Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Same stiffness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

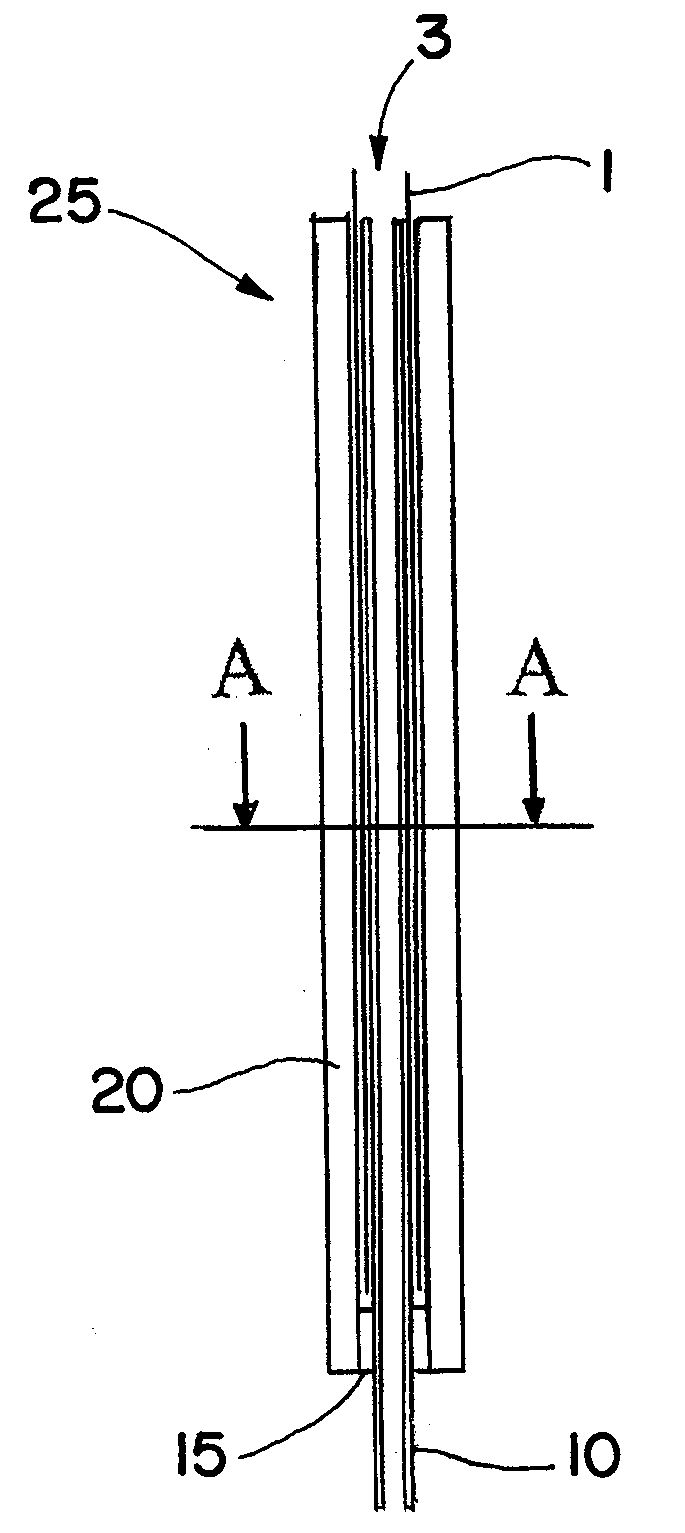

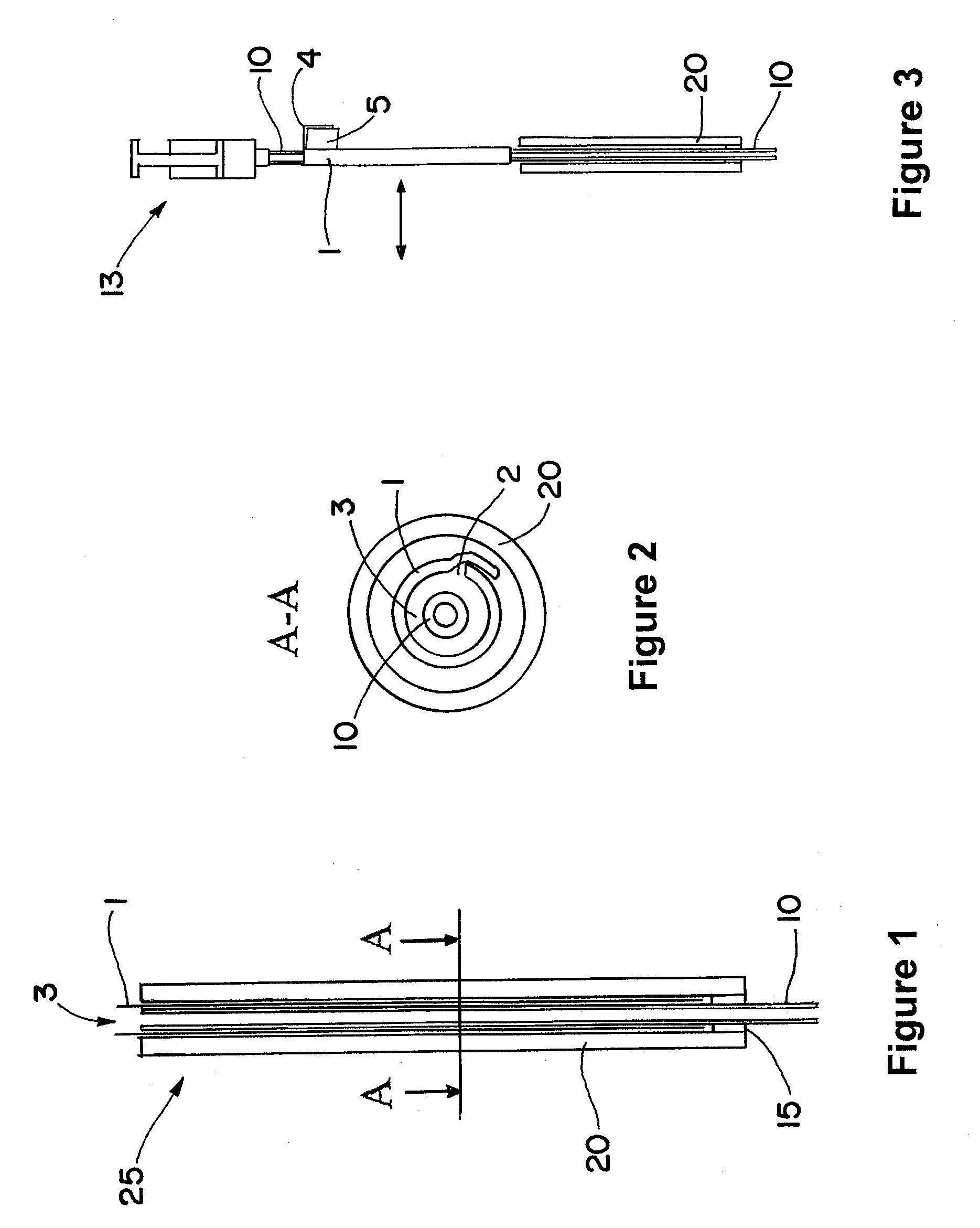

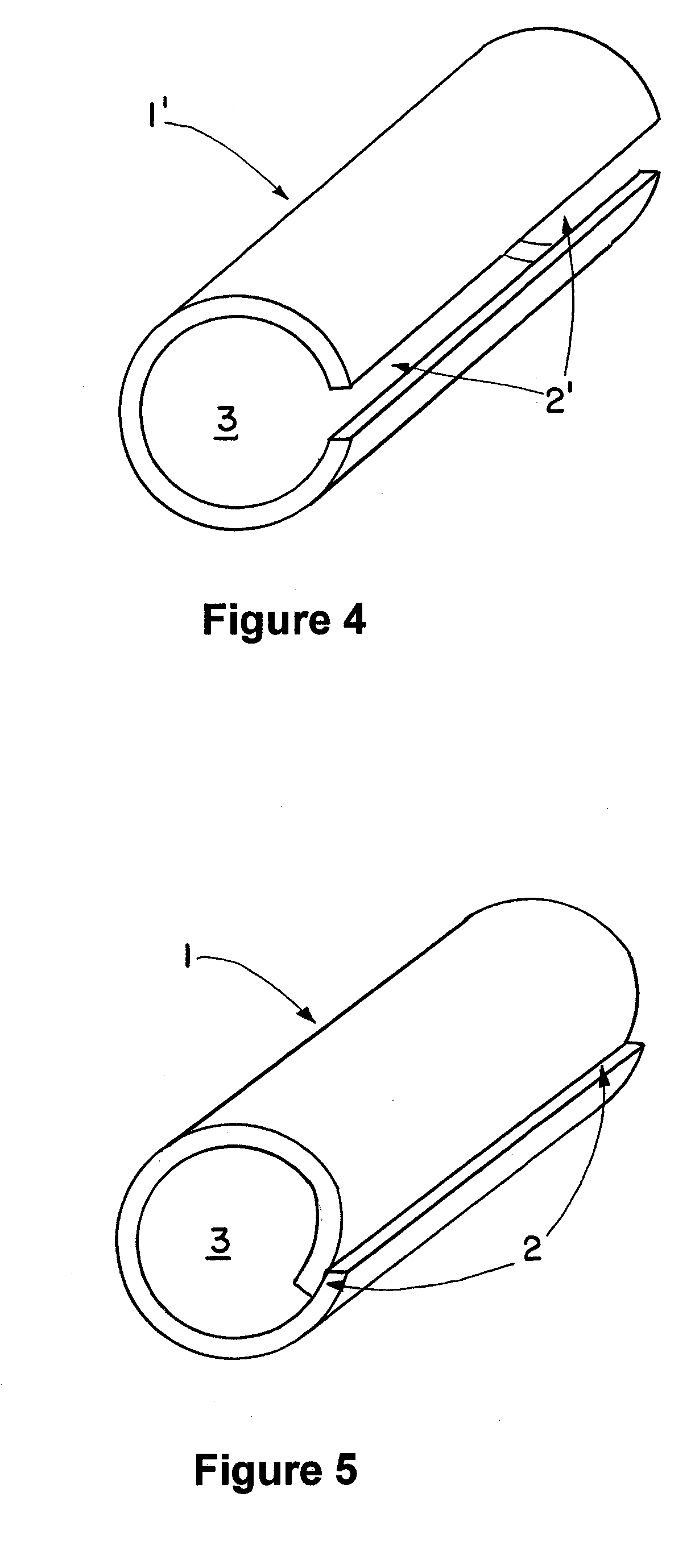

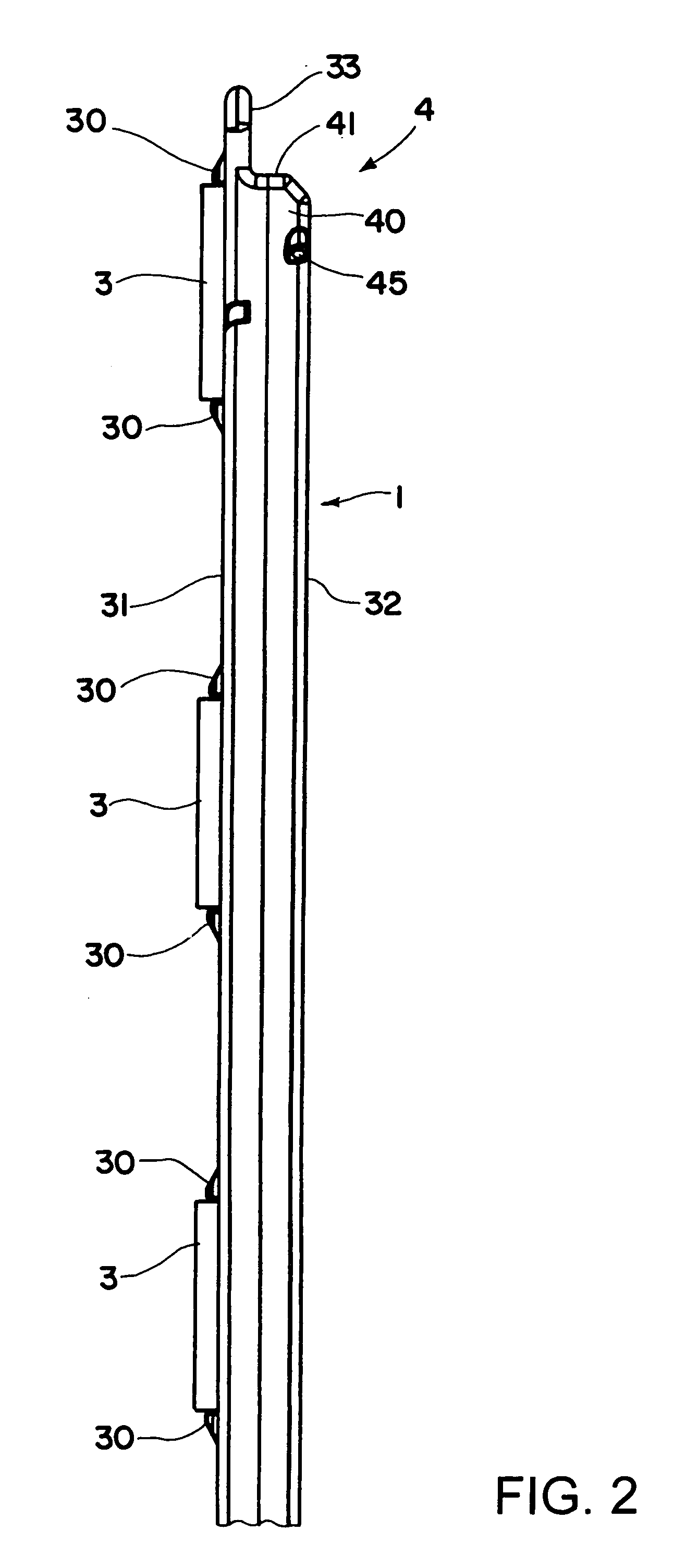

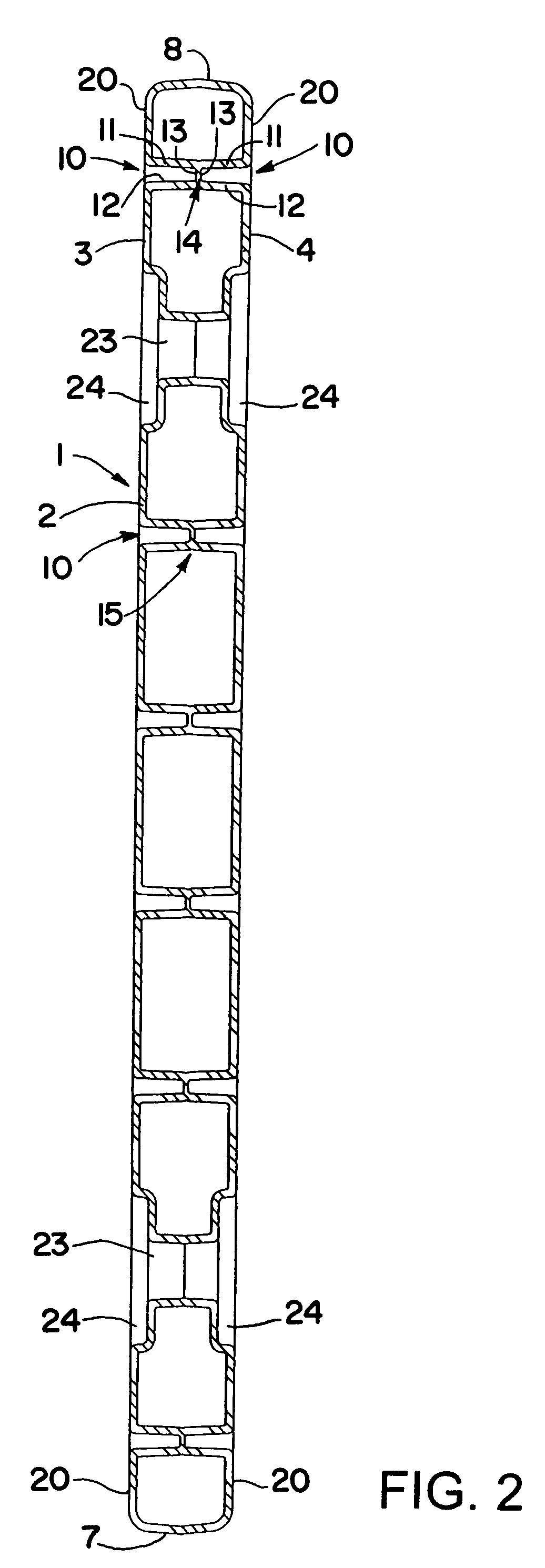

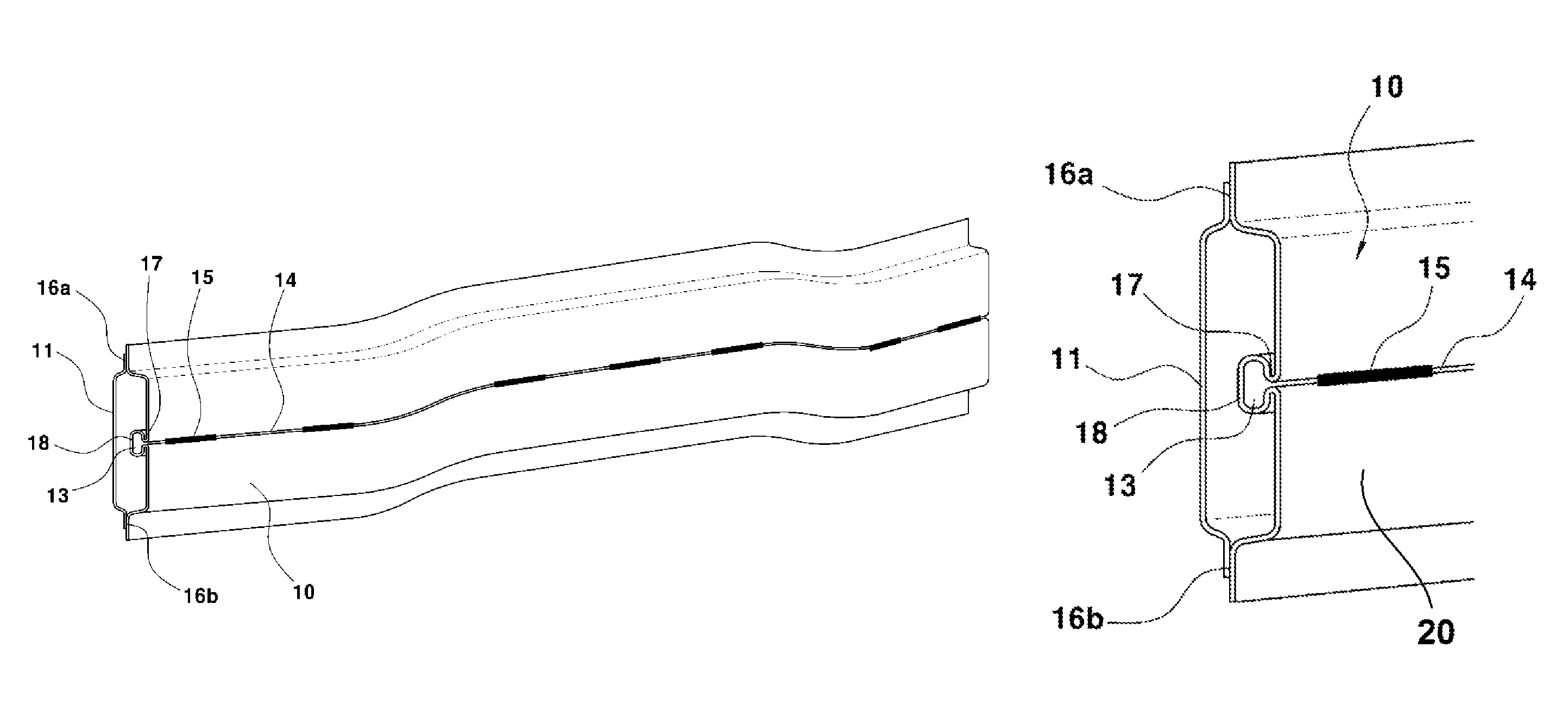

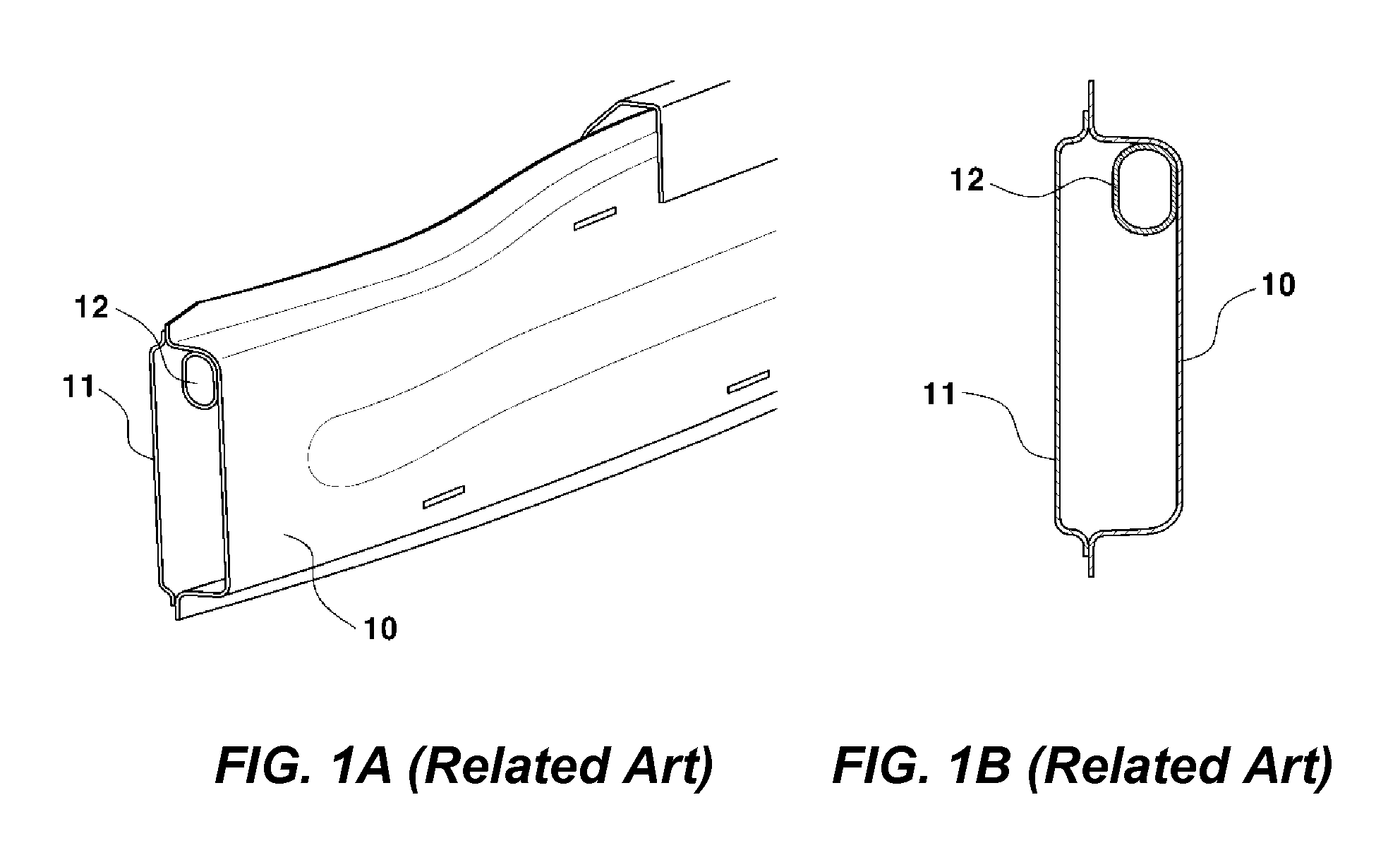

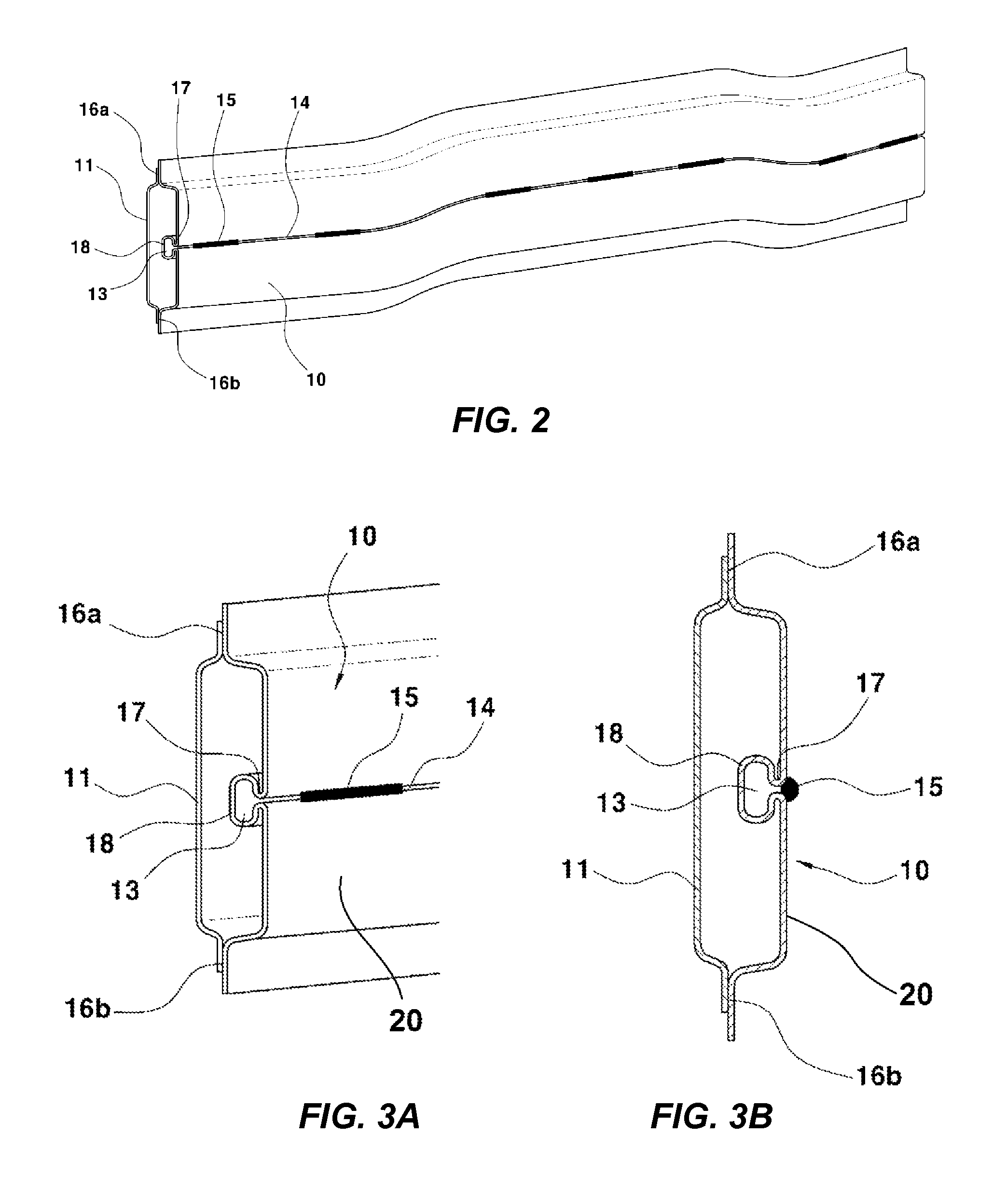

Catheter stylet with catheter accommodating lumen

ActiveUS20090143736A1Simplify manipulationEasy to placeEar treatmentInfusion syringesCatheter styletCatheter device

