Slrain and temperature change simultaneously-measured single fibre grating packaging method and its sensor

A packaging method and fiber grating technology, applied in the field of optical fiber sensing and sensing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

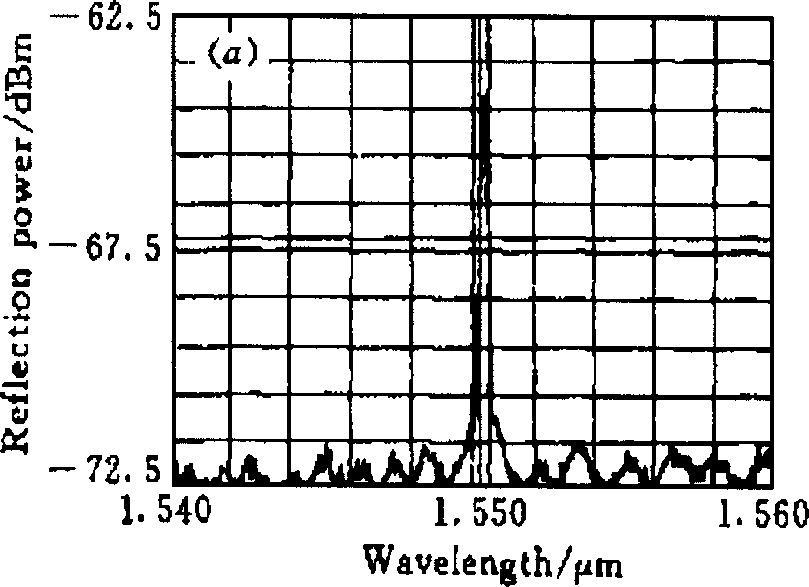

Image

Examples

Embodiment Construction

[0011] Mark two sections of Fiber Bragg Grating 1 with a marking line, and first package one section of it into a 3×3×20mm cylinder with a mold, so that the Fiber Bragg Grating 1 is located in the center of the cylinder, and package it into a polyurethane armor 3; then, After the polyurethane A 3 is cured, the entire fiber grating is packaged in a 4×4×40 mm polyamide 4, and the fiber grating must also be located at the center of the polyamide 4.

[0012] In the specific implementation example figure 2 Among them, the sensor includes fiber Bragg grating 1, cladding optical fiber 2, chemical polymer A 3, chemical polymer B 4, broadband light source 5, wavelength tester 6, 2×2 fiber coupler 7, matching liquid 8, pressure Tank 9, pressure gauge 10. Connection method: Two optical fibers on one side of the 2×2 fiber optic coupler 7, one is inserted into the matching liquid 8, the other is connected to the packaged fiber Bragg grating 1, and put it into the pressure tank 9, the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com