Dynamic centrifuge integrated rigid arm

A technology of centrifuges and rotating arms, which is applied in the direction of centrifuges, can solve the problems of limited dynamic acceleration range of centrifuges, large driving power of centrifuges, and huge structure of centrifuges, so as to ensure uniformity and consistency of mechanical properties, and ensure Stability and safety, the effect of increasing stability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing:

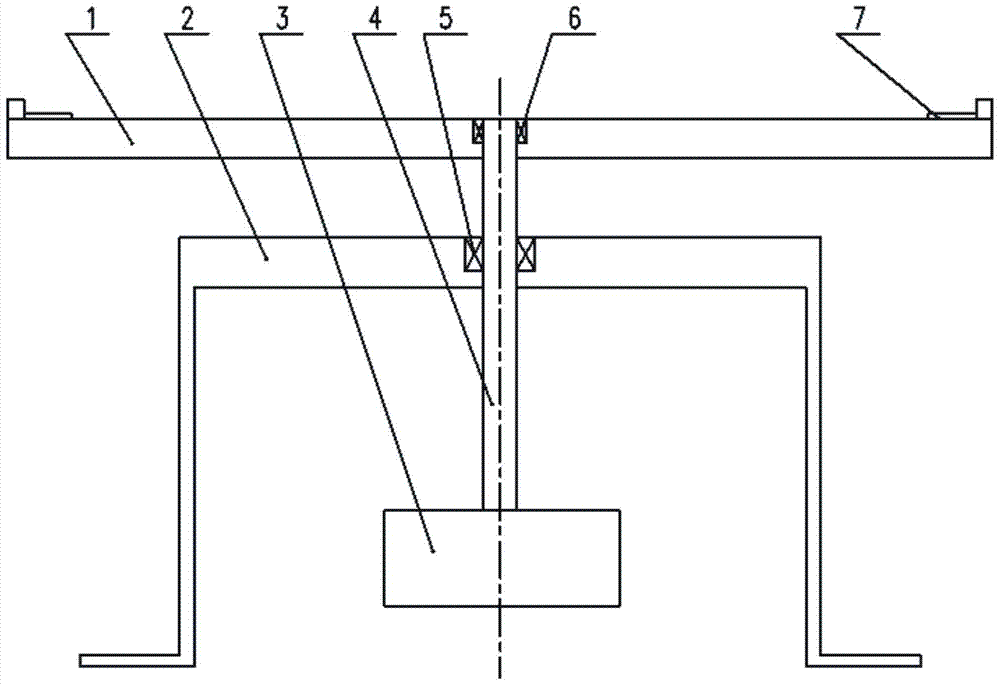

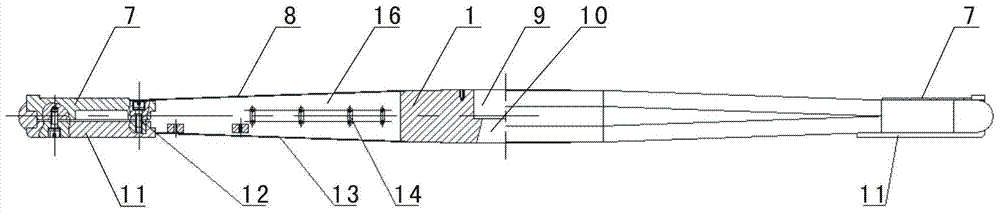

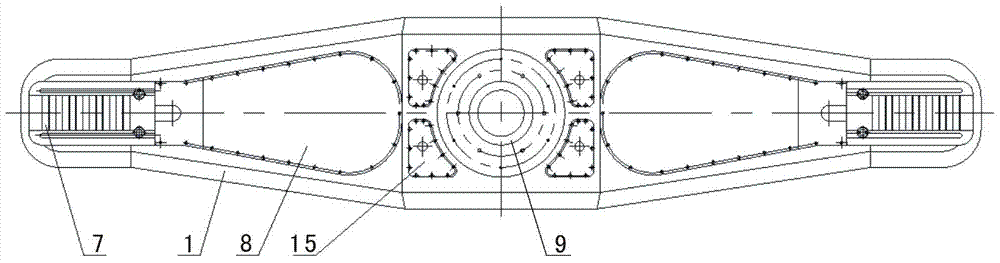

[0029] Such as Figure 2-Figure 7 As shown, the integrated rigid rotating arm of the dynamic centrifuge of the present invention includes a rotating arm body 1, and a vertical mounting hole is provided at the center of the rotating arm body 1, and the mounting hole includes an upper cylindrical expansion sleeve coupling hole 9 and the central positioning hole 10 of the upper, lower, and large conical shapes located at the bottom, the pivoting arm body 1 is a steel body with an integrated structure, and the pivoting arm body 1 is a shuttle-shaped shape with a large middle and small left and right ends, and The arm body 1 is a symmetrical structure with front and back symmetry, left and right symmetry, and up and down symmetry, and the front and rear sides of the arm body 1 are convex arc-shaped; On the sample stage 7 where the test piece is installed, a "T" shaped mounting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com