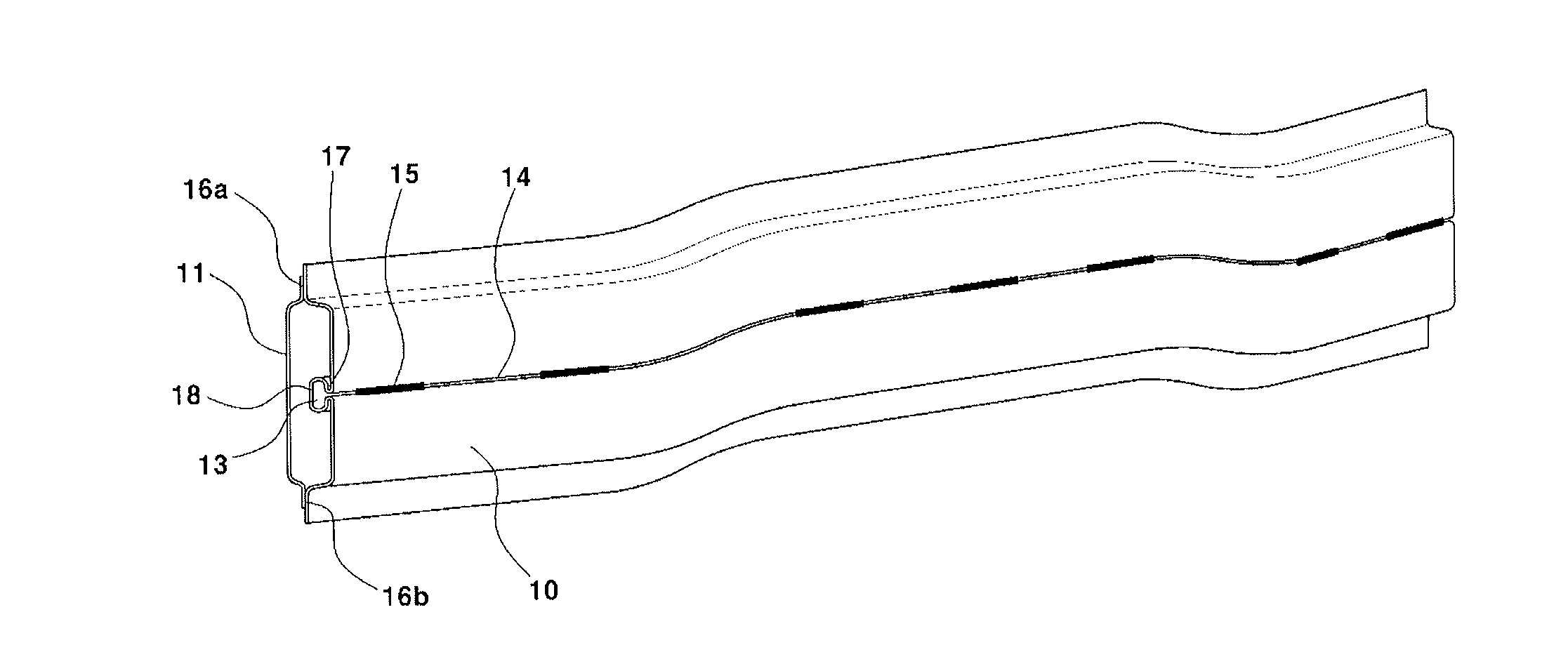

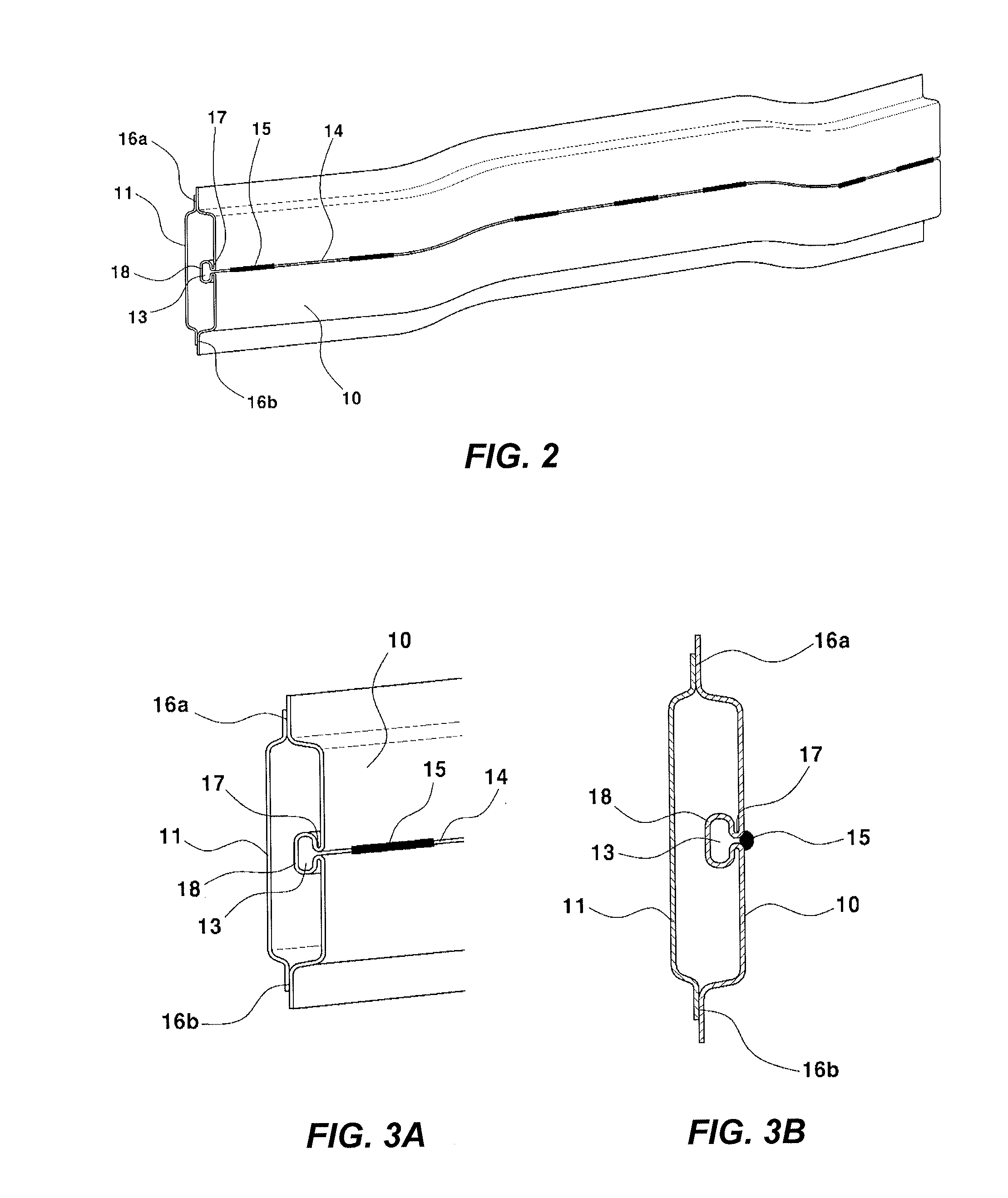

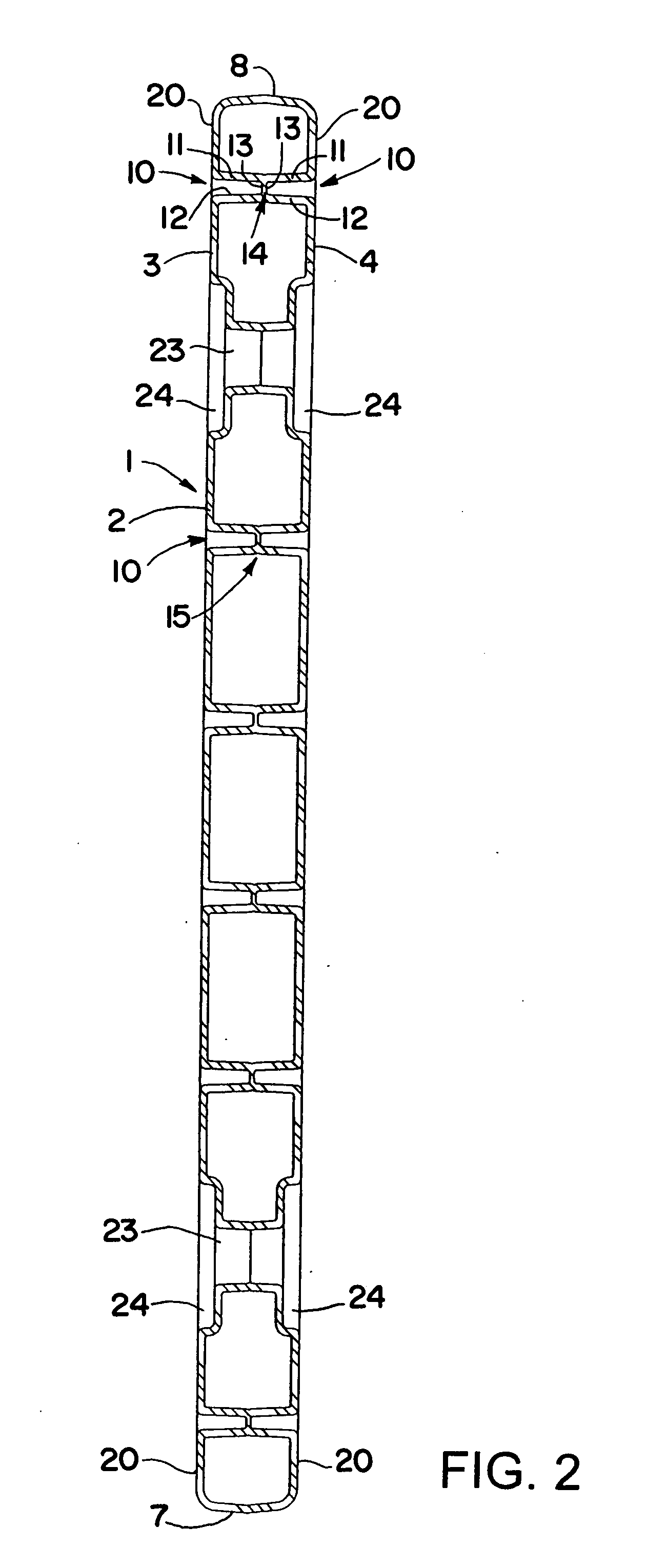

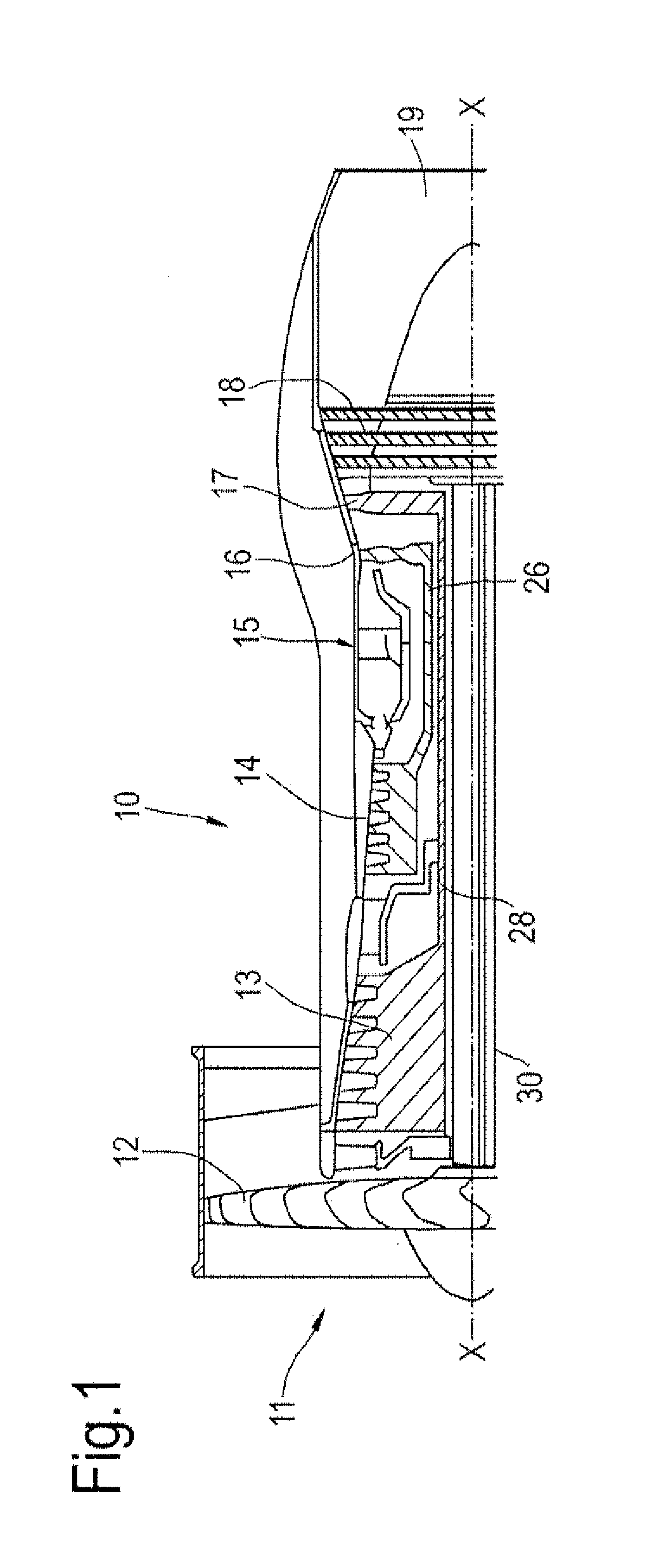

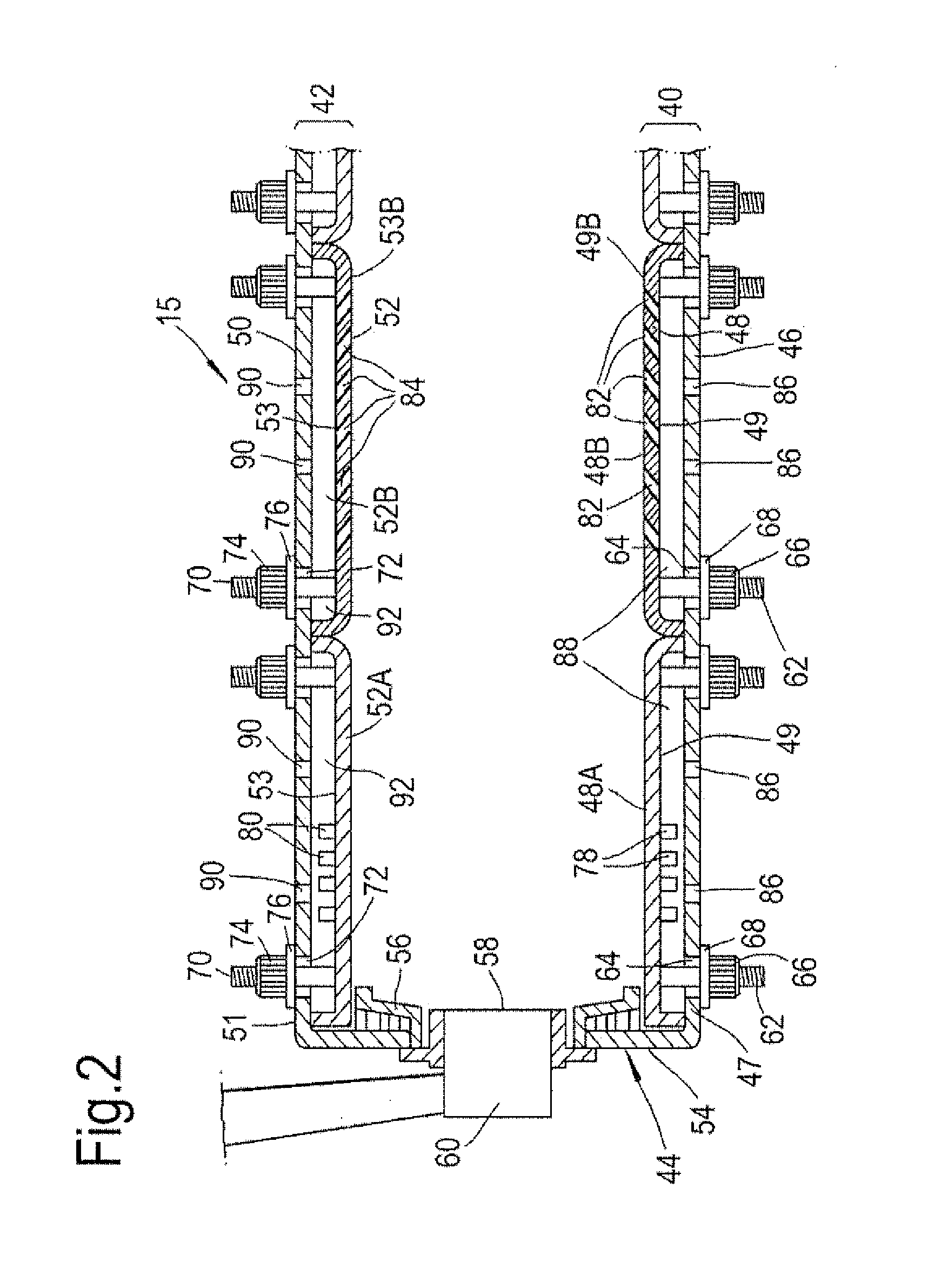

The invention relates to a catheter stylet for stiffening a catheter during the placing process, wherein the stylet comprises an accommodating lumen for at least one fluid-guiding line of the catheter. It also relates to a catheter stylet catheter system, comprising such a stylet and comprising a catheter which comprises a fluid-guiding line, and to a method for stiffening a catheter during the placing process, wherein a stylet which comprises an accommodating lumen is arranged around at least one fluid-guiding line of the catheter.

Owner:BRAINLAB

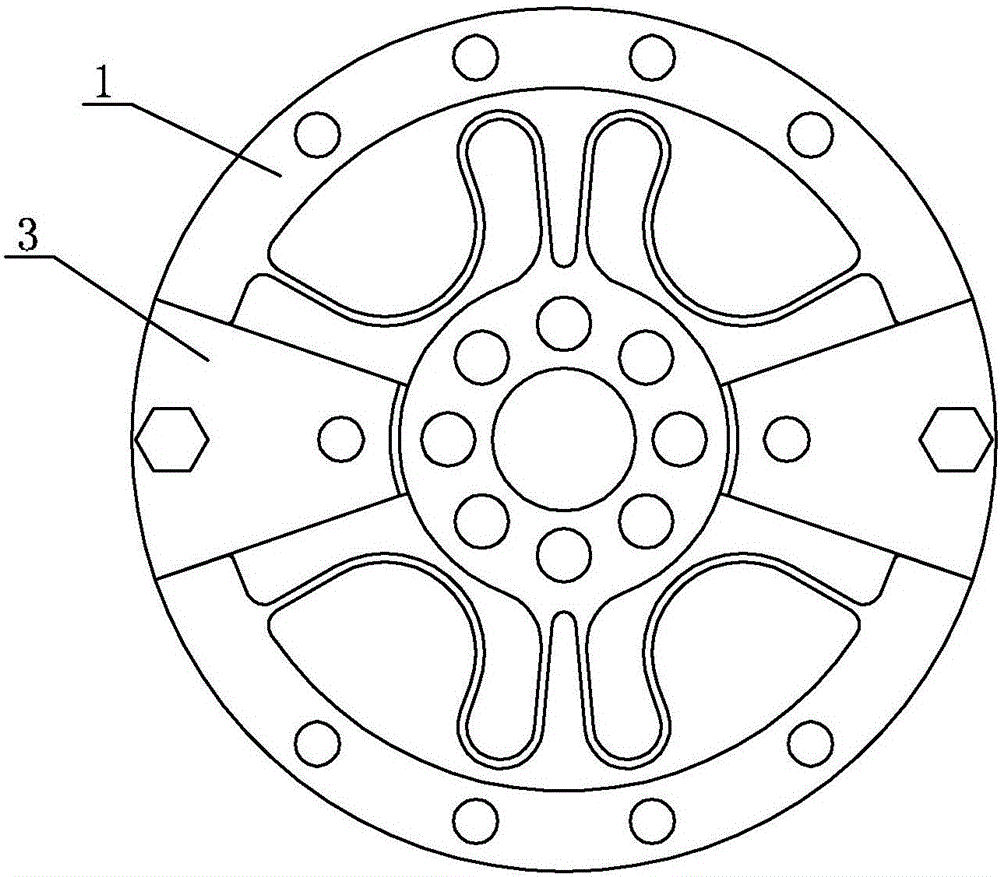

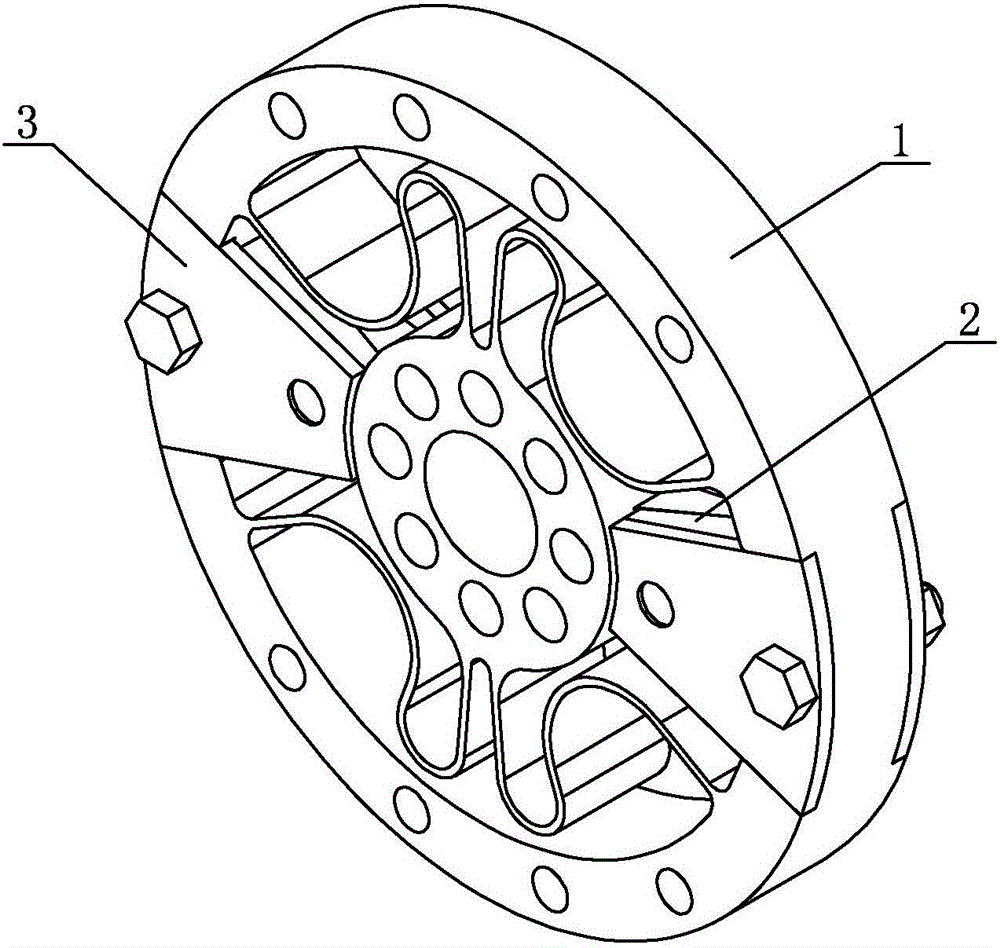

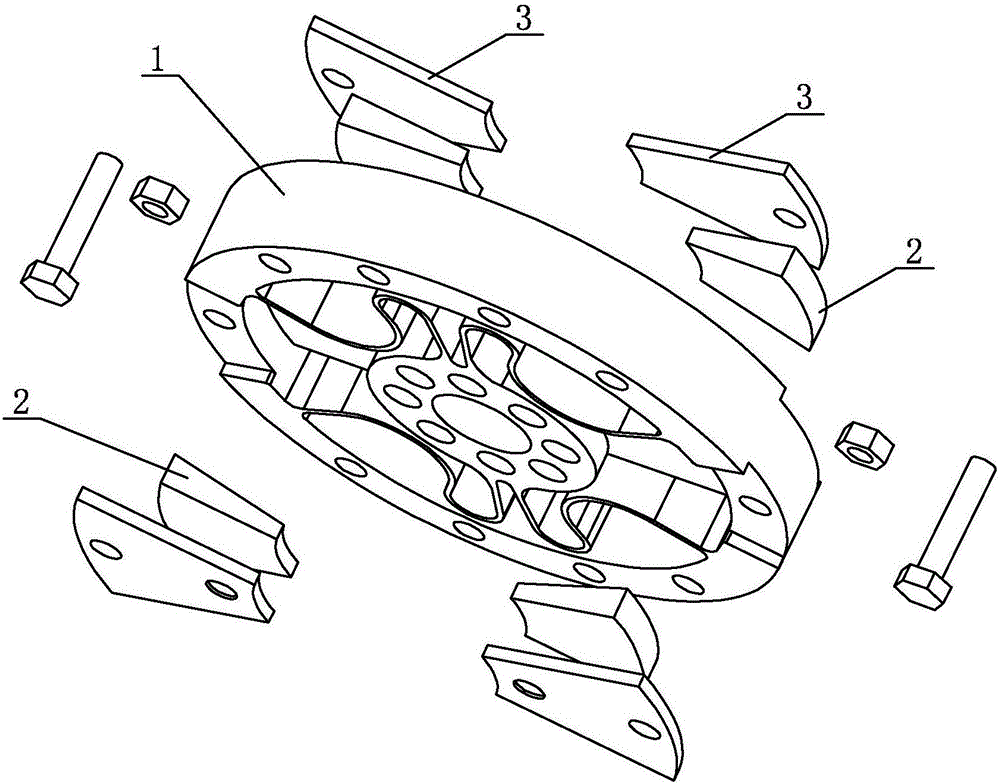

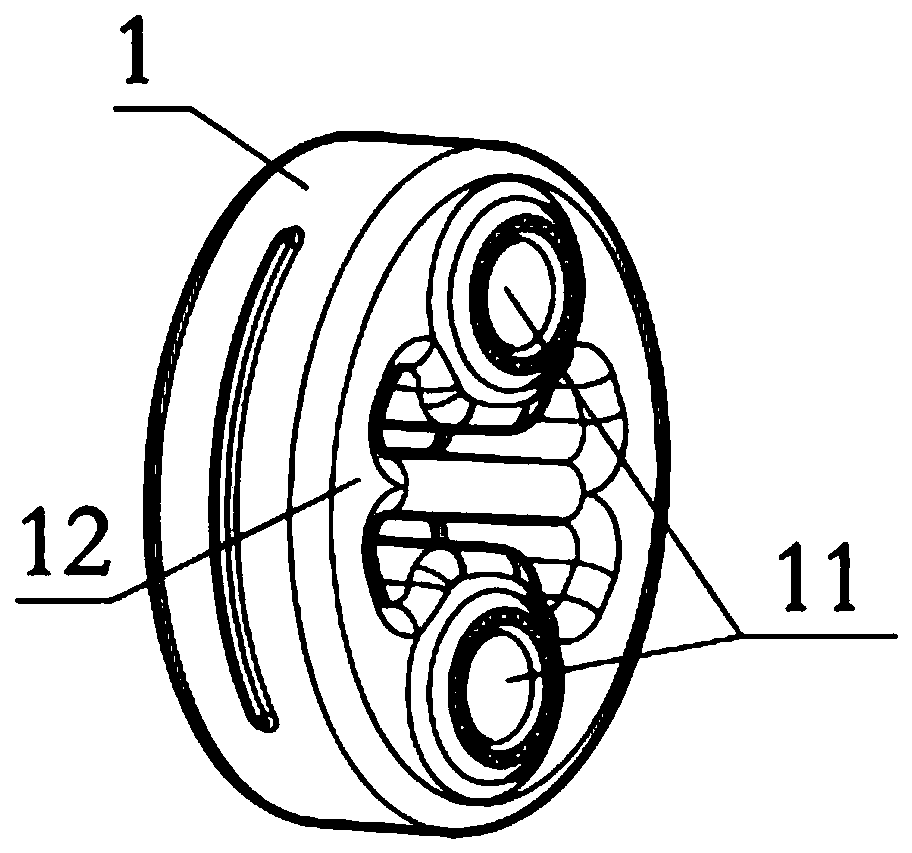

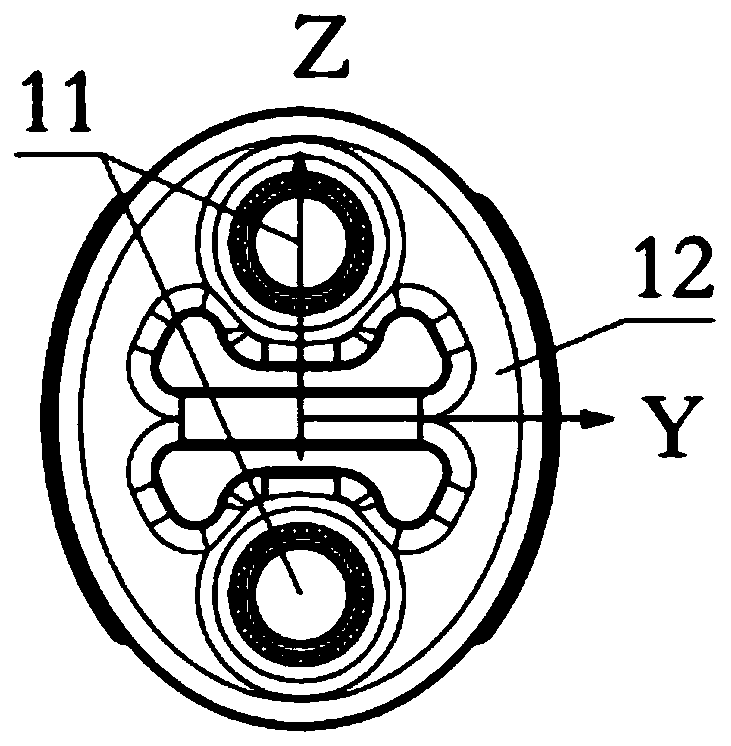

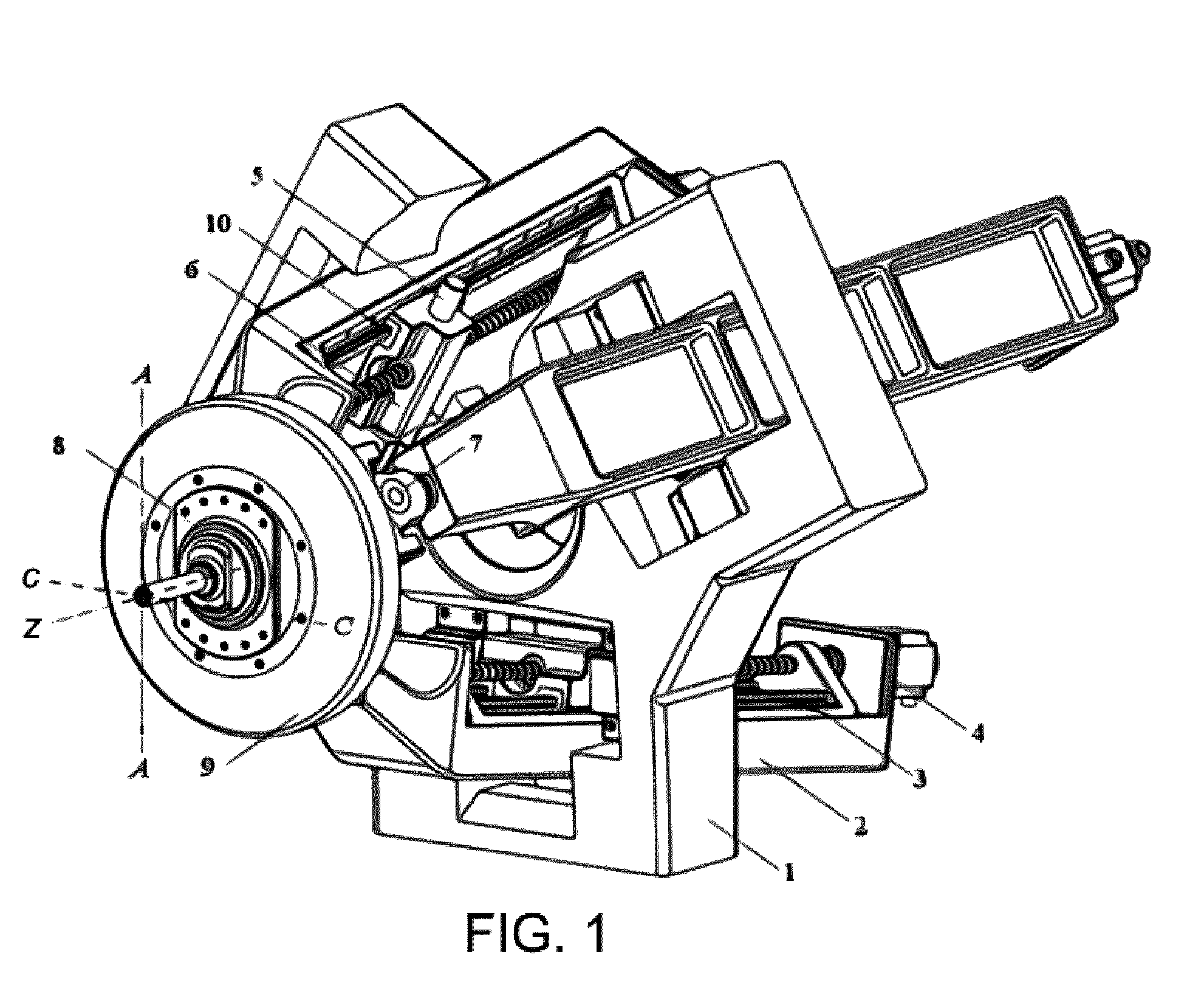

Passive vibration absorption elastic component for flexible robot joints

ActiveCN106272555AReduce vibrationWith fully passive vibration dampingJointsSemi activeElastic component

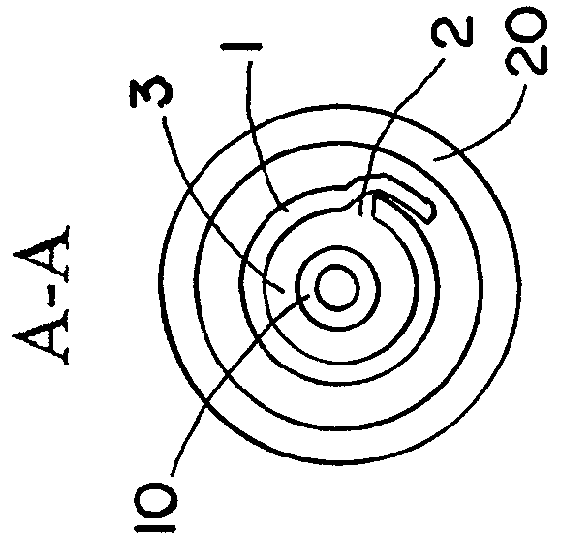

The invention discloses a passive vibration absorption elastic component for flexible robot joints, aiming at solving the problems of poor reliability, big size and complex structures of the existing active or semi-active vibration absorption methods for restraining robot vibration. An outer ring rigid body and an inner ring rigid body of the passive vibration absorption elastic component are coaxially arranged, two flexible bodies and two sector-shaped rigid pieces are arranged between the outer ring rigid body and the inner ring rigid body, the two sector-shaped rigid pieces are symmetrically arranged at the left end and the right end of the inner ring rigid body, and the internal diameter of each sector-shaped rigid piece is fixedly connected with the inner ring rigid body; the two flexible bodies are symmetrically arranged at the upper end and the lower end of the inner ring rigid body, the edge of a protruding side of each concave-convex curve rigid piece is fixedly connected with the inner ring rigid body, and the edge of a pit side of each concave-convex curve rigid piece is fixedly connected with the outer ring rigid body. A sector-shaped metal connection board is arranged in each sector-shaped slot, a sector-shaped rubber board is arranged between each of the sector-shaped metal connection boards and each of the sector-shaped rigid pieces, and the sector-shaped metal connection boards and the outer ring rigid body are connected through a connection component. The passive vibration absorption elastic component is applied to the flexible robot joints.

