Improved pipe end beveling machine

A beveling machine and an improved technology, applied in the field of beveling machines, can solve the problems of inability to accurately process U-shape, insufficient processing stability, small configuration and engineering quantity, etc., to improve processing stability and increase the processing range of pipe diameter. , Good anti-loosening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

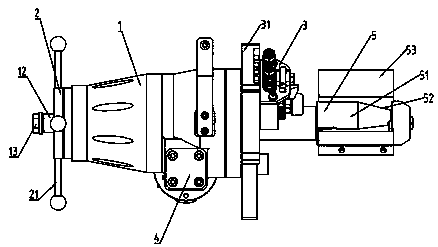

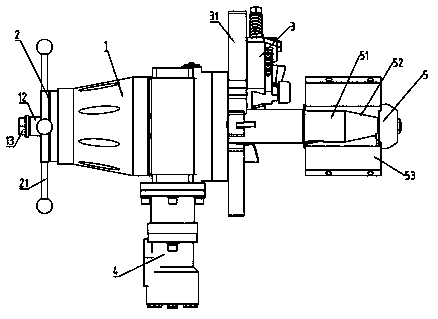

[0026] Example: According to Figure 1-4 It can be seen that an improved pipe end beveling machine includes a main shaft part 1, a feed part 2 is provided at one end of the main shaft part 1, a tie rod shaft 11 runs through the main shaft part 1, and a tie rod shaft 11 is sleeved on the main shaft part 1. Gripper shaft 12, a jaw nut 13 is installed at the tail end of the jaw shaft 12, a tapered roller bearing 14 is provided inside the main shaft part 1, and a processing cutterhead that can rotate relatively is provided at the other end of the main shaft part 1 Part 3, the hydraulic drive part 4 for driving the processing cutter head part 3 is provided under the main shaft part 1, and the other end of the pull rod shaft 11 is connected with a jaw part 5; The connecting sleeve 51 on the pull rod shaft 11, the connecting sleeve 51 is provided with an inclination angle 52, the connecting sleeve 51 is equipped with a jaw member 53, and the clamping jaw member 53 is threadedly conne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com