Linear module with built-in AC servo motor

A technology of AC servo motors and linear modules, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of low speed, high noise, flexible structure and lower overall rigidity, etc., to reduce the overall length and increase the moment of inertia , the effect of saving the total length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

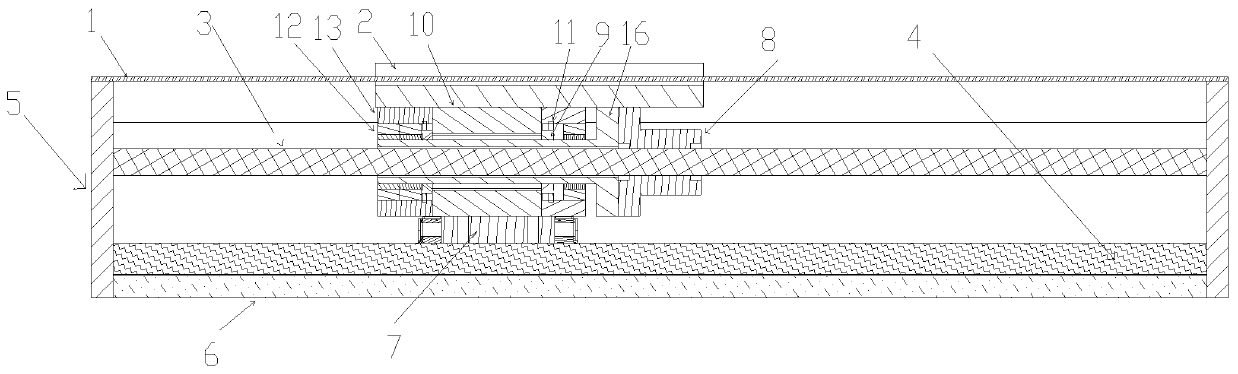

[0039] see Figure 1-2 , 6, 9-11, a linear module with a built-in AC servo motor, including a housing, an AC servo motor, a screw assembly and a bearing 12, the bottom of the AC servo motor is installed above the linear guide rail 4 through a slider 7, The linear guide rail 4 is installed on the bottom plate 6, and the top of the AC servo motor is connected with a sliding seat 2. The AC servo motor includes a motor silicon steel sheet 10, a motor coil 11, and a rotor assembly. The rotor assembly passes through the motor silicon steel The through hole in the middle of the sheet 10 is installed inside the motor silicon steel sheet 10, the motor coil 11 is wound inside the motor silicon steel sheet 10, the screw assembly includes a lead screw 3 and a ball screw nut 8, and the wire The lever screw 3 is fixedly connected between the two side end cover support plates 5, the ball screw nut 8 is installed on the lead screw 3, the bearing 12 is connected under the sliding seat 2 throug...

Embodiment 2

[0042] see figure 1 , 3 , 7, 9-11, the rotor assembly includes a motor magnet 9 and a motor rotor 16, the motor magnet 9 is pasted on the outer ring of the motor rotor 16, and the ball screw nut 8 is installed on the right side of the motor rotor 16, Other components and connection structures are the same as in Embodiment 1.

Embodiment 3

[0044] see figure 1 , 4 , 8-11, the bearing 12 is connected under the sliding seat 2 through the bearing support plate 13 and the bearing 12 is located outside the end of the ball screw nut 8 in the nut rotary ball screw, and other components and connection structures are the same Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com