Owner:HARBIN INST OF TECH

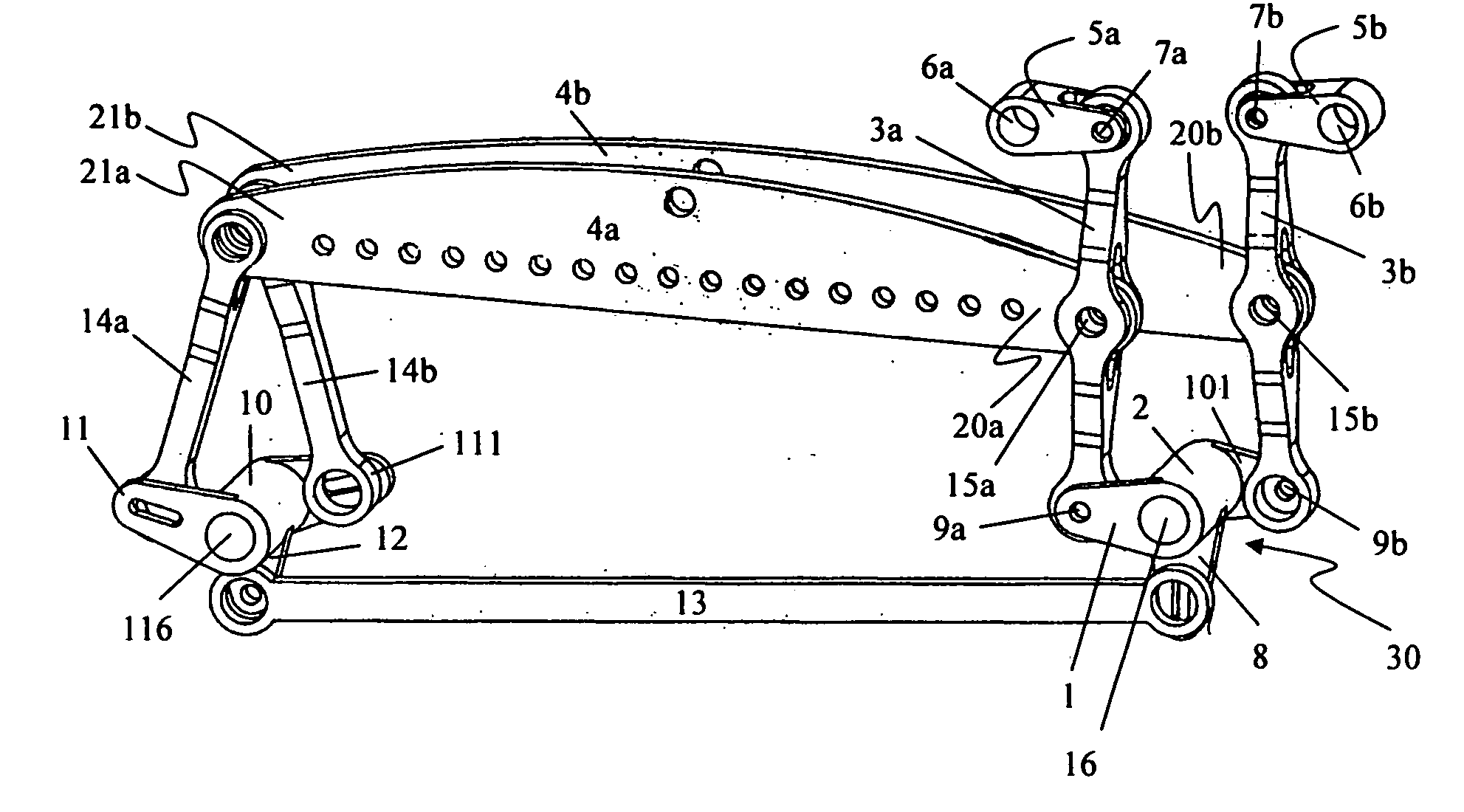

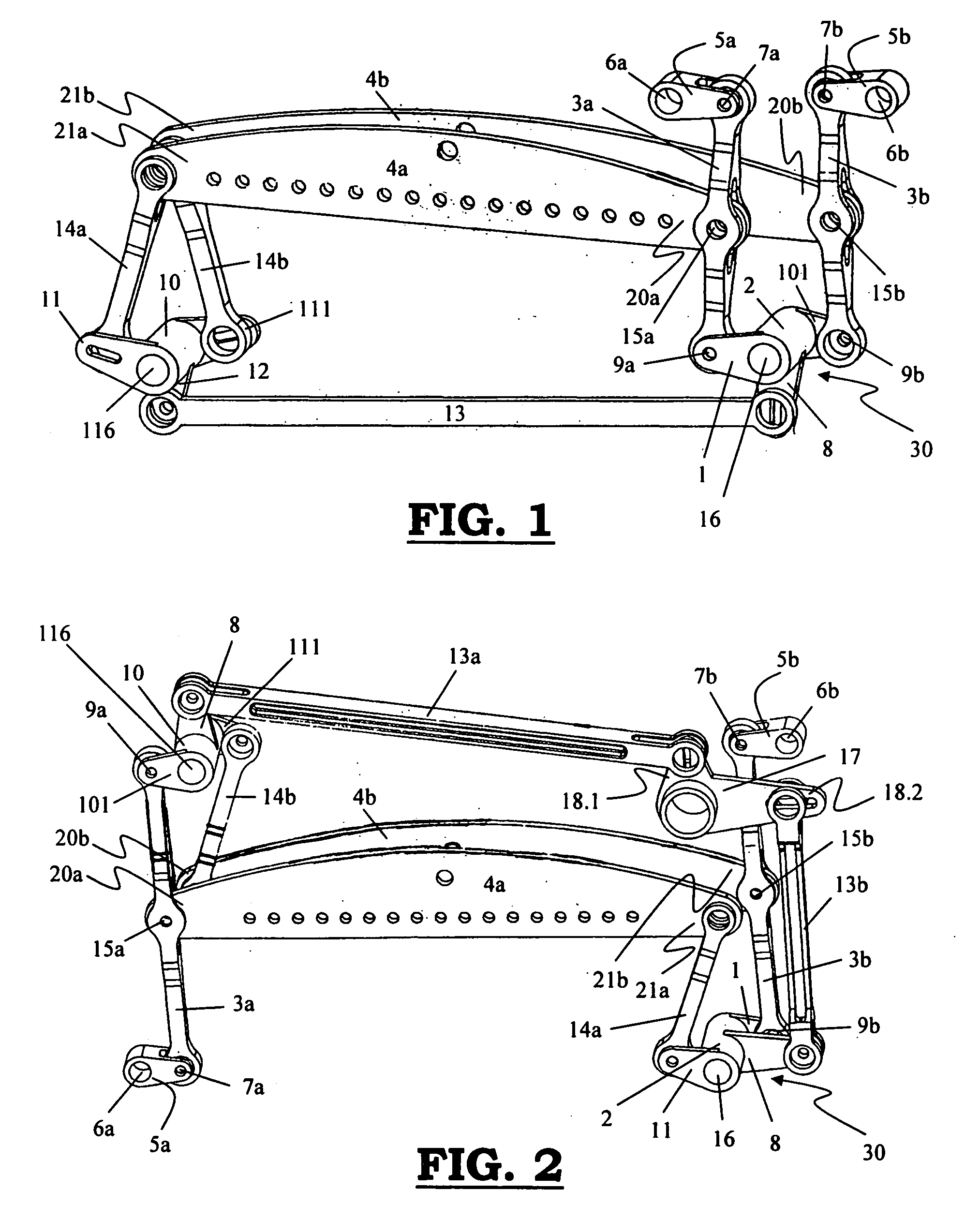

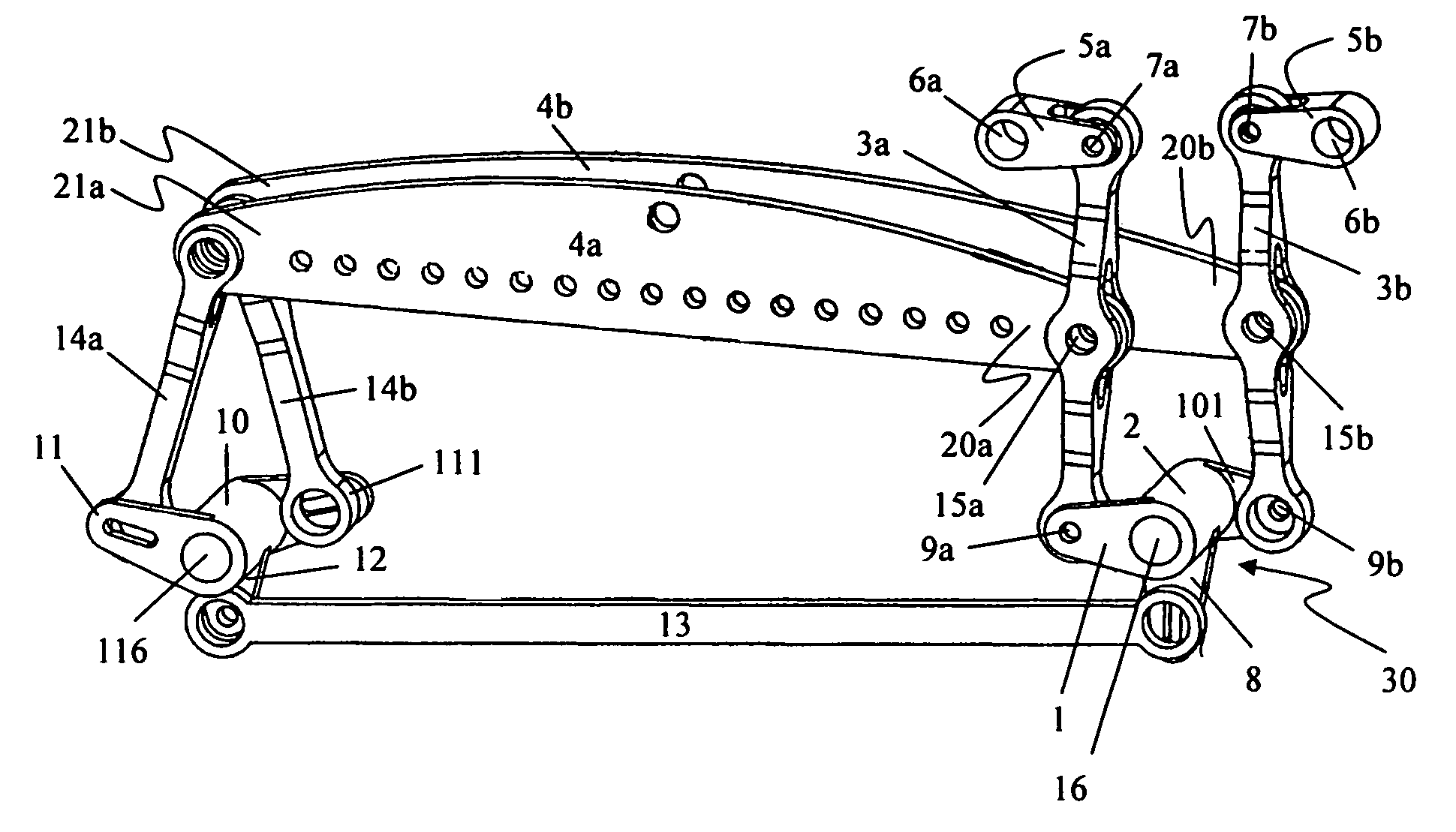

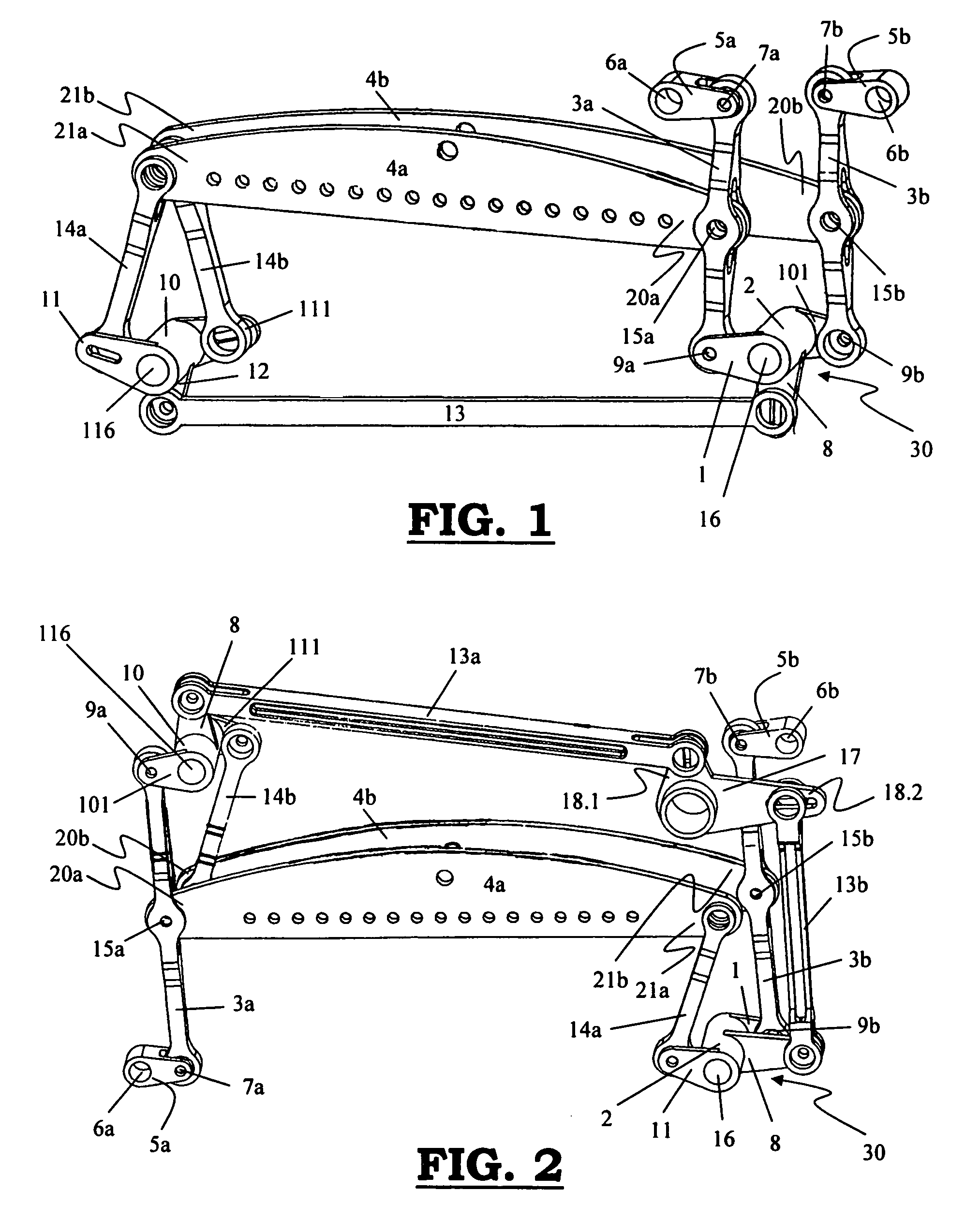

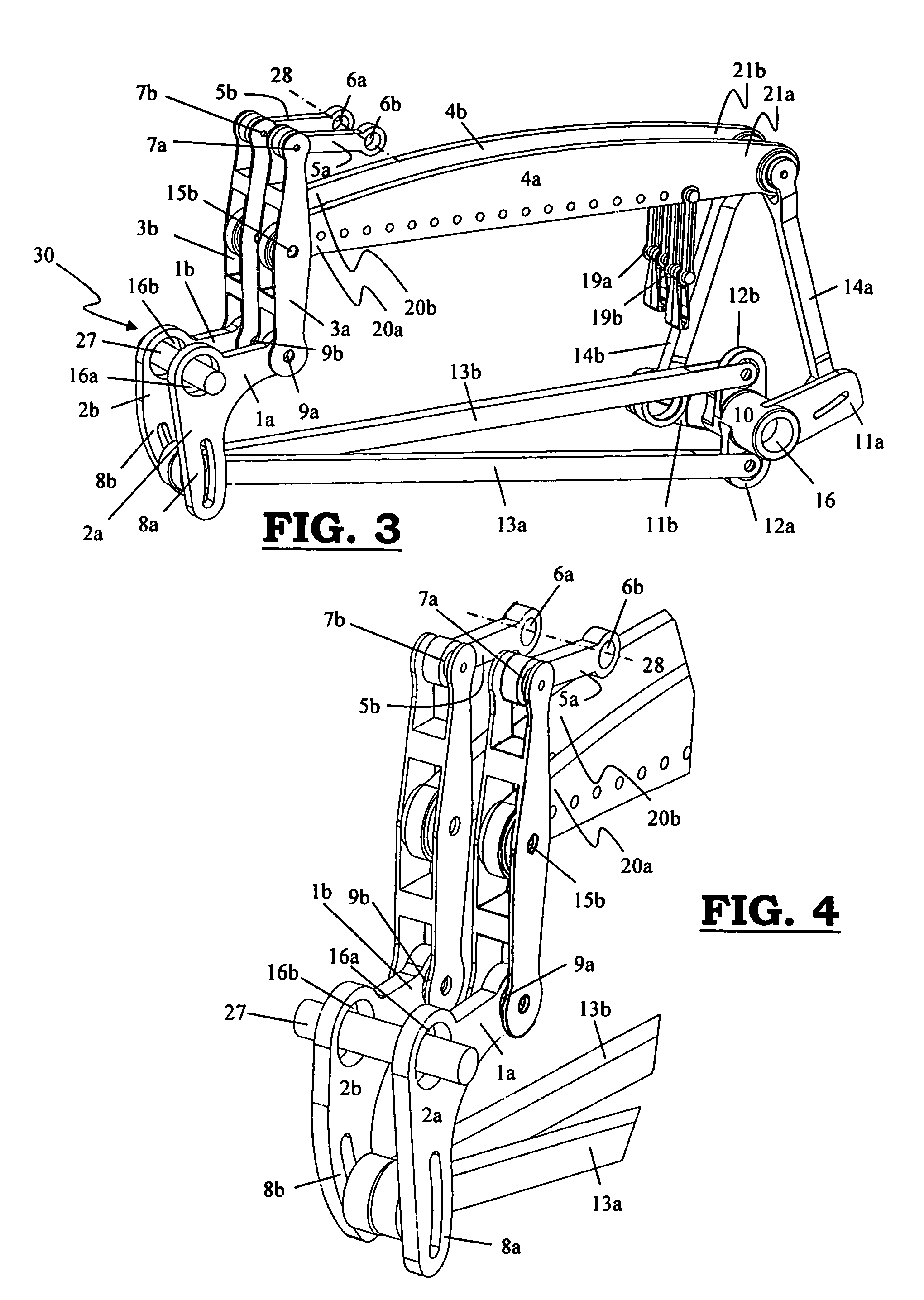

Jacquard machine

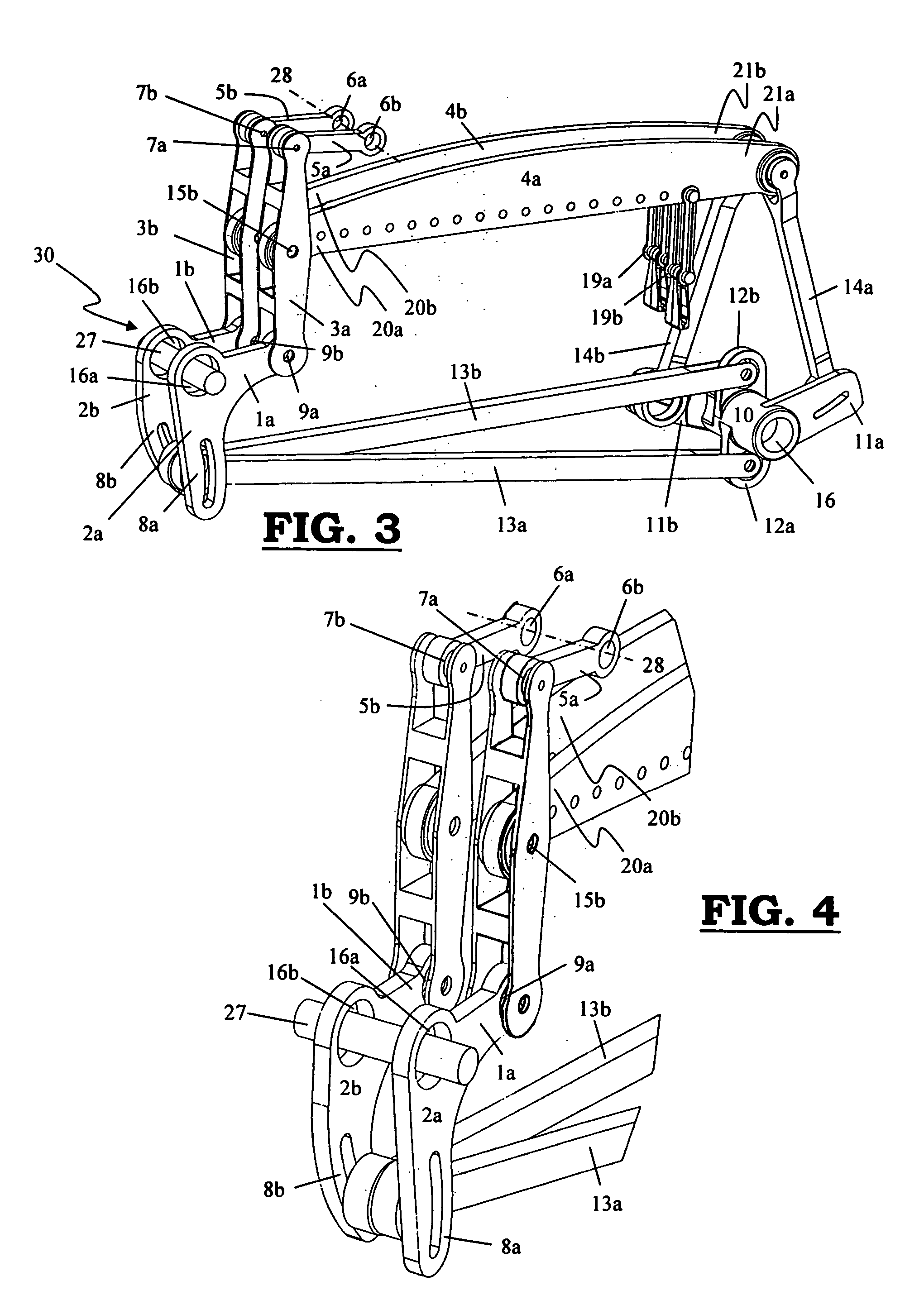

The invention relates to a Jacquard machine, comprising 2 sets of knifes moving up and down in opposition, which each, at each of their extremities, are taken up in separate knife grids (4a, 4b) being driven by a cinematic drive chain (30), and each, at one of their extremities (20a, 20b), being guided into a straight motion by means of a “Watt's linkage” rod system, the height of lift of each of these extremities (20a, 20b) of the knife grids (4a, 4b) being adjustable, and the knife grids (4a, 4b) each at their first extremities (20a, 20b) being linked with at least one first driving lever (2, 2a, 2b, 10) by means of a first linking rod (3a, 3b), and at their second extremities (21a, 21b) being linked with at least a second driving lever (2, 10) by means of a second linking rod (14a, 14b), wherein per knife grid (4a, 4b) one or several elements (1, 101, 1a, 1b, 3a, 3b) of the Watt's linkage rod system are part of the cinematic drive chain (30), and the amplitude of the motion of the said extremity (20a, 20b) of the knife grid (4a, 4b) is adjustable in the cinematic drive chain (30) before the linking point (9a, 9b) between the first rod (1, 101, 1a, 1b) and the third rod (3a, 3b) of the Watt's linkage rod system with respect to the drive motor.

Owner:VAN DE WIELE MICHEL

Laminates comprising a low temperature heat sealable layer containing poly(trimethylene succinate) or poly(trimethylene terephthalate-co-succinate)

InactiveUS20140363546A1Improve performanceStiffnessDomestic containersGlass/slag layered productsPolyethylene terephthalatePolytrimethylene terephthalate

The present invention relates to laminates comprising at least one structural layer and a heat sealable layer, wherein the heat sealable layer comprises or is produced from polytrimethylene succinate, poly(trimethylene terephthalate-co-succinate), or blends thereof. This invention also relates to packages comprising the laminates, said package is heat sealable at a heat sealing temperature below 100° C. to provide a heat sealing strength of 10 N / 15 mm or higher.

Owner:EI DU PONT DE NEMOURS & CO

Method for manufacturing light bullet-proof glass

InactiveCN101961943AHigh penetration resistanceImprove impact resistanceLamination ancillary operationsLaminationLight bulletBackplane

The invention relates to a method for manufacturing light bullet-proof glass. The method is characterized by comprising the following steps of: processing raw material glass sheets and organic glass plates into products with required specifications, cleaning and drying; sequentially laminating a panel glass sheet, a polyurethane film, an organic glass plate, a polyurethane film and a back plate glass sheet so as to obtain a combination material; putting the combination material on a flat press for pre-pressing; and feeding the pre-pressed combination material into a still kettle for steaming so as to obtain the light bullet-proof glass. The polyurethane film with high toughness and high penetration resistance and the organic glass plate replace a middle glass layer of the conventional bullet-proof glass, so that the impact resistance and penetration resistance of the glass are enhanced, the weight and thickness of the bullet-proof glass are reduced effectively, cost is lowered and the overall dead weight can be reduced by about 20 percent; simultaneously, the rigidity and intensity of the inner and outer sides of the bullet-proof glass are kept the same as those of the conventional bullet-proof glass.

Owner:JIANGSU HUIYU GLASS

Bumper rail for vehicle

InactiveUS20140138985A1Low costReduce weightVehicle seatsDashboardsMechanical engineeringEngineering

A bumper rail assembled into a bumper of a vehicle includes a bumper rail, a reinforcing member, and a forming part. A bumper rail is disposed at front. The reinforcing member is disposed at the rear side of the bumper rail and forming a closed section together with the bumper rail. The forming part is integrally formed at an inner side of the bumper rail and is disposed parallel along the longitudinal direction of the bumper rail to increase a stiffness of the bumper rail, the forming part having a pipe shape.

