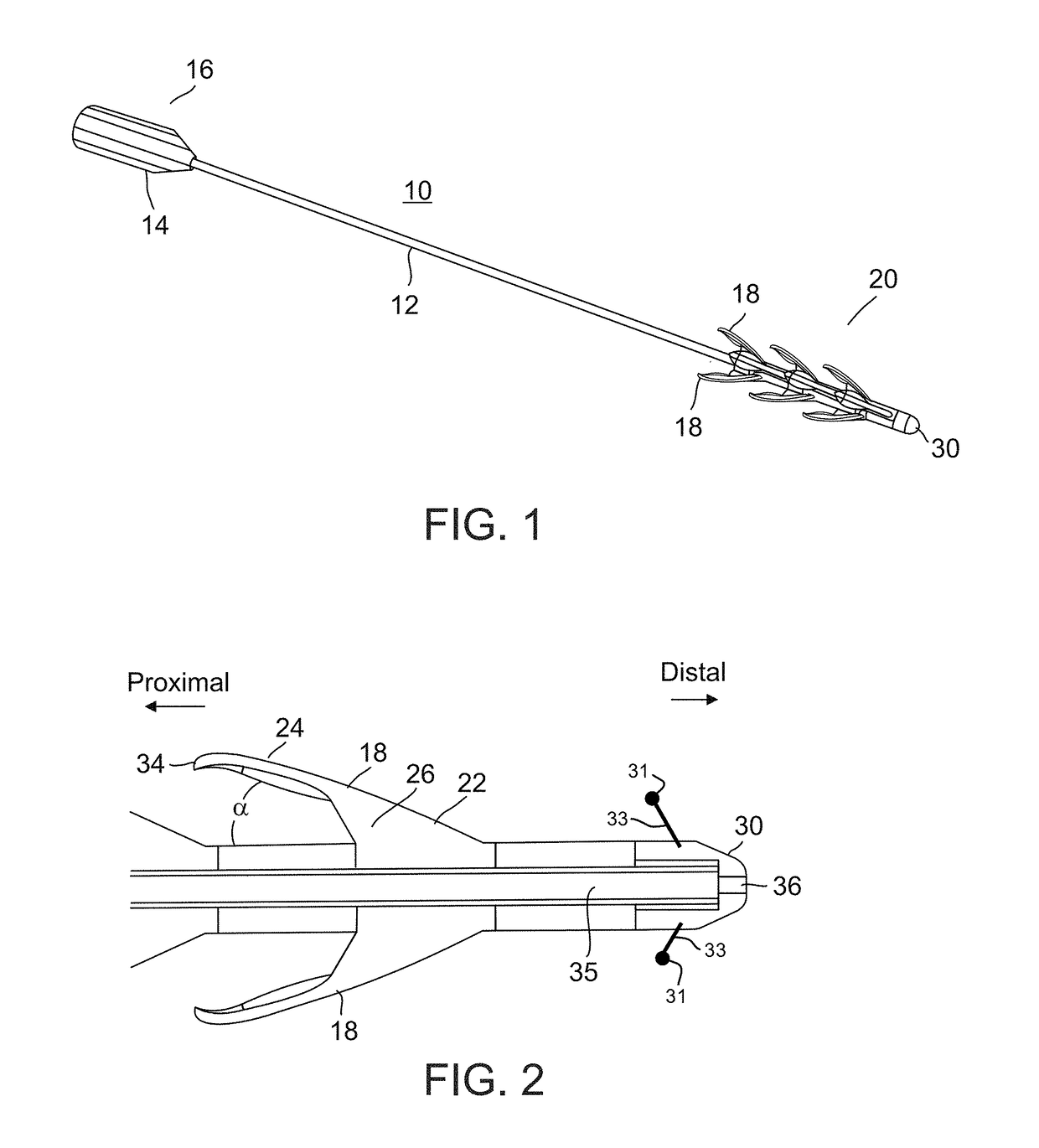

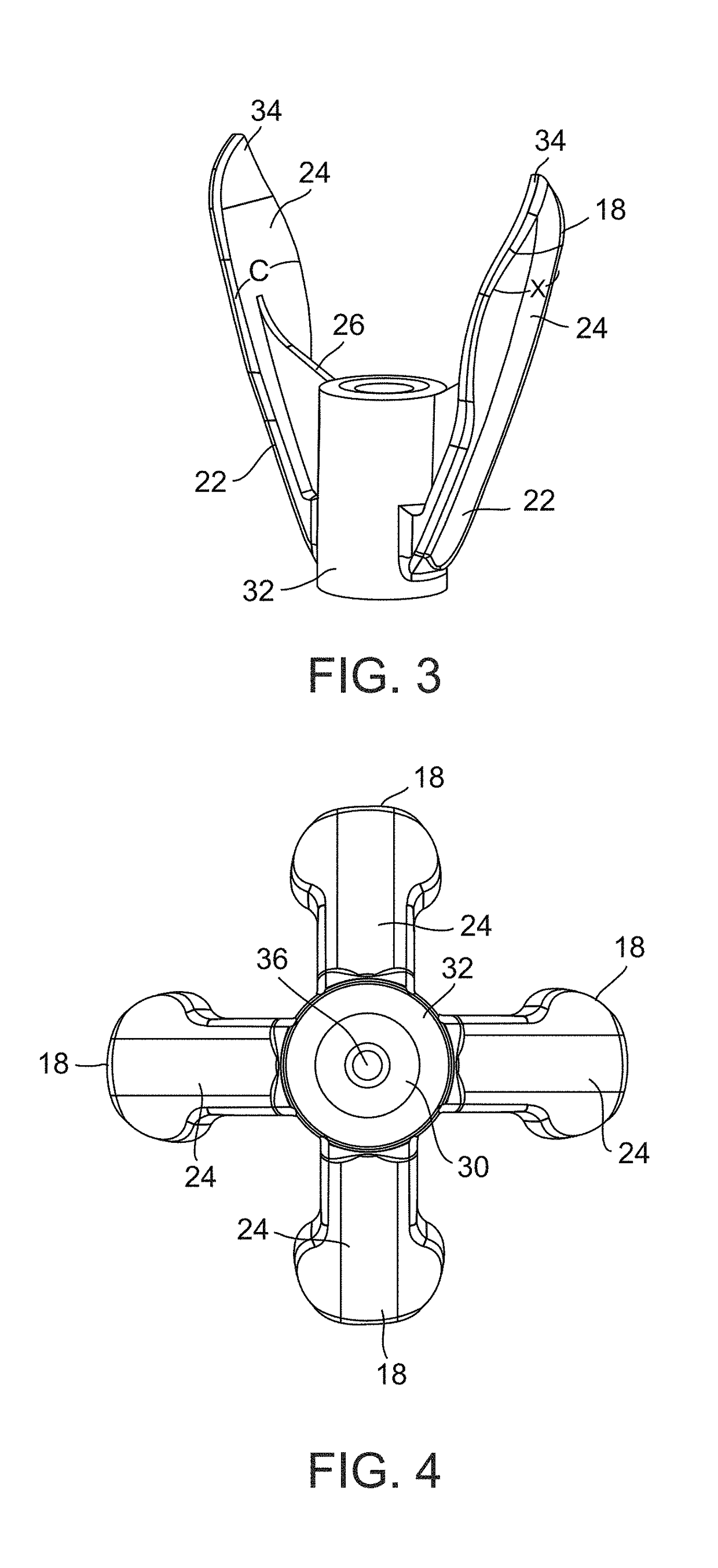

Device and method for removing occlusions in a biological vessel

ActiveUS20140309657A1Effectively and non-traumatically clearing occlusionImprove axial rigiditySurgeryDistal portionSurgery

A device for use within an occluded biological vessel and a method of using same to remove occlusion material from a vessel are provided. The device includes an elongated body configured for delivering projections arranged around a distal portion thereof into the biological vessel. Each of the projections includes a leaf-like structure connected to a stem portion having a higher axial rigidity than the leaf-like structure.

Owner:TRITICUM

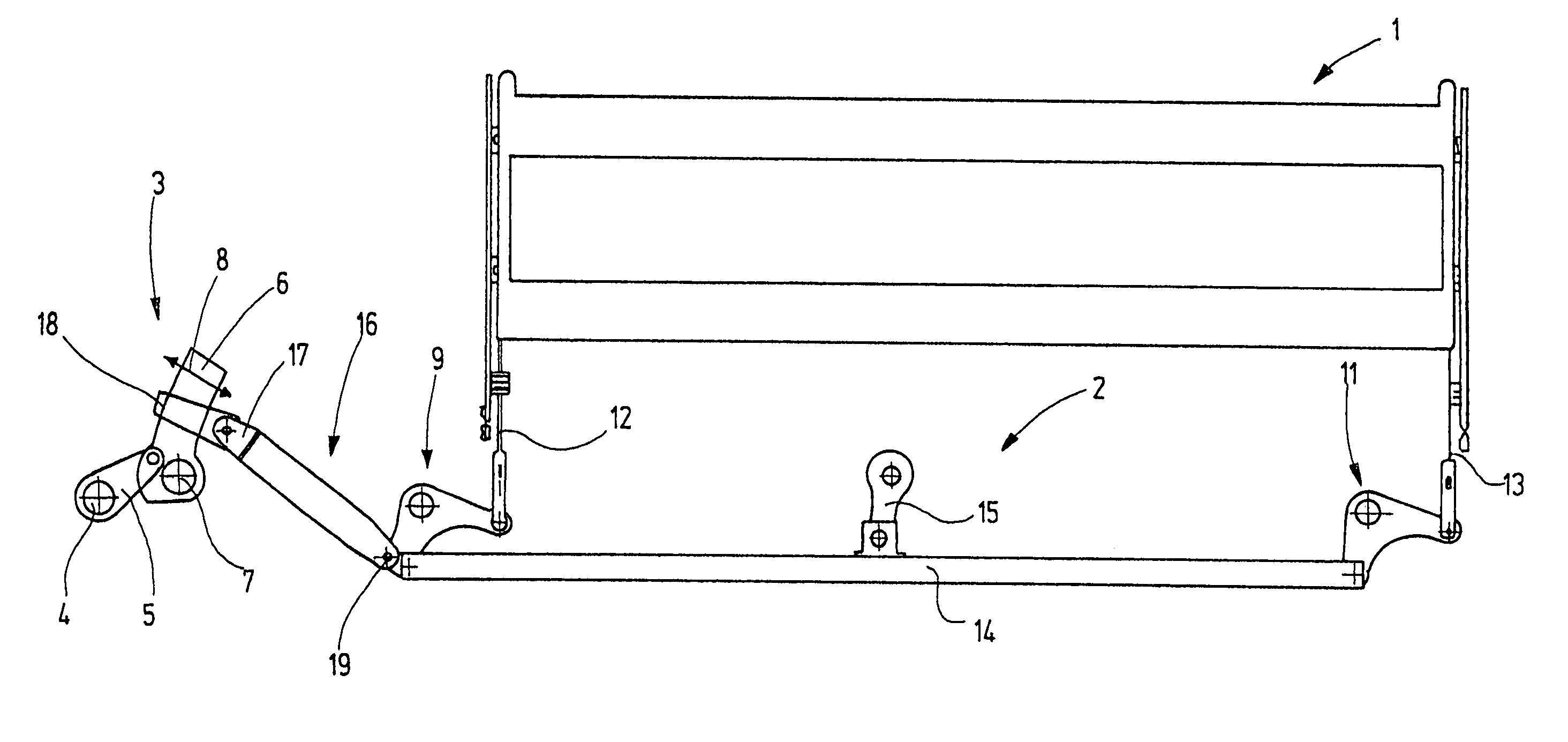

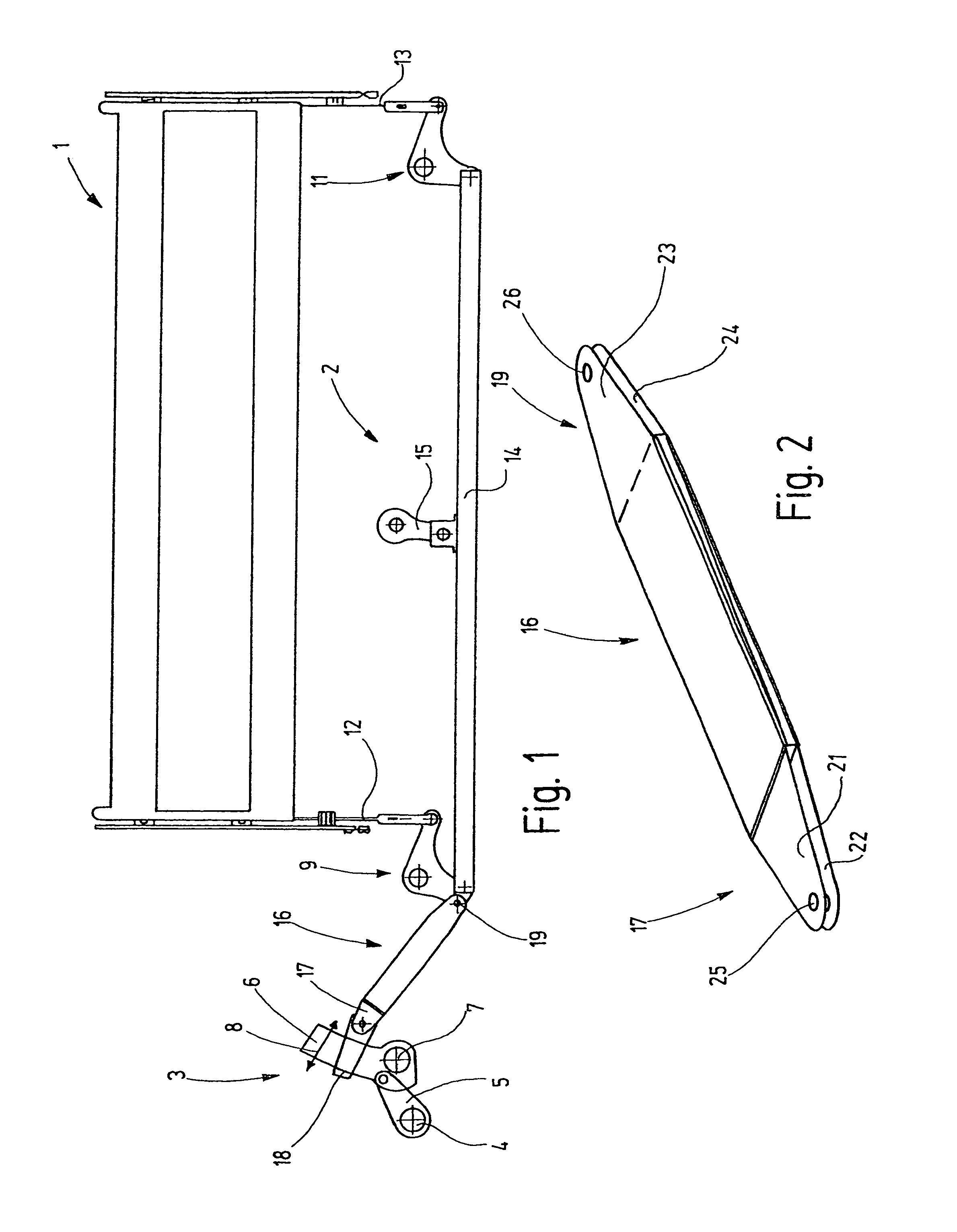

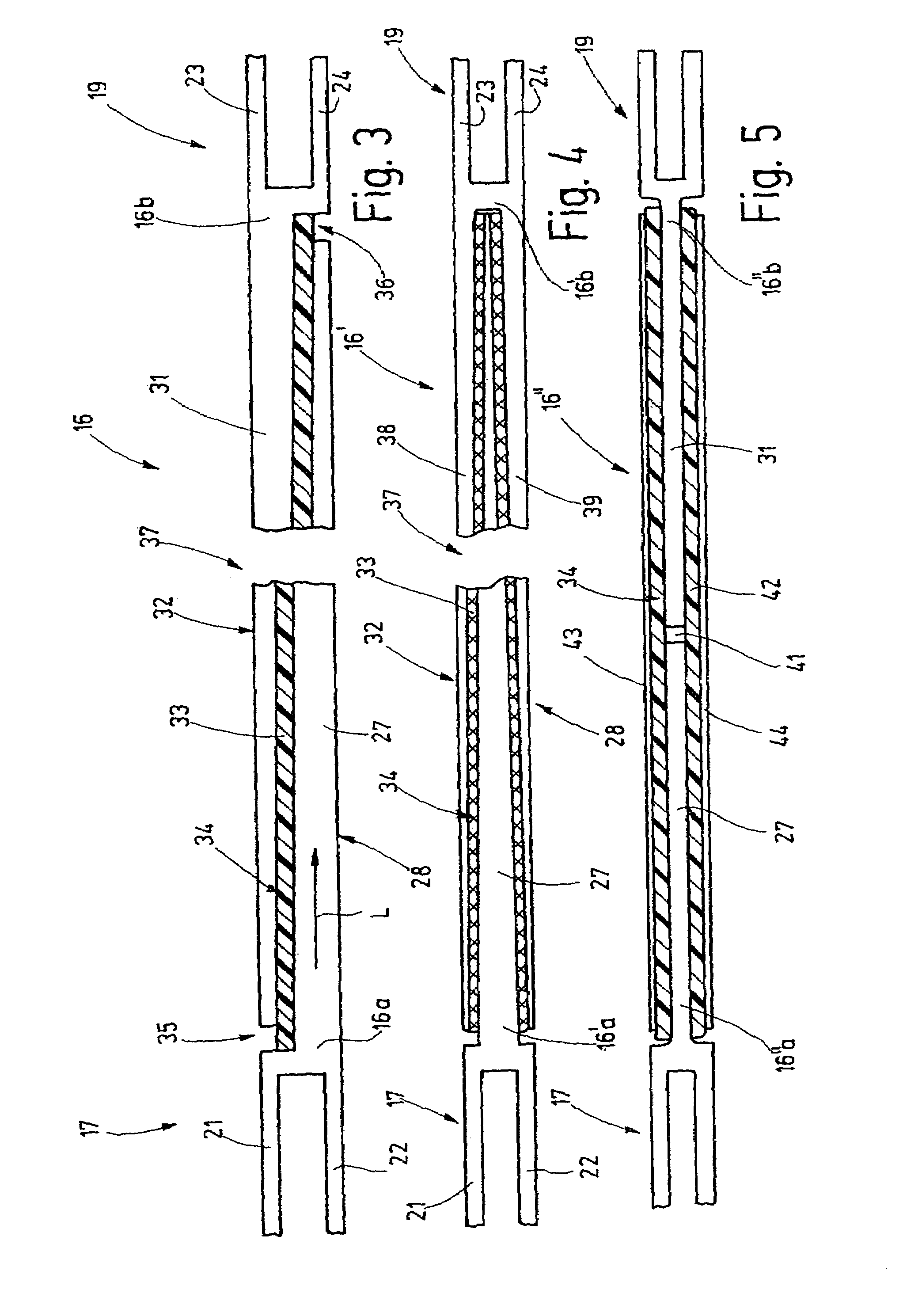

Low-vibration shedding system

A novel rod linkage for driving a heddle shaft includes at least one strap (16), which for damping oscillation has a sandwich structure (37) oriented in the longitudinal direction (L) of the strap assembly (16). The sandwich structure includes at least one rigid element (27), extending in the longitudinal direction, which is joined to one end (17) of the strap assembly (16); a second rigid element (31), likewise extending essentially in the longitudinal direction, which is joined to the other end (19); and a two-dimensional damping element (34), again extending in the longitudinal direction, disposed between the first two. The element (34) exclusively effects the mechanical connection of the two parts (16a, 16b) of the strap assembly (16). Preferably, no additional connecting elements, such as rivets, screws, or other rigid connections, between the rigid elements (27, 31) are provided. Preferably, the rigid elements (27, 31) are embodied as wedges pointing in opposite directions, which thus define a wave resistance that varies in opposite directions in the longitudinal direction. This wave resistance brings about an intentional coupling misadaptation with respect to the oscillation transmission. The element (34) disposed between them damps the oscillations additionally, so that the strap assembly (16) transmits driving motions like a filter and destroys or absorbs interfering oscillations.

Owner:GROZ BECKERT KG

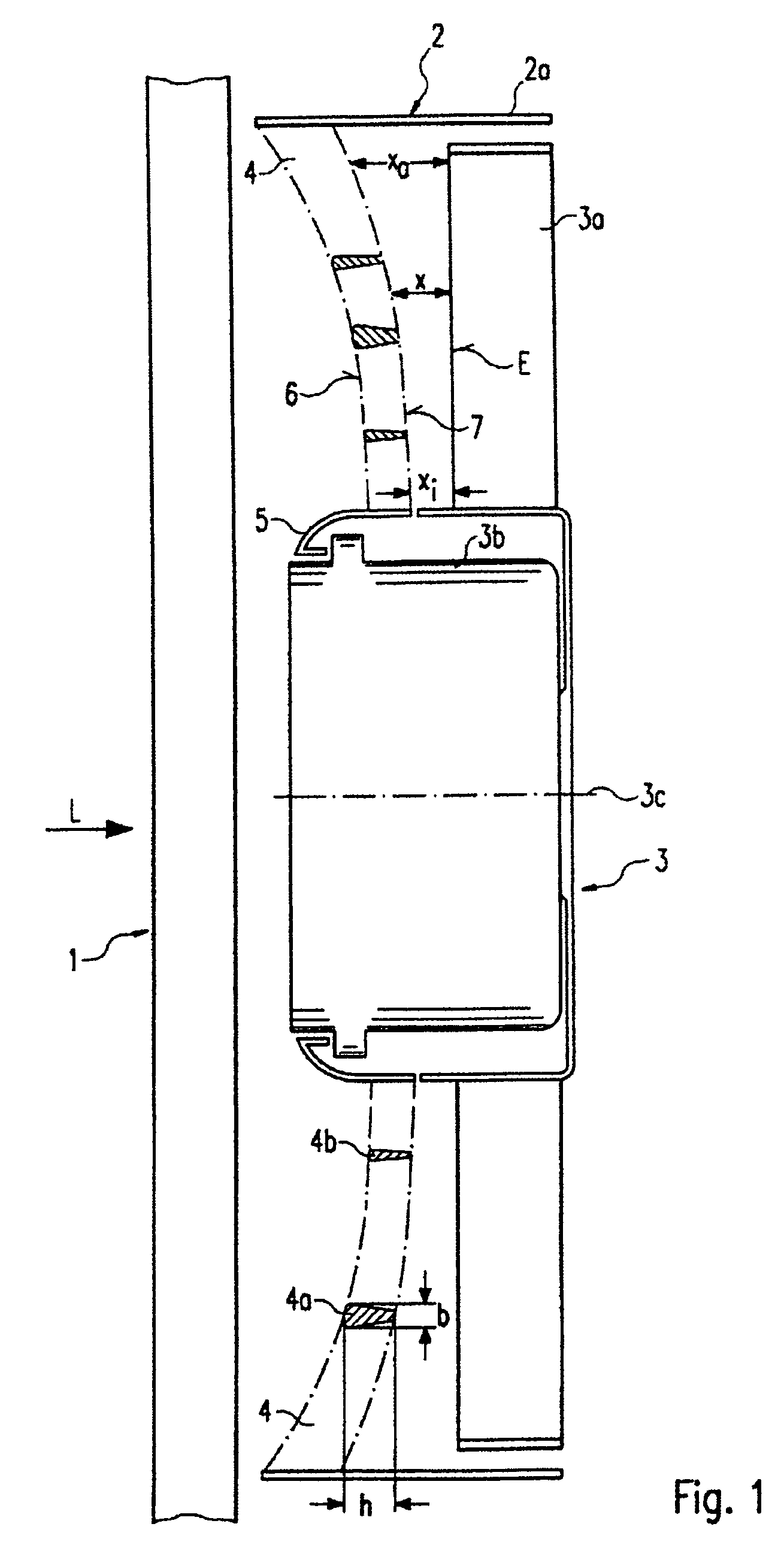

Fan housing for a heat exchanger, particular for motor vehicles

InactiveUS7811055B2High design strengthIncrease the sectionPump componentsReaction enginesMobile vehiclePlate heat exchanger

The invention relates to a fan housing for an air-flow heat exchanger having a fan blower comprising an axial-flow fan and a drive motor, the blower being connected to the fan housing by struts and the struts having a cross-sectional profile with a front edge and a rear edge. It is proposed that the struts, particularly their front and / or their rear edges, be arranged in a spherical or spheroidal surface enveloping them.

