A small-volume heavy-duty multi-stage electric cylinder

An electric cylinder, small volume technology, applied in electric components, transmission devices, electromechanical devices, etc., can solve the problems of large vertical launch, large impact on stage change, etc., and achieve increased axial rigidity, reduced volume, and enhanced bearing capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is described in further detail below in conjunction with accompanying drawing:

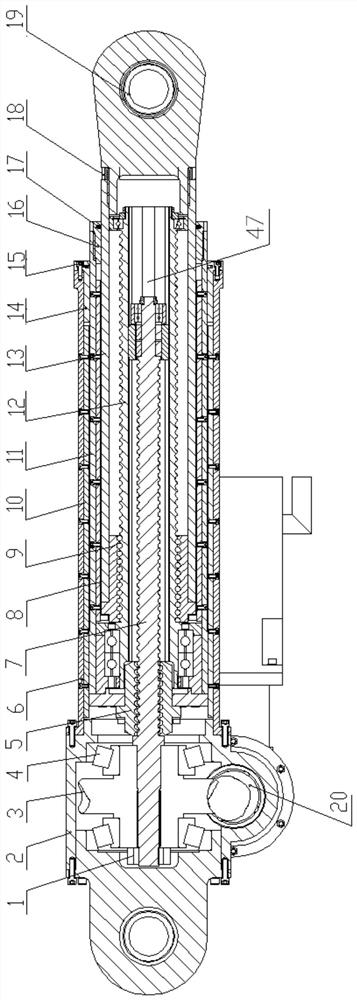

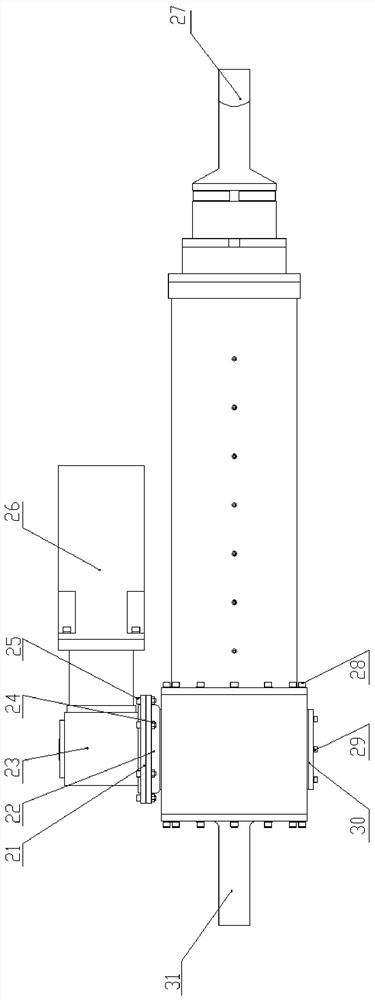

[0035] Such as Figure 1-4As shown, the electric cylinder body includes a planetary ball screw shaft 7, a hollow ball screw shaft 12, a guide rod 13, an inner support sleeve 11 and an outer support shell 6 coaxially nested sequentially from the inside to the outside, and the motor 26 passes through The planetary commutator 23 is connected with the worm 20 , the output shaft of the motor 26 is parallel to the planetary ball screw shaft 7 , and the worm 20 cooperates with it under the worm wheel 3 . The worm wheel 3 and the planetary ball screw shaft 7 are fastened and connected by threads, and are locked by the planetary ball screw end lock nut 1. The planetary ball screw end lock nut 1 is located at the position where the planetary ball screw shaft 7 passes through the worm wheel 3 one end. The planetary commutator 23 is connected through the adapter flange 21 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com