Owner:HYUNDAI MOTOR CO LTD

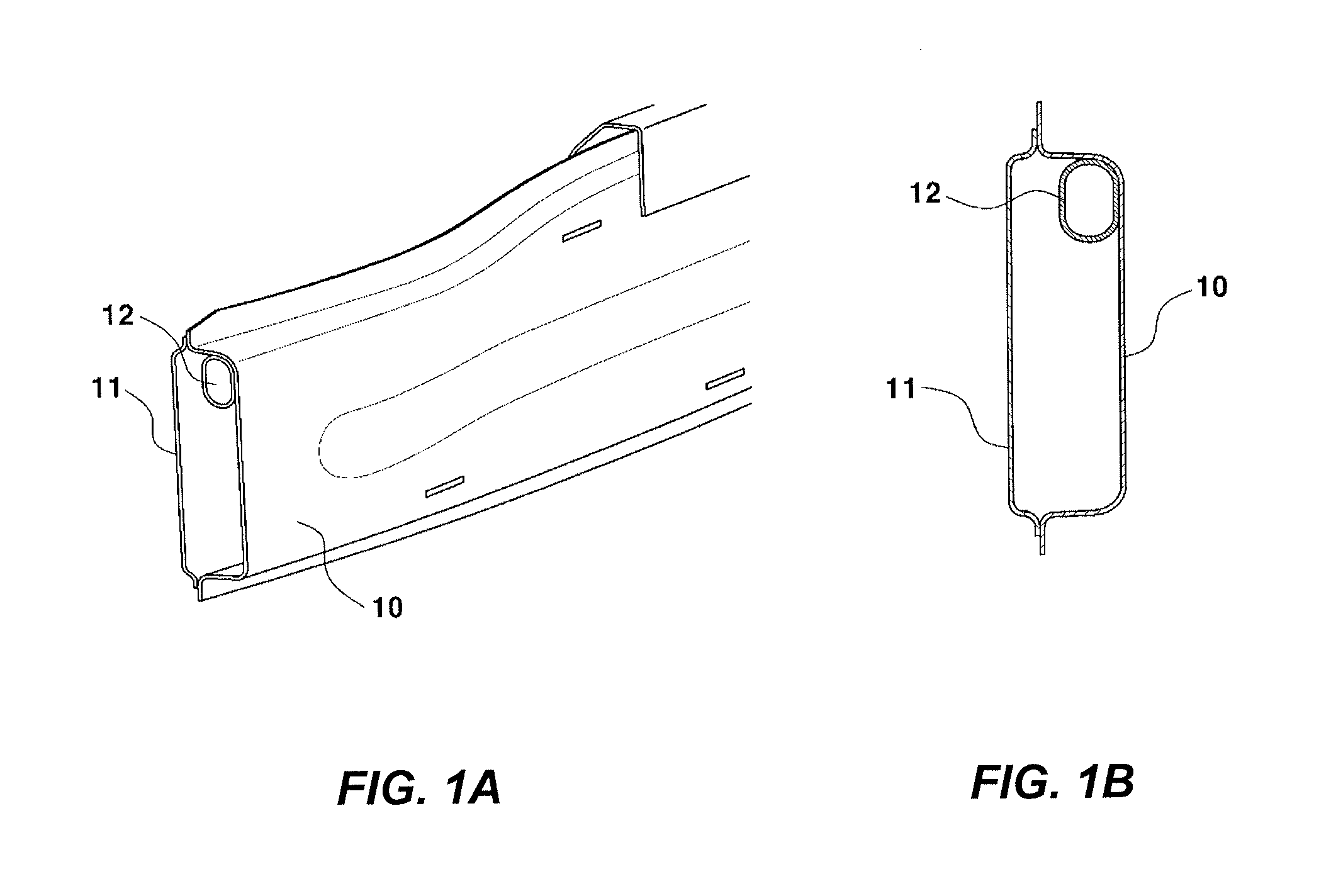

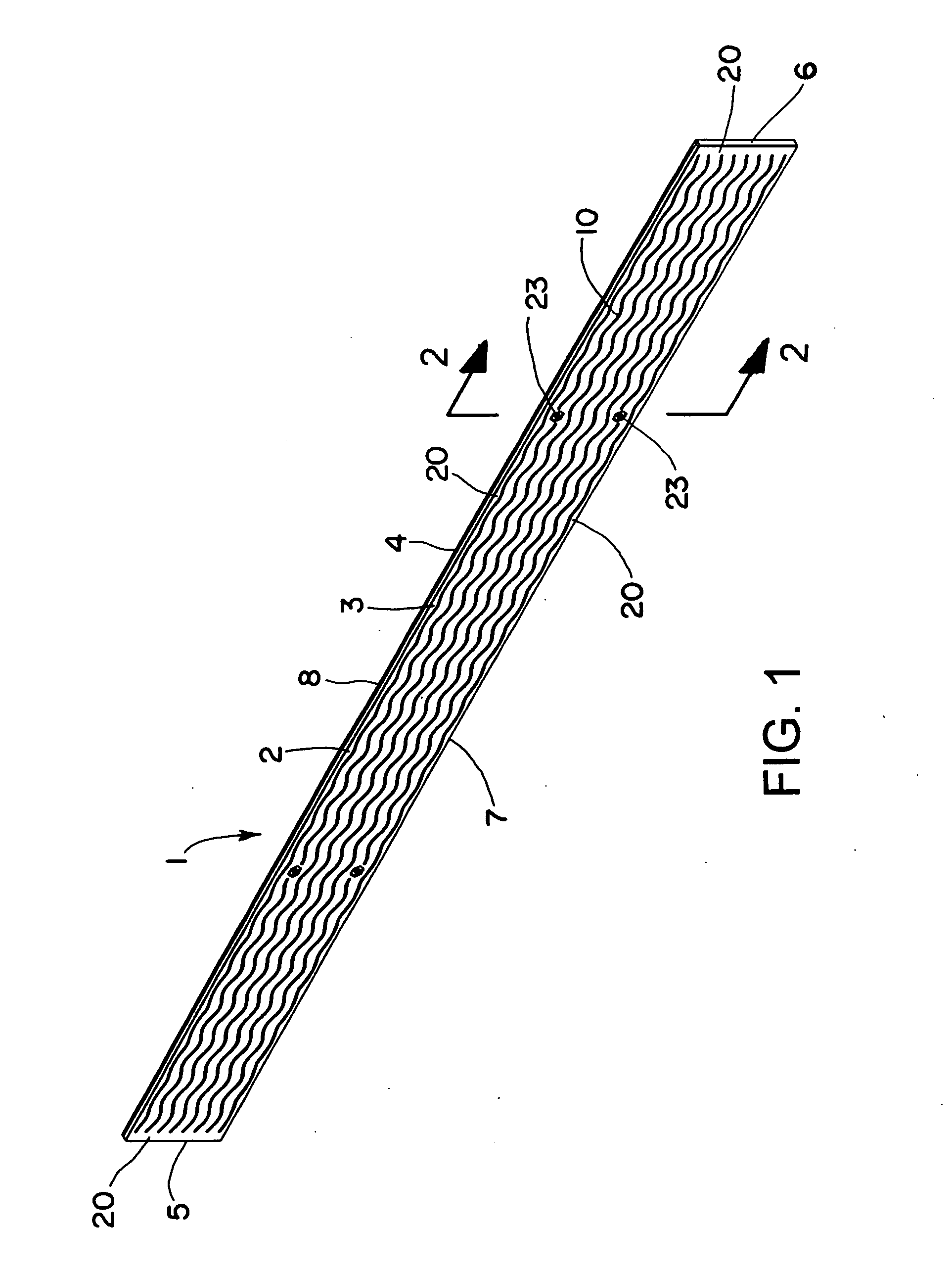

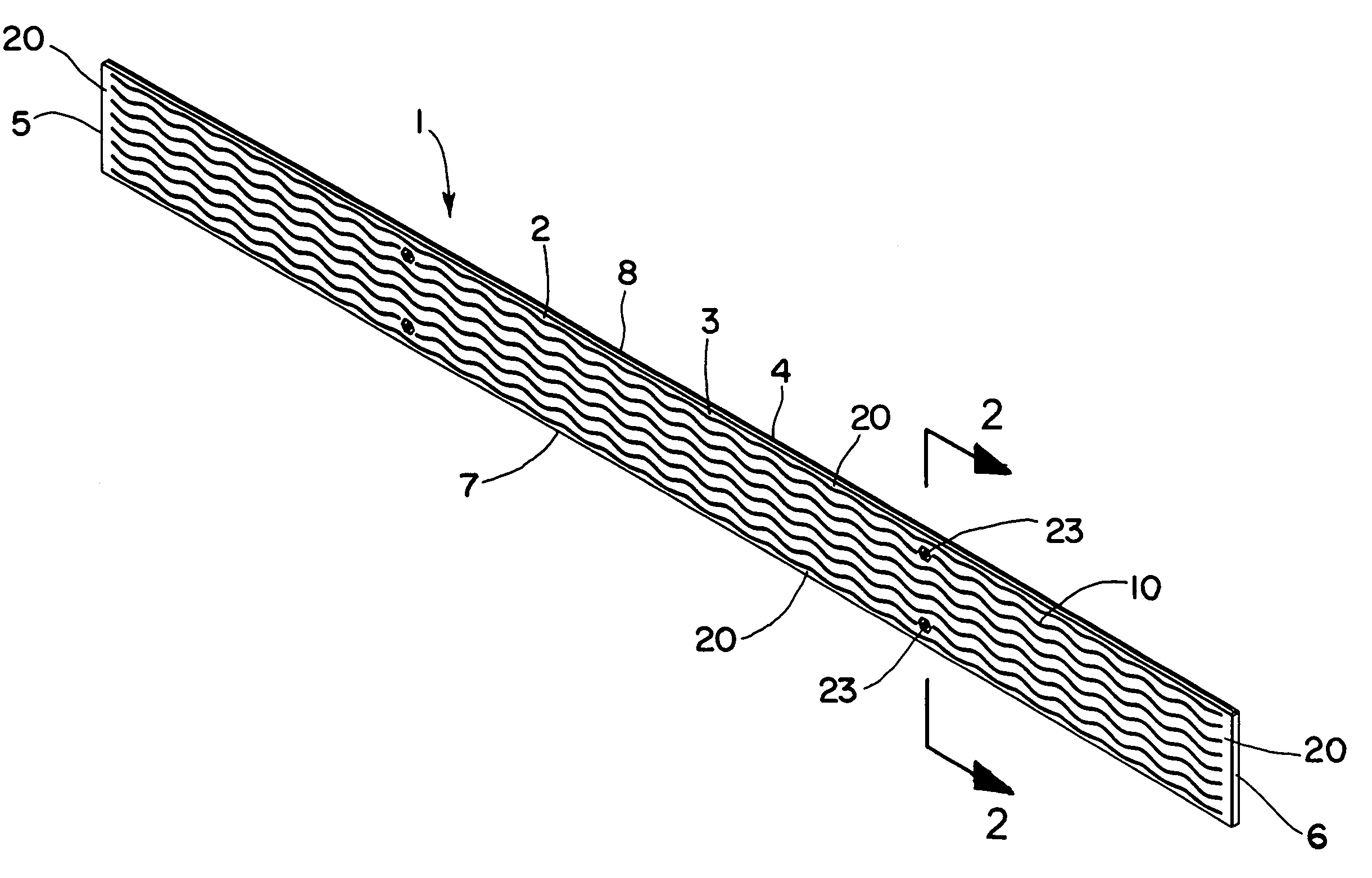

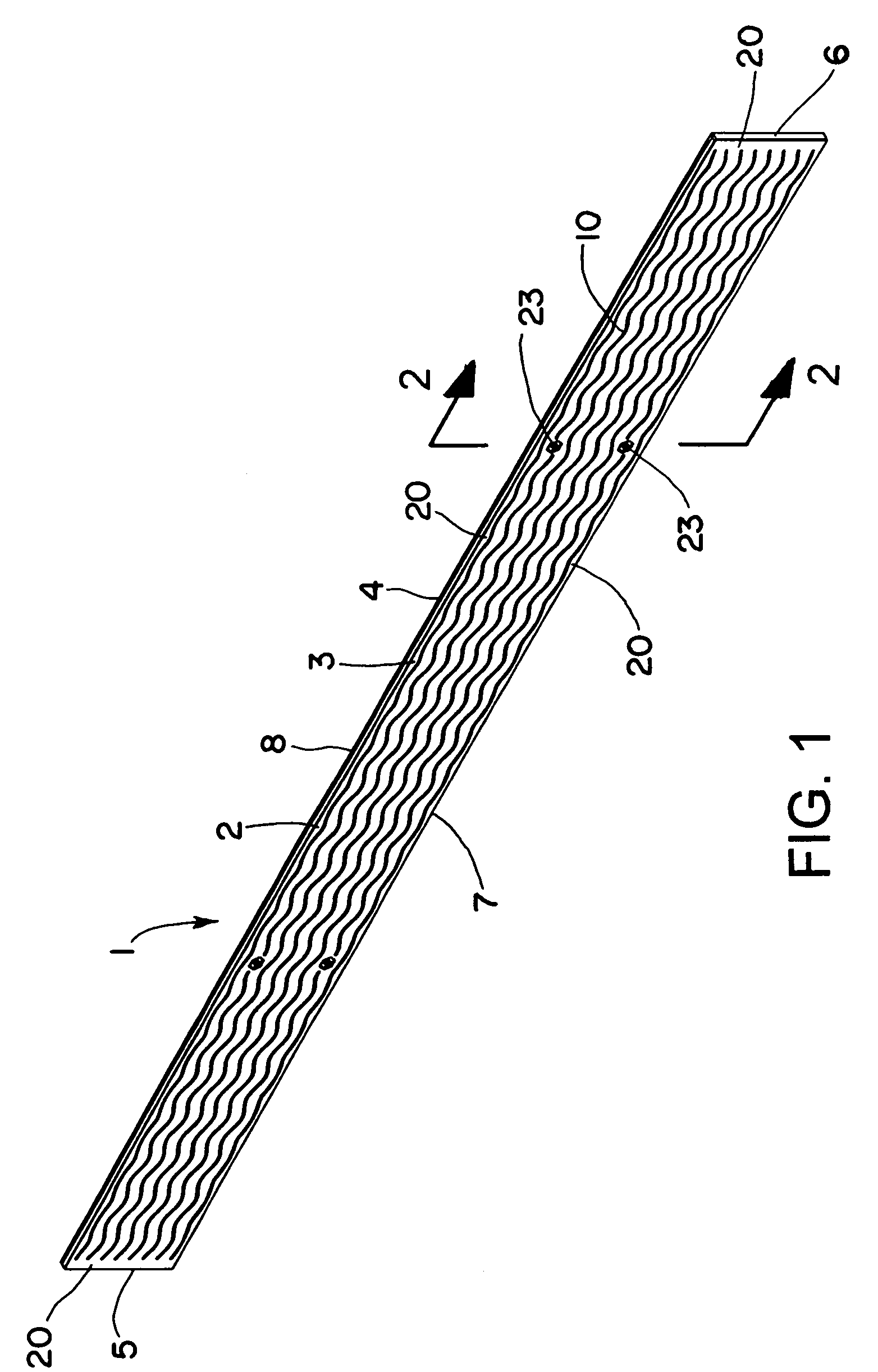

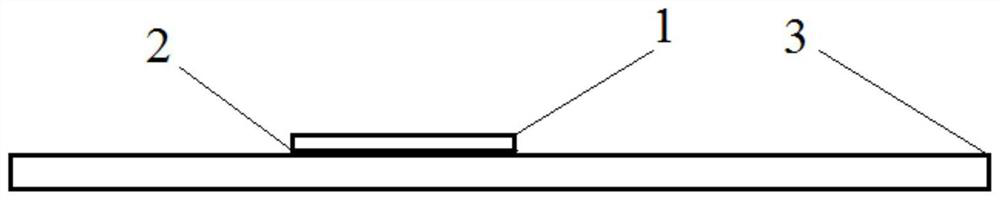

Plastic blow molded board-like members

Plastic blow molded board-like members include a plurality of longitudinally extending, laterally spaced aligned channels / grooves in opposite sides of the members. Each of the channels has closely spaced apart side walls and inner end walls. The inner end walls of aligned channels in opposite sides of the member are joined together to provide a relatively high strength reinforced core. The ends of the members are completely closed during the blow molding process for increased strength and to keep out dirt and moisture.

Owner:PLASTIC SAFETY SYST

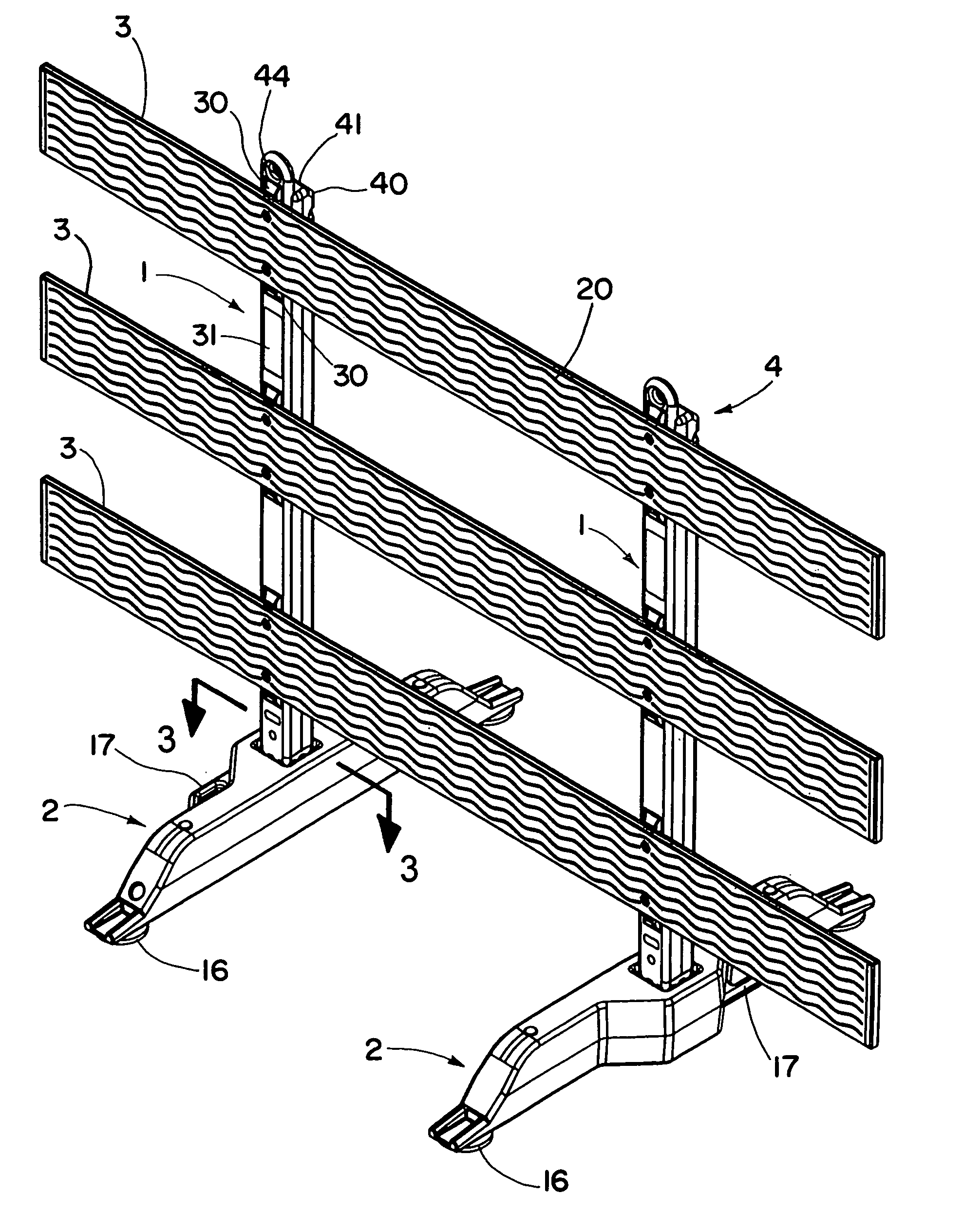

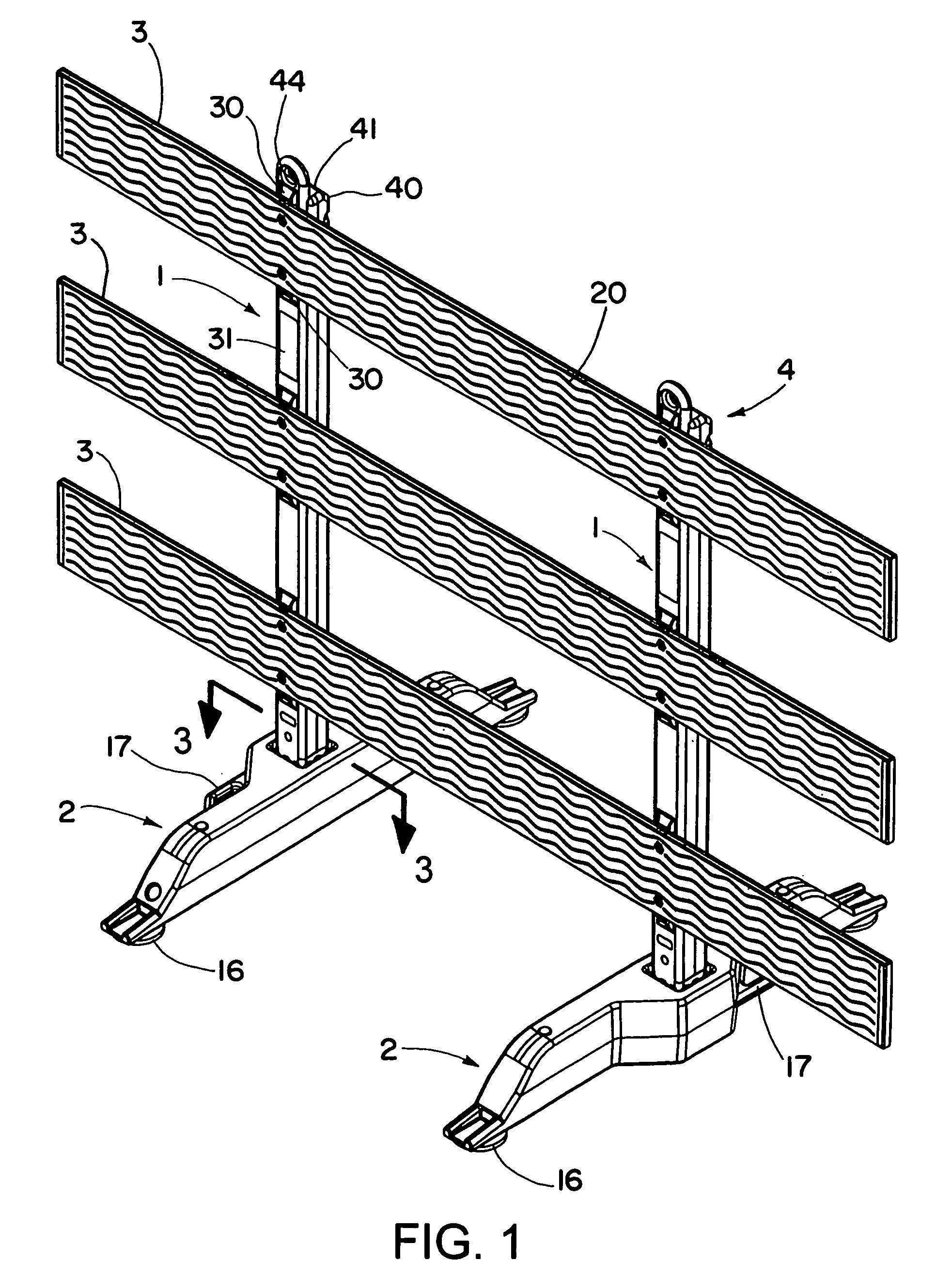

Portable sign and barricade assemblies and plastic molded uprights and light and flag mounts therefor

ActiveUS20050167553A1High strengthSame stiffnessCandle holdersLighting support devicesEngineeringFlange