Owner:BEHR GMBH & CO KG

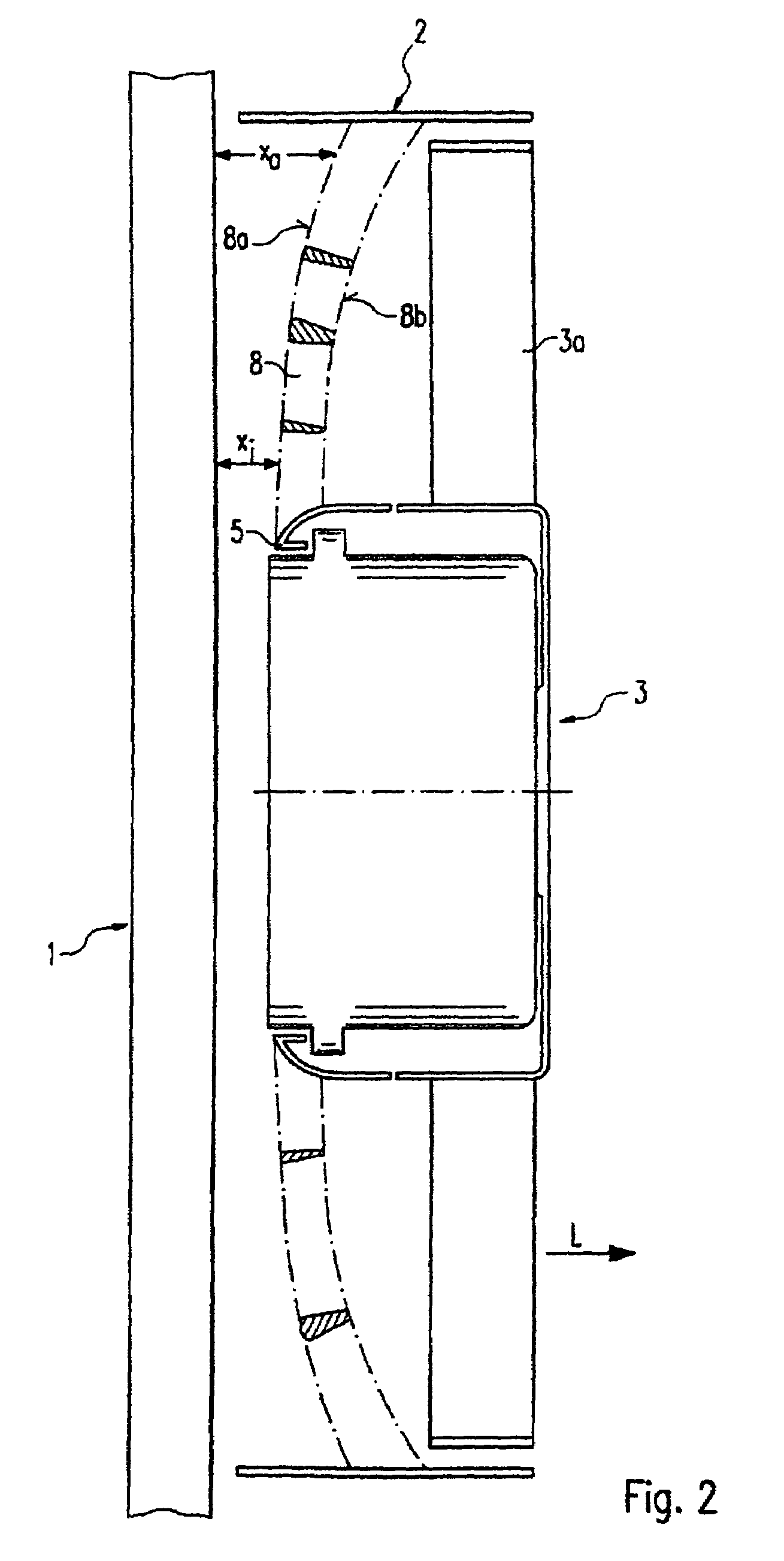

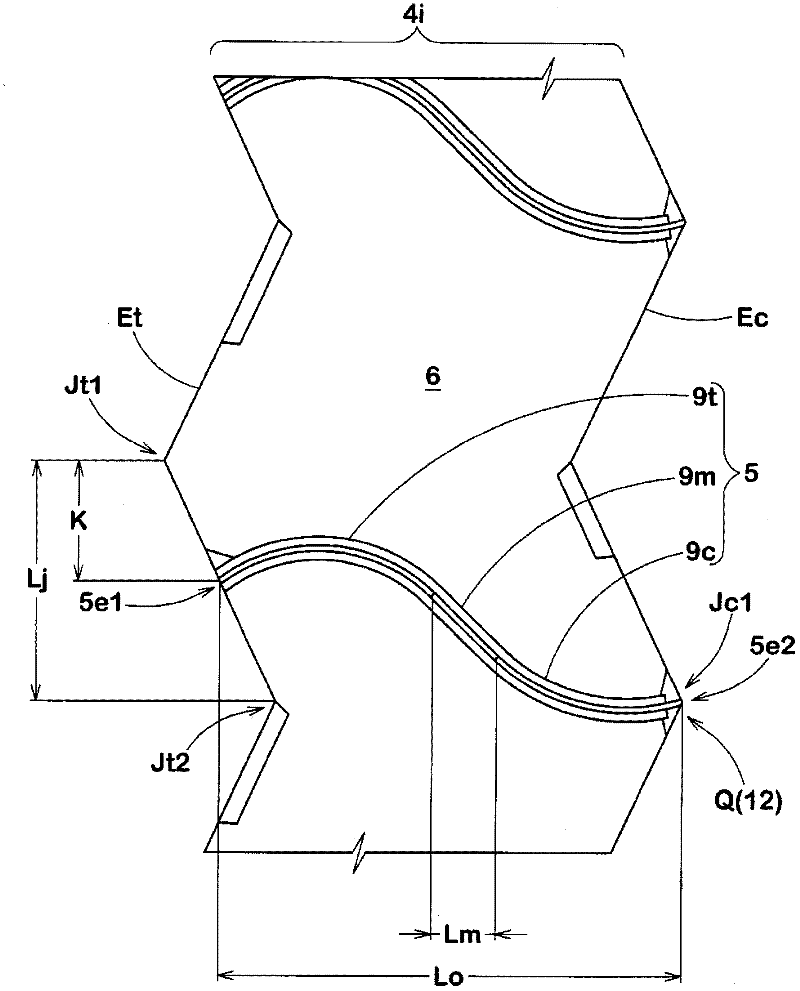

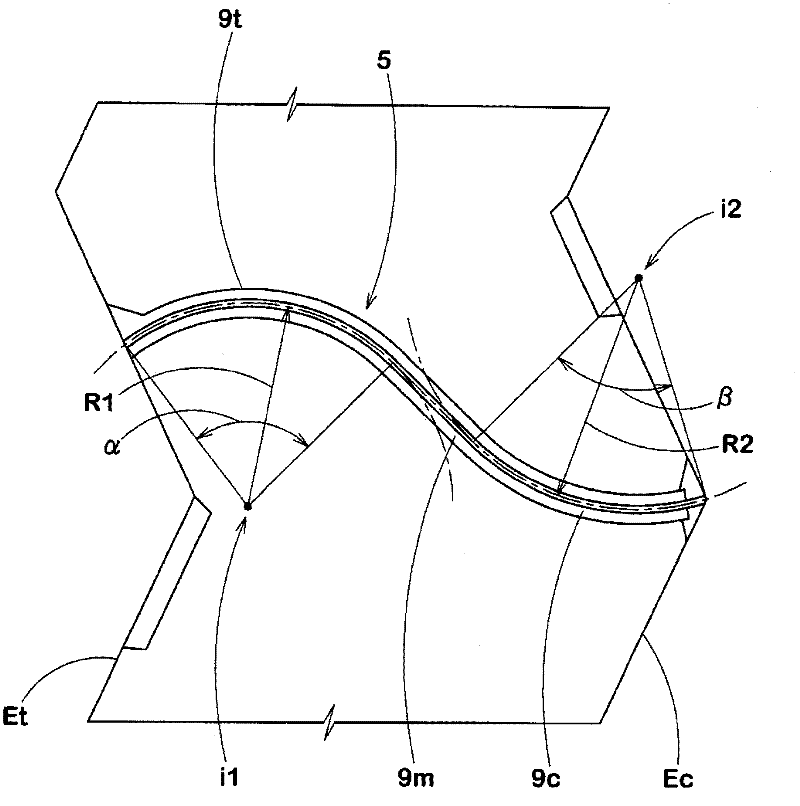

High-capacity tire

InactiveCN102476560ASpeed up the flowImprove gripTyre tread bands/patternsTransverse grooveEngineering

Disclosed is a high-capacity tire, capable of improving uneven-wearing resistance performance and wet-path ground-gripping performance. A plurality of transverse grooves are arranged at the section from the internal circumference to the land part of the two sides of the tire equator C. The transverse grooves are formed to have an S-shaped structure, composed of external arc groove of tread side having the radius of curvature of R1 and an internal arc groove having the radius of curvature of R2. One side of the external arc groove closer to the circumferential direction of the tire than the transverse groove is provided with an arc center i 1. The other side of internal arc groove closer to the circumferential direction of the tire than the transverse grooves is provided with an arc center i 2. The radius of curvature R2 mentioned above ranges from 10 to 40 mm. Moreover, the radius of curvature R1 is less than radius of curvature R2, with the difference thereof less than 5mm. The central angle alpha of the external arc groove and the central angle beta of the internal arc groove range from45 to 90 degrees.