Owner:PLASTIC SAFETY SYST

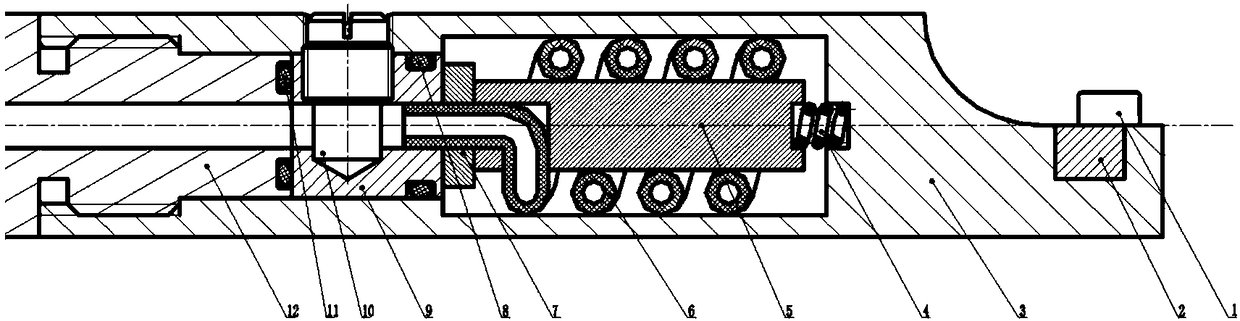

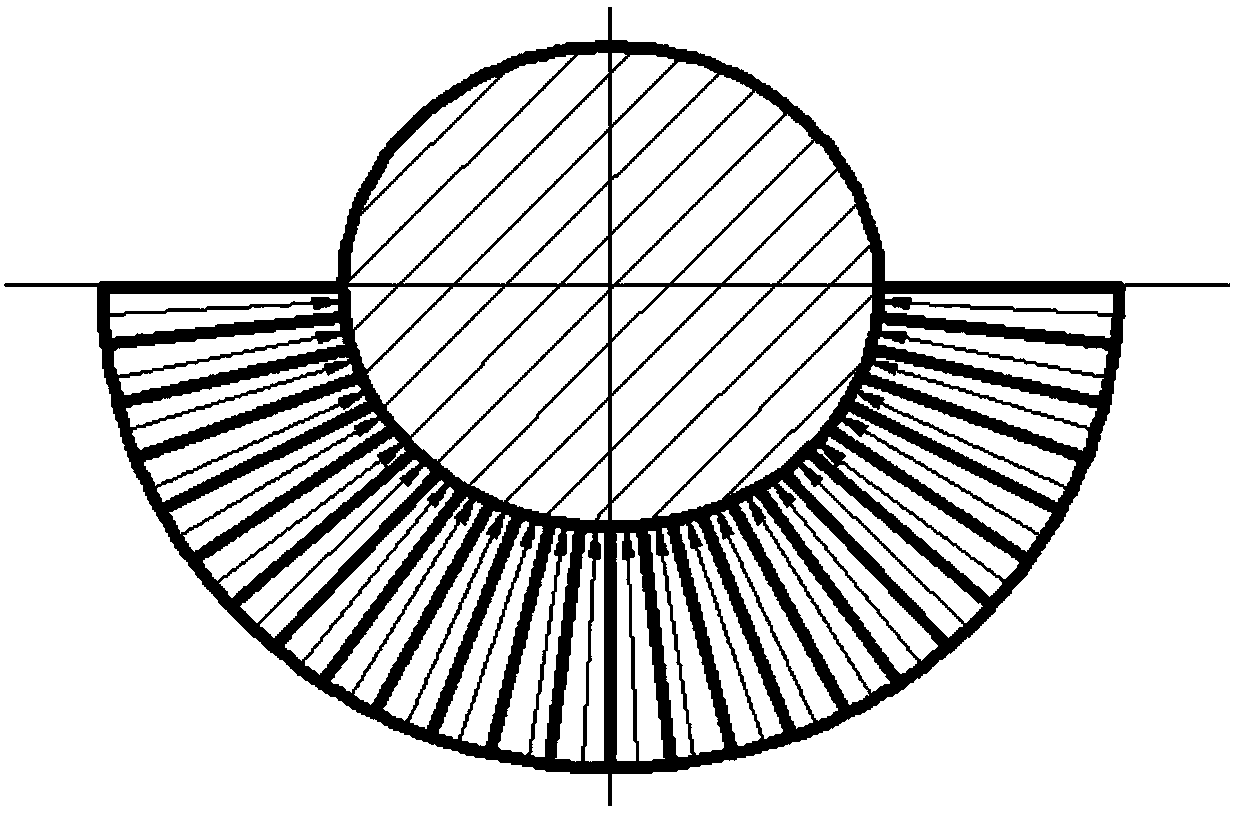

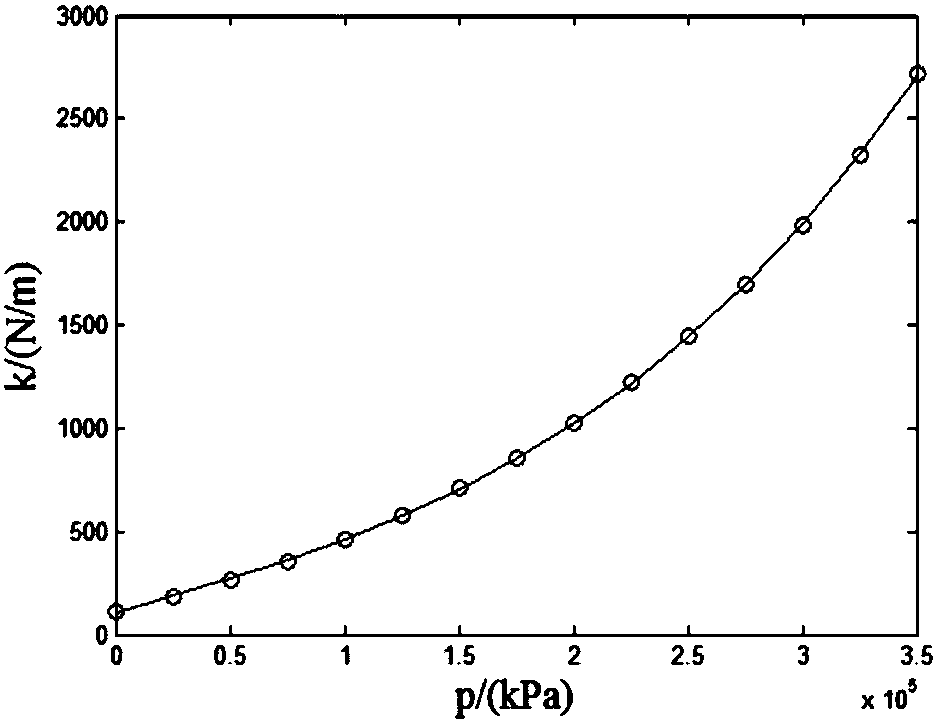

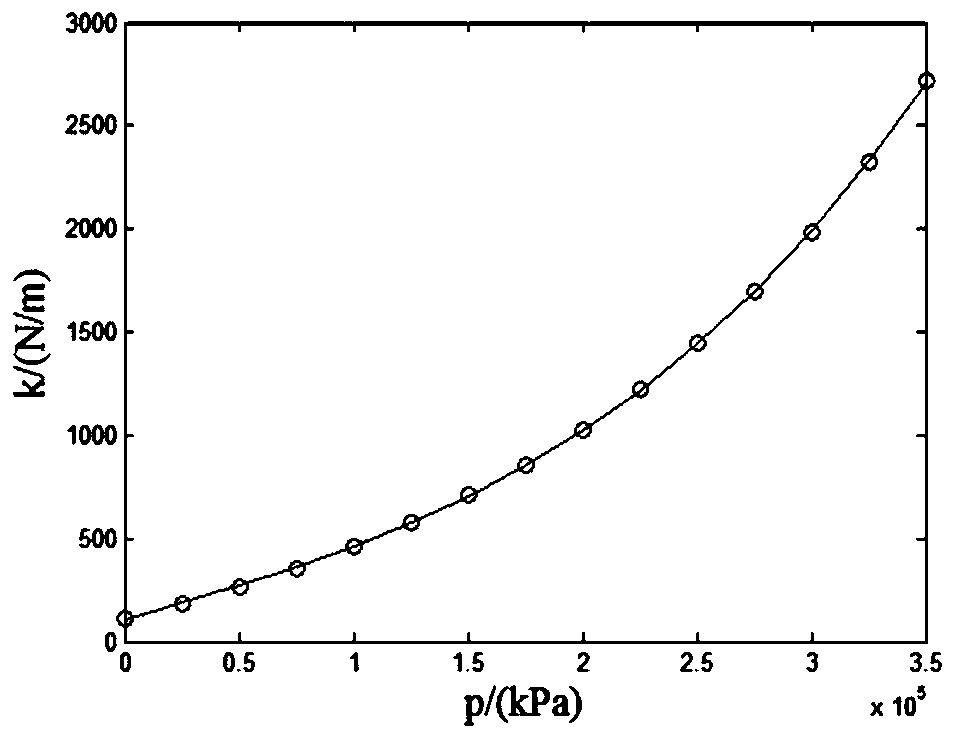

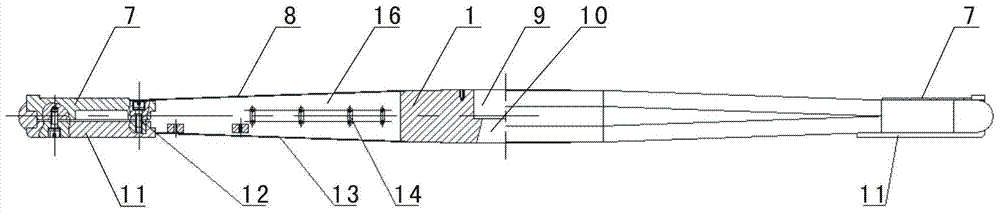

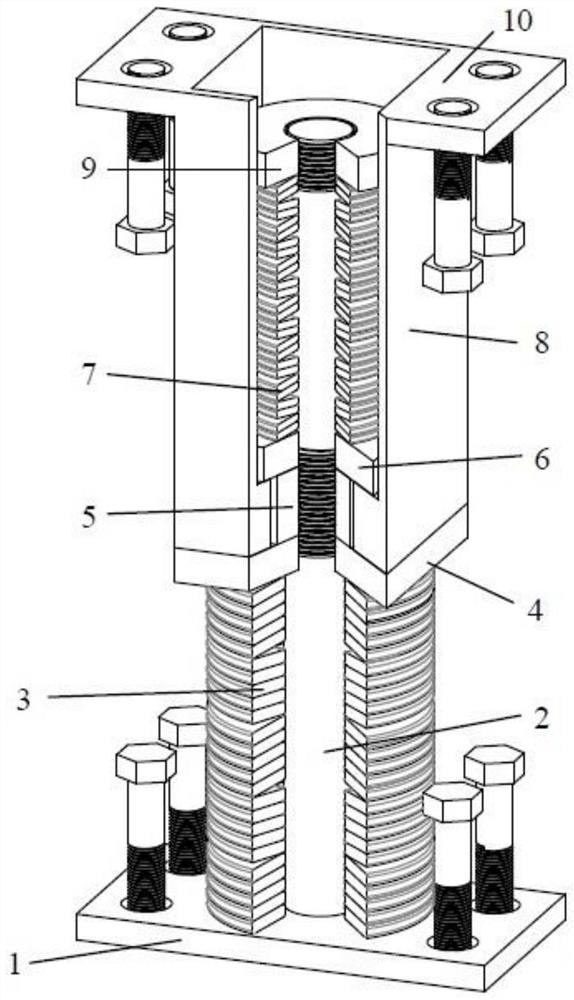

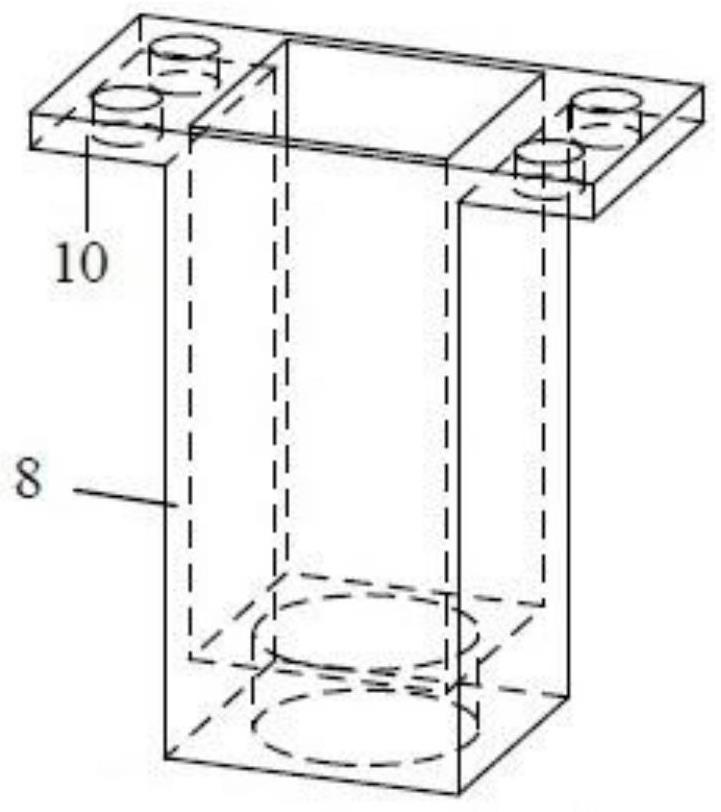

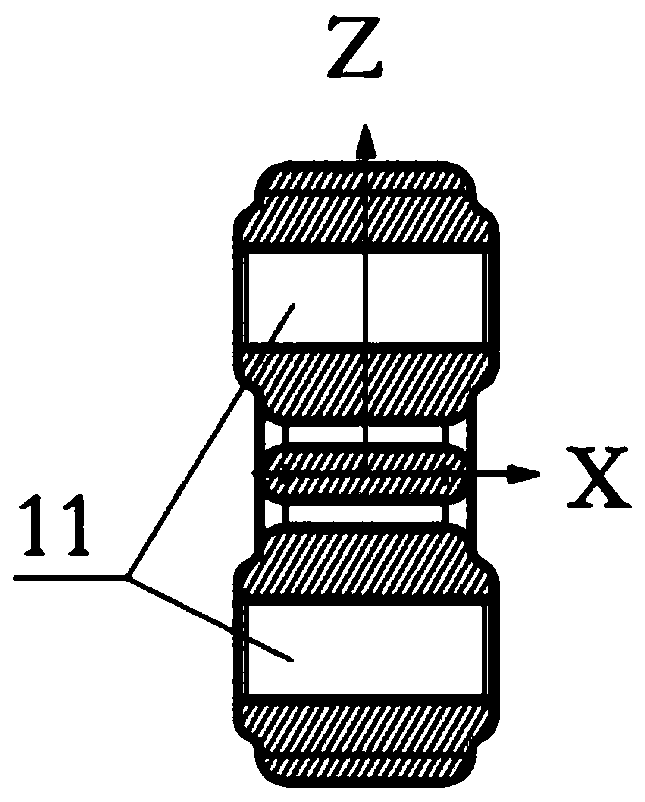

Variable-stiffness single-degree-of-freedom dynamic damping boring rod

ActiveCN108386486AGood vibration dampingStiffness adjustmentRotating vibration suppressionBoring barsVariable stiffnessControl system

The invention discloses a variable-stiffness single-degree-of-freedom dynamic damping boring rod. The variable-stiffness single-degree-of-freedom dynamic damping boring rod comprises a boring rod front half part and a boring rod rear half part, wherein the boring rod front half part is connected with the boring rod rear half part; a cavity is formed in the boring rod front half part; a mass blockis arranged in the cavity; a rubber hose is spirally wound on the mass block; an axial hole is formed in the rear end surface of the mass block; a radial hole is formed in the side wall of the rear end of the mass block; the axial hole communicates with the radial hole; one end of the rubber hose is fixedly arranged at the front end of the mass block, and is wound to the rear end of the mass blockin the length direction of the mass block; after passing through the radial hole and the axial hole, the rubber hose extends out of the mass block; and an end cap is arranged between the boring rod front half part and the boring rod rear half part. The rubber hose is charged with liquid, so that a pressure intensity regulating structure is realized; and an outside control system is not required,so that liquid of different pressure intensities only needs to be led into the rubber hose only through a hydraulic pump, and therefore, implementation is simple, and cost is relatively low.

Owner:XI AN JIAOTONG UNIV

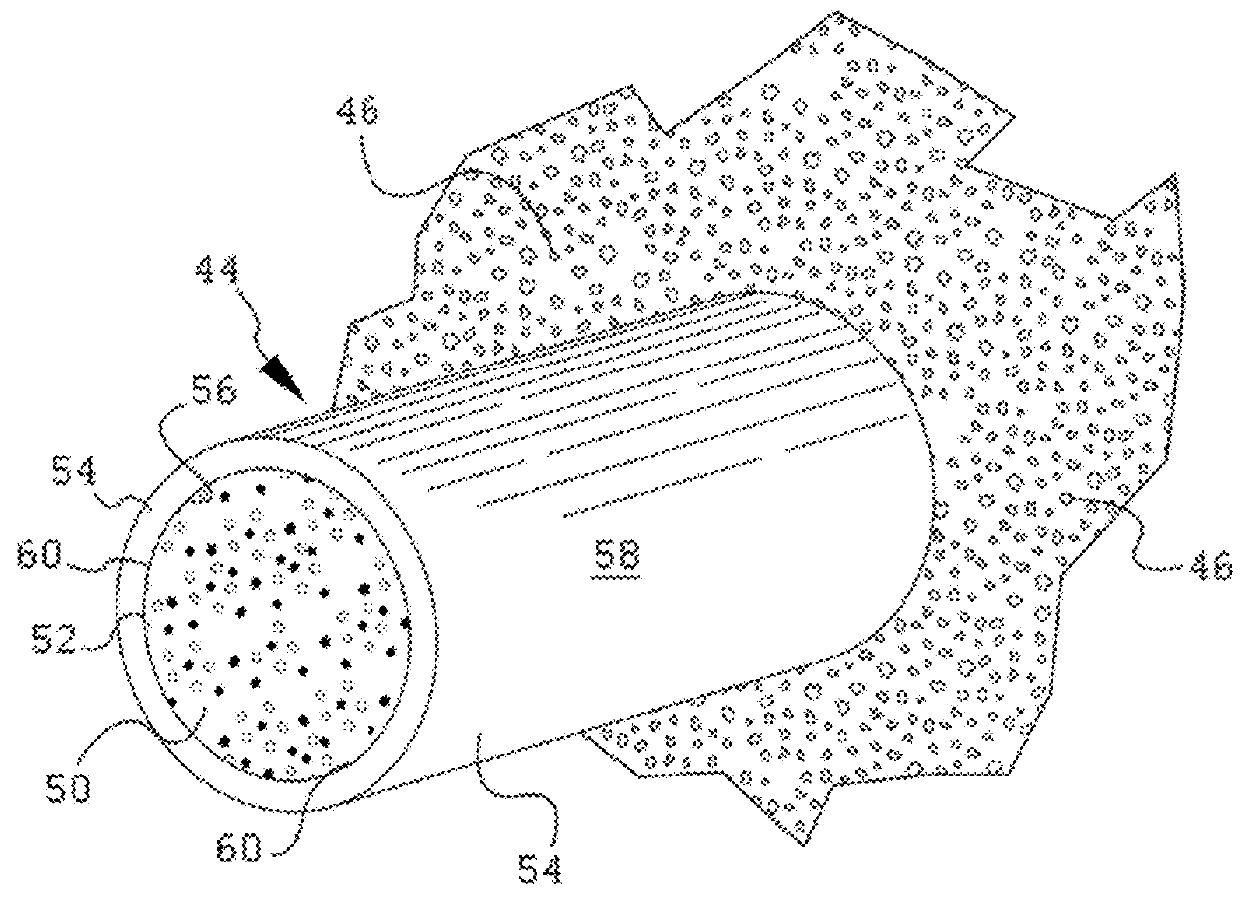

Annular combustion chamber wall arrangement

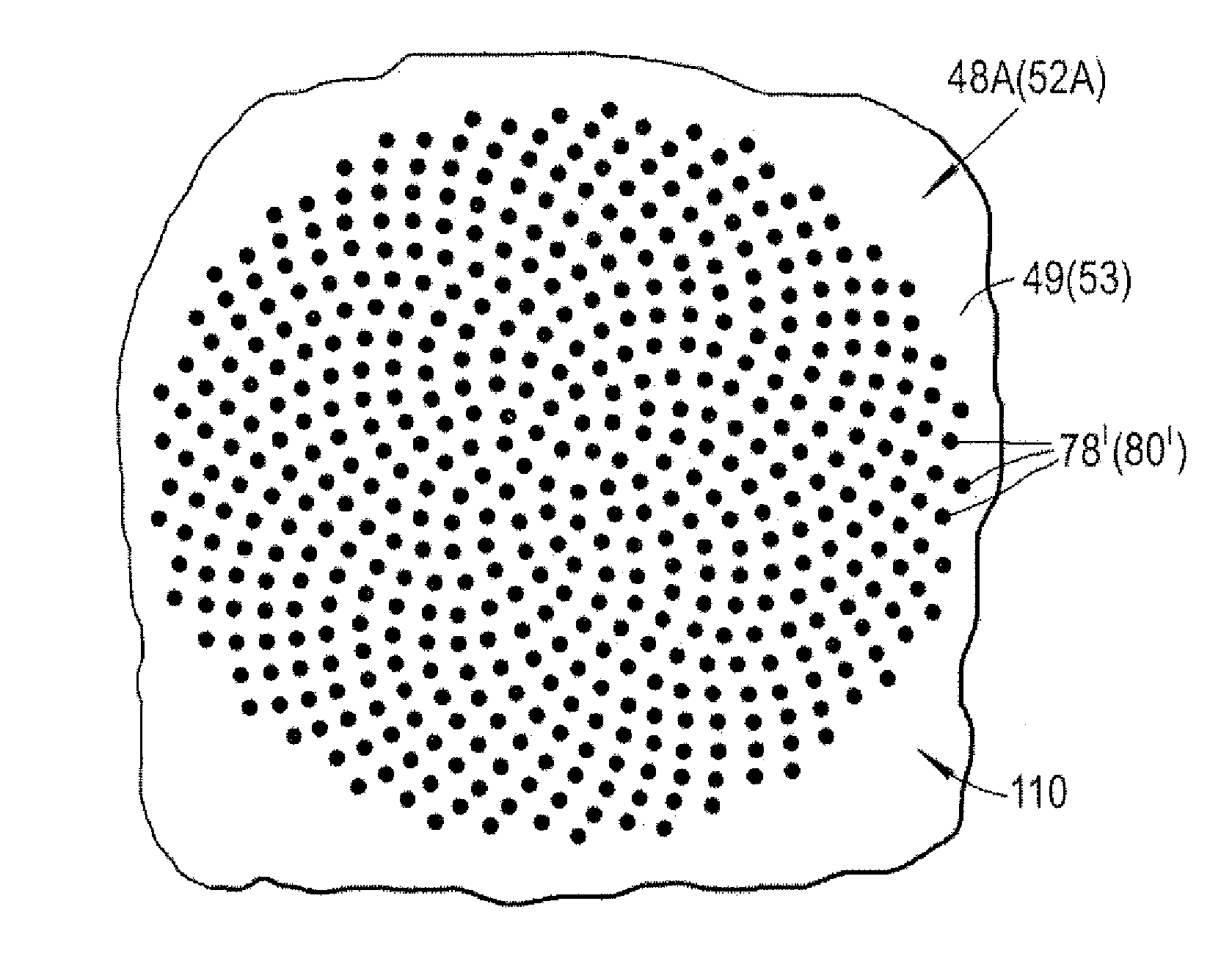

ActiveUS20160010862A1Same stiffnessSame strengthContinuous combustion chamberTurbine/propulsion engine coolingCombustion chamberEffusion

An annular combustion chamber wall arrangement includes an annular wall and a plurality of tiles and each tile is secured to and is spaced from a further annular wall. The first surface of each tile faces the annular wall and the second surface of each tile faces away from the annular wall. Each tile has a plurality of pedestals extending away from the first surface towards the annular wall and / or a plurality of effusion cooling apertures extending through the tile from the first surface to the second surface. At least one of the tiles has the pedestals and / or the effusion cooling apertures arranged in a predetermined pattern which provides the tile with a more uniform stiffness in all directions to reduce the possibility of cracking of the tile. In one predetermined pattern the pedestals are arranged in a Fermat's (parabolic) spiral with the pedestals arranged with Fibonacci number ordering.

Owner:ROLLS ROYCE PLC

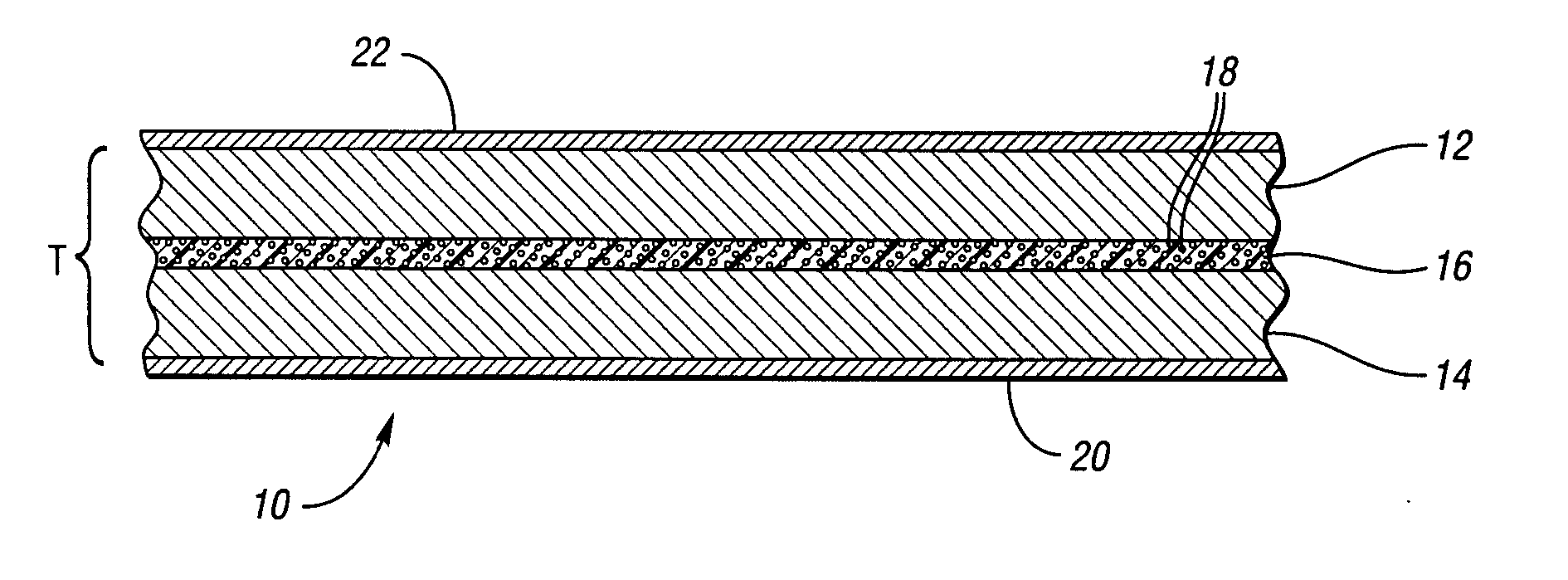

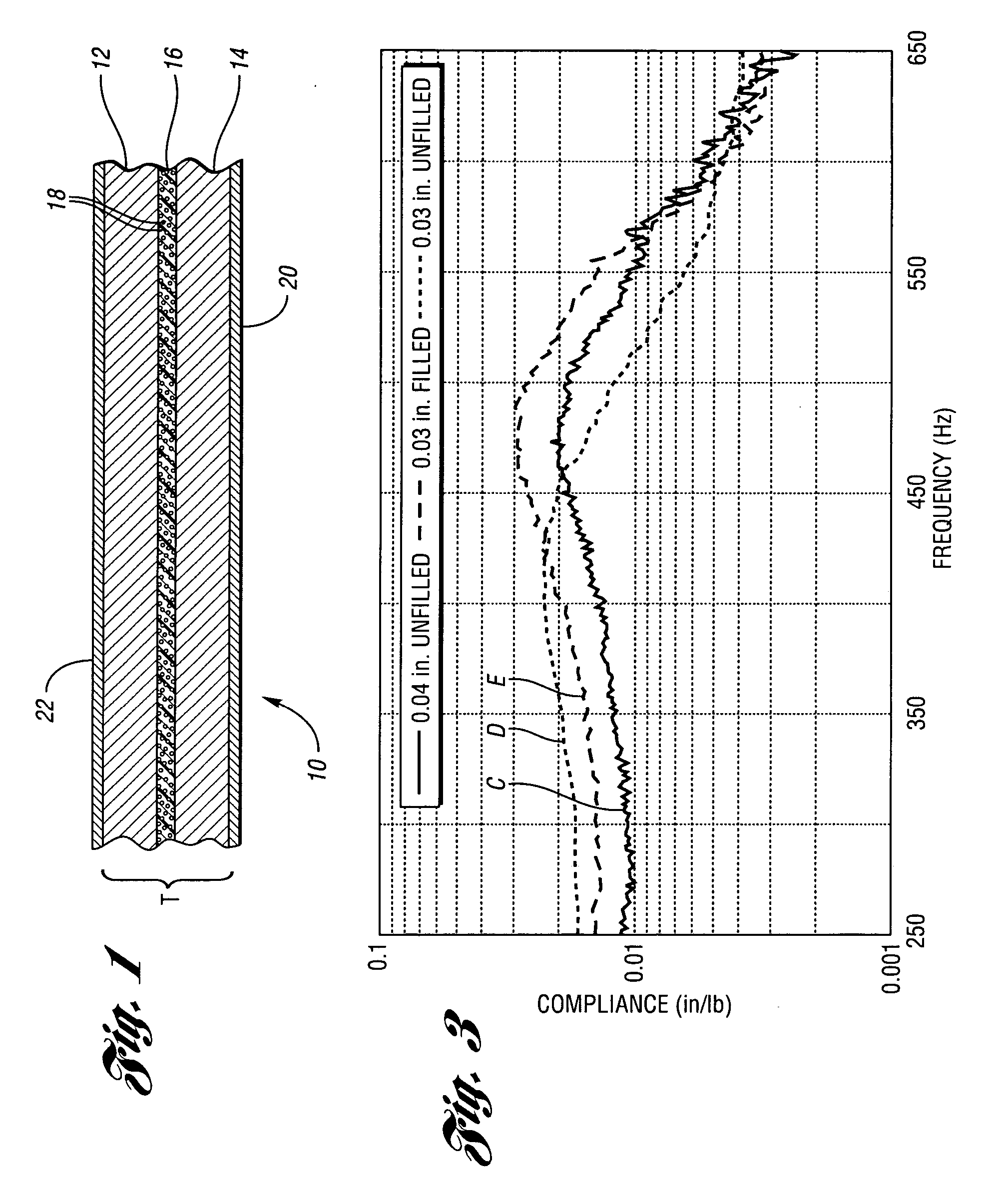

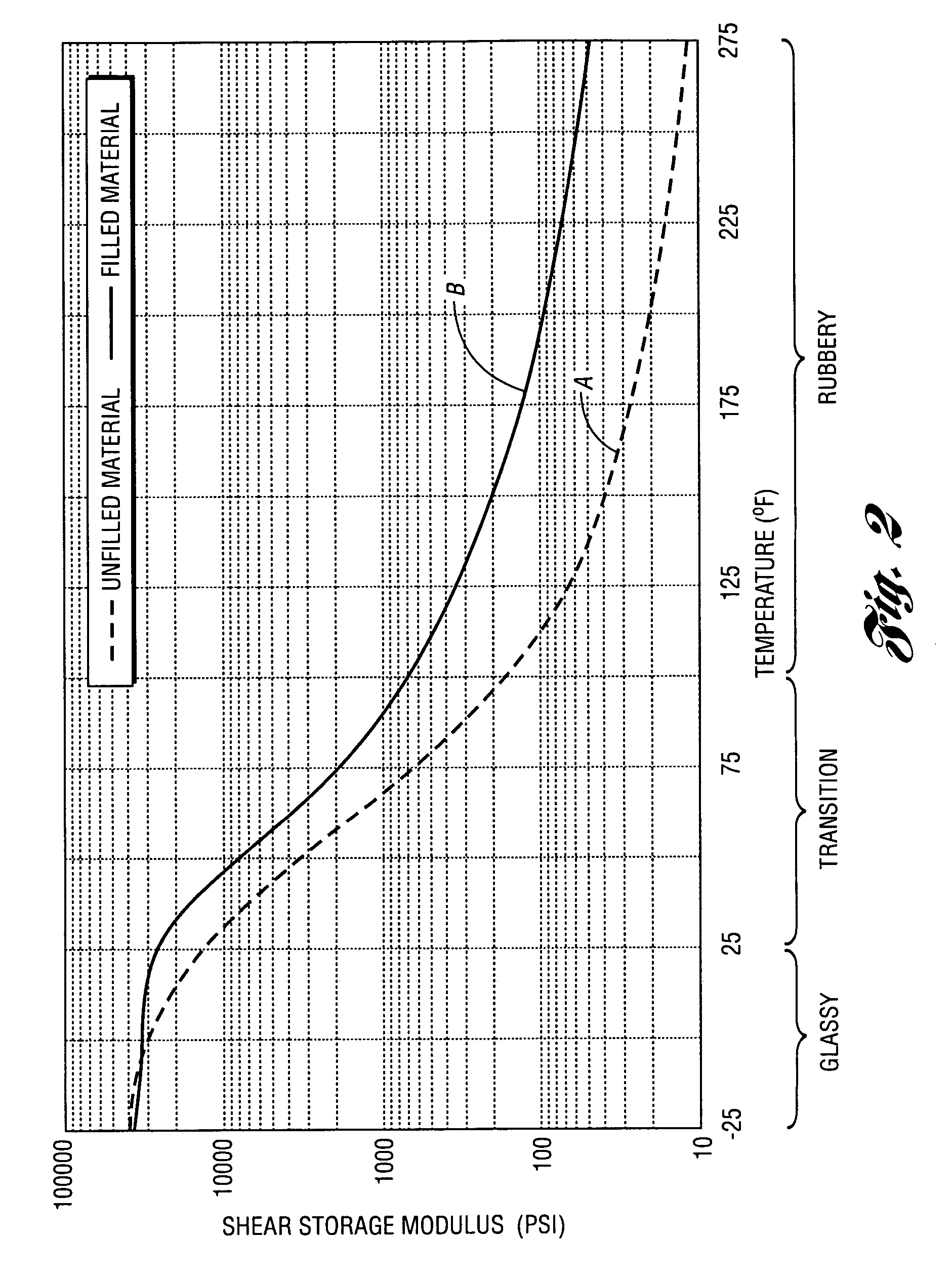

Laminated structure with a filled viscoelastic layer and method

InactiveUS20070026212A1Improve static stiffnessSame stiffnessSynthetic resin layered productsCeramic layered productsVibration attenuationFilling materials

The present invention provides a panel providing improved noise and vibration attenuation. The panel is formed from a constrained layer viscoelastic laminate material having at least two constraining layers and at least one viscoelastic layer therebetween spanning the entirety of the constraining layers. Included within the viscoelastic layer is an effective amount of filler material operable to increase the static stiffness of the panel. A method of increasing the static stiffness of constrained layer viscoelastic materials is also provided.

Owner:MATERIAL SCIENCES CORPORATION

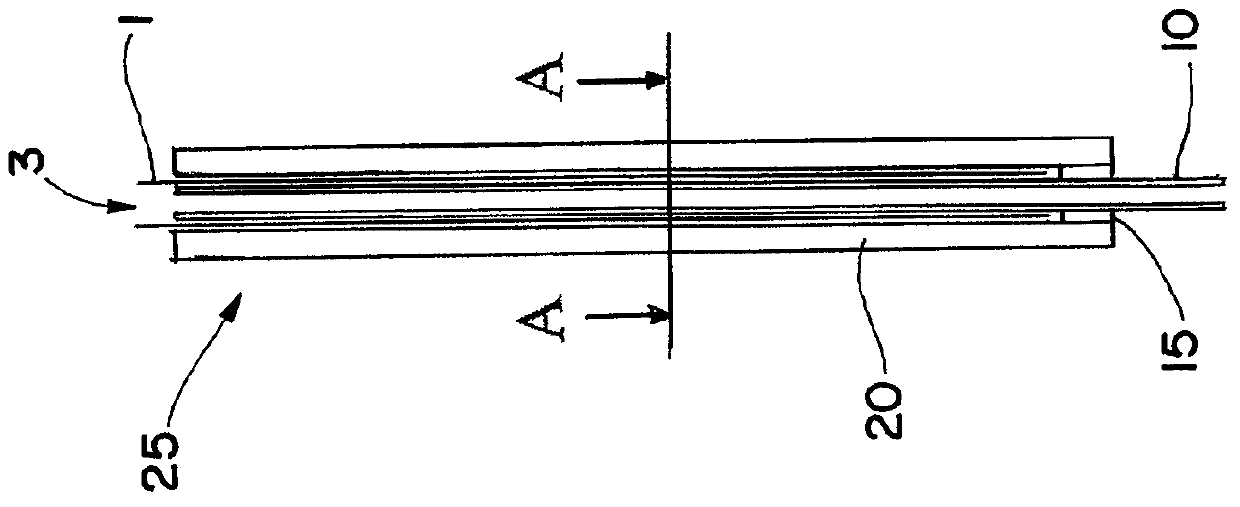

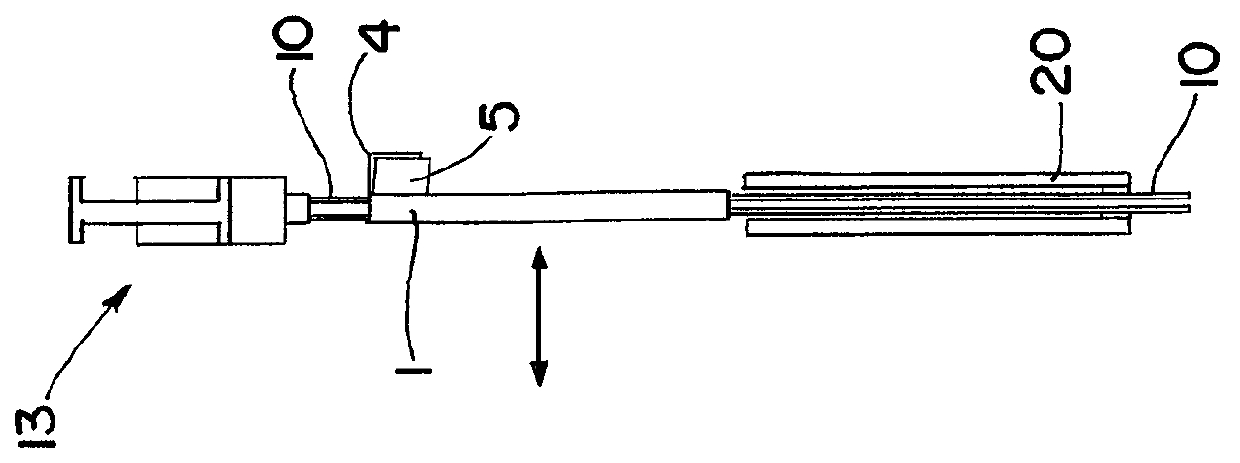

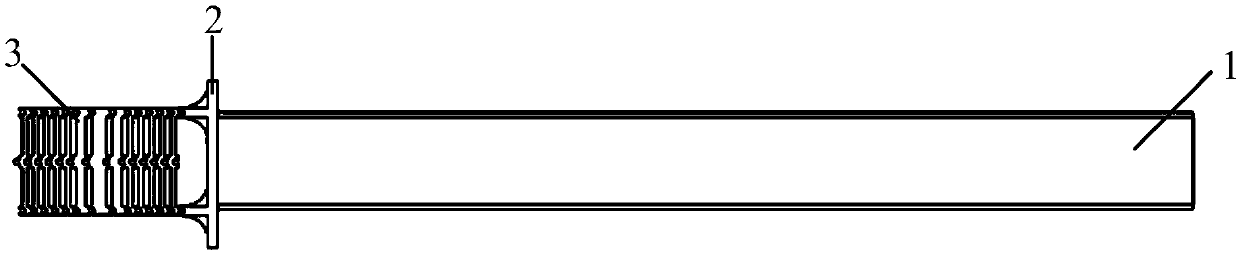

Catheter stylet with catheter accommodating lumen

ActiveUS8251955B2Simplifies manipulating and placingImprove treatment outcomesEar treatmentInfusion syringesCatheter stylet

The invention relates to a catheter stylet for stiffening a catheter during the placing process, wherein the stylet comprises an accommodating lumen for at least one fluid-guiding line of the catheter. It also relates to a catheter stylet catheter system, comprising such a stylet and comprising a catheter which comprises a fluid-guiding line, and to a method for stiffening a catheter during the placing process, wherein a stylet which comprises an accommodating lumen is arranged around at least one fluid-guiding line of the catheter.