Owner:SUMITOMO RUBBER IND LTD

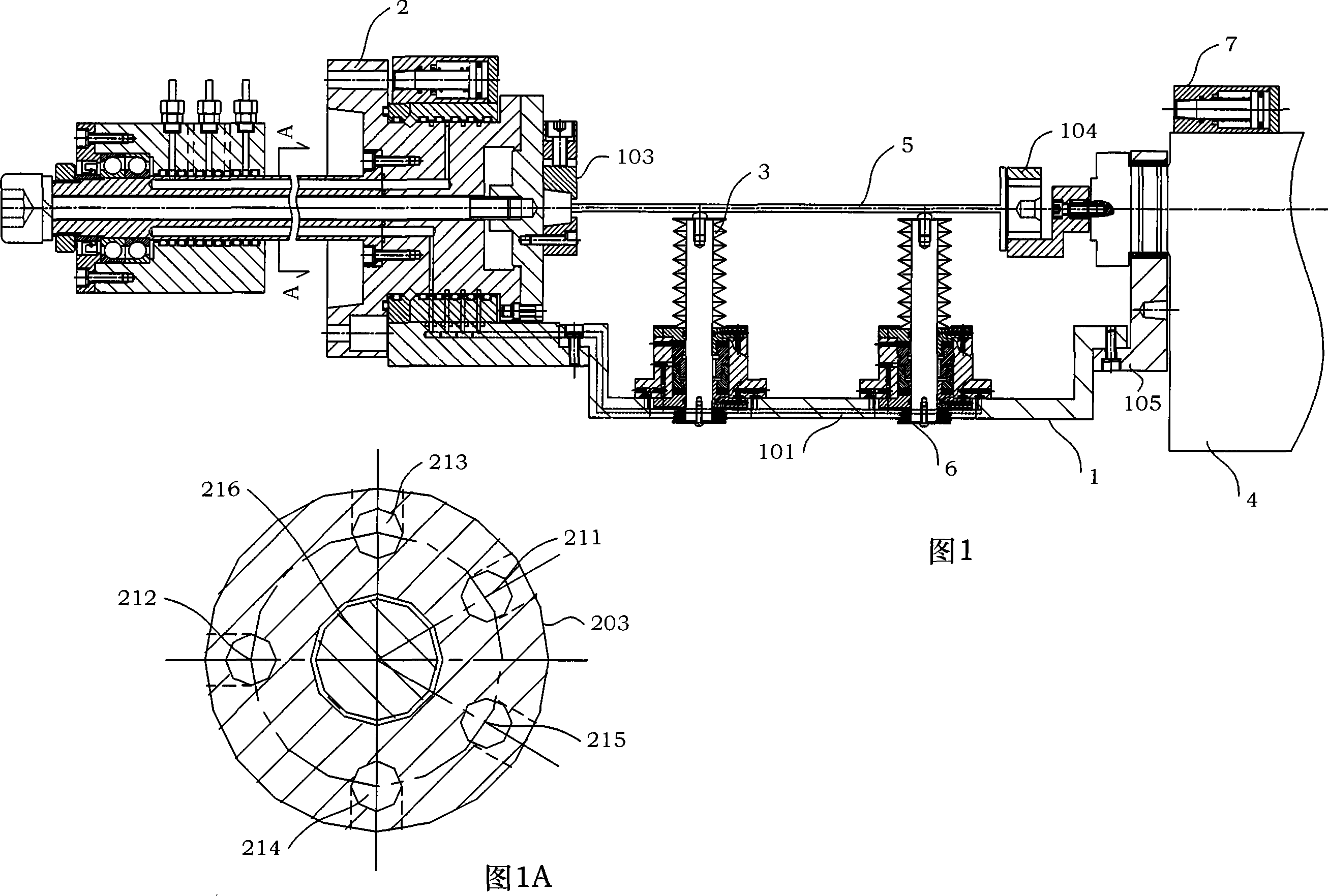

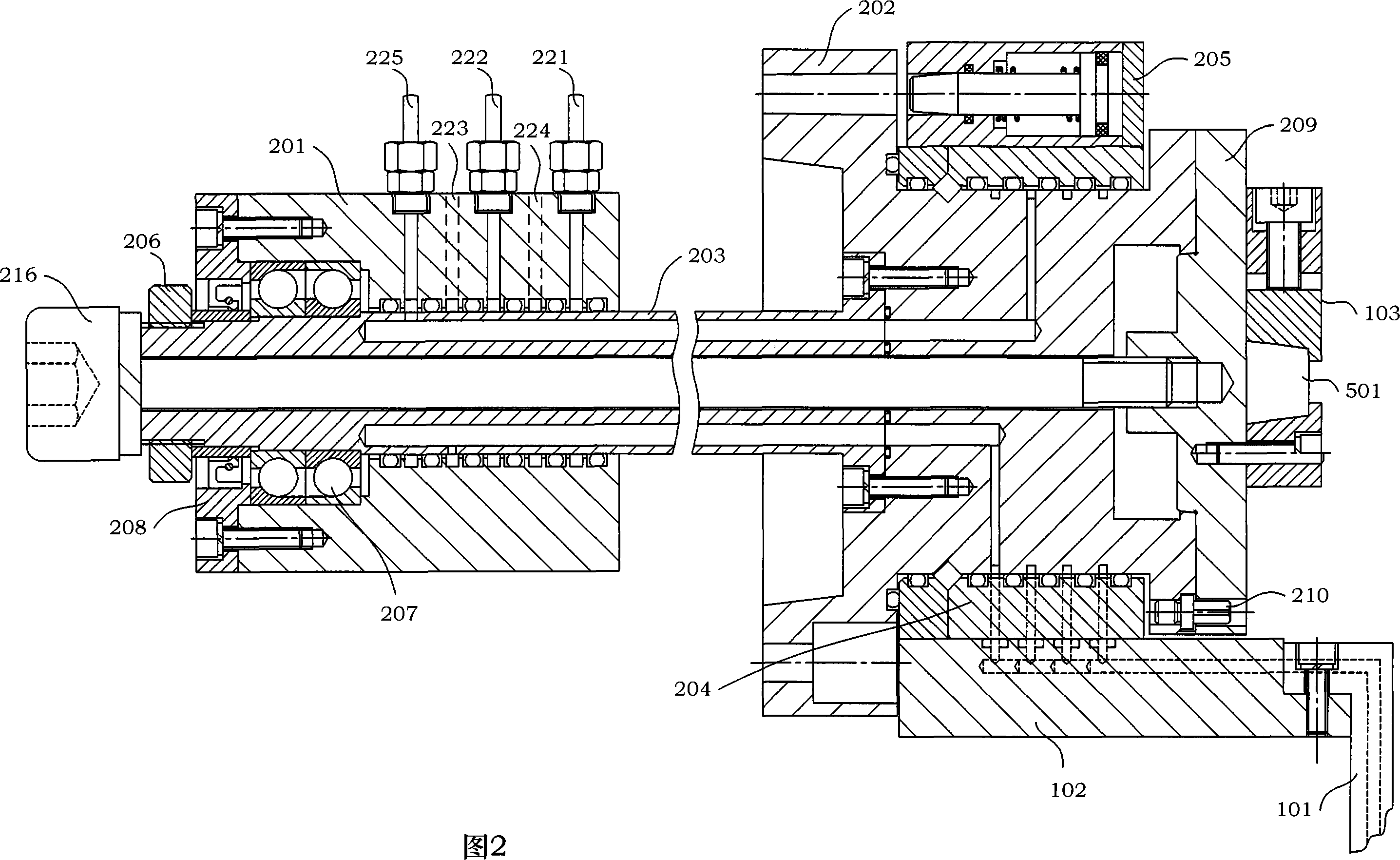

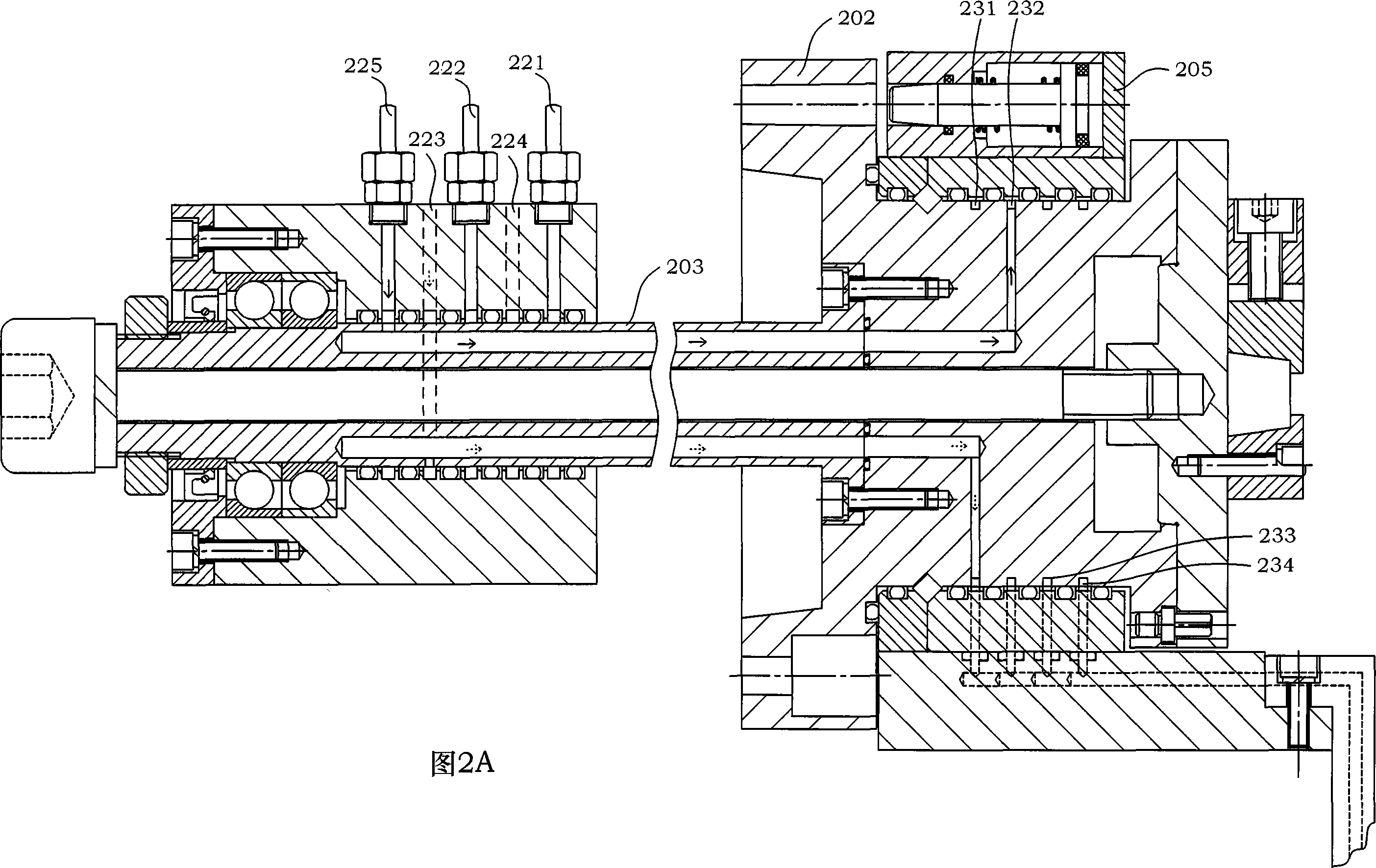

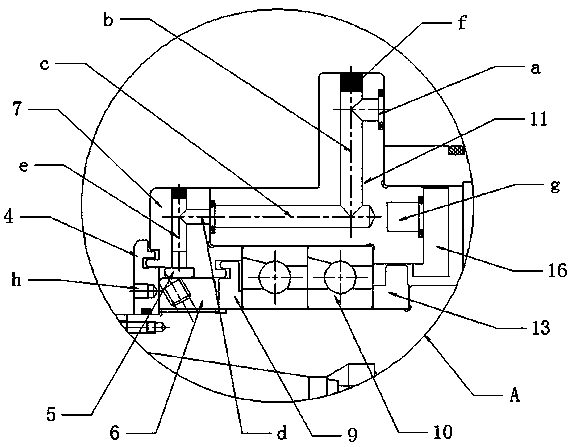

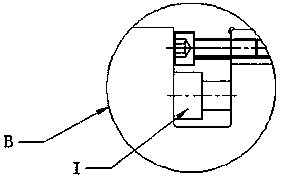

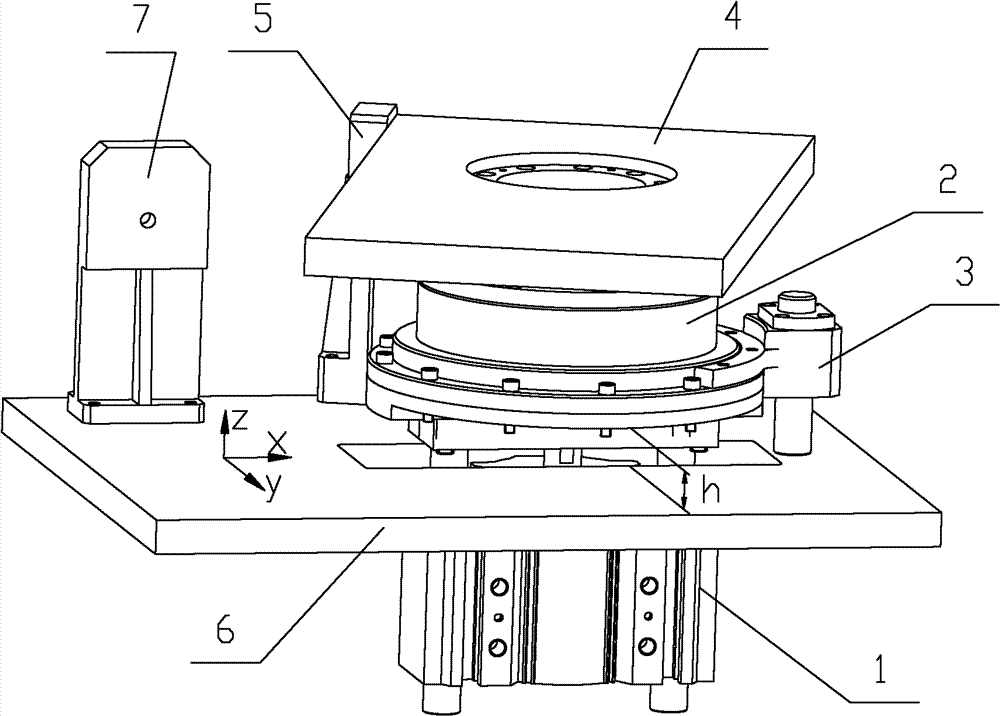

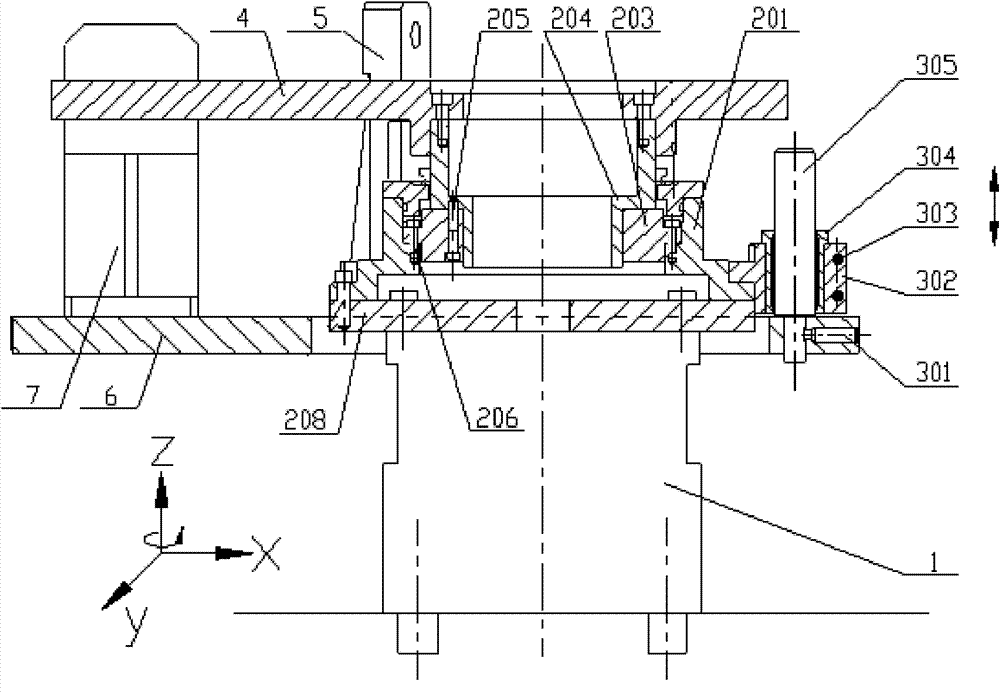

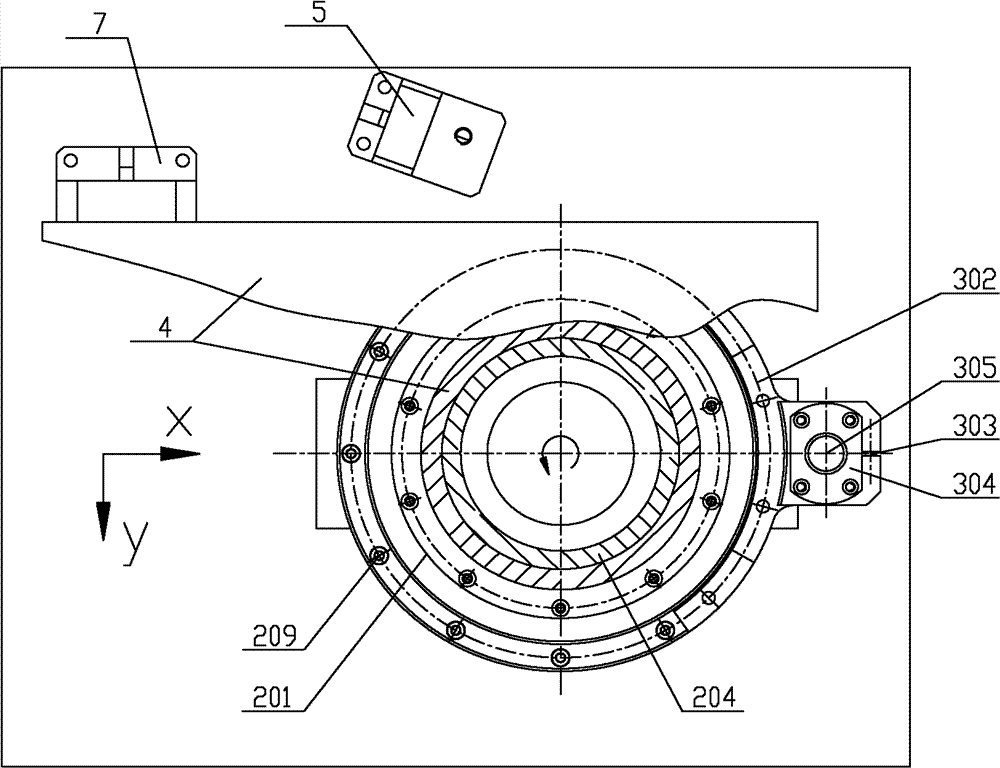

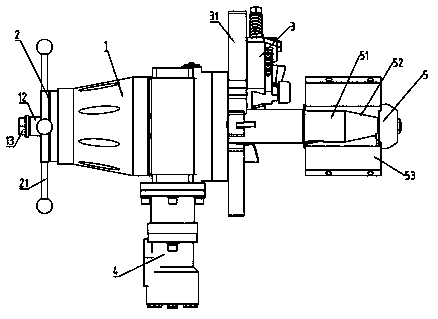

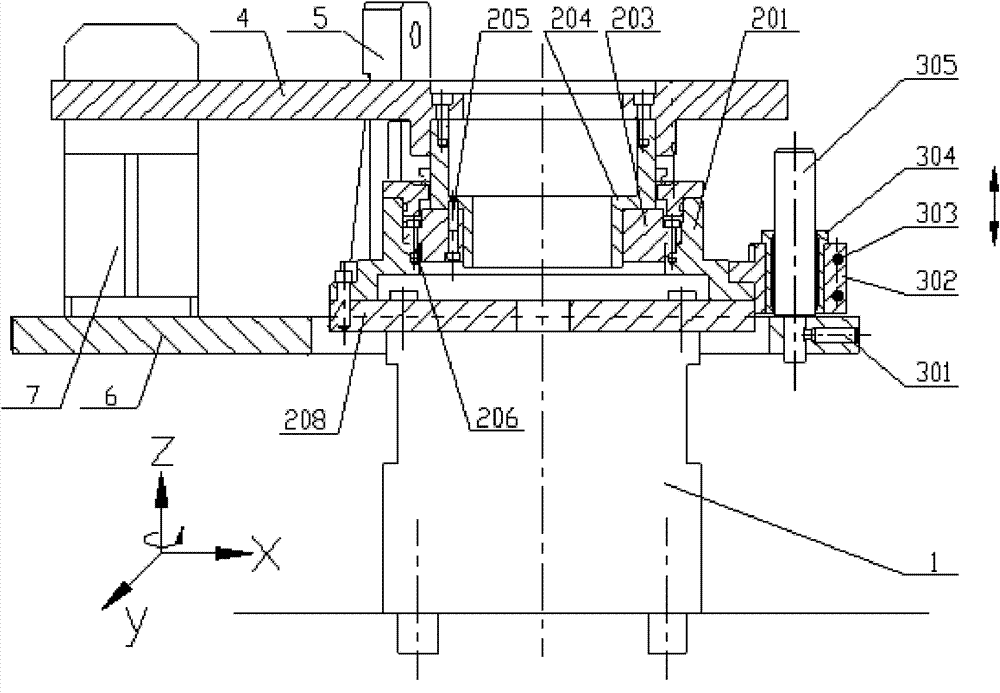

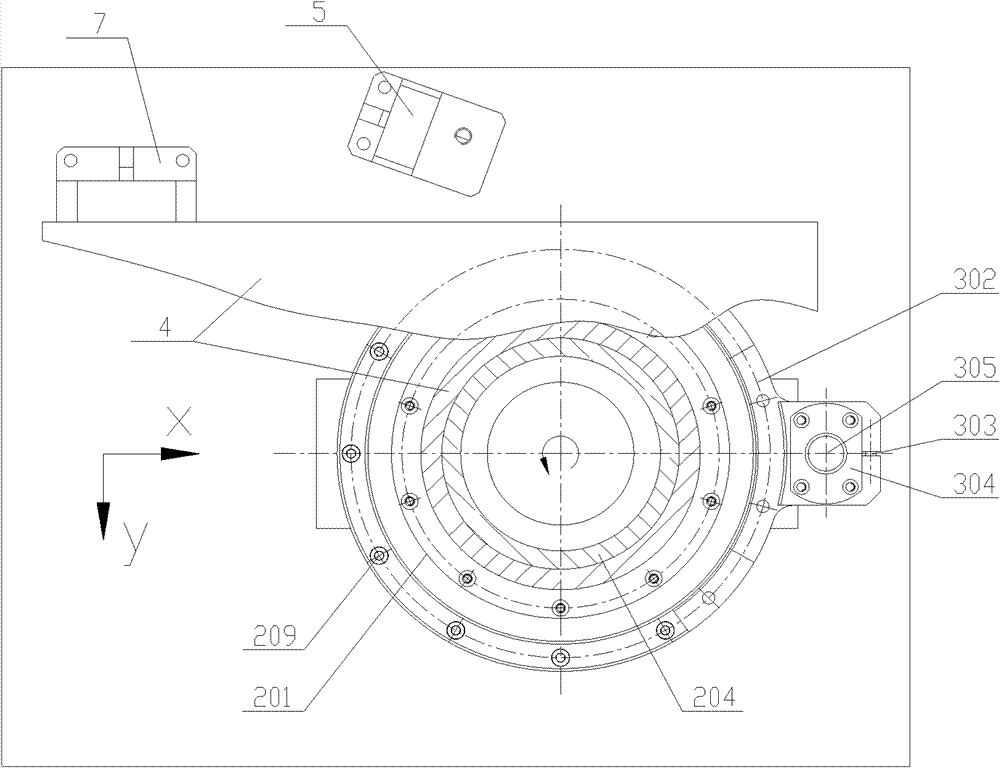

Flexible multipoint supported system in use for digital controlled machining laminae

InactiveCN101092020AAvoid interferenceSimple structurePositioning apparatusMetal-working holdersSupporting systemWorking fluid

The invention discloses a flexible multipoint supporting device for vane digital control machining. It is made up of cradle assembly, work flow feeding assembly, A flexible supporting component, and B flexible supporting component. The device realizes fixation for cradle assembly through cone pin controlled by A oil cylinder fixed on oil outlet distribution base and B oil cylinder fixed on machine tool tail base. The first machining location is used to realize synchronously turning action for cradle assembly and vane. And the second machining location is used to realize surface changing supporting for vane. The invention is mainly used to improve technical system rigidity and automation degree and machining accuracy. The flexible supporting structure also could be used as rapid and low cost assistant supporting for other weak rigidity machining.

Owner:BEIHANG UNIV

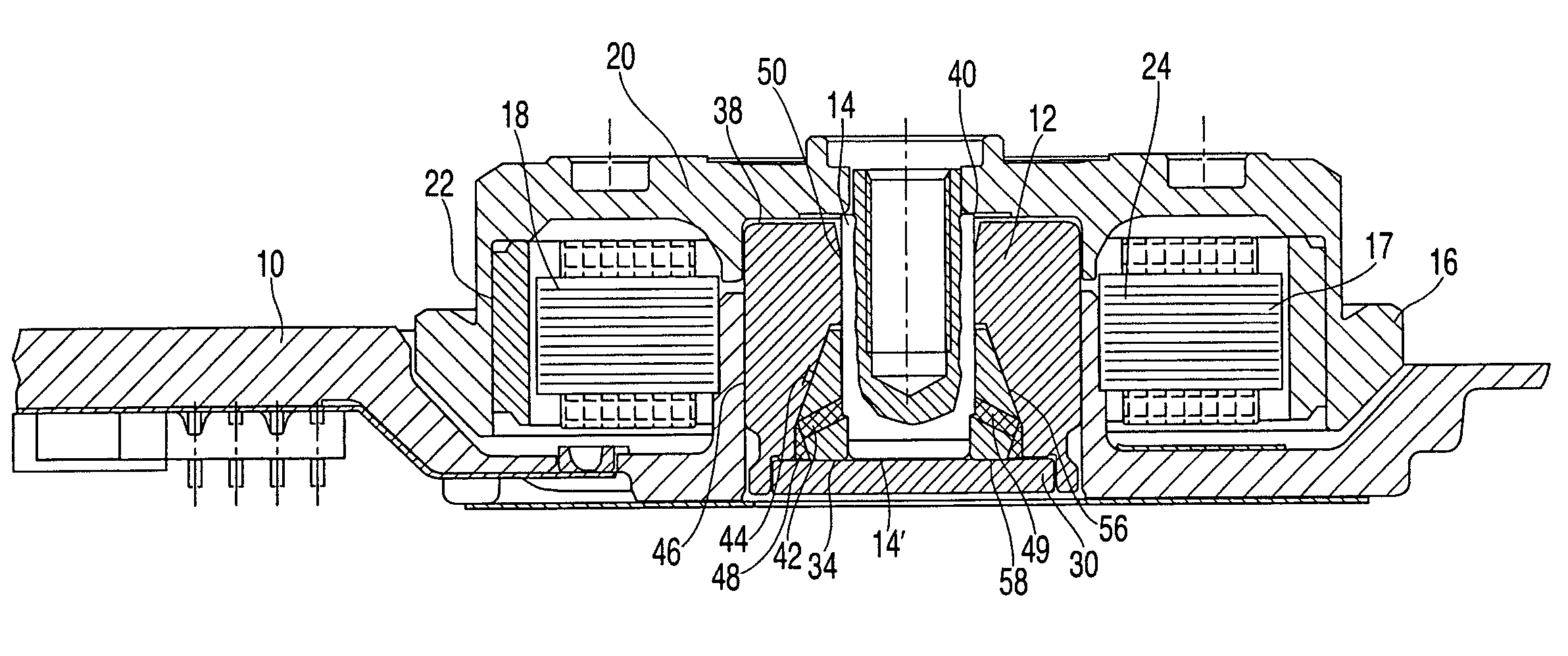

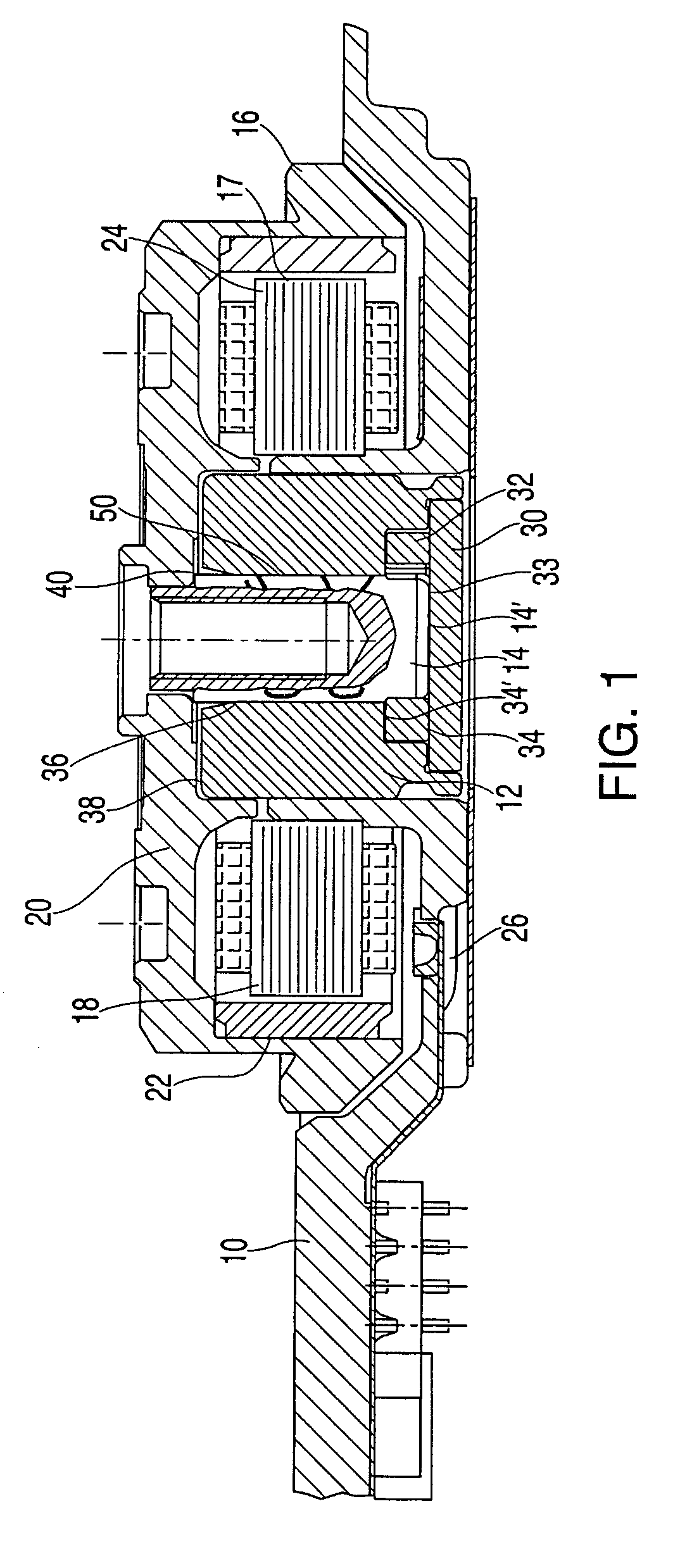

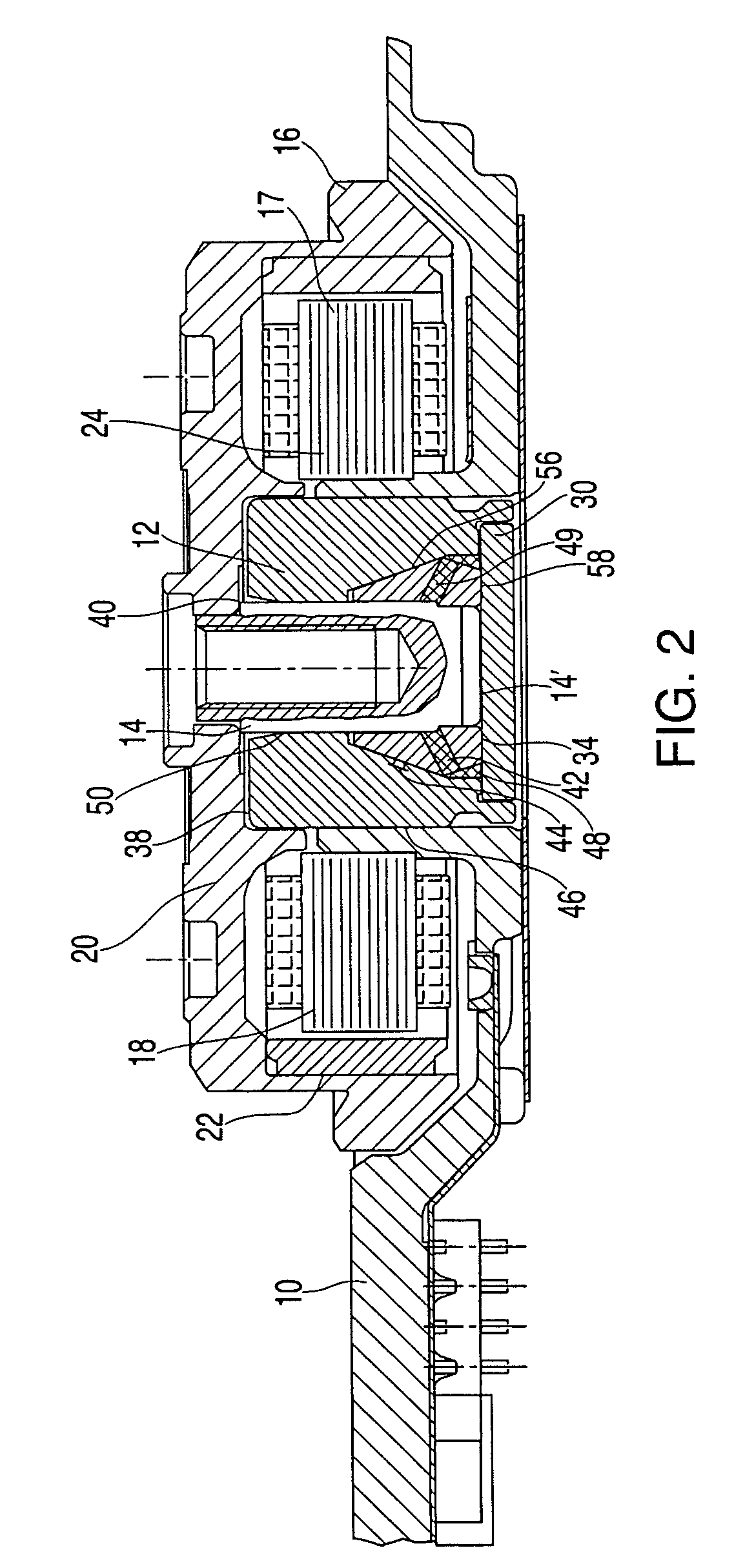

Hydrodynamic bearing for a spindle motor

InactiveUS7097360B2Little power lossImprove efficiencyShaftsRecord information storageDynamic pressureElectric motor

A hydrodynamic bearing for use in a spindle motor, having a shaft, a bearing sleeve encompassing the shaft with a small radial space, and a skewback at one end face of the bearing sleeve which is fixedly connected to the bearing sleeve. The shaft features a thrust plate or a conical or cone-like extension at its end face which faces the skewback. The diameter of the conical extension increases in the direction of the end face of the shaft. A bearing gap formed between the shaft and the bearing sleeve is filled with a bearing fluid. Dynamic pressure generating grooves are provided on one of the outer surface of the shaft and the inner surface of the bearing sleeve to generate an excess pressure in the bearing fluid.

Owner:MINEBEA CO LTD

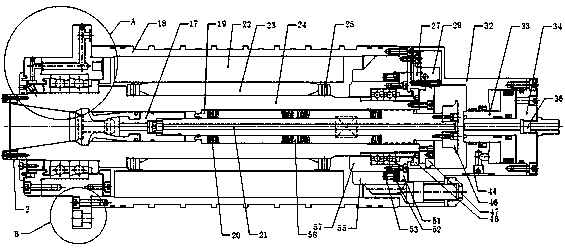

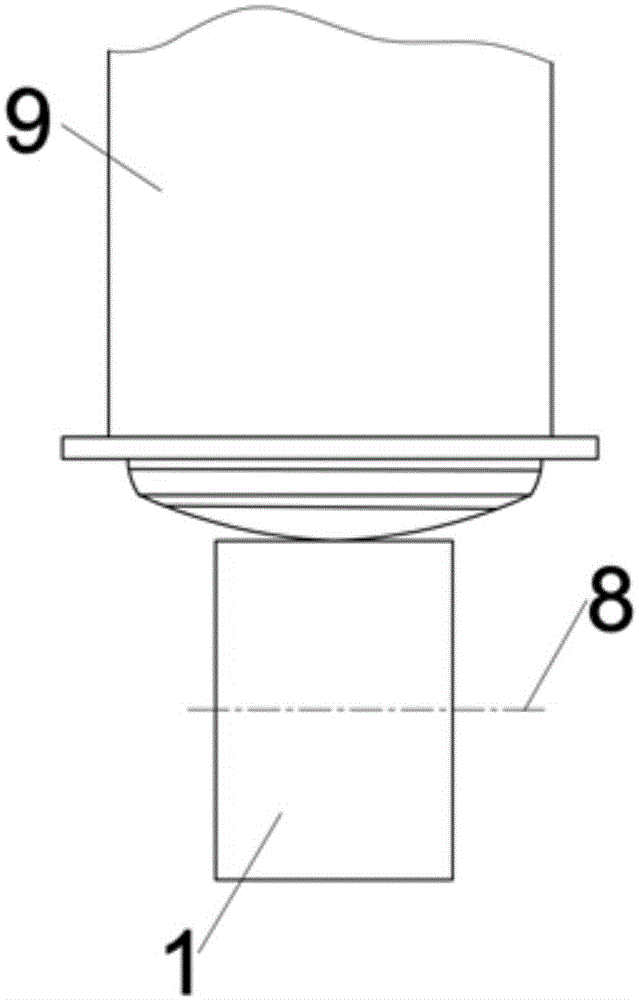

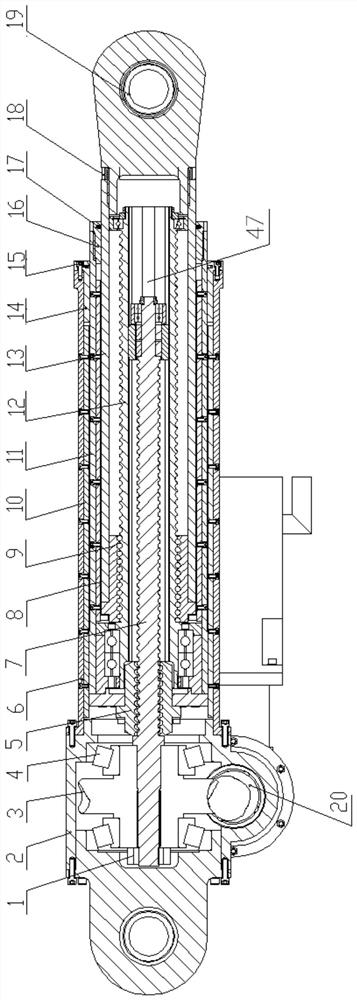

Motor main shaft

InactiveCN109412325AGood for high speedImprove stabilityMechanical energy handlingStructural associationPistonFront cover

The invention discloses a motor main shaft. The motor main shaft comprises a waterproof ring, a front cover, an angular contact bearing, a front bearing pedestal, a sleeve, a disc spring, a pull rod,a motor stator, a motor rotor, a core shaft, an encoder mounting plate, an encoder, an oil cylinder sleeve, a piston, an oil cylinder cover, a cutter block, an encoding wheel, a rear cover and a rearbearing pedestal; the motor rotor is integrated with the core shaft, and the motor stator is fixedly connected with the sleeve; the front bearing pedestal and the rear cover are arranged at the two ends of the sleeve; the sleeve is in rotation connection with the core shaft through the front bearing pedestal, the rear bearing pedestal and the angular contact bearing; the front cover is arranged atthe front end of the front bearing pedestal; the oil cylinder sleeve is arranged at the rear end of the rear cover; the piston is arranged in the oil cylinder sleeve; the oil cylinder cover is arranged at the rear end of the oil cylinder sleeve; the piston is located at the rear end of the pull rod, and the cutter block is arranged at the tail end of the pull rod; the encoder mounting plate is installed on the rear cover; the encoder is installed on the encoder mounting plate; the encoding wheel is installed at the tail end of the core shaft; and the pull rod and the disc spring are arrangedin a central hole of the core shaft. According to the motor main shaft, the rotating speed, stability and rigidity of the main shaft are improved, and the space is saved.

Owner:SWIFT NANTONG PRECISION MACHINERY

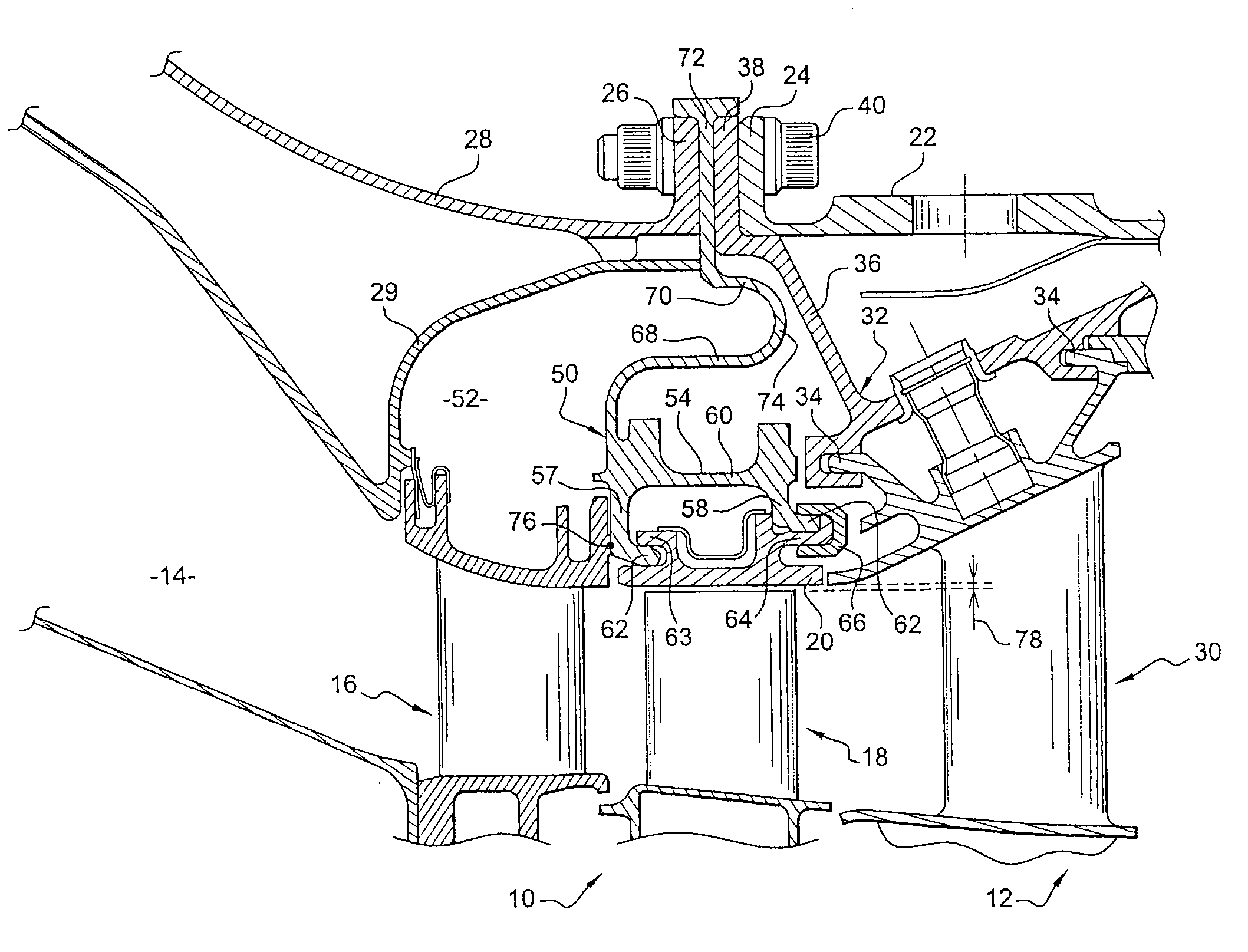

Turbine stage in a turbomachine

ActiveUS8403636B2Improve rigidityConstant diameterPump componentsRotary non-positive displacement pumpsImpellerTurbine wheel

A turbine stage in a turbomachine including ring sectors arranged about a turbine impeller, and an annular support supporting the ring sectors and attached to a turbine casing is disclosed. The annular support is able to be deformed elastically in the radial direction to cushion at least a portion of the deformations of the turbine casing in operation.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

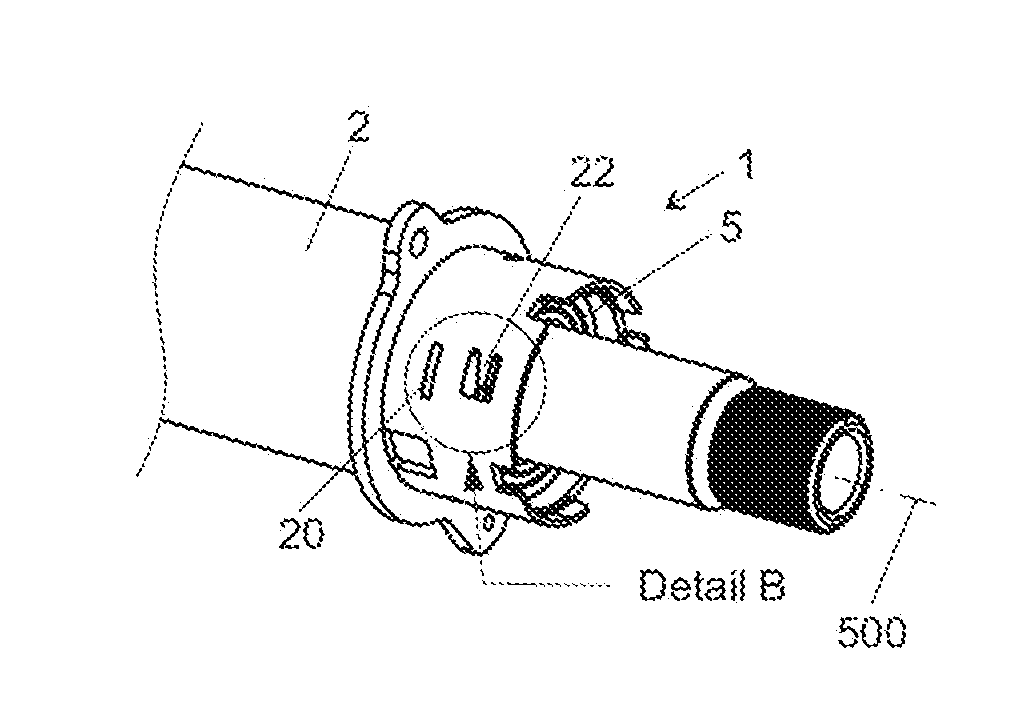

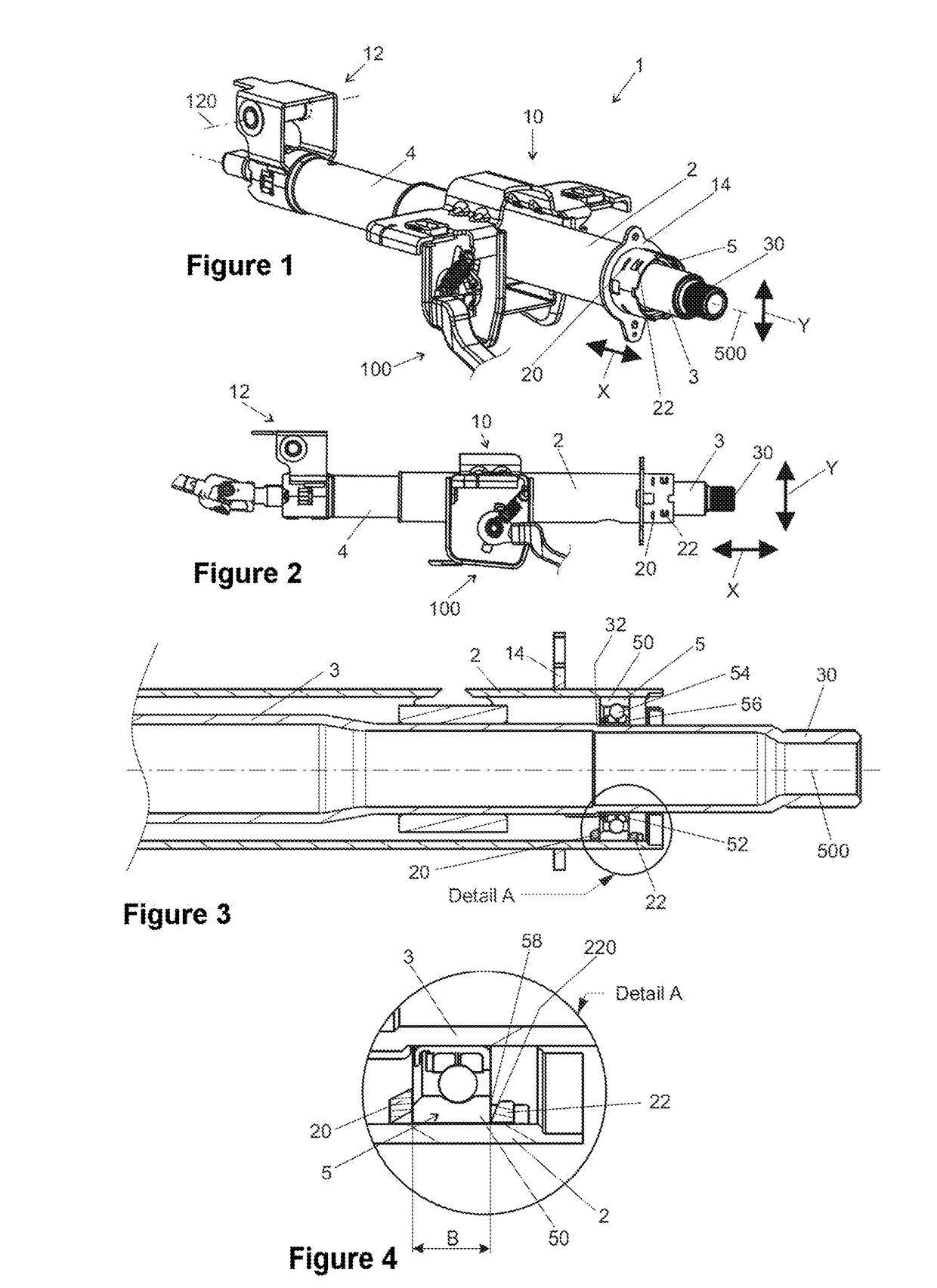

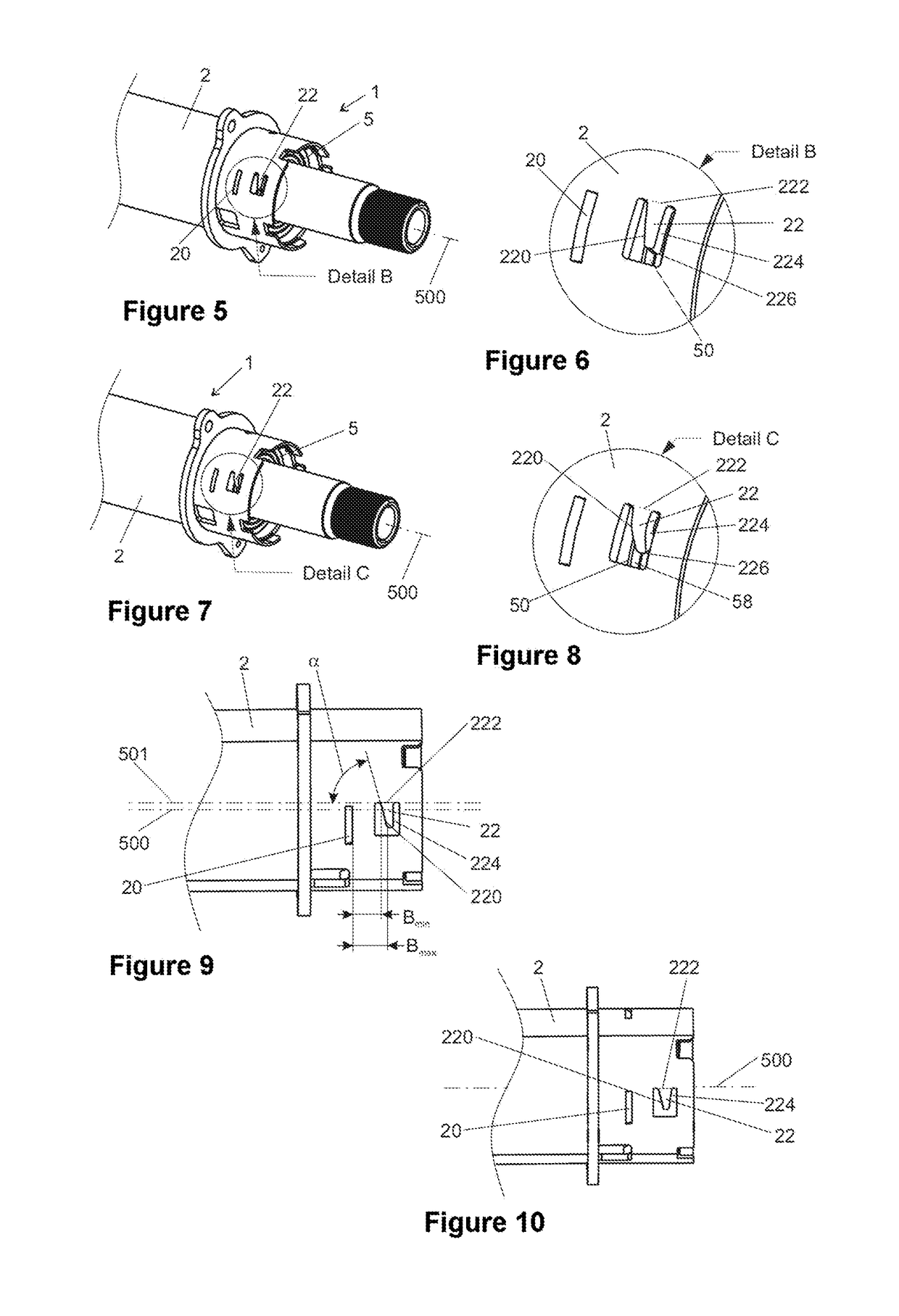

Steering column for a motor vehicle

ActiveUS20170096159A1Improve axial stiffnessSimple designBall bearingsSteering columnsSteering columnControl theory

A steering column for a motor vehicle may comprise a steering column jacket with a jacket surface having a retaining segment. The retaining segment may at least partially surround a bearing for rotatably mounting a steering spindle about an axis of rotation. The retaining segment may have at least one tab that secures the bearing in the steering column jacket in a direction of the axis of rotation. The tab may be connected to the retaining segment of the steering column jacket along a bending edge. The bending edge may form a projection angle of at maximum 45° with a projected axis of rotation. The free end of the tab is bent around the bending edge towards the axis of rotation.”

Owner:THYSSENKRUPP PRESTA AG +1

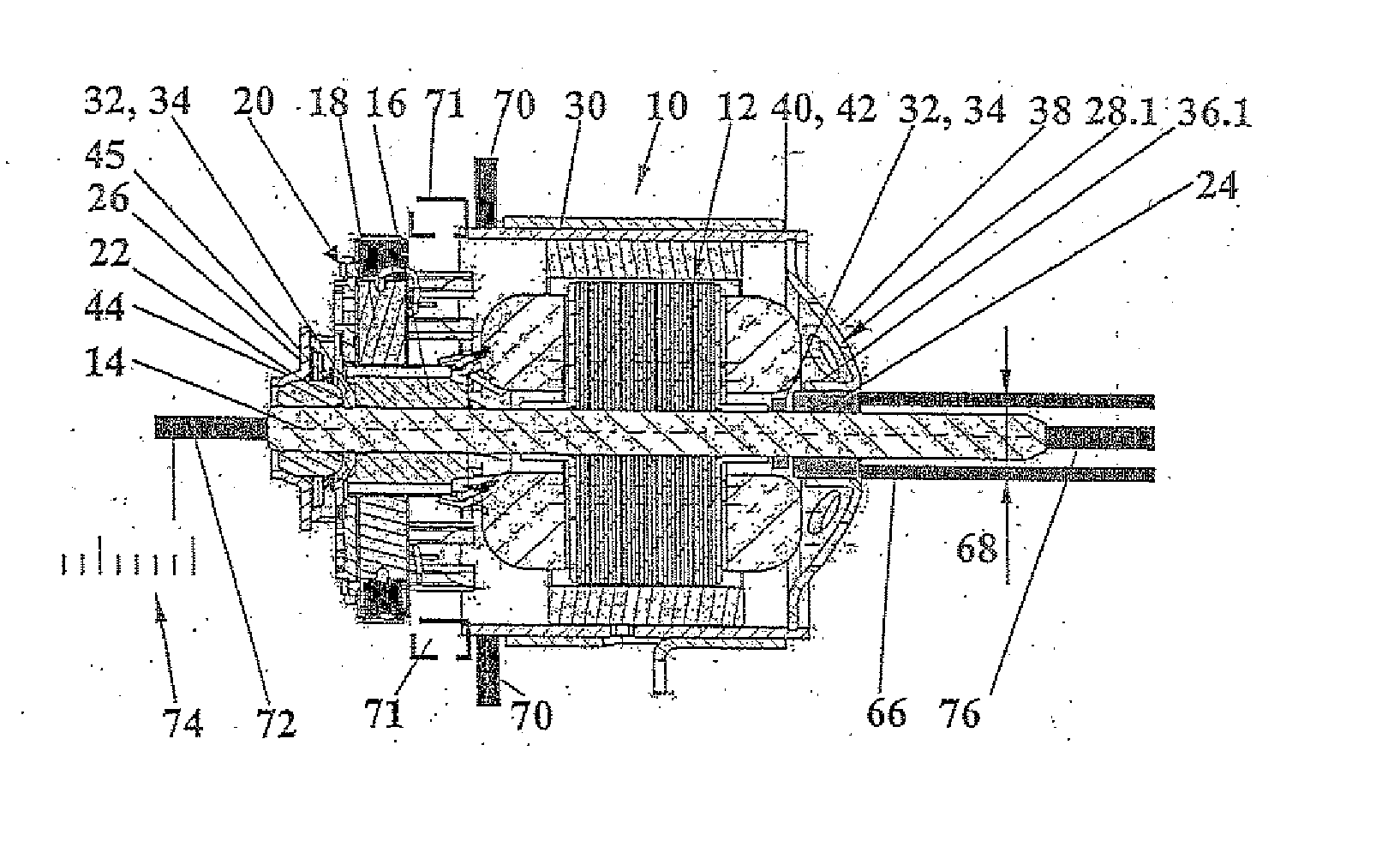

Bearing Arrangement

InactiveUS20080317394A1Small possibleReduce assemblyBearing componentsSliding contact bearingsEnvironmental effectMechanical engineering

A bearing arrangement (4) is provided with a bearing inner bush (10) and an outer bush (5), especially for the central joint (1) of a Watt's linkage. The bearing arrangement (4) is provided with a sealing arrangement (12) surrounding the front-side bearing gap between the inner bush (10) and the outer bush (5). The sealing arrangement (12) comprises an elastic sealing element (14) with static as well as dynamic sealing surfaces. The bearing arrangement (4) has a sealing arrangement (12) designed as a sealing module (12), which can be connected to the bearing inner bush (10), the sealing module (12) also comprising a running surface (15) for the axial bearing of the outer bush (5). The arrangement makes possible the especially economical production of modularly designed, highly loadable bush bearings. Furthermore, undivided, continuous bearing bushes can be used, which improves the ability to be mounted and the precision and the service life of the bearing arrangement. It is also possible, especially in case of highly stressed bush bearings, to dimension the axial rigidity as well as the radial rigidity of the bearing arrangement independently from one another, and especially good sealing is obtained against environmental effects.