Owner:BRAINLAB

Plastic blow molded board-like members

Plastic blow molded board-like members include a plurality of longitudinally extending, laterally spaced aligned channels / grooves in opposite sides of the members. Each of the channels has closely spaced apart side walls and inner end walls. The inner end walls of aligned channels in opposite sides of the member are joined together to provide a relatively high strength reinforced core. The ends of the members are completely closed during the blow molding process for increased strength and to keep out dirt and moisture.

Owner:PLASTIC SAFETY SYST

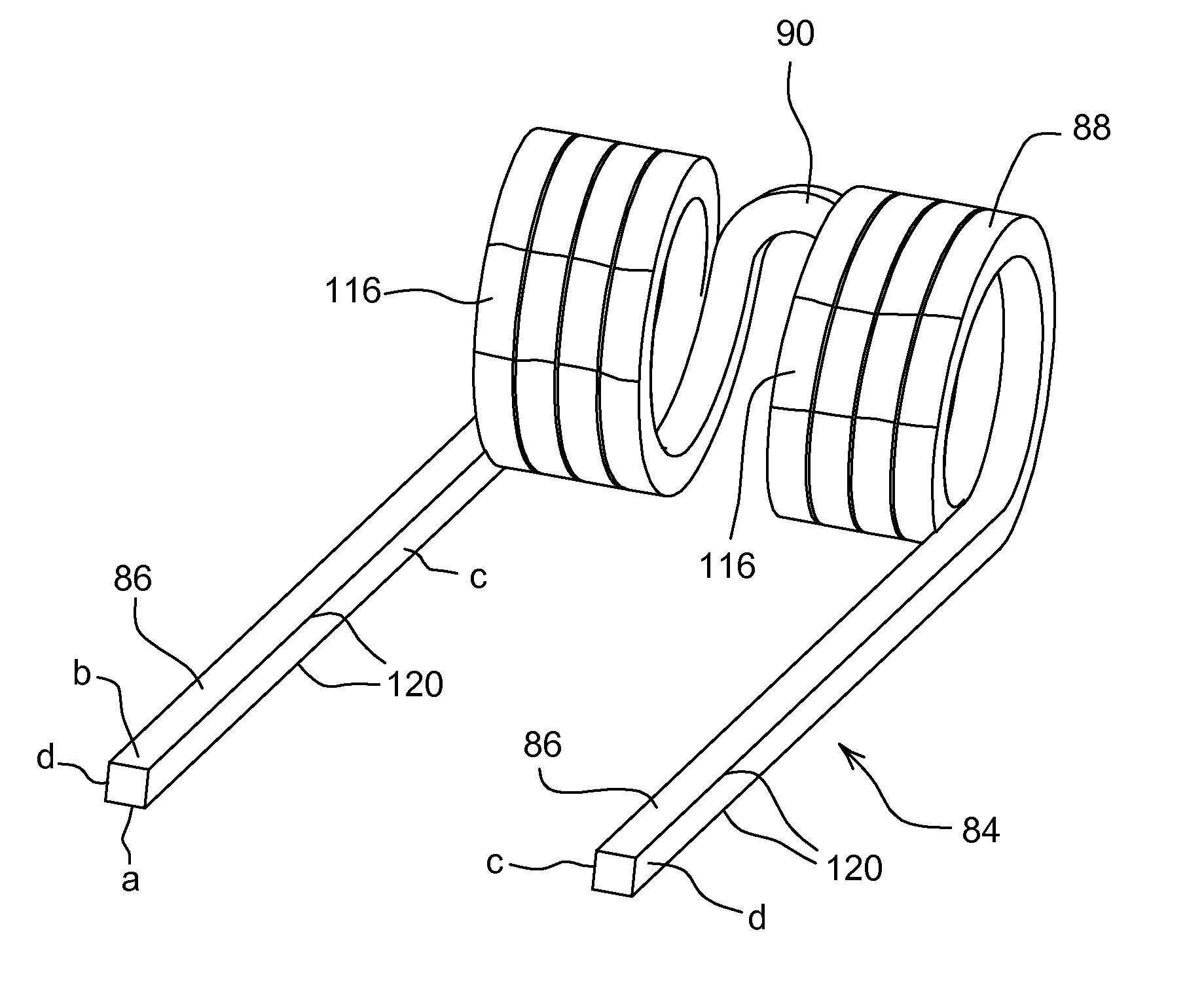

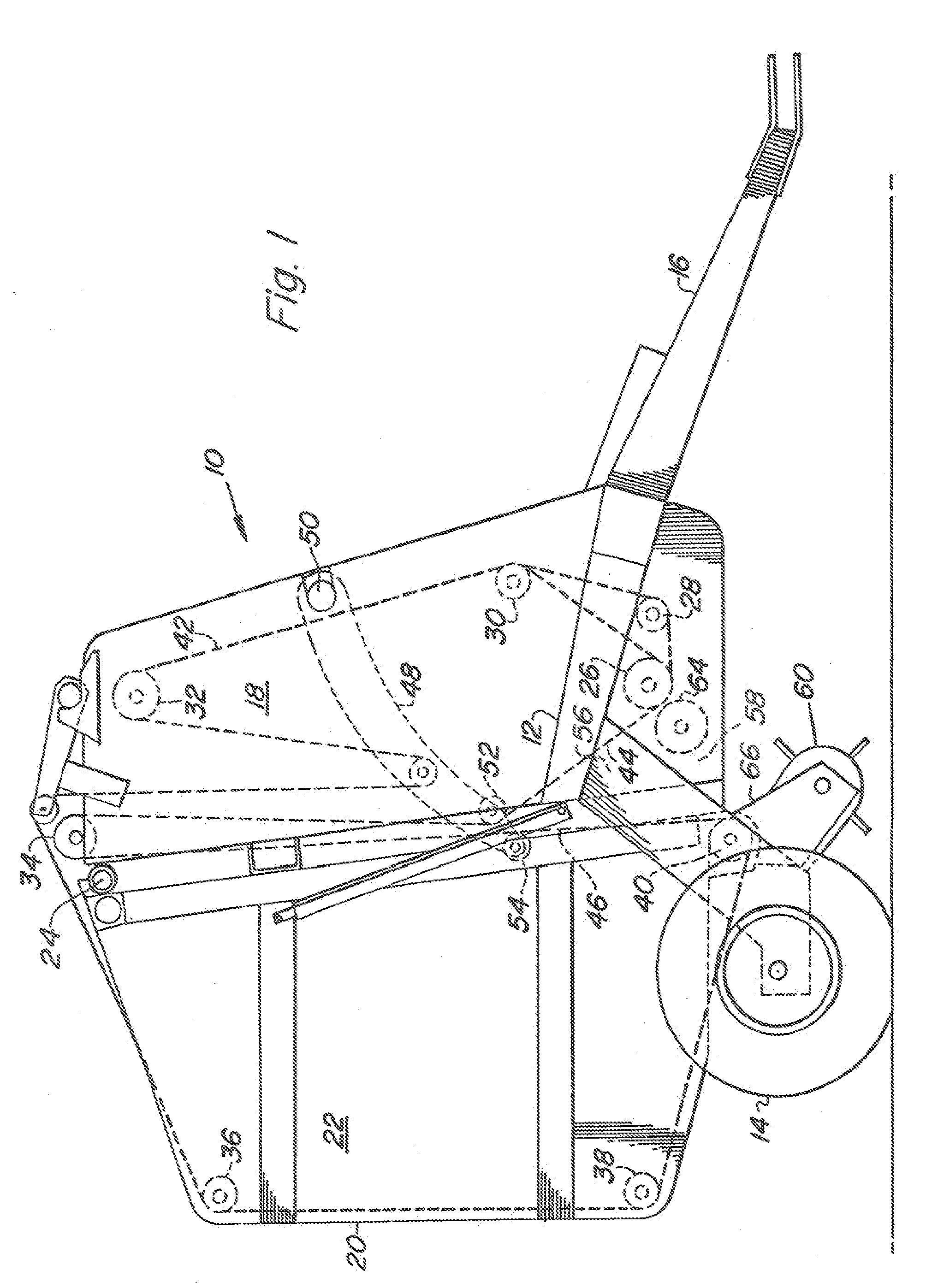

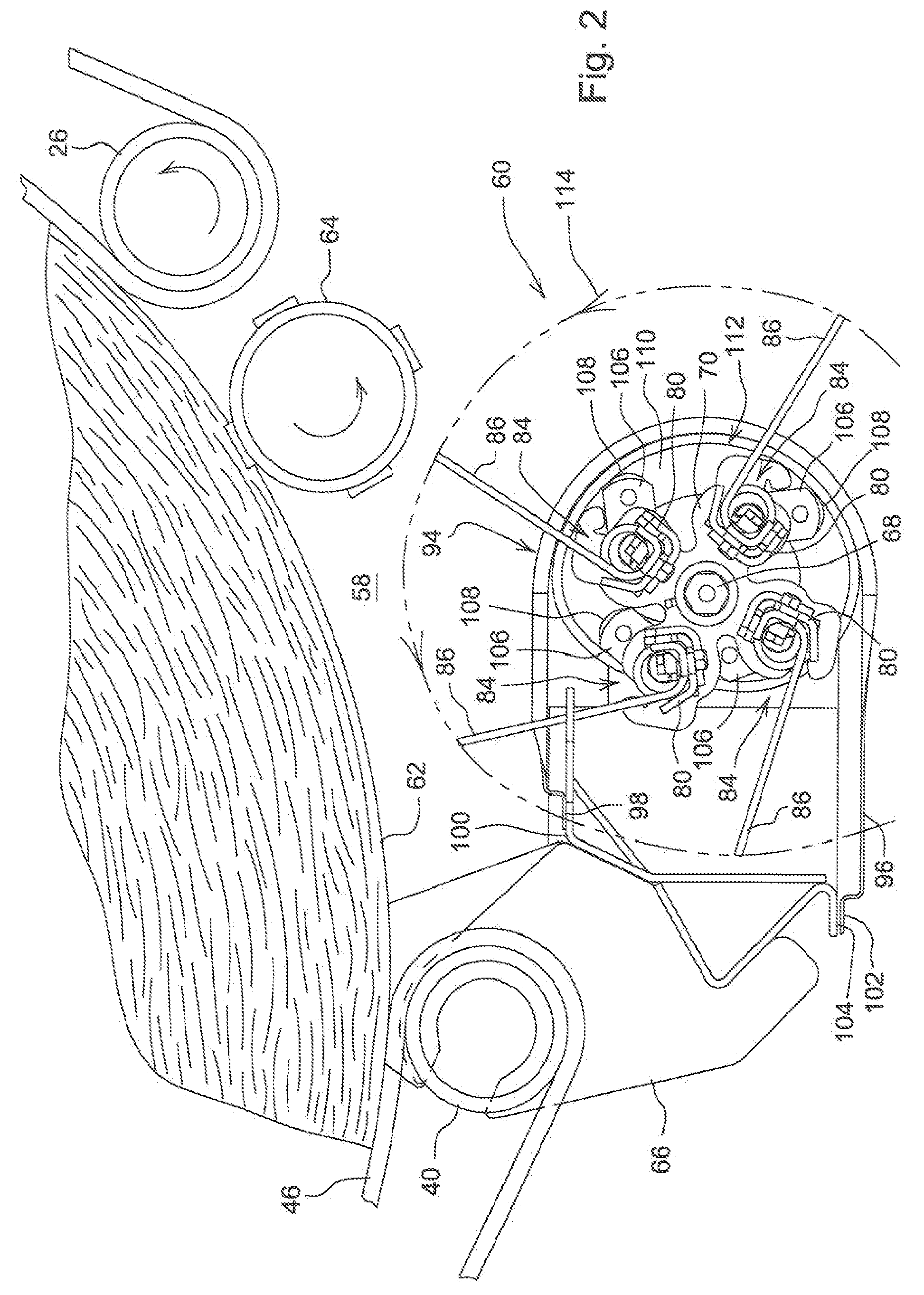

Non-Circular Wire Crop Pick-Up Tooth

Spring teeth for a harvesting machine are each constructed of spring wire having a square cross section and being wound so as to define a coil torsion spring section terminating in a tine, with the tine having a leading flat surface, considered relative to the engagement of tine with the crop during pick-up operation, and having a trailing flat surface disposed parallel to said leading flat surface. The coil torsion spring is mounted to a tooth bar formed as a channel member such that the outer surface of the coils make a relatively large area contact with the tooth bar at location spaced approximately 180° from where the tine joins the coil torsion spring. This together with the fact that the contact area of the flat sides of the wire in the coil region is also quite large leads to a damping action that lessens stress in the tooth assembly.

Owner:DEERE & CO

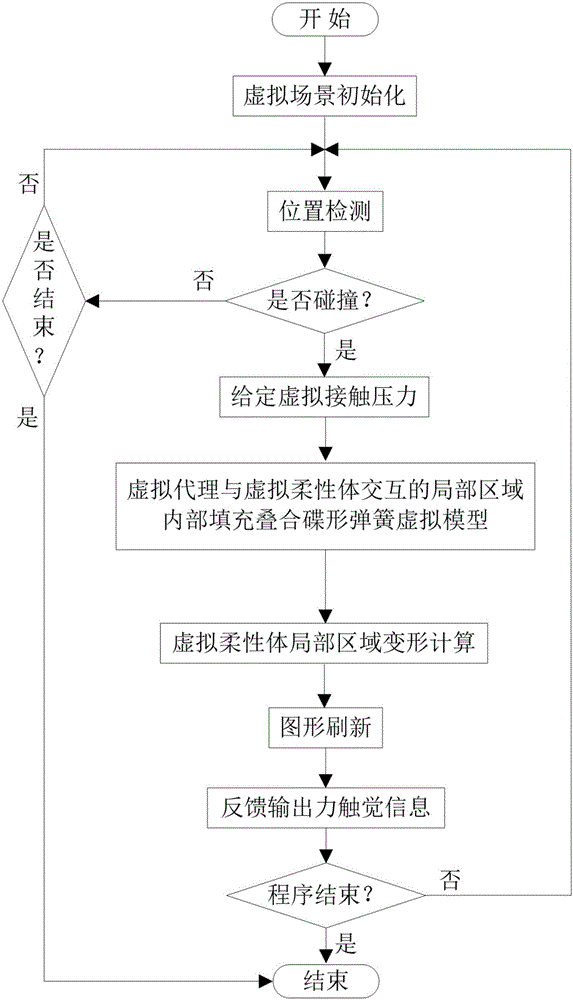

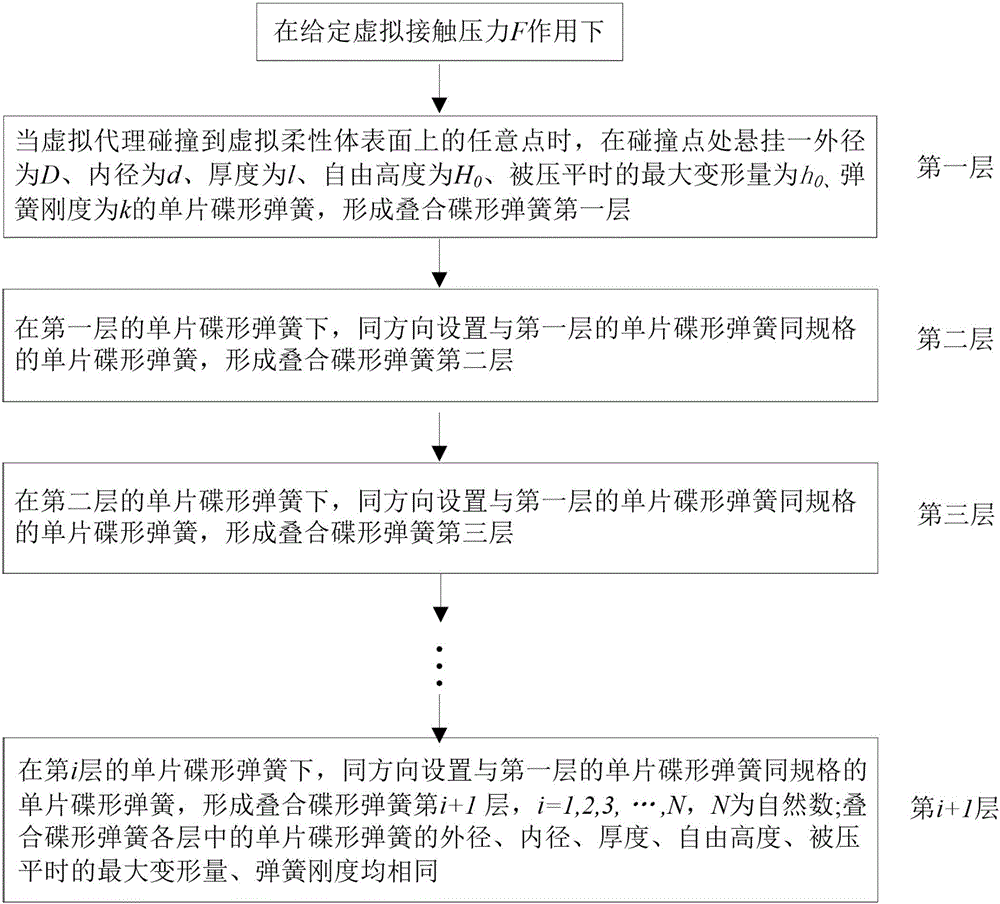

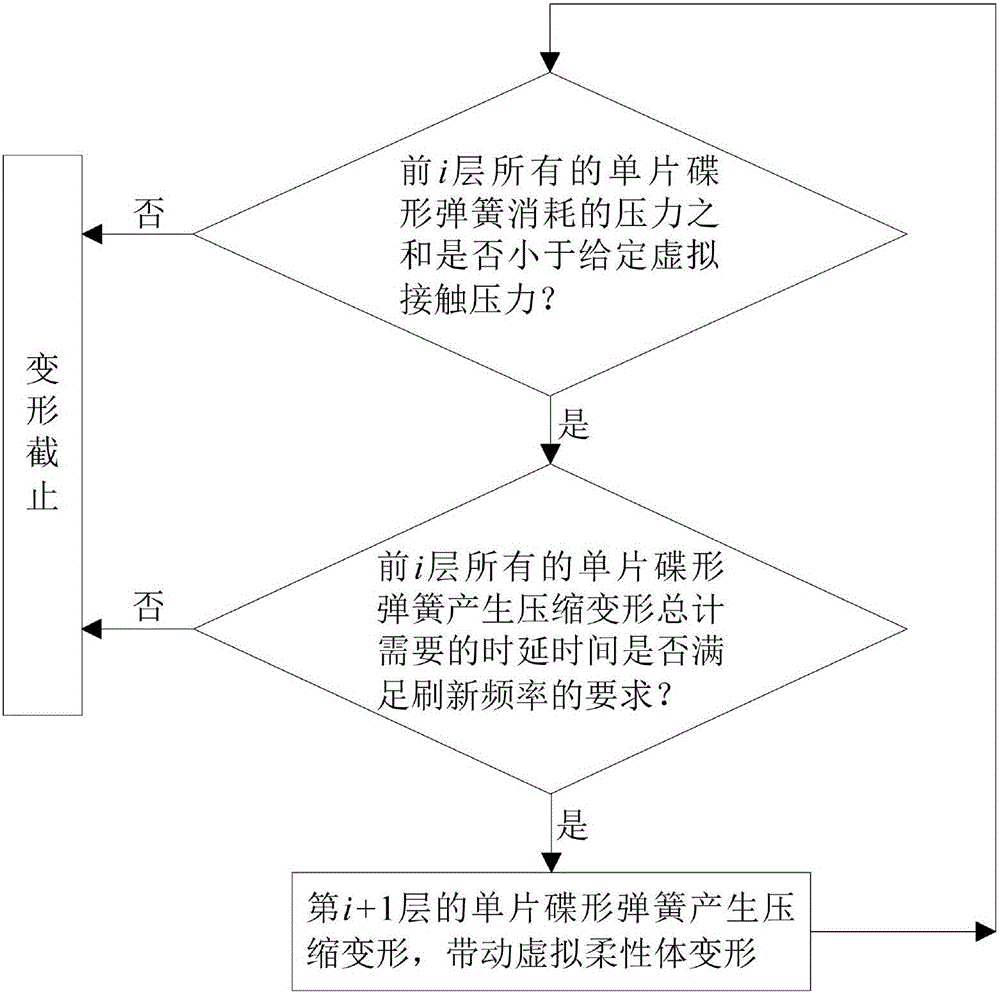

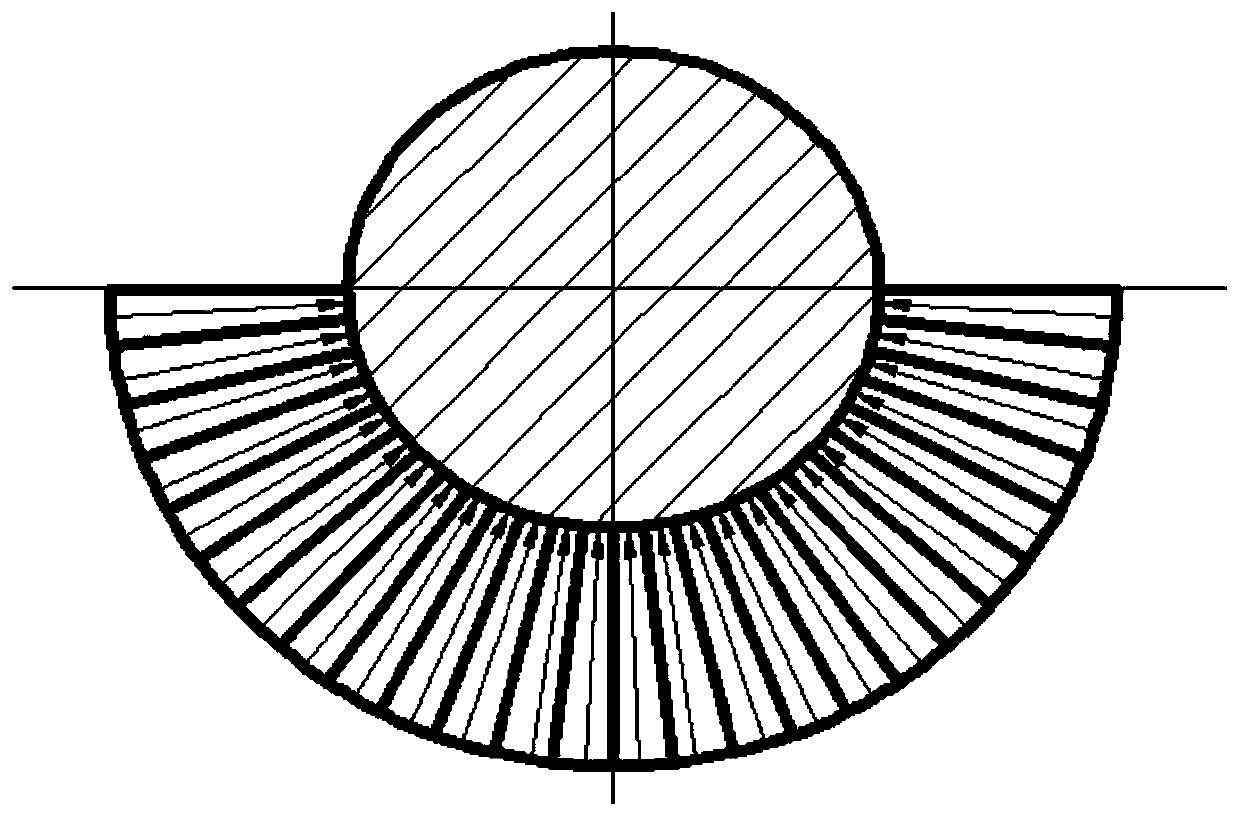

Building method of superimposed disc spring virtual model for flexible haptic rendering

InactiveCN106295085ACalculation speedGuaranteed realismDesign optimisation/simulationSpecial data processing applicationsContact pressureSimulation

The invention discloses a building method of superimposed disc spring virtual model for flexible haptic rendering. The building method is characterized in that when the circumstance that a virtual agent collides with any point on the surface of a virtual flexible body is detected, under action of given virtual contact pressure, the inside of a local area in which the virtual agent interacts with the virtual flexible body is filled with the superimposed disc spring virtual model; in the process of interaction, a signal reflecting haptic information of real-time deformation simulation of the flexible body under pressure action and calculated by adopting the superimposed disc spring virtual model is output and fed back ; addition of sums of deformation of disc springs on each layer in the superimposed disc spring virtual model is externally equivalent to deformation of the surface of the flexible body, and sum of pressure consumed when the superimposed disc springs on each layer are compressed. By the building method, the deformation process of the flexible body can be vividly simulated in real time, haptic information which is fed back is real and stable, and a feasible path is sought for practically using virtual operation simulating.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Jacquard machine

The invention relates to a Jacquard machine, comprising 2 sets of knifes moving up and down in opposition, which each, at each of their extremities, are taken up in separate knife grids (4a, 4b) being driven by a cinematic drive chain (30), and each, at one of their extremities (20a, 20b), being guided into a straight motion by means of a “Watt's linkage” rod system, the height of lift of each of these extremities (20a, 20b) of the knife grids (4a, 4b) being adjustable, and the knife grids (4a, 4b) each at their first extremities (20a, 20b) being linked with at least one first driving lever (2, 2a, 2b, 10) by means of a first linking rod (3a, 3b), and at their second extremities (21a, 21b) being linked with at least a second driving lever (2, 10) by means of a second linking rod (14a, 14b), wherein per knife grid (4a, 4b) one or several elements (1, 101, 1a, 1b, 3a, 3b) of the Watt's linkage rod system are part of the cinematic drive chain (30), and the amplitude of the motion of the said extremity (20a, 20b) of the knife grid (4a, 4b) is adjustable in the cinematic drive chain (30) before the linking point (9a, 9b) between the first rod (1, 101, 1a, 1b) and the third rod (3a, 3b) of the Watt's linkage rod system with respect to the drive motor.

Owner:VAN DE WIELE MICHEL

A dynamic damping boring bar with variable stiffness and single degree of freedom

ActiveCN108386486BGood vibration dampingStiffness adjustmentRotating vibration suppressionBoring barsVariable stiffnessControl system

The invention discloses a variable-stiffness single-degree-of-freedom dynamic damping boring rod. The variable-stiffness single-degree-of-freedom dynamic damping boring rod comprises a boring rod front half part and a boring rod rear half part, wherein the boring rod front half part is connected with the boring rod rear half part; a cavity is formed in the boring rod front half part; a mass blockis arranged in the cavity; a rubber hose is spirally wound on the mass block; an axial hole is formed in the rear end surface of the mass block; a radial hole is formed in the side wall of the rear end of the mass block; the axial hole communicates with the radial hole; one end of the rubber hose is fixedly arranged at the front end of the mass block, and is wound to the rear end of the mass blockin the length direction of the mass block; after passing through the radial hole and the axial hole, the rubber hose extends out of the mass block; and an end cap is arranged between the boring rod front half part and the boring rod rear half part. The rubber hose is charged with liquid, so that a pressure intensity regulating structure is realized; and an outside control system is not required,so that liquid of different pressure intensities only needs to be led into the rubber hose only through a hydraulic pump, and therefore, implementation is simple, and cost is relatively low.

Owner:XI AN JIAOTONG UNIV

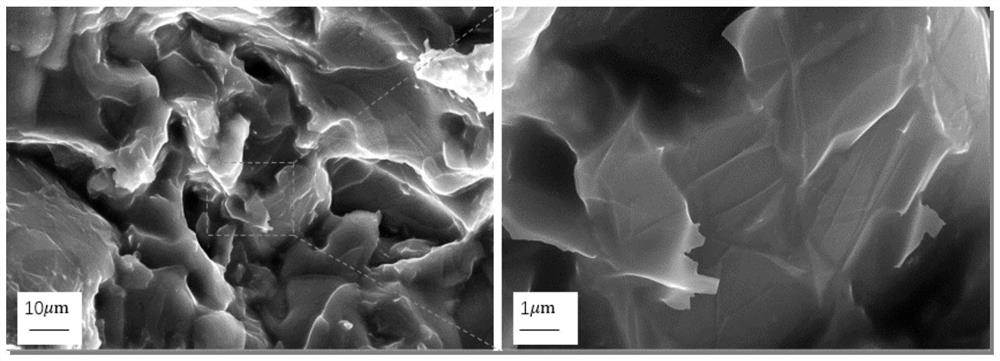

Method for repairing Glare laminate by bonding with modified adhesive

InactiveCN111849400AImprove adhesion strengthSame stiffnessNon-macromolecular adhesive additivesAdhesive processes with surface pretreatmentEpoxyPolymer science

The invention relates to a method for repairing a Glare laminate by bonding with a modified adhesive, which is characterized by comprising the following steps of: (1) preparing a repairing patch madeof the same material as a motherboard according to the size of a Glare layer motherboard damage area, (2) adding the suspension containing the modifier into an epoxy resin adhesive, and carrying out ultrasonic stirring to prepare a modified adhesive, (3) treating the damaged part of the mother board to be repaired and the surface of the patch, and (4) coating the surfaces of the treated mother board and patch with a modified adhesive, and curing at a preset temperature. The impact resistance of the modified adhesive repairing test piece prepared by the method is better than that of a traditional adhesive repairing result, the modified adhesive repairing test piece is closer to a standard test piece without damage, and in addition, the crack propagation rate after repairing is also lower than that of the traditional adhesive repairing result.