Owner:ZF FRIEDRICHSHAFEN AG

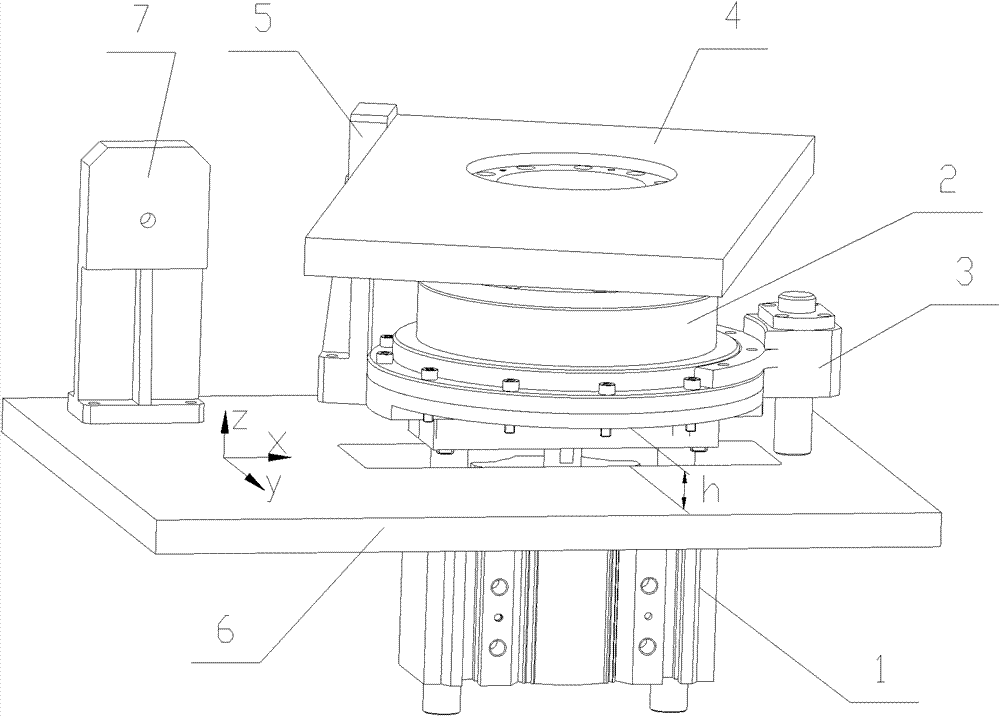

Illumination module movement device

ActiveCN102902163ASimple structureHigh positioning accuracyPhotomechanical exposure apparatusMicrolithography exposure apparatusUnit loadEngineering

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

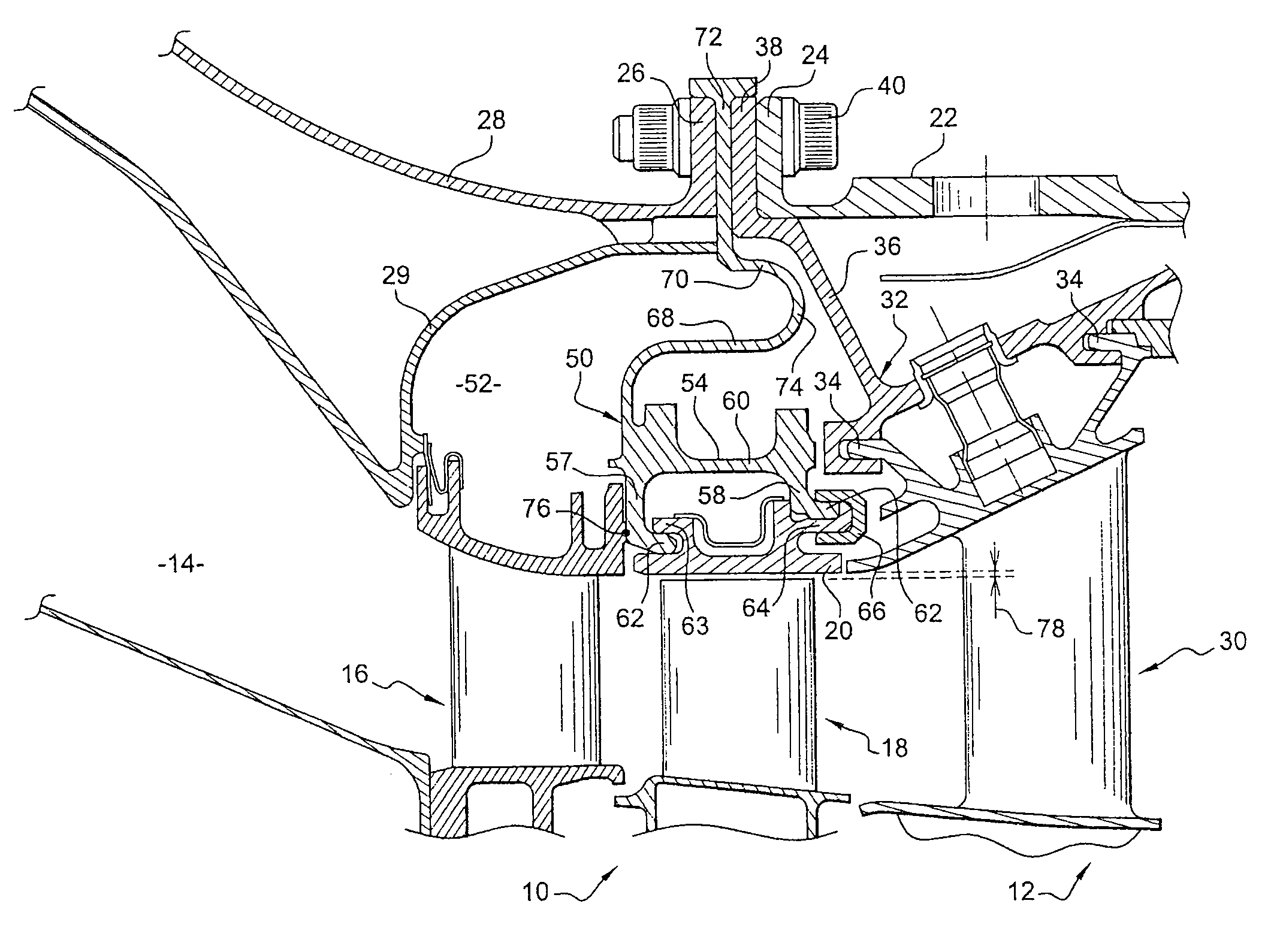

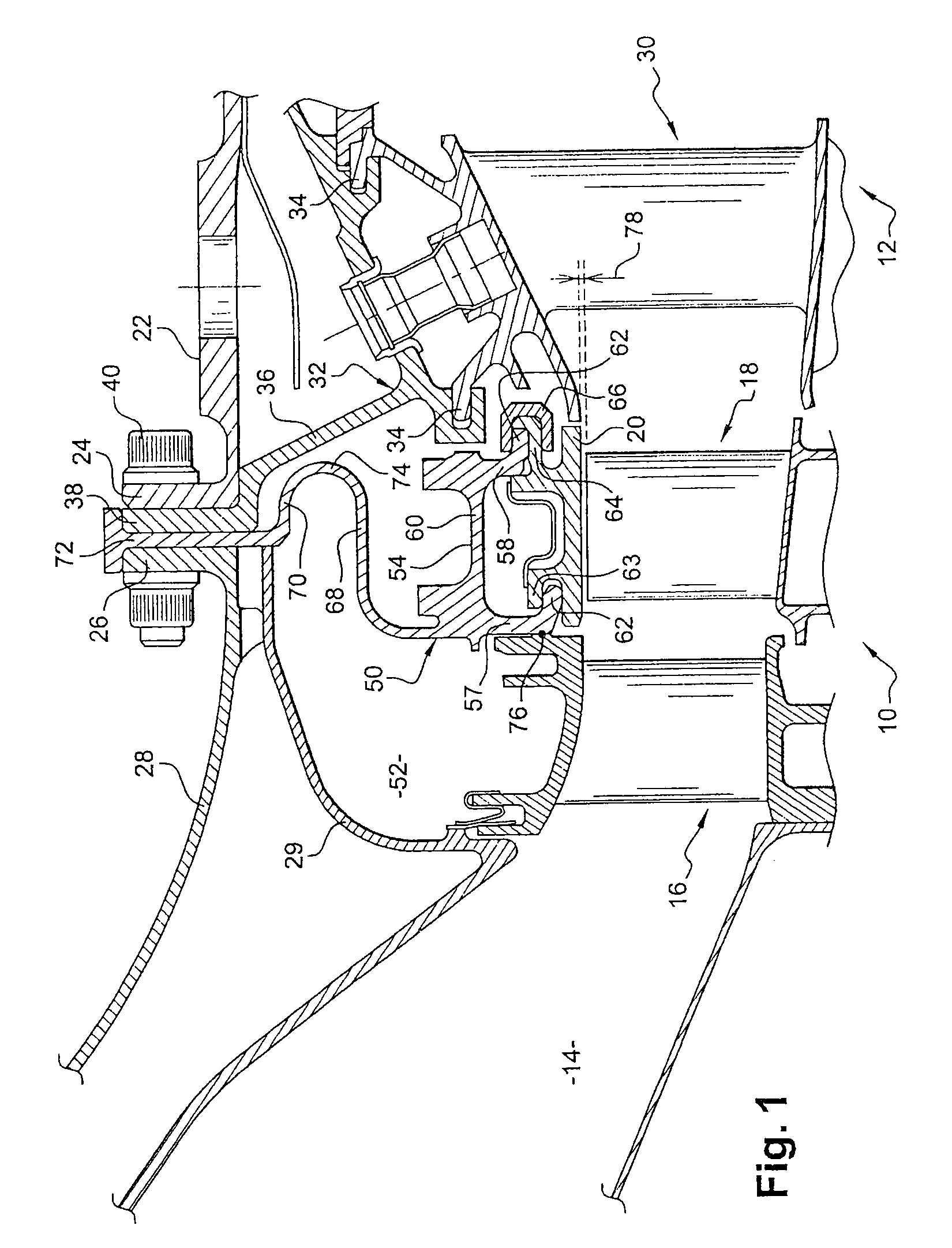

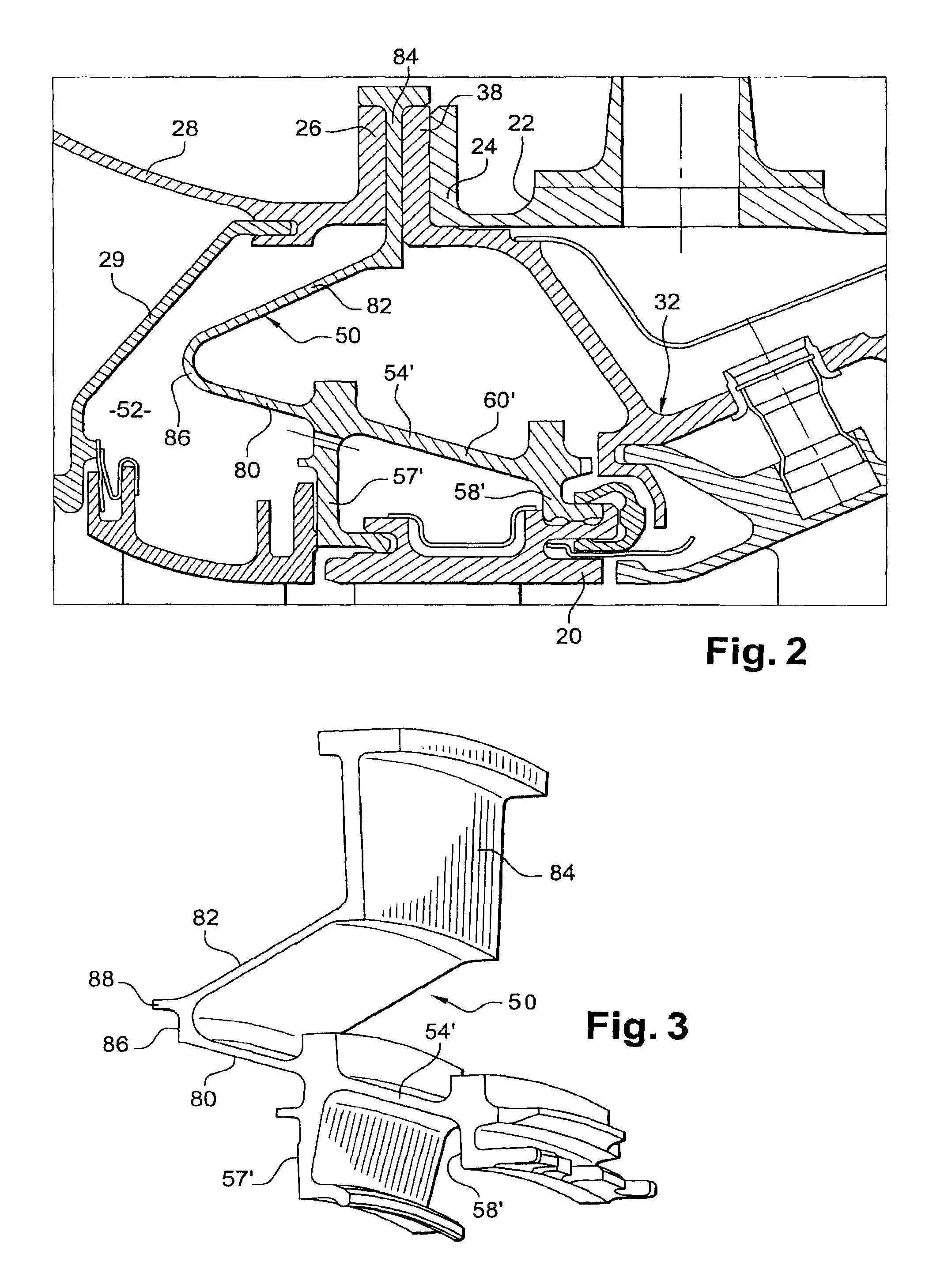

Turbine stage in a turbomachine

ActiveUS20080206047A1Simple and effective and economicalImprove rigidityPump componentsRotary non-positive displacement pumpsImpellerTurbine wheel

A turbine stage in a turbomachine comprising ring sectors (20) arranged about a turbine impeller (18), and an annular support (50) supporting the ring sectors and attached to a turbine casing (22), this annular support being able to be deformed elastically in the radial direction to cushion at least a portion of the deformations of the turbine casing in operation.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Device and method for removing occlusions in a biological vessel

A device for use within an occluded biological vessel and a method of using same to remove occlusion material from a vessel are provided. The device includes an elongated body configured for delivering projections arranged around a distal portion thereof into the biological vessel. Each of the projections includes a leaf-like structure connected to a stem portion having a higher axial rigidity than the leaf-like structure.

Owner:TRITICUM

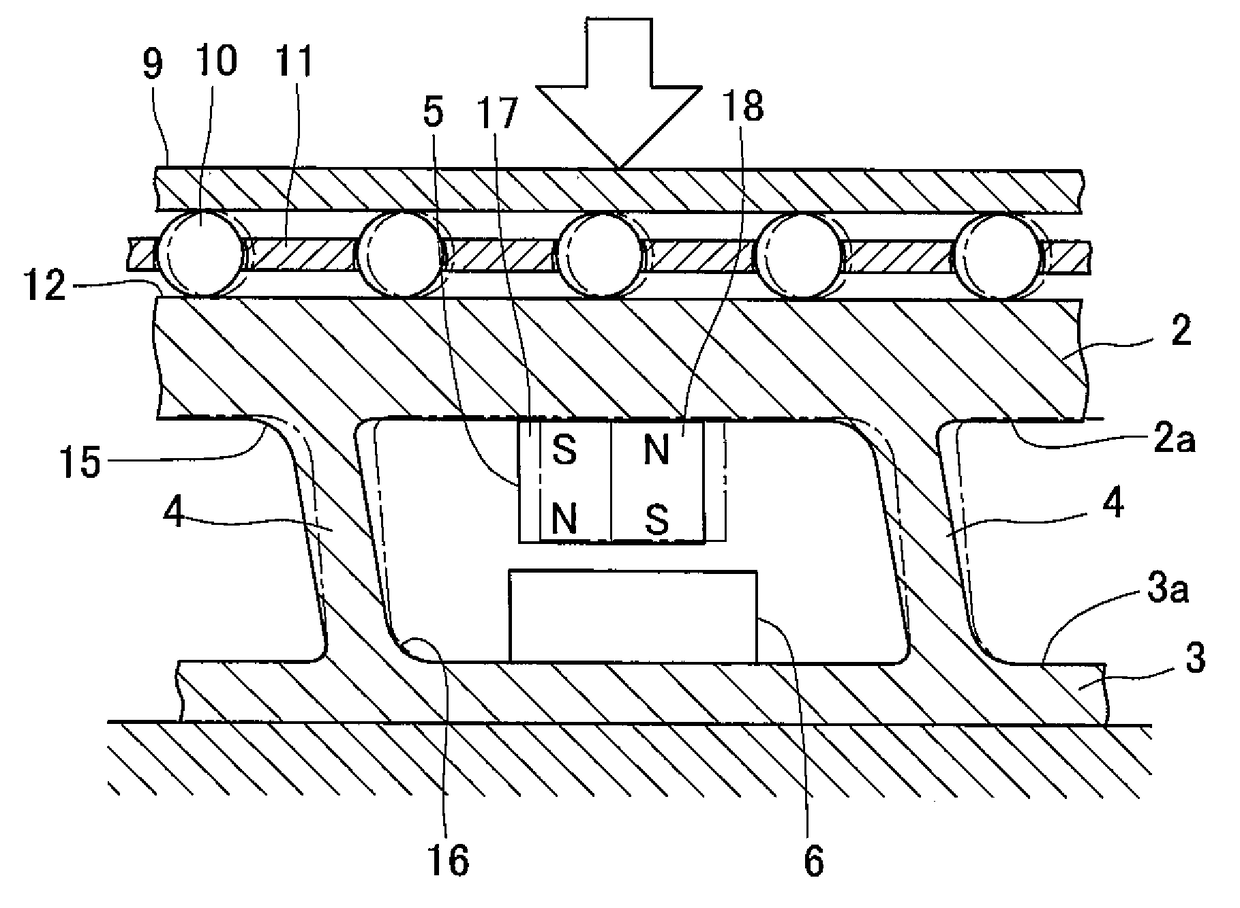

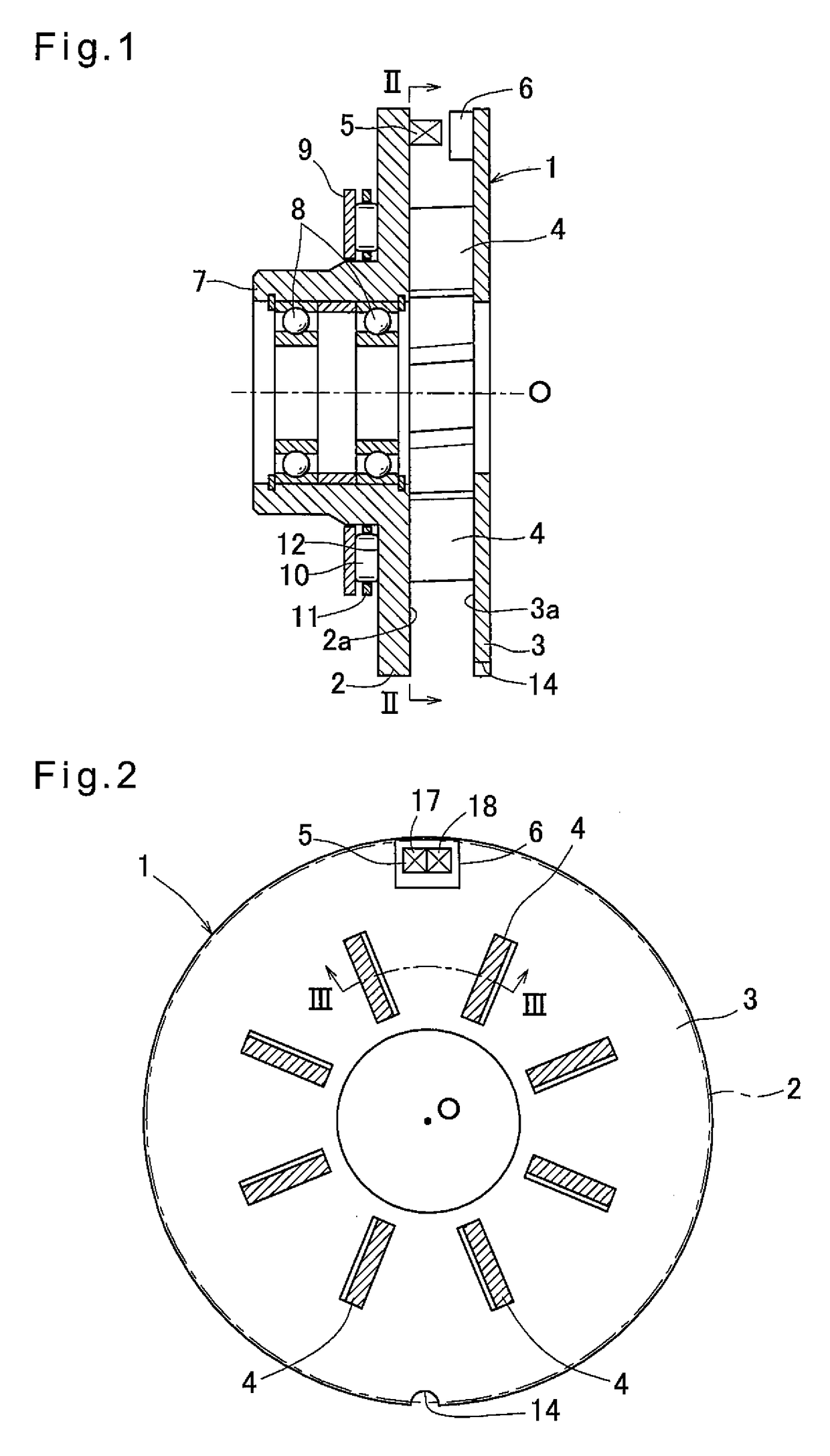

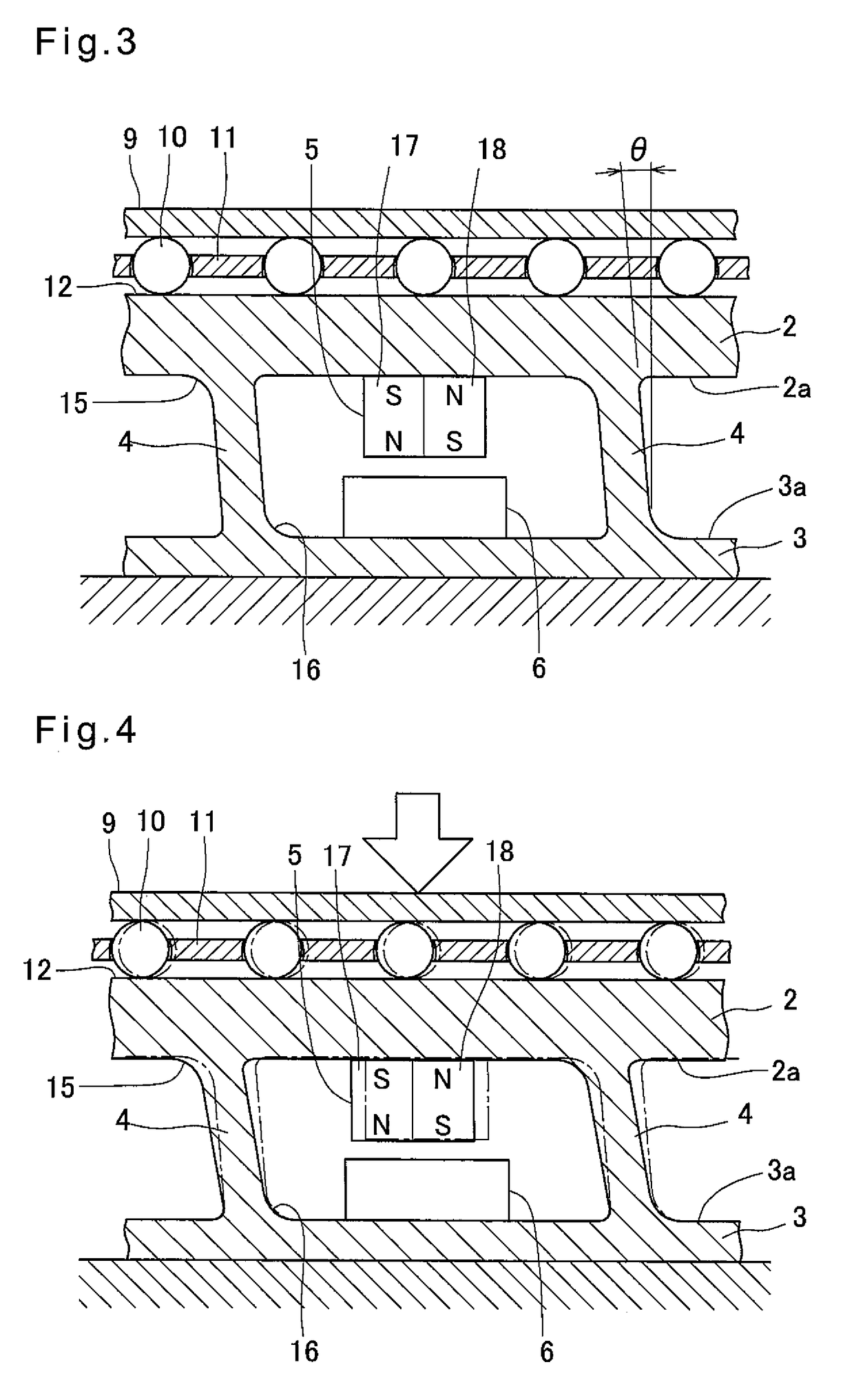

Magnetic load sensor and electric brake system

ActiveUS9599523B2Improve axial rigidityForce measurement by measuring magnetic property varationAxially engaging brakesParallel plateEngineering

A magnetic load sensor is provided which is high in axial rigidity. The load sensor includes a pair of parallel plate coupled together by coupling pieces. The coupling pieces are inclined relative to the axial direction such that when an axial load is applied to the parallel plates, the parallel plates are displaced relative to each other in a direction perpendicular to the axial direction, due to deflection of the coupling pieces. A magnetic target is mounted to the parallel plate, and a magnetic sensor element is mounted to the parallel plate such that when the parallel plates are displaced relative to each other in the direction perpendicular to the axial direction, the magnetic target and the magnetic sensor element are displaced relative to each other in the direction perpendicular to the axial direction.

Owner:NTN CORP

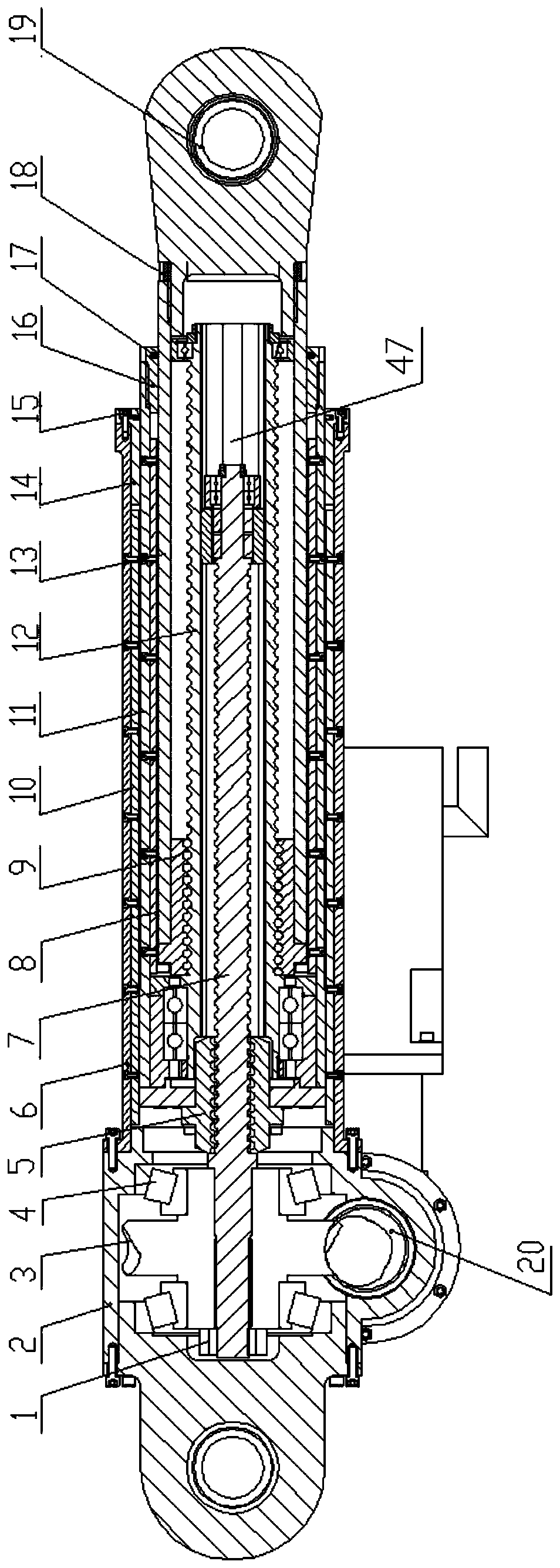

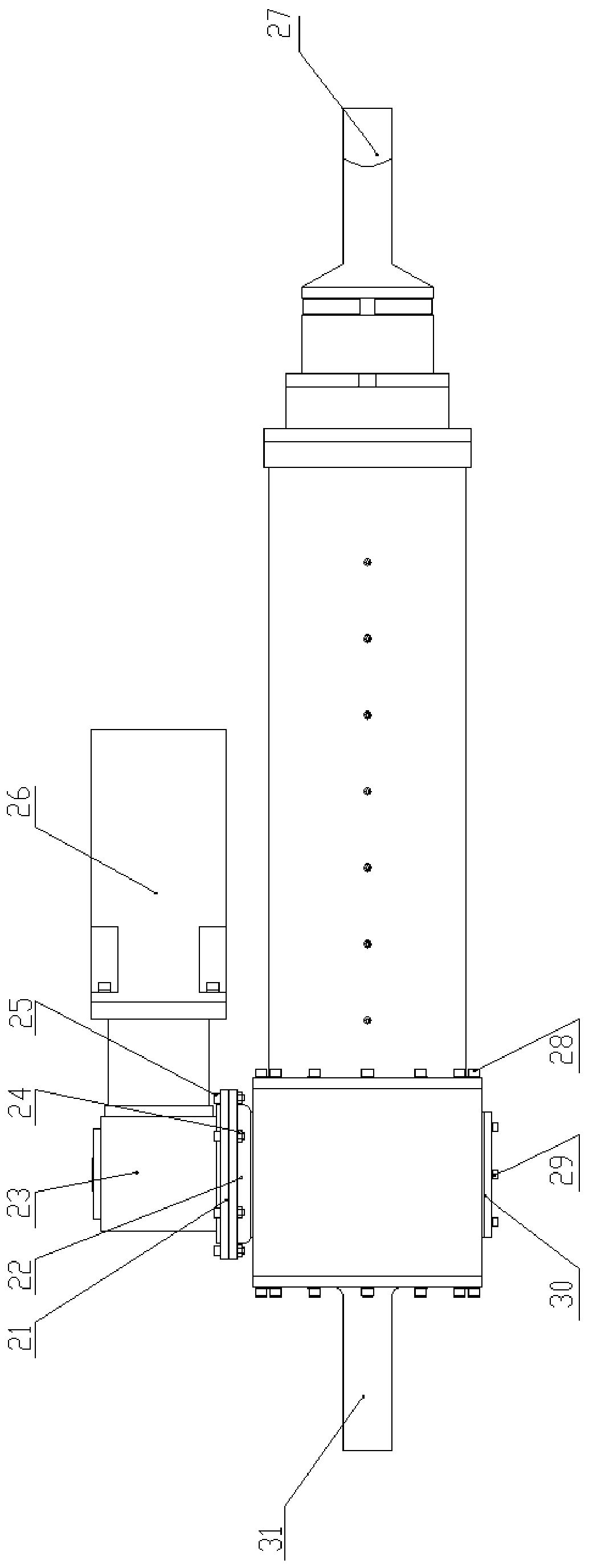

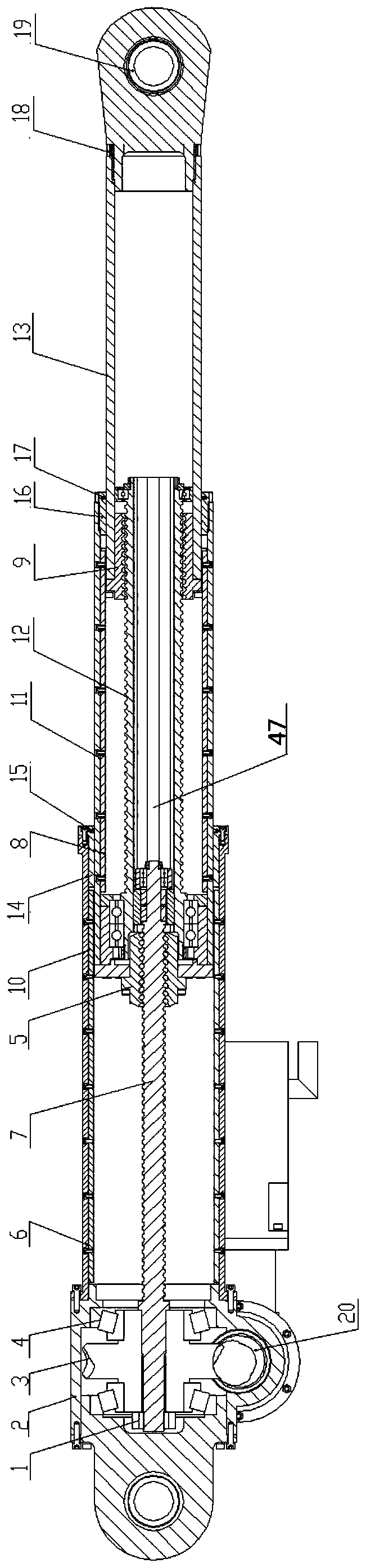

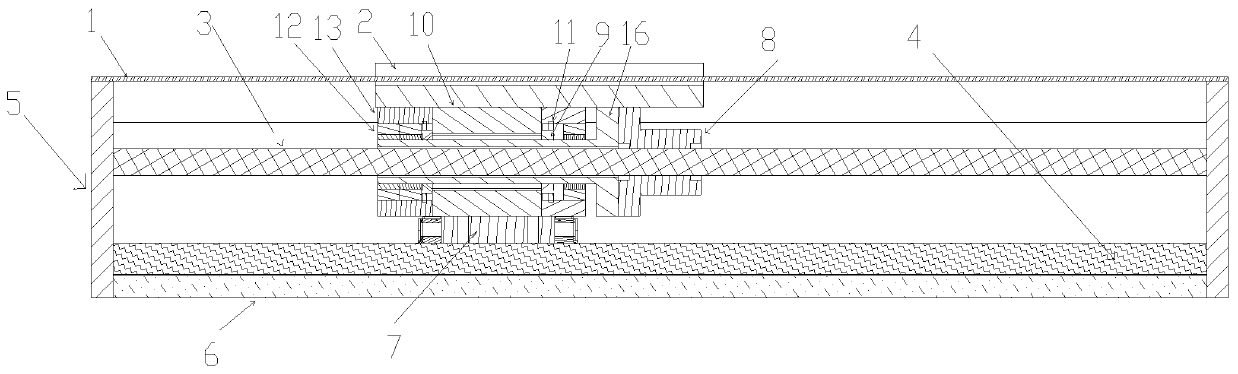

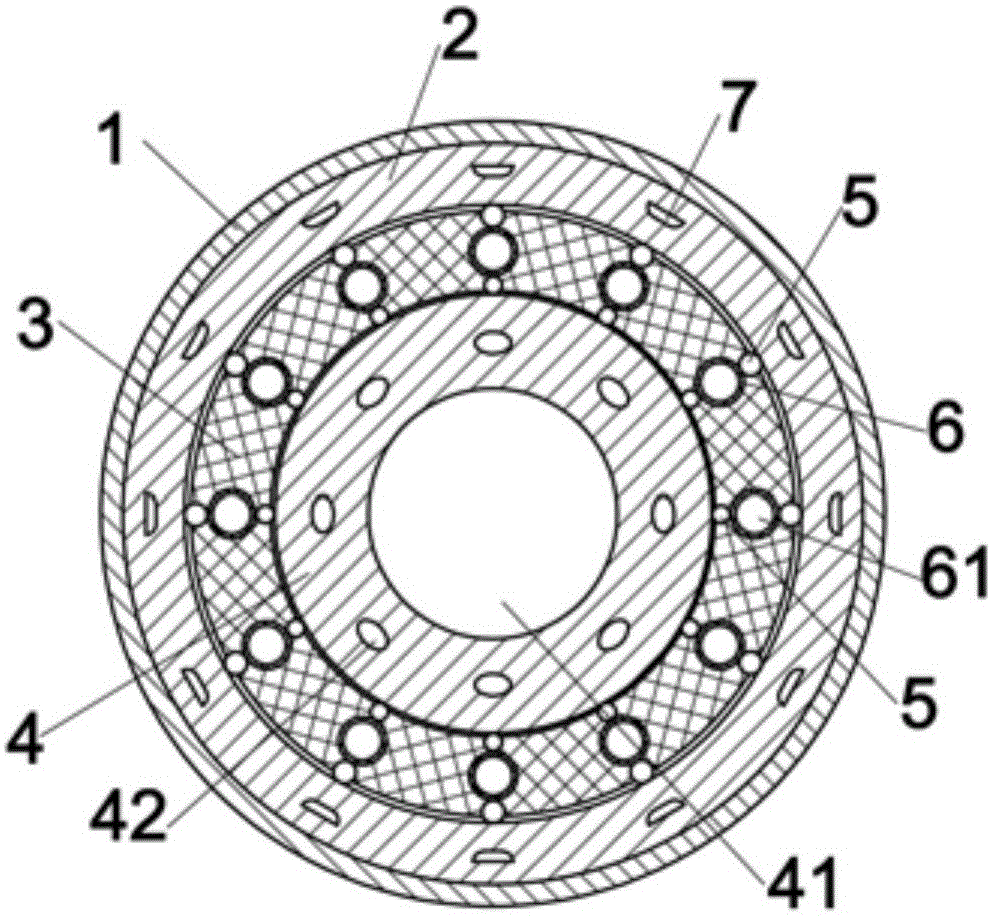

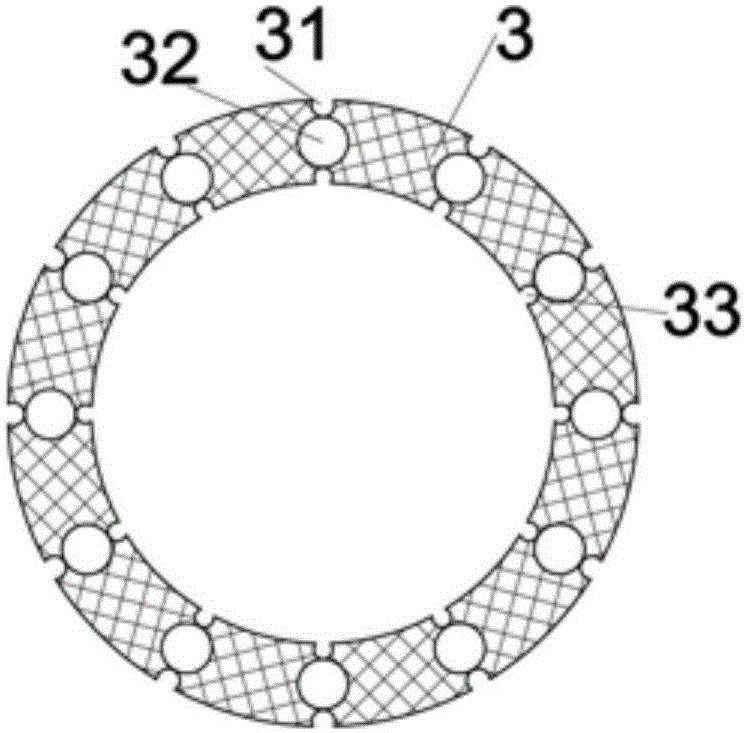

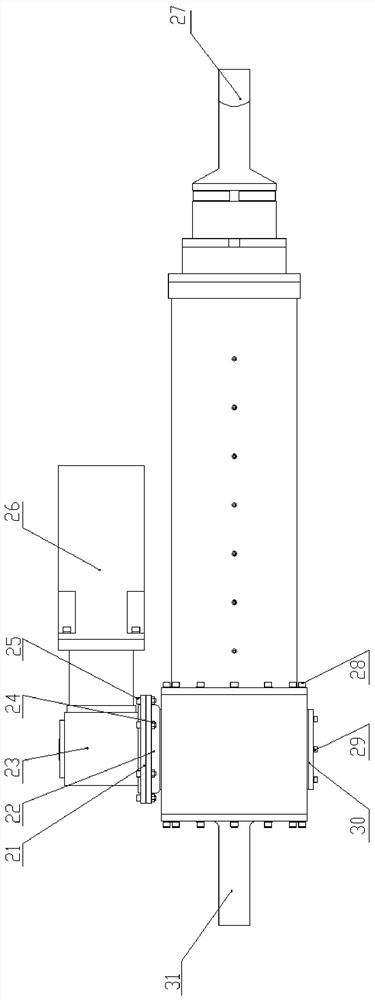

Small-volume heavy-duty multi-stage electric cylinder

ActiveCN109798340AHigh precisionLarge load and ball screw high precisionGearingMechanical energy handlingLinear motionBall screw

The invention discloses a small-volume heavy-duty multi-stage electric cylinder. The small-volume heavy-duty multi-stage electric cylinder comprises an electric cylinder body, a motor, and a reductiongearbox; the electric cylinder body is provided with a planetary ball screw shaft, a hollow ball screw shaft, a guide rod, an inner supporting sleeve, and an outer supporting shell body from the inside to the outside, wherein the planetary ball screw shaft, the hollow ball screw shaft, the guide rod, the inner supporting sleeve, and the outer supporting shell body are coaxial; linear motion of asupporting plate is realized through cooperation of a guide key groove formed in theouter circle of the supporting plate and an outer guide key arranged on the inner circle of the outer supporting shell body, the hollow ball screw shaft is connected with a hollow ball screw nut in a threaded mode and fixedly connected with one end of the guide rod through the hollow ball screw nut, and linear motion of the hollow ball screw nut is realized through cooperation of the guide key groove formed in the outer circle of the hollow ball screw nut and an inner guide key arranged on the inner circle of the inner supporting sleeve; and the reduction gearbox is fixedly connected with the motor and fixedly connected with the planetary ball screw shaft through a worm wheel, and a reduction gearbox shellbody is fixedly connected with one end of the outer supporting shell body. The space volume is reduced, thus axial stiffness is significantly increased, and the bearing capacity is enhanced.

Owner:XIAN MICROELECTRONICS TECH INST

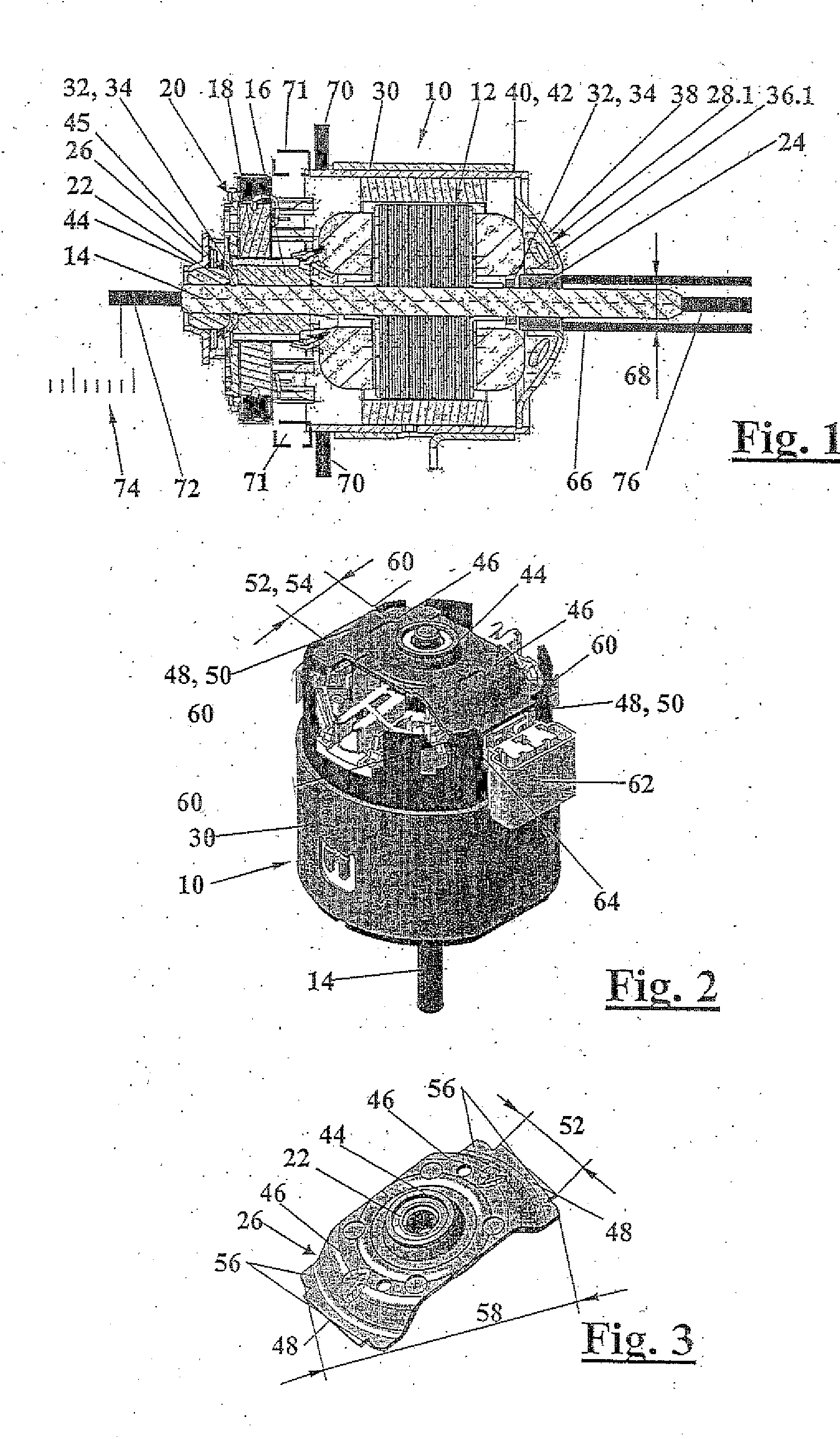

Electrical Machine

InactiveUS20080093937A1Easy to produceHigh strengthAutomatic control devicesAssembly machinesElectric machineEngineering

An electrical machine, preferably a blower drive mechanism for a motor vehicle, having a shaft which is supported in at least two bearings with a specified axial play; a cylindrical bearing is secured in a bearing seat of an end shield and rests directly on the bearing seat. The cylindrical bearing has a cylindrical outer circumference, and the bearing seat is a sleeve with a cylindrical inside diameter, into which sleeve the cylindrical bearing is secured with a press fit on the outer circumference and is held axially in the bearing seat by the thus-attained frictional engagement. This has the advantage that more-precise adjustment of the longitudinal play of the armature is possible. Moreover, no additional components such as retaining springs are necessary.