Owner:SHENYANG AEROSPACE UNIVERSITY

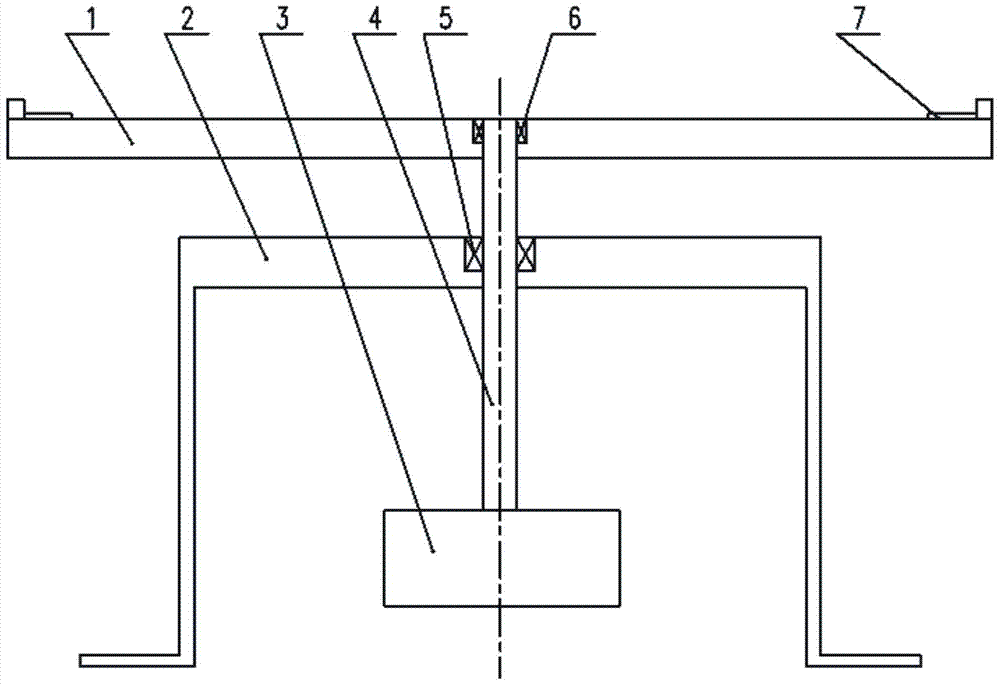

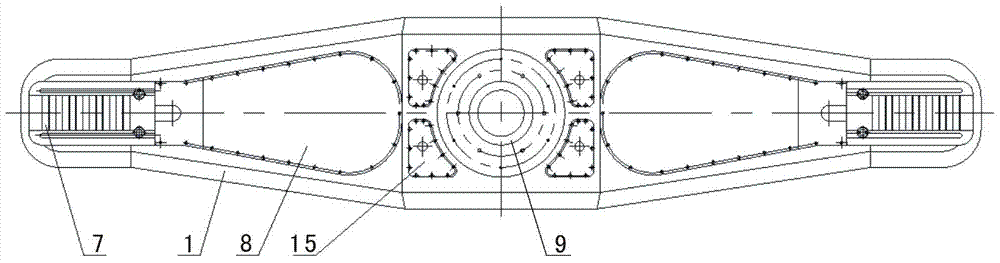

Dynamic centrifuge integrated rigid arm

The invention discloses an integrated rigid rotating arm of a dynamic centrifuge. The shape of the shuttle is large in the middle and small at the left and right ends, and the main body of the rotating arm is a symmetrical structure with front and rear symmetry, left and right symmetry, and up and down symmetry. Sample stages for installing test pieces are respectively installed above the ends of the rotary arm body, and counterweights for one-to-one correspondence with the sample stages are respectively installed under the left and right ends of the rotary arm body to realize left-right symmetry of the rotary arm body. The rigid rotary arm of the present invention has stronger rigidity, lower moment of inertia and smaller air damping, which ensures that the centrifuge has high dynamic performance, and the variable acceleration is directly generated through the variable speed movement of the rotary arm body, which solves the problem of Traditional dynamic centrifuge acceleration needs synthesis, direction change and other issues.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

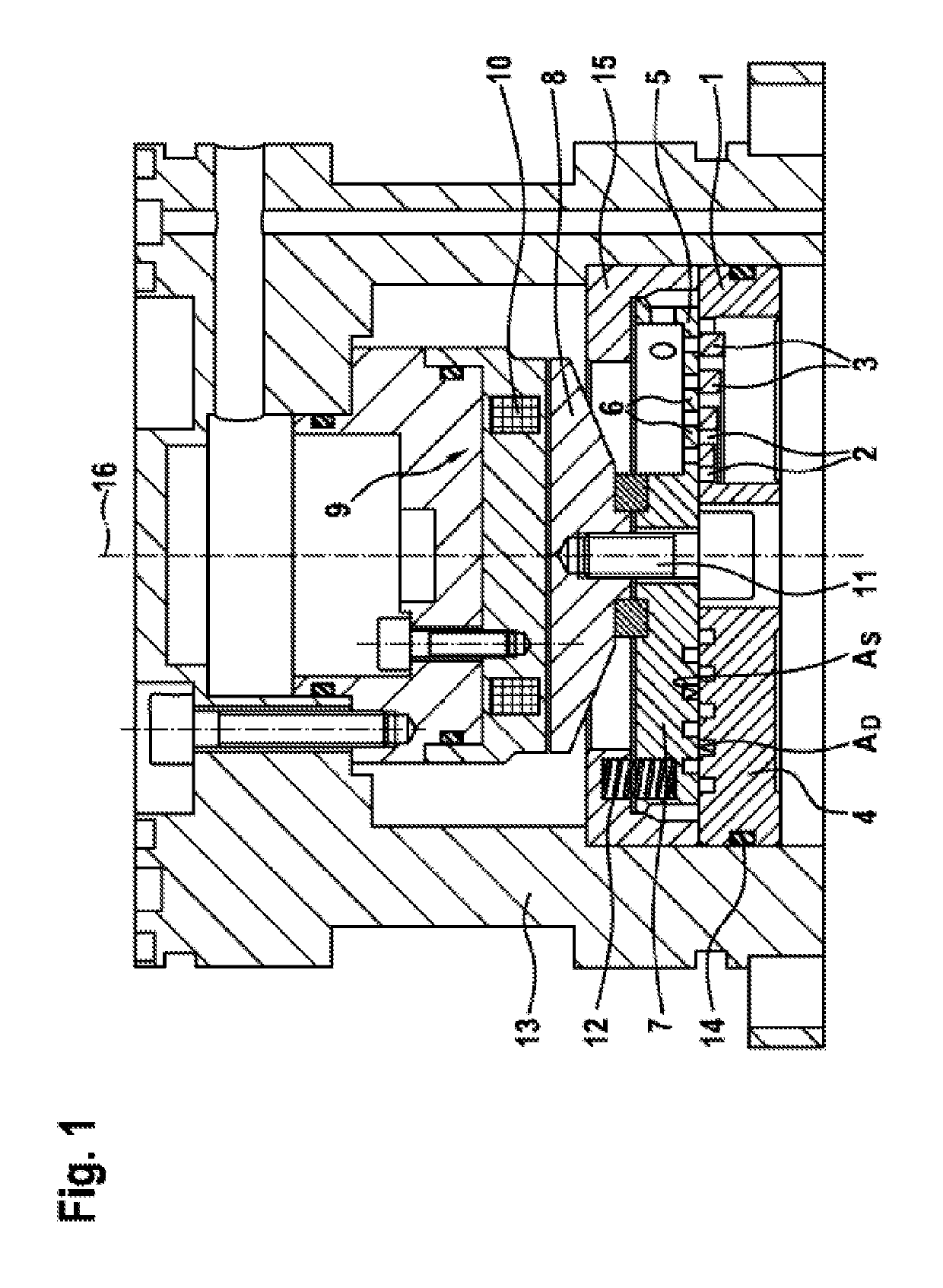

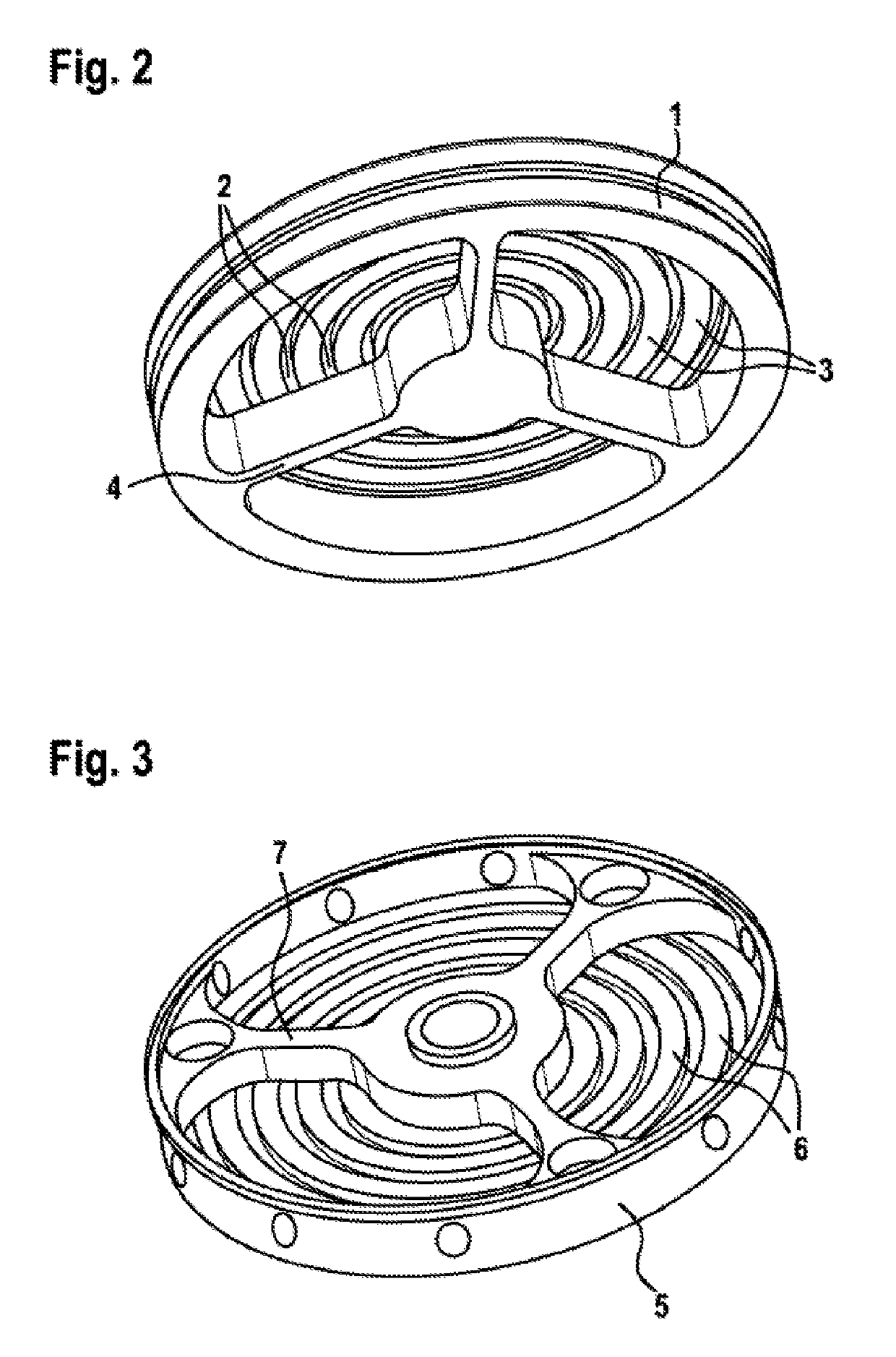

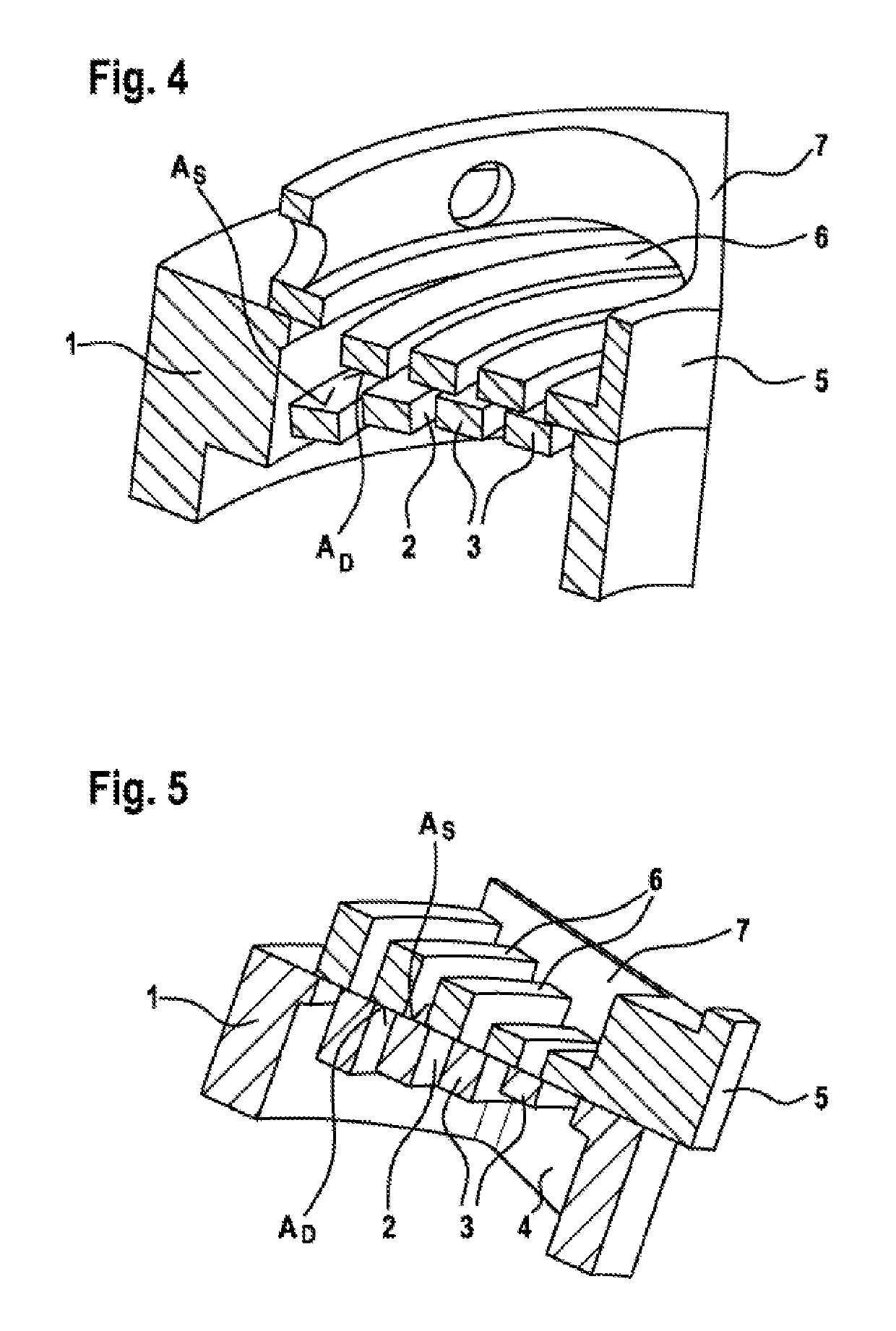

Electromagnetically actuatable gas valve, and method for increasing the seal of an electromagnetically actuatable gas valve

ActiveUS10385987B2Improve sealingAvoiding jump in stiffnessOperating means/releasing devices for valvesInternal combustion piston enginesValve seatElectric motor

The invention relates to an electromagnetically actuatable gas valve for metering a gaseous fuel into a suction tract of a motor, in particular a gas or diesel gas motor, comprising a valve seat (1) which is designed as a flat seat and which has multiple annular webs (3) that are arranged in a concentric manner and are connected via at least one radially running web (4) in order to delimit circular or semicircular through-flow openings (2). The electromagnetically actuatable gas valve further comprises a movable valve plate (5) which sealingly interacts with the valve seat (1) and which has multiple annular sealing webs (6) that are arranged in a concentric manner and can be brought into an overlapping arrangement with the circular or semicircular through-flow openings (2) of the valve seat (1). According to the invention, the rigidity of the valve seat (1) and / or the valve plate (5) is substantially constant in the radial direction, the rigidity of the valve seat (1) being greater than the rigidity of the valve plate (5). The invention further relates to a method for increasing the seal of an electromagnetically actuatable gas valve.

Owner:ROBERT BOSCH GMBH

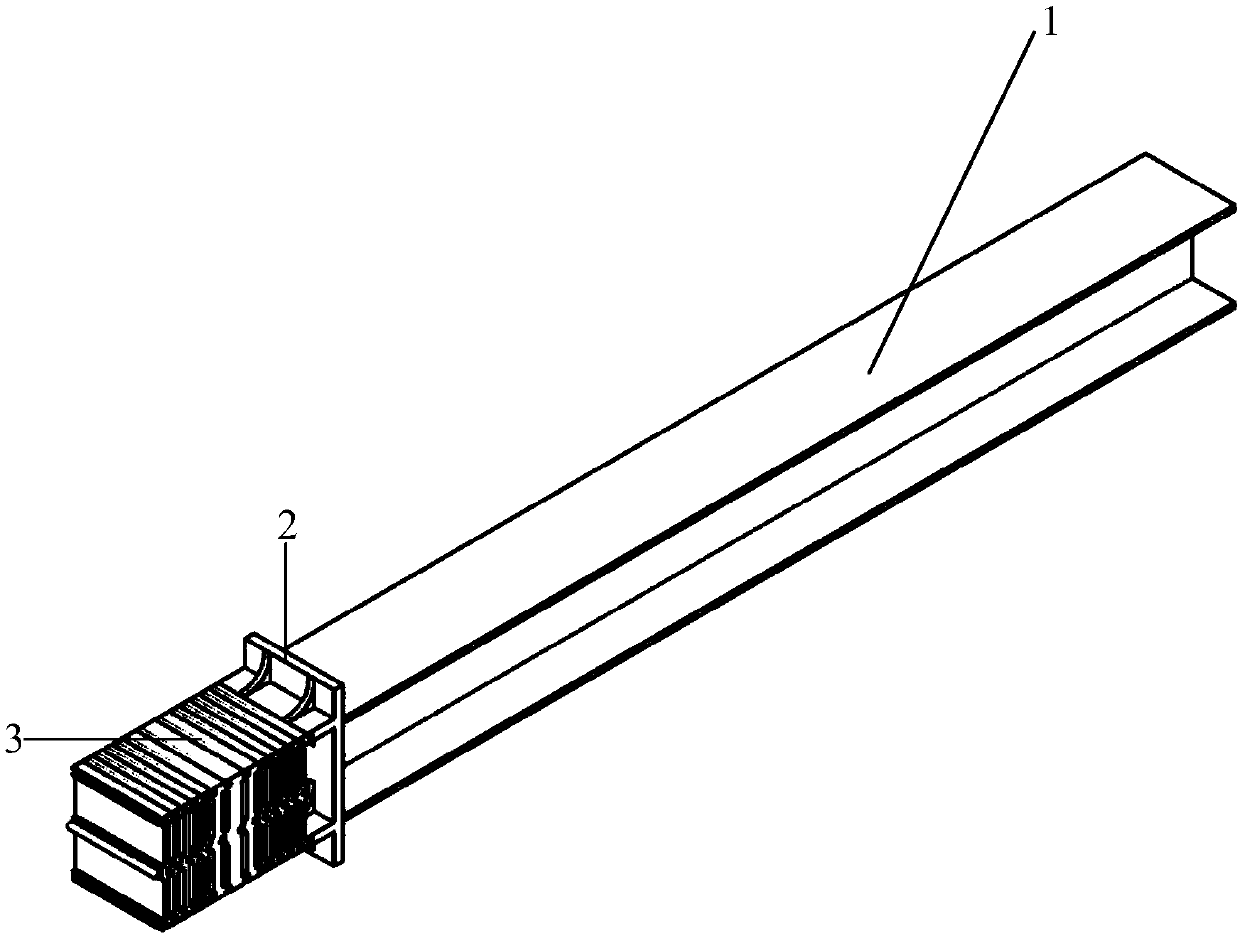

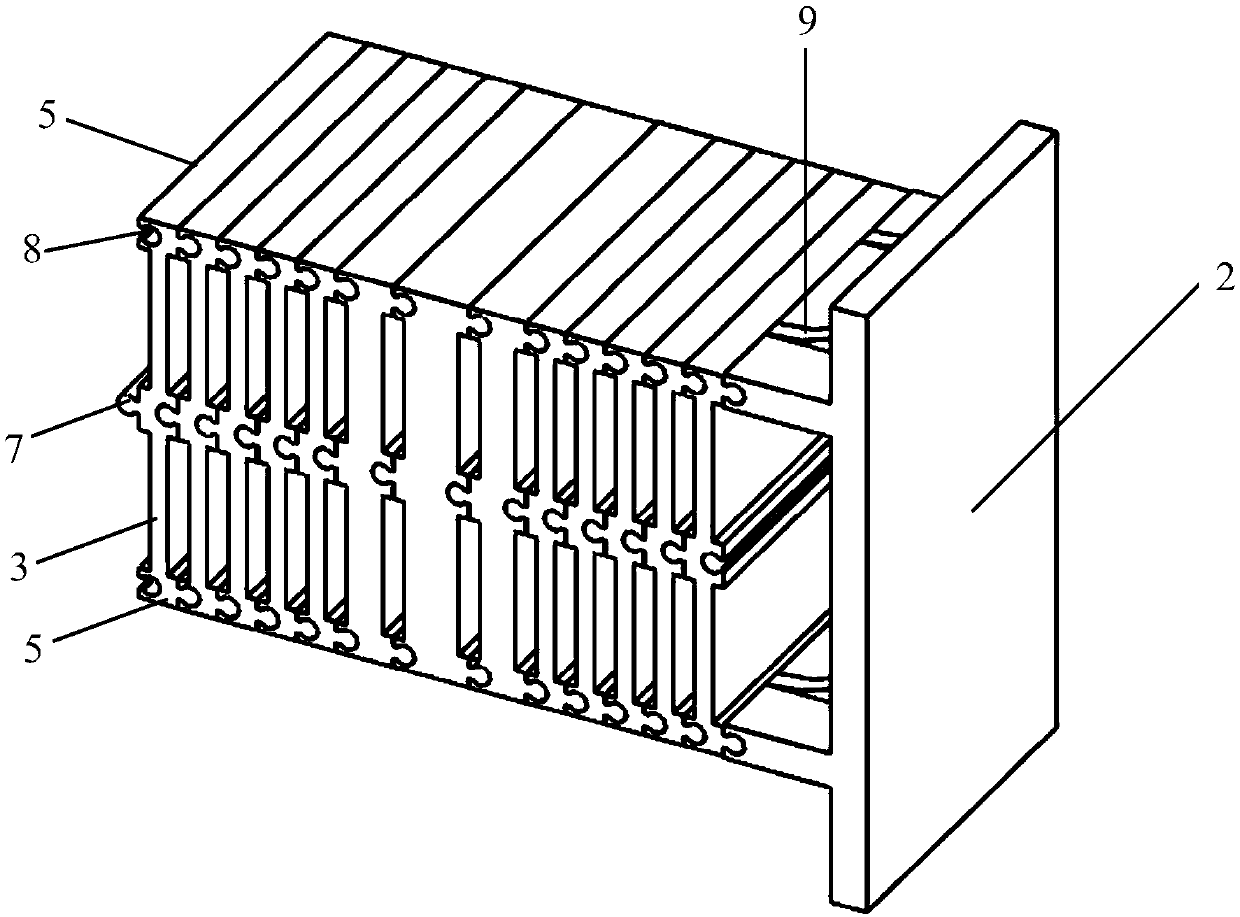

Supporting structure with damper independently adjusting rigidity and bearing capacity and design method thereof

ActiveCN108035595ASame stiffnessWon't buckleProtective buildings/sheltersShock proofingSupporting systemCoupling

The invention relates to a supporting structure with a damper independently adjusting the rigidity and the bearing capacity and a design method thereof. The supporting structure comprises a supportingsection, a damper section and a connecting end plate for being connected with the supporting section and the damper section, wherein the damper section is assembled by a plurality of connected damping plates side by side, and the damping plates are manually buckled. Compared with the prior art, the coupling aim of the traditional supporting rigidity and bearing capacity is achieved, and the aimsof controlling the yield timing sequence and achieving damage control design in the structure are achieved; modularized joint design is adopted, and a supporting system with the large rigidity-and-bearing-capacity variation range can be assembled through the damping plates with few types; the damper section is connected with the supporting section in series, yield / buckling damage of common rigidity supporting connected with the damper section can be avoided, construction and replacement are convenient, the applicability is wide, and the effect is good.

Owner:TONGJI UNIV

Bumper rail for vehicle

A bumper rail assembled into a bumper of a vehicle includes a bumper rail, a reinforcing member, and a forming part. A bumper rail is disposed at front. The reinforcing member is disposed at the rear side of the bumper rail and forming a closed section together with the bumper rail. The forming part is integrally formed at an inner side of the bumper rail and is disposed parallel along the longitudinal direction of the bumper rail to increase a stiffness of the bumper rail, the forming part having a pipe shape.

Owner:HYUNDAI MOTOR CO LTD

Hinge device with unequal tension and compression toughness and assembly method

ActiveCN113958018ASame stiffnessSame bearing capacityProtective buildings/sheltersShock proofingEarthquake resistant structuresEngineering structures

The invention belongs to the technical field of engineering structure seismic resistance, and relates to a hinge device with unequal tension and compression toughness and an assembly method. The device comprises a pressure spring for providing an anti-compression restoring force, a tension spring for providing an anti-tension restoring force, a pressure spring baffle for applying a pre-compression force to the pressure spring, a stop block for limiting springback of the pressure spring and the tension spring, a tension spring baffle for limiting springback of the tension spring, an outer pipe for driving the pressure spring baffle and the tension spring baffle, and a tension spring sealing plate for limiting the springback of the tension spring. Aiming at obvious plastic hinge formation and residual displacement of a traditional anti-seismic structure, the device replaces stressed steel bars and the like in an original plastic hinge area to carry out stress service, so that a novel structure has the same rigidity, bearing capacity and higher deformability, and does not generate plastic and residual deformation; aiming at the problem that lateral deformation of a prestress self-resetting structure system is large, the deformation mode and the stress process of the prestress self-resetting structure system are roughly the same as those of a traditional rigid connection structure, and additional increase of lateral deformation is not caused; and the device can be repaired and replaced, the initial state can be recovered through large deformation, and the requirement for replacement is extremely low in multiple times of earthquake service.