Owner:ROBERT BOSCH GMBH

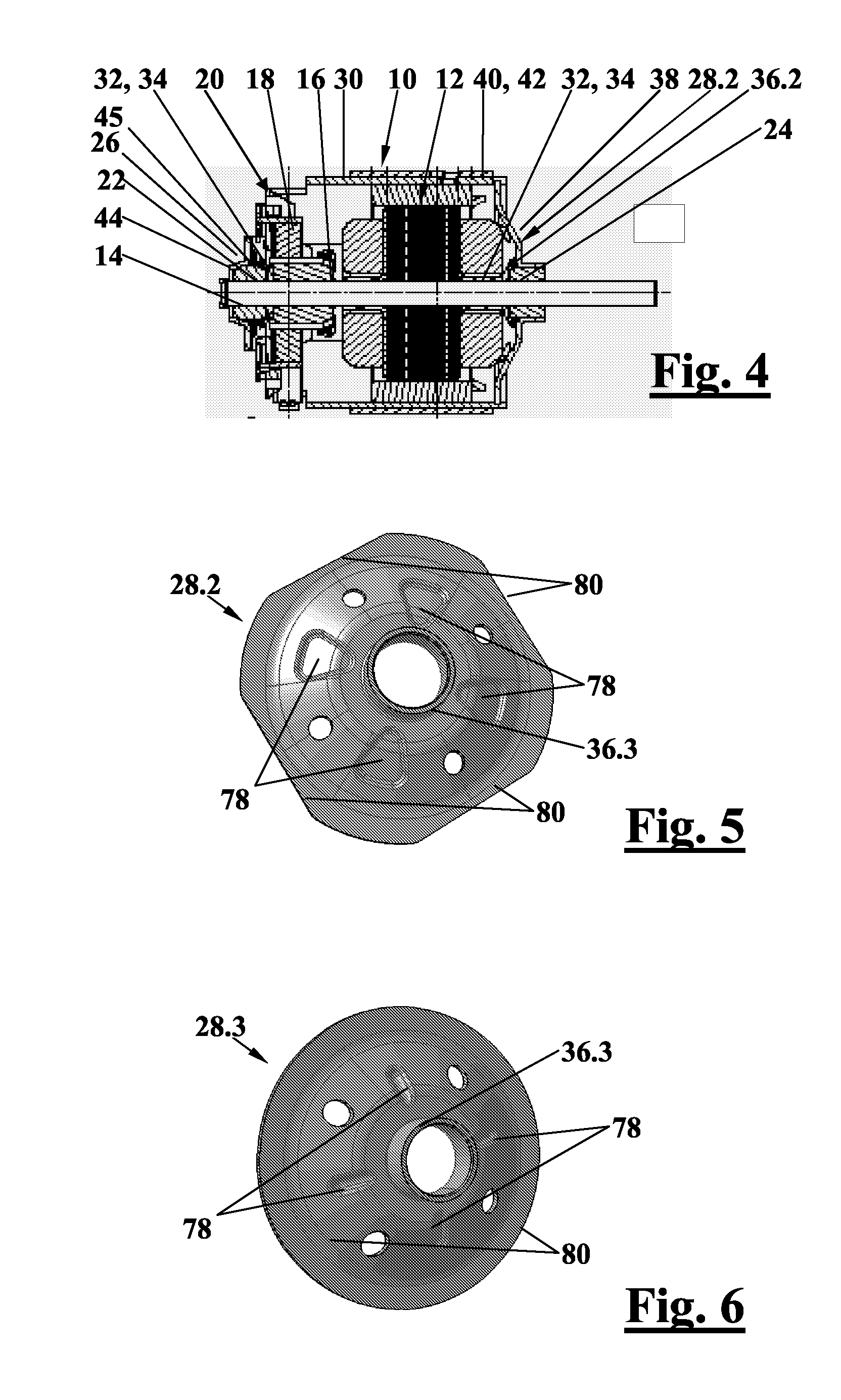

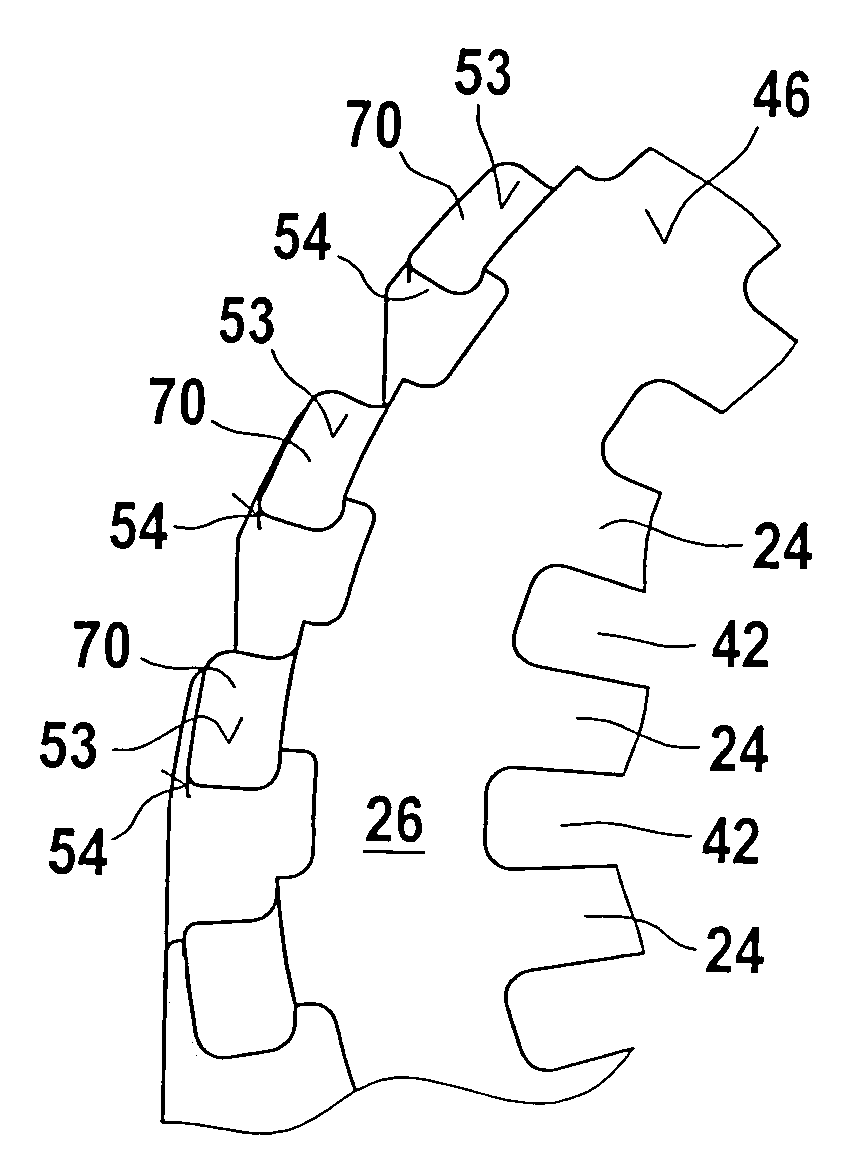

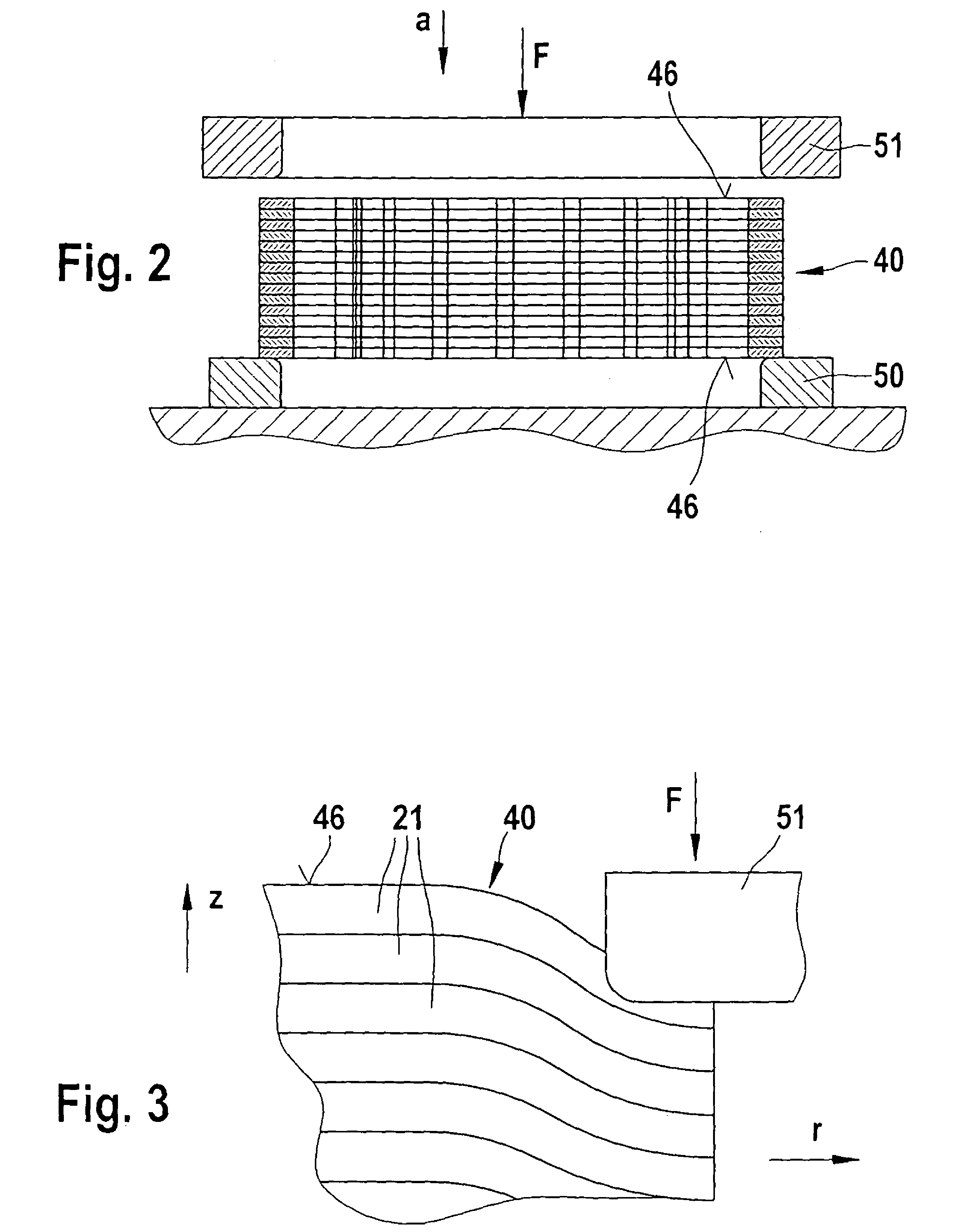

Method for production of a stator and stator produced according thereto

InactiveUS7926164B2Reduces electromagnetic lossesEasy to attachMagnetic circuit stationary partsManufacturing stator/rotor bodiesElectric machineMechanical engineering

A method for manufacturing a stator core (20) for an electric machine, in which a plurality of strip-shaped laminations (21) are first stacked to form an essentially block-shaped lamellas packet (40) that is then shaped into an annular form by means of roller bending in one of the subsequent steps so that the outer teeth are provided on the outer circumference of the lamination packets and has an axial direction (a) that corresponds to a cylinder axis (z), the annular form having axial end surfaces (46), wherein in another of the subsequent steps, the annular lamination packet (40) is plastically deformed in the axial direction (a) only on the outer teeth (70) of the axial end surfaces (46).

Owner:SEG AUTOMOTIVE GERMANY GMBH

Duct piece fixing pile device for fixing shield tunnel duct piece and using method

ActiveCN111577324AControl floatFloating is effectiveUnderground chambersTunnel liningArchitectural engineeringSlurry

The invention discloses a duct piece fixing pile device for fixing a shield tunnel duct piece. The duct piece fixing pile device comprises a grouting outer sleeve and a grouting inner sleeve; a connecting part and a step part are arranged at the front end of the grouting outer sleeve, the connecting part is fixedly connected with the step part, a sealing cover is arranged at the rear end of the grouting outer sleeve; a supporting part is arranged at the front end of the grouting inner sleeve, the supporting part is located on the step part, the step part is fixedly connected with the supporting part, a grouting bag is connected to the rear end of the grouting inner sleeve; threads are arranged on the outer parts of the ends, close to the connecting part, of the connecting part and the grouting outer sleeve correspondingly; and the invention further discloses a construction method of the pipe piece fixing pile device, and the construction method comprises the steps of grouting hole opening, grouting liquid stirring, grouting and the like. According to the duct piece fixing pile device for fixing the shield tunnel duct piece, fixing the tunnel duct piece in time can be carried out during shield construction, so that the construction efficiency is effectively improved, and the construction quality is improved.

Owner:湖南中天凿岩科技有限公司

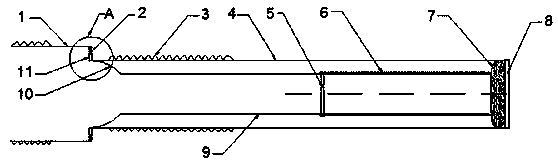

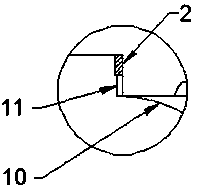

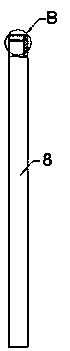

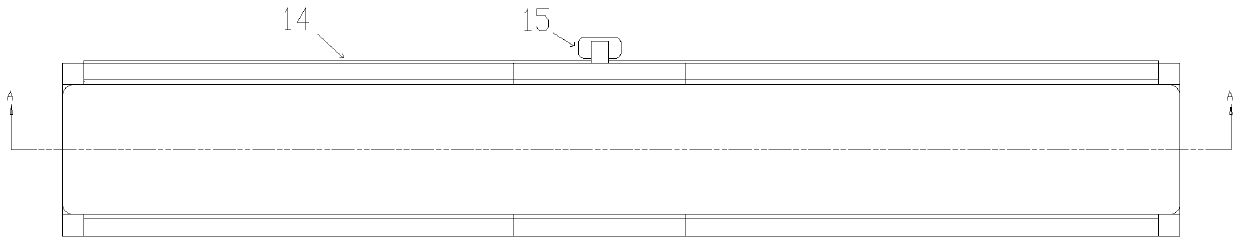

Linear module with built-in AC servo motor

PendingCN110768427AReduce frictionImprove transmission efficiencyMagnetic circuit rotating partsStructural associationMotor speedElectric machine

The invention discloses a linear module with a built-in AC servo motor. The linear module includes a housing, an AC servo motor, a lead screw assembly and a bearing. The AC servo motor includes a motor silicon steel sheet, a motor coil and a rotor assembly. The rotor assembly passes through a through hole in the middle of the motor silicon steel sheet and is installed in the motor silicon steel sheet. The motor coil is wound inside the motor silicon steel sheet. The lead screw assembly includes a lead screw and a ball lead screw nut. The bearing is connected on a sliding seat through a bearingsupport plate, and the bearing is located on both sides of the AC servo motor or the ball lead screw nut. By adopting the ball lead screw nut fixation and nut rotary motion mode, the AC servo motor is installed in the sliding seat. With the movement of the ball lead screw nut, miniaturization and microminiaturization can be achieved, vast space is saved, and multiple motors can be arranged to operate separately without mutual interference. The motor of the invention has lower cost than a linear motor, and has faster rotation speed and higher precision than a stepping motor. Motor power can bereduced, and the motor of the invention is more energy-saving and more environmentally-friendly.

Owner:苏州中机华智精密机械有限公司

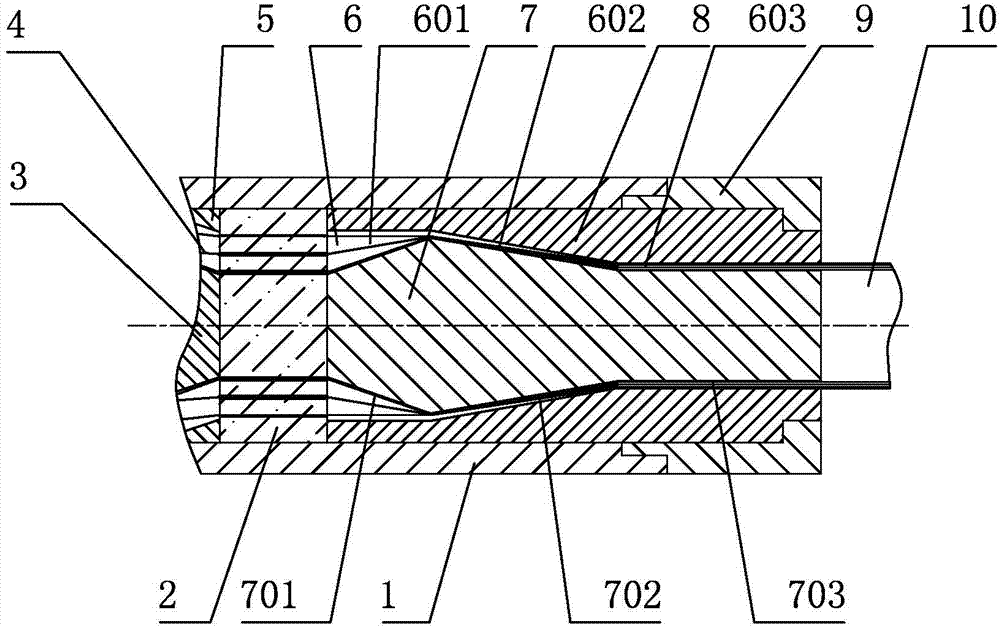

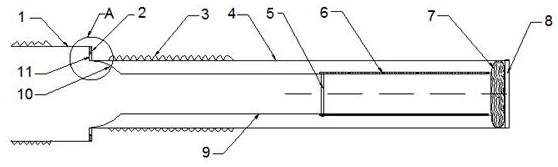

Forming die of continuous fiber-reinforced thermoplastic plastic pipe and forming method of forming die

The invention relates to a forming die of a continuous fiber-reinforced thermoplastic plastic pipe and a forming method of the forming die. The forming die comprises a machine body, wherein a shaft sleeve, a beam splitting block and a mouth die are sequentially arranged in the machine body along the axial direction; the beam splitting block is fixed by the mouth die on the rear side and the shaft sleeve on the front side, and arc-shaped beam-splitting slits are formed in the beam splitting block; the rear end of the mouth die is locked through a locking nut connected with the machine body; the front end of the beam splitting block is fixedly connected with a spindle. The forming method comprises the following steps: (1) segmenting a molten continuous fiber-reinforced thermoplastic resin-based impregnation tape into multiple arc sections; (2) superposing various layers of segmented impregnation tape; (3) adhering the various layers of impregnation tape; (4) fusing each layer of the impregnation tape to form a tube billet; and (5) sizing the pipe, cooling through a cooling device, cutting through a cutting device, and forming the pipe. The axial bearing capacity of the pipe is greatly improved, so that the axial stiffness of the pipe is greatly improved.

Owner:SHANDONG UNIV OF TECH

Device and method for removing occlusions in a biological vessel

A device for use within an occluded biological vessel and a method of using same to remove occlusion material from a vessel are provided. The device includes an elongated body configured for delivering projections arranged around a distal portion thereof into the biological vessel. Each of the projections includes a leaf-like structure connected to a stem portion having a higher axial rigidity than the leaf-like structure.

Owner:TRITICUM

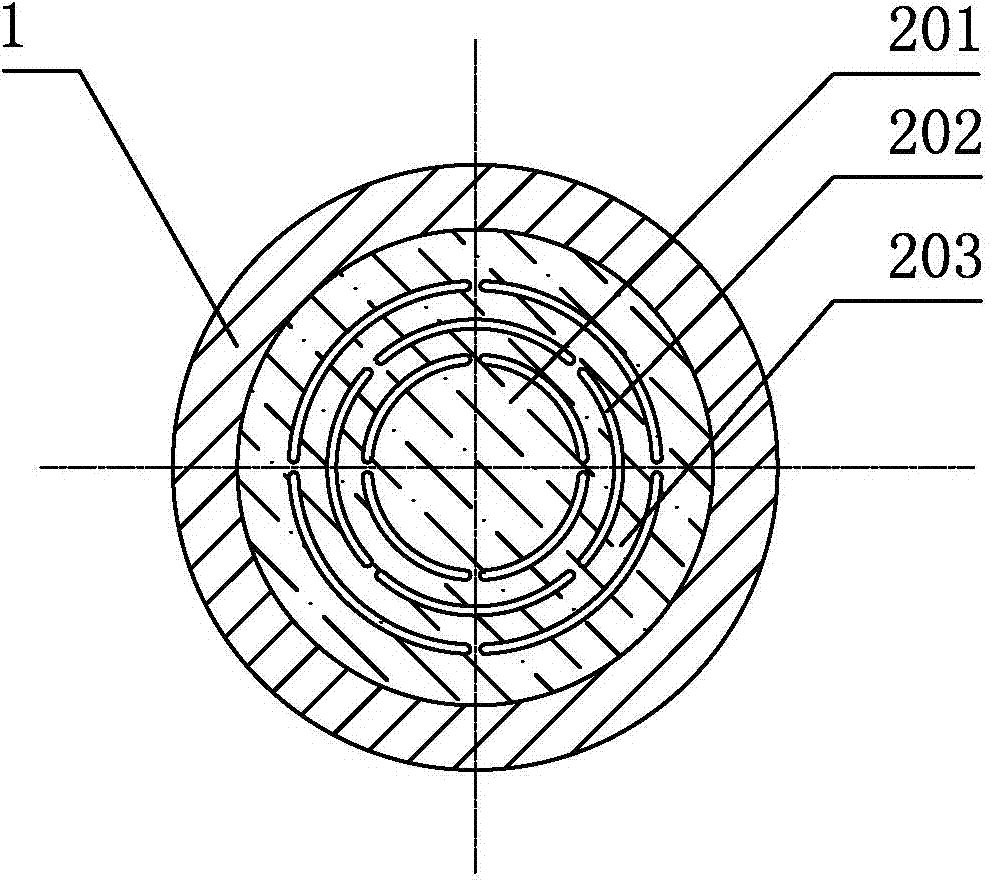

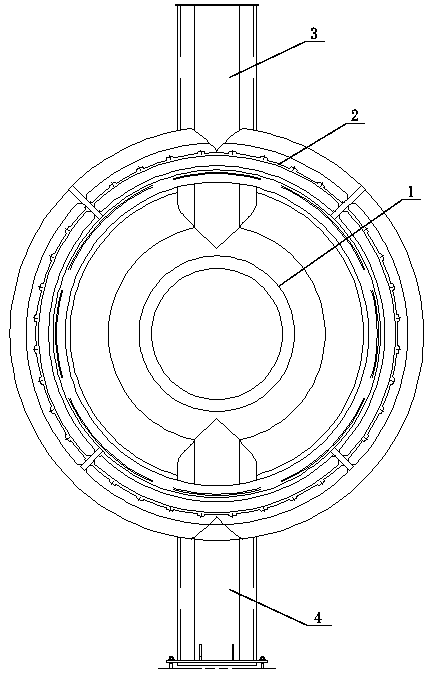

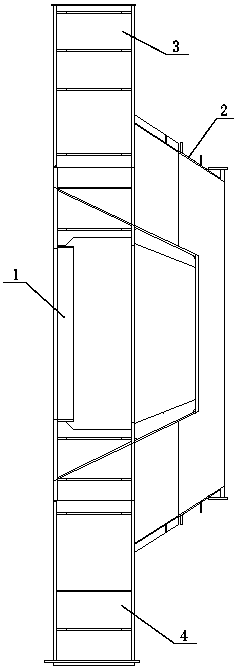

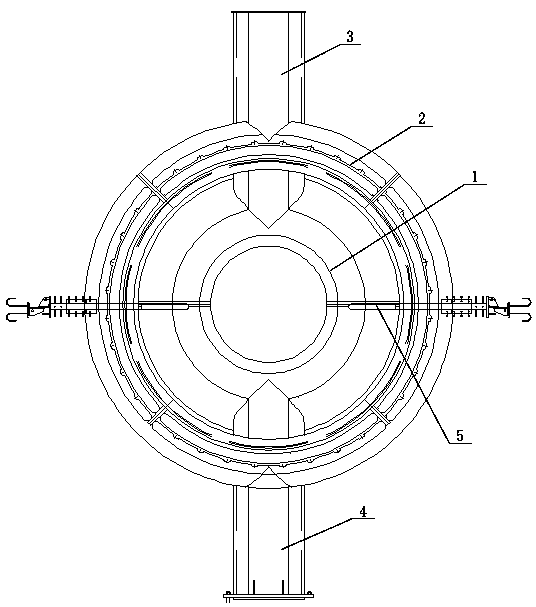

Large bulb tubular turbine stay ring support structure

ActiveCN108050005AImprove rigidityImprove axial rigidityHydro energy generationMachines/enginesTurbineAxial rigidity

The invention discloses a large bulb tubular turbine stay ring support structure comprising a stay ring upper pillar and a stay ring lower pillar which are arranged on the upper and lower sides of aninner ring of a turbine stay ring. The right and left sides of the inner ring of the turbine stay ring are symmetrically provided with horizontal auxiliary support structures arranged in a flow channel of the bulb tubular turbine stay ring, and a certain angle is formed between the horizontal auxiliary support structures and the axis of a turbine unit. According to the support structure disclosedby the invention, the shortcomings and limitations of an existing support structure of an existing bulb tubular turbine stay ring are overcome; by additionally arranging the horizontal auxiliary support structures on the inner ring of the stay ring, the traditional two-point support structure with upper and lower pillars is optimized to be four-point support, and the overall rigidity of the stay ring is improved obviously; and meanwhile, a certain angle is formed between the horizontal auxiliary support structures and the axis of the turbine unit, so that the axial rigidity of the stay ring isimproved greatly, and it is ensured that the unit is not deformed seriously under the effect of large hydraulic thrust.