Owner:BEIJING JIAOTONG UNIV

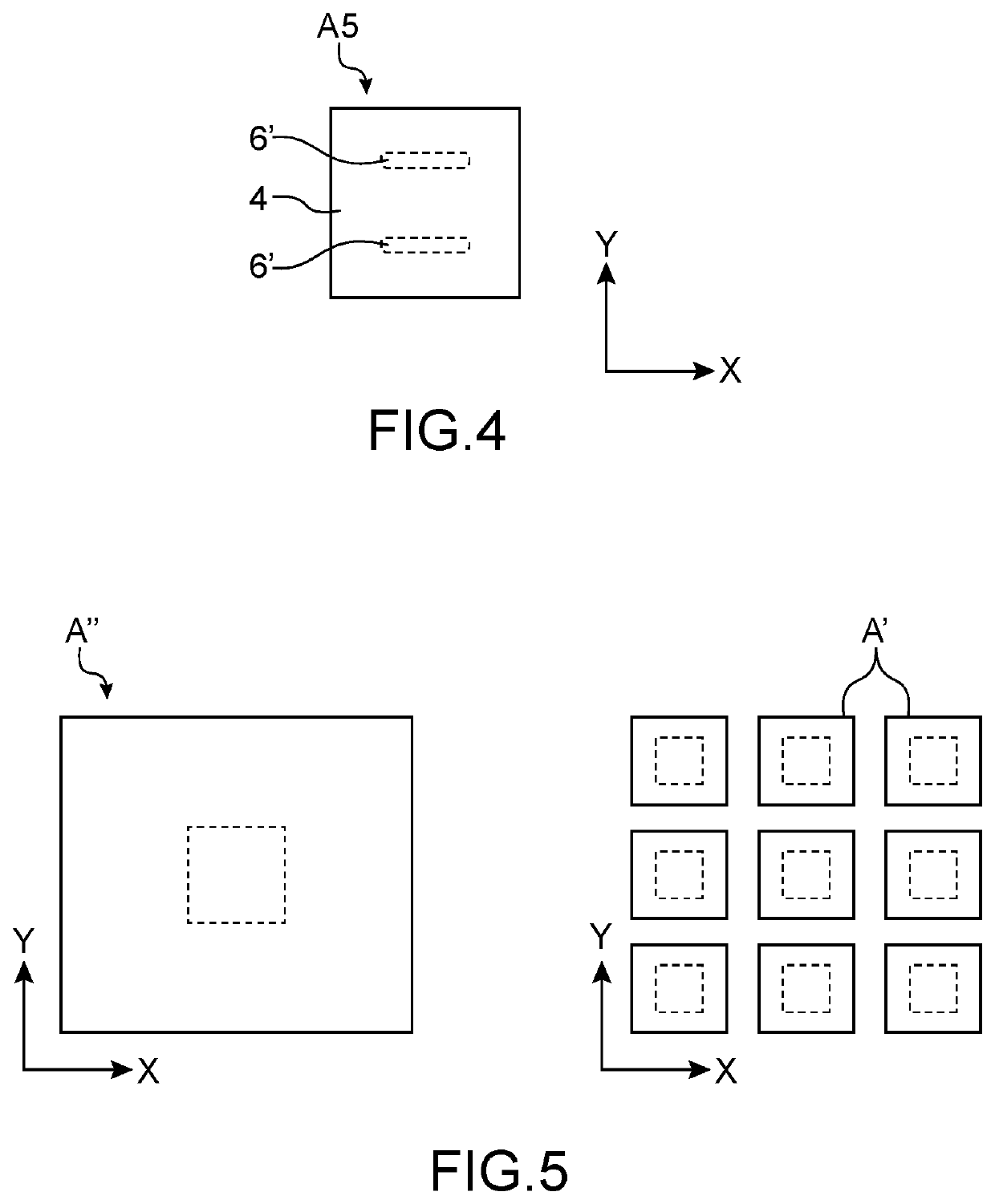

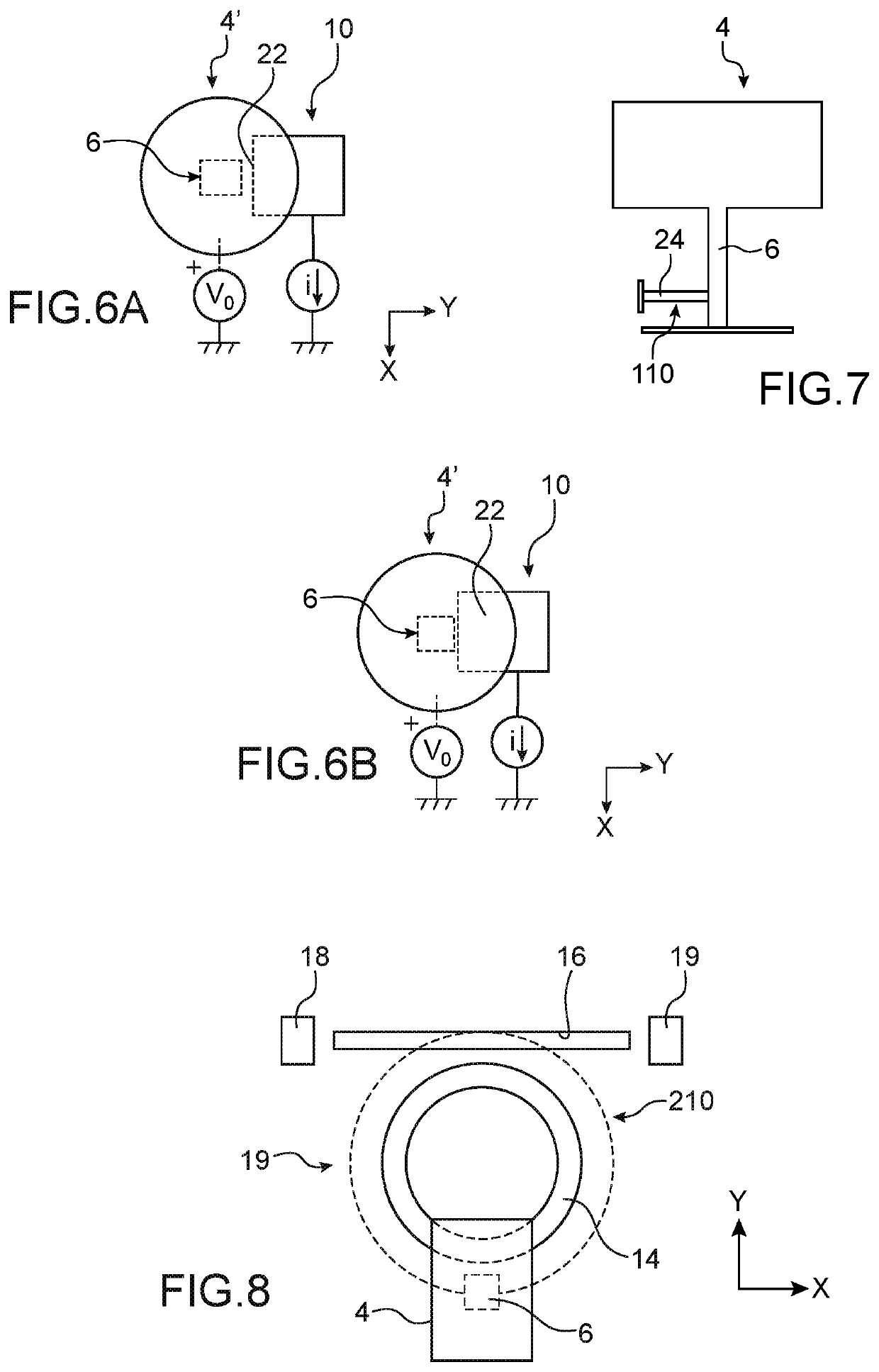

Effective accelerometer having a reduced size

InactiveUS20210132106A1EffectiveSmall sizeAcceleration measurement using interia forcesAcceleration measurement in multiple dimensionsVibration measurementAccelerometer

Microelectromechanical accelerometer comprising a support (2) and a mobile portion (4) able to be vibrated, means for measuring (10) the amplitude of the vibration of said mobile portion (4) in at least one detection direction of the plane of the accelerometer. The accelerometer comprises at least one foot (6) anchored on the support (2) by a first end and fixed to the mobile portion (4) by a second end, and allowing the mobile portion (4) to vibrate at least along said at least one detection direction under the effect of an acceleration force.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Suspension structure of mobile muffler

InactiveCN110259559AImproves firmness and durabilityAvoid deformationExhaust apparatusSilencing apparatusVehicle frameEngineering

The invention relates to a suspension structure of a mobile structure. The suspension structure comprises a rubber body and a lining installation frame used for embedding the rubber body. The lining installation frame is installed in an installation support in an embedded mode. The installation support is detachably installed on a frame. A lining installation hole used for allowing a muffler hook to be inserted is formed in the central axis of the rubber body. Four lining hollowed holes are formed around the lining installation hole in a round array mode with the circle center of the lining installation hole as the center. The suspension structure is simple, good in stability, unlikely to deformation and good in durability, installation is convenient, and universality is high.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

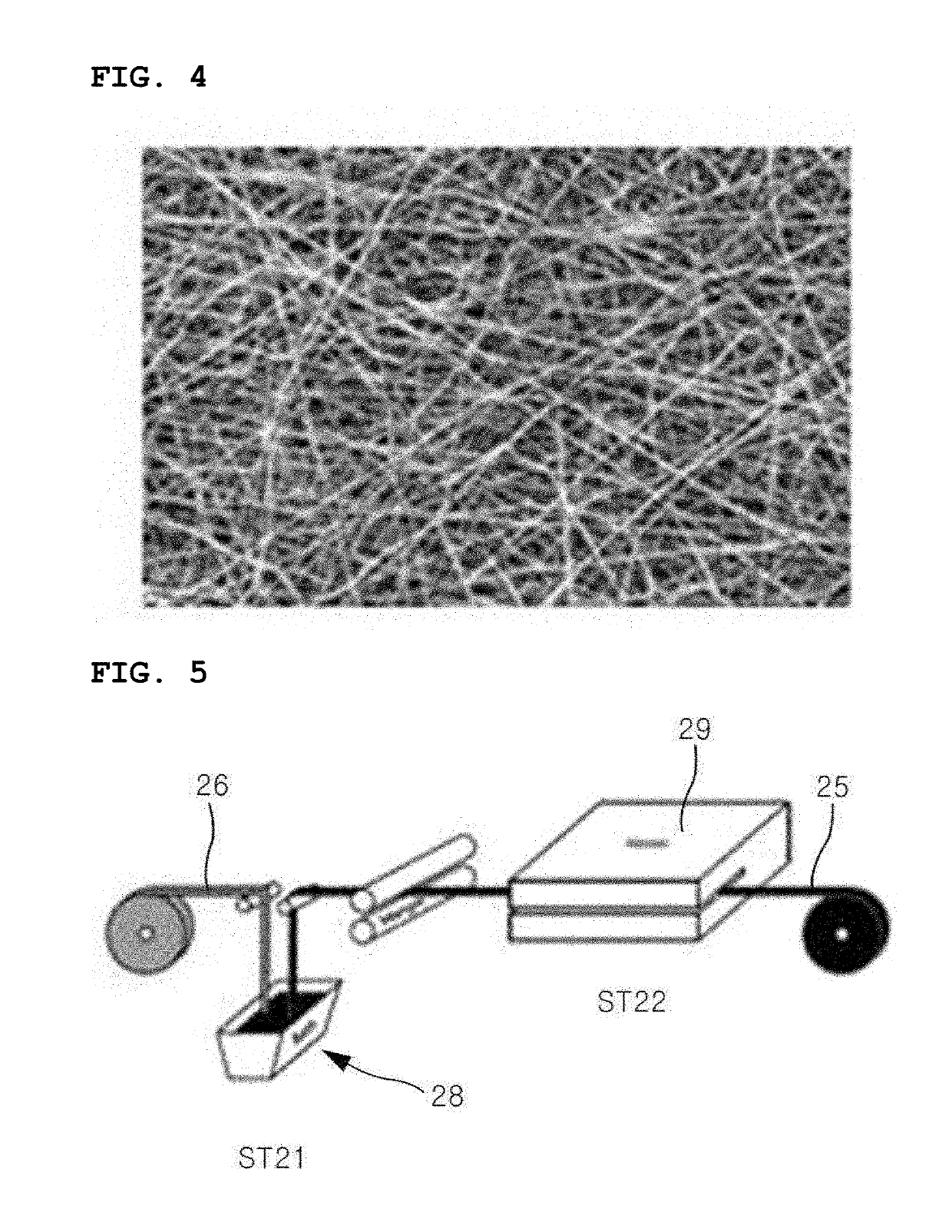

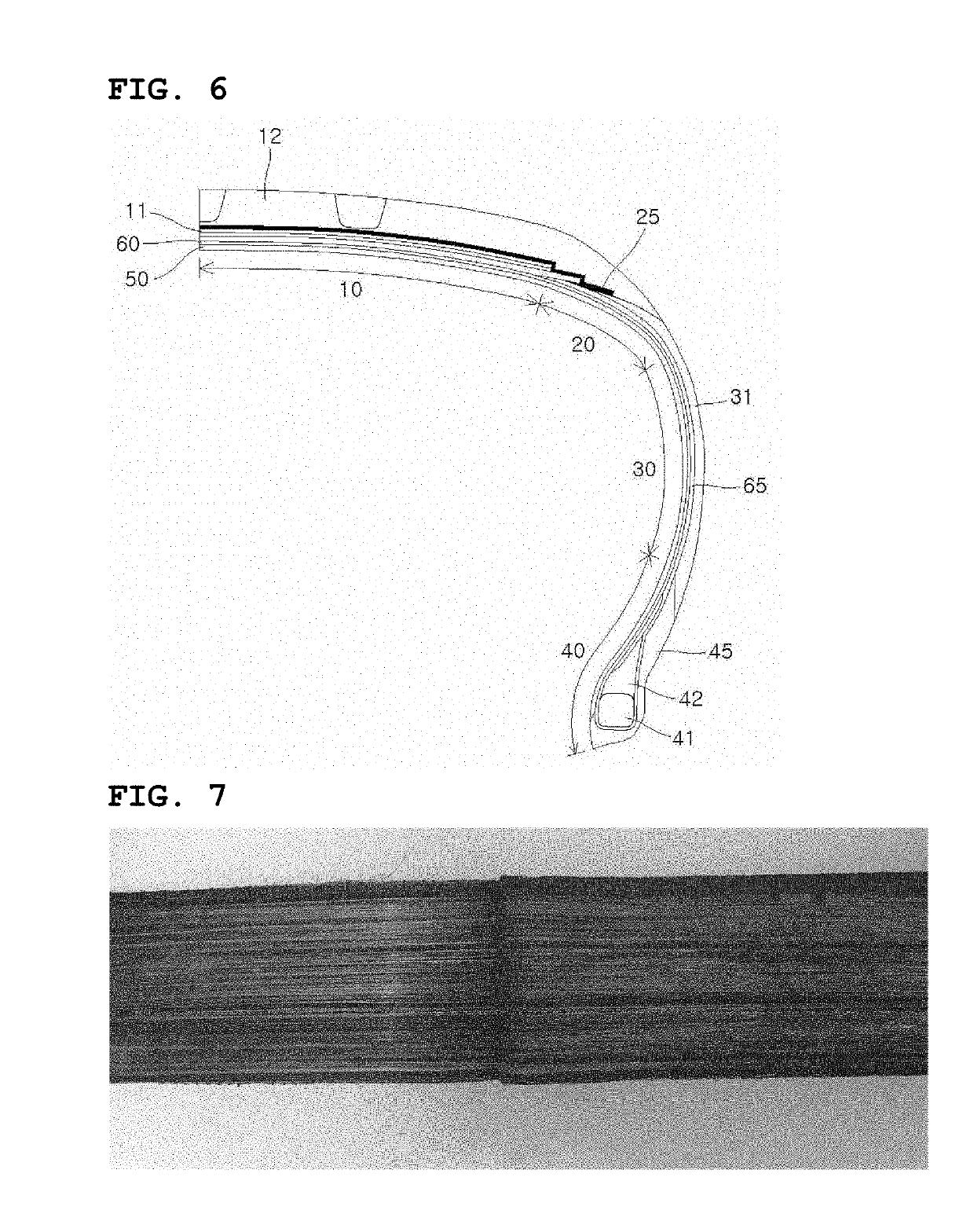

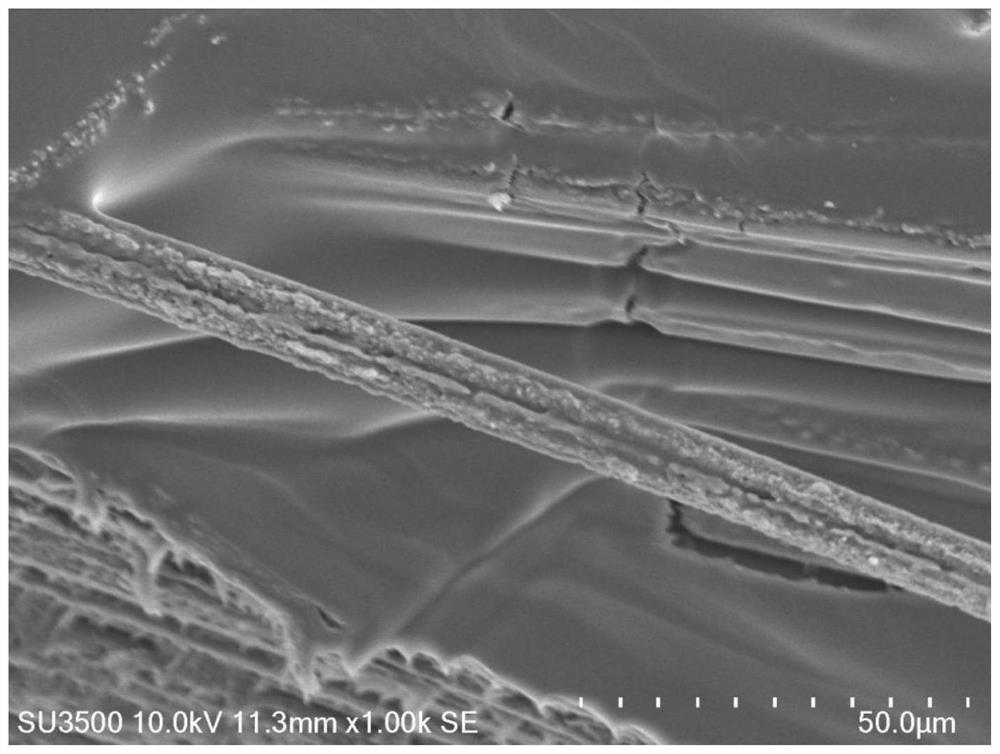

Thin layer capply and low-weight tire using the same

InactiveUS20190160874A1Reduce rolling resistanceImprove vehicle efficiencySpecial tyresTyresElectrical and Electronics engineeringFuel efficiency

The present invention provides a thin layer capply and a low-weight tire to which the thin layer capply is applied. The thin layer capply of the present invention has effects of reducing a rolling resistance of the tire through a weight reduction and improving fuel efficiency of a vehicle in which the tires are mounted while maintaining stiffness required for the tire, by forming the cord spinning layer in a thin tape form by spinning and depositing a plurality of cord strands, rather than twisting a plurality of cord strands to form the capply cord.

Owner:KUMHO TIRE CO INC

Parallel mechanism having two rotational and one translational degrees of freedom

A parallel mechanism which has a holding bracket; a movable platform; and three branch joint assemblies of the same structure that are spatially arranged symmetrically about an axis disposed between the holding bracket and the movable platform. Each branch joint assembly has a connecting rod, a linear guide, a driving device and a carriage. The linear guide and the driving device both are secured on the connecting rod. One end of the connecting rod is connected with the movable platform through a hinge having three rotational degrees of freedom. The carriage and the linear guide are connected with each other by a sliding joint, and the carriage is connected with the holding bracket by a hinge having one rotational degree of freedom.

Owner:TIANJIN UNIV

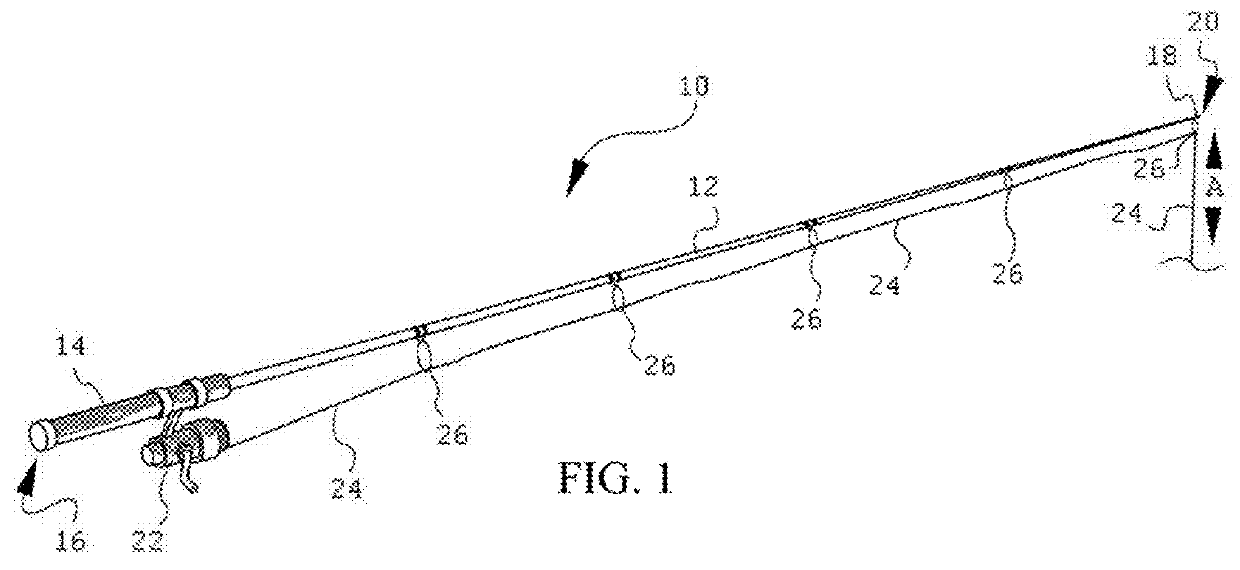

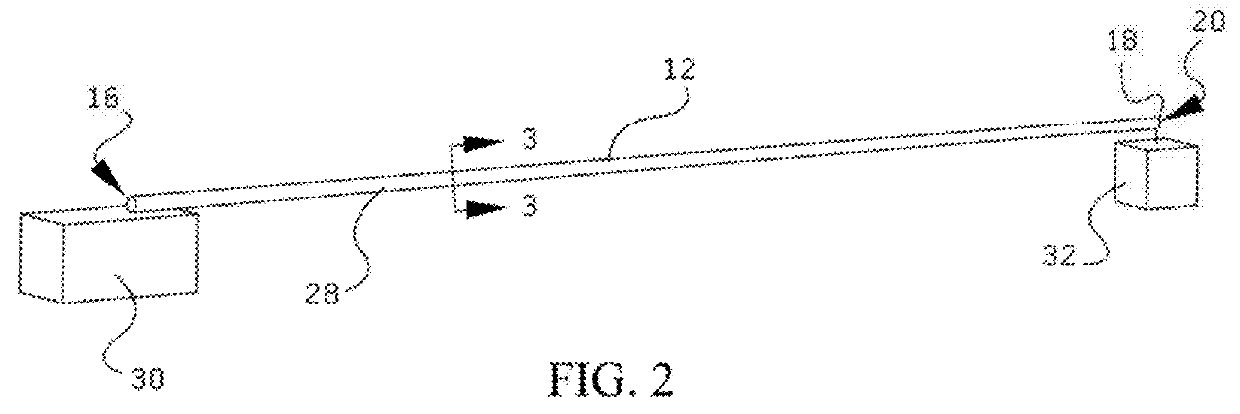

Fishing rod with enhanced tactile response

ActiveUS10005889B2High sensitivitySame stiffnessRodsThin material handlingCarbon fibersMechanical integrity

Owner:CONDUCTIVE COMPOSITES CO IP LLC

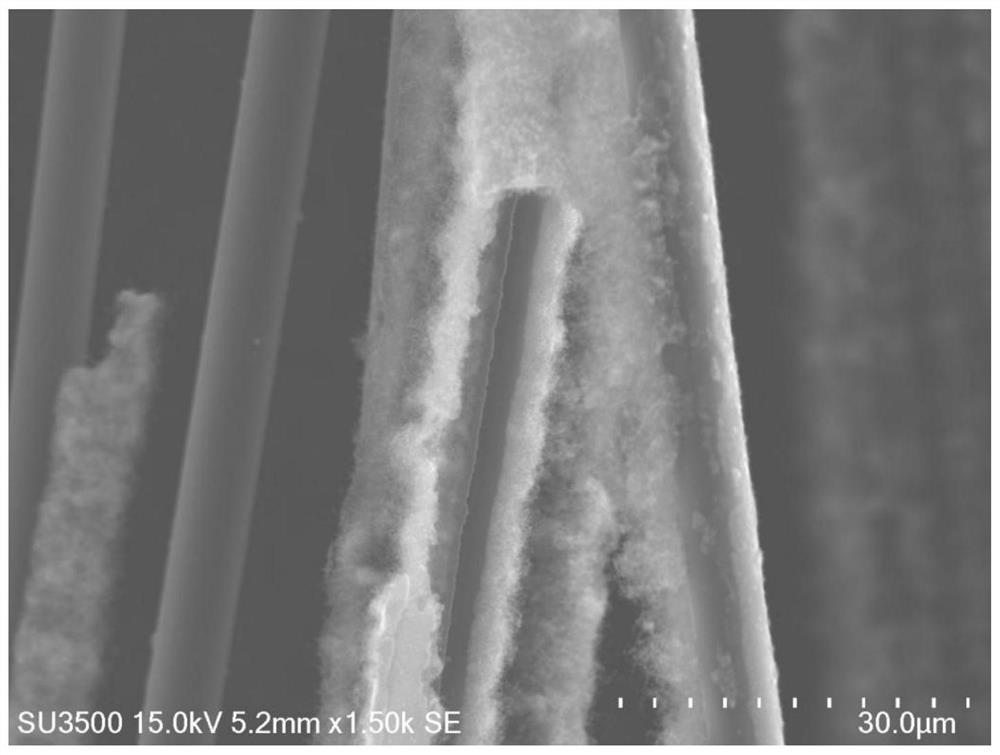

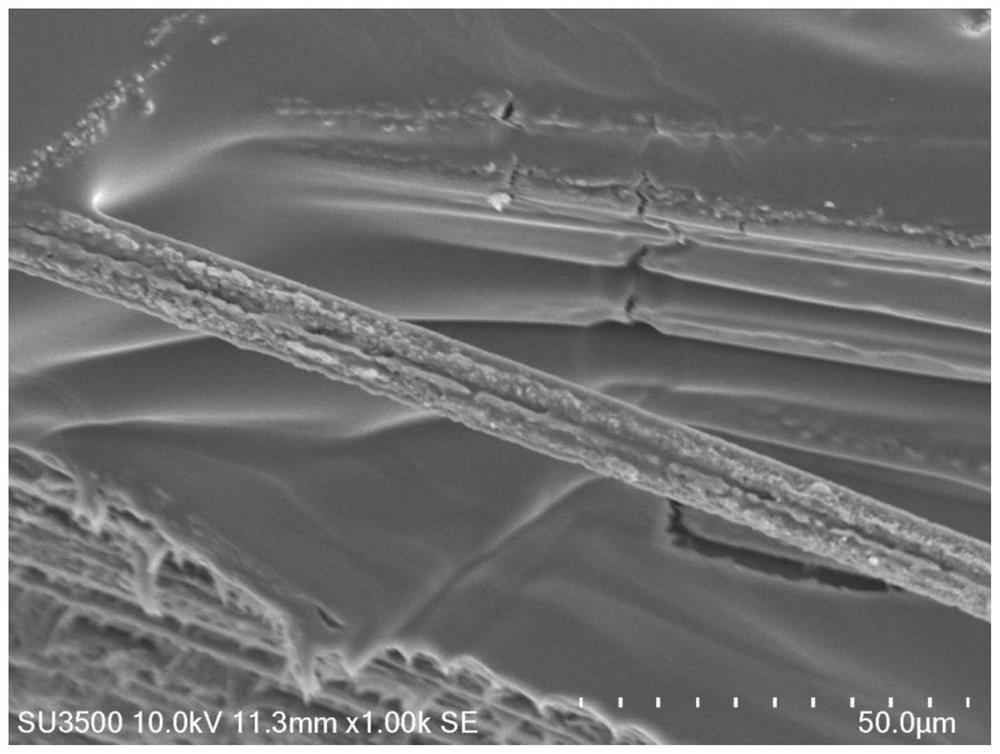

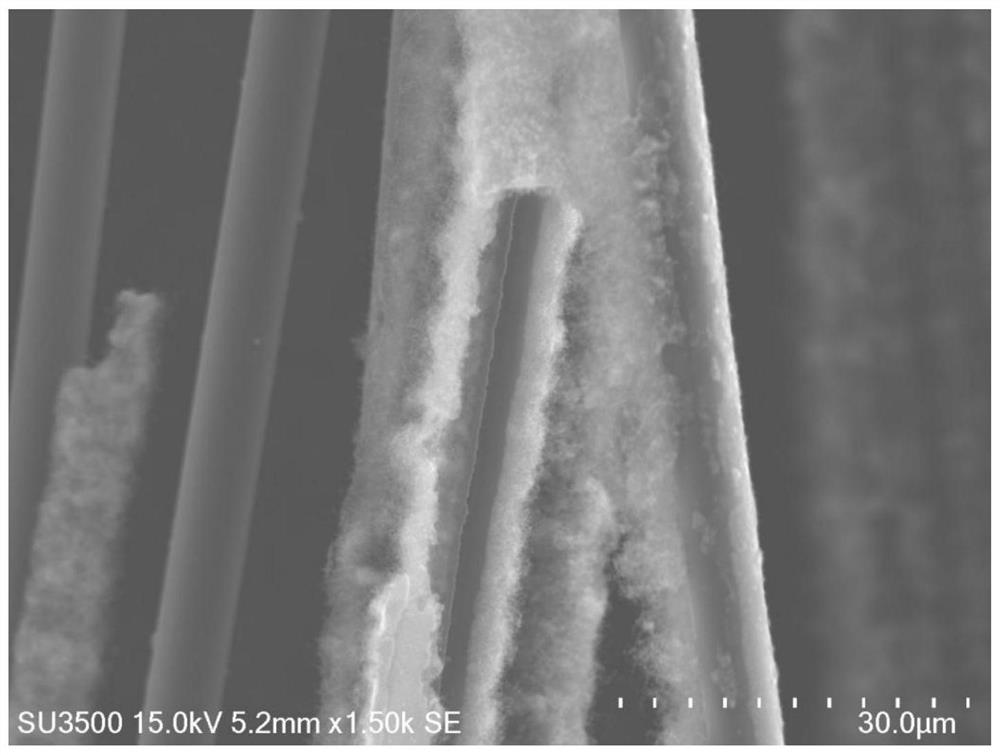

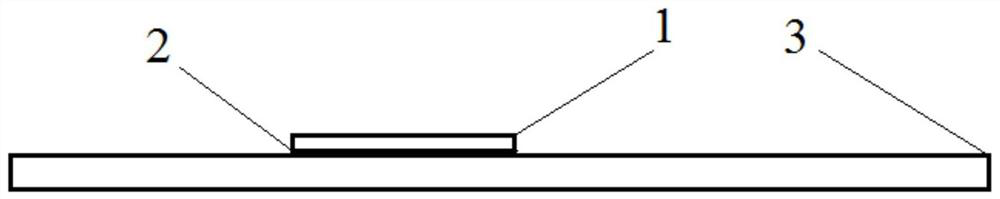

Method for repairing Glare laminate by using modified adhesive

ActiveCN112126358AImprove adhesion strengthSame stiffnessNon-macromolecular adhesive additivesAdhesive processes with surface pretreatmentPolymer scienceCarbon fibers

The invention belongs to the field of repairing of fiber metal laminated plates (Glare laminated plates), and particularly relates to a method for repairing a Glare laminated plate through adhesion ofa modified adhesive. According to the preparation method, a low-cost and low-consumption flame method is adopted to grow a carbon nanotube layer on the surface of the carbon fiber in situ to preparethe carbon nanotube coated composite carbon fiber; the chopped composite carbon fibers are mixed into the adhesive in proportion, so that the bonding strength of the interface between the adhesive layer and the light material and the body strength of the adhesive layer are enhanced, the bonding strength between the mother board and the patch in the repairing process of the Glare laminate is improved, and a better repairing effect is achieved; the patch and the mother board are made of the same material, so that the patch and the mother board are the same in rigidity and have good compatibility. The method is simple, quick and extremely low in cost, and has a wide application prospect in the field of bonding of light materials for aerospace, transportation and the like.

Owner:SHENYANG AEROSPACE UNIVERSITY

A method for repairing glare laminates by using modified adhesive

ActiveCN112126358BImprove adhesion strengthSame stiffnessNon-macromolecular adhesive additivesAdhesive processes with surface pretreatmentCarbon fibersFiber metal laminate

The invention belongs to the repairing field of fiber metal laminated boards (Glare laminates), and in particular relates to a method for repairing Glare laminates by bonding a modified adhesive. The invention adopts a low-cost, low-consumption flame method to grow carbon nanotube layers on the surface of carbon fibers in situ to prepare composite carbon fibers wrapped by carbon nanotubes; and mix chopped composite carbon fibers into the adhesive in proportion to realize adhesive The bonding strength of the interface between the layer and the lightweight material and the enhancement of the body strength of the adhesive layer, thereby improving the bonding strength between the motherboard and the patch in the Glare laminate repair, to achieve a better repair effect; the patch used in the present invention The sheet and the motherboard are made of the same material, so that both have the same rigidity and have better compatibility. The method of the invention is simple and quick, and has extremely low cost, and has wide application prospects in the bonding fields of aerospace, transportation and other light materials.

Owner:SHENYANG AEROSPACE UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com