Owner:DONGFANG ELECTRIC MACHINERY

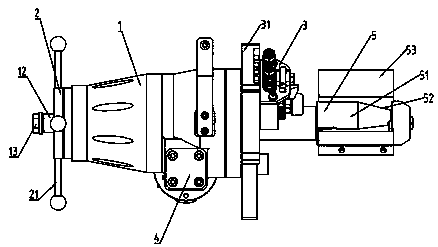

Improved pipe end beveling machine

PendingCN110899844AReduce weightGuaranteed StrengthFeeding apparatusPositioning apparatusStructural engineeringMachine

The invention discloses an improved pipe end beveling machine, which comprises a main shaft part. A feeding part is arranged at one end of the main shaft part; a pull rod shaft runs through the main shaft part; a clamping jaw shaft is sleeved on the pull rod shaft; a clamping jaw nut is mounted at the tail end of the clamping jaw shaft; a tapered roller bearing is arranged in the main shaft part;the other end of the main shaft part is provided with a processing cutter head part capable of rotating relatively; a hydraulic driving component used for driving the processing cutter head part is arranged under the main shaft part; and the other end of the pull rod shaft is connected with a clamping jaw component. The invention relates to the field of beveling machines; and through a novel mainshaft structure, the beveling machine is higher in stiffness by more than 1.5 times than a similar domestic beveling machine; the novel expansion claw structure increases the expansion force and solves the problem of indentation on the inner wall of the pipe; and equipped with a high-precision tracking cutter frame, the equipment can machine complex grooves such as U-shaped grooves and double-V-shaped grooves, and is convenient to use.

Owner:四川艾普耐斯油气工程服务有限公司

A segment fixing pile device for fixing a shield tunnel segment and its use method

ActiveCN111577324BControl floatFloating is effectiveUnderground chambersTunnel liningArchitectural engineeringShield tunneling

Owner:湖南中天凿岩科技有限公司

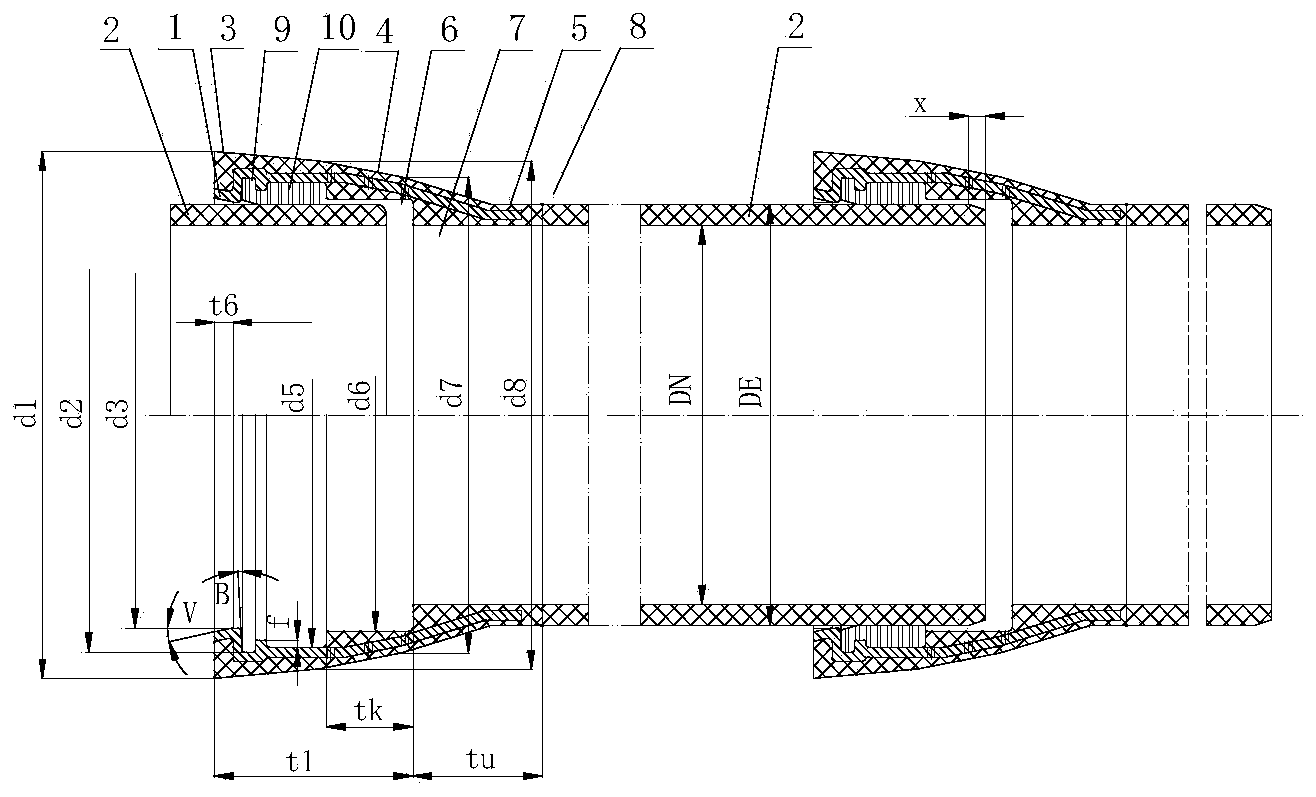

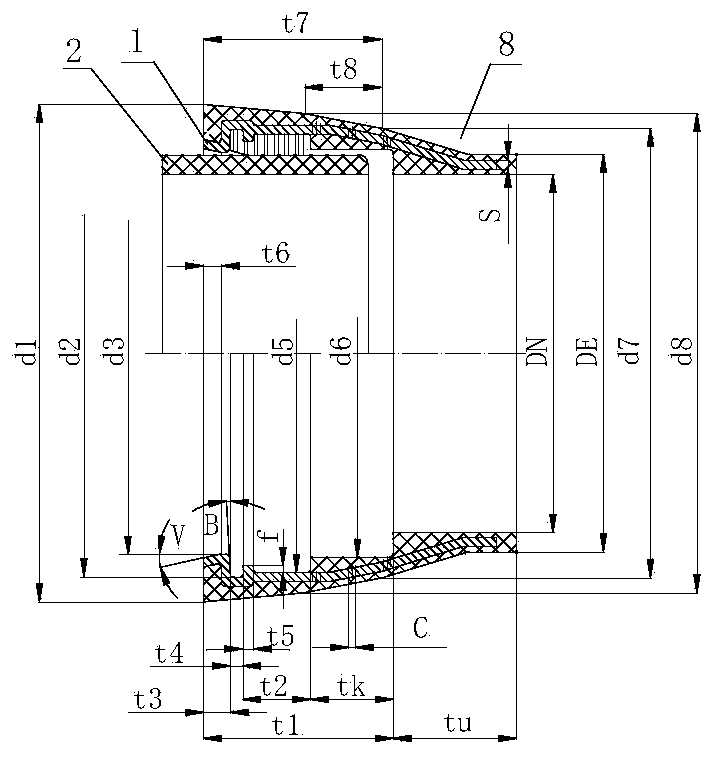

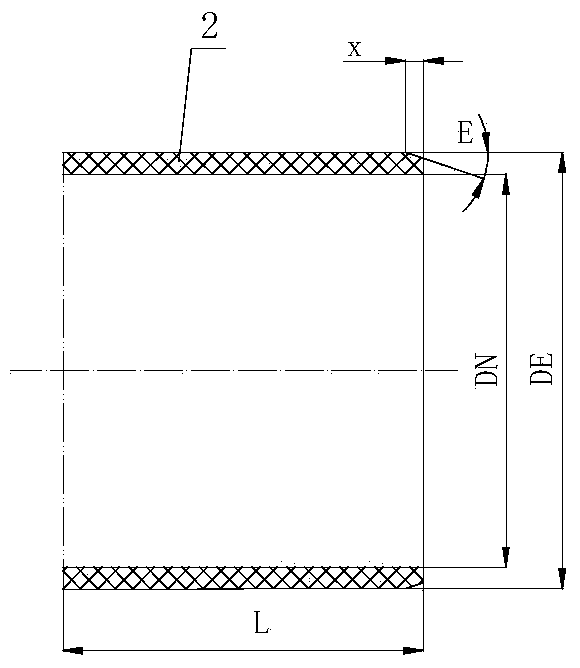

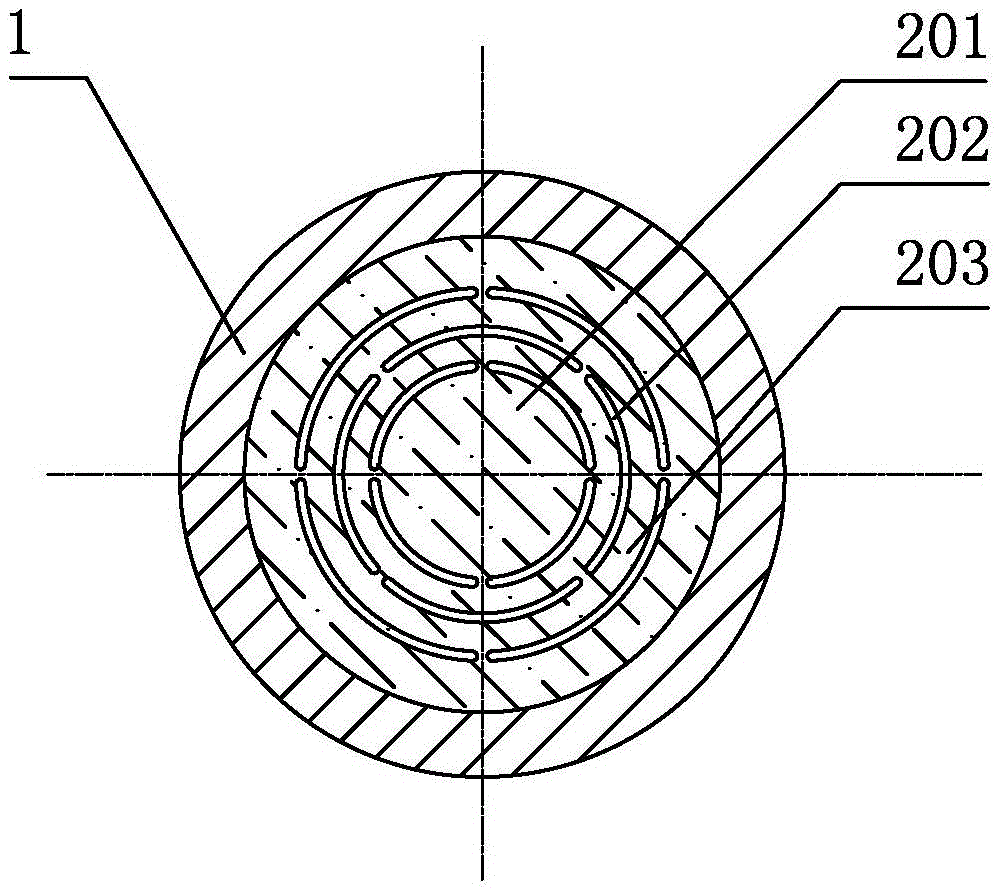

Half steel frame reinforcing type socket-and-spigot composite pipe and manufacture process thereof

Provided are a half steel frame reinforcing type adapting type composite pipe and a manufacture process thereof. The manufacture process includes manufacturing a frame by adopting casting or stamping process, and respectively manufacturing a socket-and-spigot main pipe and a socket-and-spigot auxiliary pipe in injection molding and spraying mode and assembling the pipes. A frame outer layer is characterized in that an outer wall of the socket-and-spigot main pipe is formed by a large conical wall on the front portion, a cylindrical wall on the back portion and a middle small conical wall, the inner wall of the socket-and-spigot main pipe is composed of a socket-and-spigot cavity and an overflow cavity, a socket-and-spigot composite pipe is composed of the adapting main pipe and the adapting auxiliary pipe in adaptive fit mode, a group of grooves are arranged on a front end opening of the frame, and a sealing ring is arranged in the grooves respectively in fit mode. The half steel frame reinforcing type adapting type composite pipe overcomes the shortcoming that a polyethylene resin plastic composite pipe / polyethylene (PE) pipe is easy to separate due to the fact that expansion coefficient is different in connection installation, non-roundness at the abutting connection position is increased, the welding position generates quick stress cracking and causes the fact that the connection system of the cracking portion leaks water, gas and liquid, a cast-iron pipe and the PE pipe cannot be interchanged, old project modification is affected and the like. The composite type and the manufacture process are suitable for connection pipes of various water delivery and gas delivery projects and are especially suitable for interchangeable connection of plastic pipes such as PE, PVC-U and PVC-M and nodular cast iron pipes.

Owner:HUNAN ZHENHUI PIPE IND

Forming mold and forming method of continuous fiber reinforced thermoplastic pipe

The invention relates to a forming die of a continuous fiber-reinforced thermoplastic plastic pipe and a forming method of the forming die. The forming die comprises a machine body, wherein a shaft sleeve, a beam splitting block and a mouth die are sequentially arranged in the machine body along the axial direction; the beam splitting block is fixed by the mouth die on the rear side and the shaft sleeve on the front side, and arc-shaped beam-splitting slits are formed in the beam splitting block; the rear end of the mouth die is locked through a locking nut connected with the machine body; the front end of the beam splitting block is fixedly connected with a spindle. The forming method comprises the following steps: (1) segmenting a molten continuous fiber-reinforced thermoplastic resin-based impregnation tape into multiple arc sections; (2) superposing various layers of segmented impregnation tape; (3) adhering the various layers of impregnation tape; (4) fusing each layer of the impregnation tape to form a tube billet; and (5) sizing the pipe, cooling through a cooling device, cutting through a cutting device, and forming the pipe. The axial bearing capacity of the pipe is greatly improved, so that the axial stiffness of the pipe is greatly improved.

Owner:SHANDONG UNIV OF TECH

Lifting ring structure used for shock absorber

ActiveCN105041934AImprove performanceNot affected by manufacturing errorsRubber-like material springsMultiple bufferingShock absorber

The invention discloses a lifting ring structure used for a shock absorber. The lifting ring structure comprises a lifting lug ring, a first floating sleeve, a second floating sleeve, multiple buffering sleeves and an inner sleeve. The lifting lug ring is provided with a center axis, the first floating sleeve is sleeved with an inner hole of the lifting lug ring, the second floating sleeve is sleeved with an inner hole of the first floating sleeve, the buffering sleeves are embedded inside a hole of the second floating sleeve and provided with buffering cavities, and buffering rods are arranged inside the buffering cavities. The inner sleeve is sleeved with an inner hole of the second floating sleeve and provided with a connecting hole, and after the inner sleeve is connected with an automobile, the included angle between the axis of the connecting hole and the center axis ranges from 0 degree to 5 degrees. The lifting ring structure is simple, high in bearing capacity and capable of freely floating after assembling.

Owner:ZHEJIANG IND & TRADE VACATIONAL COLLEGE

A small-volume heavy-duty multi-stage electric cylinder

ActiveCN109798340BHigh precisionLarge load and ball screw high precisionGearingMechanical energy handlingElectric machineBall screw

The invention discloses a small-volume heavy-duty multi-stage electric cylinder. The small-volume heavy-duty multi-stage electric cylinder comprises an electric cylinder body, a motor, and a reductiongearbox; the electric cylinder body is provided with a planetary ball screw shaft, a hollow ball screw shaft, a guide rod, an inner supporting sleeve, and an outer supporting shell body from the inside to the outside, wherein the planetary ball screw shaft, the hollow ball screw shaft, the guide rod, the inner supporting sleeve, and the outer supporting shell body are coaxial; linear motion of asupporting plate is realized through cooperation of a guide key groove formed in theouter circle of the supporting plate and an outer guide key arranged on the inner circle of the outer supporting shell body, the hollow ball screw shaft is connected with a hollow ball screw nut in a threaded mode and fixedly connected with one end of the guide rod through the hollow ball screw nut, and linear motion of the hollow ball screw nut is realized through cooperation of the guide key groove formed in the outer circle of the hollow ball screw nut and an inner guide key arranged on the inner circle of the inner supporting sleeve; and the reduction gearbox is fixedly connected with the motor and fixedly connected with the planetary ball screw shaft through a worm wheel, and a reduction gearbox shellbody is fixedly connected with one end of the outer supporting shell body. The space volume is reduced, thus axial stiffness is significantly increased, and the bearing capacity is enhanced.

Owner:XIAN MICROELECTRONICS TECH INST

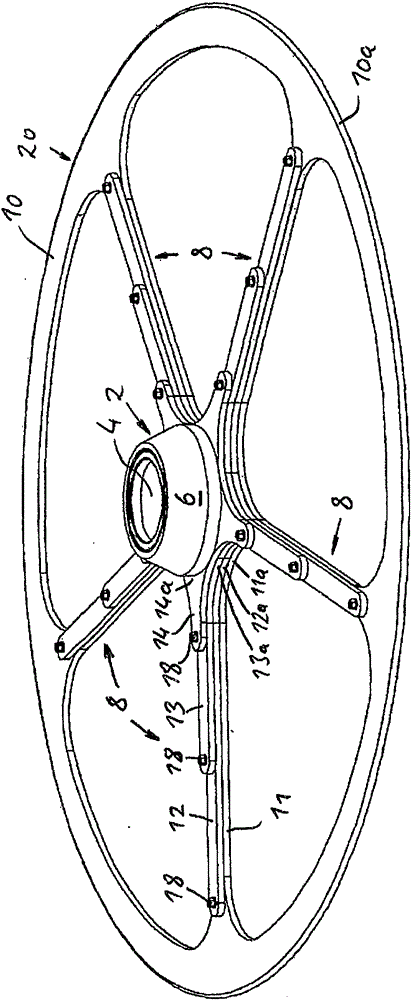

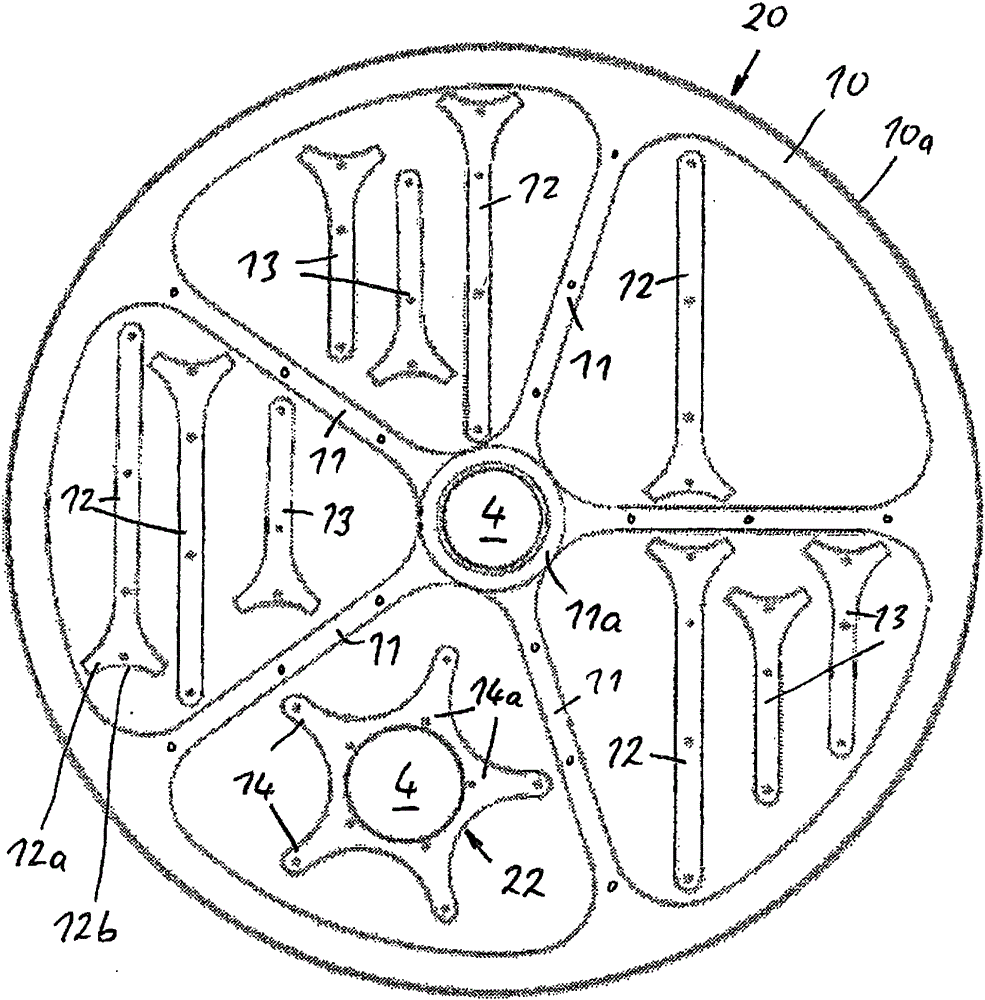

spoke wheel

The spoked wheel made of aluminum, comprises a hub (2) which includes a central bore (4) for receiving a shaft or axis, and an annular rim (10) having several radially extending plate-like spokes (8). The spokes are extended from the hub and are stacked on each other to form the spoke elements (11-14). The length of each spoke element decreases from layer to layer, and at least a spoke element (11) is connected with the rim. An independent claim is included for manufacturing method of spoked wheel.

Owner:HAUNI MASCHINENBAU AG

Illumination module movement device

ActiveCN102902163BSimple structureHigh positioning accuracyPhotomechanical exposure apparatusMicrolithography exposure apparatusUnit loadEngineering

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com